High negative pressure welding smoke dust purification device and deashing method thereof

A welding fume purification and high negative pressure technology, which is applied in cleaning methods and appliances, chemical instruments and methods, and dust removal, etc., can solve the problems of inconvenient production and installation, large shape, and high cost, and achieve thorough and clean dust removal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

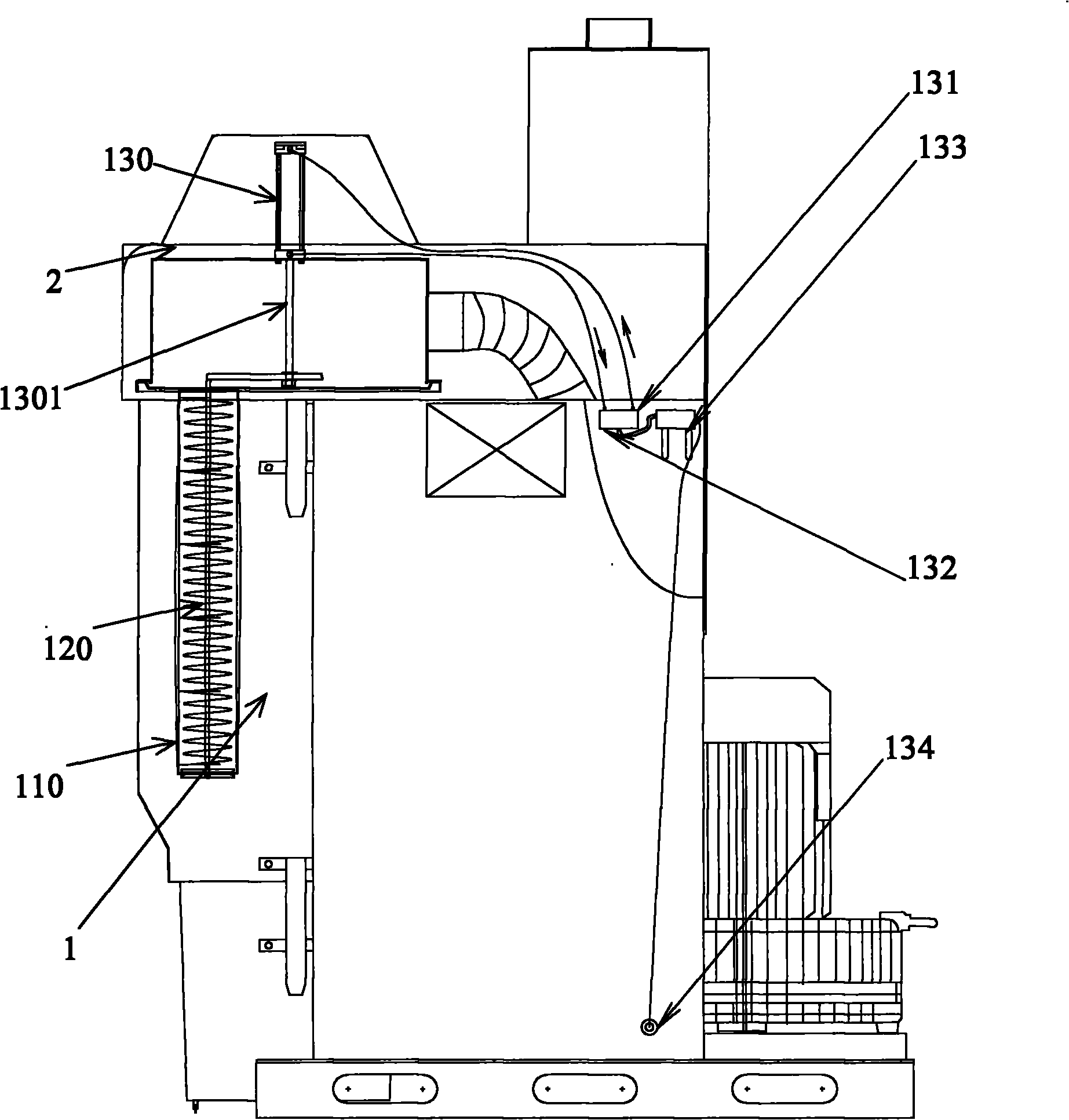

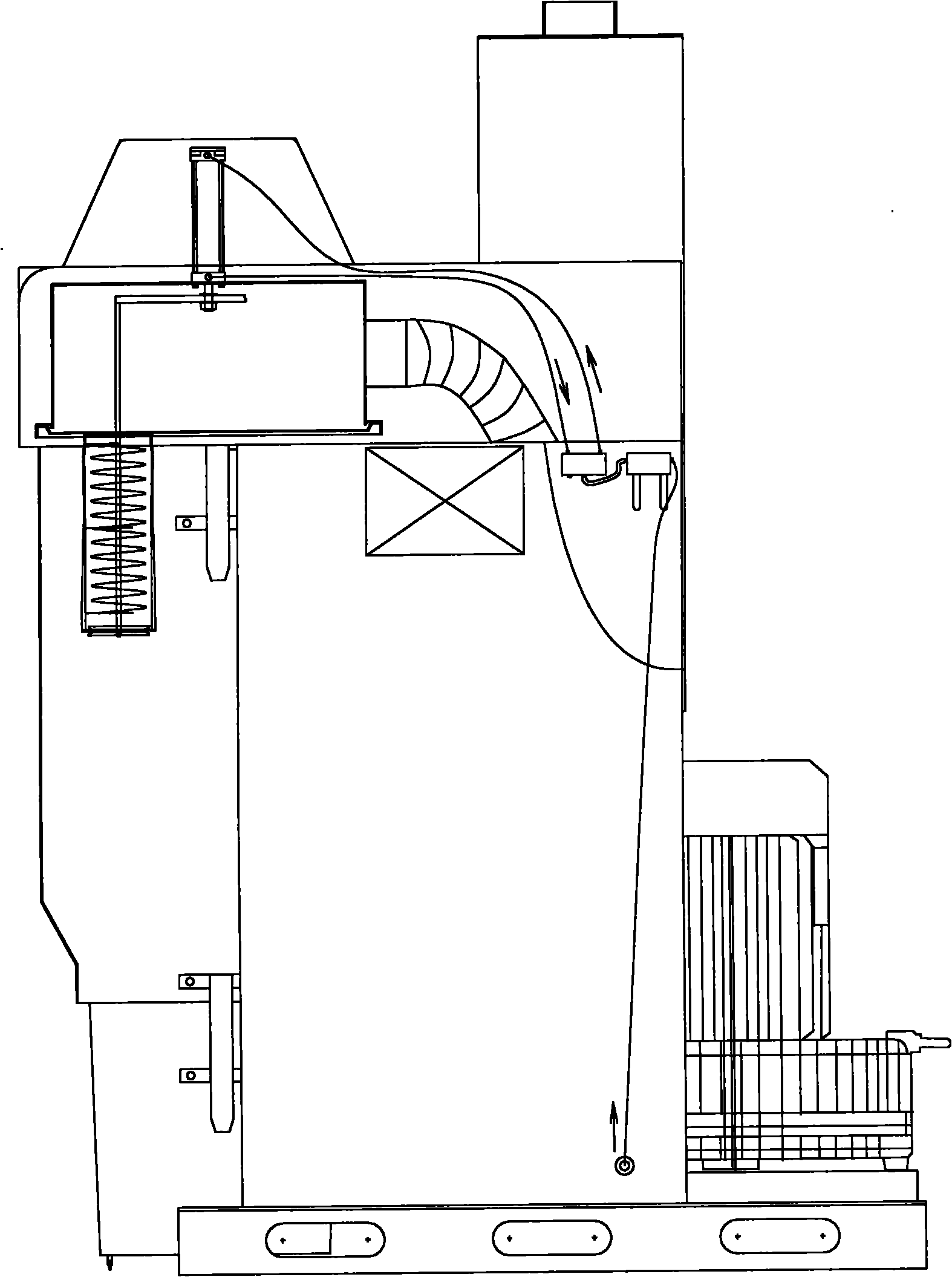

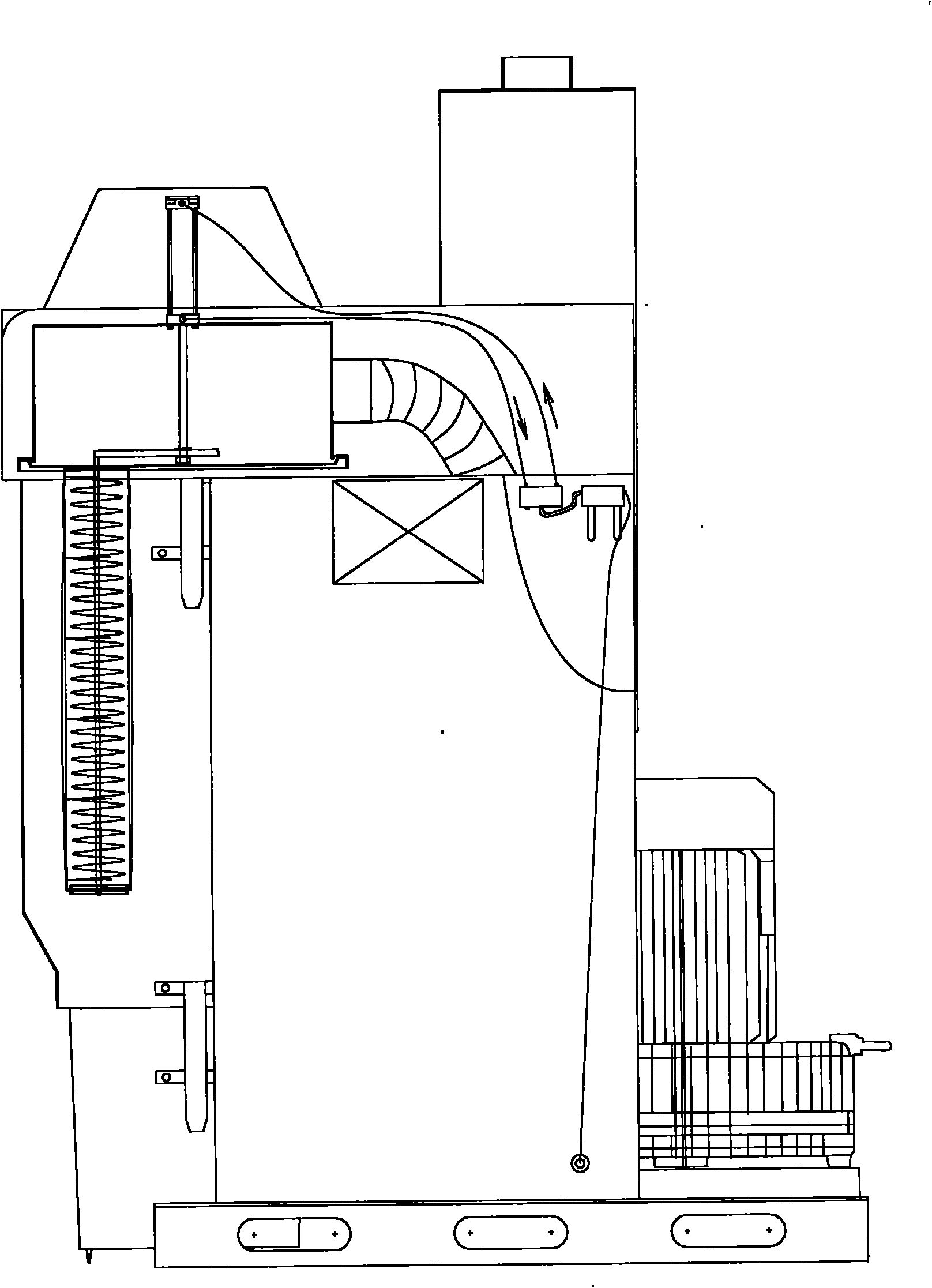

[0028] Such as figure 1 As shown, the dust removal component of the present invention is used to remove the dust deposited on the surface of the filter element of the bag filter, and the bag filter is located in the purification and dust removal bin 1 . Generally speaking, the pneumatic dust cleaning part of the bag filter of the present invention includes a mechanical part and an air control part.

[0029] The mechanical part of the cleaning unit includes a filter bag 110 , a pull rod 120 and an air cylinder 130 . Among them, the filter bag 110 is also a component of the bag filter in the purification and dust removal bin 1; the cylinder 130 is located above the top cover plate 2 of the high negative pressure welding fume purification device; one end of the pull rod 120 is located in the filter bag 110 for pushing and pulling the filter bag 110, and the other end is connected with the cylinder piston rod 1301.

[0030] The air control part of the cleaning unit includes a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com