Dust removing system of plasma cutting machine

A technology of plasma cutting machine and dust removal system, which is applied in the field of dust removal system, can solve the problems of flying dust and low dust removal efficiency, achieve high dust removal efficiency and improve dust removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

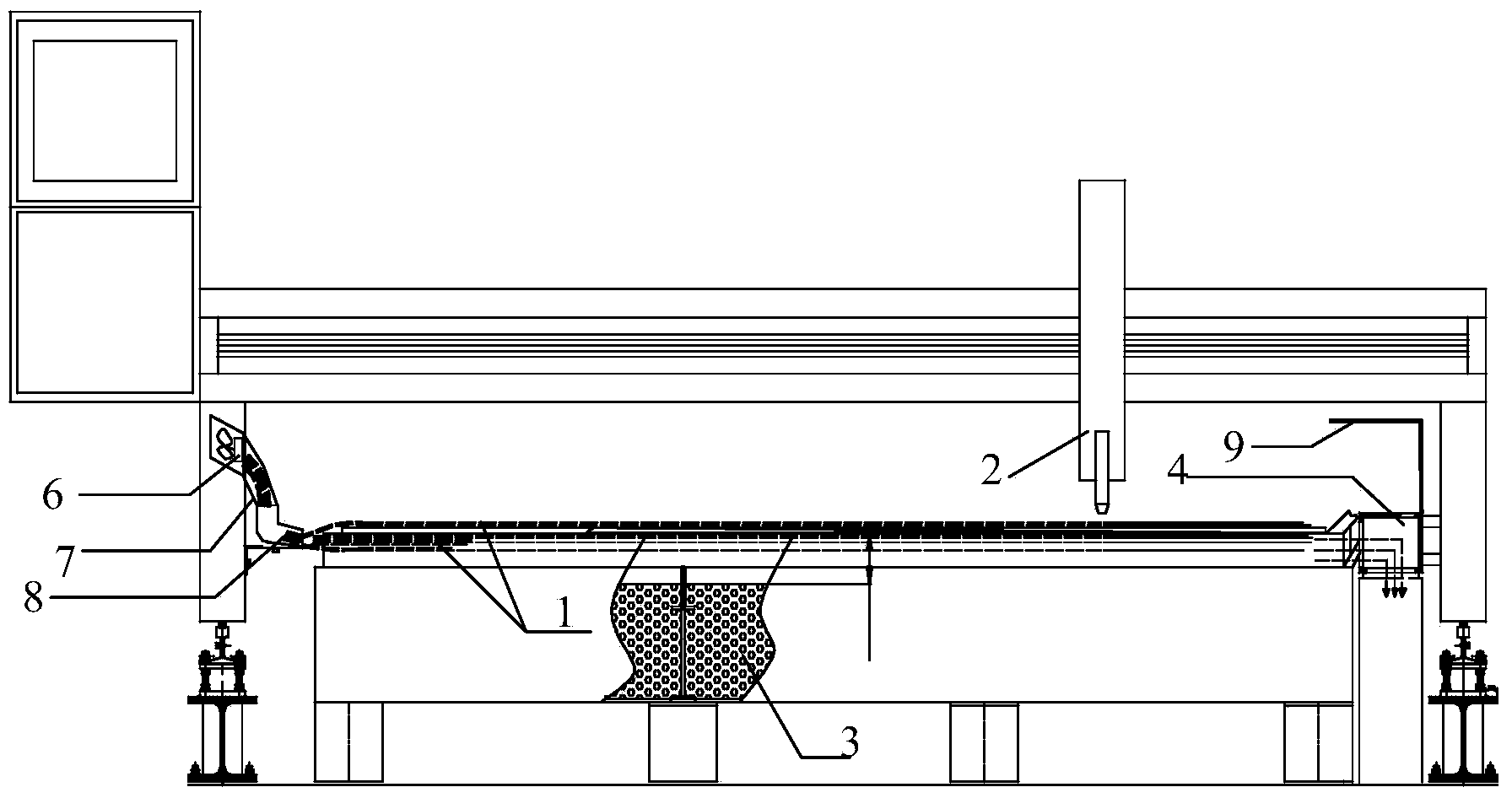

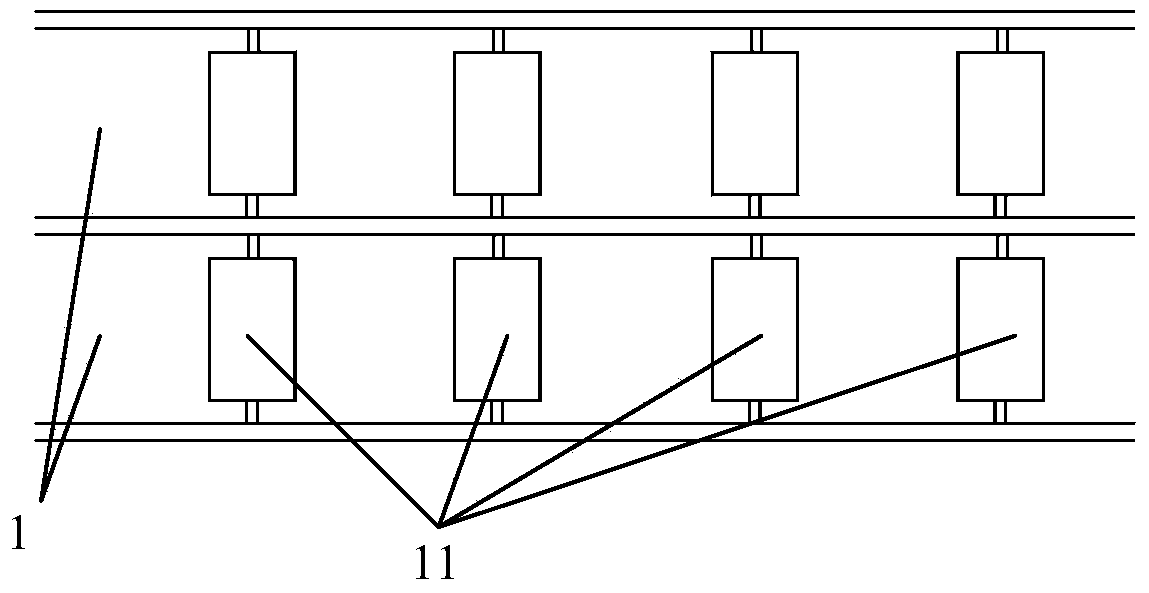

[0030] figure 1 It is the structural representation of the dust removal system of the plasma cutting machine of embodiment 1, as figure 1 As shown, the dust removal system of the plasma cutting machine involved in this embodiment includes an air duct 1 and a cutting device 2 with openings at both ends as a cutting workbench, the air duct 1 is horizontally arranged, and the cutting device 2 is arranged on the air duct 1 Directly above the outlet of the air duct 1 is connected with a suction device 4, and the other end of the air duct 1 is provided with a guide duct.

[0031] The guide pipe includes an axial flow fan interface 6, a soft connection section 7 and an outlet 8. The cross-sectional area of the axial flow fan interface 6 is larger than the outlet 8. The axial flow fan interface 6 is connected to an axial flow fan (not shown in the figure), and the outlet 8 is arranged at one end of several air ducts 1 away from the air suction device 4 .

[0032] There is an inclu...

Embodiment 2

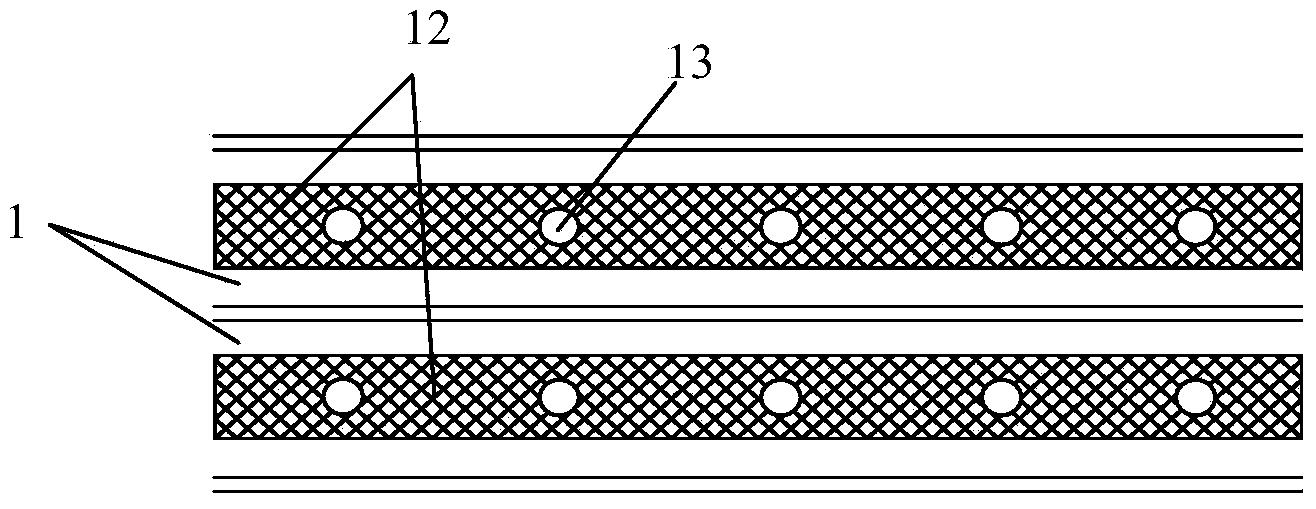

[0046] Embodiment 2 provides a dust removal system for a plasma cutting machine. The difference between Embodiment 2 and Embodiment 1 is that there is no wing-shaped sheet in the air duct of the dust removal system for a plasma cutting machine involved in Embodiment 2. image 3 It is the plan view of the air duct and dust suction duct of embodiment 2, as image 3 As shown, the suction device 4 includes a vacuum generation source (not shown in the figure) and several dust suction pipes 12, and the vacuum generation source communicates with one end of the dust suction pipe 12;

[0047] Several dust suction pipes 12 extend into each air duct 1 respectively, and several dust suction ports 13 are provided directly above the dust suction pipes 12 .

[0048] That is to say, the dust suction duct 12 sucks air upwards in the air duct, and cooperates with the wind blown by the axial flow fan to greatly increase the dust absorption efficiency in each section of the air duct 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com