Environmentally friendly glass cleaning and drying machine

A glass cleaning and drying technology, applied in dryers, drying solid materials, drying gas layout, etc., can solve the problems of unsatisfactory cleaning effect, dust washing, and heavy workload, etc., and achieve fast and convenient handling and movement. The effect of thorough cleaning and improved mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

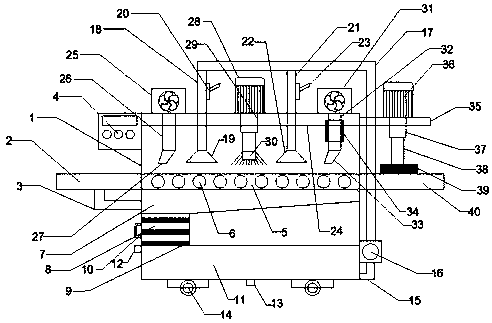

[0013] Such as figure 1 The shown environment-friendly glass washing and drying machine includes a frame 1, a feeding plate 2 is arranged on the left side of the frame 1, a bracket 3 is arranged under the feeding plate 2 to connect the frame 1, and a control is set outside the top of the left side of the frame 1. A device 4, a workbench 5 is set in the middle of the frame 1, a transfer device 6 is arranged on the workbench 5, a drainage bin 7 is arranged under the transfer device 6, and a water filter 8 is arranged under the left side of the drain bin 7. The filter A filter plate 9 is arranged in the water device 8, a handle 10 is arranged on the left side of the water filter device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com