Method for preparing composite crushing wall and composite rolled mortar wall

A technology of breaking the wall and rolling the mortar wall, applied in the field of mechanical equipment, can solve the problems of small impact strength of abrasives, a large number of pores in the material structure, and insignificant work hardening effect, and achieves good tensile and compressive properties, and wear resistance. The effect of organic unity with toughness and excellent internal structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Example: Preparation of primary columnar hard phase composite crushing wall and composite rolling mortar wall with high chromium alloy as hard phase and A3 steel as matrix

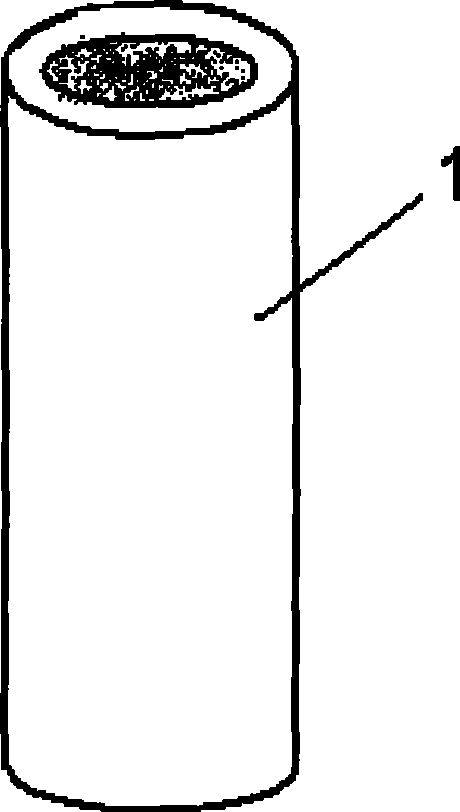

[0040] 1. Wrap the alloy powder in the low-carbon steel pipe skin to form an alloy powder core wire l with a diameter of 3mm; the alloy powder is high-carbon ferrochrome powder with a particle size of 100-150 mesh;

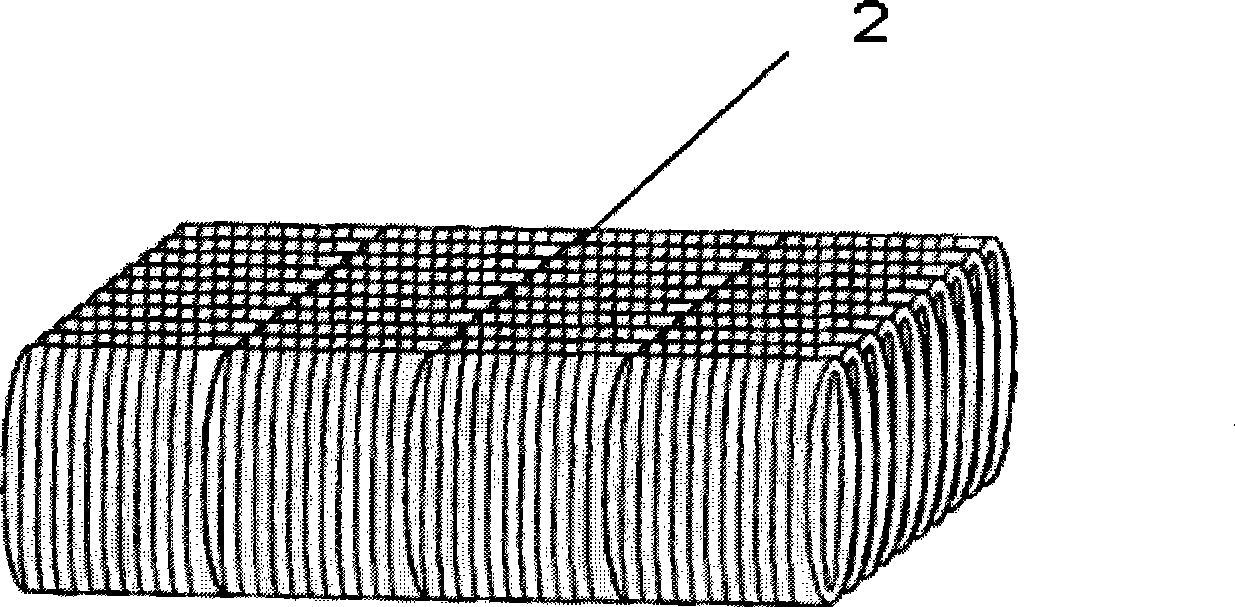

[0041] 2. The alloy powder core wire 1 is woven into a three-dimensional alloy powder core wire skeleton 2 according to the shape of the crushing wall and the lining body of the rolling mortar wall; it is fixed on the groove of the outer wall 3 of the crushing wall and the inner wall 4 of the rolling mortar wall by binding and welding In the groove; the actual volume of the alloy powder core wire skeleton 2 accounts for 20% to 80% of the total volume of the composite material of the broken wall and the rolling wall lining;

[0042] 3. According to the requirements of the casting process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com