Double-sided pressure-sensitive adhesive sheet with release sheets

A peeling sheet and tape peeling technology, which is applied in the direction of film/sheet adhesives, conductive adhesives, adhesives, etc., can solve problems such as high electrical insulation, liquid crystal panel defects, and electrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

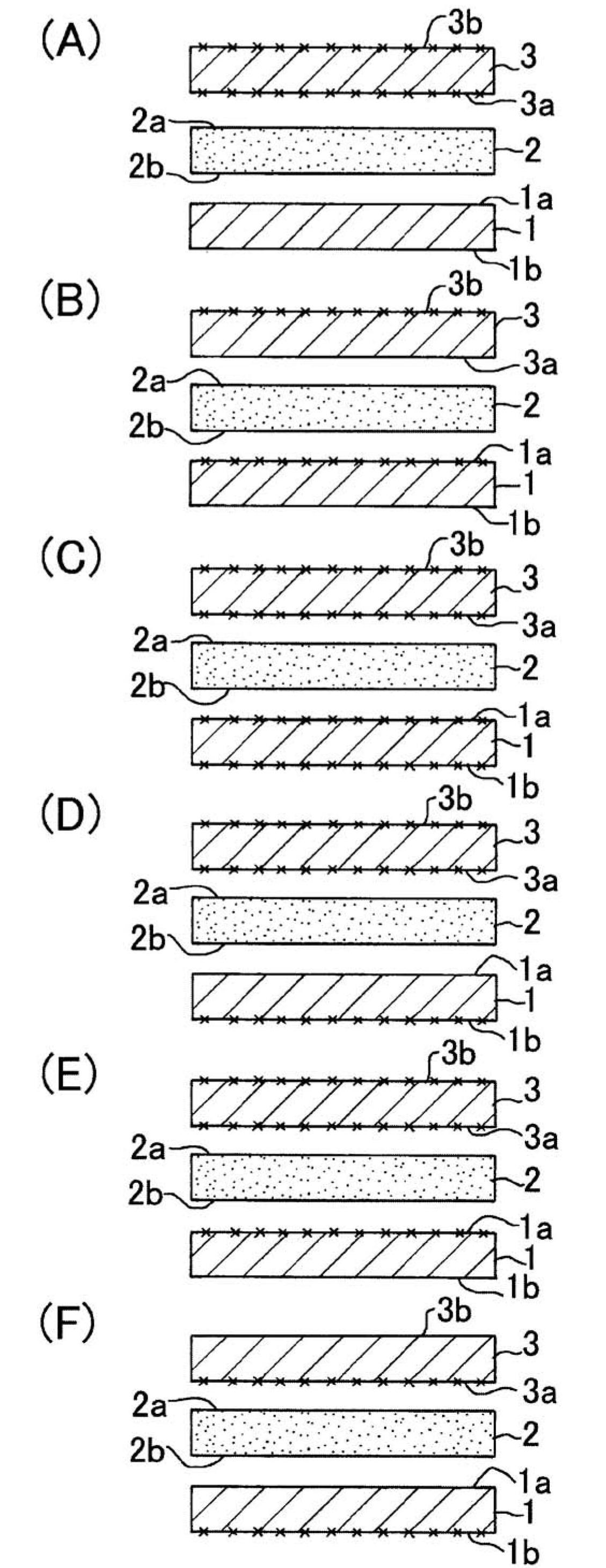

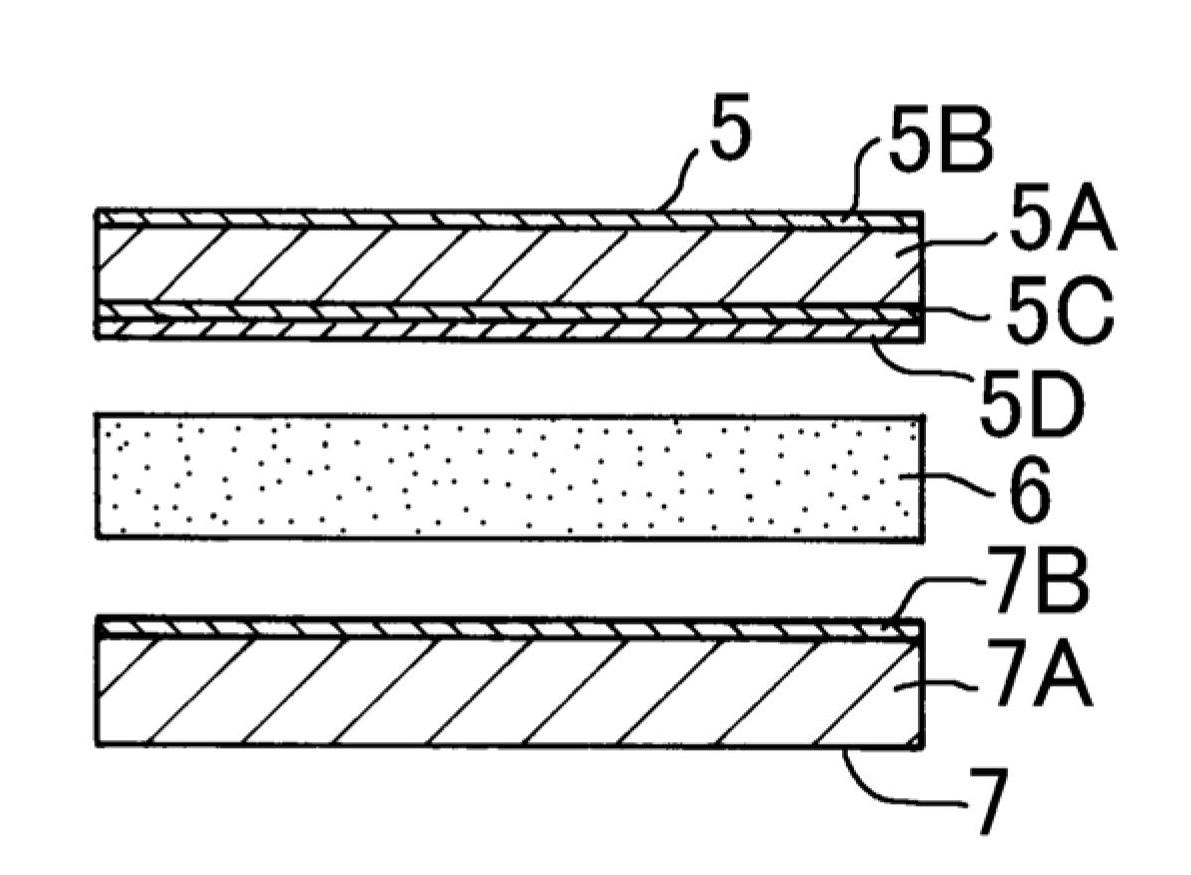

[0097] On one side of the film, a polyethylene terephthalate film (PET "75-1-K0-ASI5" manufactured by NIPPA Corporation, thickness 75 μm) 5A (Table On the other surface of the support 1) of 1, a conductive material coating ("NEOCON COAT 567" manufactured by Dainichi Seika Kogyo Co., Ltd.) was coated and dried to form a conductive layer 5B, and a release sheet 5 was produced.

[0098] For the other release sheet 7, a polyethylene terephthalate film (PET "38-1-A3" manufactured by NIPPA Corporation, thickness 38 μm) having a release layer 7B formed on one side of the film was used. 7A (: Support 2 of Table 1).

[0099] The adhesive composition is coated to a thickness of 150 μm by using an applicator, and the adhesive composition is made of 75 parts by weight of 2-ethylhexyl acrylate, 22 parts by weight of methyl acrylate, and 3 parts by weight of acrylic acid. 100 parts by weight of the copolymerized adhesive polymer (A), 1 part by weight of pentaerythritol triacrylate as a cro...

Embodiment 2

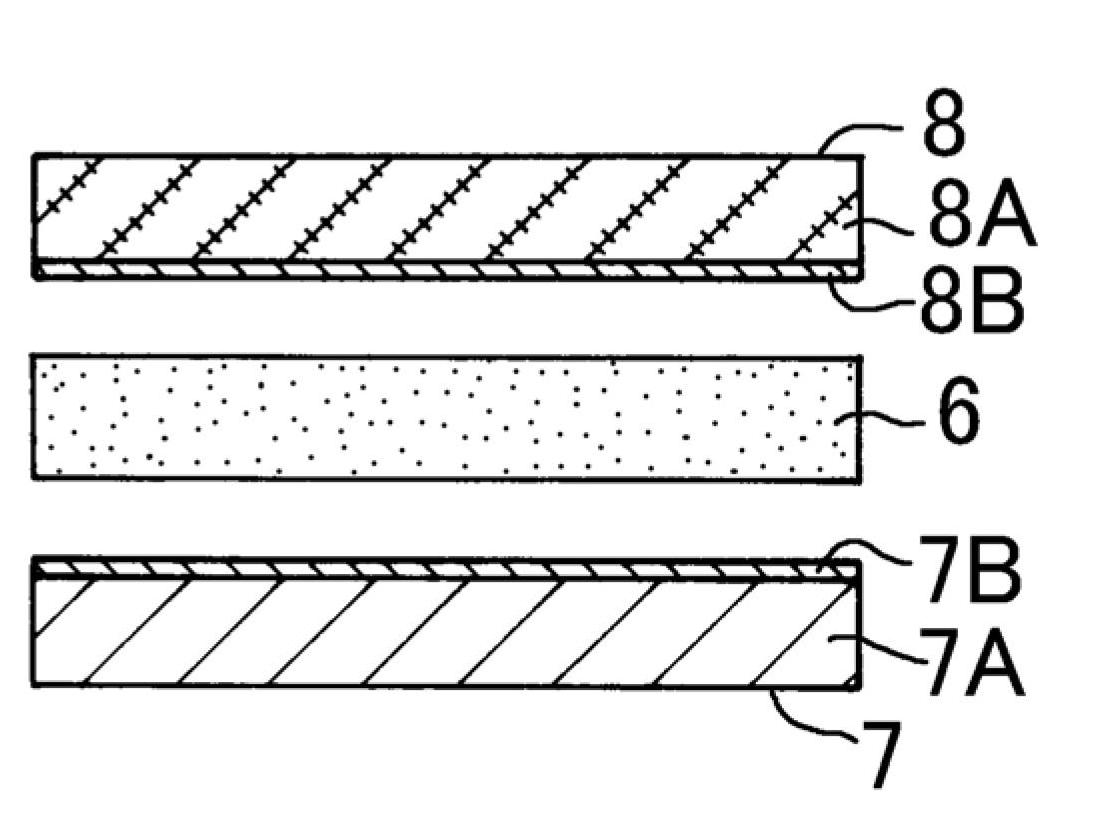

[0102] A release agent combination was applied to one surface of a polyethylene terephthalate film ("RUMIRER X53" manufactured by Toray, thickness 100 μm) 8A (: support 1 in Table 1) formed by mixing a conductive material and drying it to form a peeling layer 8B, and a peeling sheet 8 was prepared. The release agent composition was mixed with 100 parts by weight of an addition silicone (SD7320 manufactured by Dow Corning Toray Co., Ltd.) Corning Toray NC-25) 0.5 parts by weight.

[0103] Such as image 3 As shown, except that the release sheet 8 was used instead of the release sheet 7 in Example 1, a double-sided adhesive sheet with a release sheet was produced in the same manner as in Example 1 (PET mixed with a conductive material / release layer / / adhesive Mixture layer / / peeling layer / PET).

[0104] When the release sheet 8 and the release sheet 7 were peeled from the adhesive 6 at a peeling angle of 90° and a peeling speed of 300 mm / min, the peel strengths were 180 g / 50 mm ...

Embodiment 3

[0106] As the release sheet 9 on one side, a polyethylene terephthalate film (PET "75-1-K2 manufactured by NIPPA Co. - ASI 5", thickness 75 μm) (: Support 1 of Table 1).

[0107] On the other hand, the polyethylene terephthalate film ("PANACREA AS-F" manufactured by PANAC Corporation, 75 μm) having the conductive layer 10B (support 2 in Table 1) without the conductive layer was formed. A release agent composition made of silicone resin (KS-779H manufactured by Shin-Etsu Polysiloxane Co., Ltd. ) was mixed with 100 parts by weight of a curing agent (CAT-PL-50T manufactured by Shin-Etsu Silicone Co., Ltd.) 1 part by weight.

[0108] Such as Figure 4 As shown, except that the release sheet 9 and the release sheet 10 were used instead of the release sheet 5 and the release sheet 7 in Example 1, a double-sided adhesive sheet with a release sheet (PET / conductive layer / peel layer / / adhesive layer / / peel layer / PET / conductive layer).

[0109] When the release sheet 9 and the release...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com