Wrench

A wrench and body technology, applied in the field of wrenches, can solve the problems of waste time and inability to adapt to the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

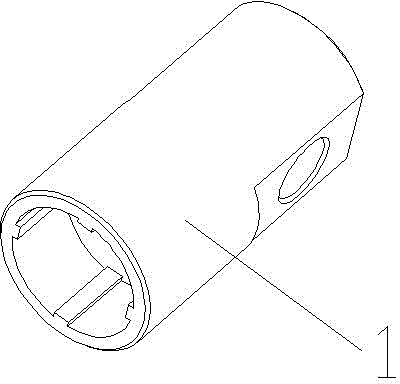

[0013] attached figure 1 The wrench according to the present invention includes a wrench body 1; the wrench body 1 is a dismounting tool for disassembling round nuts; the wrench body 1 is a hollow tube, and the inner wall at one end rotates along it Four strip-shaped bosses with the same size as the four grooves on the round nut are evenly distributed in the center, and two parallel planes are symmetrically arranged on the outer peripheral surface of the other end, and there are also two parallel planes on the two parallel planes. A through hole perpendicular to it.

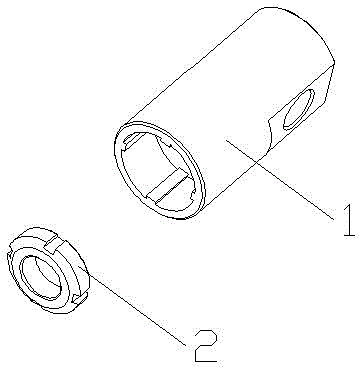

[0014] as attached figure 2 As shown, when used in a narrow space, the four strip-shaped bosses on the wrench body 1 can be inserted into the four grooves on the round nut 2 correspondingly, and the two parallel surfaces can be clamped and rotated with a tool. Realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com