Vehicle-mounted water cutting system

A cutting system and vehicle-mounted technology, which is applied to used abrasive processing devices, abrasives, metal processing equipment, etc., can solve problems such as the inability of the equipment to function effectively, and achieve the effect of rapid movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

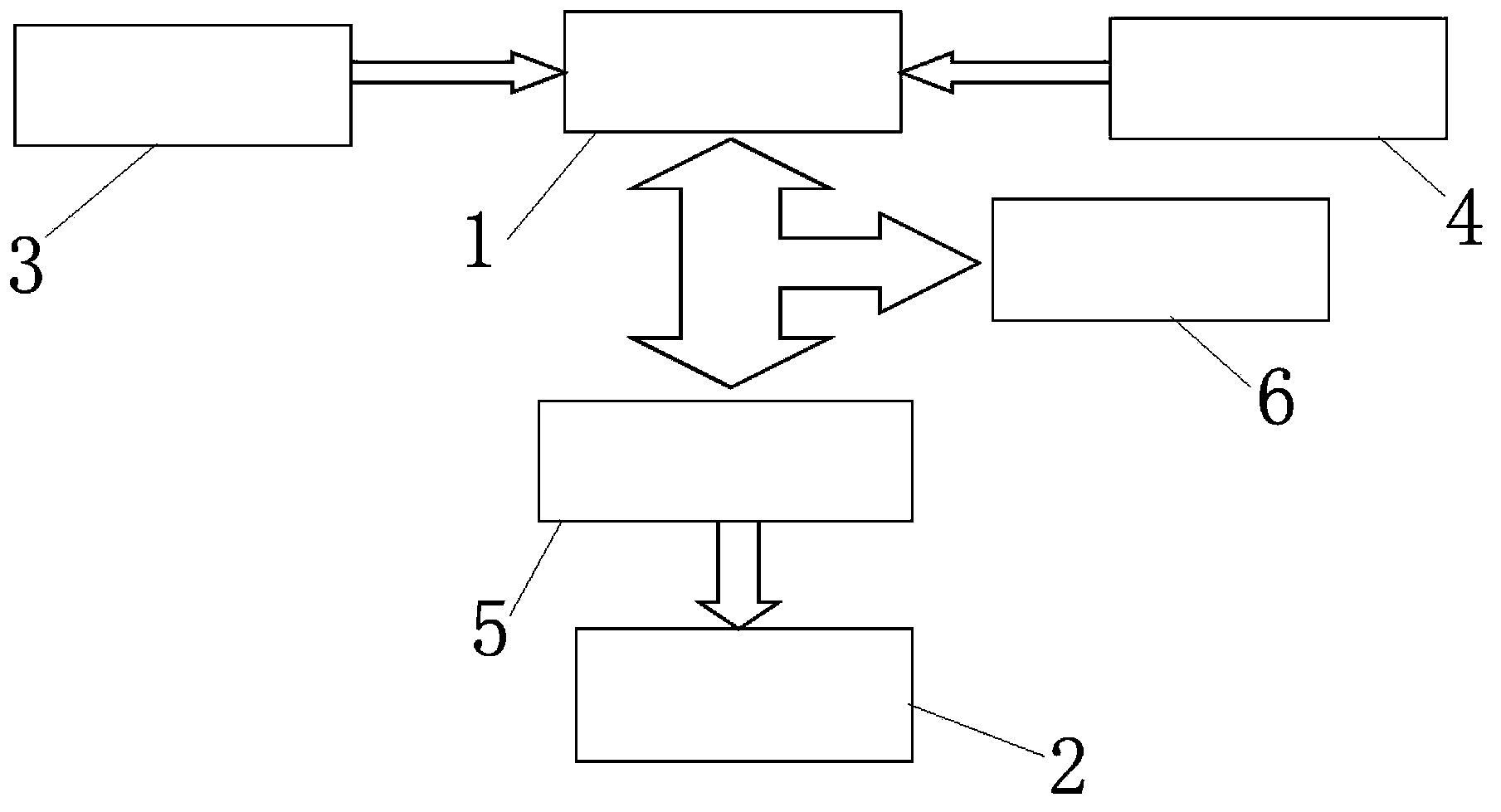

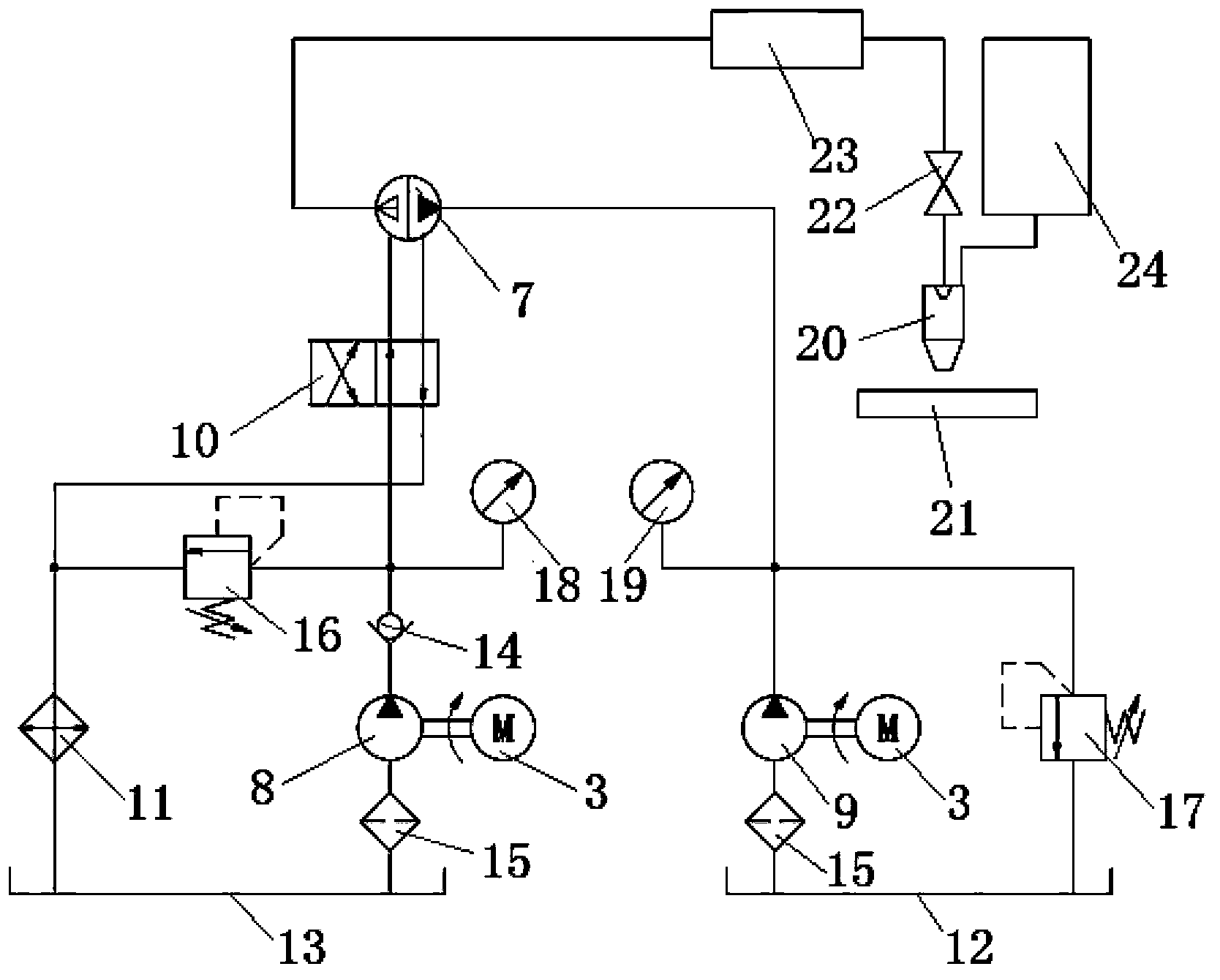

[0018] Such as figure 2 As shown, the vehicle-mounted water cutting system described in the embodiment of the present invention includes a water booster system 1 and a cutting device 2, and the water booster system 1 is connected with an engine power take-off 3 and a water supply system 4, and the water booster system An abrasive mixing device 5 is provided between the system 1 and the cutting device 2 , and an overpressure protection device 6 is provided between the abrasive mixing device 5 and the water pressurization system 1 .

[0019] The water pressurization system 1 includes a supercharger 7, a hydraulic pump 8 and a water pump 9. One end of the supercharger 7 is connected to the cutting device 2, and the other end of the supercharger 7 is connected to a cooling device through a reversing valve 10, respectively. 11 and the hydraulic pump 8 are connected to the water tank 12 through the water pump 9, the hydraulic pump 8 and the cooler 11 are connected to the vehicle fu...

specific Embodiment 2

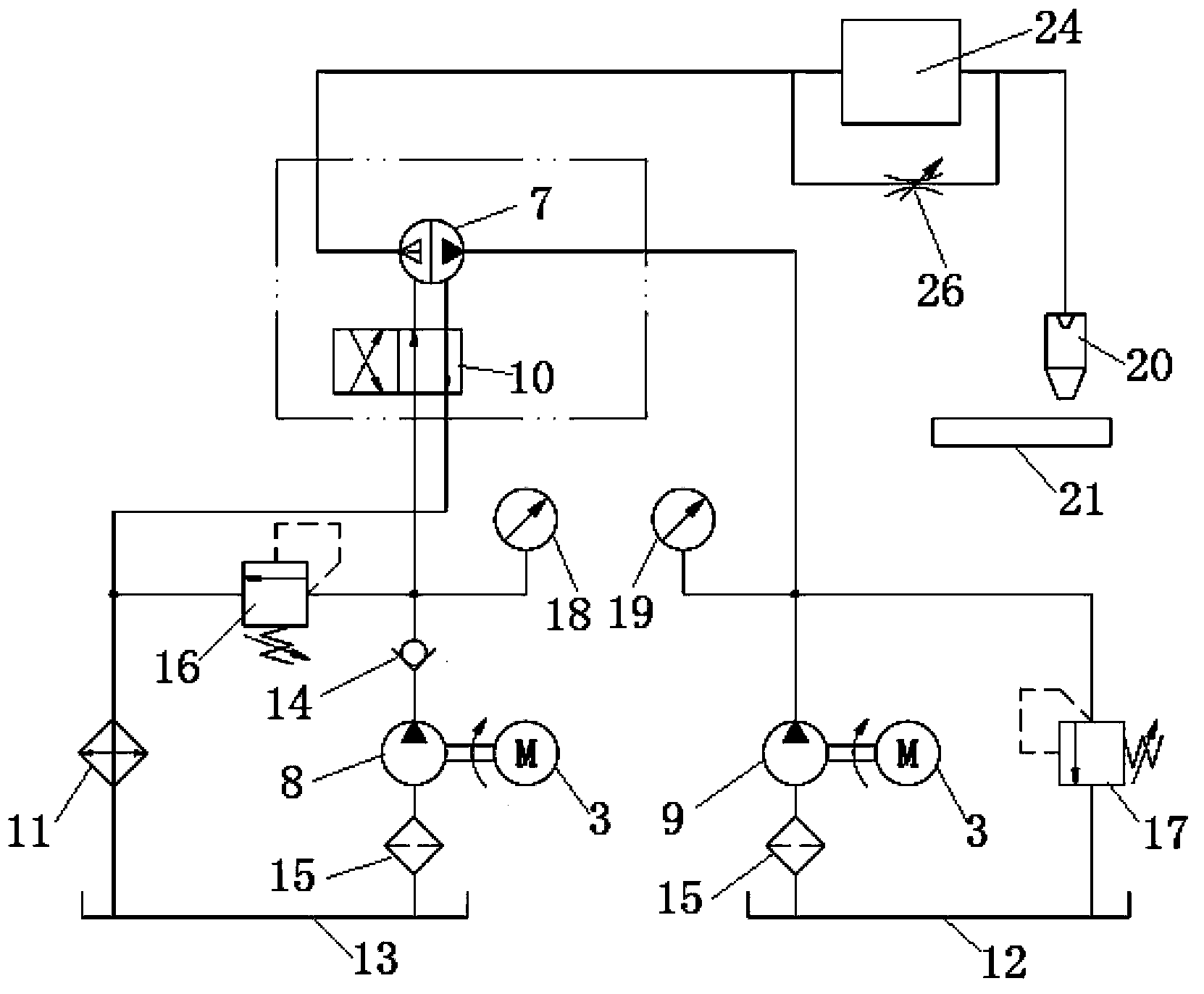

[0023] Such as image 3 As shown, the vehicle-mounted water cutting system described in the embodiment of the present invention includes a water booster system 1 and a cutting device 2, and the water booster system 1 is connected with an engine power take-off 3 and a water supply system 4, and the water booster system An abrasive mixing device 5 is provided between the system 1 and the cutting device 2 , and an overpressure protection device 6 is provided between the abrasive mixing device 5 and the water pressurization system 1 .

[0024]The water pressurization system 1 includes a supercharger 7, a hydraulic pump 8 and a water pump 9. One end of the supercharger 7 is connected to the cutting device 2, and the other end of the supercharger 7 is connected to a cooling device through a reversing valve 10, respectively. 11 and the hydraulic pump 8 are connected to the water tank 12 through the water pump 9, the hydraulic pump 8 and the cooler 11 are connected to the vehicle fuel...

specific Embodiment 3

[0028] Such as Figure 4 As shown, the vehicle-mounted water cutting system described in the embodiment of the present invention includes a water booster system 1 and a cutting device 2, and the water booster system 1 is connected with an engine power take-off 3 and a water supply system 4, and the water booster system An abrasive mixing device 5 is provided between the system 1 and the cutting device 2 , and an overpressure protection device 6 is provided between the abrasive mixing device 5 and the water pressurization system 1 .

[0029] The water pressurization system 1 includes a high-pressure water pump 25 and a water pump 9, the high-pressure water pump 25 and the water pump 9 are connected to the engine power take-off 3, and one end of the high-pressure water pump 25 is connected to the cutting device through a one-way valve 14 2. The other end of the high-pressure water pump 25 is connected in series with one end of the water pump 9, and the other end of the water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com