Patents

Literature

91results about How to "No need for high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

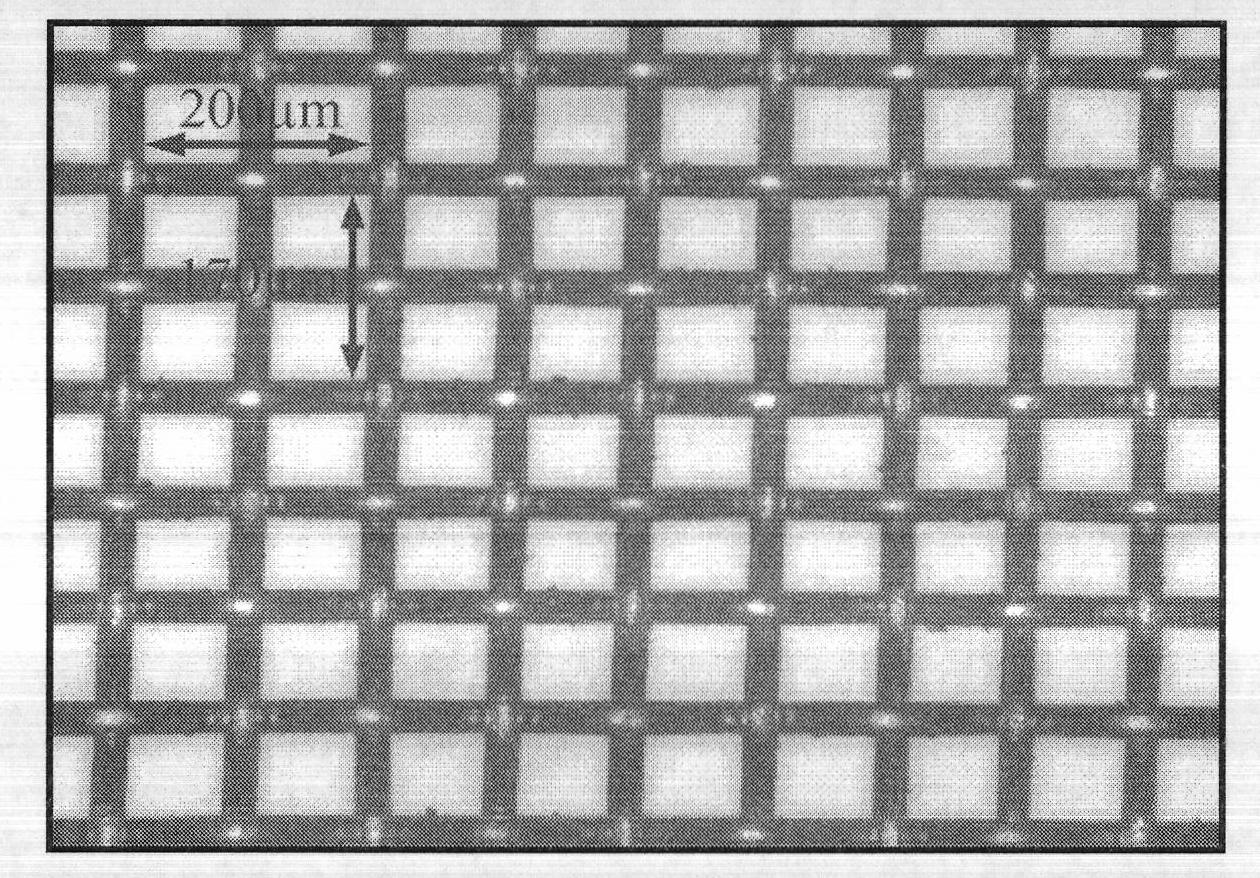

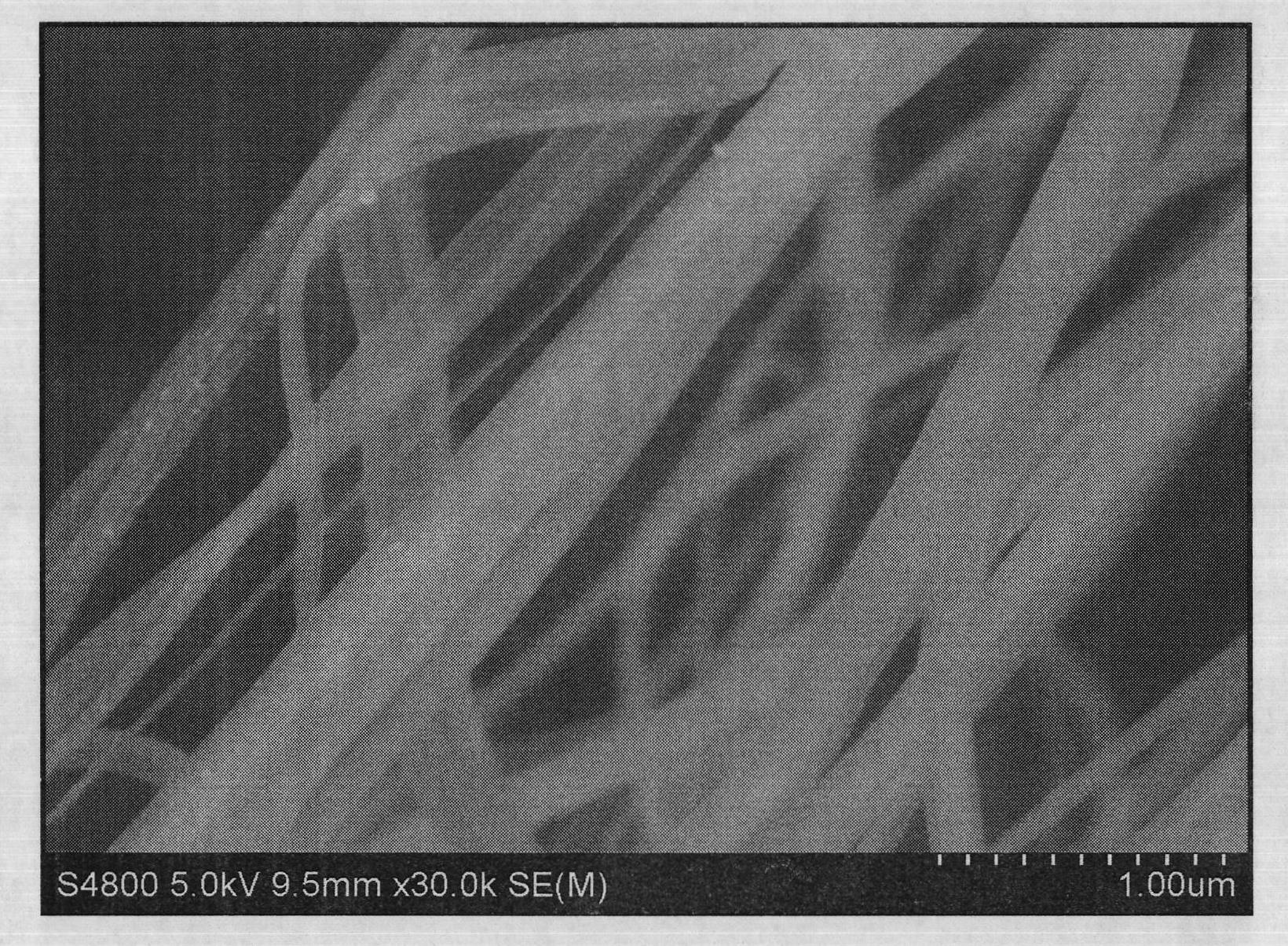

Manufacturing method of carbon nano tube paper

A carbon nanotube paper is prepared from carbon nanotubes through adding them to acid, heating or thermal reflux, and / or ultrasonic stirring, removing impurity, diluting in water, filtering, washing the filtered cake, dispersing the carbon nanotubes in water by ultrasonic stirring, spreading on carrier, and drying. It has regular structure, high uniformity, purity and electric conductivity, and enough mechanical strength.

Owner:TSINGHUA UNIV

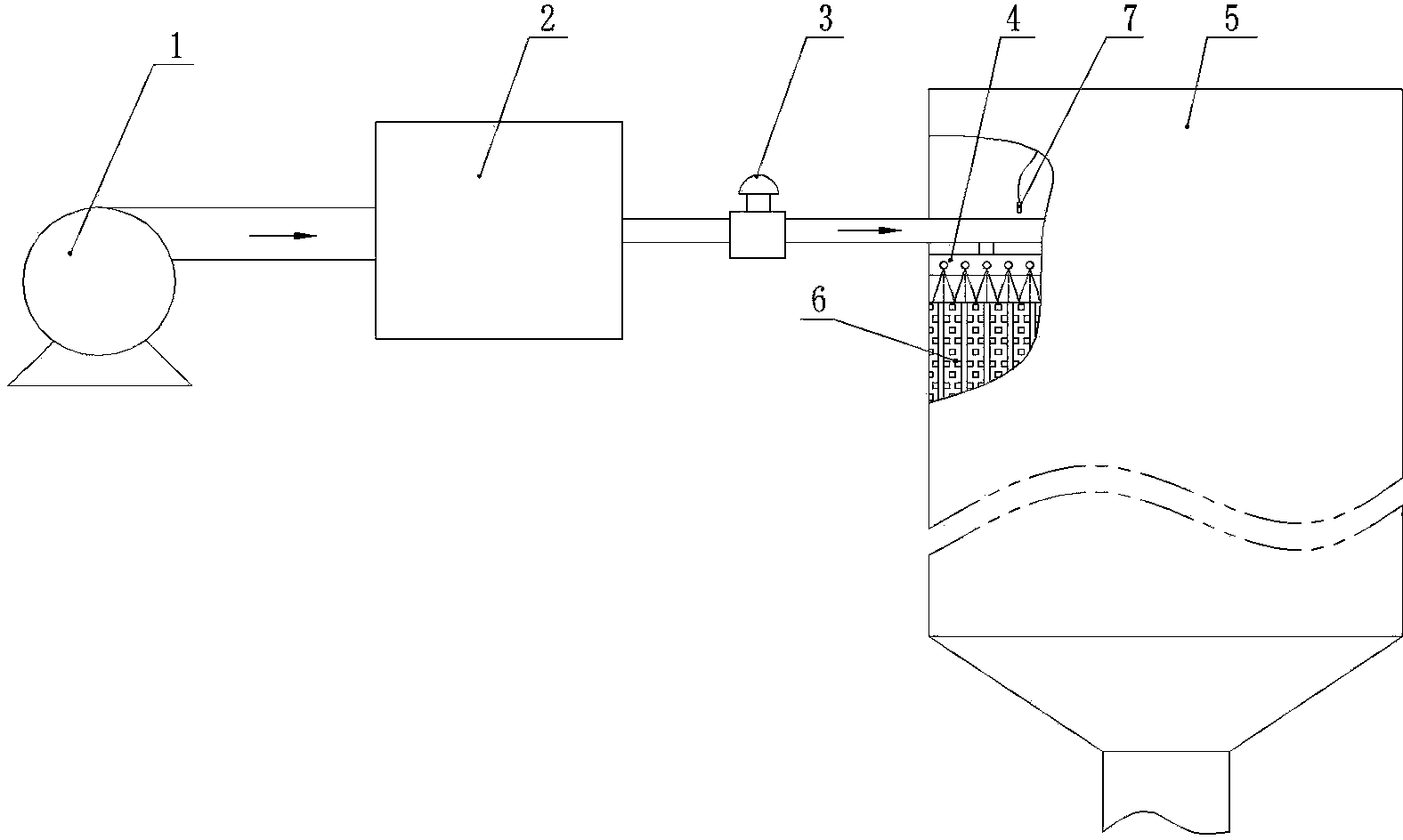

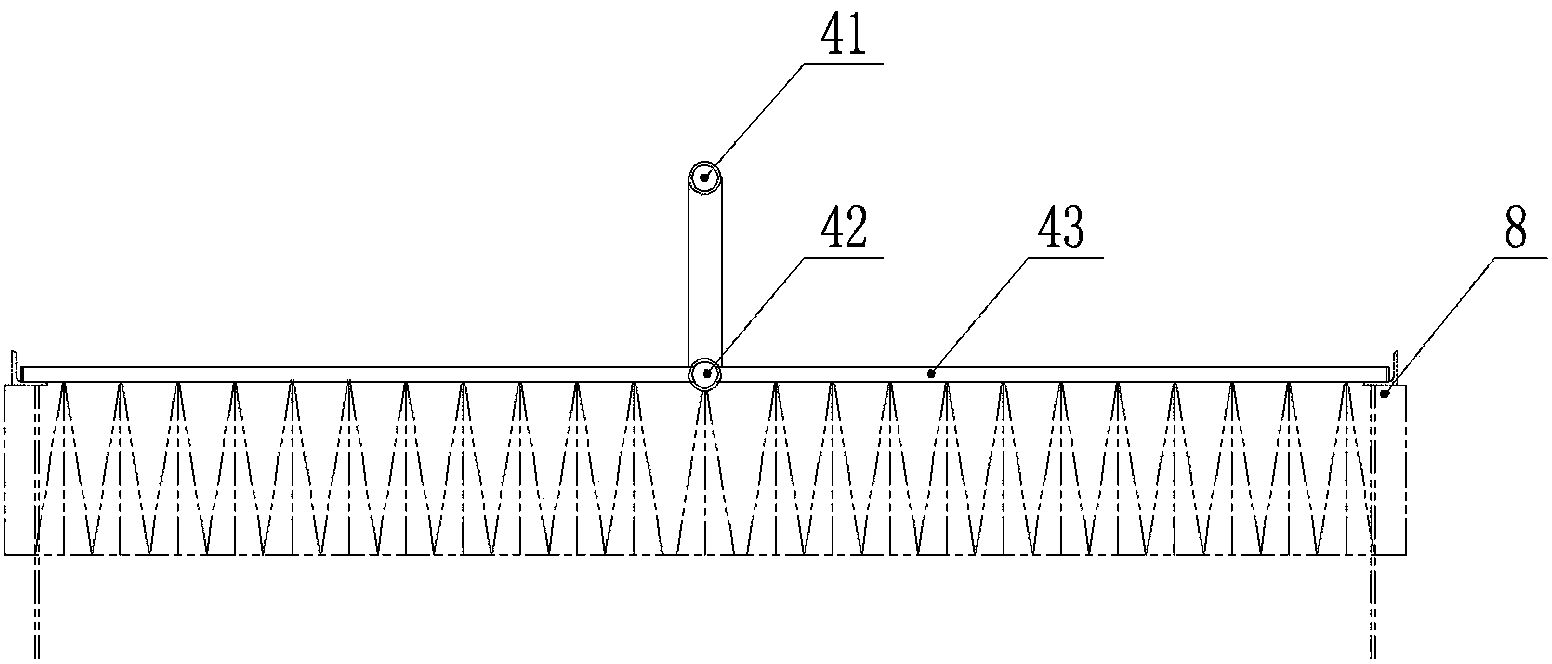

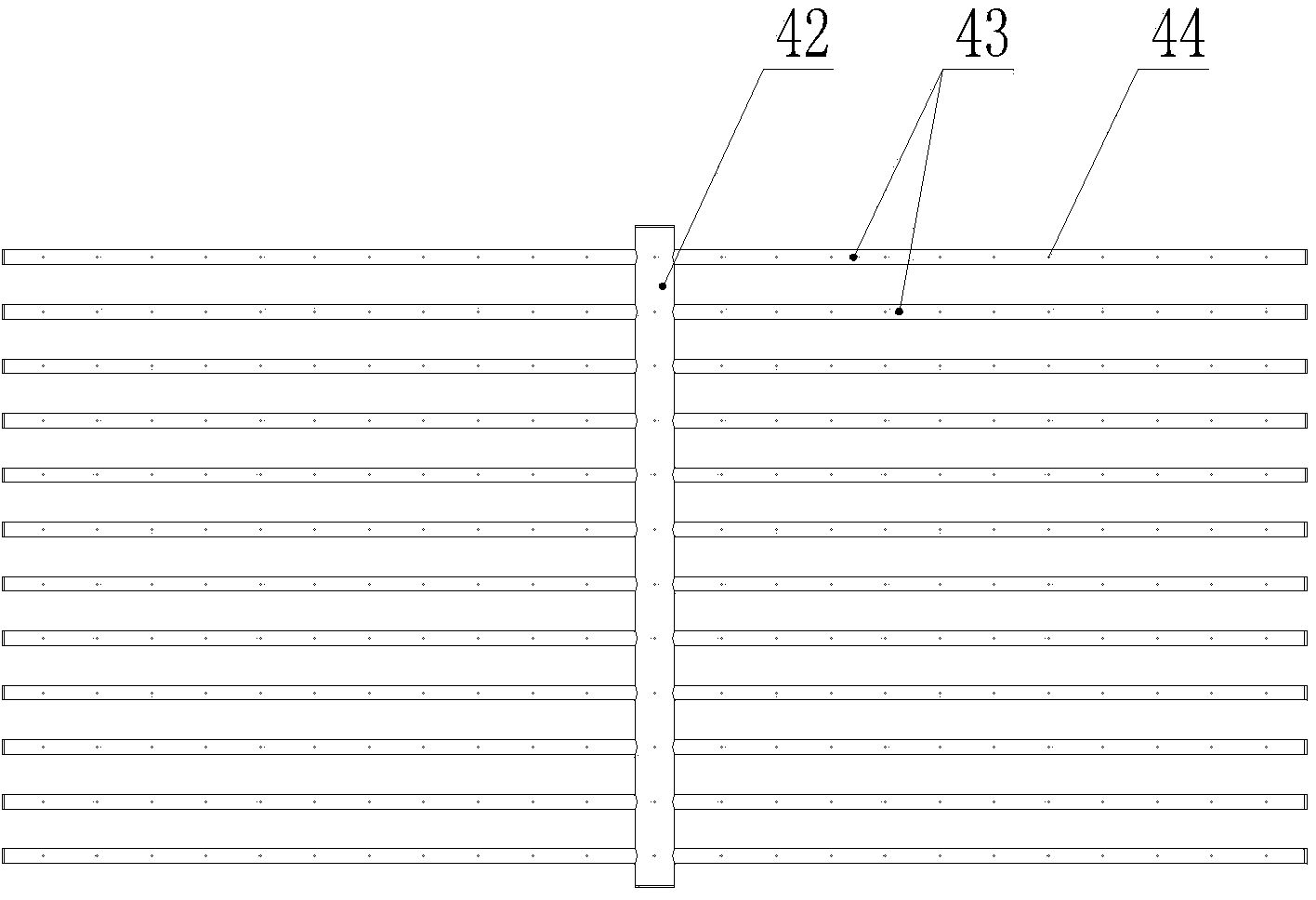

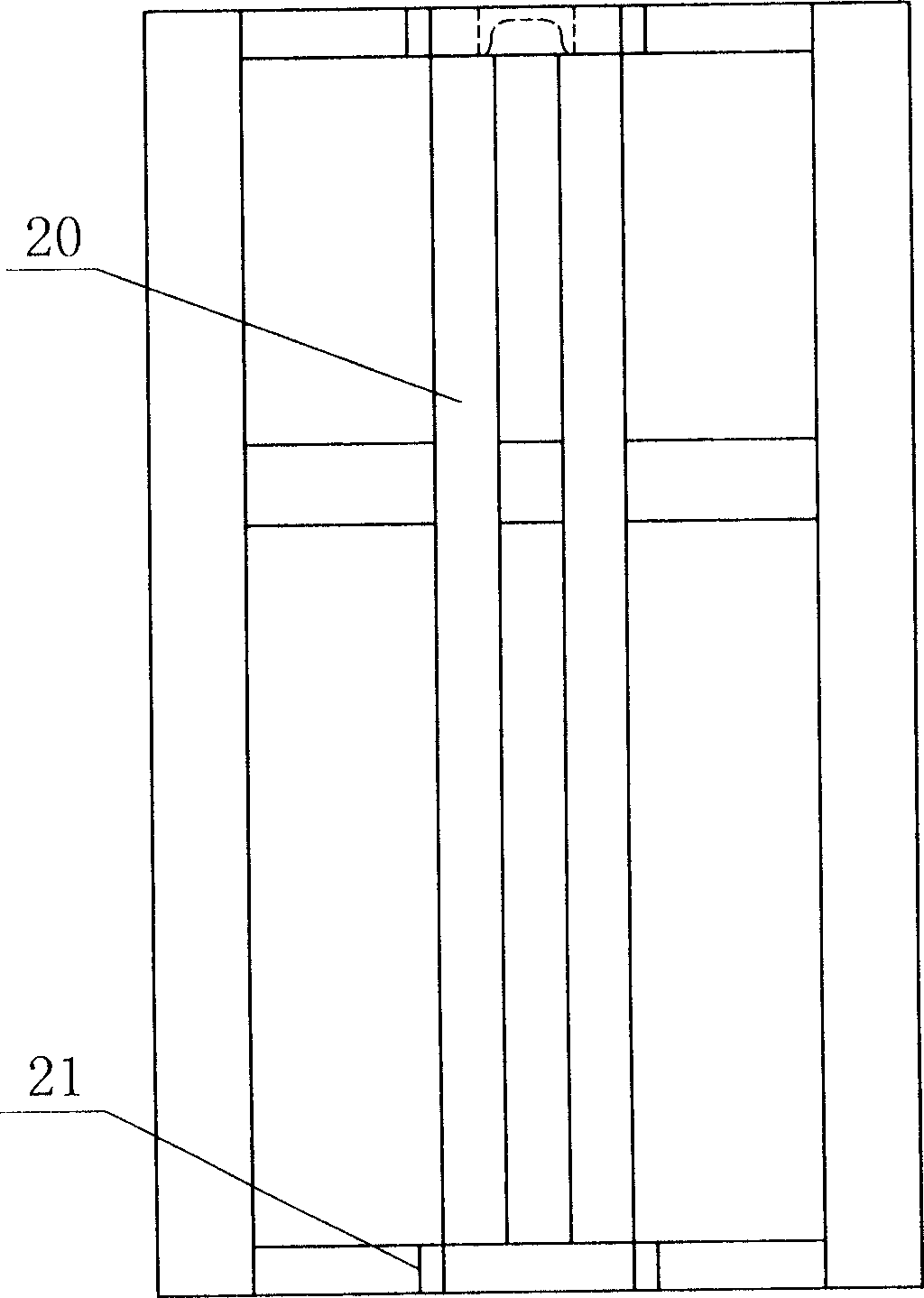

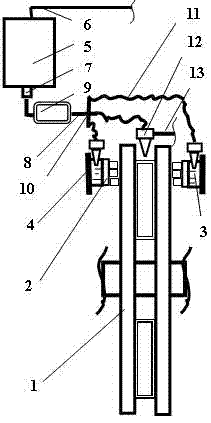

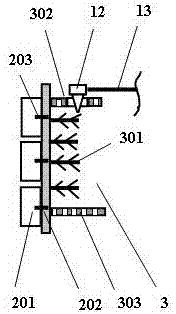

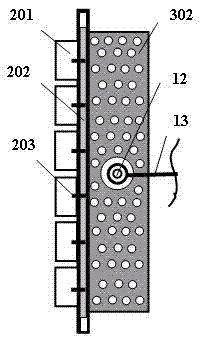

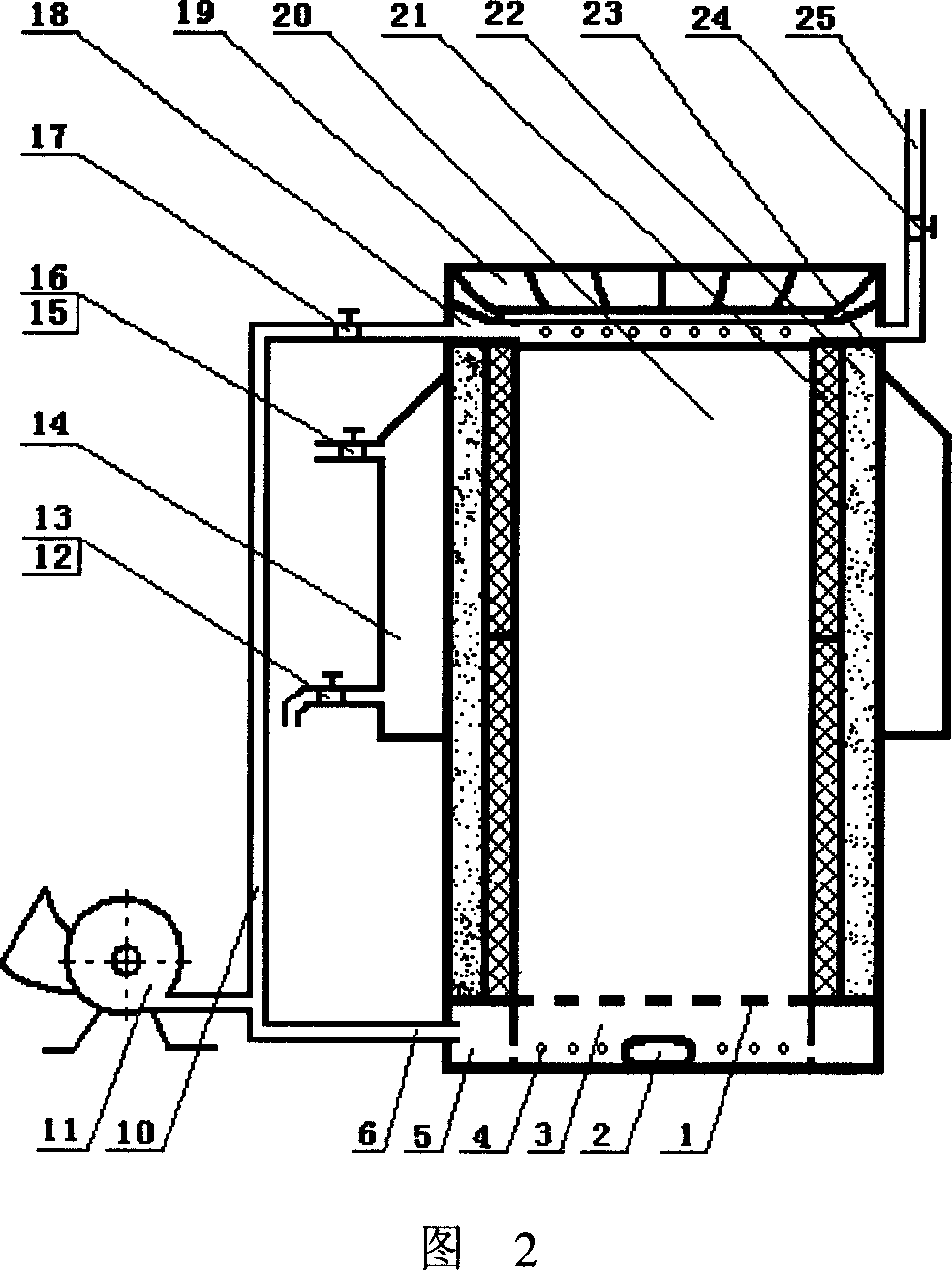

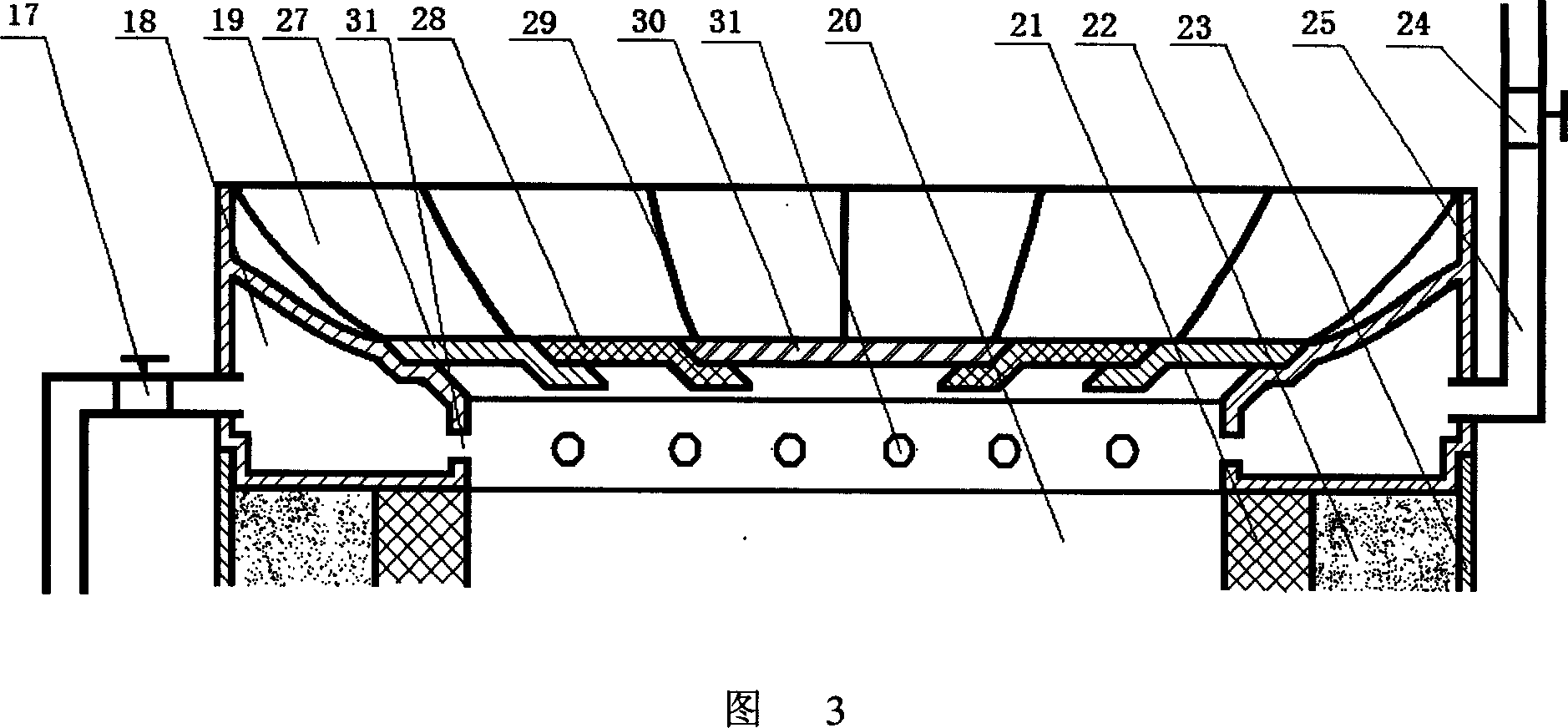

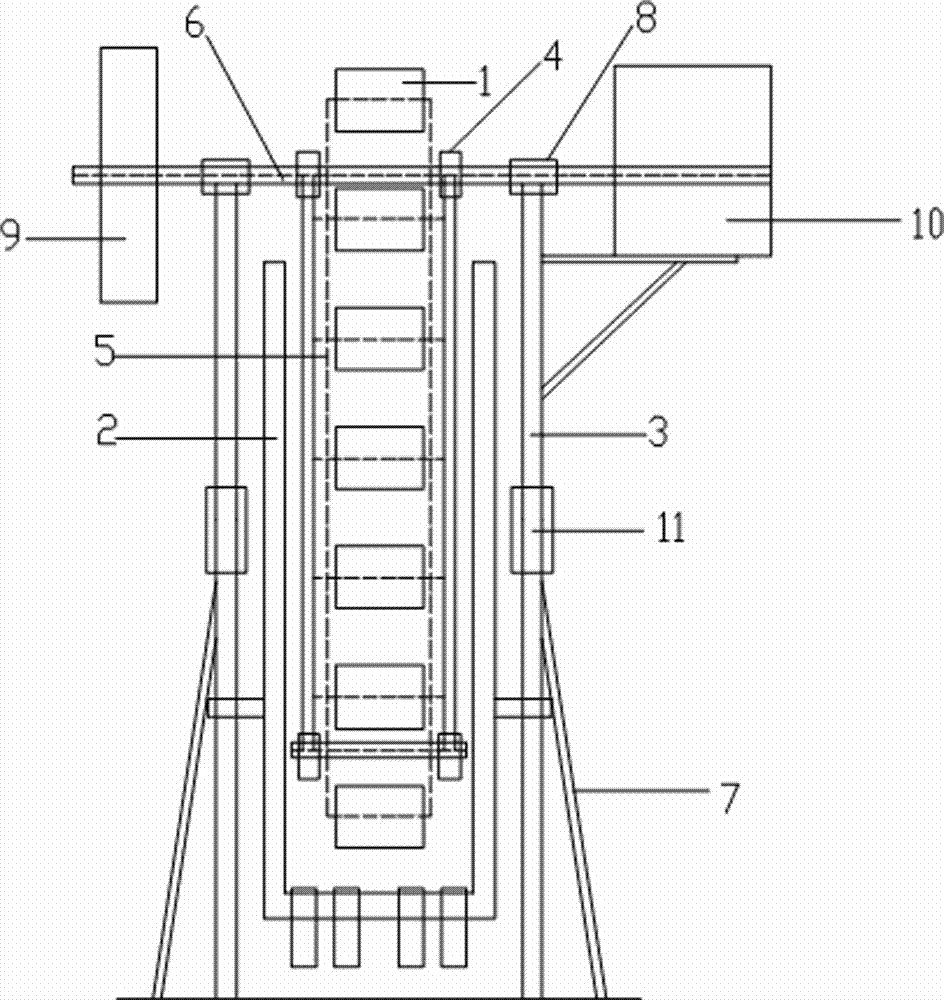

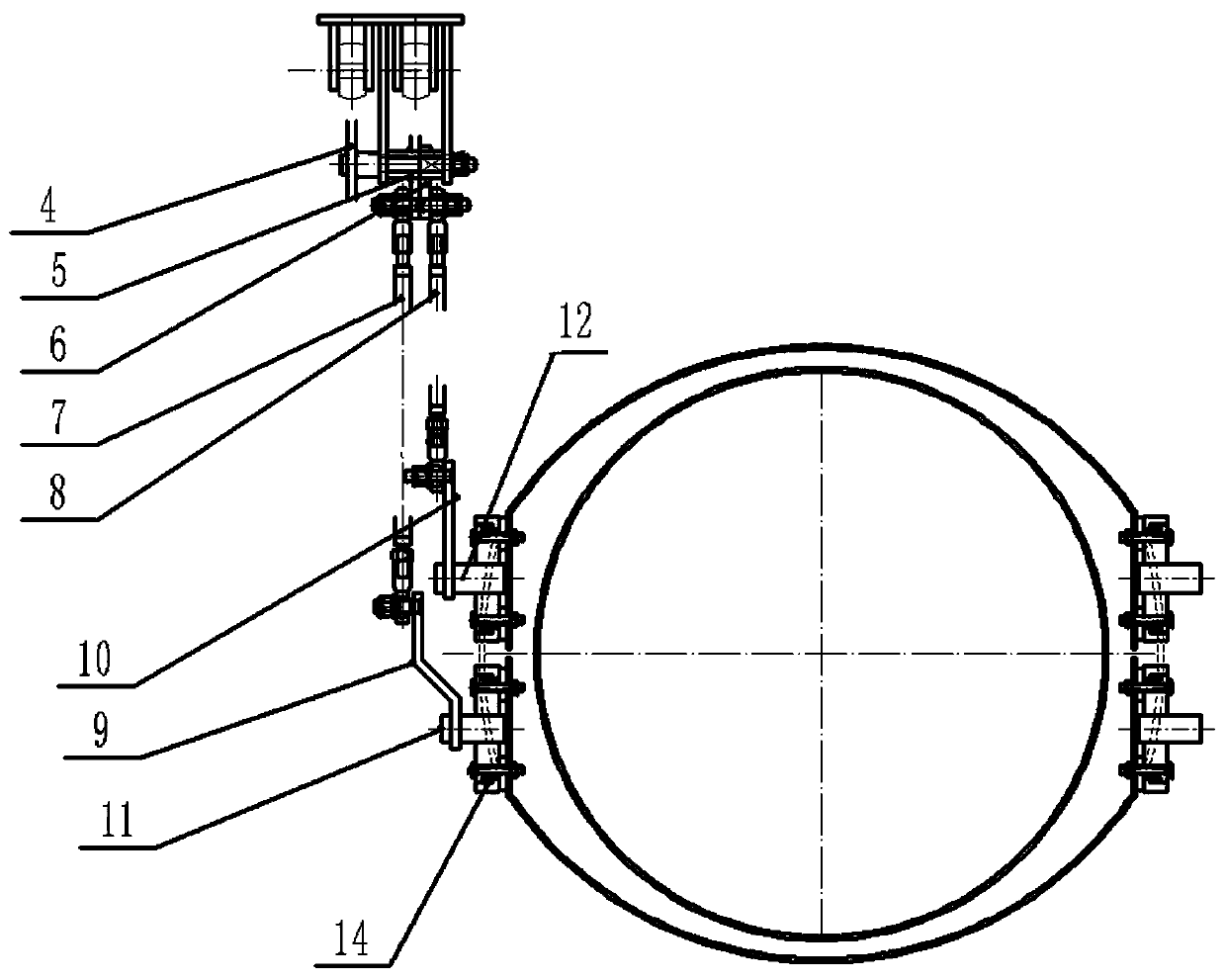

Dust blowing device for selective catalytic reduction (SCR) denitration reactor

InactiveCN103432904ASoot blowing forceThorough cleaningDispersed particle separationBuffer tankSolenoid valve

The invention discloses a dust blowing device for a selective catalytic reduction (SCR) denitration reactor. The dust blowing device comprises an air compressor, a buffer tank, a solenoid valve and jet pipe network unit module which are communicated in sequence; the jet pipe network unit module is positioned on catalyst units positioned in the SCR denitration reactor and jet pipes in the jet pipe network unit module are in one-to-one correspondence with the catalyst units. In the dust blowing device, a dust blowing air source is provided for the jet pipe network unit module by utilizing the air compressor; compressed air is stored and released by utilizing the buffer tank; the opening and the closing of the buffer tank is controlled by utilizing the solenoid valve; the jet pipes which are in the jet pipe network unit module and are in one-to-one correspondence with the catalyst units blow away dust in a manner of being dead against catalysts. The dry compressed air serves as a dust blowing medium, so that the normal work of the catalyst in a dry state is guaranteed. The dust blowing device has no vibration, no high temperature, no dead angle or no gathered dust residue, and has a large coverage surface when the gathered dust is cleaned by the compressed air; the service life of the catalysts is prolonged; the replacement cycle of the catalysts is prolonged; the denitration efficiency is effectively improved; an energy resource is saved.

Owner:HUNAN LUNAN DESULFURIZATION & DENITRATION TECH

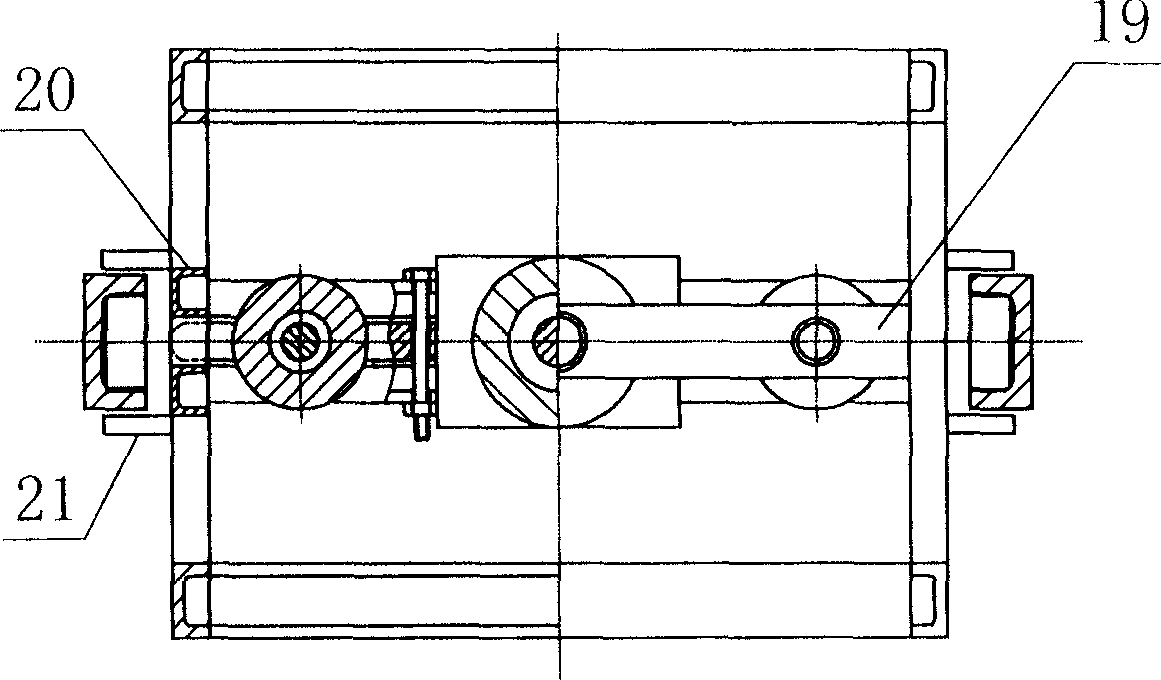

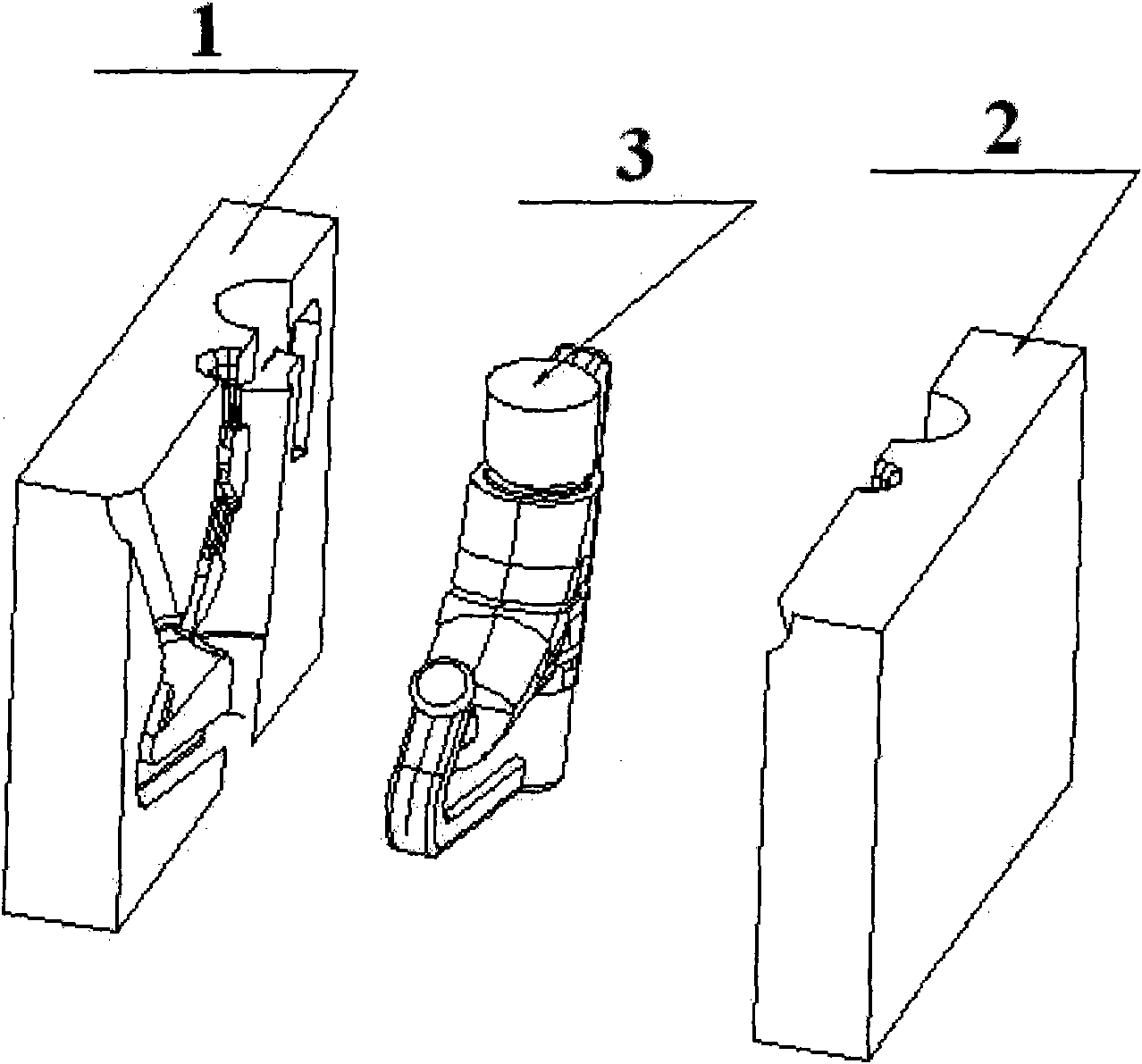

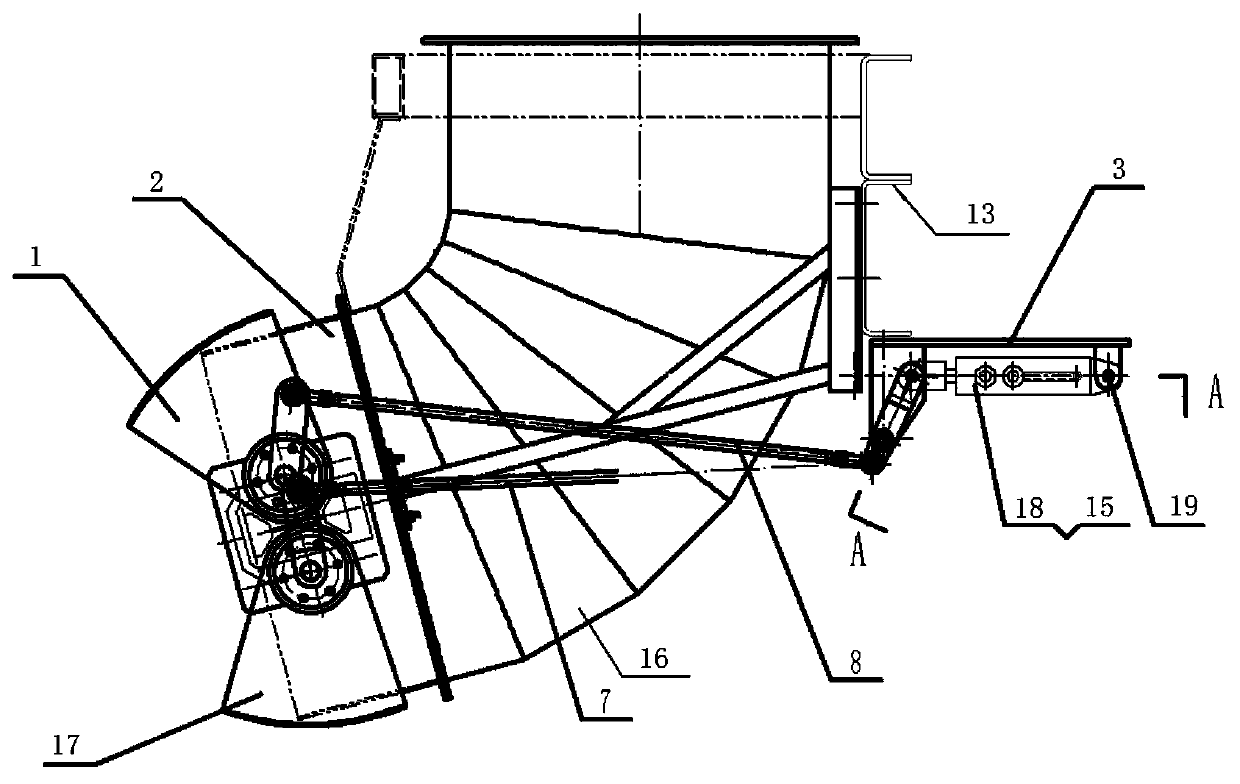

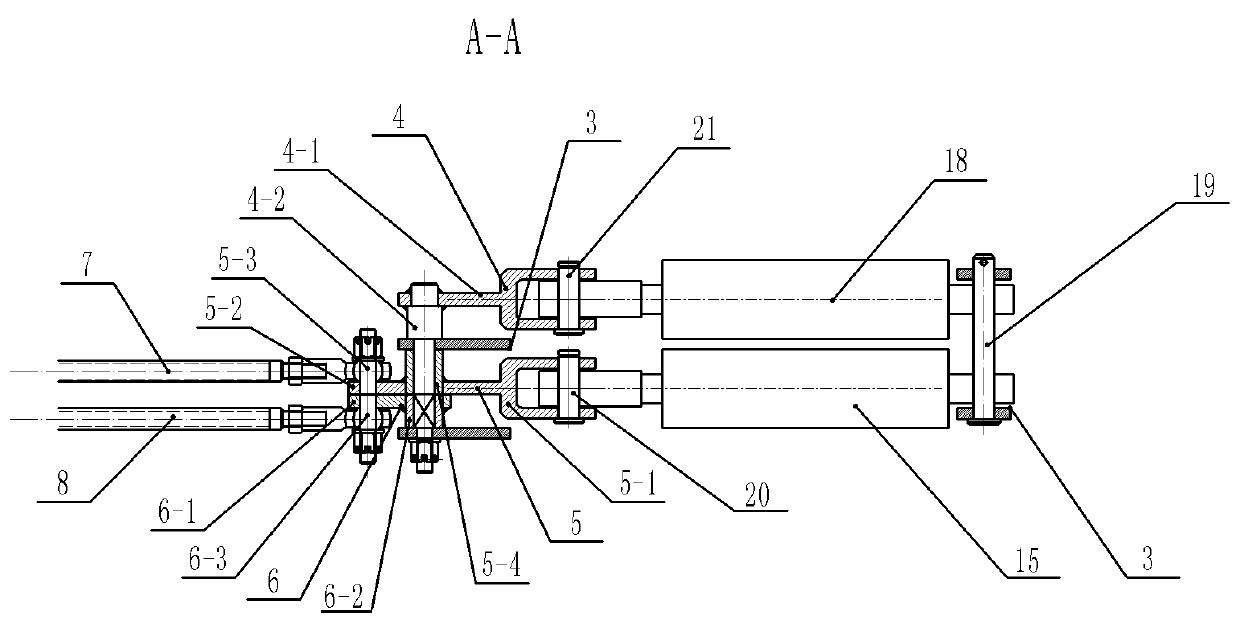

Buffer-braking anti-falling device for disposing rope breakage of vertical conveyor

The invention discloses a cut-wire baffle brake anti-drop device of vertical lifter, which comprises a guide rail support and a compartment. It is characterized in that: the upper part of compartment is mounted with a brake; said brake is formed by a brake beam inside the compartment and the brake rods symmetry mounted on two sides of brake beam via brake axle; the top surface inside the compartment is mounted with a cut-wire sensor; said cut-wire sensor is formed by a sensing rod, a compress plate at the lower end of sensing rod, and a sensing spring and a sensor sheath that sheathing the sensing rod; the upper end of sensing rod is guided out the top surface to connect steel wire; said compress plate is at the upper end of brake rod; the brake beam is mounted with buffers that at two sides of cut-wire sensor; the lower end of buffer is near to the brake rod; and the inner side of guide rail support is uniformly mounted with blocks. The invention has the advantages that: it will not generate high temperature and splash, and abrade work-piece, with short brake distance, high safety, and reliable operation.

Owner:王朝前 +1

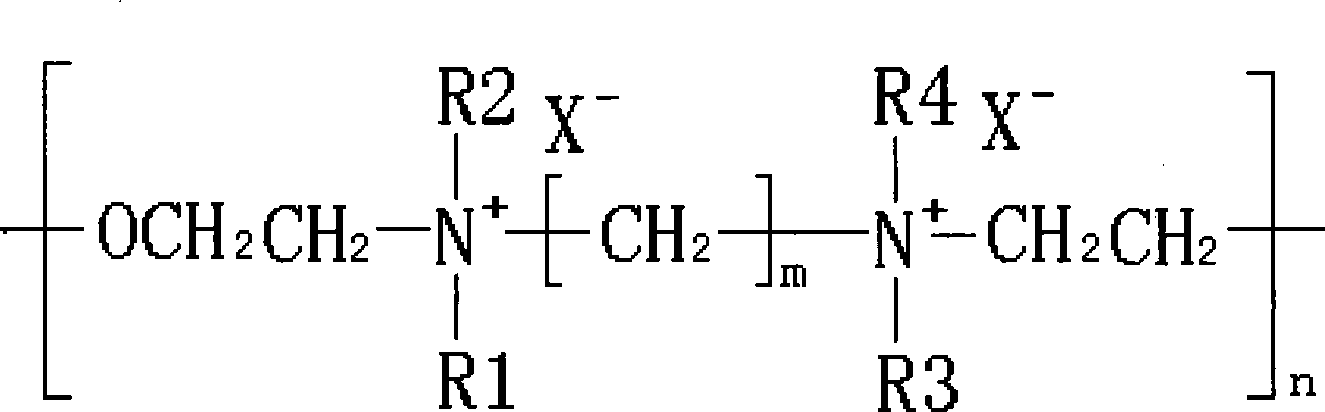

Preparation method for disinfection algicide for swimming pool

InactiveCN101121557ANon-irritatingThe preparation method is simple and environmentally friendlyWater/sewage treatment using germicide/oligodynamic-processHalogenAqueous solution

The present invention discloses a manufacturing method of the high-efficient, innoxious and safe sterilizing and alga-destroying thing used in the natatorium. The method mainly comprises the following steps: under the protection of the inert gases, the frank-chain fat diamines is reacted with the dihydroxy ethyl aether in the water solution, and then are treated by the treating thing. The reaction liquid is adjusted to litmusless. The sterilizing and alga-destroying thing with the structure can be obtained. Thereinto, R1, R2, R3, R4 are respectively selected from H and a saturated or unsaturated alkyl including at least one carbon atom; m is among 1 to 14; n is among 1 to 5000; X represents a halogen ion combined with a positive ion. The product can be widely used for sterilizing and alga-destroying for the natatorium.

Owner:SOLVAY ZHANGJIAGANG SPECIALTY CHEM

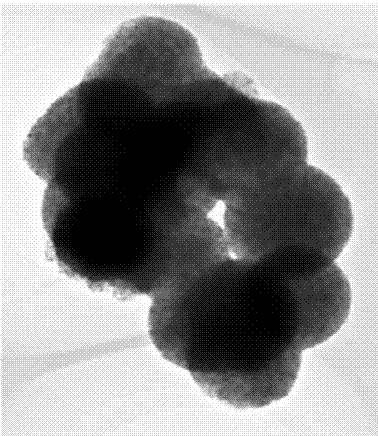

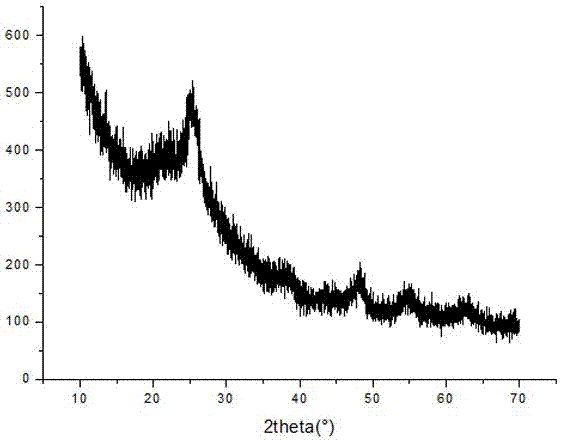

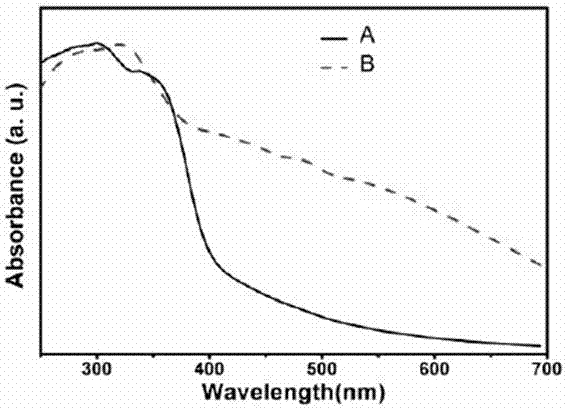

High-efficiency visible light response amorphous plasma heterojunction nano TiO2 sol

ActiveCN106914236AImprove photocatalytic performanceBroaden the photoresponse rangeAntifouling/underwater paintsWater/sewage treatment by irradiationPrecious metalSemiconductor

The invention discloses an amorphous plasma heterojunction nano TiO2 sol having high-efficiency visible light response as well as a preparation method and an application thereof. The amorphous plasma heterojunction nano TiO2 sol is formed by taking a heterojunction structural body formed by precious metals and nano TiO2, or other semiconductor-precious metals and nano TiO2 by chemical connection as nano particles, schottky junction generated by cooperation among precious metals and nano TiO2 or other semiconductor-precious metals and nano TiO2 is used for performing resonance effects with local surface plasma to obtain the excellent visible-light photocatalysis effect, and the problem of low visible-light utilization rate of common TiO2 photocatalysts can be solved.

Owner:FUZHOU MINGGU NANOMETER SCI & TECH

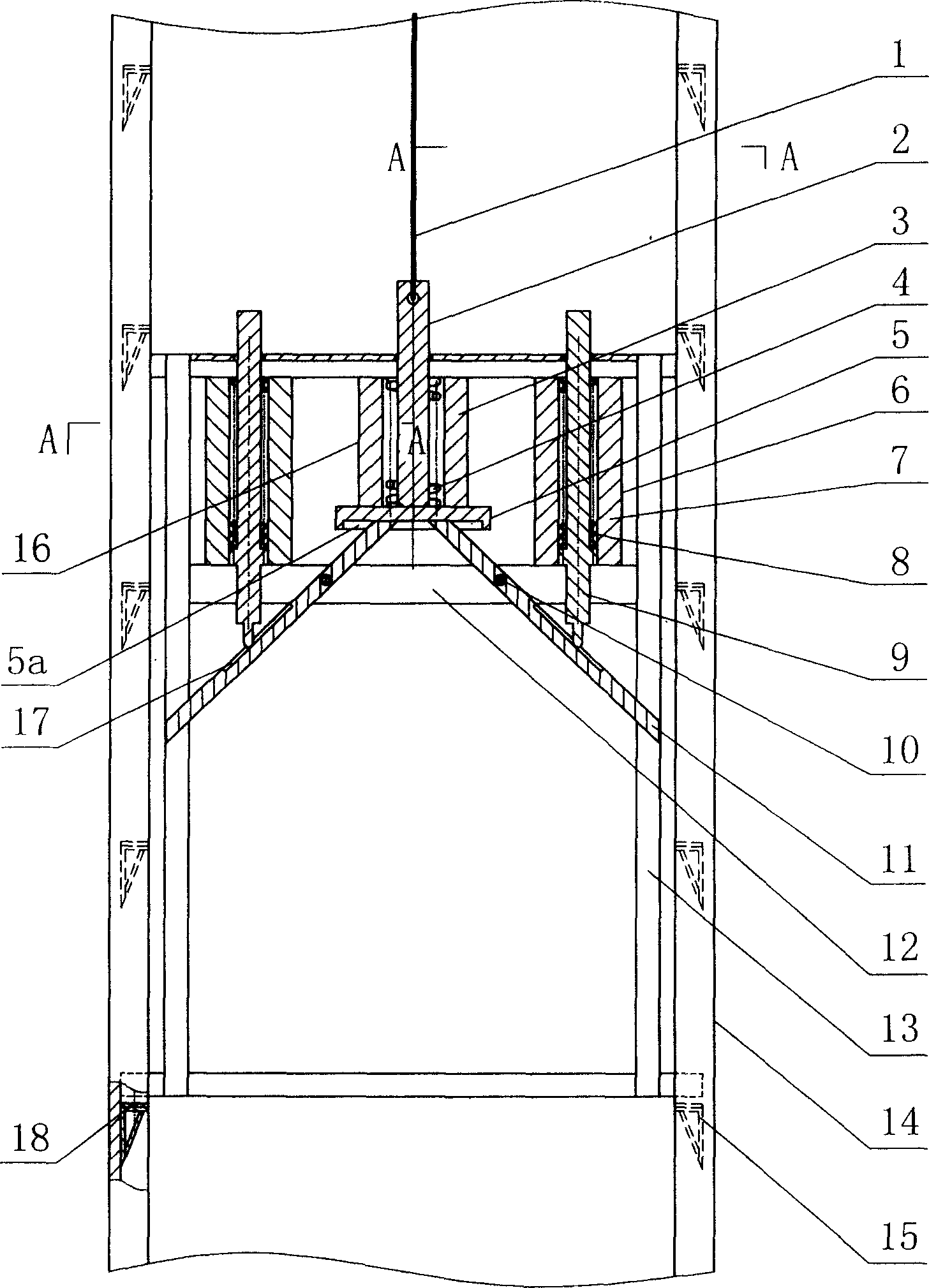

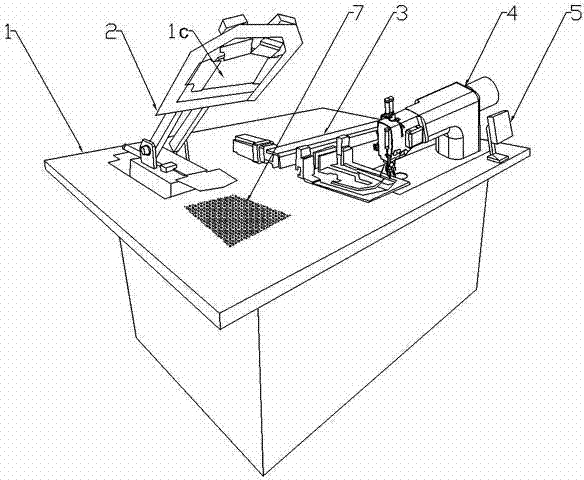

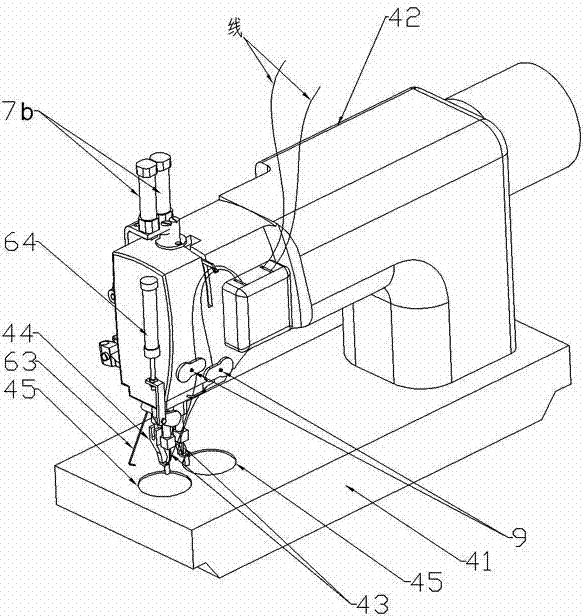

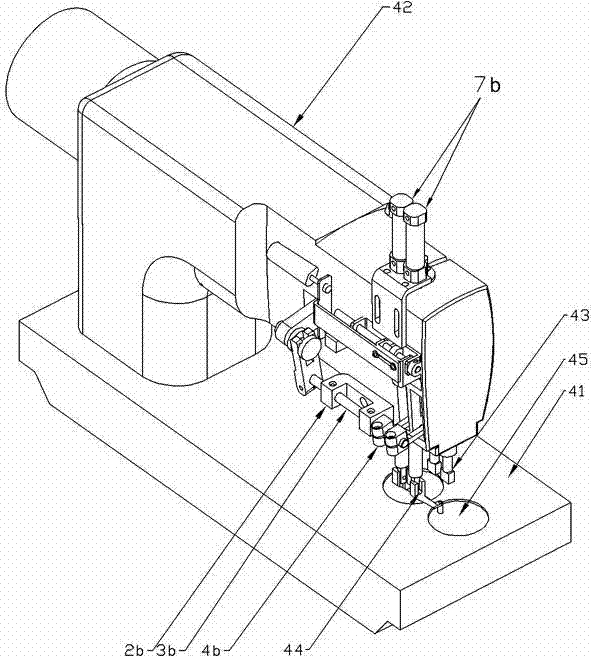

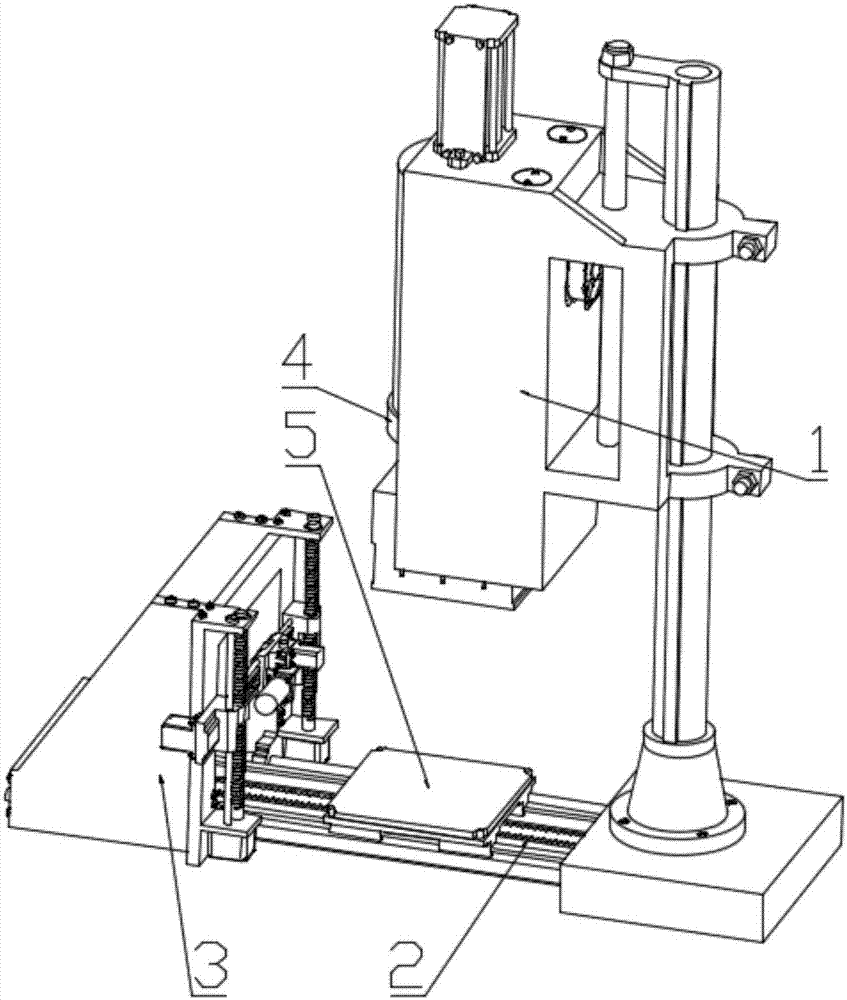

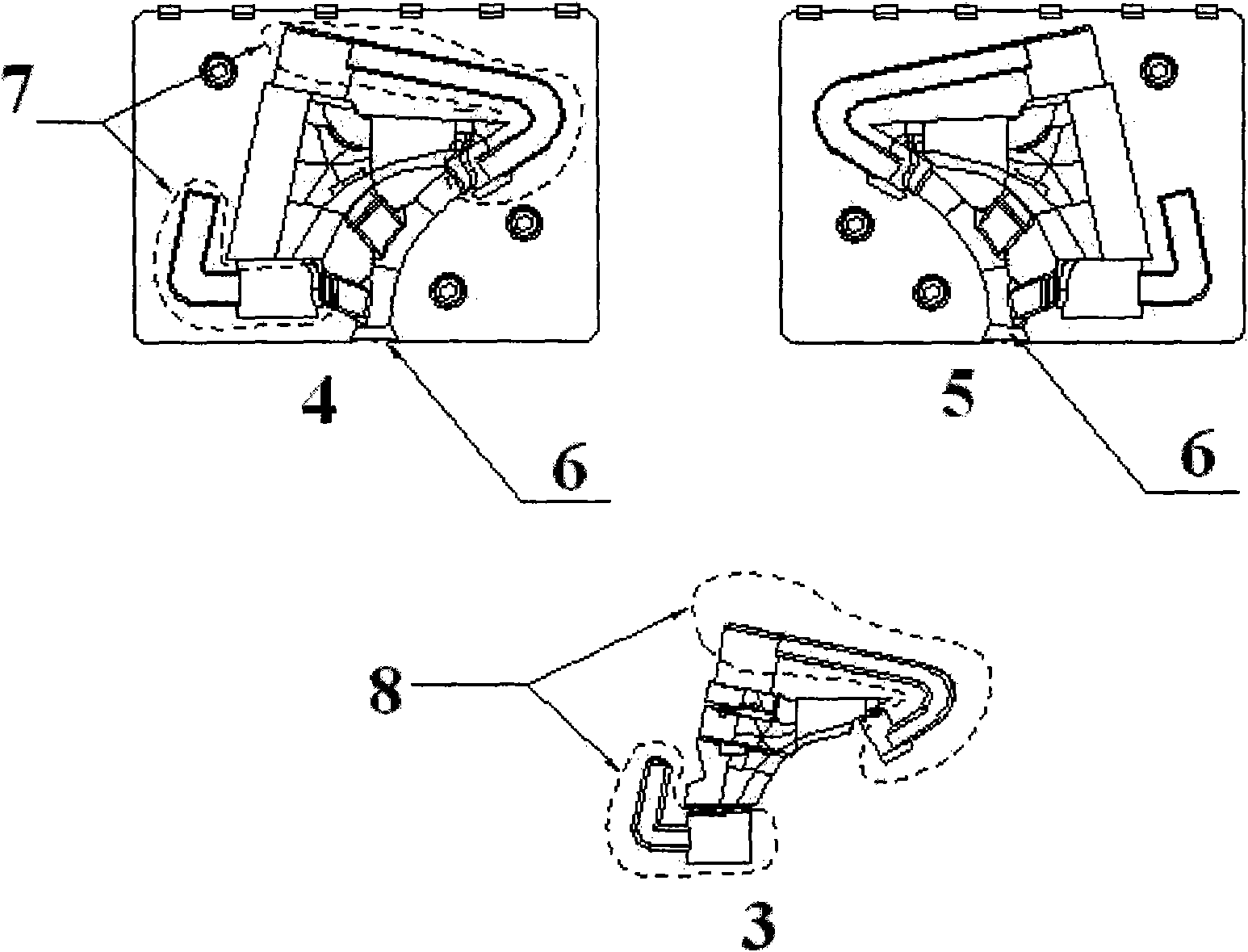

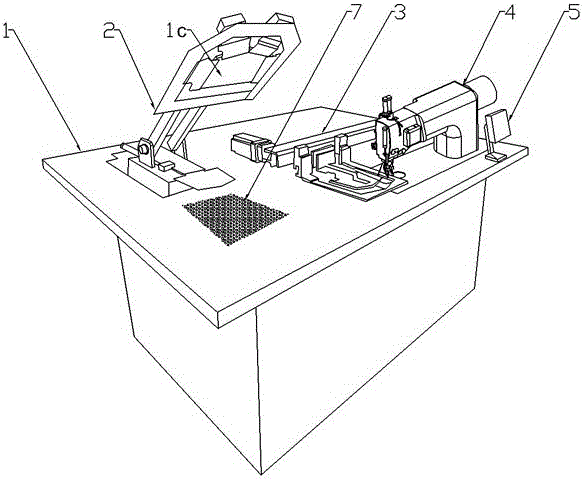

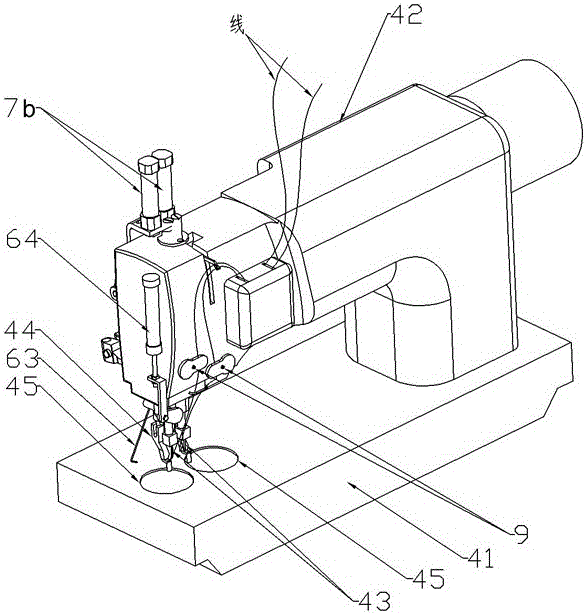

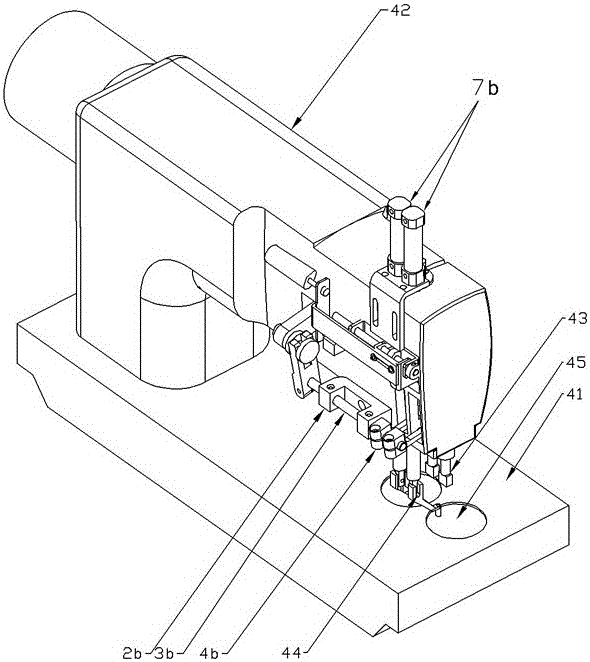

Full-automatic pocket patching machine

ActiveCN104746243ASo as not to damageSolve the contradiction between supply and demandWork-feeding meansPressersEngineeringFully automated

The invention discloses a full-automatic pocket patching machine and accordingly the working efficiency is high, the degree of automation is high, and sewn finished products comprise double sides and multiple colors. The full-automatic pocket patching machine comprises a base station (1) and a material folding mechanism (2), a feeding mechanism (3), a sewing mechanism (4) and a controller (5) which are arranged on the base station (1); the sewing mechanism (4) comprises a sewing table, a head, at least two working needles, a plurality of pressing feet, an automatic needle replacement module and a pressing foot lifting mechanism; the working needles are arranged on the head; the pressing feet are matched with the working needles respectively; the pressing foot lifting mechanism is matched with the pressing feet; the sewing table is provided with at least two spindles which are matched with the working needles respectively. The full-automatic pocket patching machine is applied to the technical field of automatic sewing equipment.

Owner:深圳市达益信智能设备有限公司

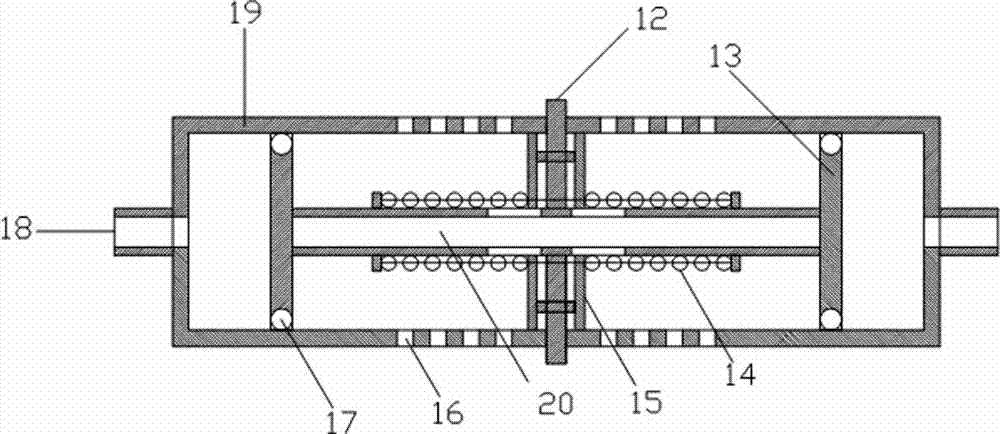

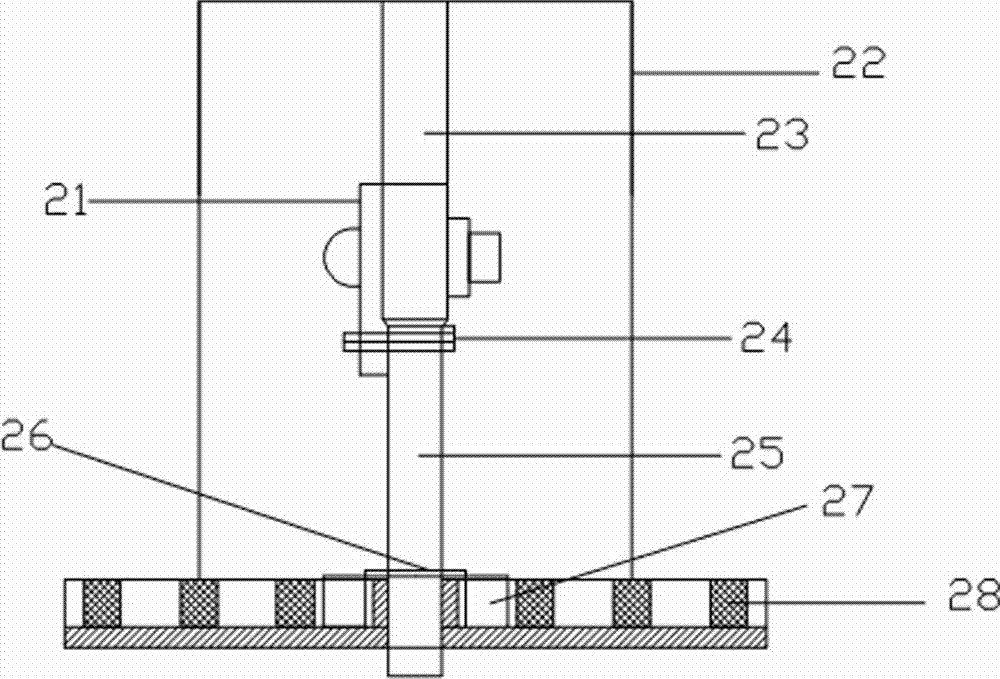

Compound ultrasonic fusion deposition additive-manufacturing device and compound ultrasonic fusion deposition additive-manufacturing method

ActiveCN107244072AHigh mechanical strengthImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringUltrasonic vibration

The invention relates to a compound ultrasonic fusion deposition additive-manufacturing device and a compound ultrasonic fusion deposition additive-manufacturing method, and belongs to the technical field of additive manufacturing. An ultrasonic enhancement device is fixed to a guide rod I and a guide rod II of an ultrasonic support platform; a moving base plate is installed on a guide rail I and a guide rail II of an X-directional guide connection system, and fixed to a synchronous belt simultaneously; the moving base plate is driven to move through an X-directional motor; and a fusion deposition additive-manufacturing system and the ultrasonic support platform are connected through a connection rod I and a connection rod II in the X-directional guide connection system. Parts with poor adhesion among fusion deposition wire materials and between the deposition wire materials and a deposition layer can be re-melted by virtue of ultrasonic vibration, and the deposition wire materials in formed parts are compounded into one piece, so that the comprehensive mechanical property of fusion deposition additive-manufactured parts, and in particular, the mechanical strength in the vertical direction of a forming axis, is remarkably improved.

Owner:李桂伟

Method for preparing reducing sugar by promoting lignocellulase to hydrolyze by ultrasonic pre-treatment in pressurized hot water

The invention belongs to the technical field of green chemistry and clean energy and relates to a method for preparing reducing sugar by promoting lignocellulase to hydrolyze by ultrasonic pre-treatment in pressurized hot water. The method comprises the following steps: mixing deionized water with lignocellulose in a mass ratio of (10-100) to 1 and introducing 3-10MPa carbon dioxide or nitrogen at 80-120 DEG C; applying an ultrasonic field with the frequency being 40-60kHz and the power being 90-600W for 10-120 minutes; releasing the pressure to normal pressure within 2-10 minutes and drying; adding an 0.2M acetic acid-sodium acetate buffer solution with the pH of 4.8 to the lignocellulose, wherein the mass ratio of the buffer solution to the lignocellulose is 50 to 1; and then adding cellulase, and hydrolyzing to obtain the reducing sugar, wherein the mass ratio of the cellulase to the lignocellulose is (0.5-1.2) to 1. The method provided by the invention is time-saving, mild in condition, low in energy consumption, simple in process, low in cost, green and free from pollution.

Owner:DALIAN UNIV OF TECH

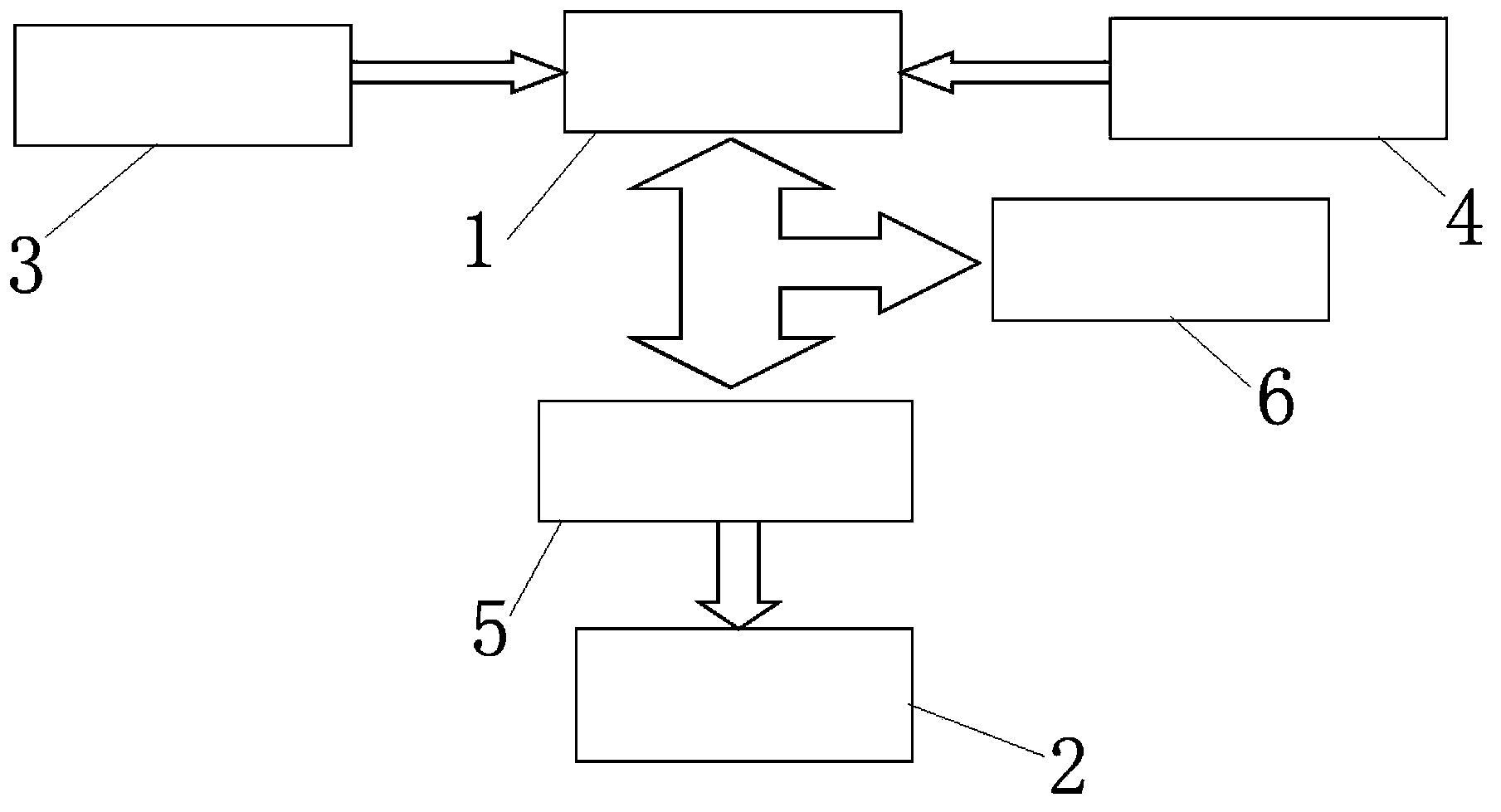

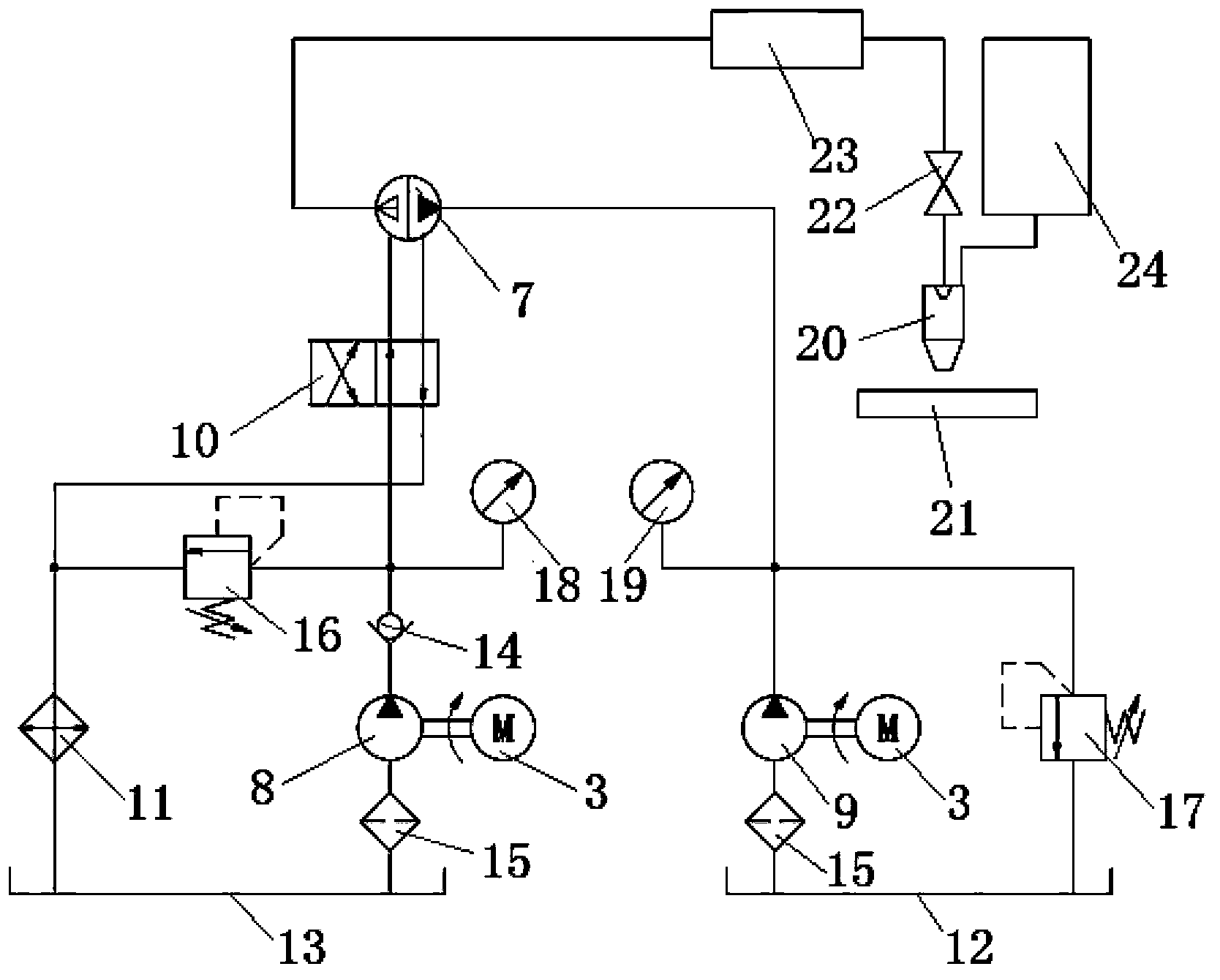

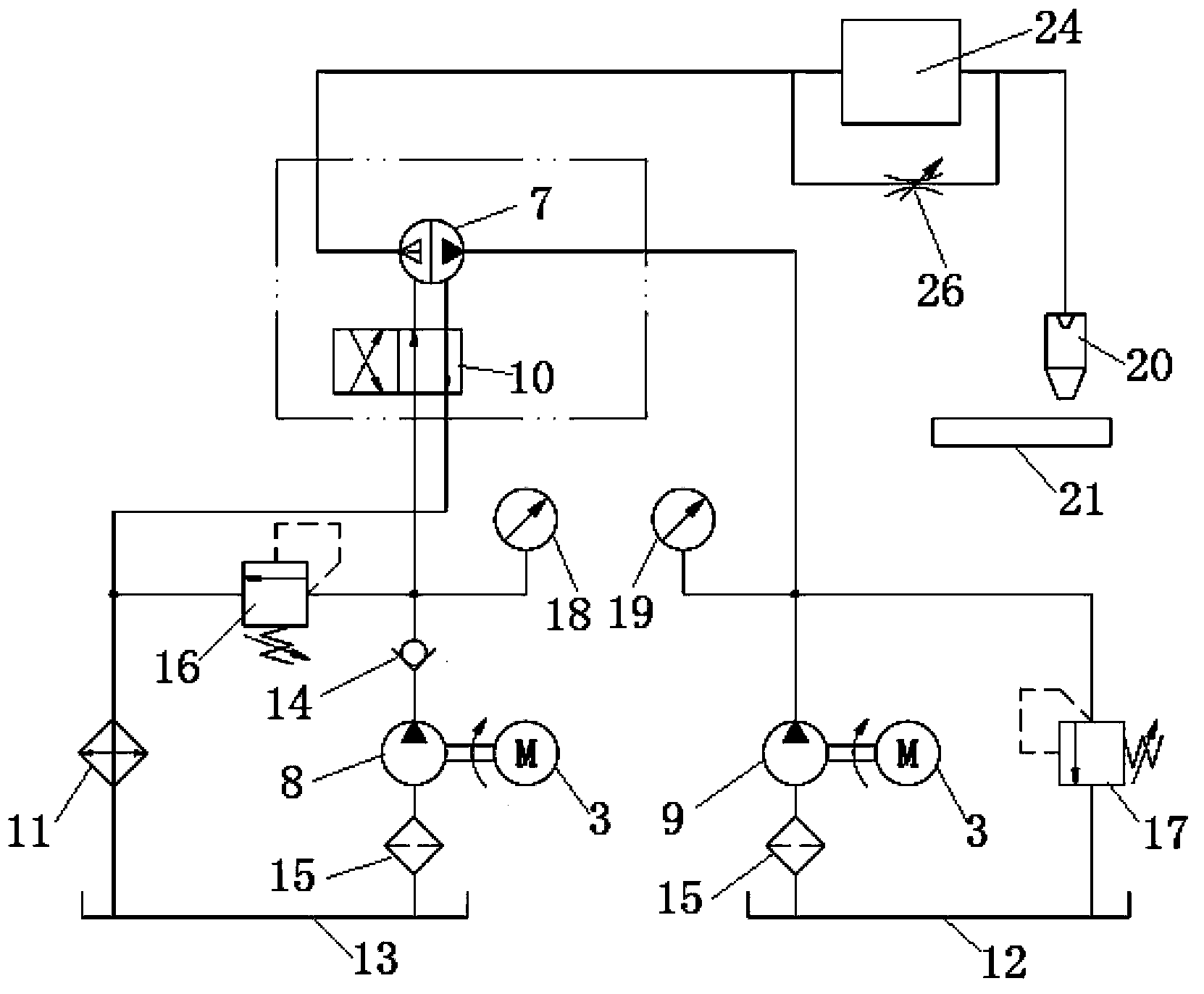

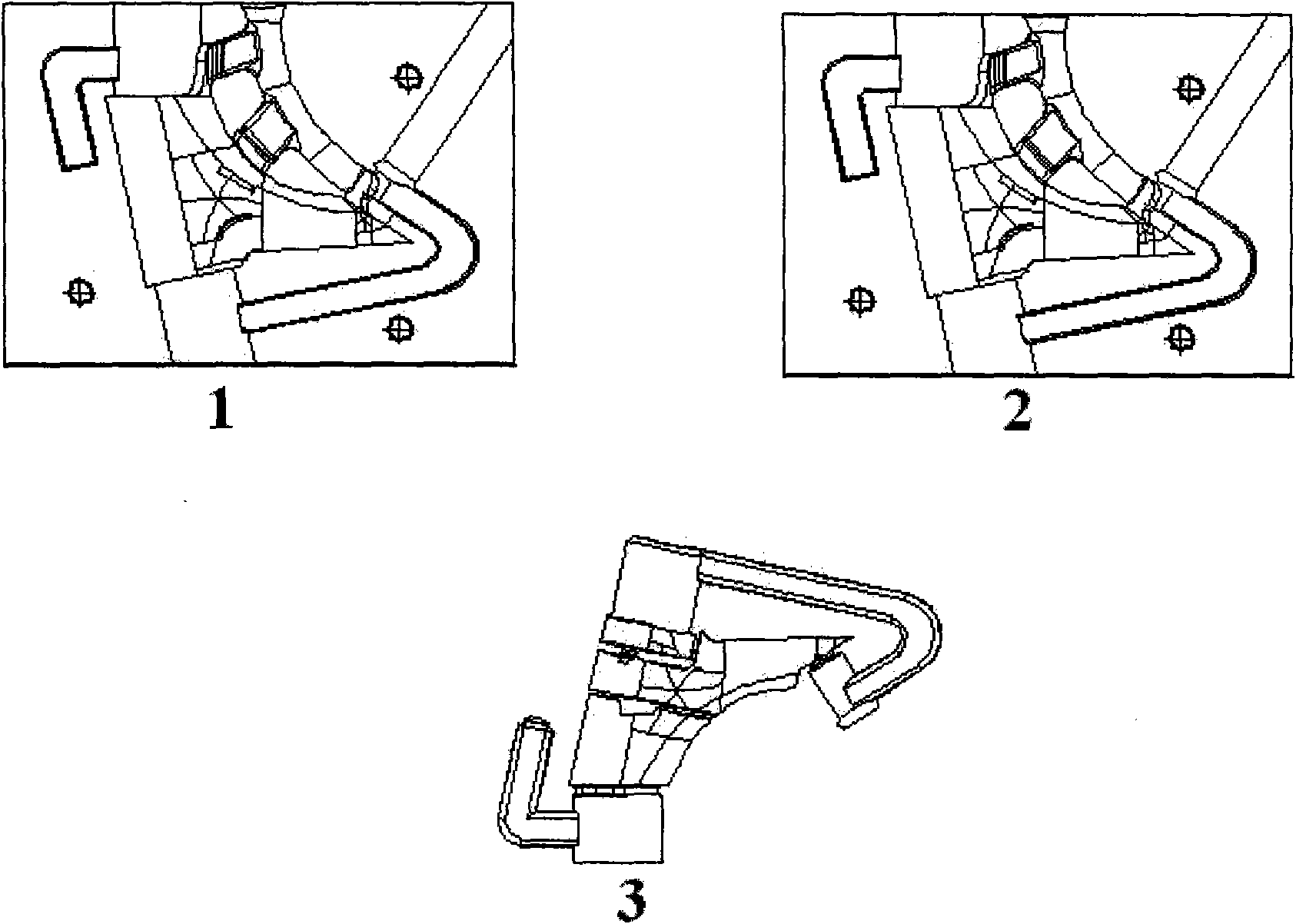

Vehicle-mounted water cutting system

ActiveCN103447970AMove quicklyNo need for high temperatureAbrasive feedersAbrasive machine appurtenancesChemical transformationThermal deformation

Owner:纪新刚

Sand mold rotary gravity mould and casting method thereof

InactiveCN101602089AHigh thermal conductivityWon't drain quicklyFoundry mouldsFoundry coresMaterial consumptionMaterials science

The invention relates to a sand mold rotary gravity mould and a casting method thereof. The mould comprises an inner structure sand core and an exterior sand mold gravity mould, wherein the exterior sand mold gravity mould comprises resin, curing agent and crude sand. The casting method includes the following steps: (1) a sand core mould comprising the inner structure sand core and the exterior sand mold gravity mould is well installed on a sand core machine; (2) the sand is mixed: resin, curing agent and crude sand; (3) the mould is heated: according to the structural sizes of the sand core and the sand mold, the mould is warmed to a proper curing temperature to manufacture the core and the mold, and residual parts on the sand core are scraped; (4) the inner structure sand core is arranged in the exterior sand mold gravity mould according to a positioning head, and rotary casting is carried out in the mode of front casting or lateral casting after mould closing; (5) after casting, the cast is taken out from the exterior sand mold gravity mould, and the time of taking the cast is determined according to the curing states of the dead head of the cast and a thicker part; and (6) the cast is processed by slinging and shot blasting. The invention can avoid the disadvantages of the traditional casting method, and has the advantages of low material consumption and lower cost.

Owner:付政权

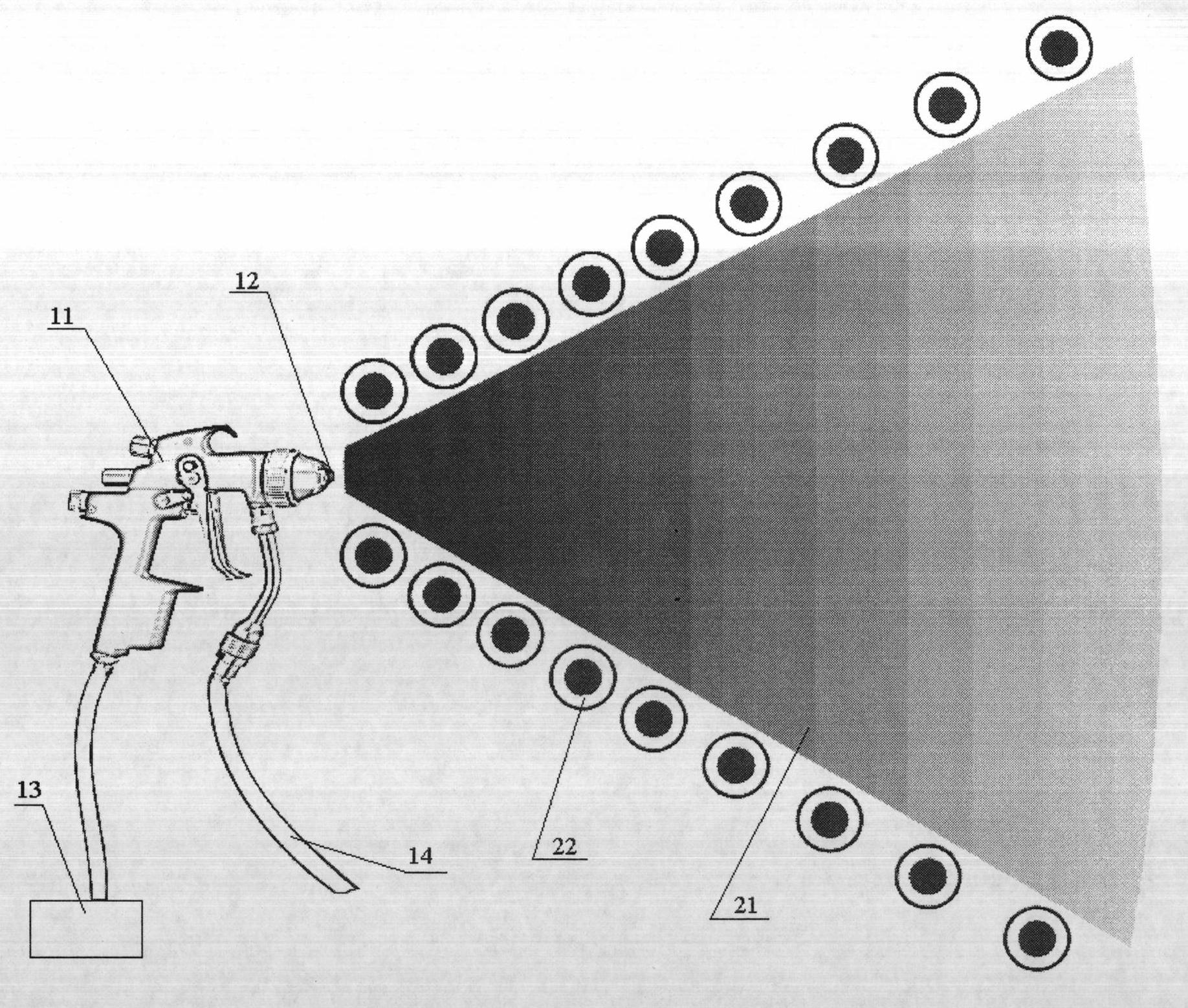

Preparation method of nanofiber

InactiveCN102220649ASimple processHigh yieldMonocomponent synthetic polymer artificial filamentSpinning solutions preparationMicrometerFiber drawing

The invention relates to a preparation method of nanofiber, wherein the method comprises the following steps of: (1) preparing a solution, wherein, after polyvinyl pyrrolidone and alcohol are mixed according to a certain proportion, stirring for 3-4 hours to obtain transparent viscosity solution, and filling the viscosity solution in a liquid storage bottle; (2) connecting the liquid storage bottle with a liquid conveying port of a spray gun through a solution input pipe, and connecting the air conveying port of the spray gun with an air compressor; (3) disposing the nozzle of the spray gun opposite to the front end of a fiber drawing cavity, starting the air compressor, and ejecting the viscosity solution into the fiber drawing cavity, wherein the liquid drops of the viscosity solution is drawn into nanofibers with the diameters of 100-300 nm at once, and the nanofibers are fallen in a collecting device from the fiber outlet of the fiber drawing cavity. With spraying fiber drawing technology, the micrometer liquid drops are finally drawn into uniform nanofibers under the effect of a temperature field formed by an iodine tungsten filament lamp so that the defect that the traditional nanofiber has low yield is solved.

Owner:LANZHOU UNIVERSITY

Method for preparing nano calcium carbonate by regeneratively cycling oyster shell

InactiveCN103274439AAvoid heavy pollutionReduce manufacturing costCalcium/strontium/barium carbonatesMaterial nanotechnologyCarbonizationOyster shells

The invention discloses a method for preparing nano calcium carbonate by regeneratively cycling an oyster shell. The method comprises the steps that the oyster shell is directly used as a raw material without roasting and digestion procedures; recovery and cyclic utilization are performed by utilizing a large amount of carbon dioxide generated by dissolving the oyster shell with hydrochloric acid; and nano calcium carbonate with high whiteness and high purity is obtained by an ammonia water carbonization technology. The raw oyster shell adopted by the method is extensive in source and low in cost, solves the environmental pollution caused by the oyster shell, does not generate secondary pollution, and has good popularization and application prospects.

Owner:GUANGDONG OCEAN UNIVERSITY

Braking device of high-speed train

ActiveCN105443628AReduce heat loadLess stringent requirementsBraking elementsWater vaporHigh pressure water

The invention discloses a braking device of a high-speed train, which is provided with a water spray cooling device. The braking device at least comprises a brake disc, a brake pad, a brake pad heat radiating cavity, calipers, a water tank, a water inlet pipe, a tank bottom valve, a water outlet pipe, a high-pressure water pump, a four-way pipe, water delivery hoses, nozzles, locating rods and a driving mechanism. During train braking, the driving mechanism controls the calipers to clasp the brake disc, the tank bottom valve is opened, the high-pressure water pump is started, high-pressure water is sprayed out of the nozzles after entering the water delivery hoses through the four-way pipe, one path of high-pressure water is sprayed inwards through a ventilating duct, which is provided with heat radiating ribs, of the brake disc, the other two paths of high-pressure water are sprayed inwards through the heat radiating cavity specially designed at one side of a backing plate of the brake pad, fogdrops are instantly vaporized because of being heated when being in contact with a high-temperature metal surface, and a great deal of heat in water vapor is taken with air, so that the heat radiating effect of the braking device is far better than that of the traditional braking device only depending on air cooling, the brake disc and the brake pad can be always in a relatively low temperature, furthermore, the braking reliability and safety are ensured, meanwhile, the service life of the brake pad is prolonged, and the braking requirement of a higher-speed train can be met.

Owner:上海洲跃生物科技有限公司

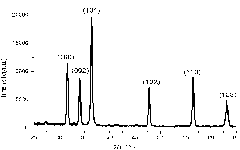

Preparation method of Al-Doped ZnO film

The invention discloses a preparation method of an Al-Doped ZnO film, which comprises the following steps of: adding AZO nano particles in a medium; ultrasonically processing a solution for 10-30 minutes to obtain uniform and dispersive nano particle seriflux; adding a coupling agent and a photoinitiator in the seriflux; after adding the coupling agent, carrying out ultrasonic treatment for 0.5-8 hours; spreading AZO nano particle seriflux on glass by using a pulling method or a spinning method and irradiating by ultraviolet light; and then carrying out heat treatment to obtain the ZAO film. The invention does not need vacuum equipment or high temperature, has simple structure, and is suitable for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

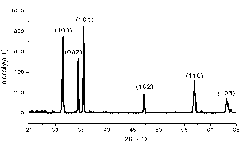

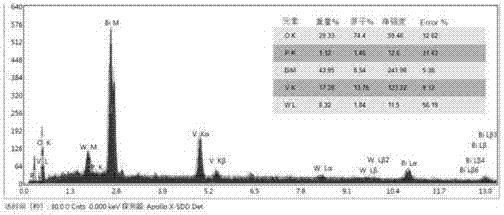

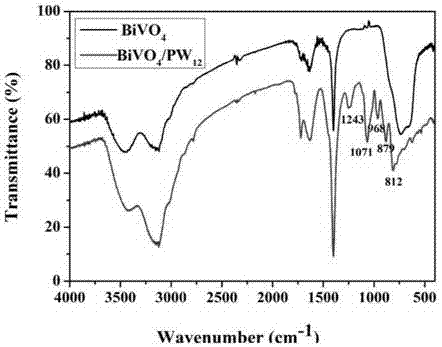

Method for preparing bismuth vanadate-polyacid gas sensing composite nano-material

InactiveCN107064250AMild working conditionsNo need for high temperatureMaterial nanotechnologyNanosensorsNitrogen dioxideBismuth vanadate

The invention provides a method for preparing a bismuth vanadate-polyacid gas sensing composite nano-material. A prepared polyacid modified bismuth vanadate nano-rod composite gas sensitive material can be used in a photoelectric gas sensor. The gas sensitive material is a bismuth vanadate-polyacid composite nano-material which is formed by using a bismuth vanadate nano-rod as a main body and modifying with Keggin-type phosphotungstic acid. In a room temperature environment, under irradiation of a xenon lamp, the sensor has a remarkable sensing detection function for toxic nitrogen dioxide gas. The method for preparing the bismuth vanadate-polyacid gas sensing composite nano-material is simple, has low cost, can be used for effectively detecting low-concentration nitrogen dioxide gas in the air at room temperature, and is applicable to development and production of a novel high-performance gas sensor.

Owner:NORTHEAST NORMAL UNIVERSITY

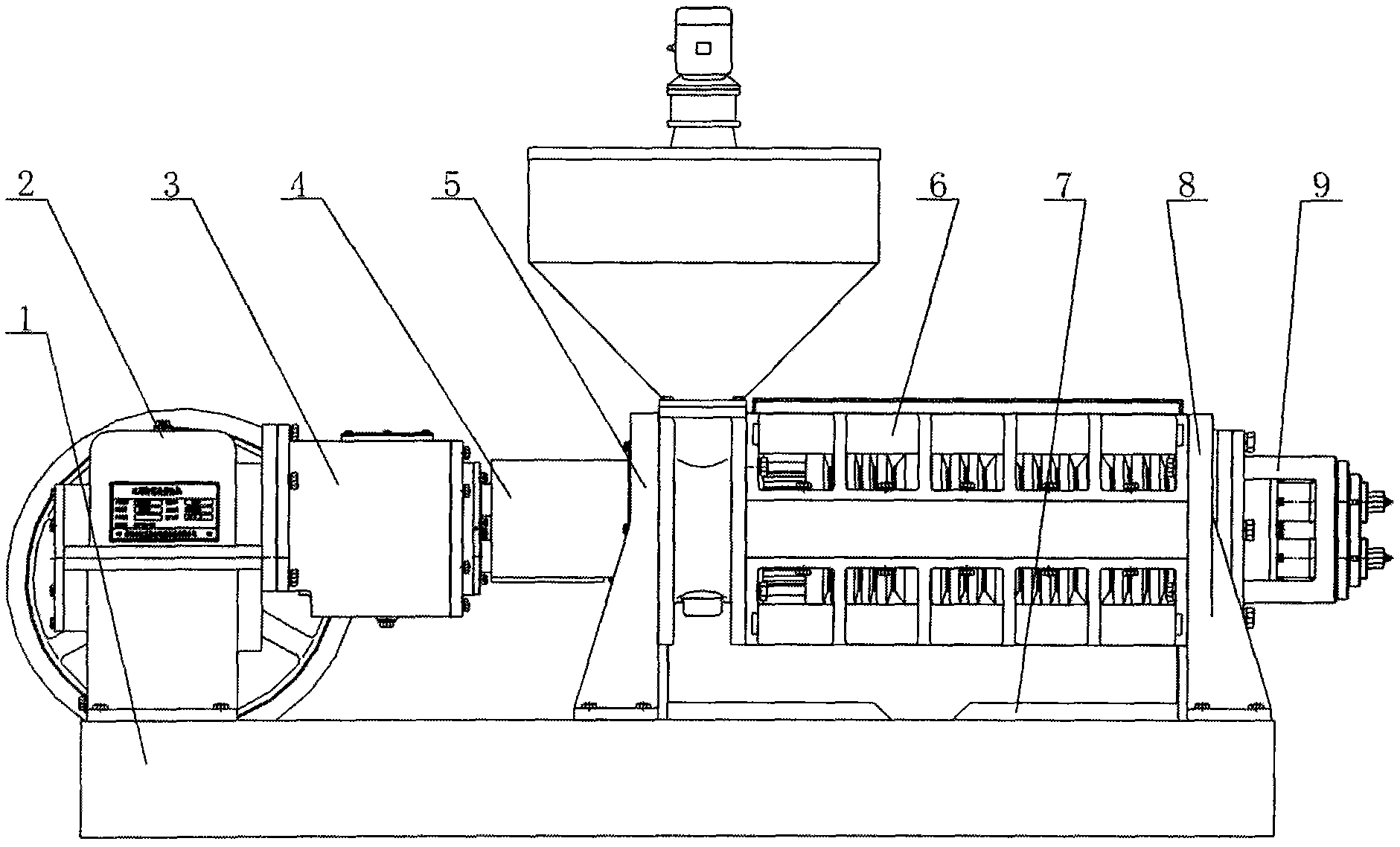

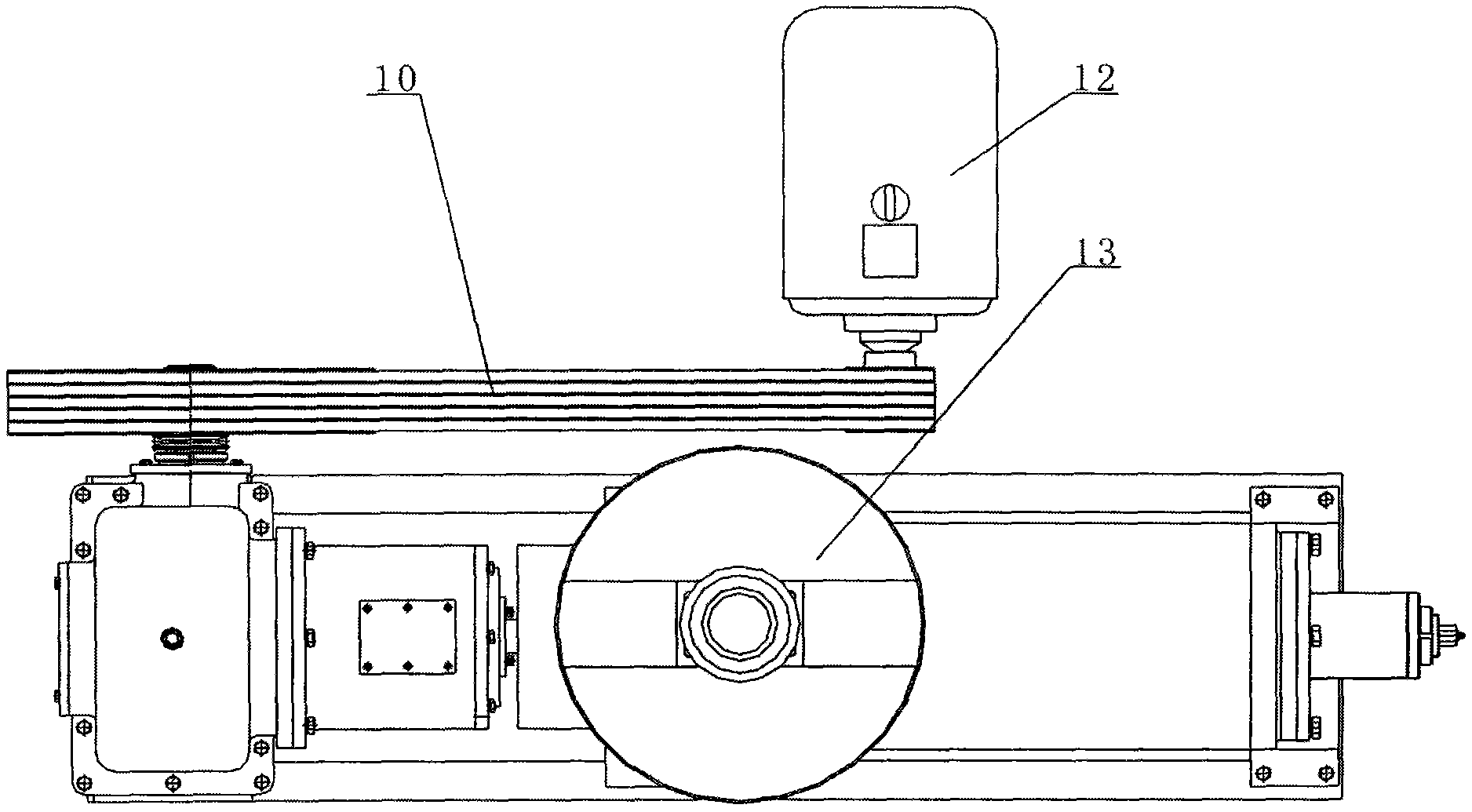

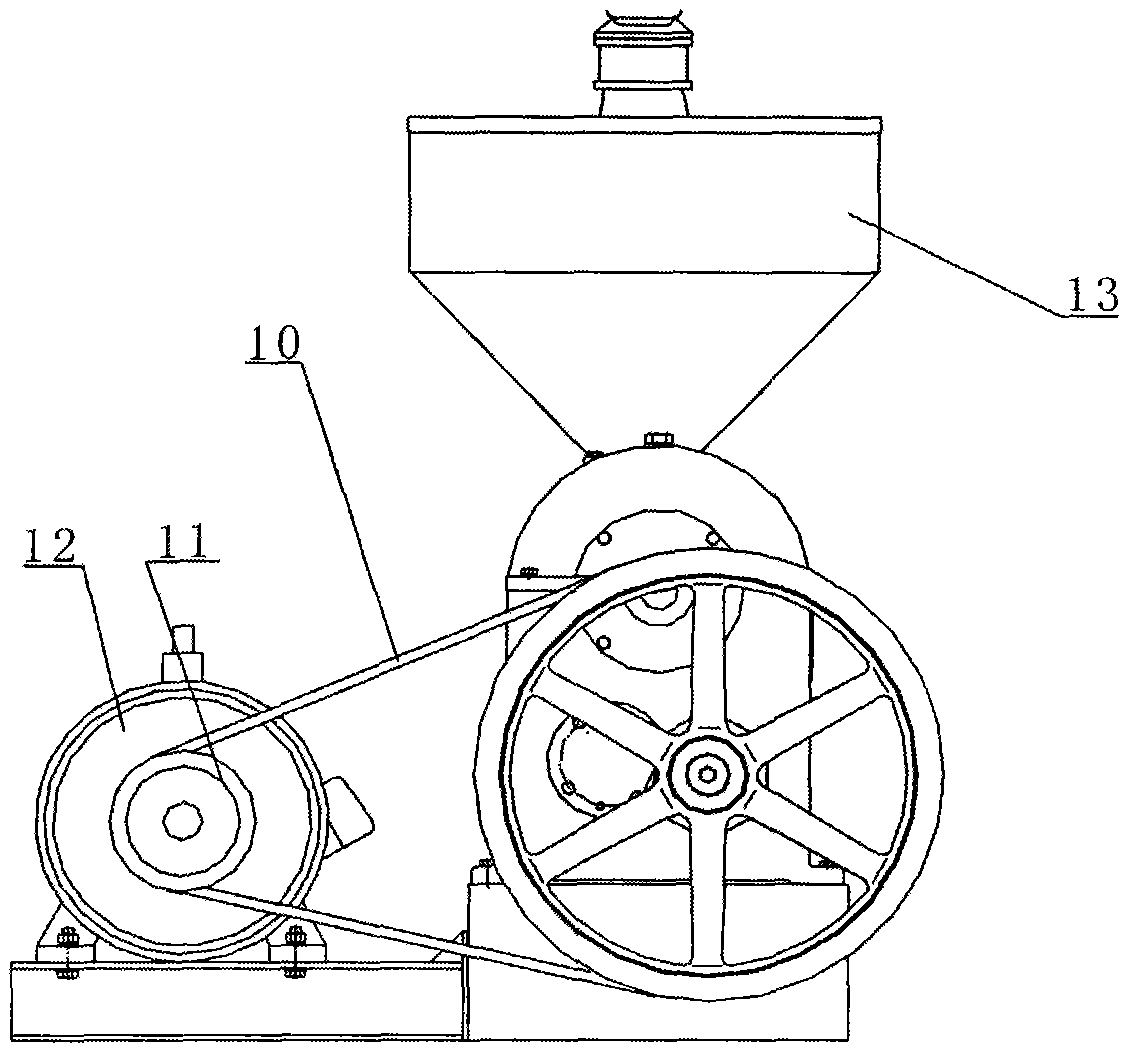

Pressing ring type double-screw spiral oil press

InactiveCN103895249AIncrease pressureImprove oil output efficiencyToothed gearingsPressesEngineeringRing type

The invention discloses a pressing ring type double-screw spiral oil press comprising a base, a motor mounted on the base, a transmission mechanism, a left support and a right support. The motor is connected to the transmission mechanism through a conveying belt. A pressing cage mechanism is mounted between the left support and the right support, an oil collecting plate is mounted below the pressing cage mechanism, and the tail of the pressing cage mechanism is provided with an oil cake regulating mechanism. A three-way feeding hole communicated with the pressing cage mechanism is formed in the left support, and the left support is provided with a feeding mechanism communicated with the three-way feeding hole. The pressing ring type double-screw spiral oil press is characterized in that the transmission mechanism is connected to a power distribution mechanism which is connected to the pressing cage mechanism; the pressing chamber of the pressing cage mechanism comprises a plurality of pressing rings mounted in a pressing cage; the end face of one side of the pressing ring is provided with a plurality of oil discharging grooves. The pressing ring type double-screw spiral oil press has the advantages that structure is simple, parts are few, equipment manufacturing cost is low, operation and maintenance can be performed simple and conveniently, and cold pressing and hot pressing can be performed both.

Owner:苟安富 +1

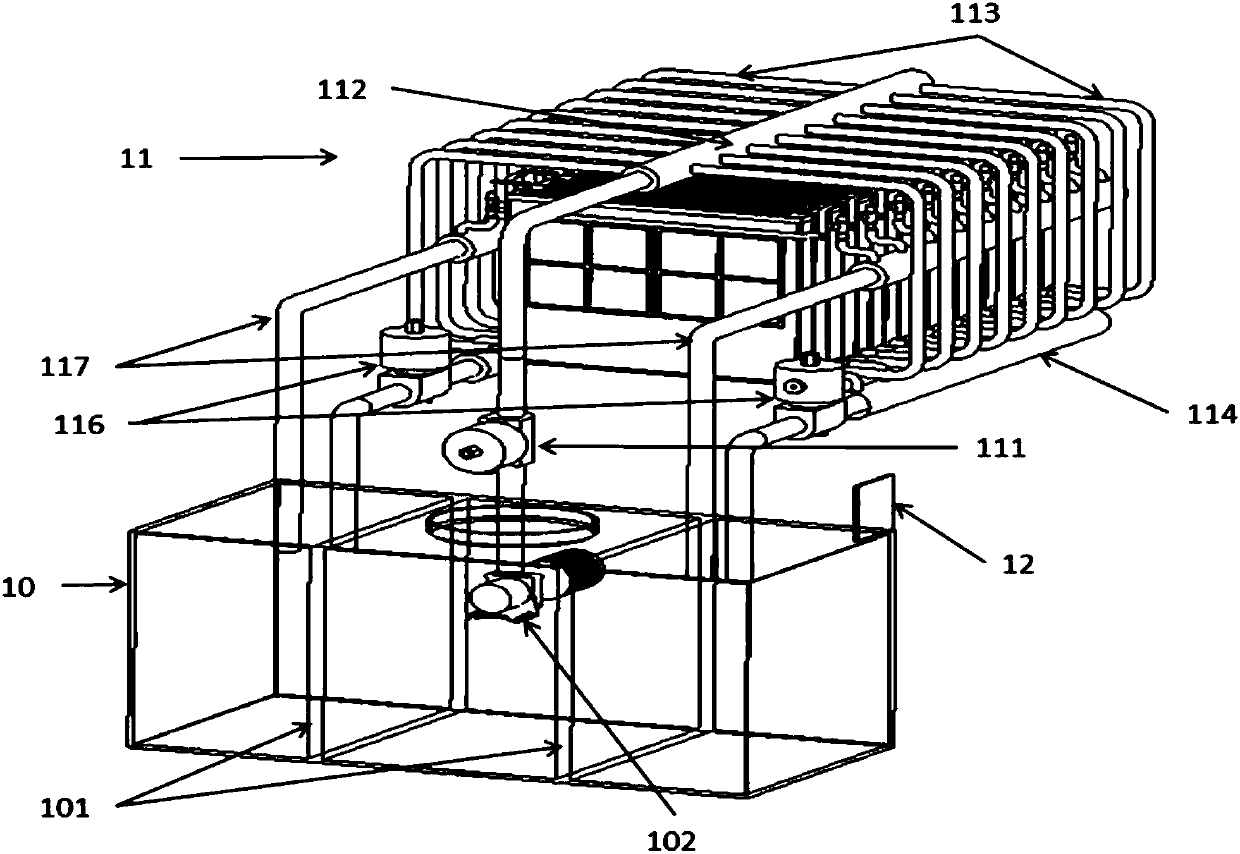

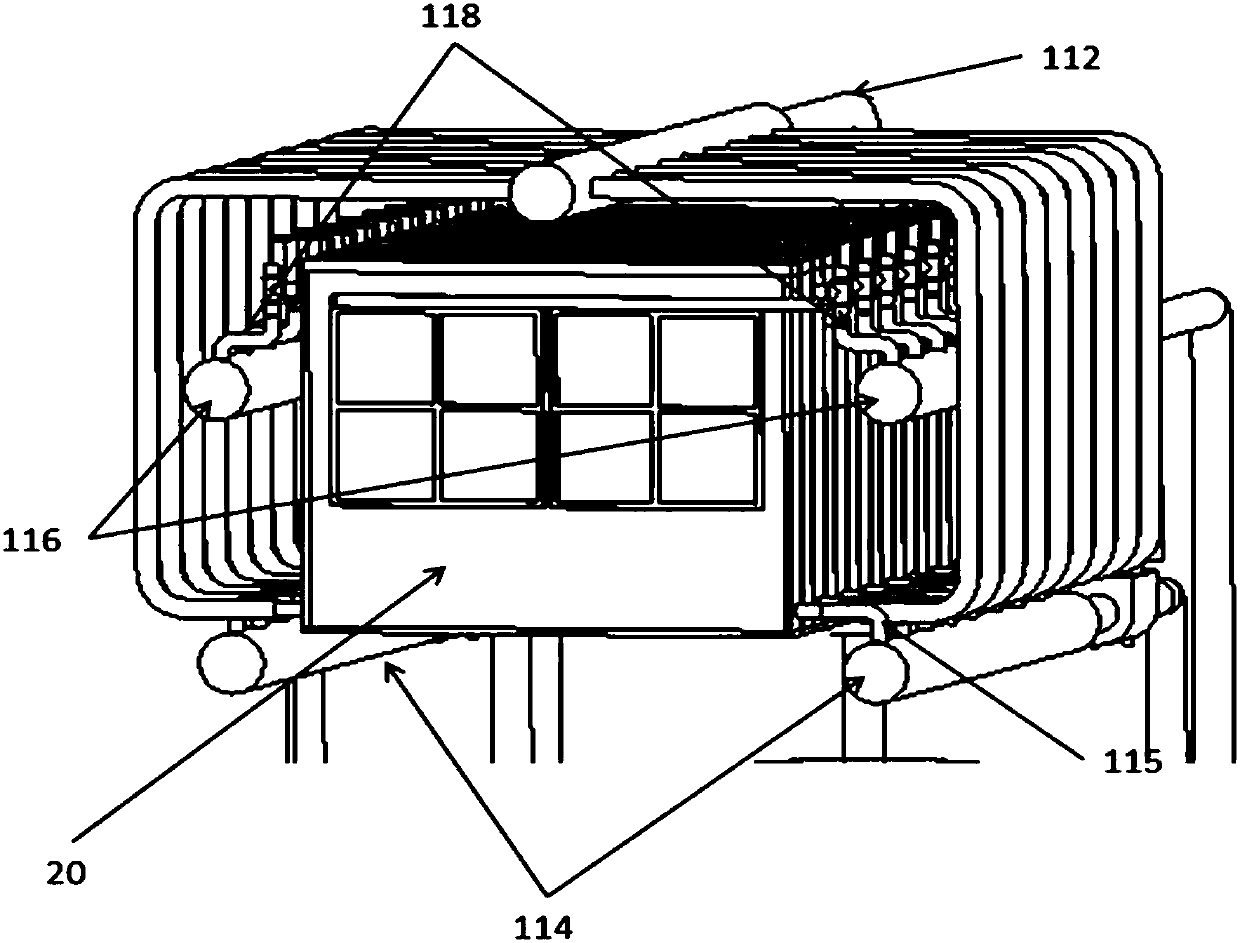

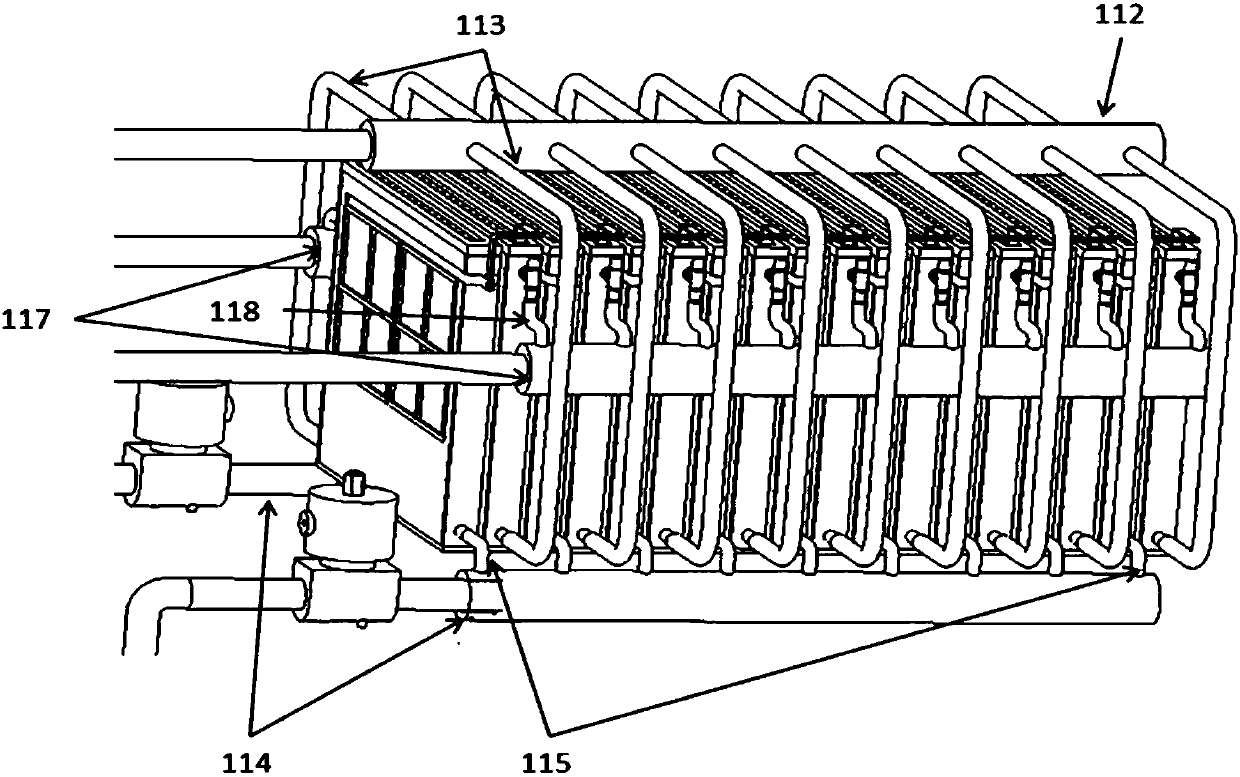

High-power neutral electrolyte metal-air battery system and using method thereof

ActiveCN107611525ASolve temperature problemsSolve cleaningFuel and primary cellsElectrolyte stream managementBusbarElectrical battery

The invention relates to a high-power neutral electrolyte metal-air battery system and a using method thereof. The battery system comprises two or a plurality of basic cell units connected in series or in parallel, an electrolyte filtering box, a circulating pump, a control valve, an electrolyte input distributor, an electrolyte discharge manifold, a drain valve, an electrolyte overflow manifold,a control circuit, a controller, a connecting pipeline and the like. Each basic cell unit consists of a reaction box, an anode, a cathode, electrolyte, a cathode busbar and an anode busbar; and an electrolyte input port, an electrolyte discharge port and an electrolyte overflow exhaust port are formed at both sides of the reaction box. The electrolyte is neutral liquid, such as salt water, seawater and the like. The electrolyte of each basic cell unit is communicated with each other without using an electrolyte isolator. The high-power neutral electrolyte metal-air battery system and the usingmethod thereof, which are disclosed by the invention, are applicable to the high-power power utilization requirements and have the characteristics that after the anodes are used up, the anodes can bereplaced so as to reuse the high-power neutral electrolyte metal-air battery system; the high-power neutral electrolyte metal-air battery system can be stored for long time in a safe and maintenance-free mode, and is simple to start up and use; a load can be cut off at any time; the high-power neutral electrolyte metal-air battery system and the using method thereof have no pollution to the environment; and reaction precipitates can be recovered and recycled.

Owner:IMAY DESIGN

Automatic bag sticking machine

ActiveCN104746243BSo as not to damageSolve the contradiction between supply and demandWork-feeding meansPressersEngineeringAutomation

Owner:深圳市达益信智能设备有限公司

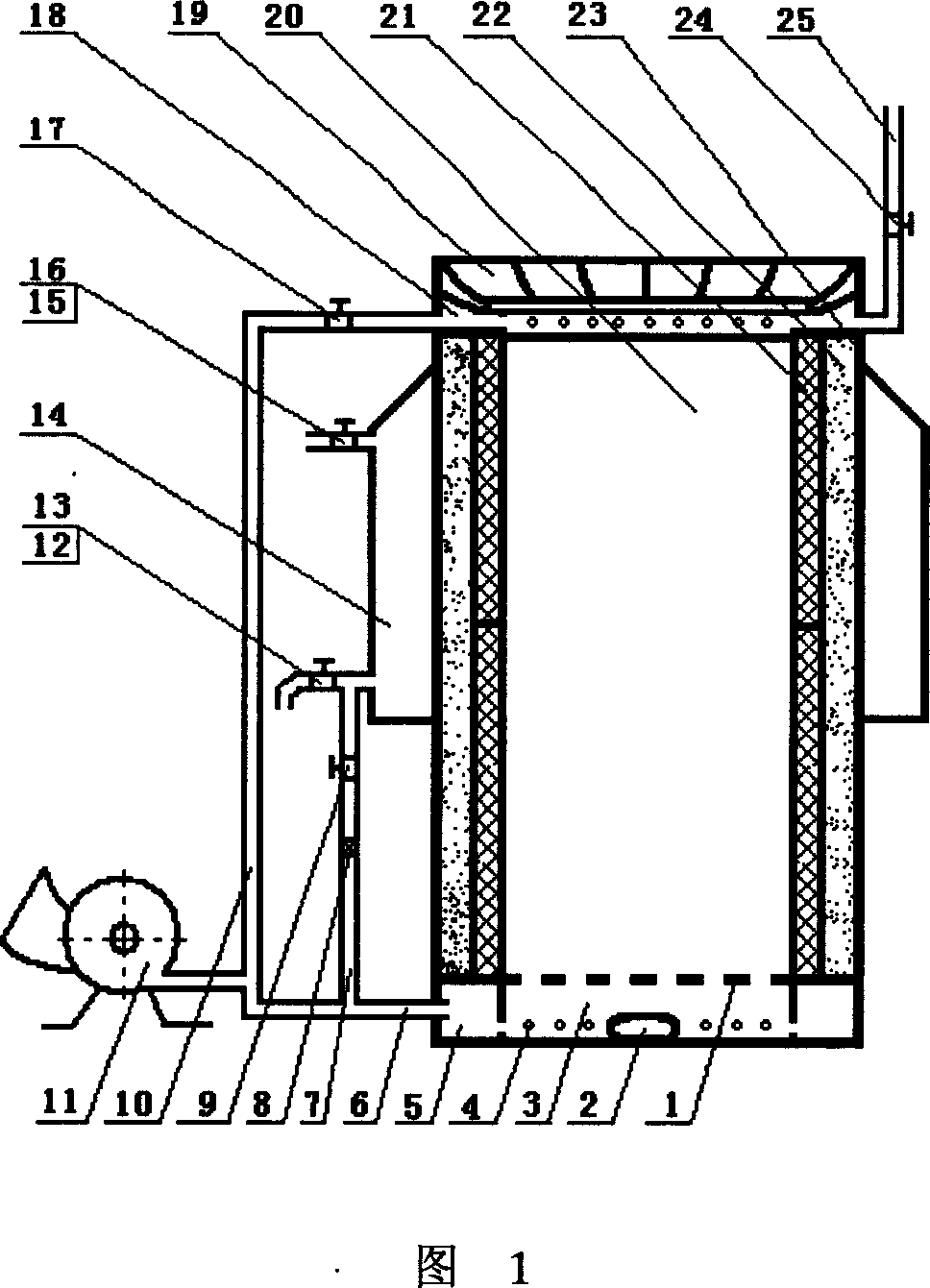

Biological-material-tall stove

InactiveCN1936429AEasy centralized processingEasy to addDomestic stoves or rangesEnergy inputHearthBiological materials

This invention relates to a biological material ball stove including a fan, a secondary wind pipe, a valve, a flowmeter, a supply pipe, a gasification agent pipe, a loop air pre-heating chamber, a loop air conduction chamber, a stove head, a stove body, a heat preservation layer, an inner container and biological material balls, in which, the upper part of outside of the stove is a water tank made of stainless steel, the fan is connected with the loop air pre-heating chamber at the bottom of the hearth via a gasification agent pipe, the heat preservation layer, the inner container and the hearth are orderly placed in the body, a grate is under the hearth and the stove head is above it, the loop air conduction chamber is at the bottom of the head, the secondary wind pipe and the chimney are at the outside wall of the conduction chamber with a stage along the internal wall for placing a stove cover.

Owner:刘春生

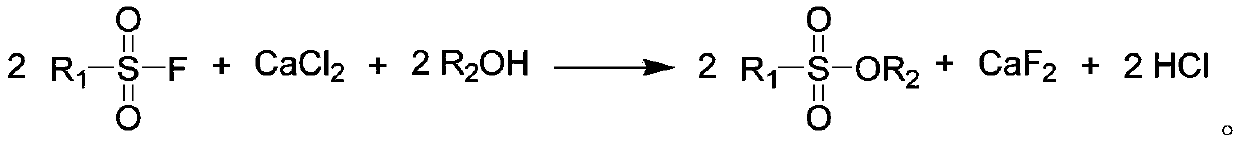

Synthesis method of alkali metal trifluoromethanesulfonate

ActiveCN111116429AAdequate responseSimple processing methodSulfonic acids salts preparationSulfonic acid esters preparationAlcoholChloride

The invention relates to a synthesis method of alkali metal trifluoromethanesulfonate, and belongs to the technical field of fine chemical engineering. The method comprises the following steps: firstly, adding anhydrous calcium chloride and alcohol into a reactor, vacuumizing, controlling the temperature in the reactor to be -40-25 DEG C, introducing excessive a sulfonyl fluoride compound, stirring, controlling the temperature to be -40-70 DEG C and the pressure to be 0.05-0.15 MPa, and reacting for 2-3 h; discharging the unreacted sulfonyl fluoride compound after the reaction is finished, anddistilling to obtain an ester compound; and adding an alkali metal hydroxide into the ester compound, stirring, reacting for 2-5 h under the pressure of 0.05-0.15 MPa at the temperature of 20-70 DEGC, filtering after the reaction is finished, and drying to obtain the alkali metal trifluoromethanesulfonate. The reaction yield is effectively improved, and introduction of impurities in a conventional method is avoided; and post-reaction treatment is simple, and pollution in the synthesis process is reduced.

Owner:PERIC SPECIAL GASES CO LTD

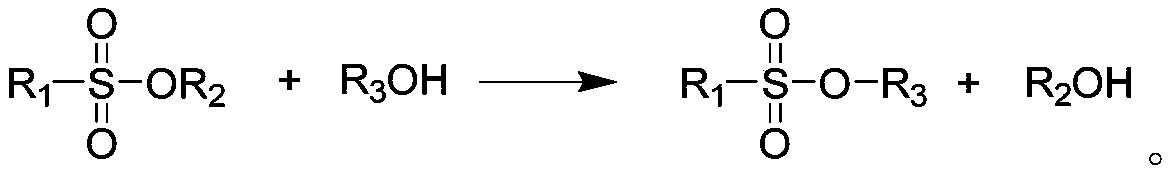

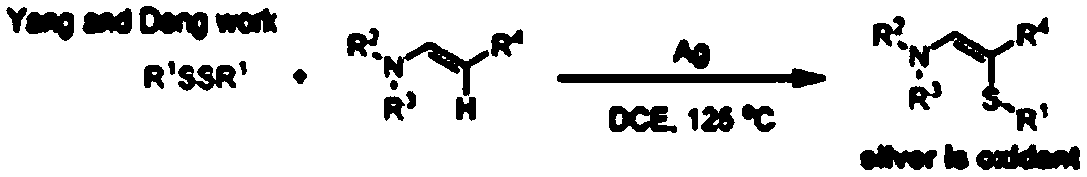

Green synthesis method of alpha-thioenamine compound

ActiveCN109402659AAvoid waste and metal residuePromote the improvement of synthesis efficiencyElectrolysis componentsElectrolytic organic productionSolventAtom economy

A green synthesis method of an alpha-thioenamine compound includes dissolving a sulfur phenol compound, an electrolyte and an enamine compound in a solvent and powering on for reaction in the nitrogenatmosphere to obtain the alpha-thioenamine compound. A reaction equation in the synthesis method is defined in the description, wherein R1 is methyl, allyl or phenyl; R2 is phenyl of various functional groups substituted at 2-, 3-, or 4-, or a naphthalene ring, or substituted furan or substituted thiophene; Ar is phenyl of various functional groups substituted at 2-, 3-, or 4-, or the naphthalenering, or substituted thiazole, substituted oxazole, substituted thiadiazole, substituted imidazole or substituted tetrazole. The method is simple and efficient in synthesis process, high in atomic economy and environmentally friendly. The reaction operation is simple, the reaction condition is mild, and high temperature is not required.

Owner:XUCHANG UNIV

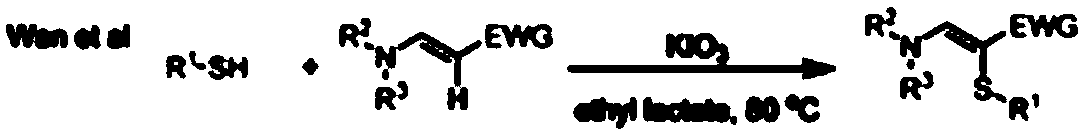

4-methyl-2-nitroaniline synthesis method

InactiveCN107759479AMild reaction conditionsNo need for high temperatureCarbamic acid derivatives preparationOrganic compound preparationNitrosoMethylaniline

The invention discloses a 4-methyl-2-nitroaniline synthesis method, which comprises: carrying out amino protection with ethyl chloroformate by using 4-methylaniline as a raw material to generate N-(p-toluene)ethyl carbamate; adding an oxidant and a copper salt catalyst, and carrying out a reaction for a certain time at a temperature of 50-120 DEG C in a reaction solvent by using a nitroso-containing compound as a nitrating agent to prepare a corresponding protected o-nitro-p-toluidine; and carrying out hydrolysis to obtain the target product. According to the present invention, the method hasadvantages of simple preparation process, mild reaction condition, high yield and environment protection.

Owner:NANJING UNIV OF SCI & TECH

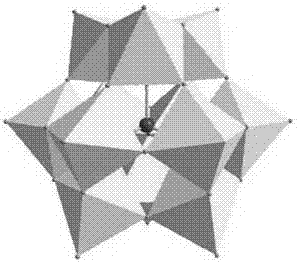

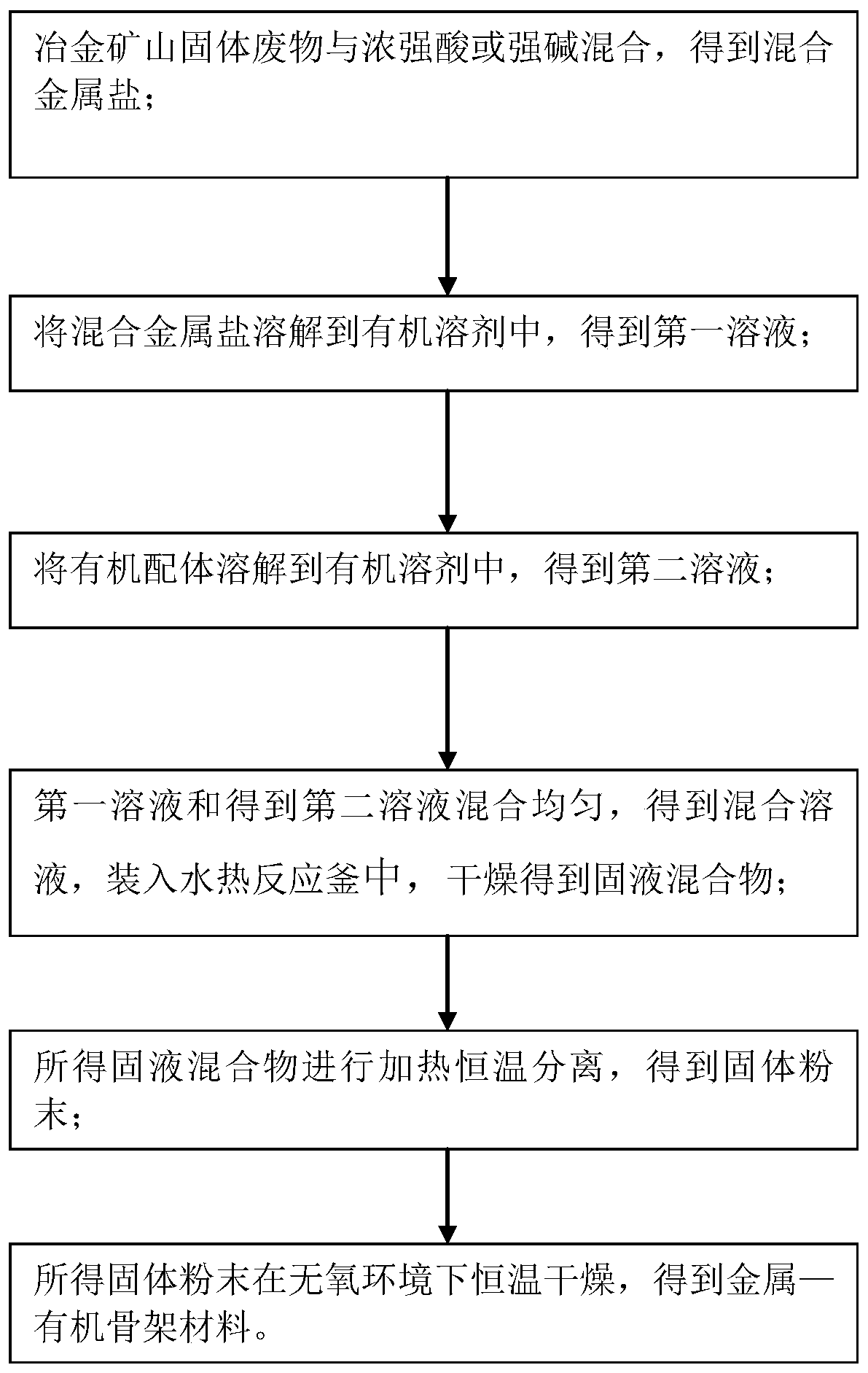

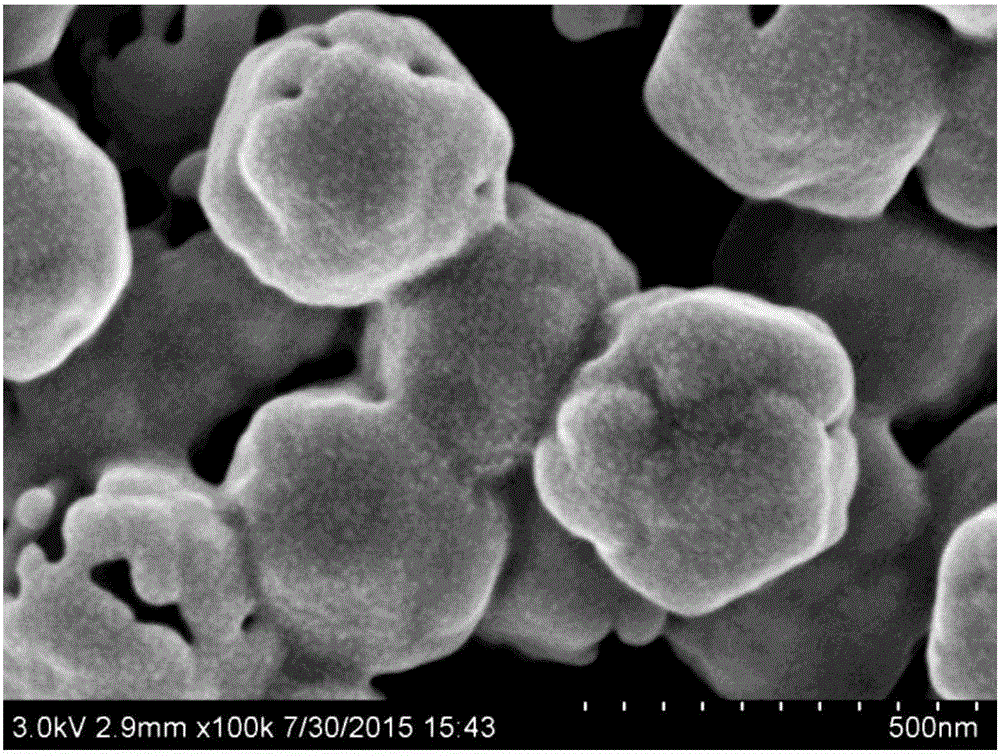

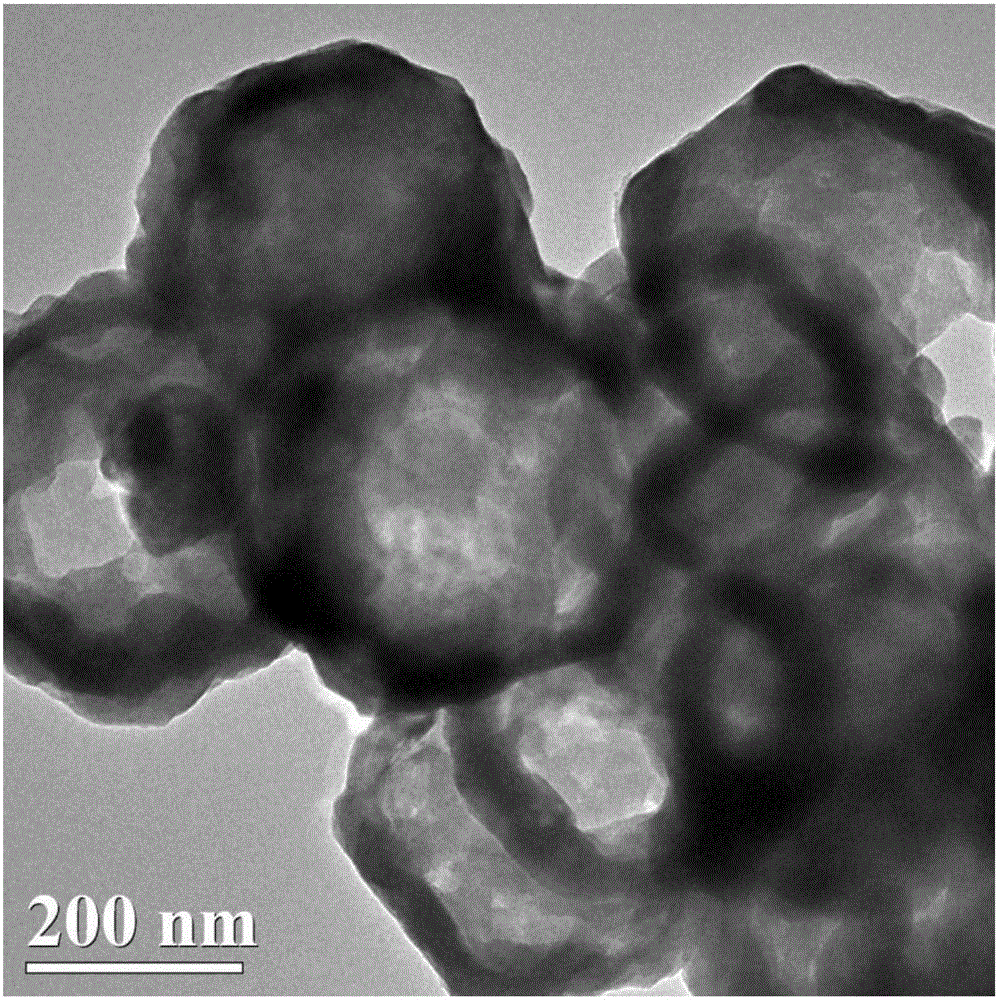

Method for preparing metal-organic framework material from metallurgical mine solid wastes

InactiveCN110407885ANo need for high temperatureNo need for nitroxOrganic compound preparationIron group organic compounds without C-metal linkagesMetallurgical slagOrganic solvent

The invention belongs to the field of comprehensive utilization of resources, and especially relates to a method for preparing a metal-organic framework material from metallurgical mine solid wastes.The method comprises the following steps: dissolving the metallurgical mine solid wastes by using a concentrated strong acid and a strong alkali to obtain a mixed metal salt, dissolving the mixed metal salt and the organic ligand in an organic solvent by using the organic metal as an organic ligand, and keeping the temperature constant at 70-150 DEG C for 18-30 h to synthesize the metal-organic framework material. The new method for preparing the MOF material containing valuable metal elements from the metallurgical mine solid wastes has the advantages of wide sources of raw materials, effectiveness in utilization of metallurgical slag, minerals, dust and other waste metal alloys containing valuable metal elements, simple synthesis process and mild synthesis conditions. The method is suitable for the comprehensive utilization of metallurgical slag, minerals, dusts and waste metal alloys.

Owner:UNIV OF SCI & TECH BEIJING

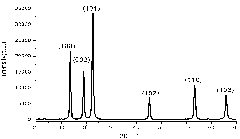

Technology for preparing micro-nano cuprous oxide hollow polyhedrons through reduction method

InactiveCN105314669ANo etchant requiredNo need for high temperatureCopper oxides/halidesMicro nanoPhotocatalysis

The invention discloses a technology for preparing micro-nano cuprous oxide hollow polyhedrons through a reduction method on the condition that a template, an etching agent and high temperature are not needed. The technology comprises the steps that a prepared CuCl2 solution is added into a sodium dodecyl sulfate (SDS) aqueous solution prepared in advance, and a mixed solution is magnetically stirred to be uniform; a prepared NaOH solution is dropwise added into the mixed solution, and a mixed solution is magnetically stirred to be uniform; a prepared hydroxylamine hydrochloride (NH2OH.HCL) solution is quickly added into the mixed solution, magnetic stirring is performed at room temperature for 1 h, and then the micro-nano (about 400 nm) cuprous oxide hollow polyhedrons are obtained. Through reasonable technology control, preparation of the cuprous oxide hollow polyhedrons which are clear in outline, uniform in particle and good in dispersion is achieved. Compared with a traditional preparation method, the technology has the advantages that the template, the etching agent and the high temperature are not needed, simpleness and high efficiency are achieved, and the physical and chemical properties of the product are excellent and can be applied to the fields of gas sensing and photocatalysis.

Owner:CHONGQING UNIV

Decolor method for fly ash

InactiveCN1872767ASimple production processNo need for high temperatureSolid waste managementFly ashMaterials science

This invention relates to a method for decoloring fly ashes. The method comprises: (1) soaking first grade fly ashes with 0.1-1% carbon content in water, and boiling; (2) heating carbon dioxide to 200 deg.C, and introducing into the boiling water soaked with fly ashes; (3) contacting fly ashes with carbon dioxide for 5-15 min for decoloration. The method uses carbon dioxide as the major raw materials, thus having such advantages as simple process, mild conditions, and improved fly ashes whiteness.

Owner:SHENYANG JIANZHU UNIVERSITY

Extraction method for laminarin

The invention discloses an extraction method for laminarin. The method includes the steps of airing and smashing fresh laminaria japonica to obtain laminaria japonica powder, conducting hot water extraction after conducting ethyl alcohol degreasing on the laminaria japonica powder, centrifuging the extracting solution to obtain supernate, conducting concentration and impurity removal on the supernate, conducting microfiltration film filtration, sequentially classifying filtrate, conducting ultrafiltration through filter materials of different molecular weights, and conducting drying to obtain laminarin of different molecule classifications. No high-temperature or chemical changes are caused in the operation process, it is sufficiently ensured that activity of polysaccharide and protein is not damaged, and components are highly enriched; by means of the combined effects of centrifugation, microfiltration and ultrafiltration, the high flow rate is kept, the obtained polysaccharide is high in purity and diverse in specification, and the extraction method has the advantages that continuous production and automatic operation are achieved, the energy consumption is low and the production period is short.

Owner:SHANDONG HOMEY AQUATIC DEV +1

Low-temperature difference air heat power generation method

InactiveCN102852748ALow costEliminate long distance transmission lossMachines/enginesMechanical power devicesThermal energyCapacitance

The invention relates to a low-temperature difference air heat power generation method. Normal-temperature air is absorbed in atmosphere and, 65-DEG C hot air is obtained by increase of a heat pump and fed into a heat-preservation water tank with specific height, so that the temperature of the water tank can achieve 60 DEG C. A rotational structure device arranged in the water tank is provided with a thermal-operated device (1), a laminated memory alloy butterfly spring in the thermal-operated device (1) is sunk in 60-DEG C hot water from a martensite configuration under normal temperature, and is heated and changed into an austenite configuration so as to enable a variable-capacitance valve (13) of the thermal-operated device (1) to move and the buoyancy of an energy transduction tube (19) to be increased, the energy transduction tube (19) emerges from the water, the austenite configuration enters the normal-temperature atmosphere, and is evaporated and cooled so as to enable the laminated memory alloy butterfly spring to be changed into the martensite configuration once again and enter in the hot water. The process is circulating again and again, thus generating mechanical rotation movement and driving a power generator for power generation. The low-temperature difference air heat power generation method has the advantages of having exhaustible clean energy, being high-efficiency and easy to maintain, having no high temperature and no pollution and being green and environment-friendly.

Owner:WUHAN GAOZHI INNOVATION TECH

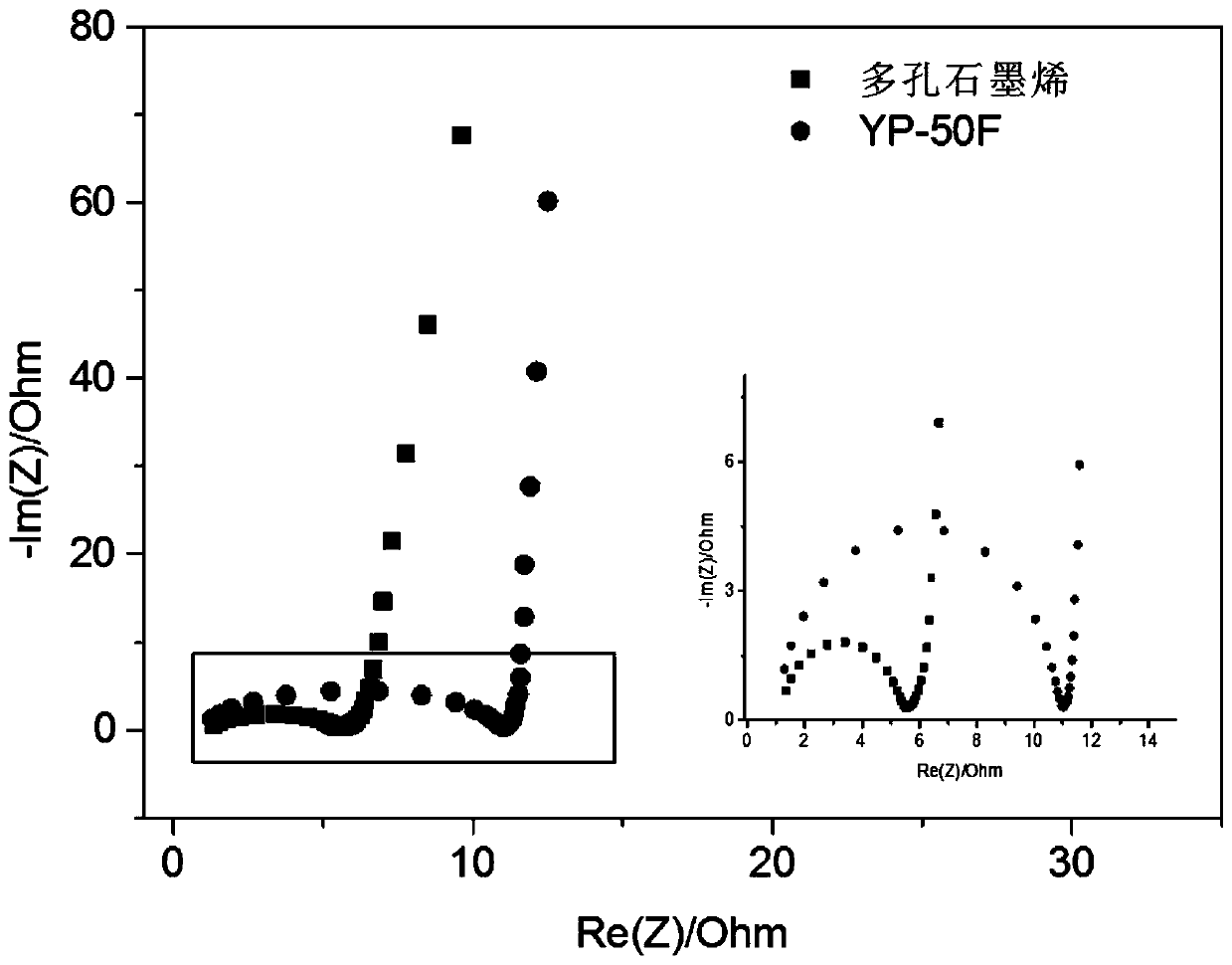

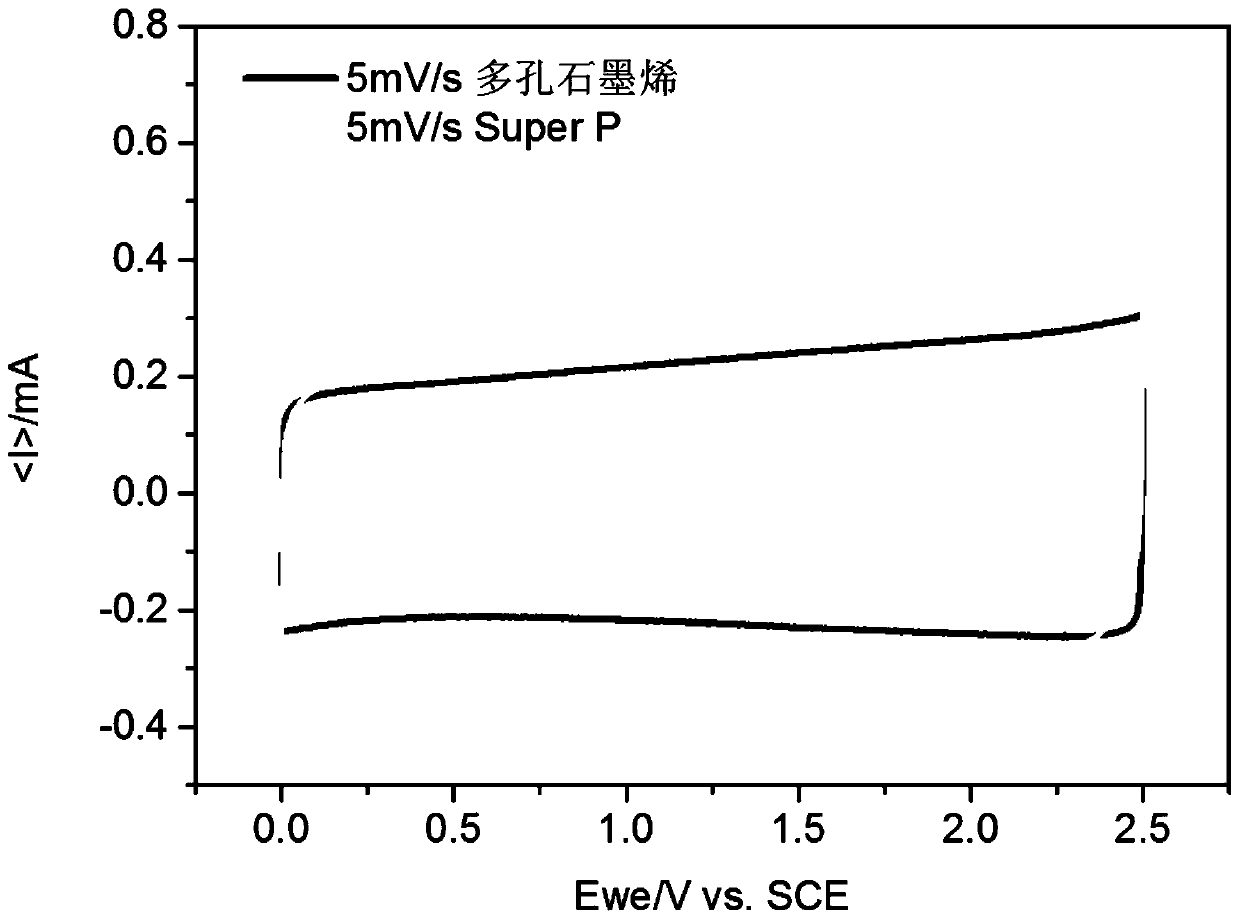

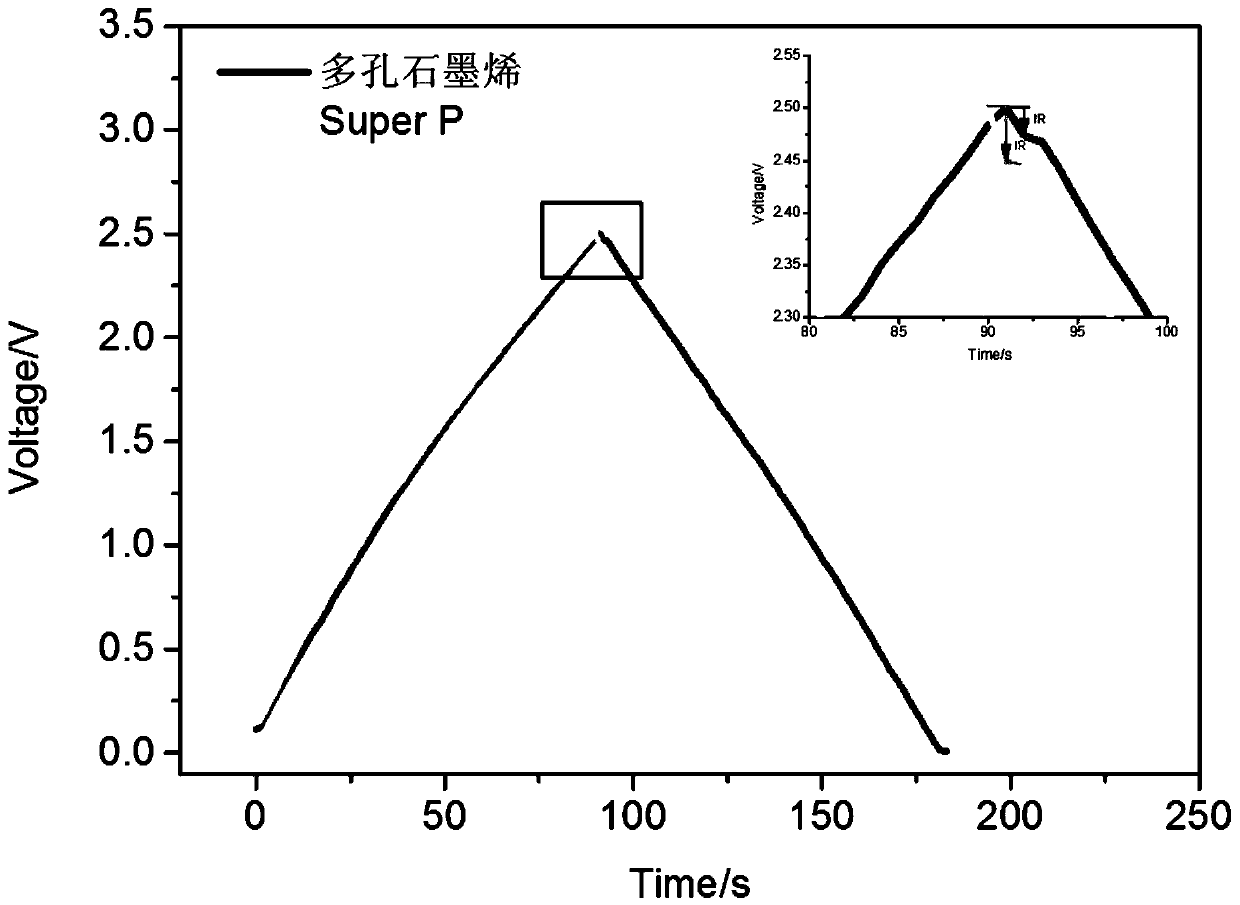

Porous graphene enhanced supercapacitor and preparation method thereof

InactiveCN110895999AHigh specific capacitanceImproved magnification performanceHybrid capacitor electrodesHybrid/EDL manufacturePorous grapheneHigh energy

The preparation method comprises the following steps: mixing activated carbon, porous graphene and PVDF (Polyvinylidene Fluoride), adding an N-methyl pyrrolidone solvent, carrying out ball-milling andstirring to prepare electrode slurry, and coating a carbon-coated aluminum foil with the electrode slurry; putting the coated carbon-coated aluminum foil into a blast drying oven for drying treatment, putting the dried carbon-coated aluminum foil into a vacuumizing drying oven for continuous treatment, and putting the carbon-coated aluminum foil on an electric double-roller machine for roller compaction to prepare a pole part; and cutting and packaging the prepared pole part to prepare the super capacitor. The method is simple in design, pollution-free in preparation process, free of high temperature and safe in process. And the cost can be reduced, large-scale production can be carried out, and wide application of the porous graphene-based supercapacitor with high energy density is realized.

Owner:杭州阳名新能源设备科技有限公司

Snow blowing nozzle of jet snow remover

The invention belongs to the technical field of jet snow removers, and particularly relates to a snow blowing nozzle of a jet snow remover. The snow blowing nozzle of the jet snow remover is characterized by comprising a fixed nozzle which is arranged on a nozzle jet of the jet snow remover, an upper nozzle adjusting piece and a lower nozzle adjusting piece which are rotatably connected with thatfixed nozzle through a sliding bearing, an upper fixed rotating shaft which is fixedly connected with the upper nozzle adjusting piece, a lower fixed rotating shaft which is fixedly connected with thelower nozzle adjusting piece, and a driving mechanism which is respectively hinged to the upper fixed rotating shaft and the lower fixed rotating shaft. The snow blowing nozzle of the jet snow remover is simple in structure and small in occupying size, and the upper and lower parts can act separately, and the high-speed air flow of the jet snow remover can be appropriately regulated according tothe actual operation situation, so that the utilization rate of the jet air flow is greatly improved, and the purging effect is improved.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

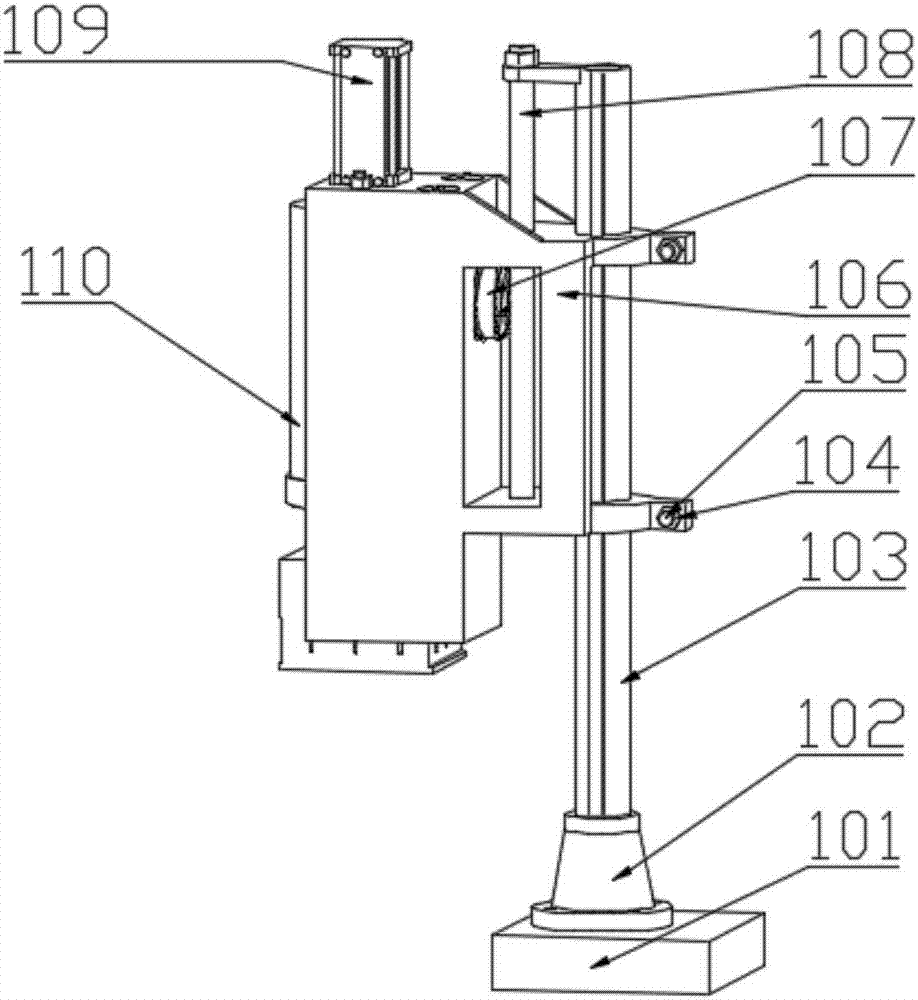

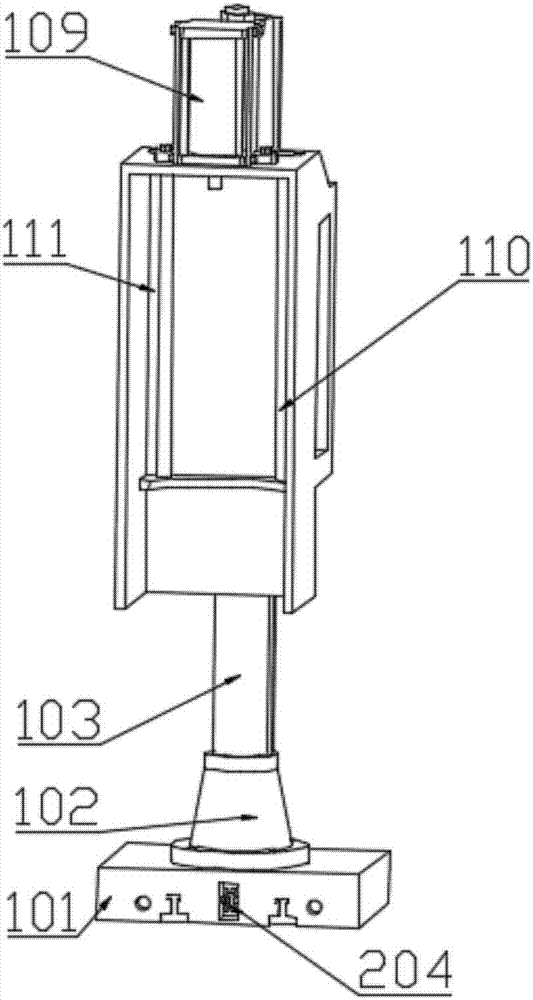

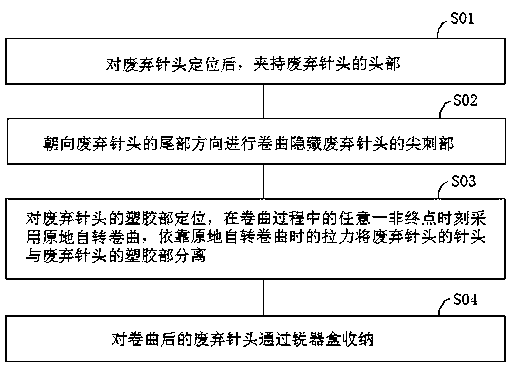

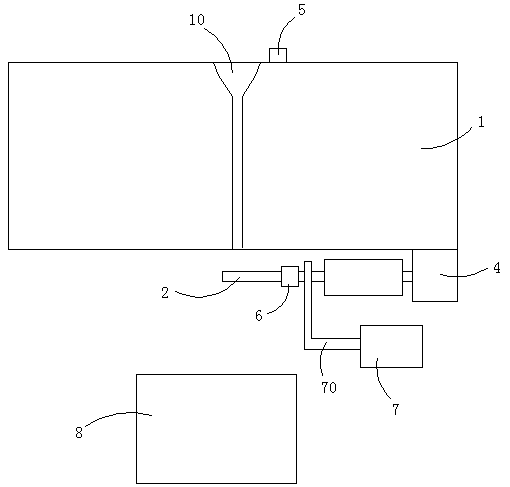

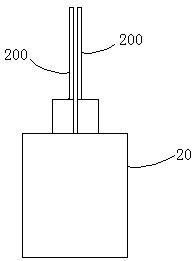

Method and device for disposing discarded needles

The invention relates to a method for disposing discarded needles. The implementation method comprises the steps that after the discarded needles are positioned, the heads of the discarded needles areclamped; and curling is carried out toward the tails of the discarded needles for hiding the sharp parts of the discarded needles. The method adopts a non-destroying-type pretreatment method, the infection caused by the second injury of the needles is completely avoided, after the discarded needles are positioned, the heads of the discarded needles are curled for hiding the sharp parts, the operation is convenient, high temperature is not generated, heating is not carried out, violent cutting is not carried out, sparks and odor are not generated, and the problem of disposal of the discarded needles can be better solved.

Owner:深圳新融典科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com