Patents

Literature

111results about How to "No static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

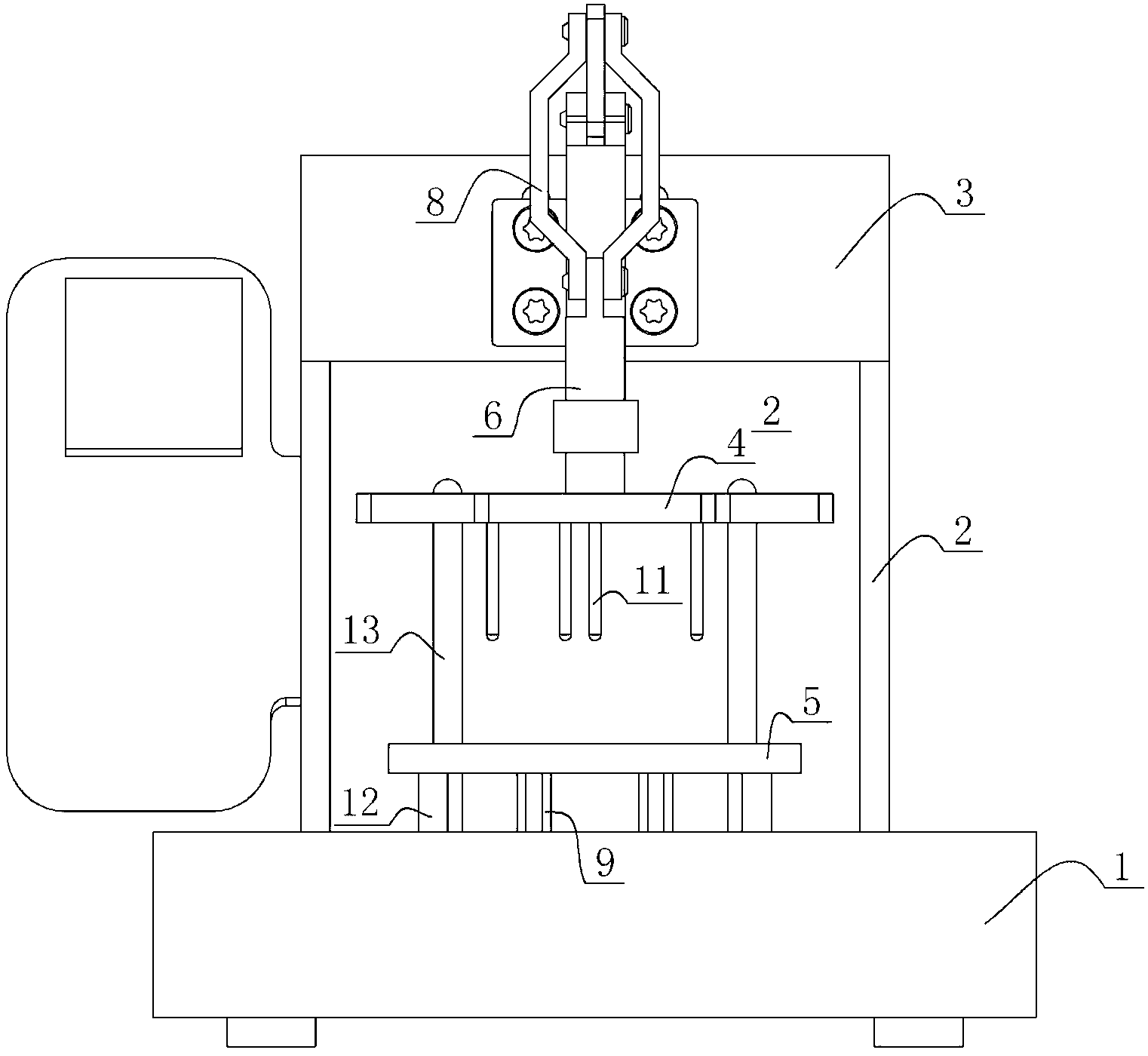

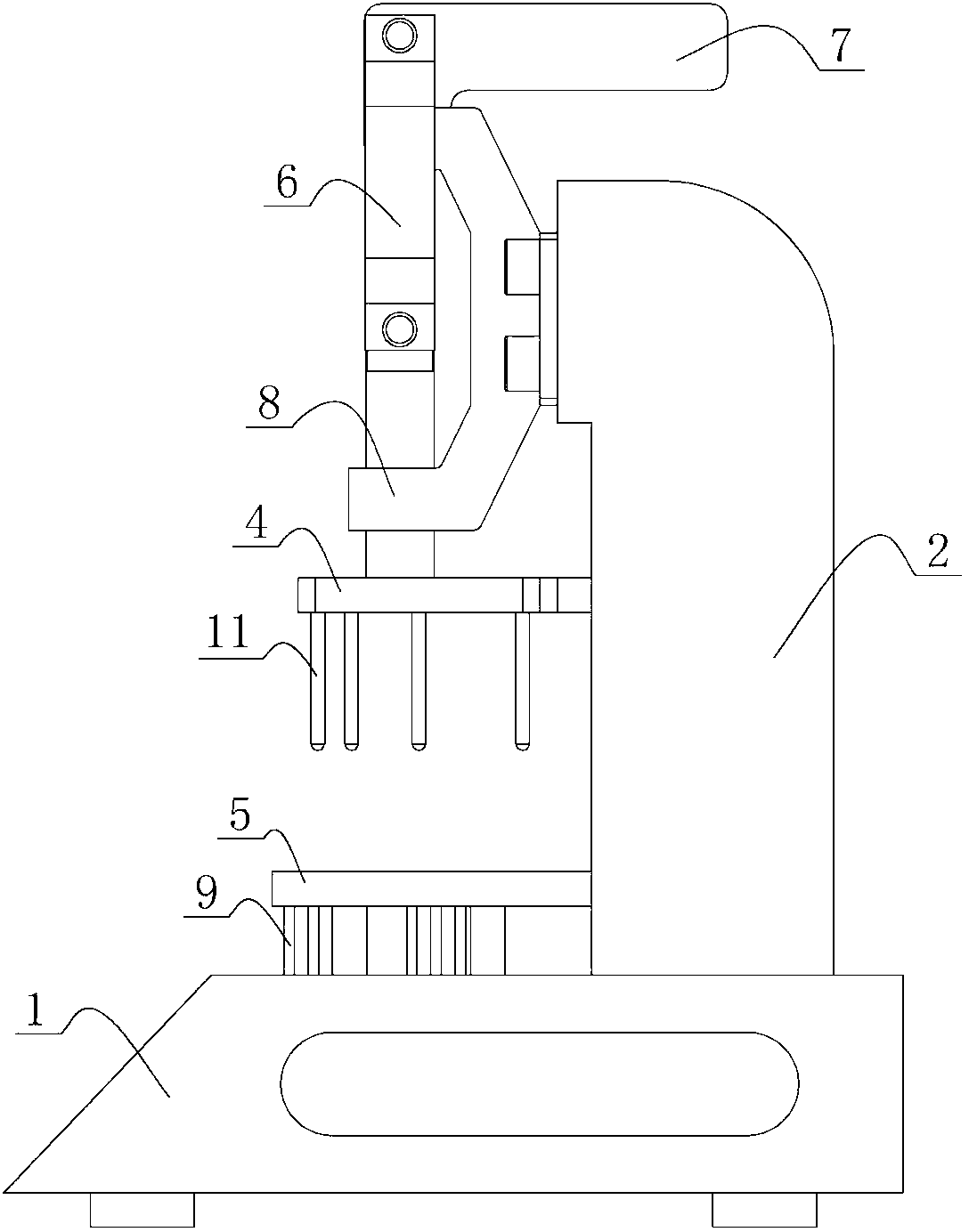

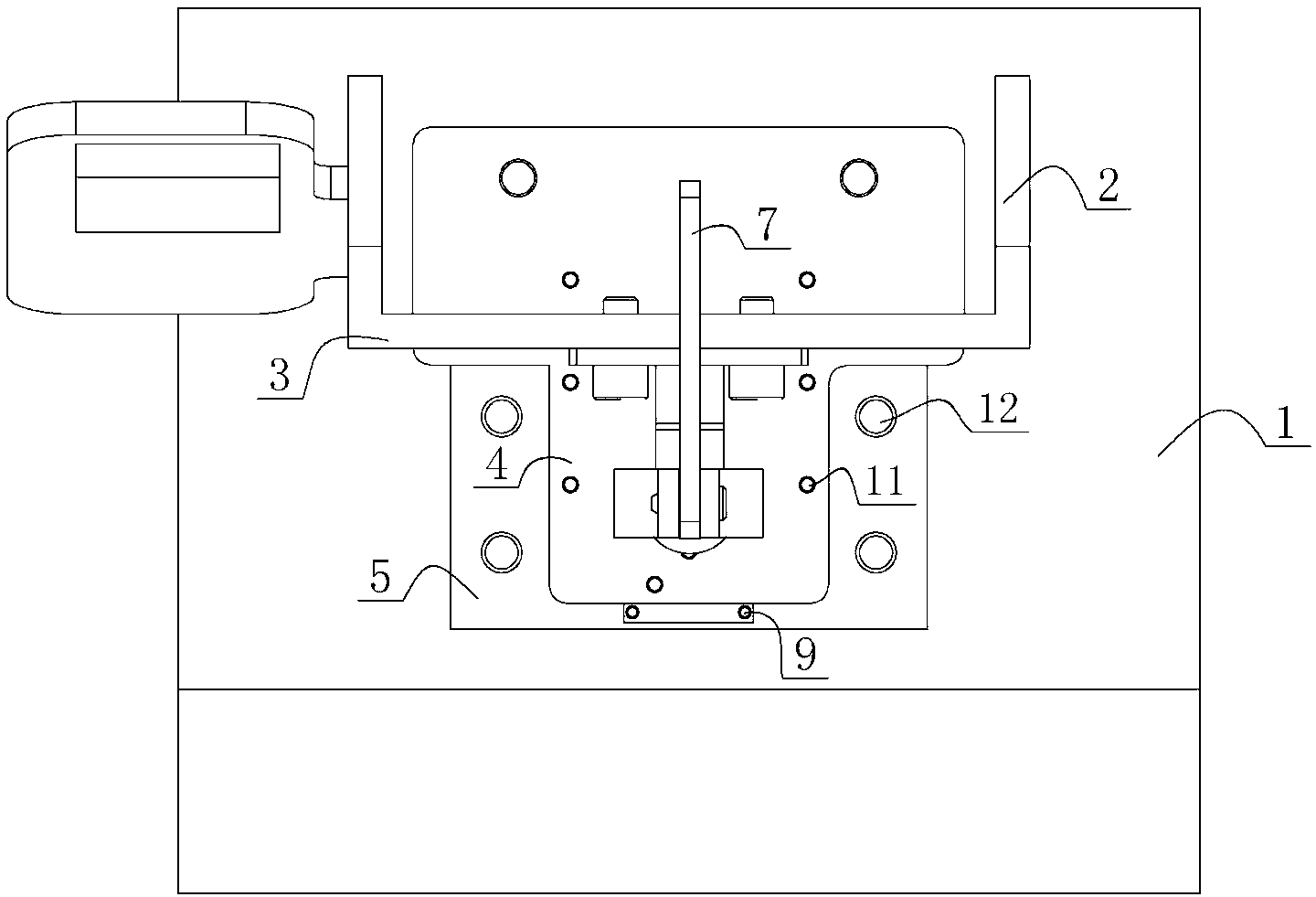

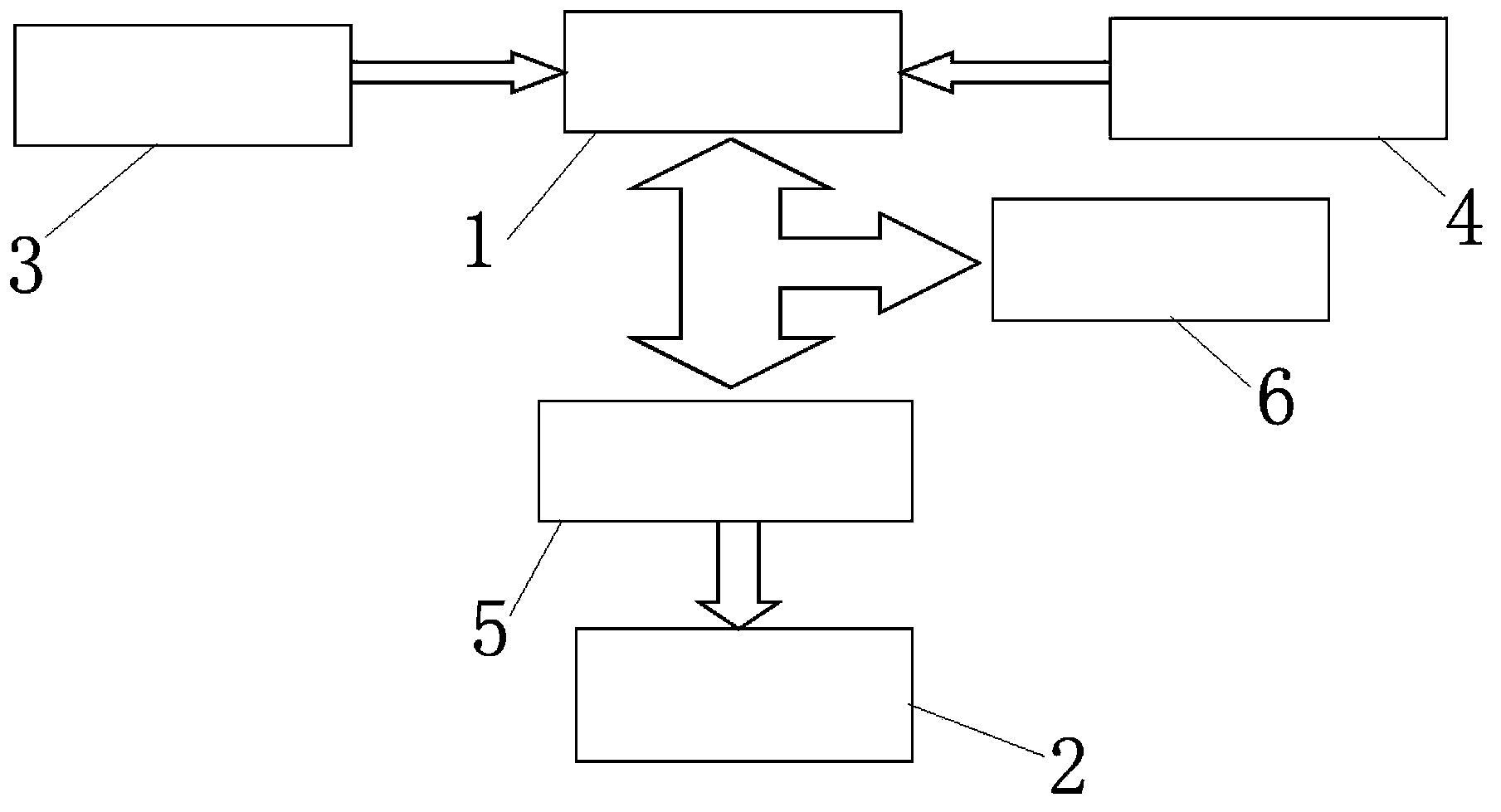

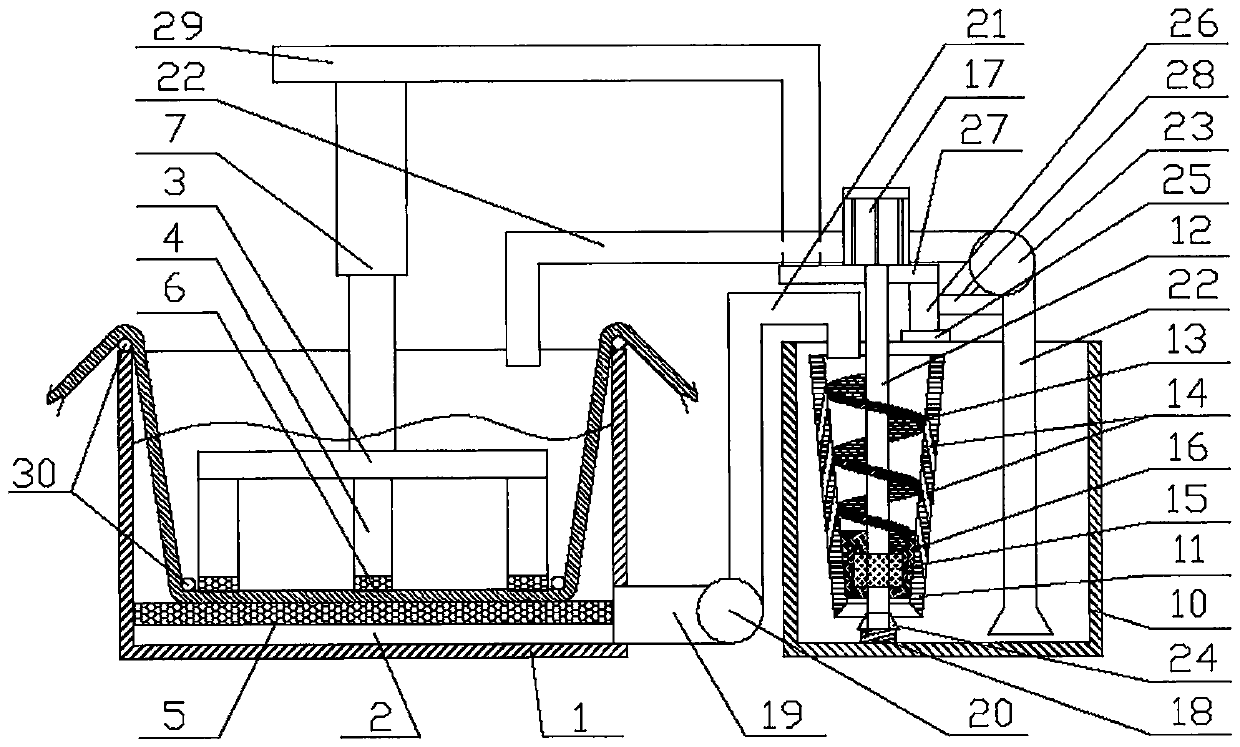

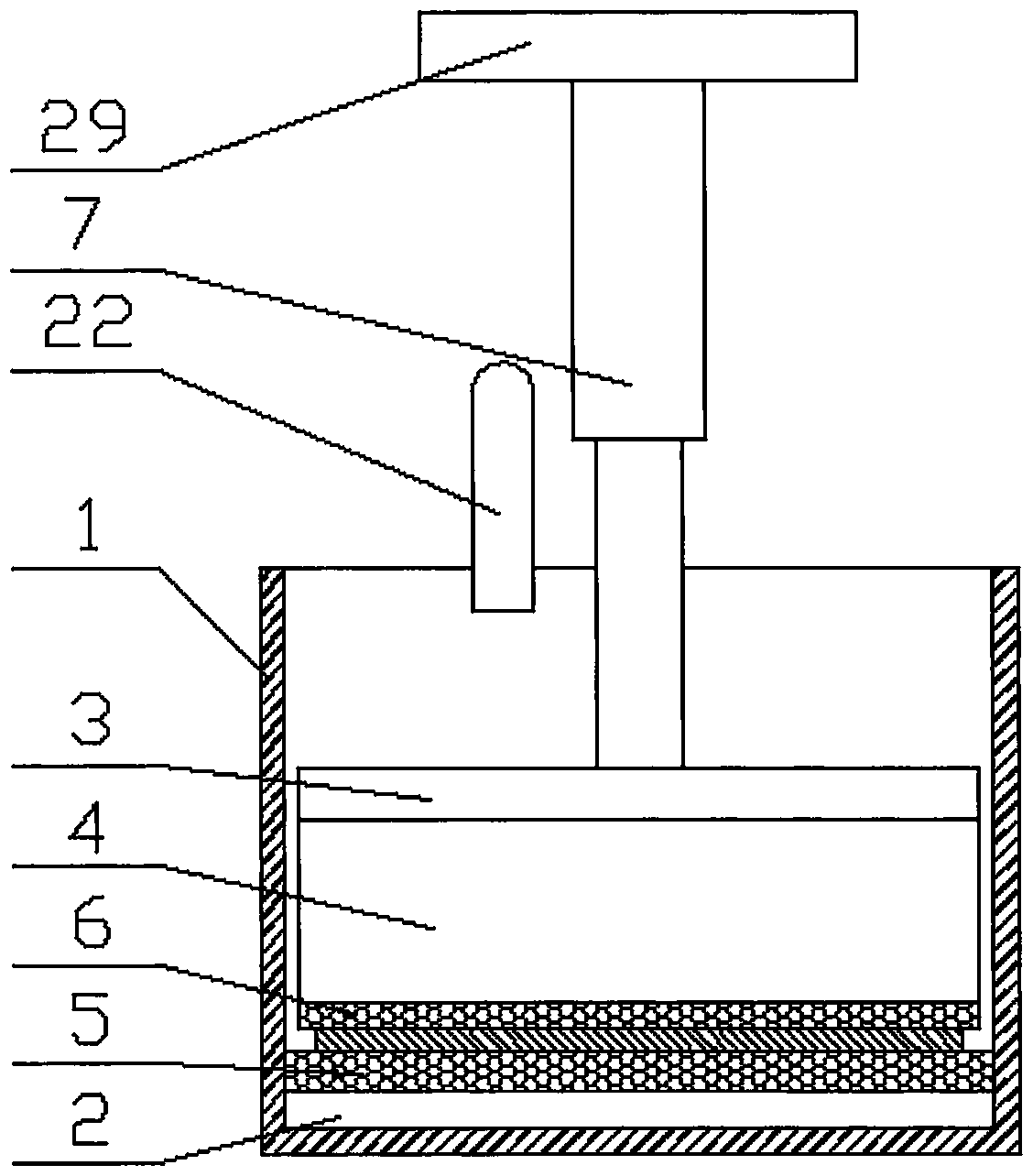

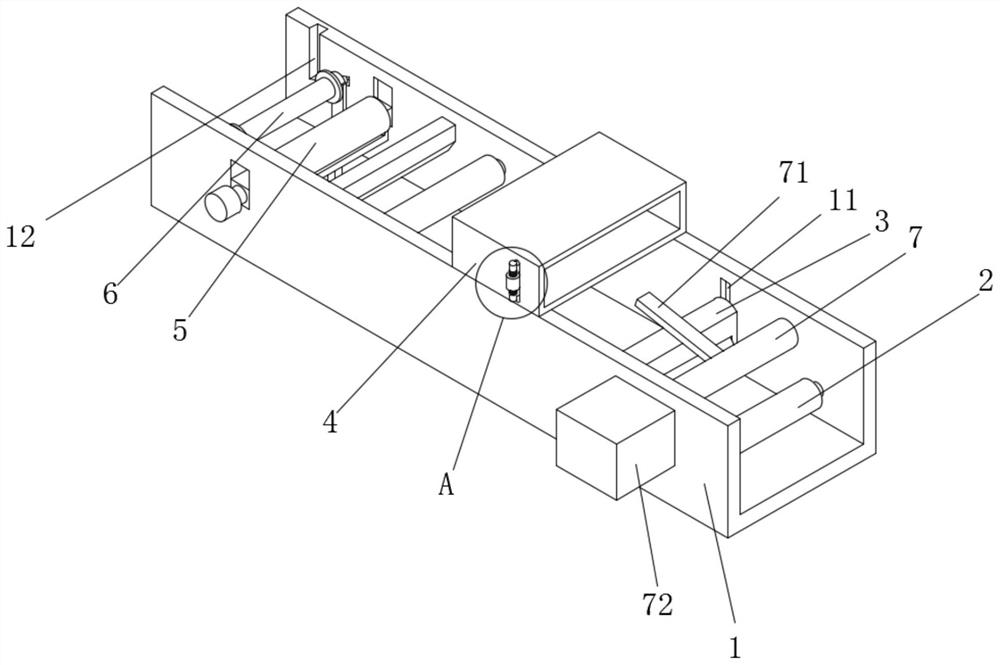

Safe relay module tester

InactiveCN103267944AImprove detection efficiencyNovel structureCircuit interrupters testingTester deviceAlarm signal

The invention provides a safe relay module tester which comprises a mechanical structure portion and a circuit portion. The safe relay module tester is characterized in that a beam is fixed on a base through two vertical beams, a lifting arm is fixed on the beam through a supporting frame, an upper movable board is fixed at the lower end of the lifting arm, a lower bearing board is fixed on the base, a plurality of conducting probes which are matched with wiring terminals and testing points of a PCB board of a safe relay are fixed on the lower bearing board, and a plurality of pressing rods which exert pressure on the PCB board of the safe relay are fixed on the lower surface of the upper movable board. The tester can effectively and rapidly fix a safe relay module, and can rapidly and accurately achieve measurement of performance of the safe relay module. When an inferior-quality product appears, inspection personnel can be reminded of the inferior-quality product through a sound-light alarm signal, and detection efficiency of the safe relay module is effectively improved. The safe relay module tester has the advantages of being novel in structure, easy to operate, high in work efficiency and convenient to apply and popularize.

Owner:SHANDONG LAIEN OPTIC ELECTRONICS TECH

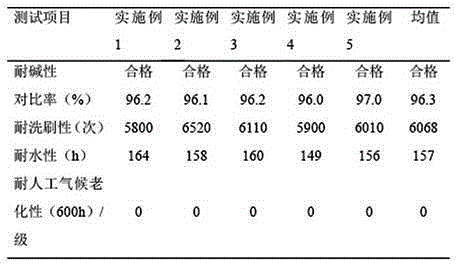

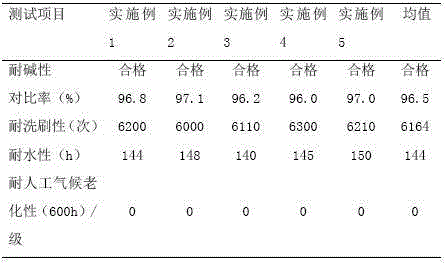

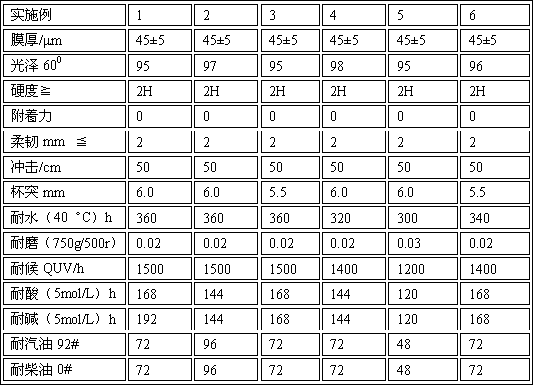

Environment-friendly latex paint and preparation method thereof

InactiveCN108329765AStrong adhesionLight smellAntifouling/underwater paintsPaints with biocidesFiberWeather resistance

The invention discloses an environment-friendly latex paint and a preparation method thereof, and relates to the technical field of latex paint. The latex paint is prepared from the following raw materials in parts by weight: 85-105 parts of styrene-acrylic emulsion, 35-45 parts of nano-silica sol, 20-25 parts of diatom ooze, 10-15 parts of nano-TiO2, 10-15 parts of tourmaline anion powder, 10-15parts of glutinous rice glue, 7-8 parts of plant dehydrated filaments, 7-8 parts of antibacterial powder, 4-6 parts of active powder, 4-6 parts of essential oil components, 20-22 parts of an aid and 70-75 parts of deionized water. The latex paint has relatively powerful adhesive force, a paint film has light smell, low VOC and high adhesive force and is combined with the wall stably, peeling and bursting of the paint surface are not easily produced, and weather resistance of the latex paint is greatly improved.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Organic and inorganic complex finishing varnish

InactiveCN105001728AHas hardnessHas densityAntifouling/underwater paintsPaints with biocidesDispersityEmulsion

The invention provides an organic and inorganic complex finishing varnish. An inorganic photocatalysis material is added into a complex organic liquid of silica sol and an elastic acrylic emulsion so as to form an organic and inorganic complex finishing varnish main-body material. The silica sol is added into the emulsion-formed film. Through compounding of the silica sol and the self-crosslinking emulsion, an organic and inorganic complex paint film is formed. The organic and inorganic complex paint film has hardness and density of silica sol and will not generate static charge. No pollutants will adhere to the paint film. Meanwhile, the elastic emulsion endows the paint film with flexibility, and the whole paint film is soft. Thus, the finishing varnish with good dispersity, high surface hardness and excellent anti-pollution performance is obtained.

Owner:上海贝塔建筑科技有限公司

Inorganic waterproof anti-aging external wall coating and preparation method thereof

The invention discloses an inorganic waterproof anti-aging external wall coating and a preparation method thereof. The inorganic waterproof anti-aging external wall coating is prepared from, by weight, 55-60 parts of silica solution, 8-12 parts of sepiolite, 6-10 parts of aluminium hydroxide, 6-10 parts of pigment, 8-18 parts of filler and 0.5-1 part of thickening agent. The preparation method includes the steps of adding sepiolite, aluminium hydroxide and calcium powder to a silica solution to be soaked for 2 h and then dispersed for 10 min at the rotating speed of 6000 r / min, adding other filler to be soaked for 1h and dispersed for 20 min at the rotating speed of 3000 r / min till the fineness is smaller than 50 microns, reducing the rotating speed to 800 r / min, adding thickening agent to be evenly dispersed, and obtaining the target product. The coating has excellent waterproof performance and aging resistance, does not contain any organic components, and is free of toxin and environmentally friendly; the preparation method is easy to operate, low in device requirement and suitable for industrial large-scale production.

Owner:深圳力效新材料科技有限公司

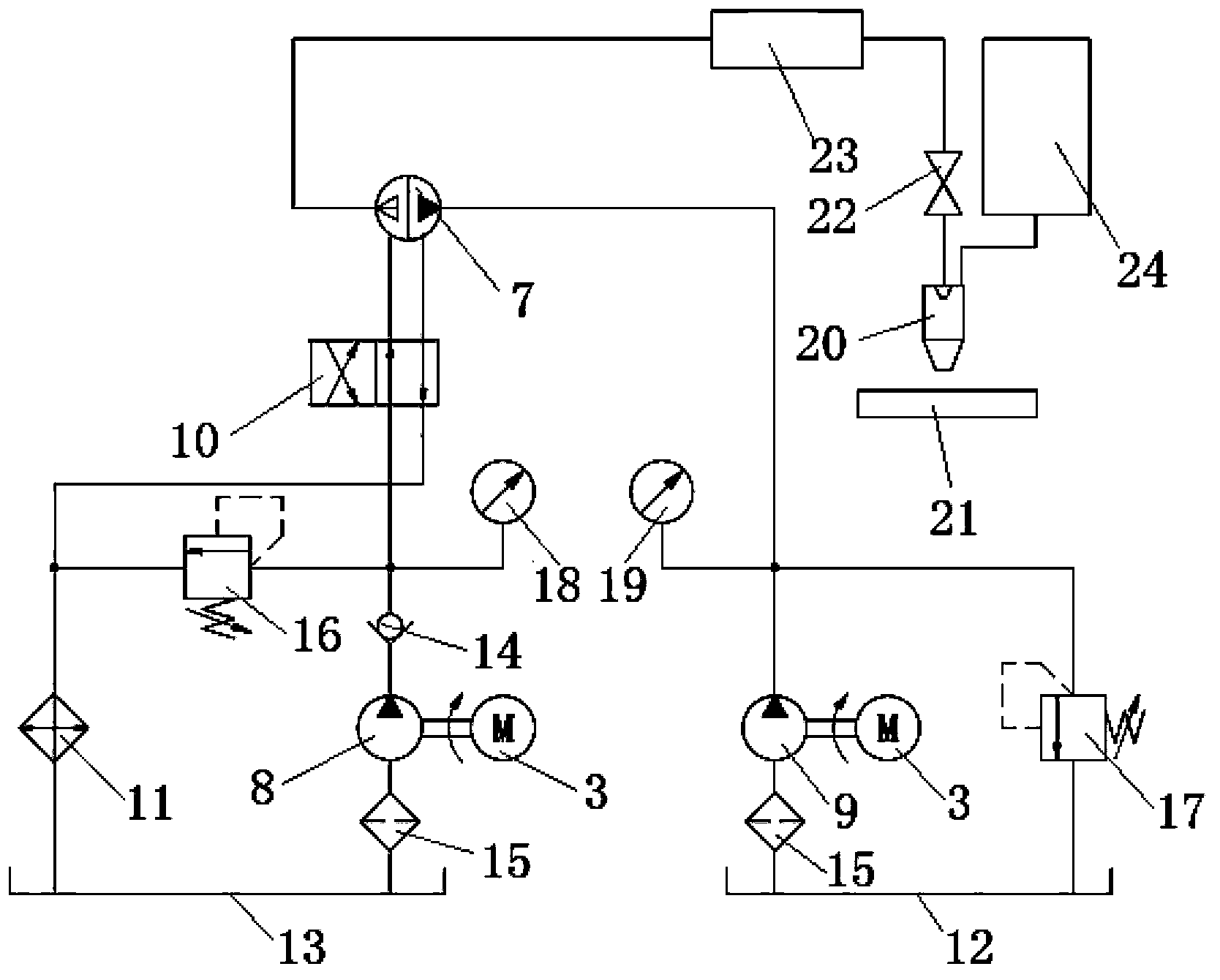

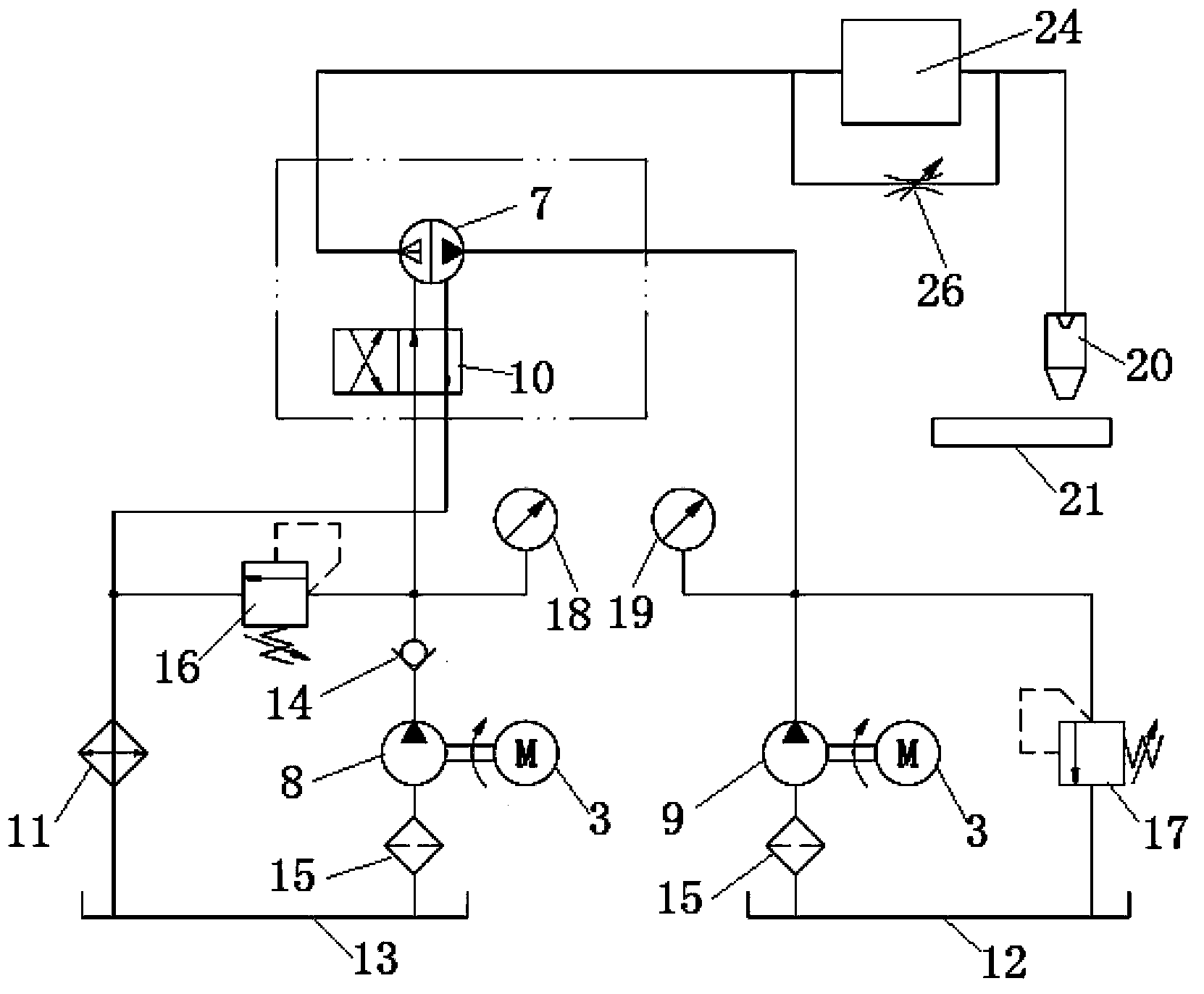

Vehicle-mounted water cutting system

ActiveCN103447970AMove quicklyNo need for high temperatureAbrasive feedersAbrasive machine appurtenancesChemical transformationThermal deformation

Owner:纪新刚

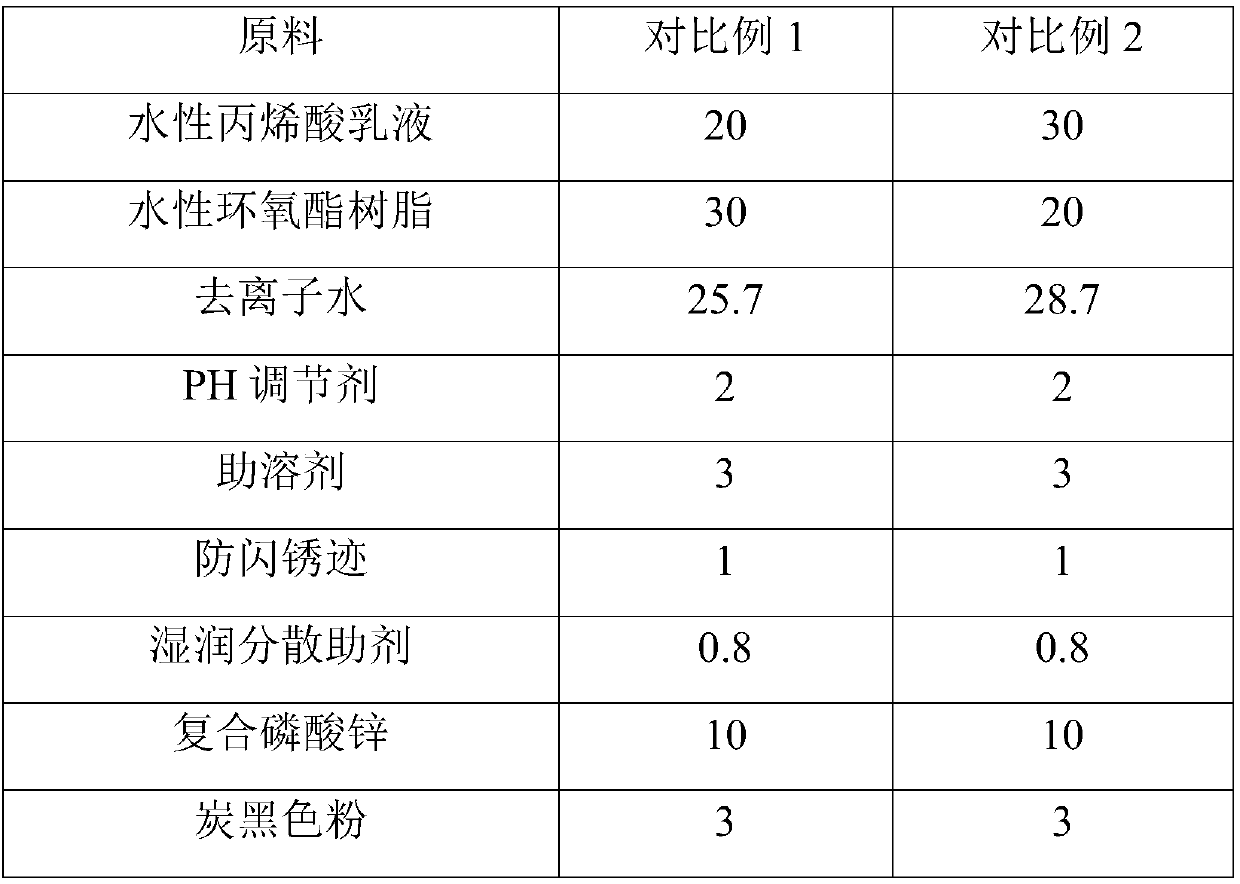

Waterborne acrylic acid anti-corrosion coating material containing graphene and preparation method thereof

InactiveCN109627872AImprove high temperature resistanceImprove thermal conductivityAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

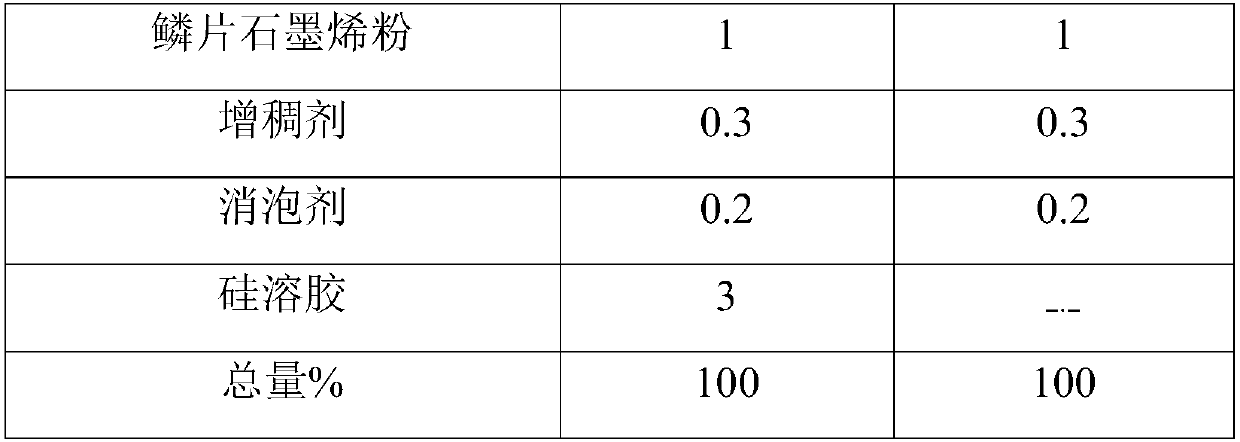

The invention relates to a waterborne acrylic acid anti-corrosion coating material containing graphene and a preparation method thereof, and belongs to the technical field of anti-corrosion coating materials. The coating material comprises, by weight, 30-40% of waterborne acrylic acid emulsions, 10-20% of waterborne epoxy ester resin, 1-2% of a pH regulator, 2-3% of a solubilizer, 1-2% of an anti-flash-rust agent, 0.8-1.2% of an wetting-dispersing additive, 10-15% of an anti-rusting filler, 1-3% of carbon black powder, 1-3% of graphene, 0.3-0.6% of a thickening agent, 0.2-0.6 % of a defoamingagent, 3-5% of silica sol and balanced of deionized water. The waterborne acrylic acid anti-corrosion coating material containing the graphene has the advantages that the drying is rapid, the coatingmaterial is high-temperature resistant, the anti-corrosion performance is high, the VOC content is low, the construction is convenient, and the production cost is low.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

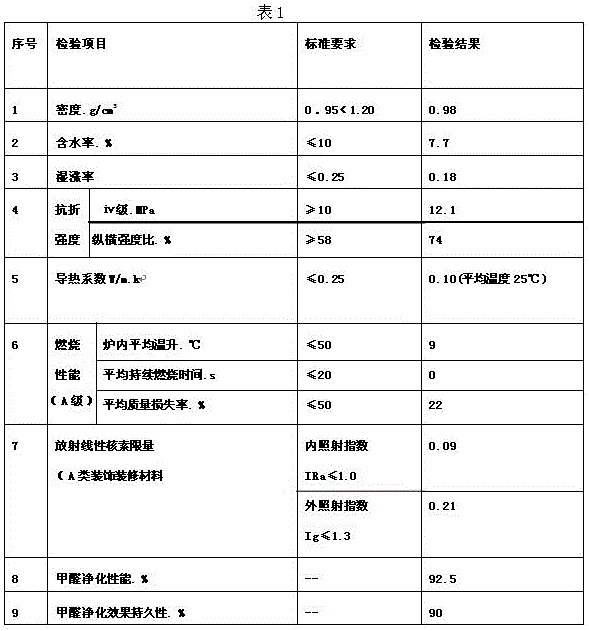

Photocatalyst diatom-mud lightweight high-strength plate

The invention discloses a photocatalyst diatom-mud lightweight high-strength plate, composed of a base plate and a photocatalyst layer, wherein the base plate is coated with the photocatalyst layer. The photocatalyst diatom-mud lightweight high-strength plate has the advantages that the formula is scientific, so that production raw materials are various and compatible; the plate itself has no any pollution; air can be purified, and the formaldehyde purification performance can reach 92.5 percent; the persistence of a formaldehyde purification effect reaches 90 percent; the indoor humidity can be adjusted, so that moisture in the air is absorbed and stored under a wet condition, and is released under a dry condition, and therefore a breathing wall is formed; the service life is 30 years or more, the disadvantages of edge warping, falling off and fading are prevented, the effect of oxidation resistance is achieved, and the plate is always like new; the wall is self-cleaning and is free from production of static electricity, so that dust is not adsorbed; the effects of sound adsorption and noise reduction are achieved; the effects of heat insulation and energy saving are achieved, and the heat insulation performance of the plate is more than six times of that of cement and mortar; the effects of fire prevention and flame resistance are achieved, and a high temperature of 1300 DEG C can be tolerated; the color is soft, so that the eyes are difficultly fatigued; the plate is widely applied to architectural decoration and industrial equipment.

Owner:白山市东北亚新型建筑材料有限公司

Inorganic anti-cracking aging-resistant coating and preparation method thereof

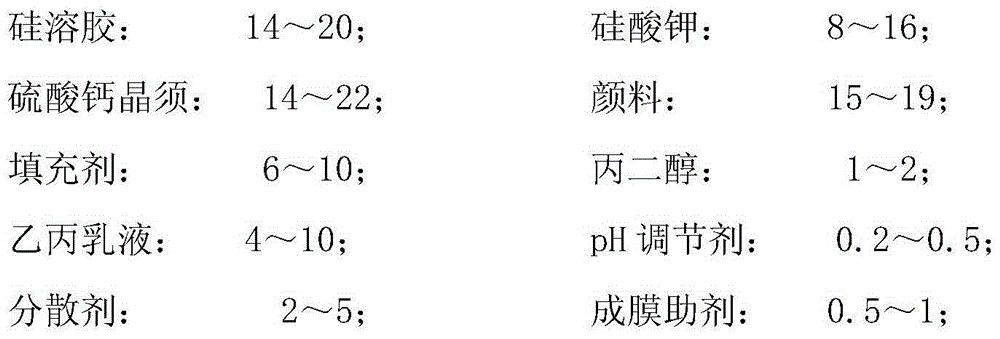

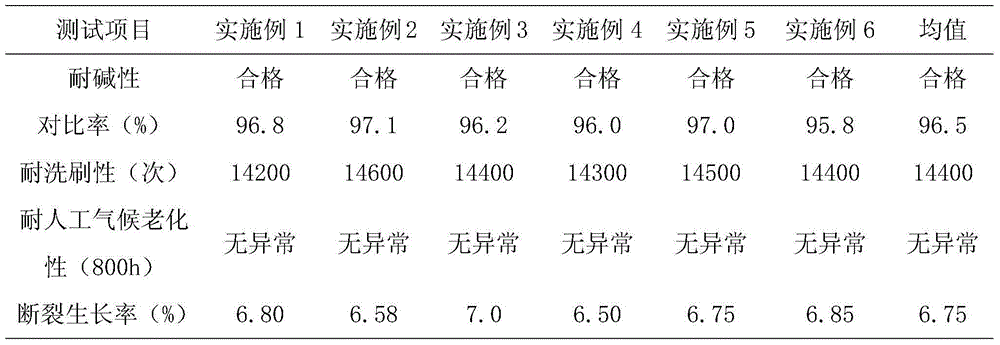

ActiveCN104592792ALarge specific surface areaStrong adhesionAntifouling/underwater paintsAlkali metal silicate coatingsSilica gelDefoamer

The invention discloses an inorganic anti-cracking aging-resistant coating and a preparation method thereof. The coating is prepared from silica sol, potassium silicate, calcium sulfate whiskers, pigments, filler, propylene glycol, a polyvinyl acetate acrylate emulsion, a pH adjustor, a dispersant, a coalescing agent, a defoamer, a thickener and water. The preparation method comprises the following steps: weighing and dividing the defoamer into parts A and B which are equal; adding water into a container, adding the A part of the defoamer, propylene glycol and pH adjustor under a low rotating speed, and uniformly dispersing; increasing the rotating speed, adding the pigments, filler, calcium sulfate whiskers and potassium silicate and dispersing till the grain fineness is less than 50 microns; and after decreasing the rotating speed, adding the B part of the defoamer, a coalescing agent, silica sol, polyvinyl acetate acrylate emulsion and a thickener and uniformly dispersing. The coating disclosed by the invention is strong in adhesion property, good in construction, aging-resistant, anti-cracking, long in service life, non-toxic and environmental-friendly. The preparation method is simple to operate, convenient in production, low in requirement on equipment and suitable for industrial production on a large scale.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Inorganic waterproof ageing-resistant coating and preparation method thereof

The invention discloses an inorganic waterproof ageing-resistant coating and a preparation method thereof. The inorganic waterproof aging-resistant coating is prepared from, by weight, 50-60 parts of silicon sol, 8-12 parts of sepiolite, 3-8 parts of mica, 5-8 parts of pigment, 10-18 parts of a filling agent, 0.5-1 part of a thickening agent and 0.2-0.5 part of a defoaming agent. The preparation method comprises the steps that a packing is added into the silicon sol to be soaked for 3 hours, then scattering is performed under the 1500 r / min condition for 10 minutes, the rotating speed is improved to be 3000 r / min, high-speed dispersion is performed for 20 minutes till the fineness is smaller than 50 micrometers, the rotating speed is reduced to be 800 r / min, the defoaming agent, the thickening agent, a pH regulator and a sterilization fungicide are evenly dispersed and then a finished product is obtained. The inorganic waterproof ageing-resistant coating has waterproof and aging-resistance performance, is non-toxic, is environment-friendly, has low device requirements and is suitable for industrial large-scale production, and the preparation method is simple in operation.

Owner:深圳力效新材料科技有限公司

Antibacterial thermal fabric and preparation method thereof

ActiveCN111098564AGood hygroscopicityGood moisture wicking effectLiquid/gas/vapor open-width material treatmentSynthetic resin layered productsYarnPolymer science

The invention discloses an antibacterial thermal fabric and a preparation method thereof, and belongs to the technical field of textile silk yarns. The fabric comprises the following components (by weight): 30 to 45 parts of bamboo fiber, 10 to 20 parts of Coppron copper ion fibers, 30 to 45 parts of cotton fibers, 20 to 30 parts of kapok fibers, 10 to 15 parts of filament goose down, and 10 to 15parts of thermal fibers. The preparation method comprises the following steps: firstly, blending the cotton fibers and the filament goose down fibers into silk yarns A; blending kapok fibers and partof bamboo fibers into silk yarns B; twisting the two kinds of silk yarn together to be woven into a first fabric, then blending the Coppron copper ion fibers and the remaining bamboo fibers into silkyarns C, weaving the silk yarns C and the thermal fibers into a second fabric, then bonding the two kinds of fabric together to obtain a gray fabric, and then dyeing the gray fabric and shaping. Theantibacterial thermal fabric prepared according to the preparation method provided by the invention has efficient antibacterial thermal performance, and is relatively good in air permeability and comfort.

Owner:YANCHENG SILIDE COCOON SILK

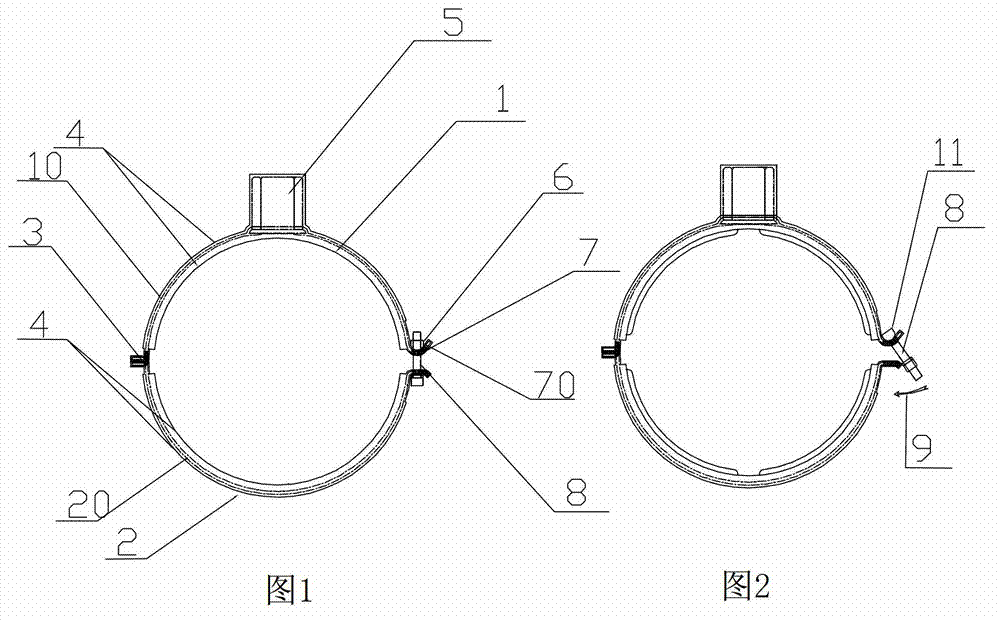

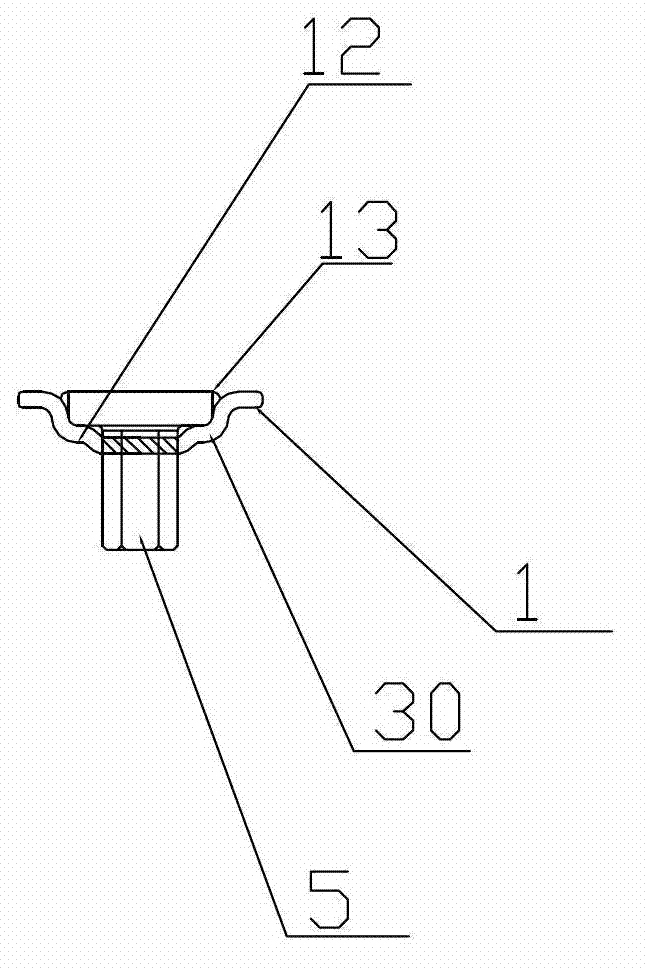

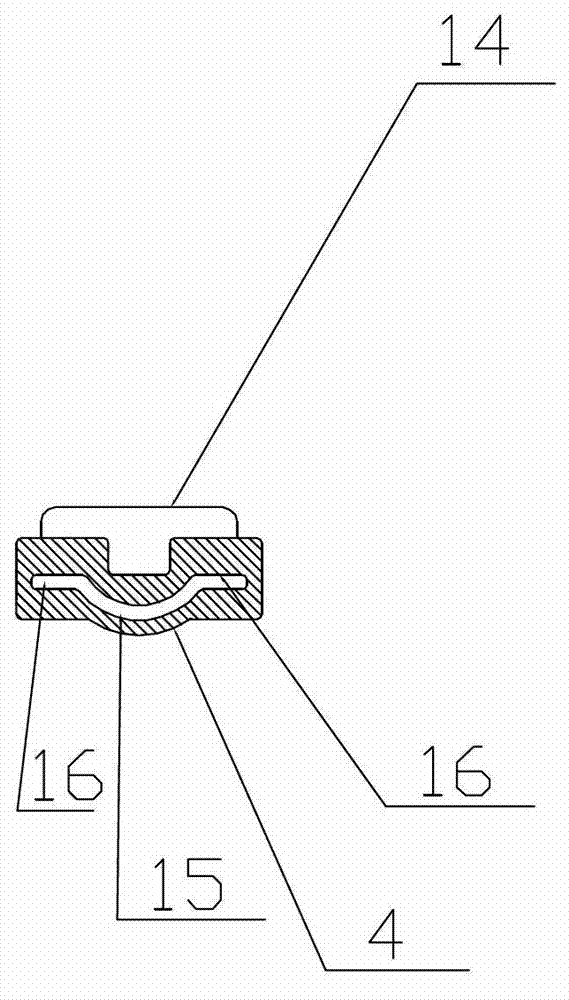

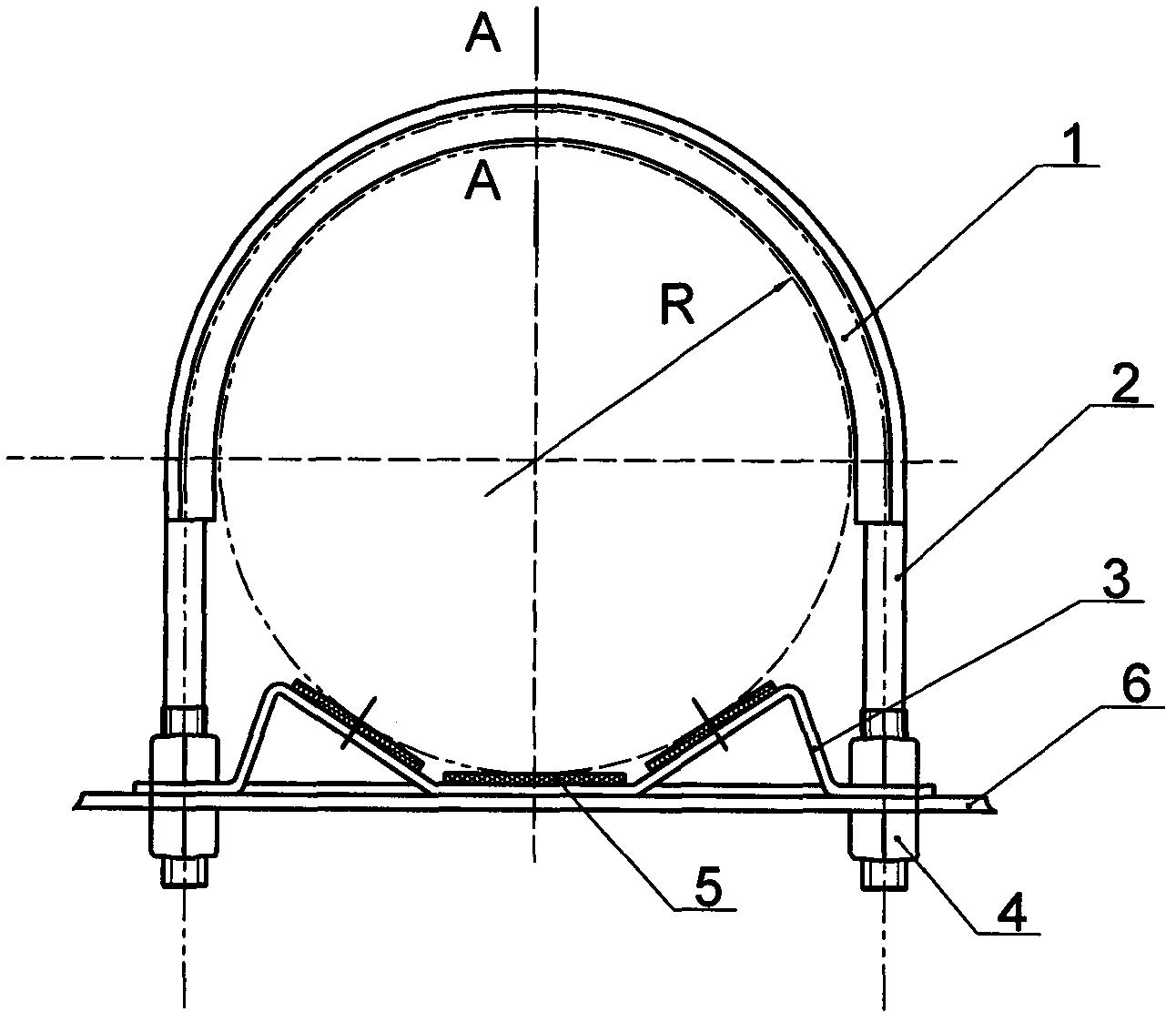

Multifunctional safety pipe hoop

The invention provides a multifunctional safety pipe hoop which comprises a first metal hoop ring and a second metal hoop ring. The first metal hoop ring and the second metal hoop ring are combined to enclose a pipe. One ends of the first metal hoop ring and the second metal hoop ring are connected in a movable mode, and the other ends of the first metal hoop ring and the second metal hoop ring are fastened by a connecting component. Anti-skidding anti-corrosion layers are arranged on the metal hoop rings. Connecting nuts or connecting screws are arranged on the metal hoop rings. The hoop rings have various safety functions, such as shockproof function, reliable load-bearing function and anti-corrosion function. Besides, the hoop rings are simple in structure and low in cost. The multifunctional safety pipe hoop is long in service life, and technologies which produce pollution, such as acid treatment and electrofacing are eliminated. The multifunctional safety pipe hoop is particularly suitable for public places and undergrounds which has anti-corrosion requirements. Besides, pipes in complex pipelines are enabled not to generate static electricity and conduct electricity. Furthermore, the anti-skidding anti-corrosion layers are made of fire-proof materials, the problem that the pipes fall down to block a road due to metal creep in a fire is solved, and opportunities are created for escaping and firefighting.

Owner:斯泰科技(杭州)有限公司 +2

Silk scarf fabric with health care functions

A silk scarf fabric with health care functions comprises bio-magnetic fibers, bamboo carbon functional fibers, far infrared functional fibers, silk, titanium fibers, silver fibers, long stapled cotton, combed cotton and anion fibers. The fabric made by the formula is dry, clean and air-permeable, has multiple health care functions such as sterilization, anti-inflammation, pain relief, constriction and hemostasis, is soft and free of deformation, does not generate static electricity, and has high warmth keeping performance and high wet permeability. The fabric can promote cell metabolism of a human body, strengthen and improve immunity functions, relieve fatigue, promote physical strength recovery, eliminate insomnia and delay aging, etc.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

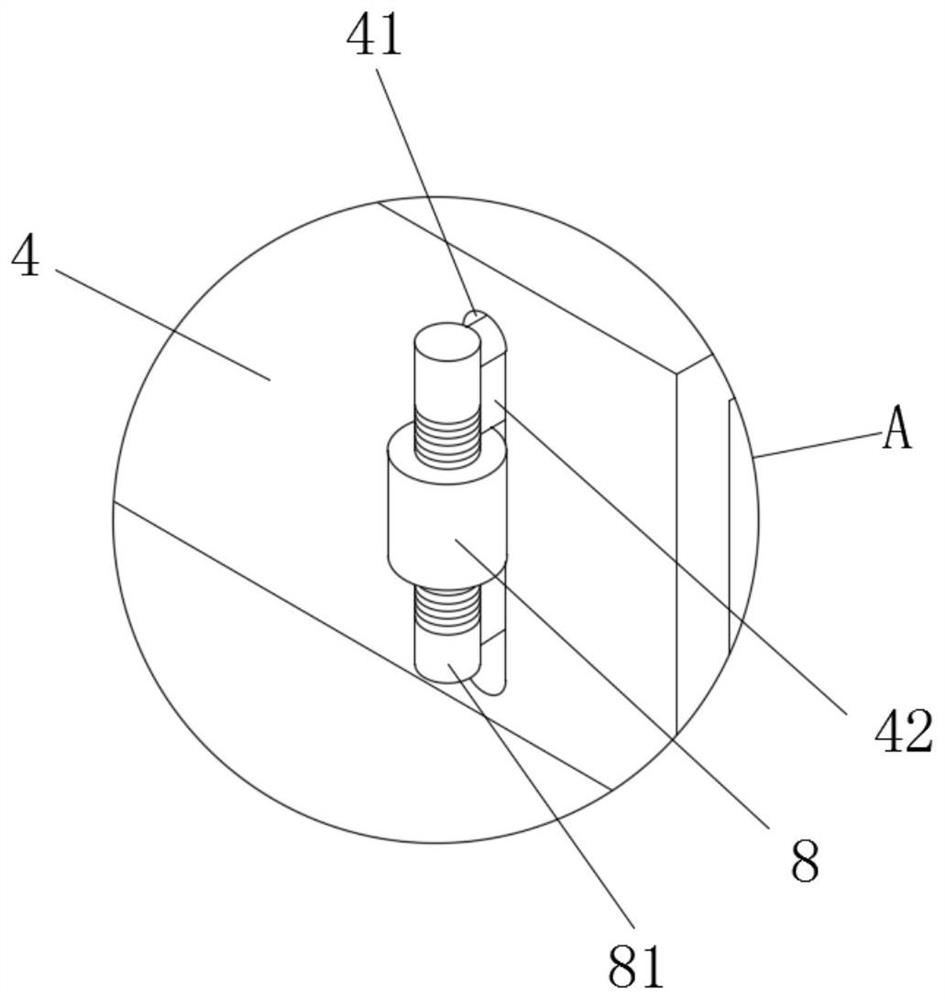

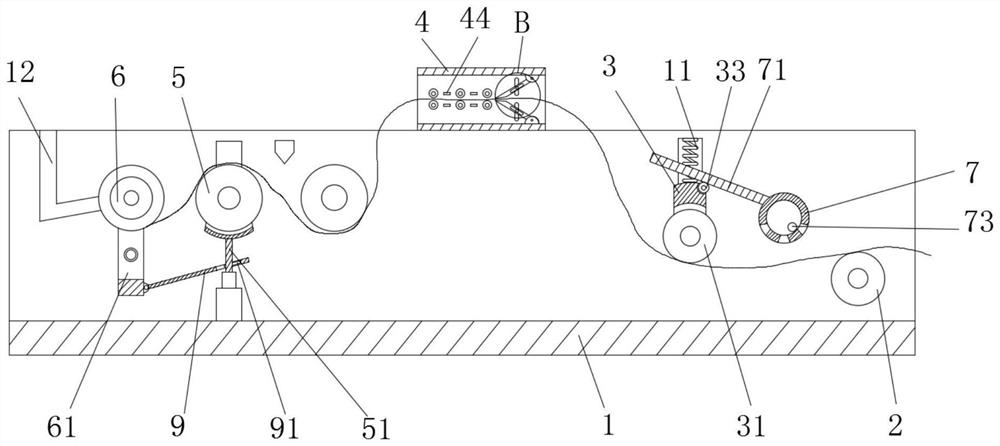

Anti-wrinkle non-woven fabric winding device and using method thereof

PendingCN113307076ASolve the problem of wrinkles in windingWithout compromising integrityCleaning using toolsElectrostatic chargesEngineeringNonwoven fabric

The invention discloses an anti-wrinkle non-woven fabric winding device and a using method thereof, and relates to the field of non-woven fabrics. The anti-wrinkle non-woven fabric winding device comprises a workbench, wherein a conveying roller is rotatably mounted in the workbench, a supporting frame is slidably mounted in the workbench, a pressing roller is rotatably mounted at the bottom of the supporting frame, and a processing box with an opening inside is fixedly mounted in the middle of the upper portion of the workbench; two symmetrical and inclined scraping plates are rotatably mounted inside the processing box; and a plurality of transmission rollers are rotatably mounted inside the processing box. According to the anti-wrinkle non-woven fabric winding device and the using method thereof, the two scraping plates are symmetrically arranged, so that fluff on the surface of a non-woven fabric is scraped away at a time; and then the fluff on the surface of the non-woven fabric is thermalized and ironed in a heating plate ironing mode, so that the the problem that in the prior art, gaps exist in the rolled non-woven fabric due to the fluff in the rolling process, and wrinkles are generated in the rolling process as certain fluff still exists on the surface of the non-woven fabric in the rolling process is solved.

Owner:安徽苏博伦服饰有限公司

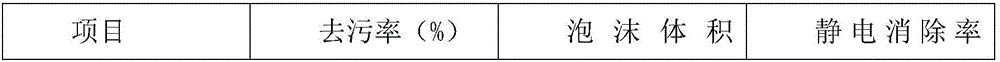

Antistatic detergent used for carpet and preparation method thereof

InactiveCN106244348AStrong decontaminationImprove washing effectNon-ionic surface-active compoundsOrganic detergent compounding agentsPhosphateFatty alcohol

The invention discloses an antistatic detergent used for a carpet and a preparation method thereof. The antistatic detergent is composed of the following raw materials in parts by weight: 8 to 13 parts of polyoxyethylene fatty alcohol sodium sulfate, 4 to 7 parts of sodium lauroyl sarcosine, 5 to 9 parts of alpha-sulfo fatty acid alkyl ester salt, 7 to 11 parts of hydrogenated castor oil polyoxypropylene ester, 9 to 15 parts of alkylamine oxide polyoxyethylene ether, 3 to 6 parts of coconut acid diethanolamide, 6 to 9 parts of phosphate polyoxyethylene nonyl phenol, 2 to 5 parts of dodecyl dimethyl benzyl ammonium bromide and 60 to 80 parts of water. The detergent prepared by using the method provided by the invention has strong detergency and good washing effect, and can guarantee that the carpet does not generate electrostatic phenomenon, so dust adsorption is reduced.

Owner:合肥永佳新材料科技有限公司

Quick-drying and anti-cracking oil paint and preparation method thereof

InactiveCN106957551AImprove mixing uniformityHigh glossArtist's paintsPolyurea/polyurethane coatingsOil paintN-Butyl acetate

The invention provides quick-drying and anti-cracking oil paint and a preparation method thereof. The oil paint is prepared from the following raw materials in parts by weight: 20 to 30 parts of acrylic emulsion, 10 to 15 parts of polyurethane resin emulsion, 5 to 10 parts of vinyl versatate, 15 to 20 parts of zeolite powder, 10 to 15 parts of pigment toner, 3 to 6 parts of dipropylene glycol butyl ether, 3 to 6 parts of butyl acetate, 0.5 to 1 part of a polyethylene-ethylene glycol-methacrylic acid copolymer, 0.2 to 1 part of bee wax, 0.2 to 1 part of a drier, 0.2 to 1 part of sodium benzoate and 10 to 20 parts of distilled water. According to the quick-drying and anti-cracking oil paint, all the components have a common effect and an air drying speed of the oil paint is effectively improved; meanwhile, the color and luster, hardness and stability of the paint can be improved and the drawing efficiency is improved; the quick-drying and anti-cracking oil paint has very good popularization and application value.

Owner:台州瑞祥教育科技有限公司

Production process of RFID tag ultrahigh frequency antenna

InactiveCN106274008AHigh selectivityWon't breakLamination ancillary operationsAntenna supports/mountingsComposite filmEngineering

The invention provides a production process of an RFID tag ultrahigh frequency antenna. The production process comprises the following steps: 1) carrying out a compound process: firstly, blending required compound glue, then coating the glue on coated paper by using a compound machine and compounding with an aluminum foil, thus producing a composite film, curing the glue through an oven of the compound machine to complete the compound process; 2) carrying out a printing process: printing patterns of a product required to be produced on the compounded composite film through a printing machine; 3) carrying out etching process: c processes of etching by an etching machine, ink removal, cleaning and drying on the printed composite film to produce the finish product; 4) carrying out a cutting process: cutting the etched finished product by a cutter according to the dimensional requirements of a customer. The production process of the RFID tag ultrahigh frequency antenna disclosed by the invention is conducive to industrial development; the static electricity is not generated, thereby not causing damage to the antenna product; the production process of the RFID tag ultrahigh frequency antenna further has multiple advantages of capability of resisting high temperature, being beneficial to environmental protection and the like.

Owner:WUXI GRANDTAG ELECTRONICS

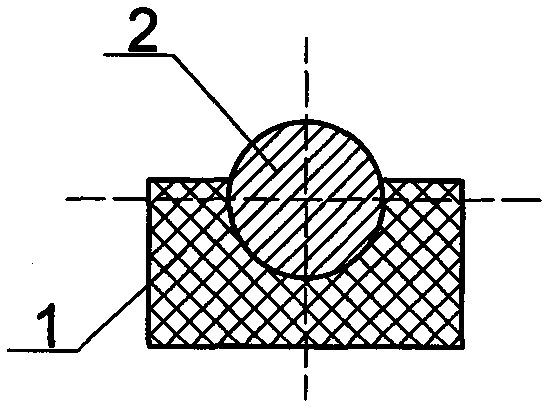

Anti-static pipe clamp

The invention discloses an anti-static pipe clamp, comprising of a lining, an U-type bolt, a base plate, a nut and a cushion block. The U-type bolt has a structure of double threads. The base plate is a panel veneer which is symmetrically bended in the length direction and is equipped with through holes on the extended edges of both ends. The middle of the base plate is like a trilateral groove and the diameter of the circle internally tangent to the midpoints of the groove's three sides is equal to the outer diameter of a cargo pipe line to be clamped in length. The lining and the cushion block is made of insulation materials. The lining is U-type and the outer wall of the lining is equipped with a semicircle groove matched with the inner wall of the U-type bolt. The cushion block is a rectangle sheet. The installed lining and cushion block form an insulation structure between the pipe clamp and the cargo pipe line to be clamped. Even if an axial displacement of the cargo pipe line happens, no static electricity is generated. The anti-static pipe clamp has a simple structure and is reliable in connection and is safe to use, and can match cargo pipe lines with various pipe sizes.

Owner:JIANGYAN TELI MACHINERY SEALING MFG

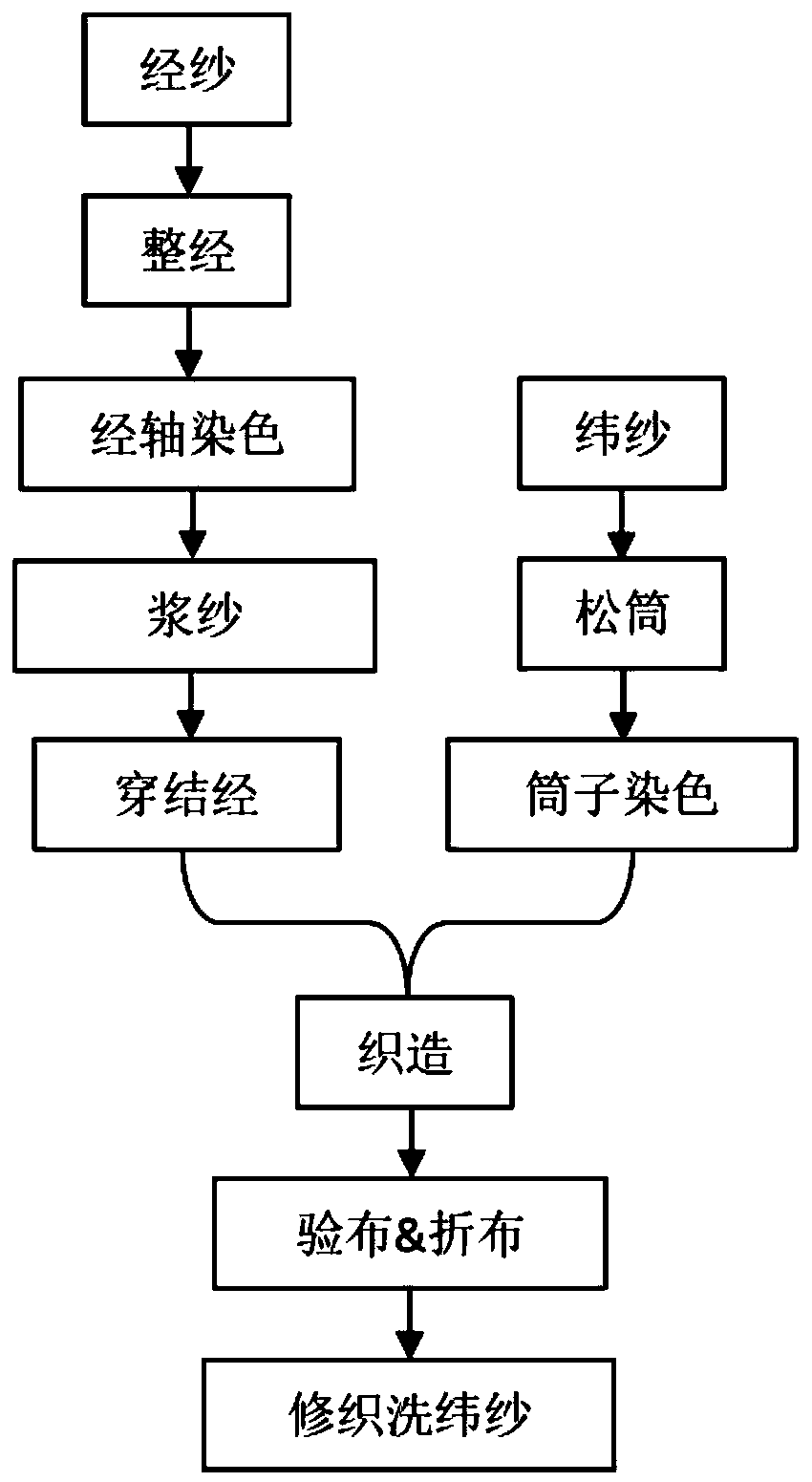

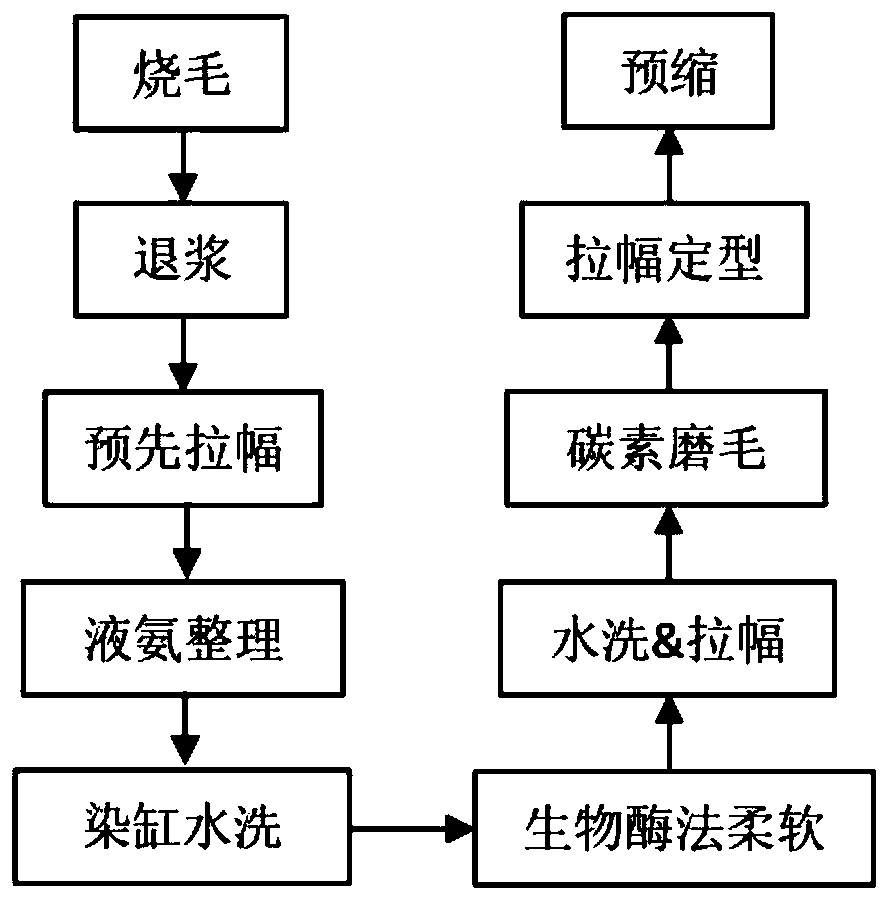

Wood fiber/tencel cashmere imitation double-layer fabric

InactiveCN109930278AImprove anti-pilling performanceImprove comfortBiochemical fibre treatmentMulti-ply fabricsFiberSkin surface

The invention relates to a fabric, in particular to a wood fiber / tencel cashmere imitation double-layer fabric. The invention relates to a weft double double-sided fabric, which is characterized in that warp yarns adopt 100% long-staple cotton high-count warp yarns, inner weft yarns adopt long-staple cotton and wood fiber 50S high-count blended yarns, surface weft yarns adopt long-staple cotton and tencel 50S / 2 blended yarns, the fabric adopts a 1 / 3+3 / 1 double-sided twill weave, the surface weave is 1 / 3 right twill, and the inner weave is 3 / 1 right twill. The fabric combines fiber blending anddouble-layer fabric design, so that the surface and interior organizations of the fabric have different functional characteristics; the high-count warp yarns are used, and the surface and interior organizations expose the weft yarns but do not expose the warp yarns; the characteristics of the weft yarns are shown, the yarns are made of high-quality long-staple cotton and adopt a compact spinningmode, so that the strength of the high-count warp yarns is ensured; the cotton is combined with the wood fiber and the tencel, and the liquid ammonia is used for finishing, so that the fiber has certain moisture absorption and air permeability, the water content of the skin surface layer is ensured to be 12-15%, the skin of the human body is always in the most moistened state, and static electricity is not generated.

Owner:WUXI TAIBO GARMENT

Low-temperature water-based corrosion-resistant metal coating

InactiveCN106883691AReduce viscosityGood chemical resistanceAntifouling/underwater paintsPaints with biocidesWater basedBenzoic acid

The invention discloses a low-temperature water-based corrosion-resistant metal coating which comprises the following components in parts by weight: 10-15 parts of polyo-toluene glycidyl ether, 15-20 parts of bisphenol F epoxy resin, 10-20 parts of polyphenyl glycidyl ether, 20-30 parts of silica sol, 3-10 parts of a coloring pigment, 1-5 parts of a curing agent, 30-60 parts of water, 6-10 parts of dibutyl ester, 8-10 parts of salicylic acid, 1-6 parts of propiconazole, 0.6-1.6 parts of chromium oxide green, 15-20 parts of benzoic acid and 30-60 parts of a styrene-acrylic emulsion. The coating disclosed by the invention is good in film-forming property and high in film strength, and selects a natural and pollution-free corrosion-resistant agent from a water-based epoxy resin coating; the natural corrosion-resistant agent is bonded with a special emulsion for the water-based corrosion-resistant coating, so that the corrosion resistance is good and superior to that of a traditional water-based coating.

Owner:德阳森华新材料科技有限公司

Synthesis of animal's horn and hoof raw material

The technology process of processing animal's horn and hoof material includes the steps of steaming at over 100 deg.C for 7-12 hr to eliminate fat, eliminating bone, sorting material to eliminate surface layer, decoloring to eliminate black matter through soaking with hydrogen peroxide solution of 60-99 % concentration for 2-4 days, steaming for 2-5 hr to soften and extruding or stoving at 60-300 deg.c to dry, mixing with saturated resin and molding or naturally cooling to form.

Owner:周至春

Method for producing film coating agent for phytase coating

InactiveCN101485391ABright colorGood water solubilityAnimal feeding stuffAccessory food factorsSolubilityPhytase

The invention relates to a method for preparing a film coating agent for coating phytase, in special coating multilayer outside phytase feed additive granules. The film coating agent is prepared from polyvinyl alcohol, co-povidone iodine, hydroxypropyl methylcellulose, talcum powder, magnesium stearate, tween-80 and ricinus oil which are evenly mixed at a high speed according to certain weight percentage. The method has the advantages that because of the presence of an isolated layer, the phytase feed additive granules can keep property of enzyme stable during usage, storage and sale, and have remarkably enhanced capability of resisting external adverse environments such as high temperature, high moisture and the like. After the surfaces of the granules are coated, the granules have better compactness, the activity content evenness of the enzyme is high, the animal feed is easy to be mixed evenly, and the animal is fed in balance; the granules have bright color, are round and beautiful, and have good flowing property; the granule specific gravity is similar to the feed specific gravity, and the granules are easy to be mixed evenly, and do not grade, generate static electricity, mutually adsorb and unite; and the coating material has good water solubility, can be quickly disintegrated and released in gastric juice, and has high bioavailability.

Owner:伦西全 +4

Waterproof building external wall coating

InactiveCN110358420AImprove waterproof performanceEnhance water resistance and crack resistanceAntifouling/underwater paintsPaints with biocidesKaolin clayMaterials science

The invention discloses a waterproof building external wall coating. The waterproof building external wall coatingis prepared from the following components in parts by weight: pure acrylic emulsion, methacrylic acid emulsion, alkyd resin, silica sol, defoamer, titanium dioxide nanometer powder, 2-hydroxyl-4-n-octyloxy-benzophenone, cyclohexanone-oxime, modified kaolin clay, titanium dioxide, sepiolite, methylsilicone oil, methyl alkoxy silicone oil, octyltriethoxysilane, silane quaternary ammonium salt, surfactants, and mildew preventive. According to the waterproof external wall coating, a waterproof agent with good waterproof performance is introduced, so that the external wall coatingishigh in waterproof performance.

Owner:曾敏偲

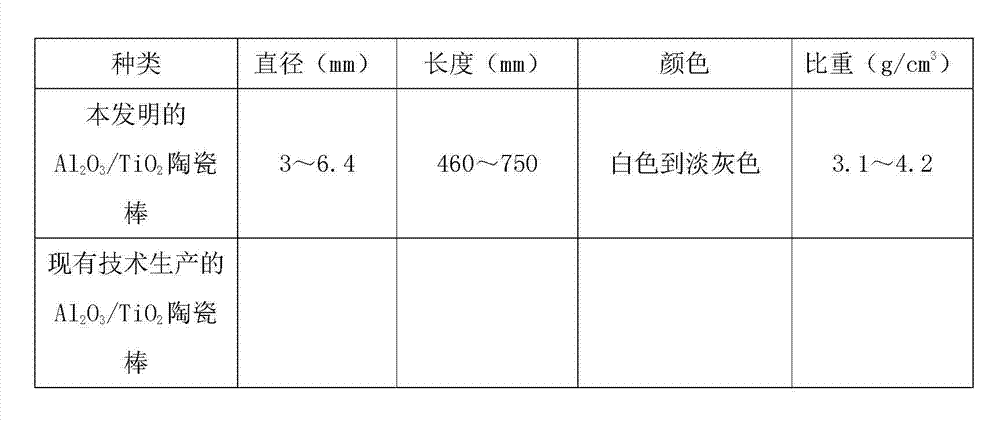

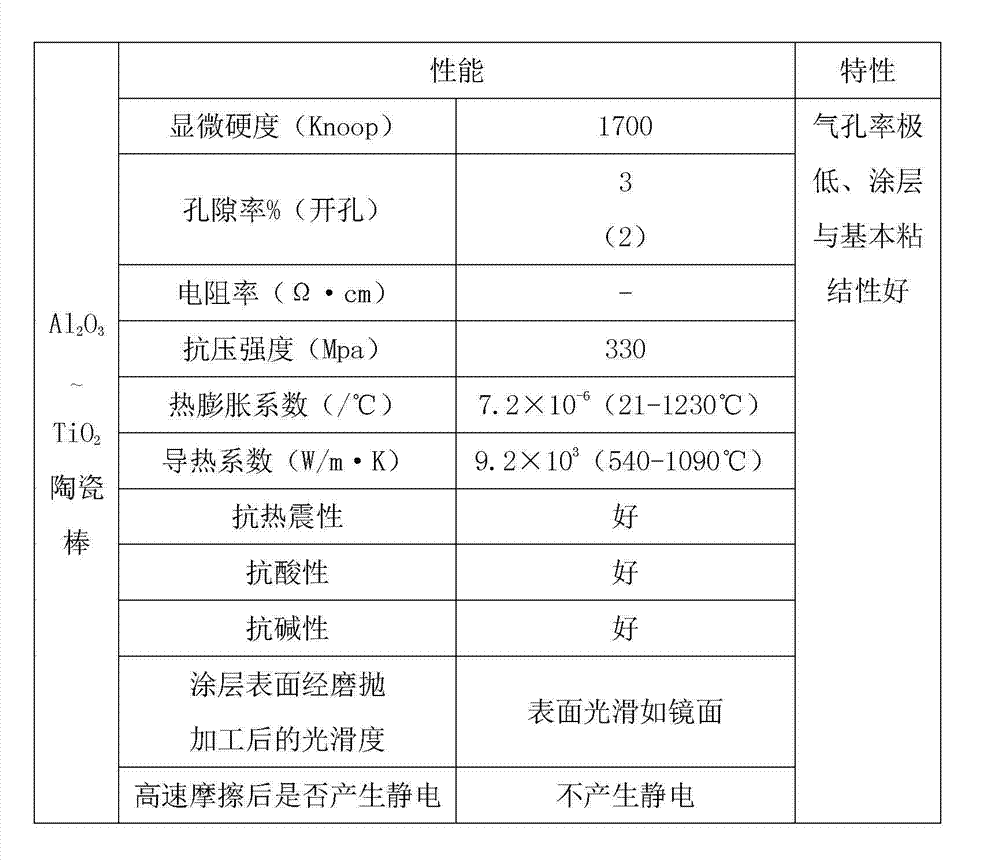

Preparation method of Al2O3/TiO3 ceramic stick for flame spraying

The invention discloses a preparation method of an Al2O3 / TiO3 ceramic stick for flame spraying. The preparation method comprises the following steps of: weighing ceramic raw materials, and batching; processing via ball milling; then blending in a dry way, so as to obtain mixed powder; adding modification styrene-acrylic emulsion and the like in the powder; mixing the materials; preparing and pugging; transferring the plastic clay block into a vacuum extruder to be extruded and formed; heating to degum through a horizontal burning way; and finally roasting at a certain temperature, thus obtaining the Al2O3 / TiO3 ceramic stick. The preparation method disclosed by the invention is simple in technology, high in product percent of pass, and greatly reduces producing coat. The prepared ceramic stick has a better coating performance; and the coated ceramic coating has a better mechanical property, and synchronously has a better heat insulation property, an insulating property, a corrosion resistance property, an antistatic property and high smoothness of a spray coating layer, and no static generated in friction at high speed, and the like, and has a good application prospect in cotton spinning and chemical fiber industries.

Owner:HEFEI RUIYONG CERAMIC MATERIAL TECH

High-performance aqueous acrylic polyurethane bicomponent coating material

InactiveCN110746870ANo static electricityImprove wear resistancePolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention relates to a high-performance aqueous acrylic polyurethane bicomponent coating material with high glossiness, high plumpness, high weatherability and high ornamental performance capableof improving an appearance value of a workpiece. The high-performance aqueous acrylic polyurethane bicomponent coating material is prepared from a main agent and a curing agent, wherein a mass ratio of the main agent to the curing agent is (3 to 8): 1, hydrophilic aliphatic polyisocyanate serves as the curing agent, the main agent comprises the ingredients in parts by weight: 30-70 parts of polymer emulsion, 0.1-5 parts of surface assistant, 1-15 parts of film forming assistant, 0.1-2 parts of anti-settling agent, 0.1-1 part of thickener, 5-30 parts of pigment / filler, 1-5 parts of organosilicone dispersion, 1-5 parts of ultraviolet absorbent and 20-30 parts of deionized water, and the curing agent comprises 60-80 parts of isocyanate curing agent and 20-40 parts of PMA. According to the high-performance aqueous acrylic polyurethane bicomponent coating material, reinforcement is carried out in the aspects of the polymer emulsion, the organosilicone dispersion and the assistants, thus, water resistance, weather resistance, chemical resistance, hardness and wear resistance of the finished aqueous acrylic-polyurethane bicomponent top coating are improved greatly, and a preparation method for the bicomponent coating material can be applicable to mass production.

Owner:郑州一安水性高分子材料有限公司

Kendir farinfrared health-care material

A health-care far-infrared kender fabric is prepared from kender yarn (50-75%), polypropylene fibre as functional fibre (20-40%) and polyurethane fibre (5-10%) through interweaving. Its advantages are more health-care functions, good softness, no deformation, no generation of static electricity, and high elasticity, thermal insulation and moisture permeability.

Owner:天津市天益华泰科技发展有限公司

Novel blended yarn

The invention relates to a novel blended yarn. The blended yarn is made of cotton fibers, seaweed carbon fibers, silkworm protein fibers and bamboo fibers. The blended yarn is characterized by comprising the following raw materials, by weight, 10-20 parts of the cotton fibers, 50-80 parts of the seaweed carbon fibers, 15-30 parts of the silkworm protein fibers and 15-30 parts of the bamboo fibers. The blended yarn has the advantages that the blended yarn is capable of emitting far infrared rays and generating anions, good in air permeability, moisture absorption and drapability, comfortable in hand feeling, high in wear resistance, and good in dyeing property, has the natural anti-microbial, anti-bacteria, snail killing, odor-resistant and uvioresistant functions, and can meet requirements of people.

Owner:邹雪芬

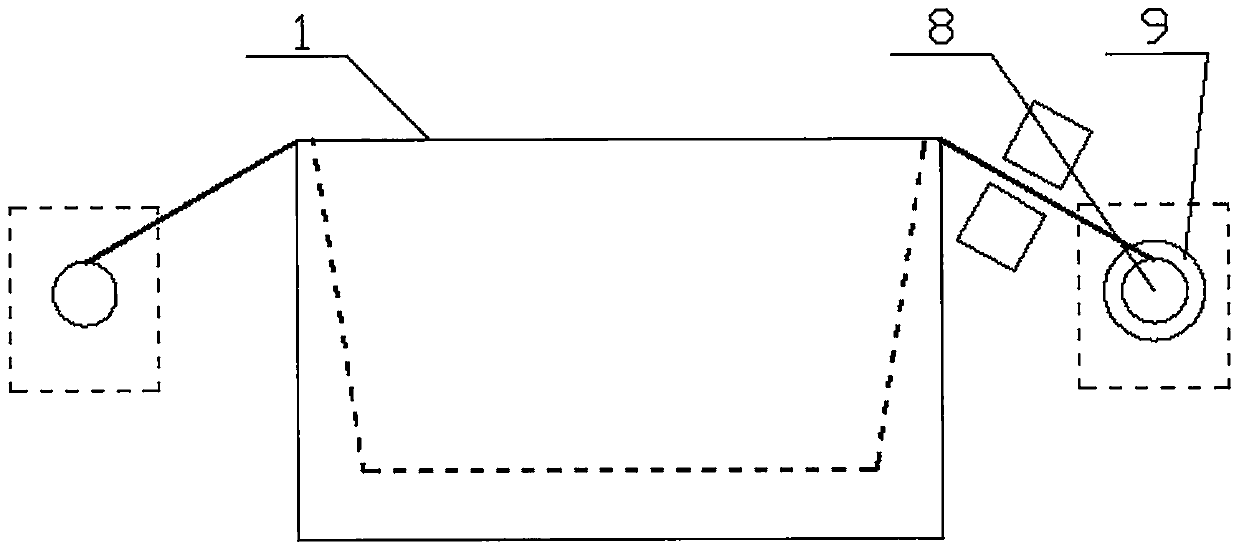

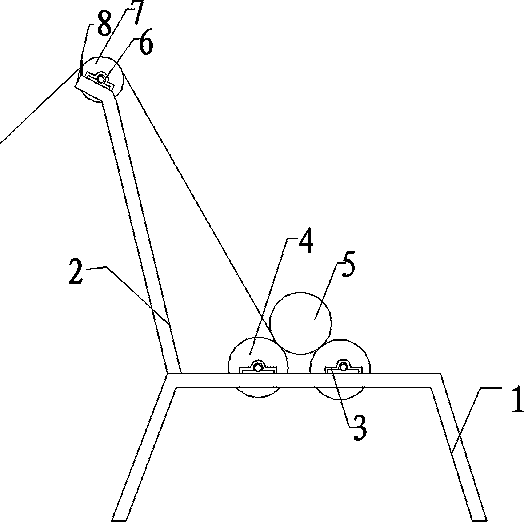

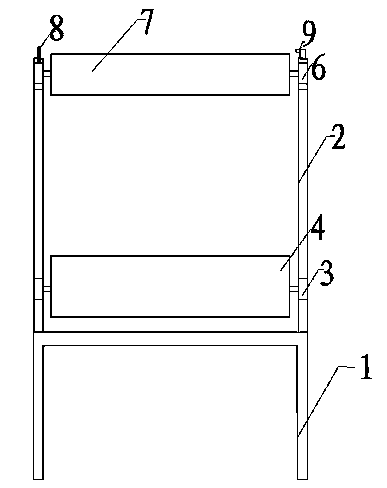

Novel cloth-feeding device

ActiveCN103662909AIncrease profitPrevent static electricityArticle deliveryWebs handlingMeasuring instrumentEngineering

The invention discloses a novel cloth-feeding device. The novel cloth-feeding device comprises a trapezoid support. An inclined support is arranged upwards on the left end of the trapezoid support, two bearing seats are fixed on both the front side and the rear side above the trapezoid support, and a cloth-feeding roller penetrates through the two corresponding bearing seats on the front side and the rear side. A roller bearing seat is arranged on both the front side and the rear side of the upper end of the inclined support, a cloth-guiding roller penetrates through the roller bearing seat, a laser length measuring instrument for measuring length of the cloth is mounted on one side of the inclined support, and a nozzle with a spray device is mounted on the other side of the inclined support. By the aid of the novel cloth-feeding device, the cloth is pulled manually for cutting, and during pulling, the cloth can be straightened, irregular cutting is avoided, and the novel cloth-feeding device is high in cloth utilization rate. The novel cloth-feeding device is simple in structure, convenient to manufacture, and is capable of cutting a cloth under a steam condition, static electricity is not caused, and measuring length of the cloth during cutting.

Owner:江苏梦香家纺有限公司

Metal stamping part surface treating agent and surface treatment process

InactiveCN106928758AImprove corrosion and wear resistanceImprove anti-corrosion and anti-rustFireproof paintsAntifouling/underwater paintsEpoxyDimethyl siloxane

The present invention proposes a surface treatment agent and a surface treatment process for metal stamping parts. The surface treatment agent comprises the following parts by mass: 20-30 parts of silica sol, 1-5 parts of vinyl acetate, and 0.5-2 parts of alkyl glycoside , 2-5 parts of epoxy fatty acid methyl ester, 3-6 parts of alkanolamide, 2-4 parts of lithium silicate, 1-3 parts of trifluoroethyl methacrylate, 3 parts of hydroxyl-terminated polydimethylsiloxane ‑5 parts, water 0‑30 parts, made by heating, stirring, water bath, ultrasonic and other steps, combined with tung oil for the surface spraying treatment of metal stamping parts, greatly improving the wear resistance, corrosion resistance, corrosion resistance of metal stamping parts Rust, waterproof and stain-resistant properties, and strong bonding with the metal surface, with a certain degree of self-drying, which significantly improves the overall performance of metal stamping parts and prolongs the service life.

Owner:周楠

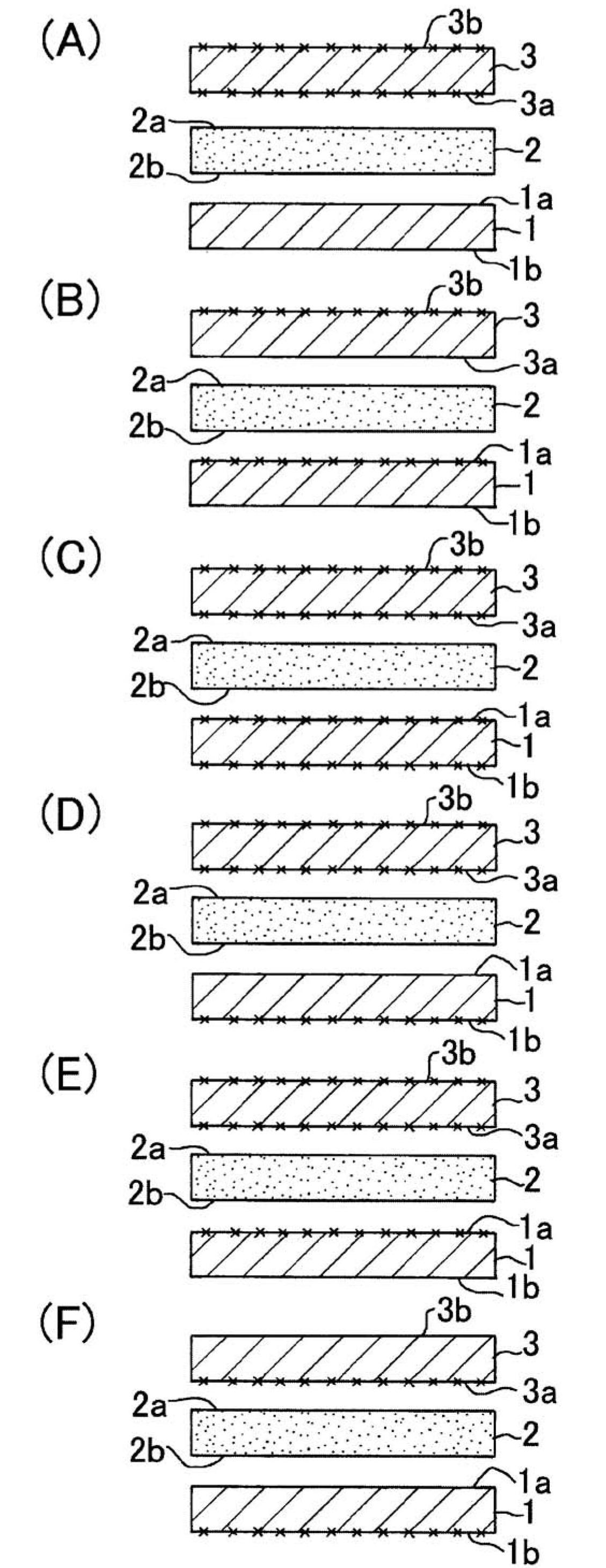

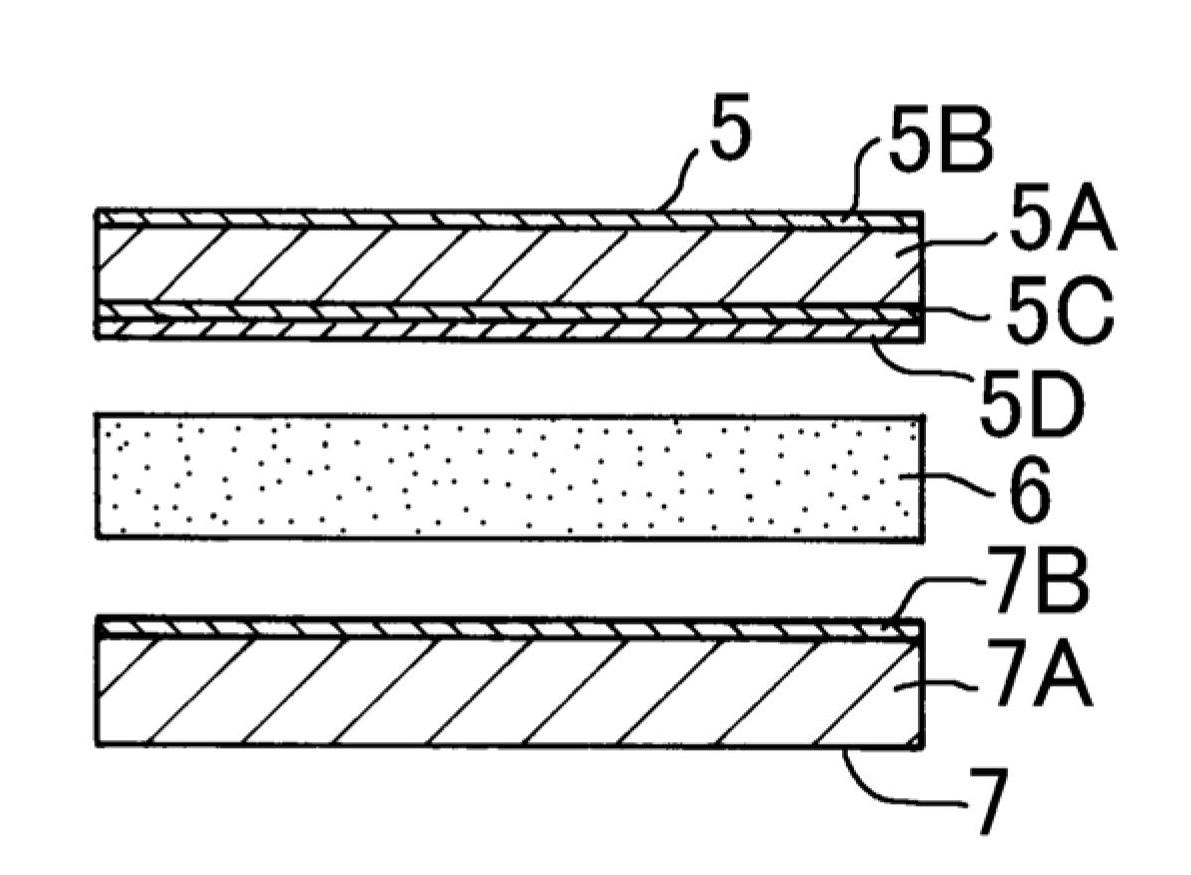

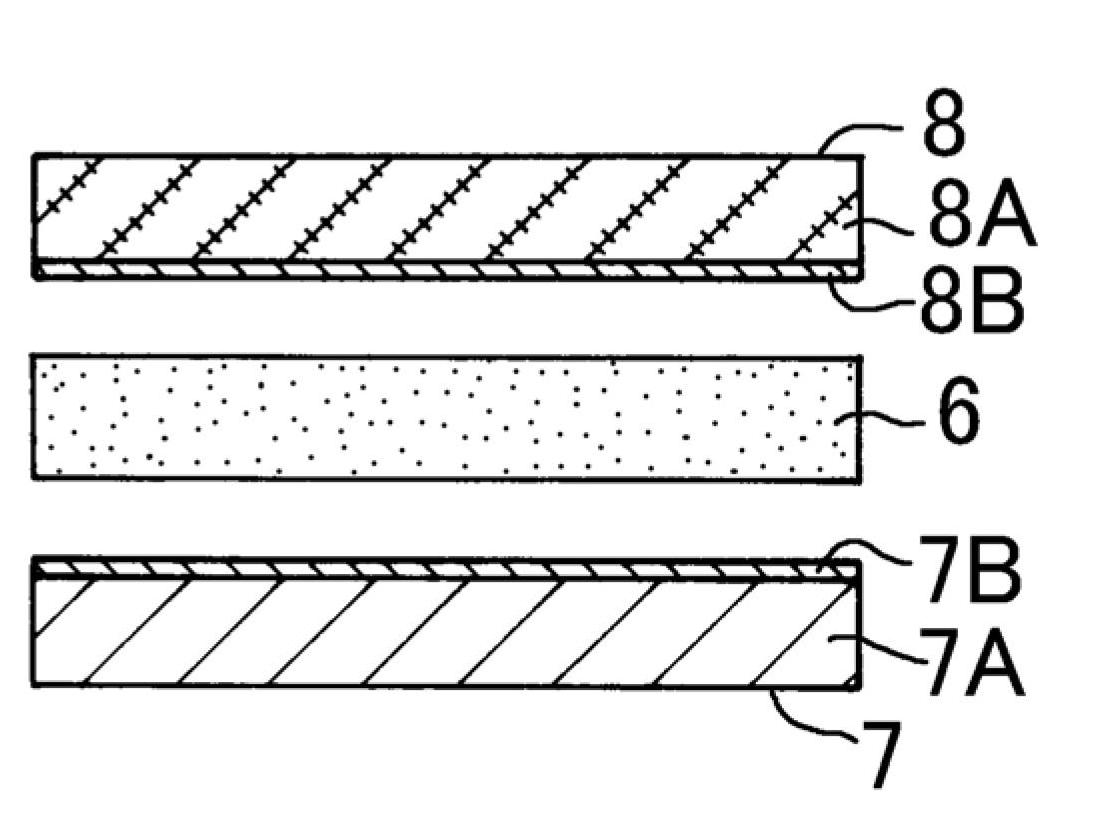

Double-sided pressure-sensitive adhesive sheet with release sheets

InactiveCN102597144ANo static electricityImprove environmental reliabilityFilm/foil adhesivesSynthetic resin layered productsEngineeringPressure sensitive

Provided is a double-sided pressure-sensitive adhesive sheet with release sheets, which is not charged with static electricity even when wound, cut, or stacked, more specifically, a sheet which comprises a pressure-sensitive adhesive layer and two release sheets provided on both surfaces thereof, wherein the surface on the pressure-sensitive-adhesive-layer side of at least one release sheet and the surface on the non-pressure-sensitive-adhesive-layer side of at least one release sheet are configured so as to exhibit electroconductivity.

Owner:MITSUBISHI PLASTICS INC

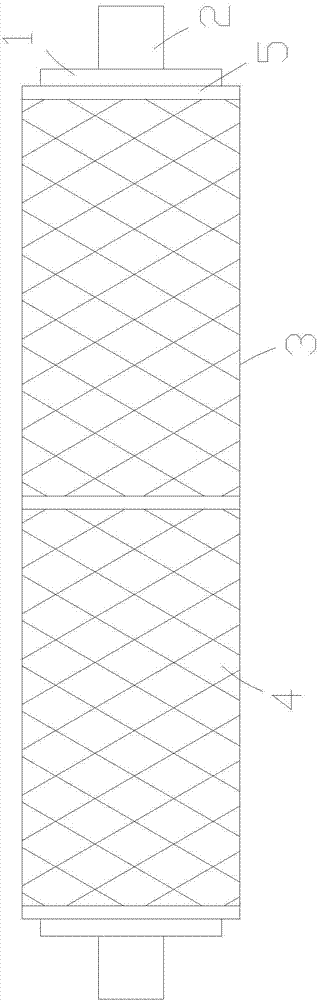

Film roller for metallized film slitter

InactiveCN103569723AIncrease frictionImprove cut qualityCapacitor manufactureWebs handlingSpecial designEngineering

A film roller for metallized film slitter relates to the technical field of machining equipment for capacitor materials and comprises a metal roller body; a central rotary shaft is arranged in the metal roller body; a roller sleeve is sleeved outside the metal roller body; mutually connected diamond-shaped lines are printed at the surface of the roller sleeve; the diamond-shaped lines are fully distributed on the circumferential surface of the whole roller sleeve; diamond-shaped areas in the diamond-shaped lines are upwards convex. Due to the special design on the roller film, the friction force generated when the roller film is contacted with the film is increased, the film can be better driven to move, no static is generated basically, the slitting quality of the film is improved and the generation of wrinkles is reduced.

Owner:TONGLING QILI ELECTRONICS MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com