Jet type scallop rim cleaning device

A technology of scallop skirt and cleaning device, which is applied in the direction of bivalves processing, etc., can solve the problems of reduced production efficiency, high price, long cleaning time, etc., and achieve the effect of stable work, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

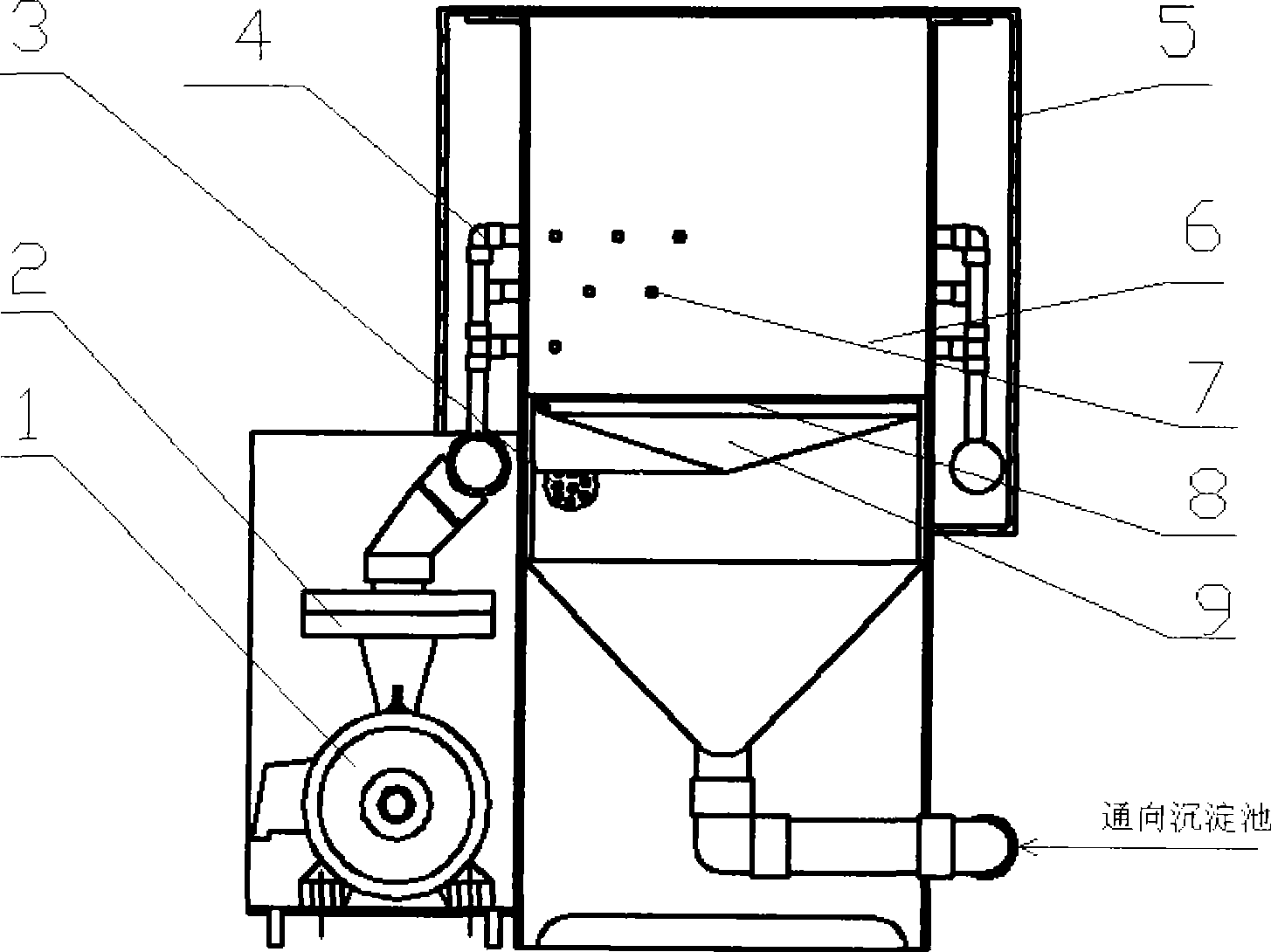

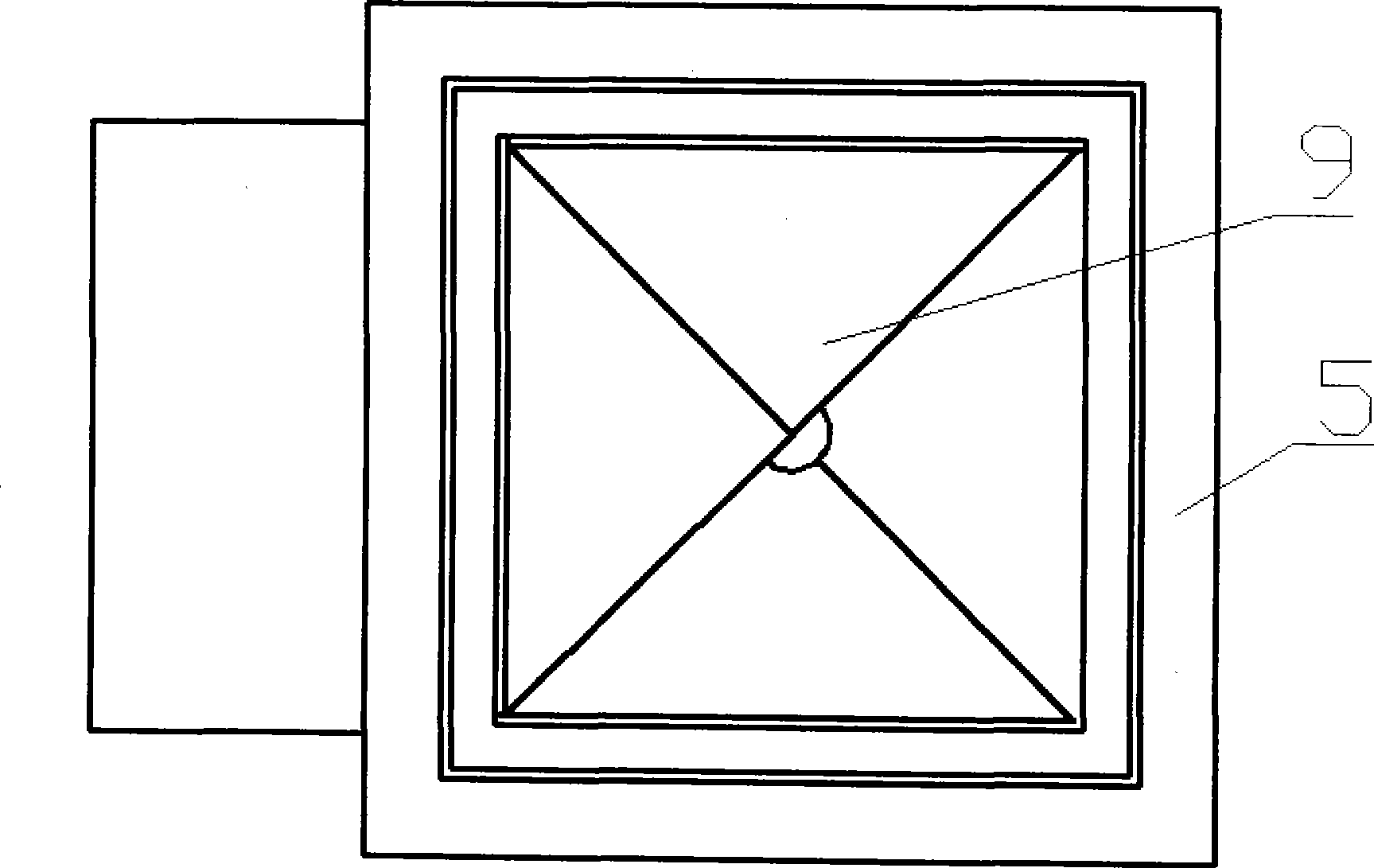

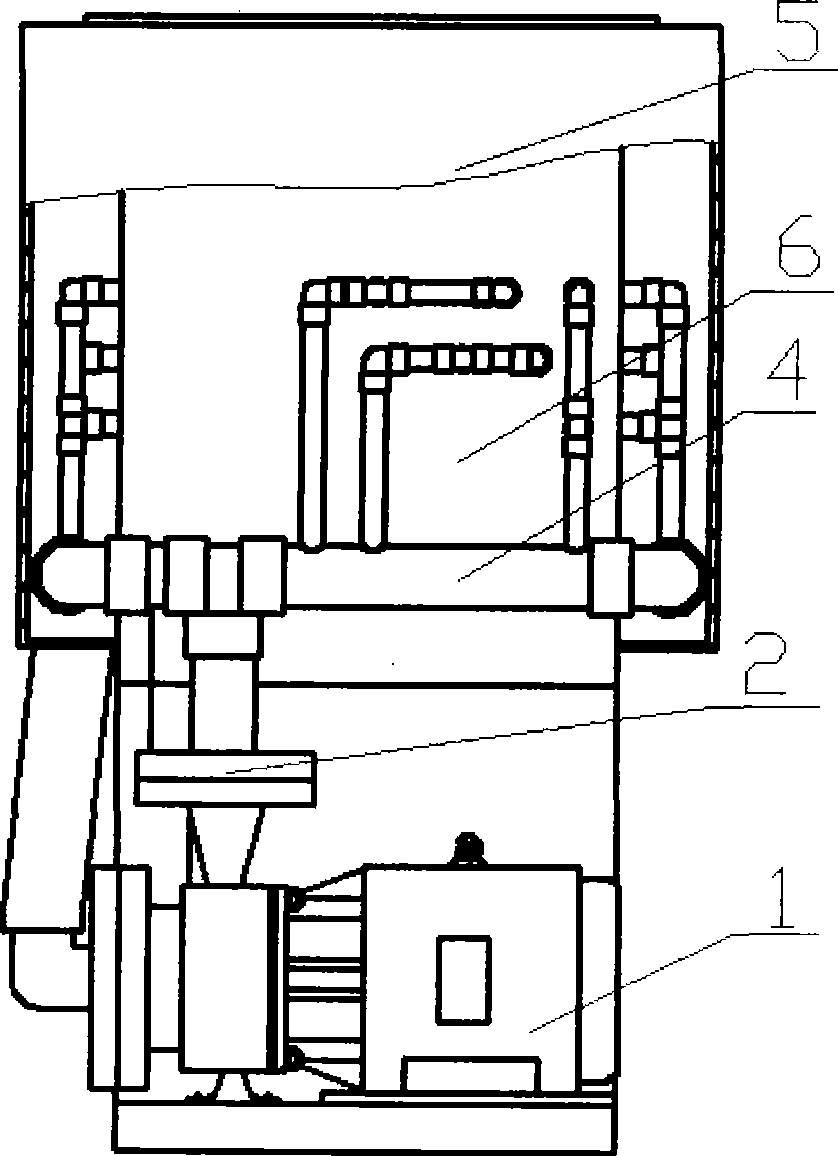

[0012] The box body 6 of the present invention is welded by a certain thickness of polyethylene material, and the seawater circulation pipeline 4 is welded on the box body 6 by polyethylene material, and the seawater circulation pipeline 4 is welded through the water spray hole 7 on the box body wall. It communicates with the inside of the tank 6 to ensure the overall circulation of water. The motor 1 drives the centrifugal pump 2 and connects with the seawater circulation pipeline 4 to provide power for the water circulation to ensure that the jet formed at the spray hole 7 has a certain pressure. The filter screen 3 is packaged at the water inlet of the centrifugal pump 2 to filter impurities. The baffle 9 divides the box body 6 into a cleaning area and a sedimentation area. Separation to achieve the purpose of cleaning.

[0013] The material selection and application of the device are not limited to the materials, and different materials can be selected according to differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com