Fodder windrow turning and drying machine

A feed and stacking technology, which is applied in the field of feed stacking and tumble drying machines, can solve the problems of inconsistent material output, easy damage to the device, uneven drying degree, etc., and achieves the effects of uniform drying and fast feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

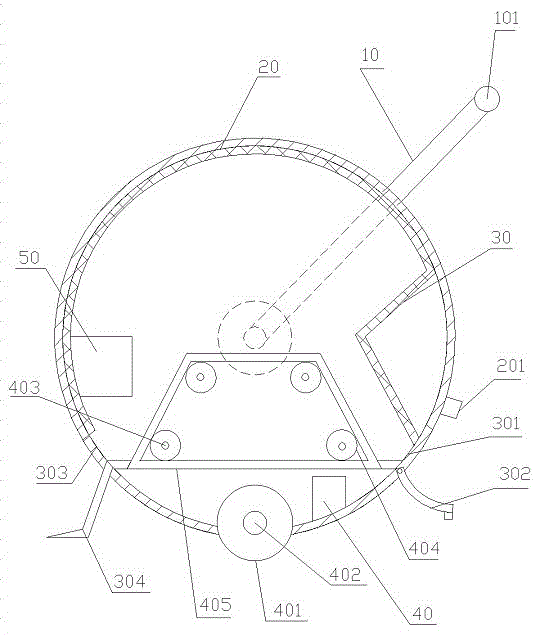

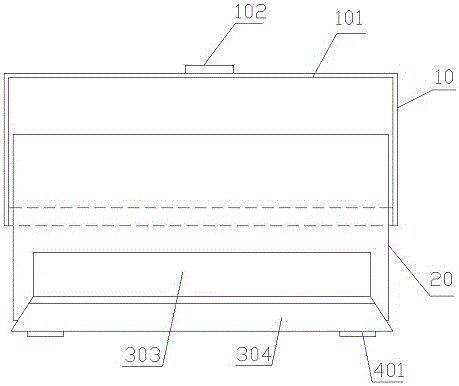

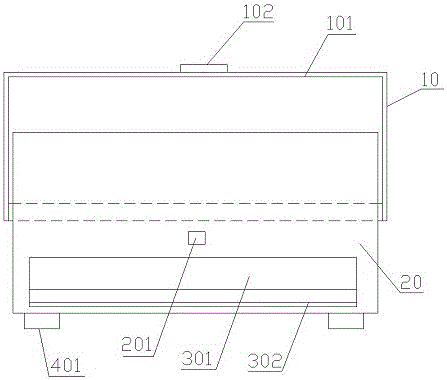

[0018] The reference signs in the accompanying drawings of the description include: fixed frame 10, handle 101, switch 102, material turning cylinder 20, connector 201, material storage cylinder 30, material outlet 301, material outlet plate 302, material inlet 303, shovel Material plate 304 , variable speed motor 40 , roller 401 , first transmission shaft 402 , second transmission shaft 403 , transmission gear 404 , conveyor belt 405 , and absorption device 50 .

[0019] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a feed stacking machine, including a fixed frame 10, a material turning cylinder 20, a variable speed motor 40, a roller 401, a material storage cylinder 30 and an absorption device 50, and the fixing frame 10 is installed at both ends of the material turning cylinder 20 , A handle 101 is installed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com