Patents

Literature

35results about How to "Improve environmental reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

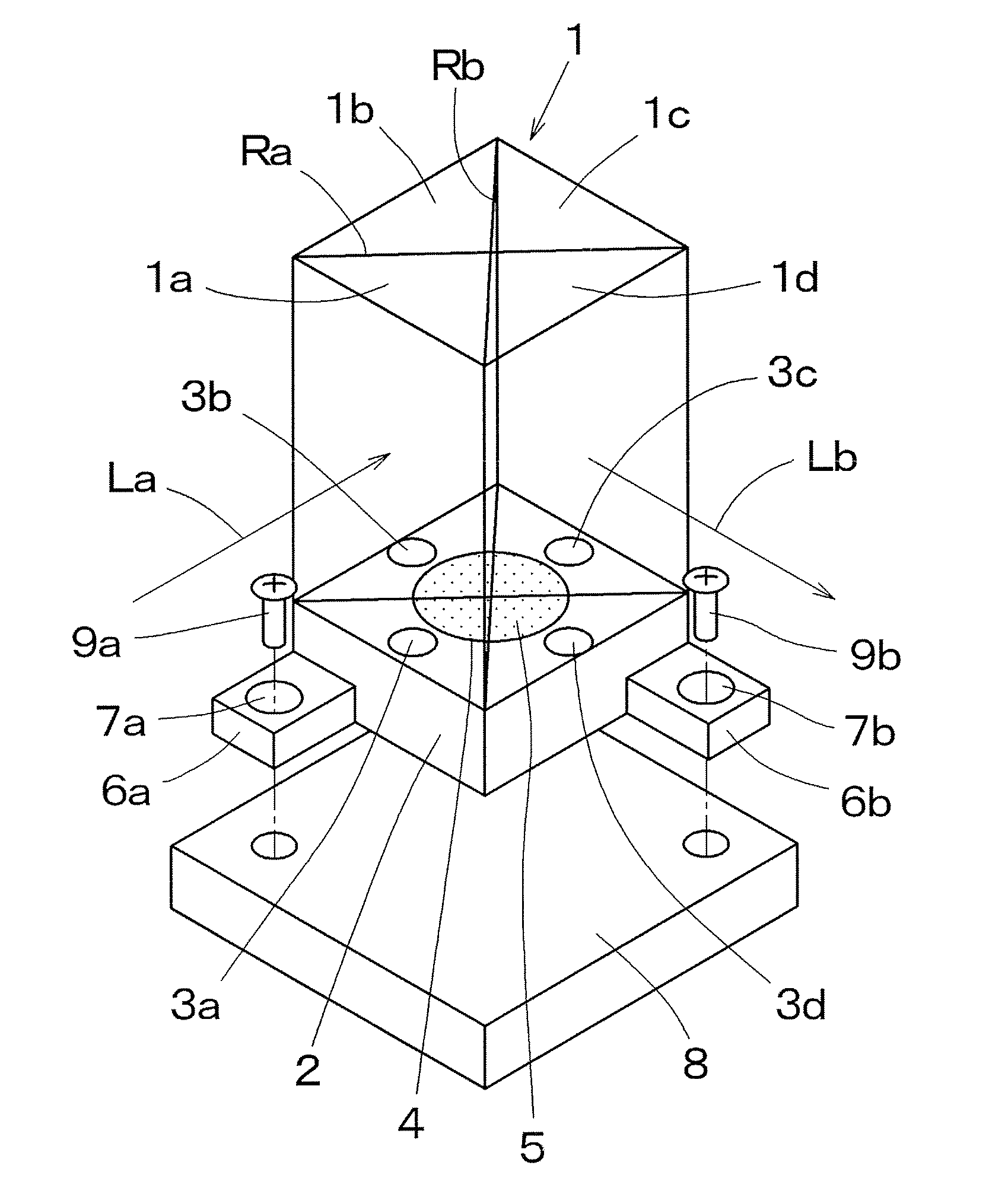

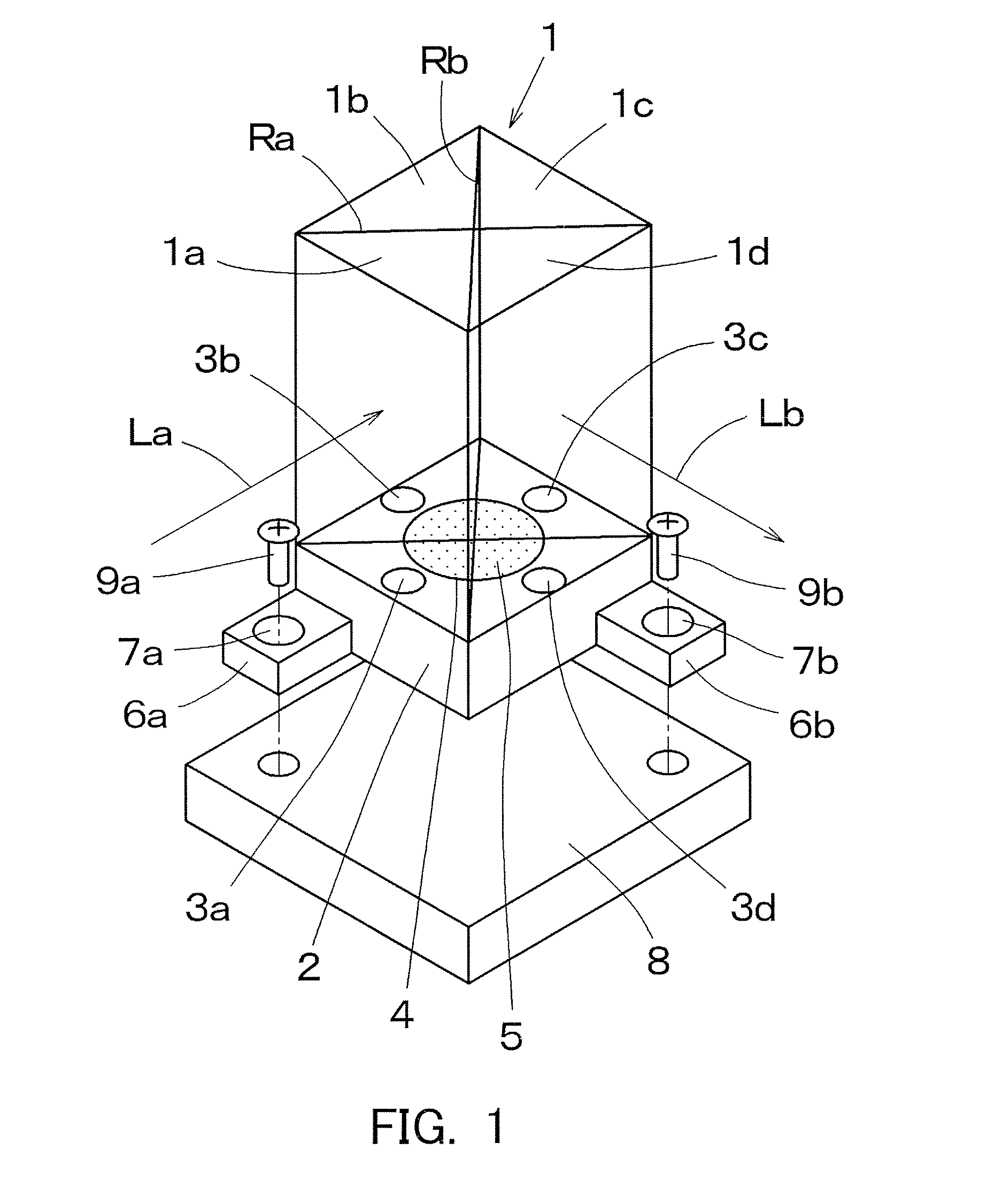

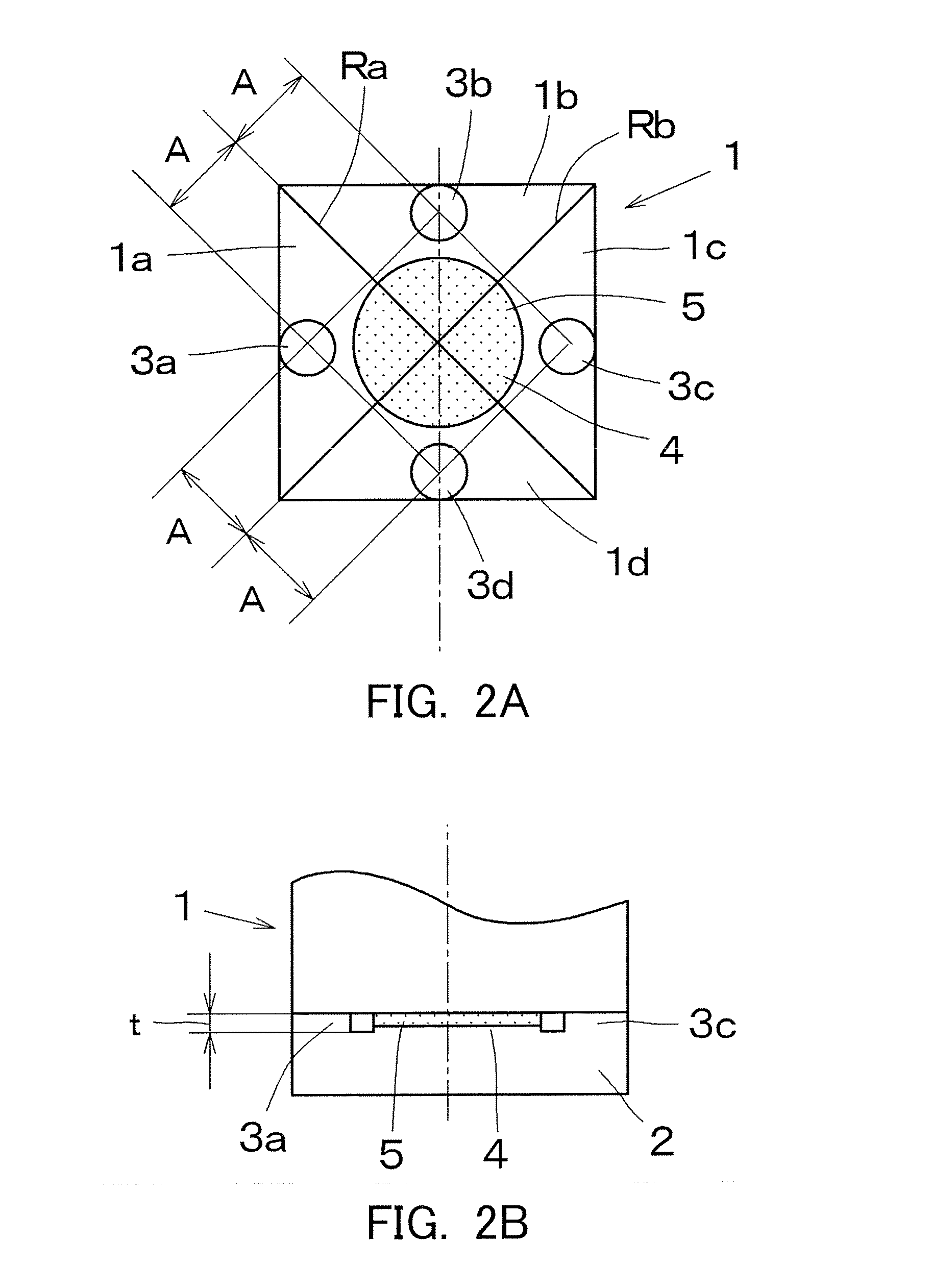

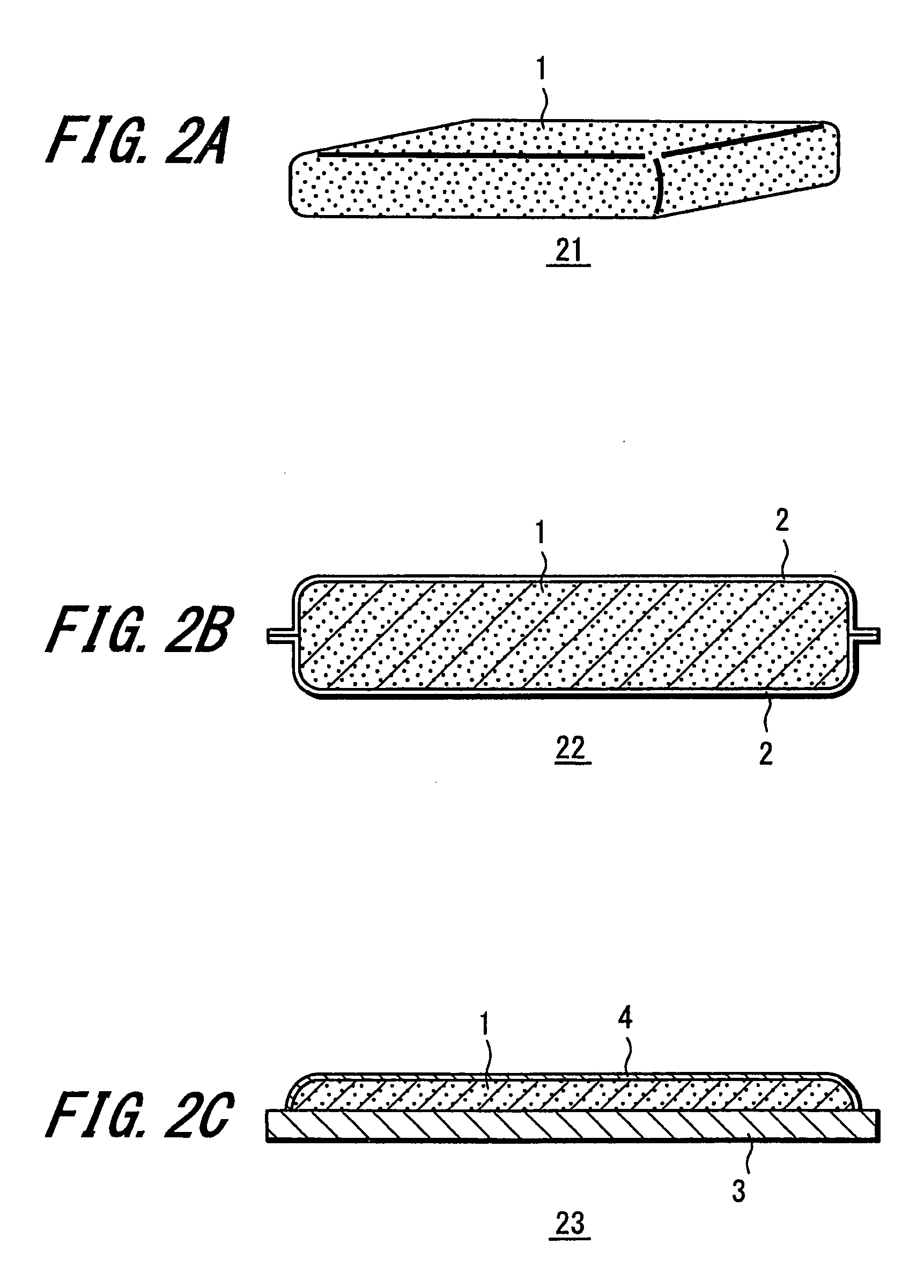

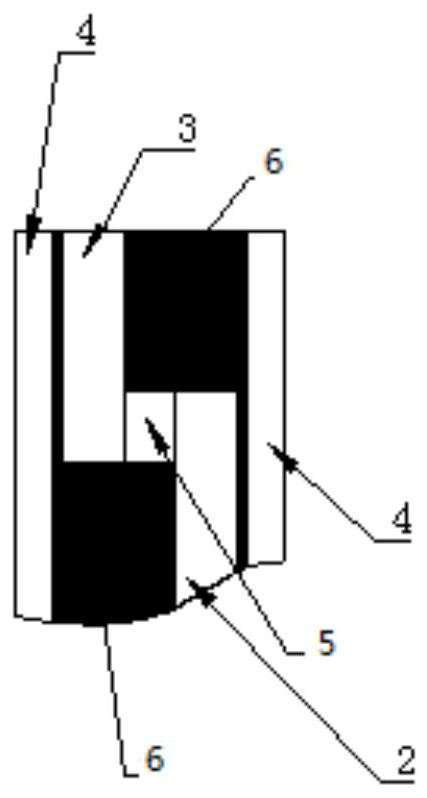

Prism unit and a projection image display apparatus

ActiveUS20090141360A1Prevents deterioration of optical performanceImprove environmental reliabilityPrismsMountingsProjection imagePrism

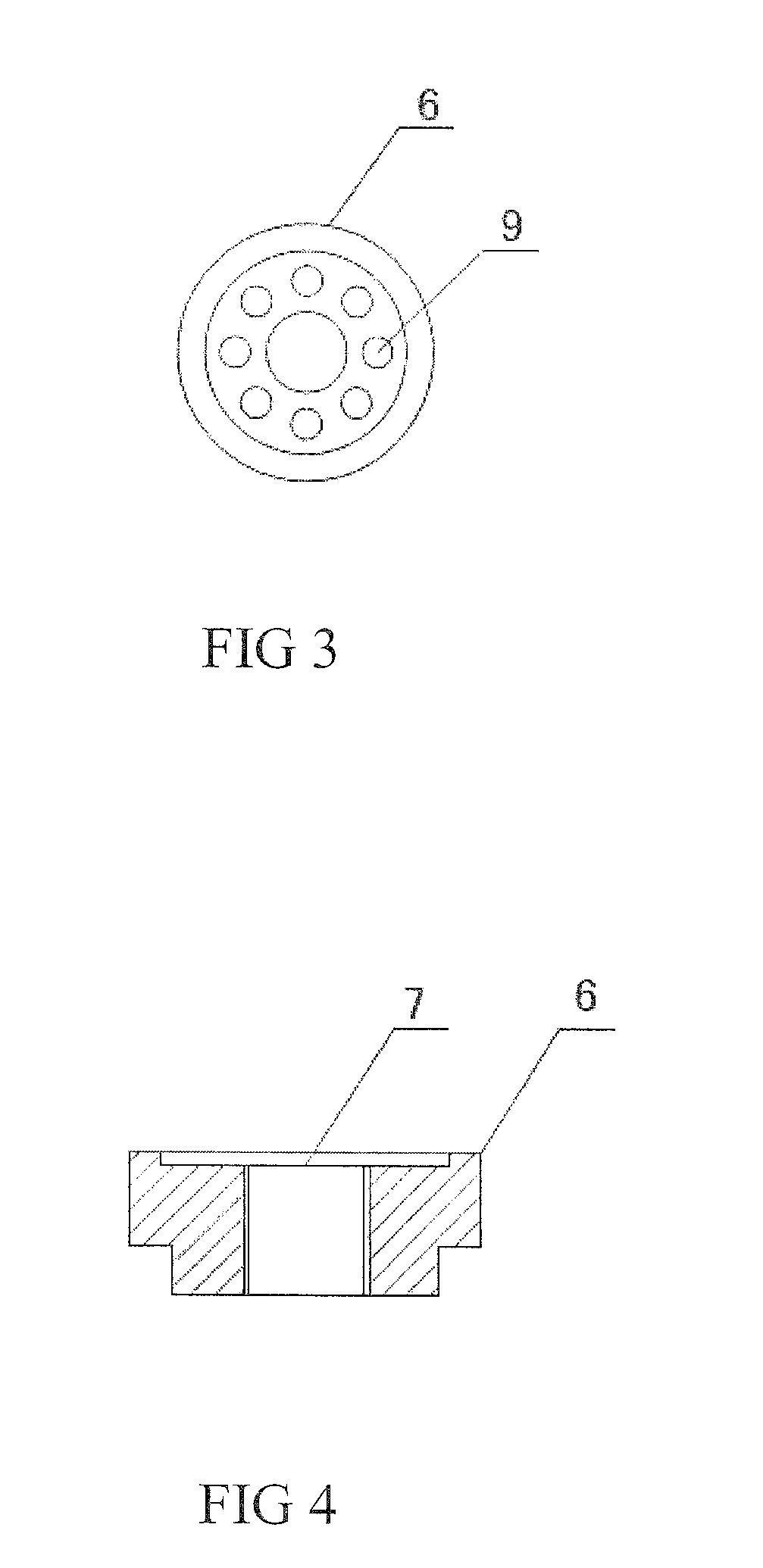

A prism unit includes a prism having at least one optical surface in its inside, and a prism base disposing the prism, the prism base including at least three seating surfaces that are attached to a surface orthogonal to the optical surface of the prism, a seating surface bonded part that is bonded to the prism by an adhesive. At least the three seating surfaces and the seating surface bonded part are symmetrically arranged on the optical surface of the prism.

Owner:CANON KK

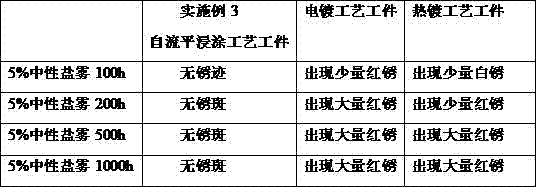

Ultrathin nano-scale anticorrosion coating and self-leveling dip-coating process thereof

ActiveCN107216768AGood anti-corrosion performance and wear-resistant and scratch-resistant performanceEnhance physical isolationLiquid surface applicatorsAnti-corrosive paintsSolventWax

The invention discloses an ultrathin nano-scale anticorrosion coating and a self-leveling dip-coating process thereof. The ultrathin nano-scale anticorrosion coating does not contain metal and has ultra-strong scraping resistance, wear resistance and corrosion resistance. The coating has a good self-leveling effect in a coating process and can be used for replacing traditional electro-galvanizing and hot galvanizing processes, and after dip-coating, a coating layer is ultra-thin, wide in adaptability and low in production cost. According to the technical scheme, the ultrathin nano-scale anticorrosion coating contains the following components in percentage by weight (100% in total): 10%-40% of modified resin, 2%-5% of a curing agent, 0.1%-0.5% of a curing accelerator, 2%-8% of an anticorrosion inhibitor, 1%-2% of a nano-scale wax powder, 0.01%-0.05% of graphene powder, 5%-15% of a metal composition and 30%-70% of a solvent.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

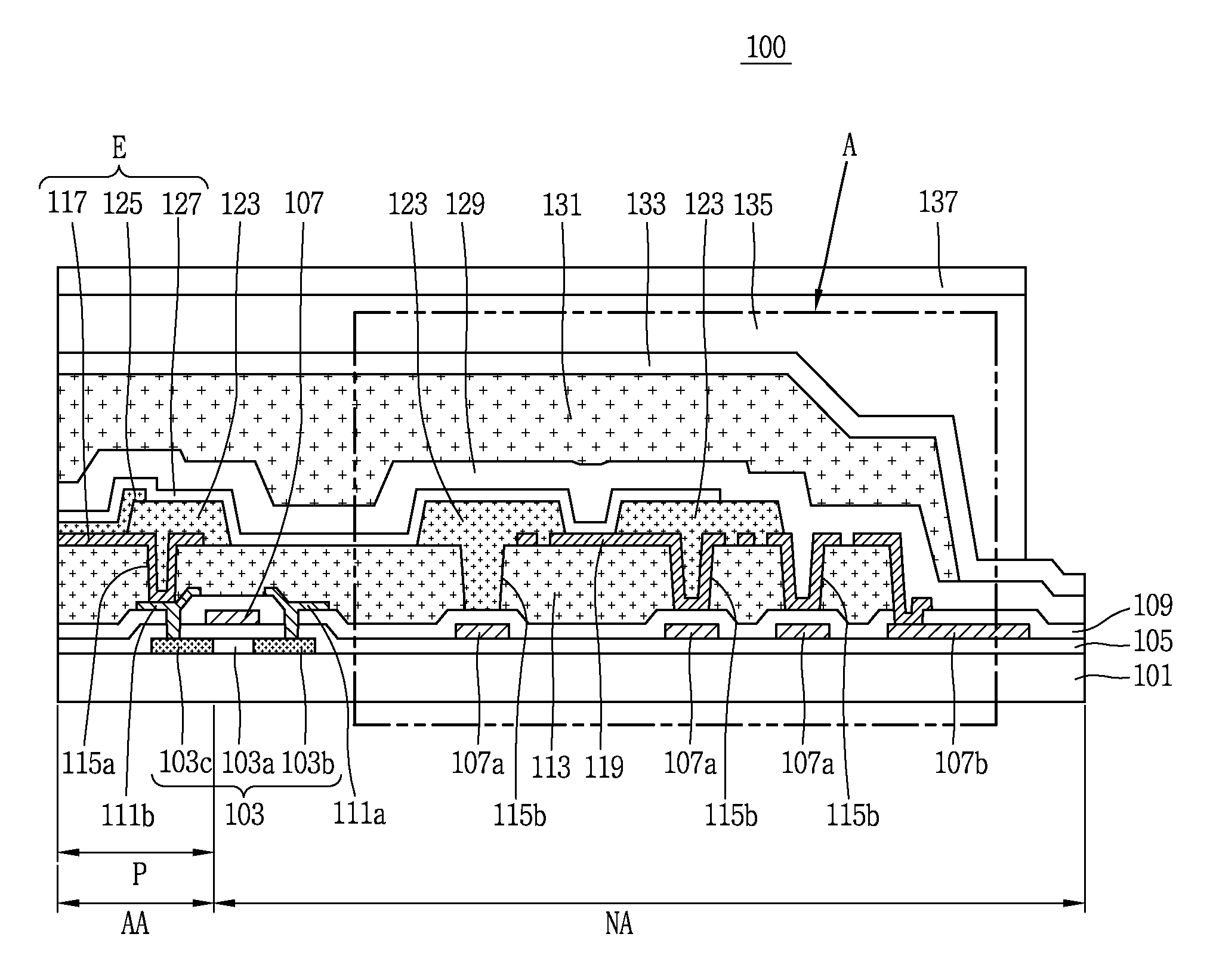

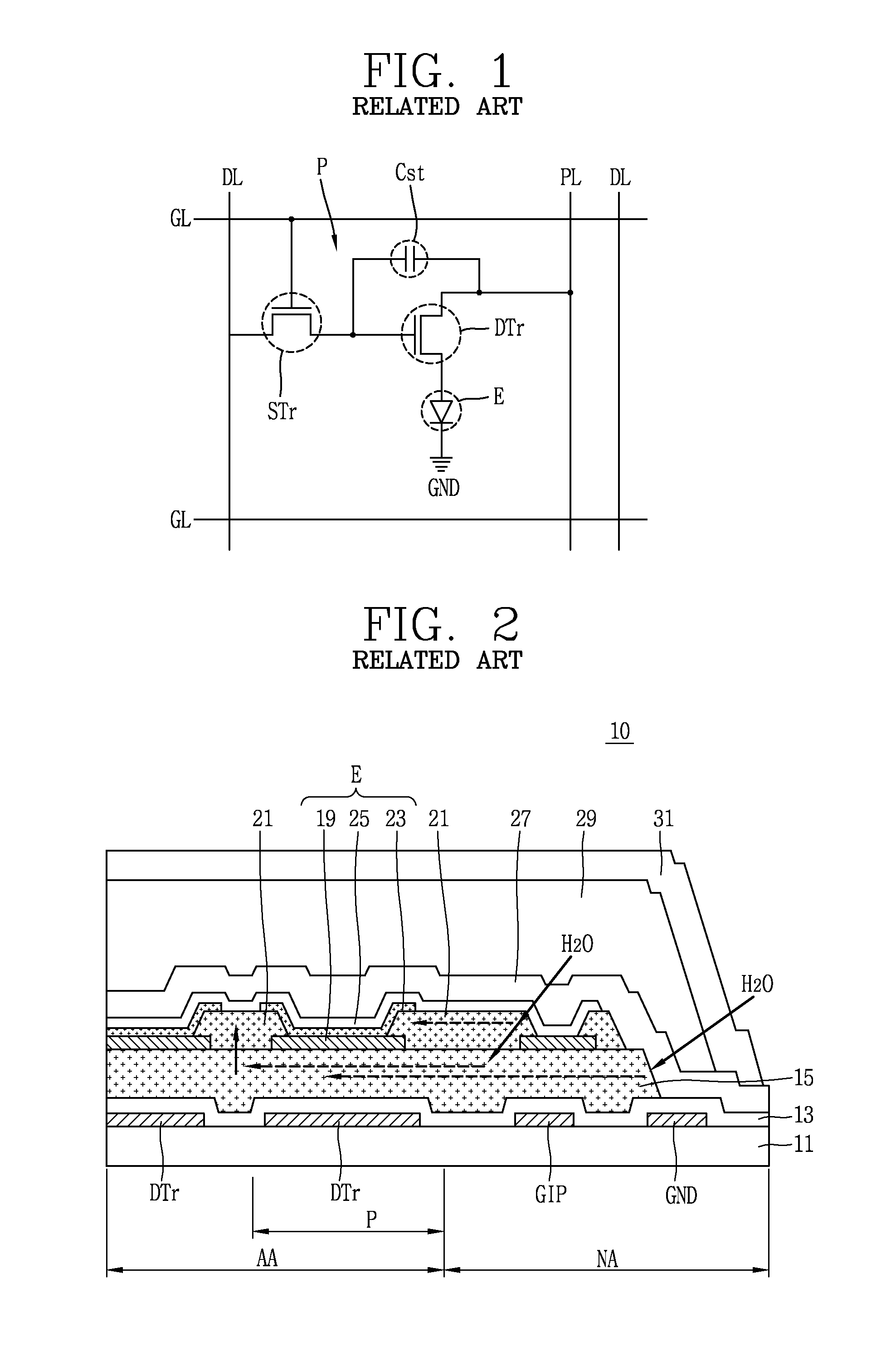

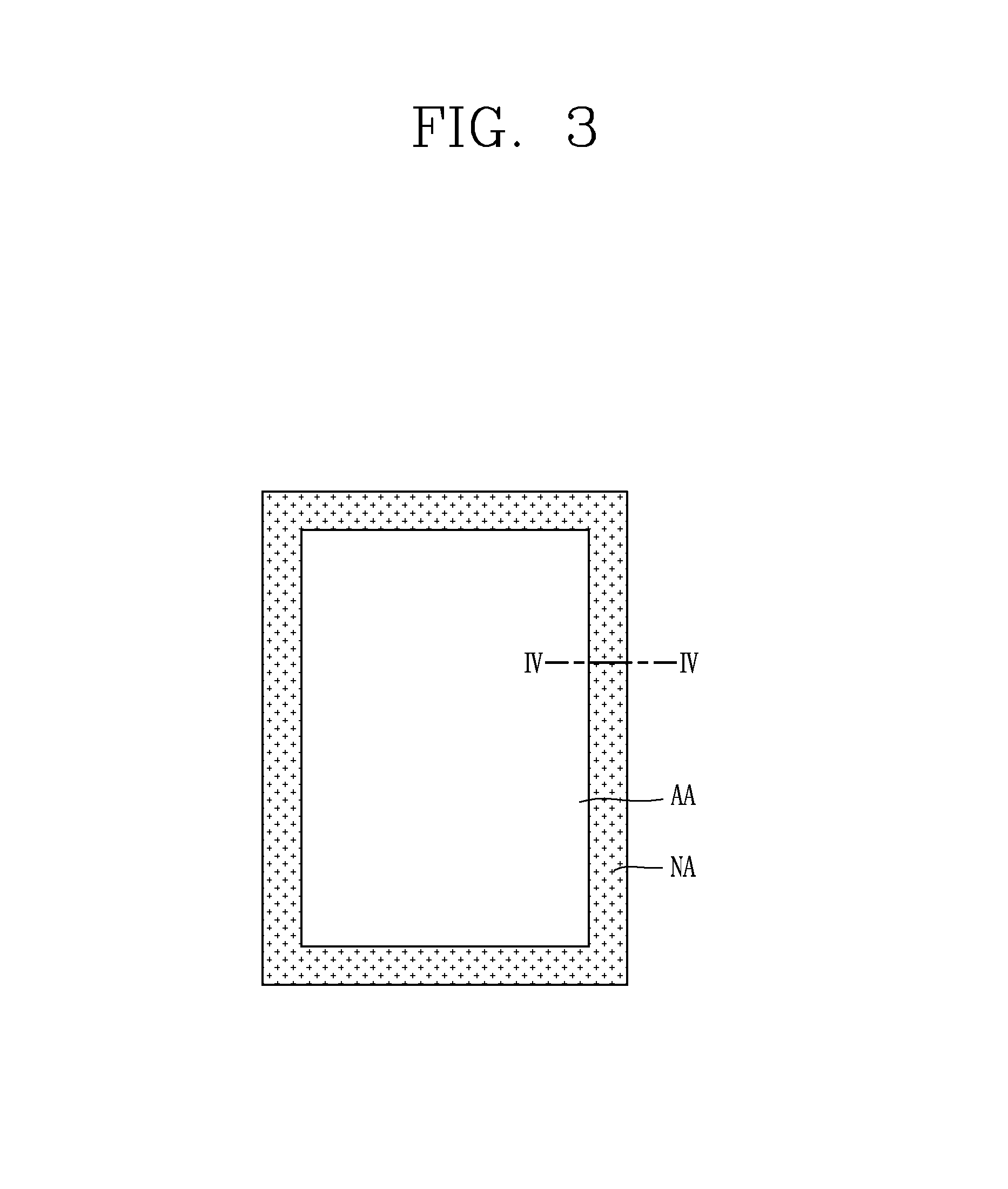

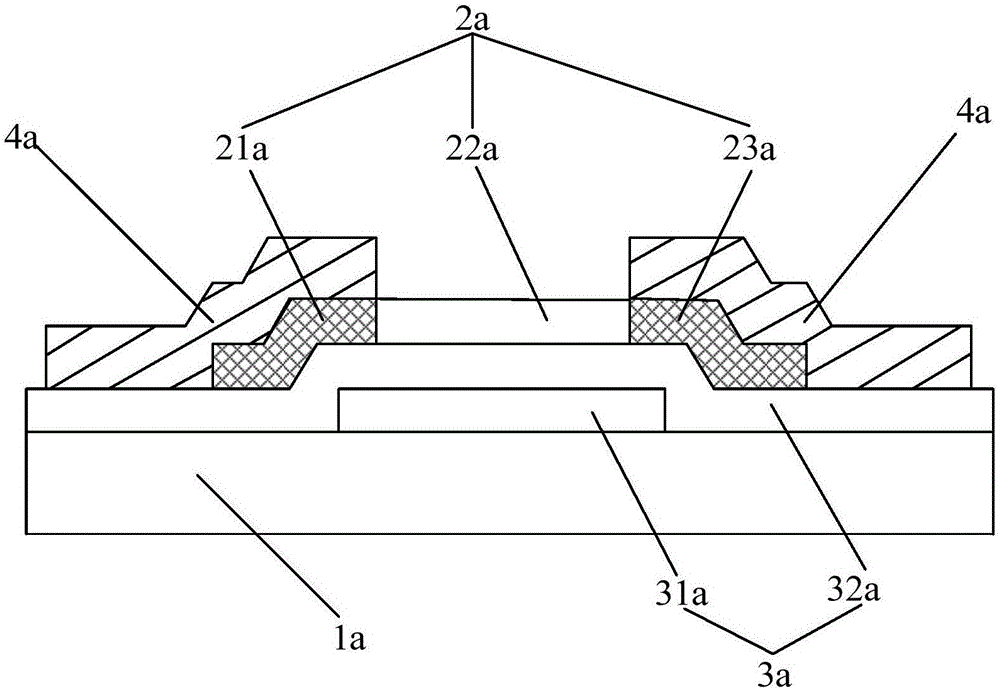

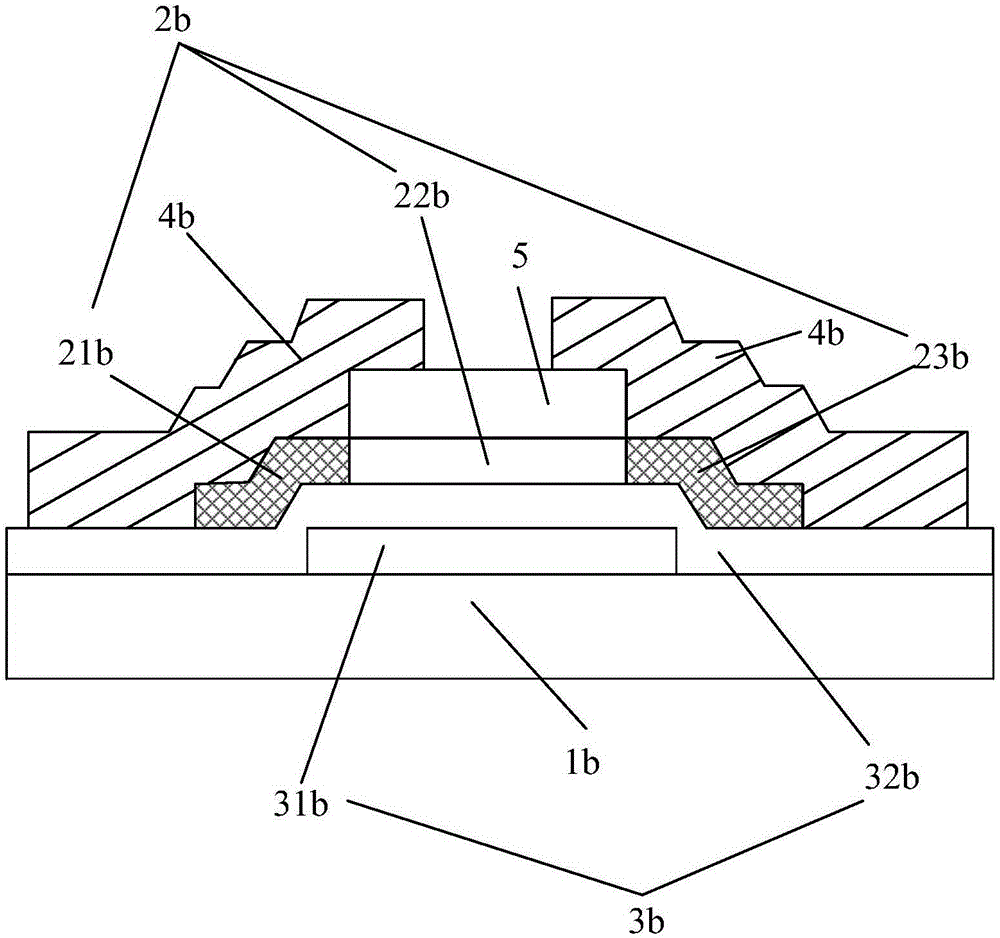

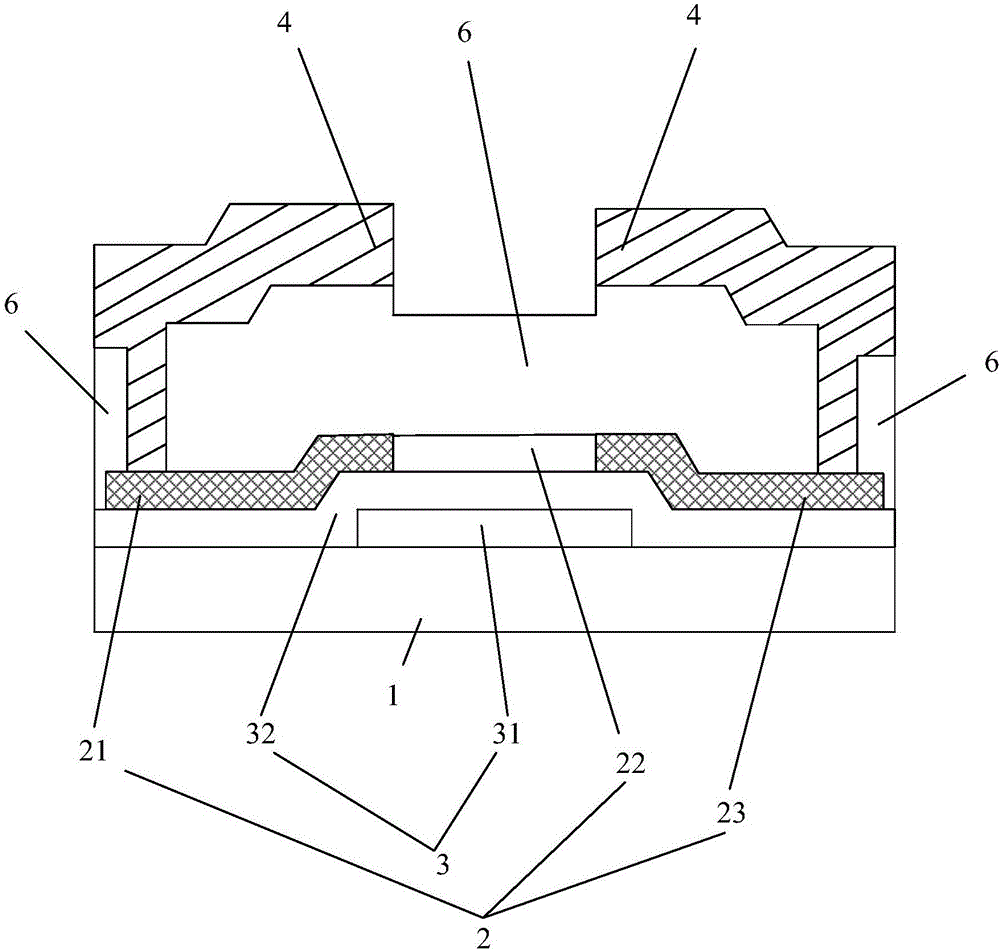

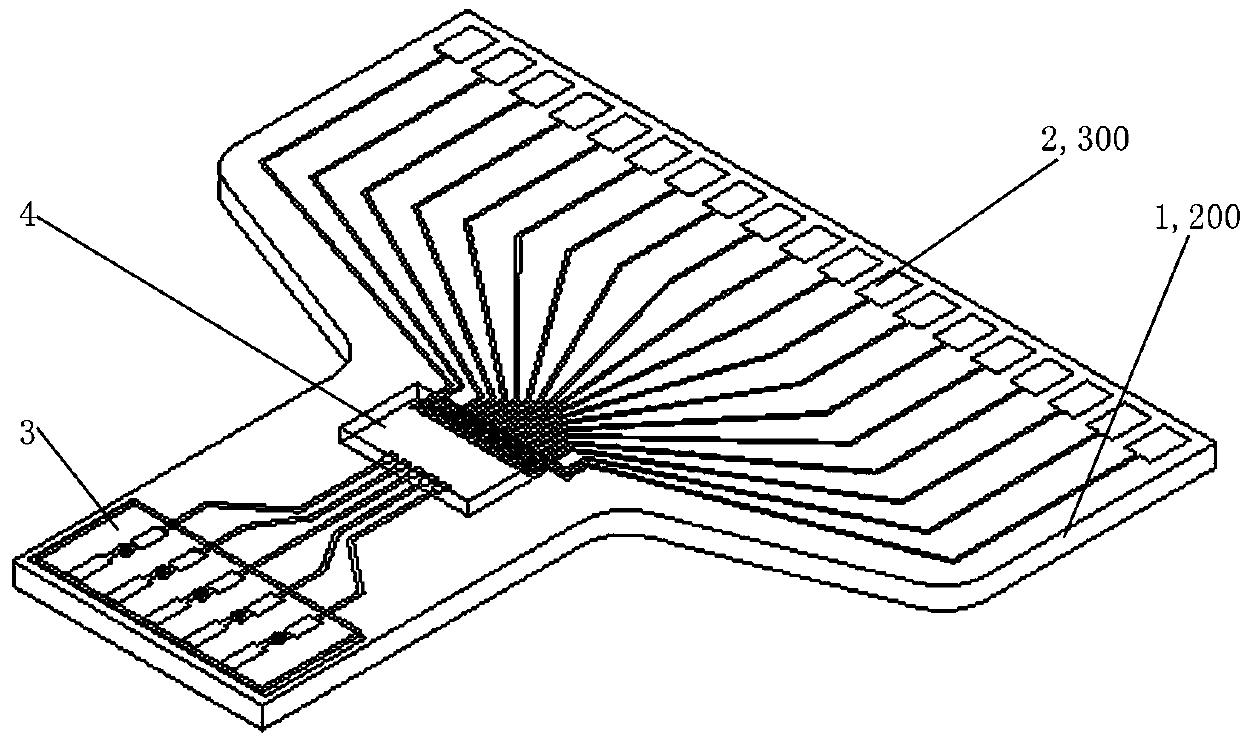

Organic light emitting diode device and method for fabricating the same

ActiveUS9312319B2Improve environmental reliabilityPrevent movementElectroluminescent light sourcesSolid-state devicesOrganic layerLight-emitting diode

Disclosed are an organic light emitting diode device, and a method for fabricating the same. The organic light emitting diode device comprises a non-active area formed outside an active area of a substrate; a switching thin film transistor and a driving thin film transistor at each of the pixel regions; a planarization layer on the substrate; a first electrode on the planarization layer; a bank formed in the non-active area outside each pixel region; an organic light emitting layer on the first electrode; a second electrode on an entire surface of the substrate; a first passivation layer on the substrate; an organic layer on the first passivation layer; a second passivation layer on the organic layer and the first passivation layer; a barrier film disposed to face the substrate.

Owner:LG DISPLAY CO LTD

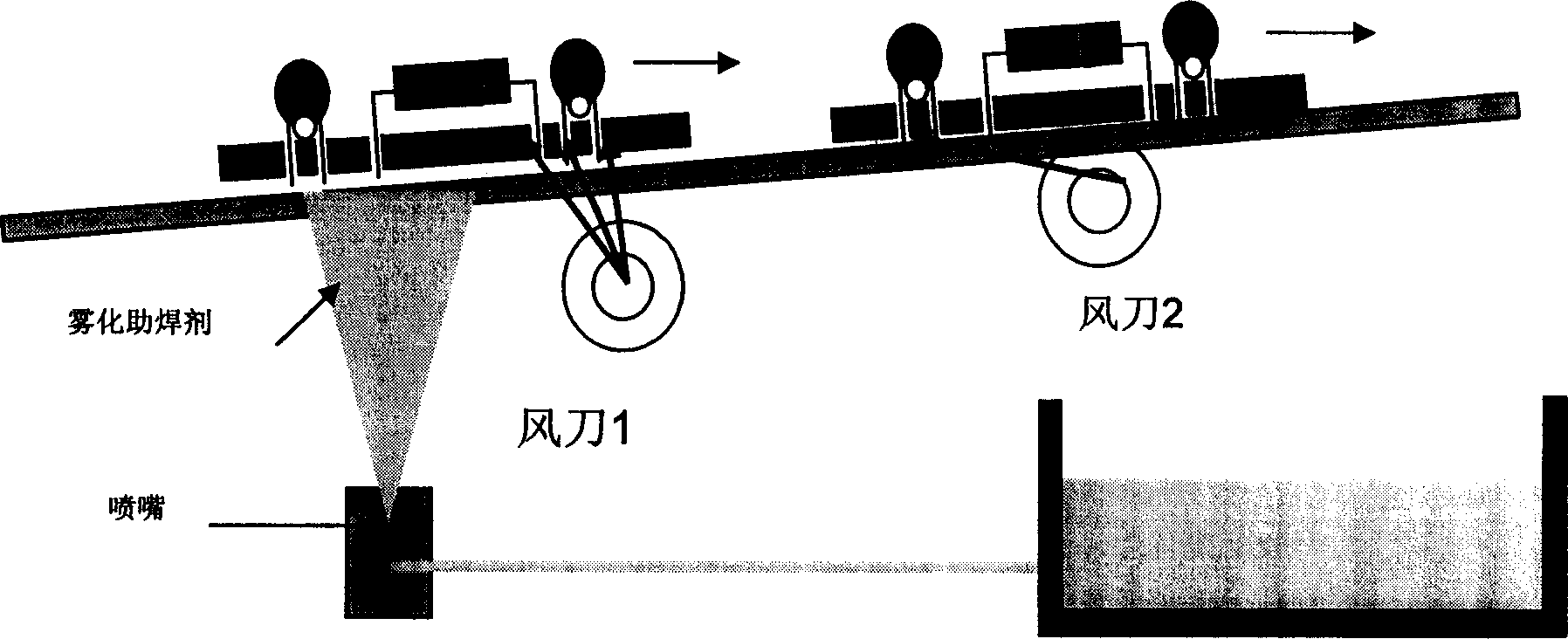

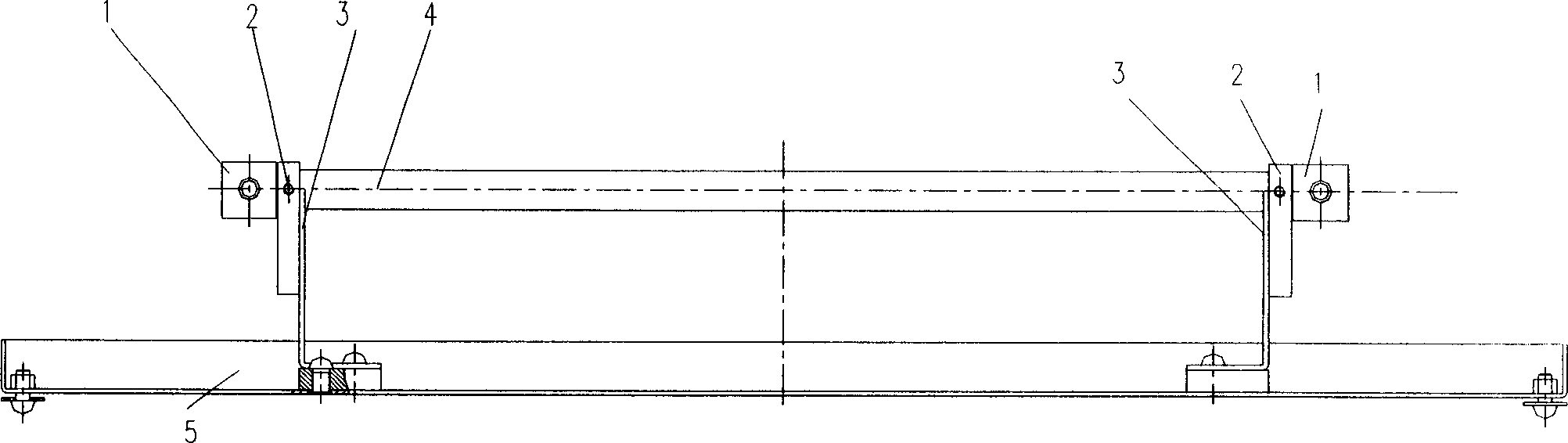

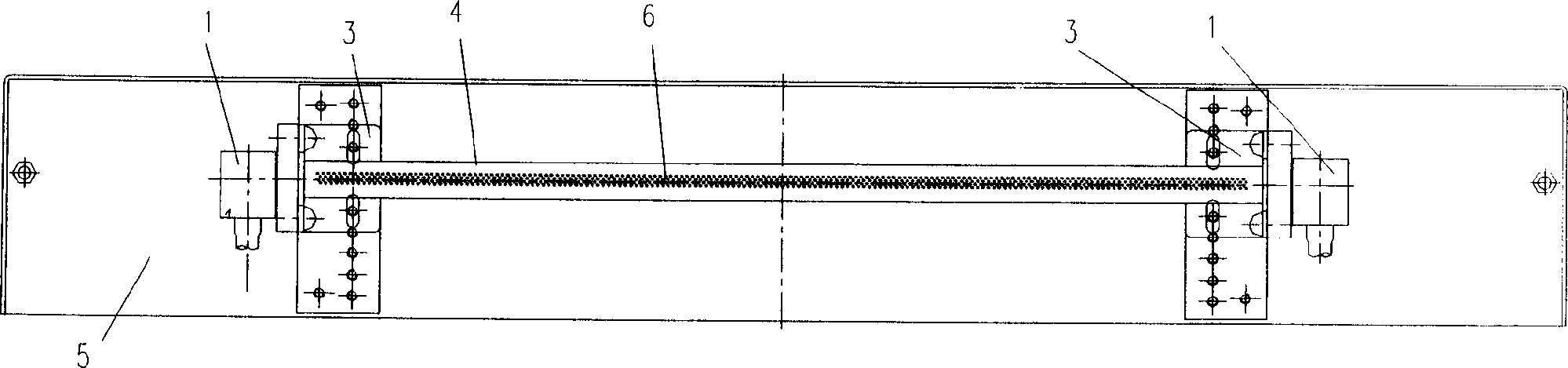

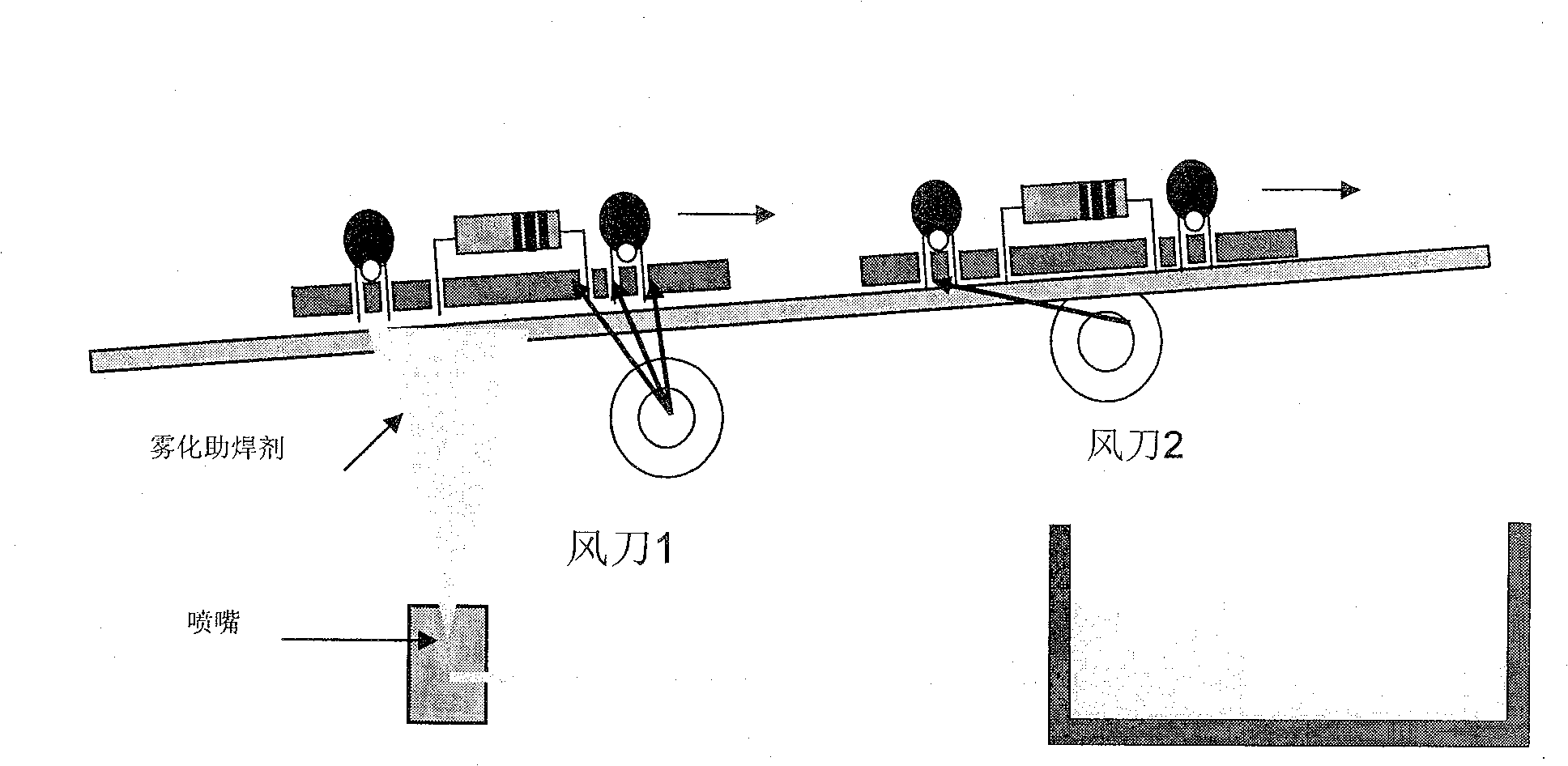

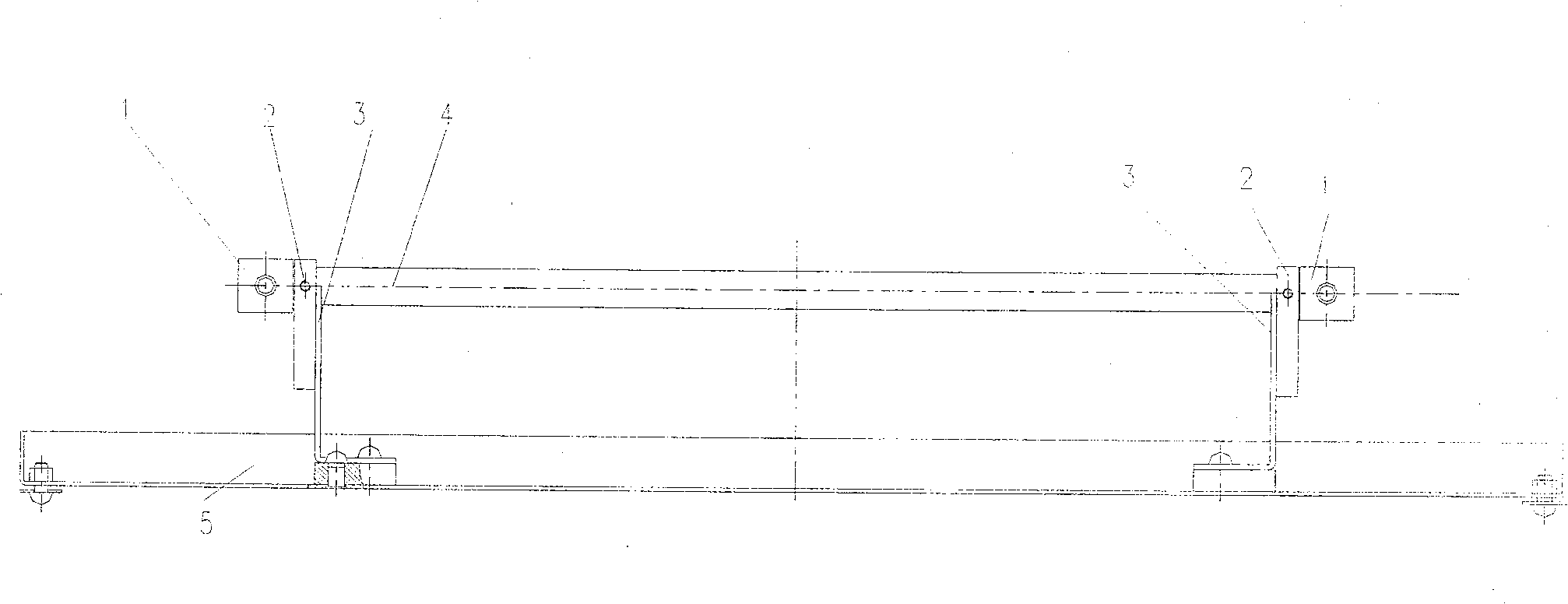

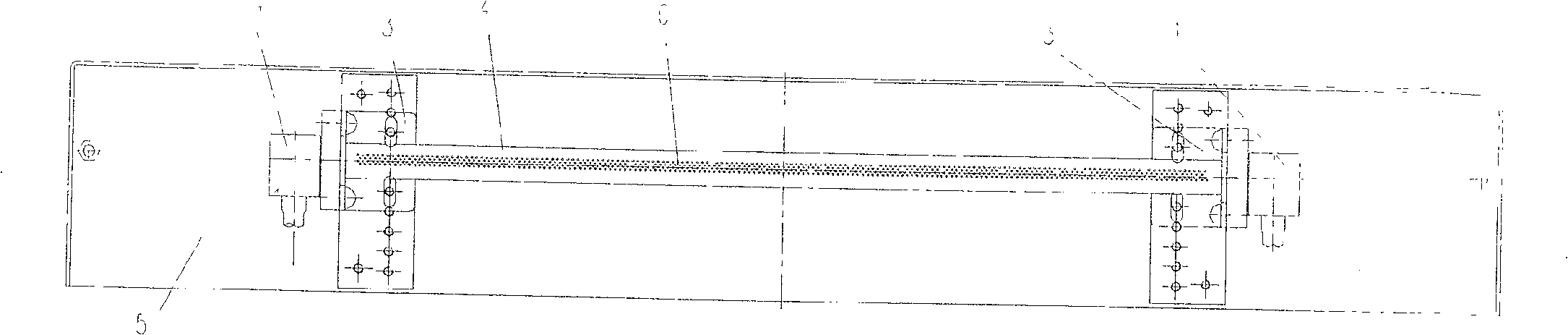

Method for improving circuitboard welding quality and air knife device therefor

InactiveCN1863439AIncrease spray volumeReduce ion residuePrinted circuit assemblingCleaning using gasesMetallurgyAir knife

This invention discloses a method for improving solder quality of CB and a device, in which, the method includes: spraying scaling powder on the CB, blowing the scaling powder on the lower surface of the CB in the through--ole of the CB to increase the coating volume of the powder in the through-hole and wash out the OSP coating of the hole wall to increase the solder ability of the hole, removing the scaling powder coated on the solder resistant film of the lower surface of the CB to reduce residual ions of the welded CB, preheating the CB welding the CB by a wave crest welder.

Owner:HUAWEI TECH CO LTD

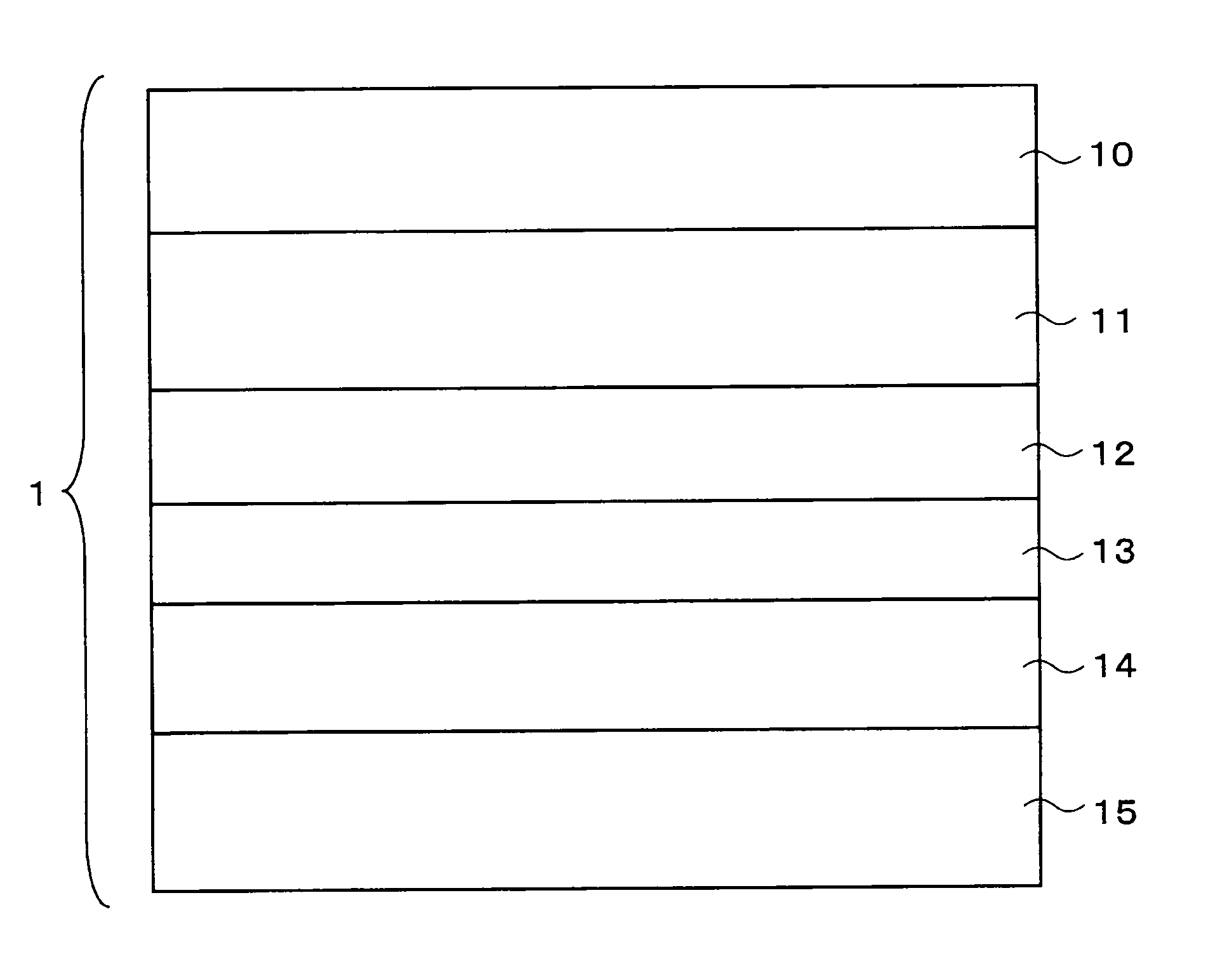

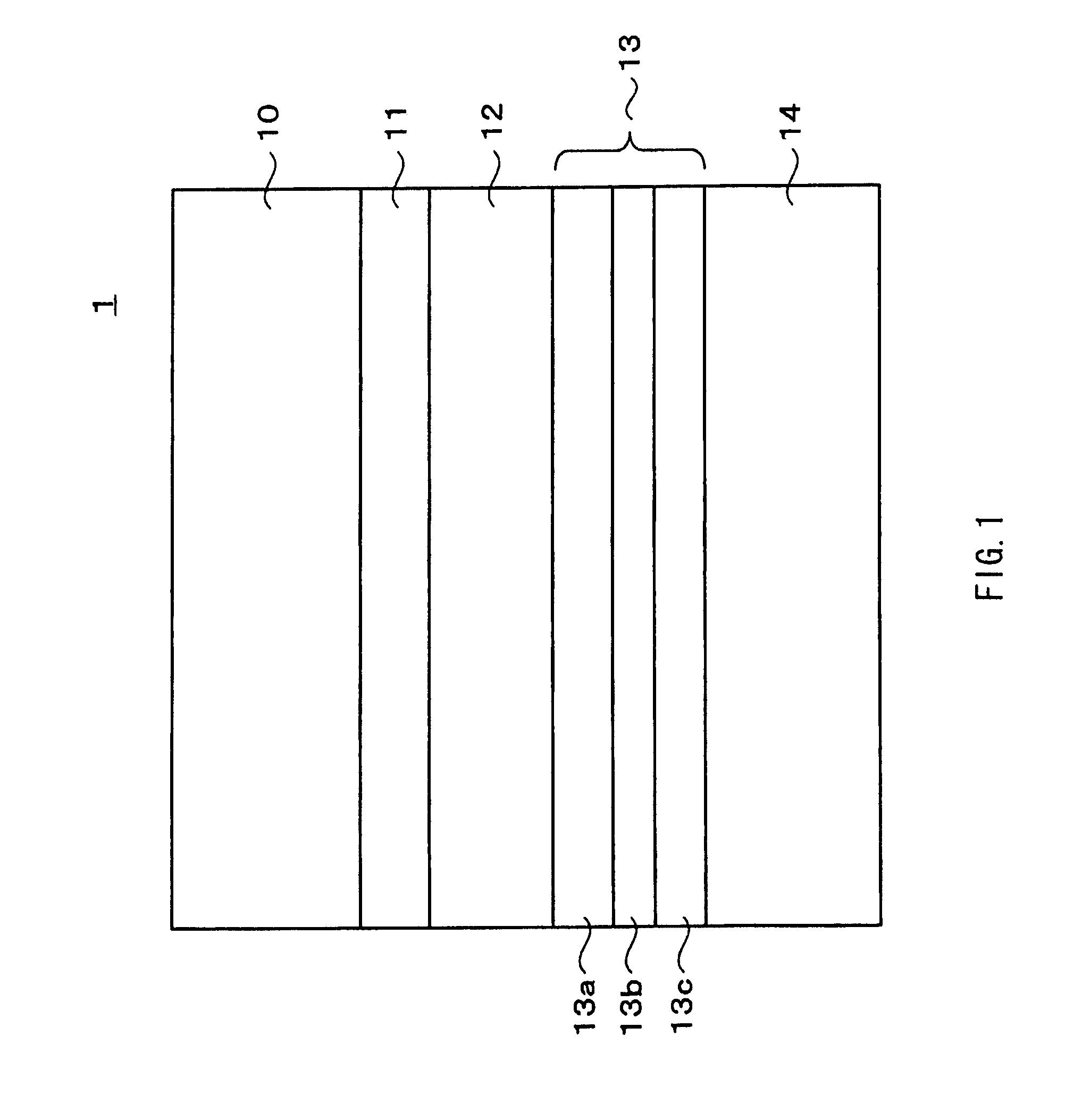

Optical information recording medium and method of recording and/or reproducing therein

InactiveUS20090268579A1Stable storageSimple manufacturing processRecord information storageThermographyReflective layerRecording layer

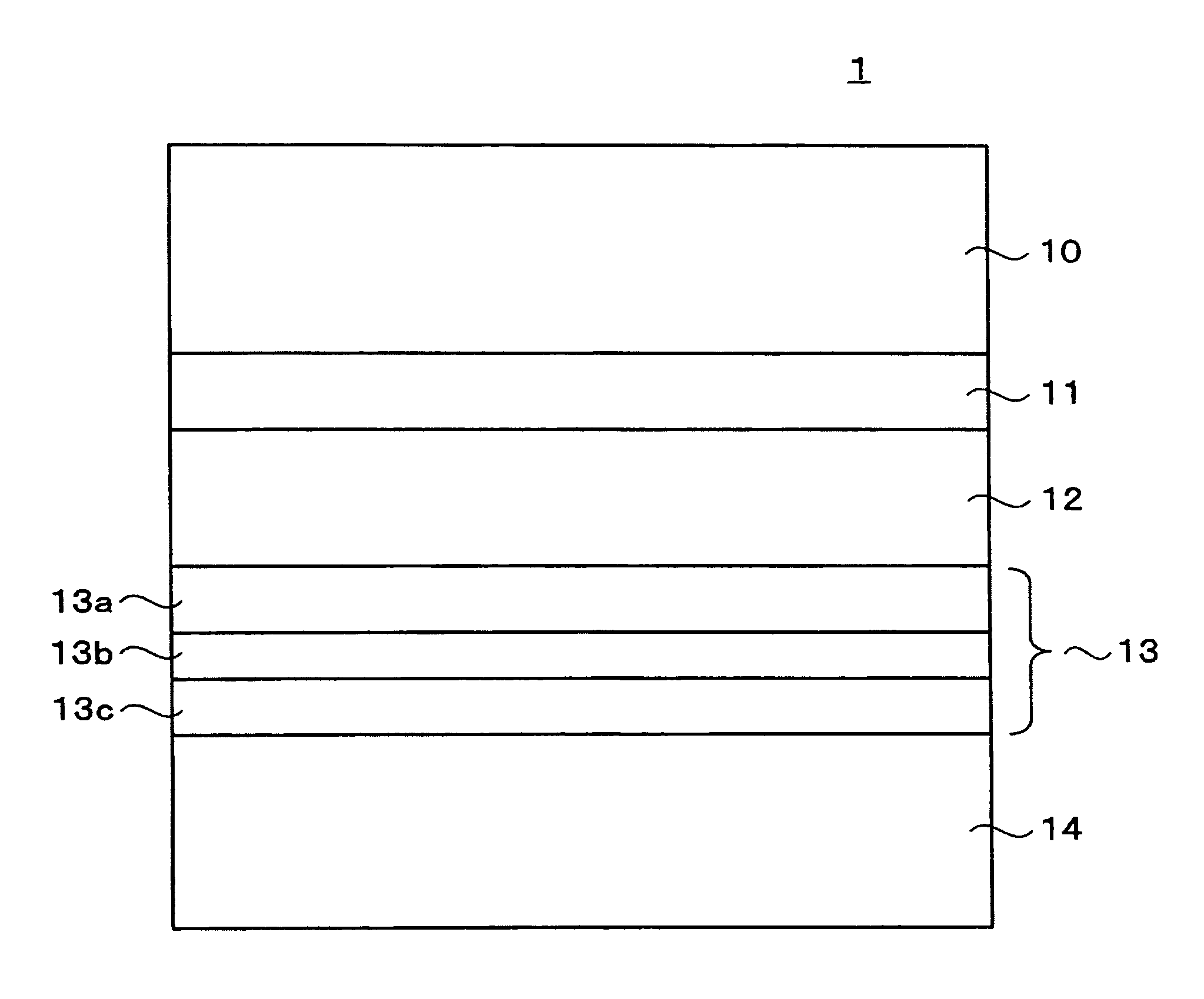

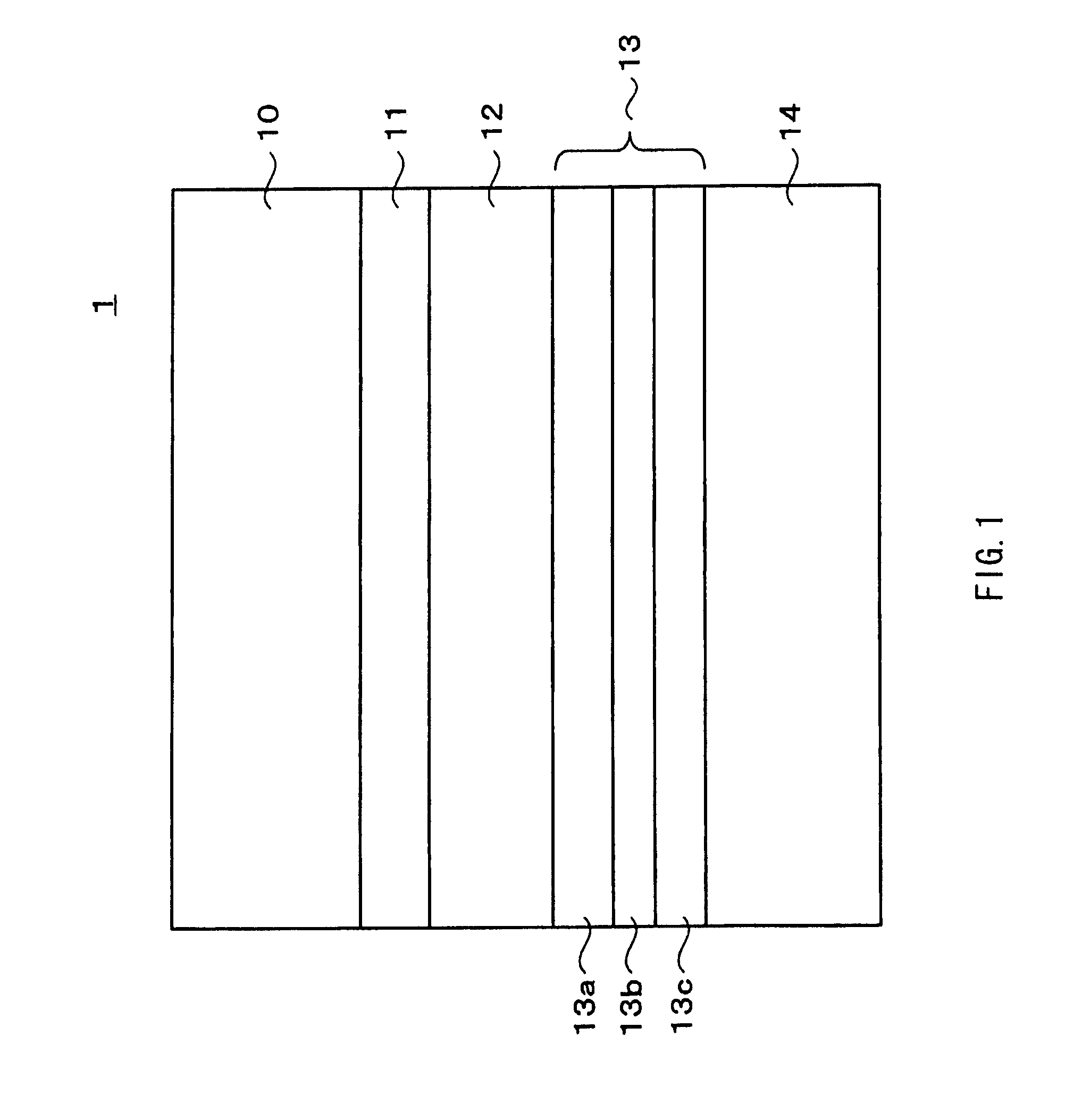

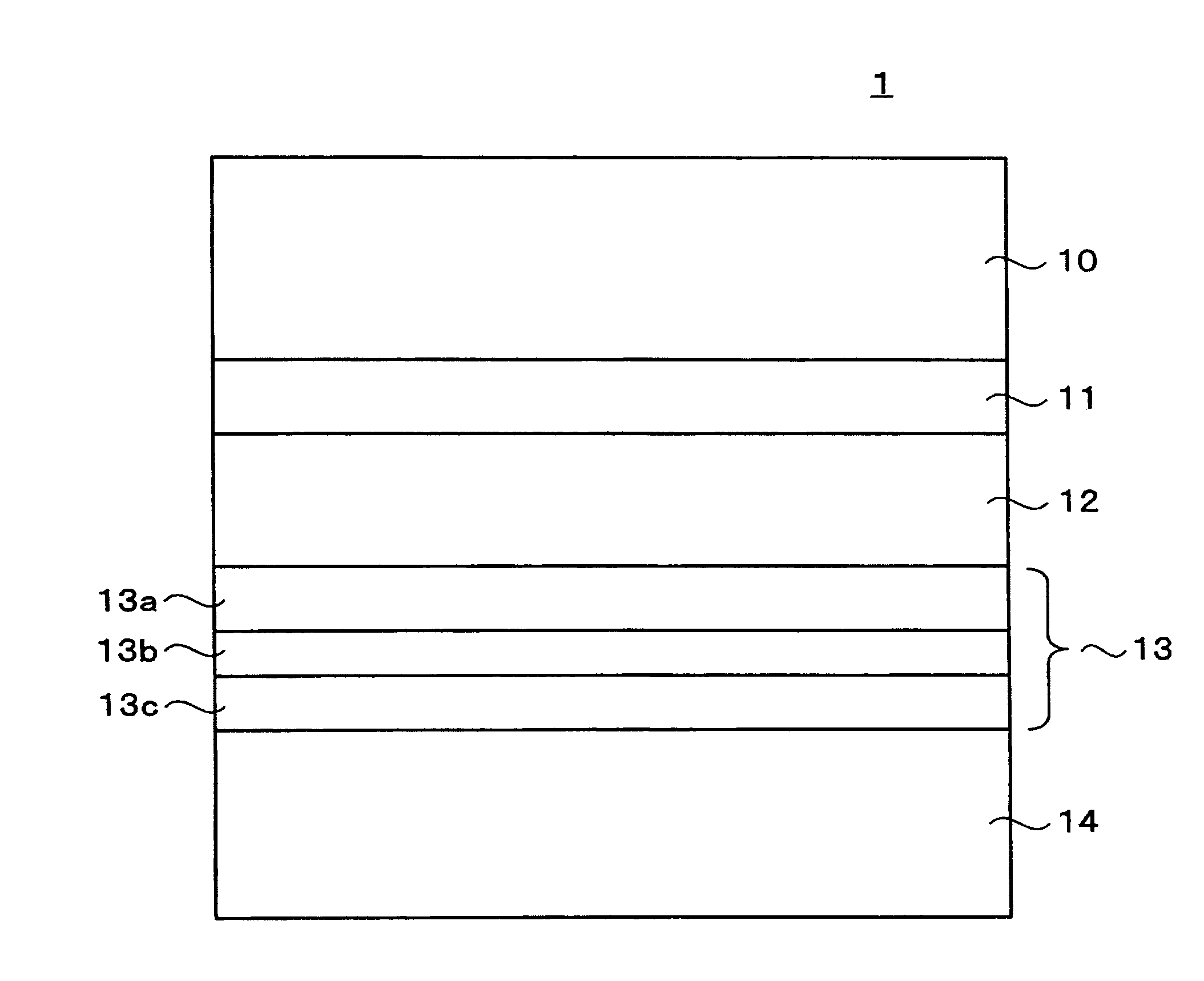

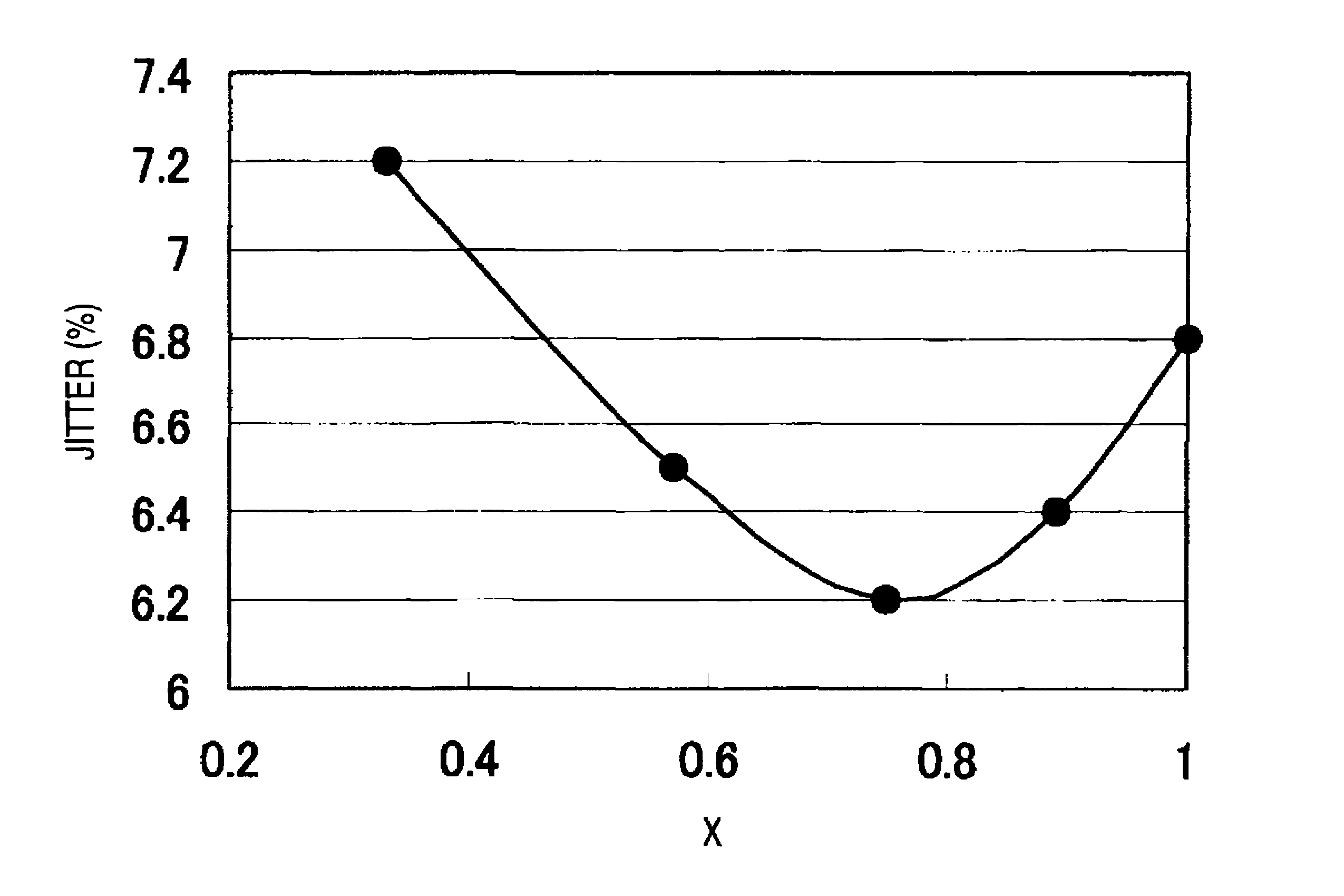

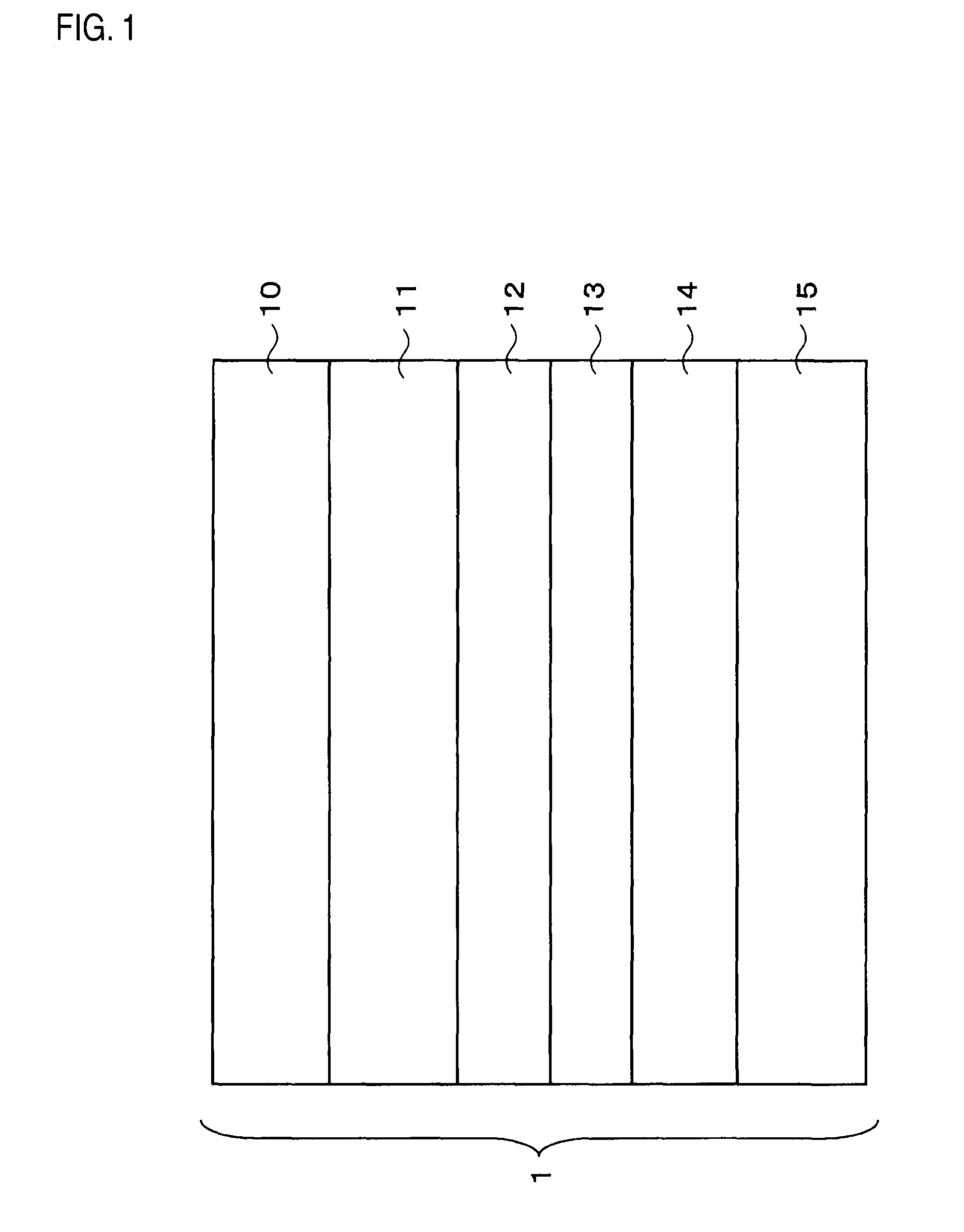

An optical information recording medium 1 is constructed by sequentially layering a reflective layer 11, a protective layer 12, a recording layer 13, a protective layer 14, and a light transmissive protective layer 15 on a substrate 10. As the recording layer 13, a recording layer containing ZnS, SiO2, and Sb as principal components, or preferably, a recording layer expressed by a compositional formula [(ZnS)x(SiO2)1-x]y(SbzX1-z)1-y (where 0<x≦1.0, 0.3≦y≦0.7, and 0.8<z≦1.0 are met and X denotes at least one element selected from a group of Ga, Te, V, Si, Zn, Ta, and Tb) is adopted.

Owner:SONY CORP

Thin film transistor and manufacturing method and display panel

InactiveCN106449763ALow resistivityEliminate Defect DensityTransistorSolid-state devicesElectrical resistance and conductanceDisplay device

A thin film transistor comprises: a substrate and an active layer made of a metal oxide disposed on said substrate, said active layer being adjacent to a gate stack;the active layer is partially covered with an electrode, and an insulating layer is further included between the electrode and the active layer; wherein the active layer forms a source region and a drain region in a region covered by the electrode, and a region under which the electrode is not covered forms a channel region. The present invention also relates to a thin film transistor manufacturing method and a display panel having the above-described thin film transistor. The thin film transistor described above has both a small size of a conventional back channel etched structure transistor and a superior performance over conventional etching barrier structure transistors, including low source and drain parasitic resistance, better on-state and off-state performance, Enhanced reliability. The display panel with the above-described thin film transistor has the advantages of high performance, high reliability and low cost, and more in line with the development trend of the display panel.

Owner:陆磊 +2

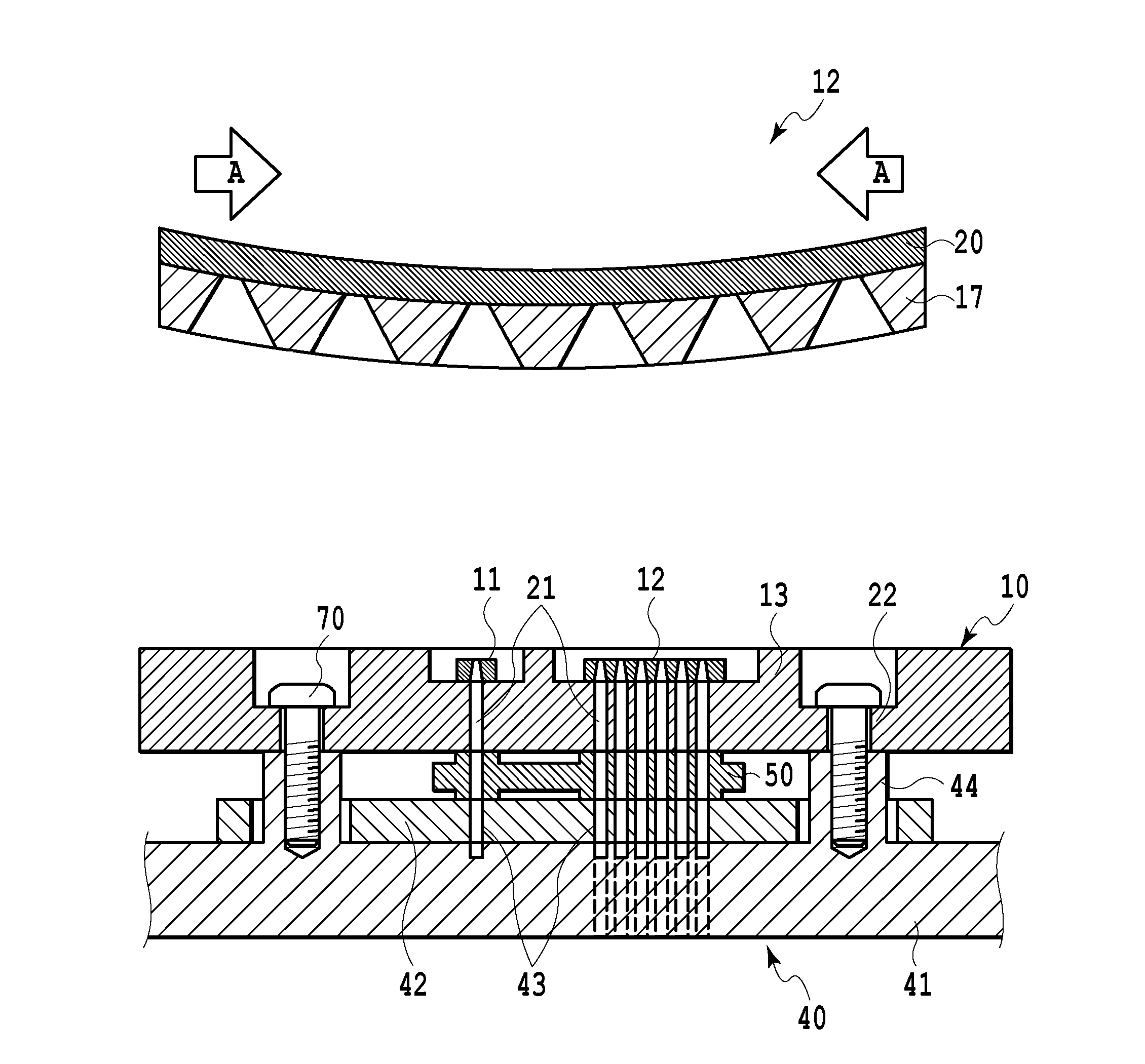

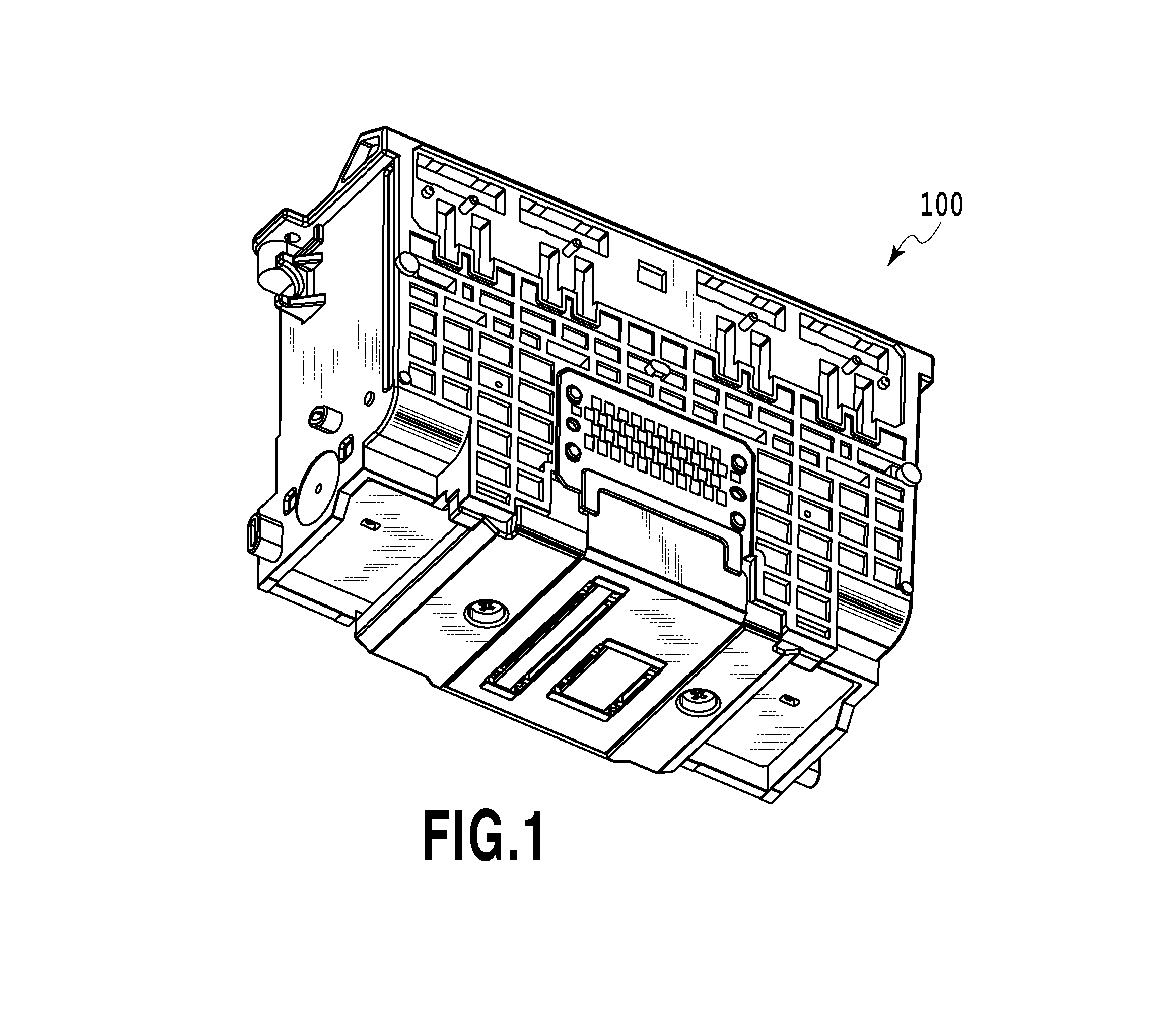

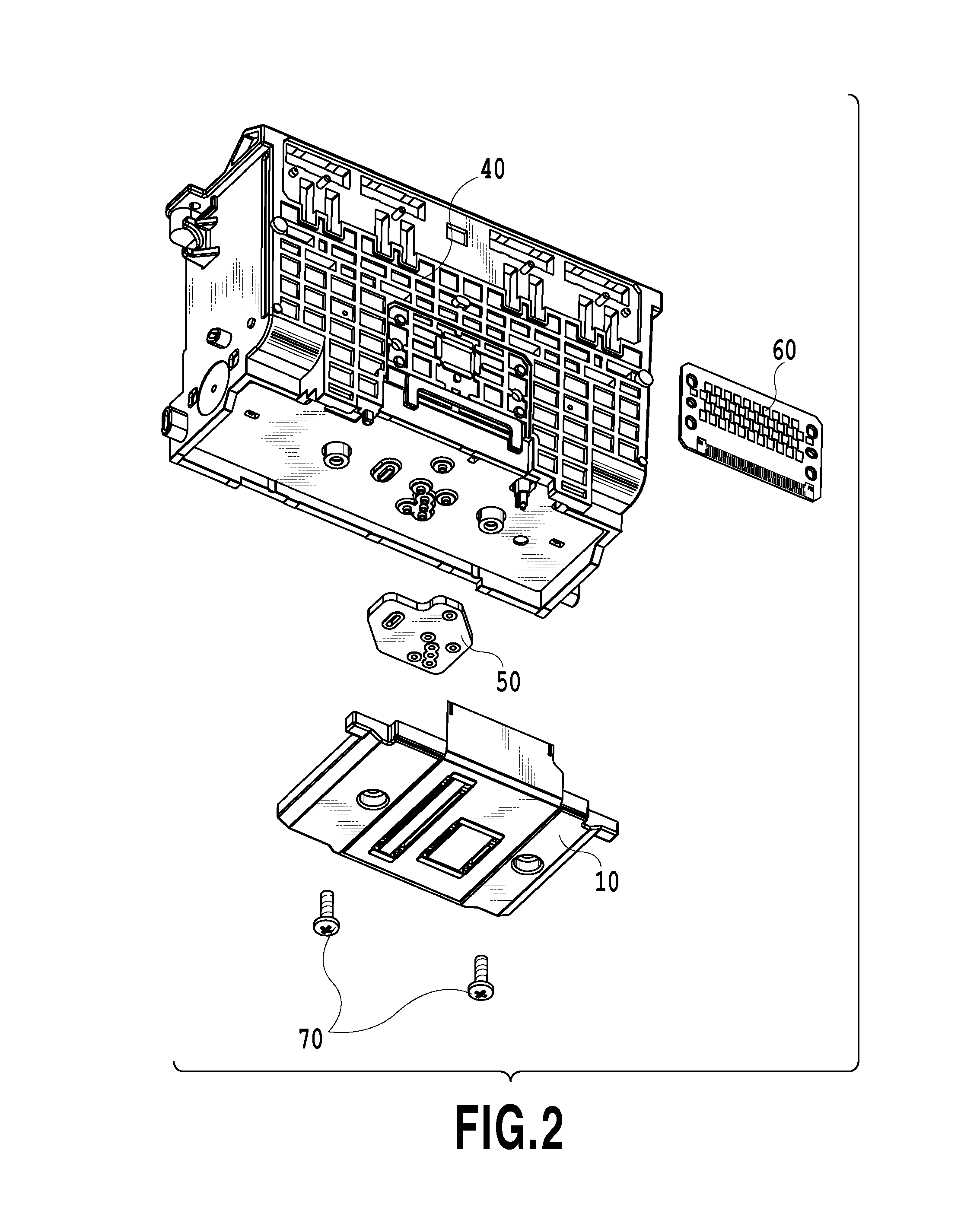

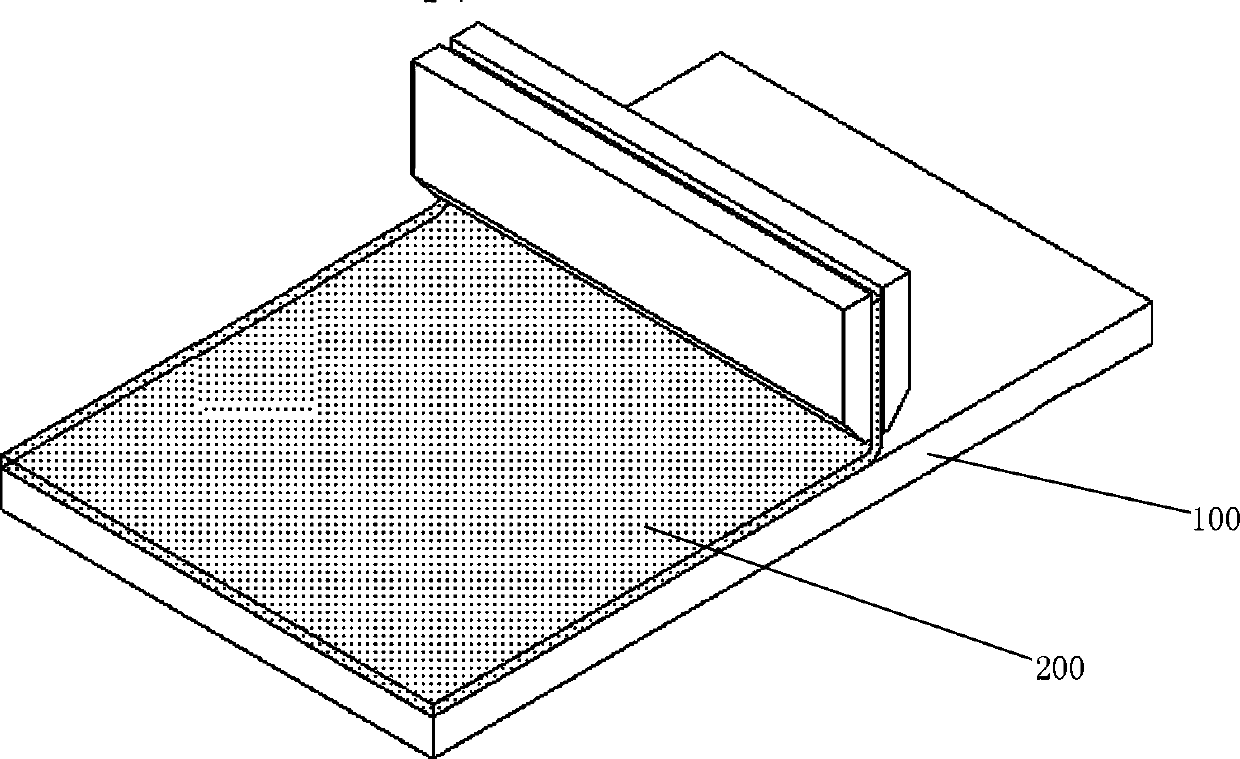

Liquid ejection head and manufacturing method of liquid ejection head

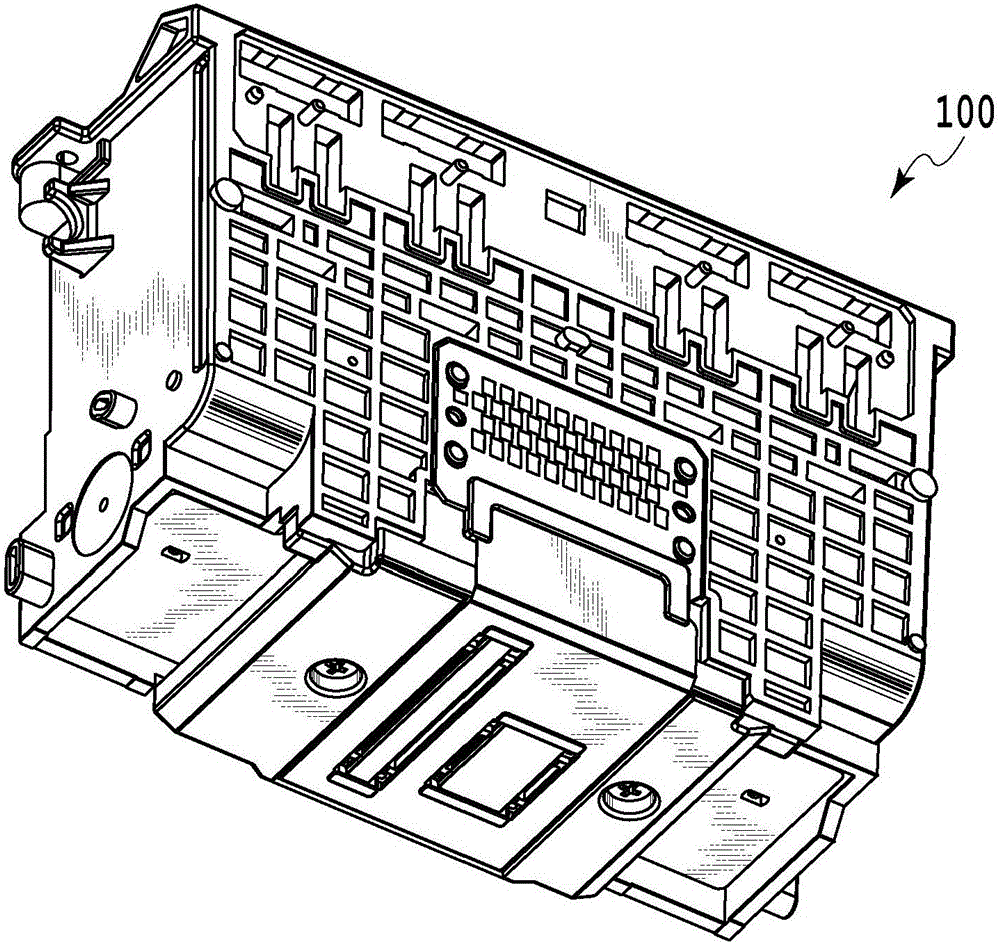

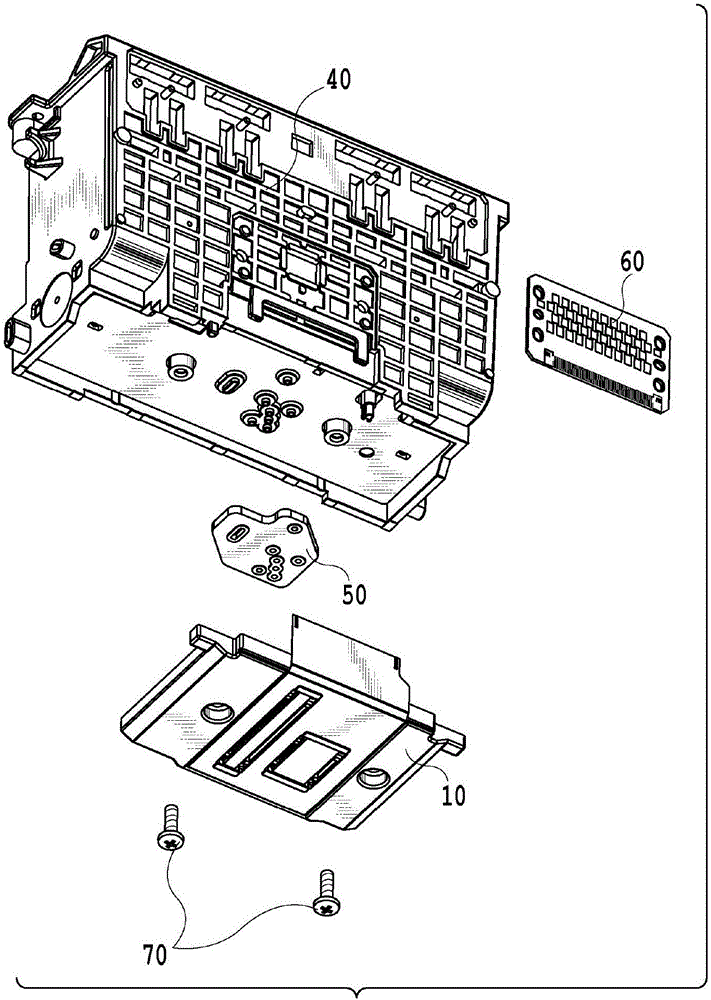

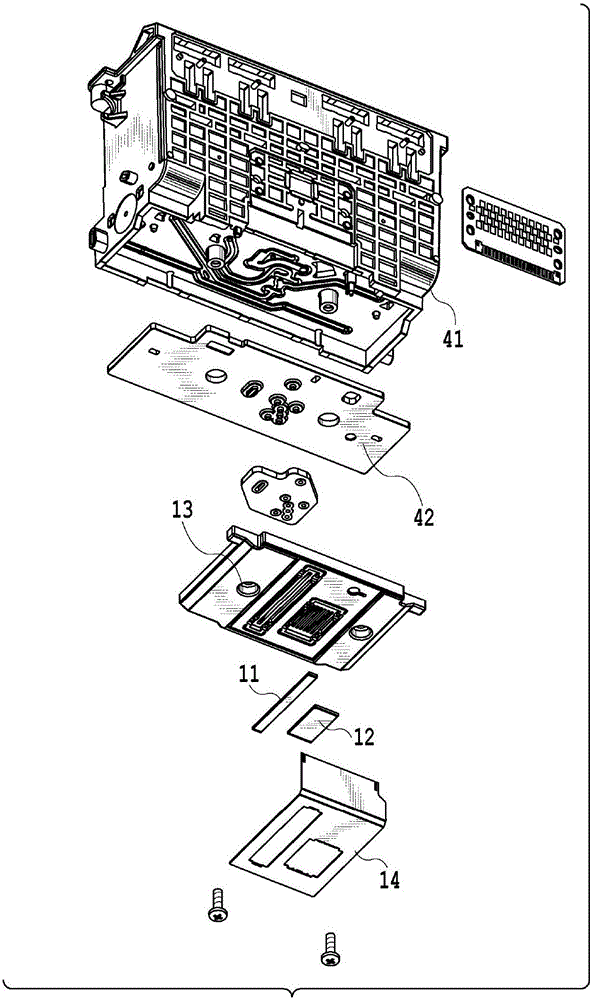

A liquid ejection head with high environmental reliability which suppresses a crack of a Si substrate and peeling-off of an ejection port forming member by relaxing a residual stress in a printing element substrate and a manufacturing method of a liquid ejection head are provided. For that purpose, after the printing element substrate is bonded and fixed to a support member, the support member is screwed and fixed through an elastic member.

Owner:CANON KK

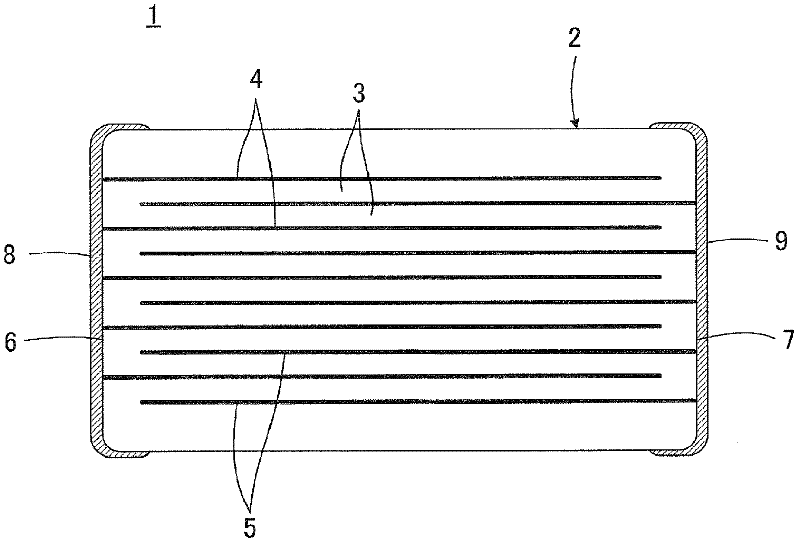

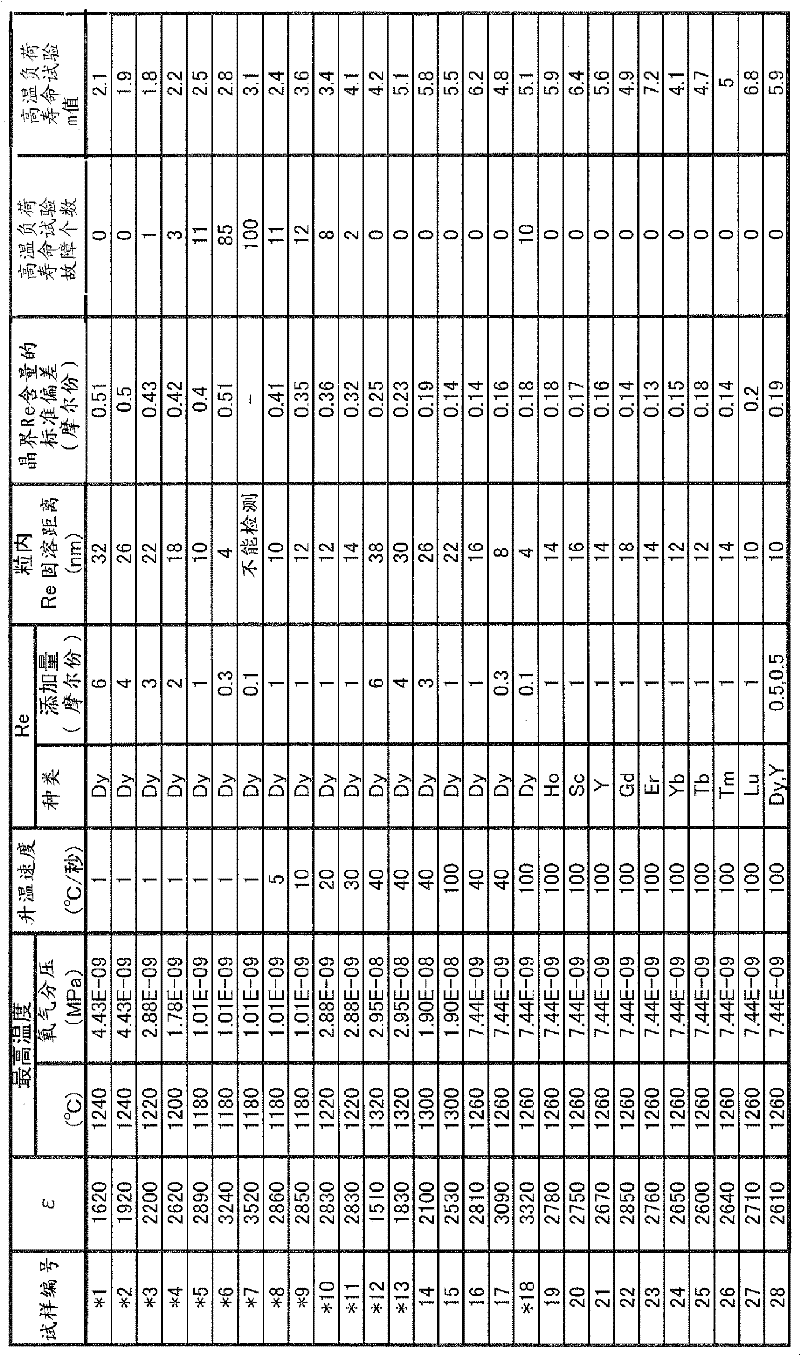

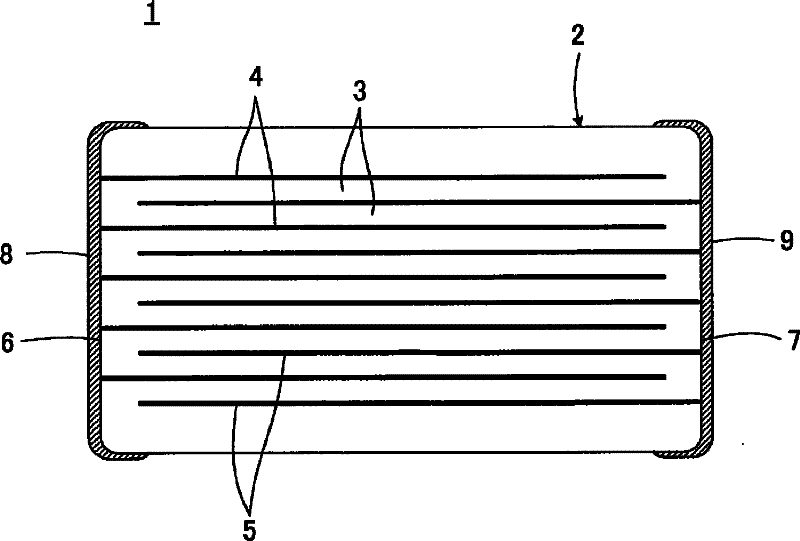

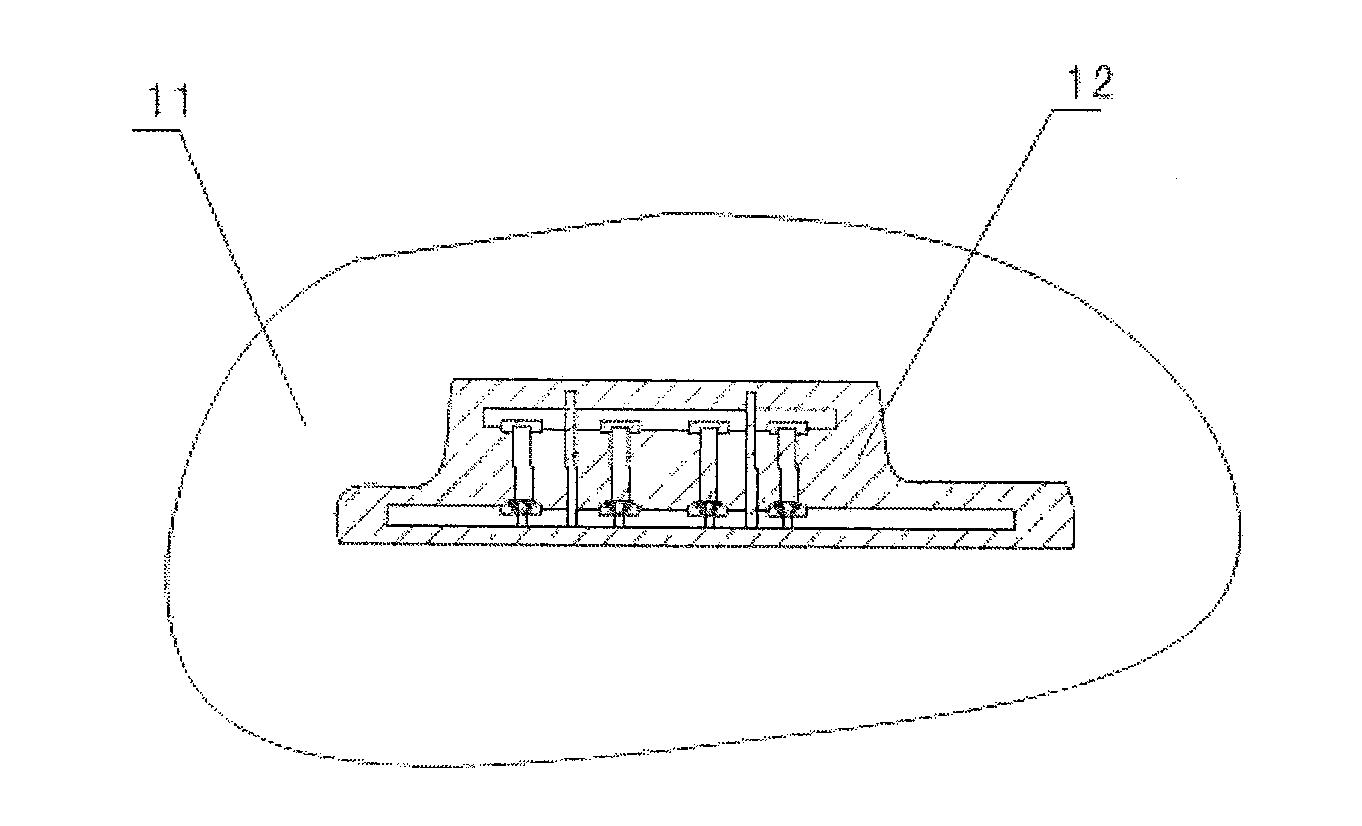

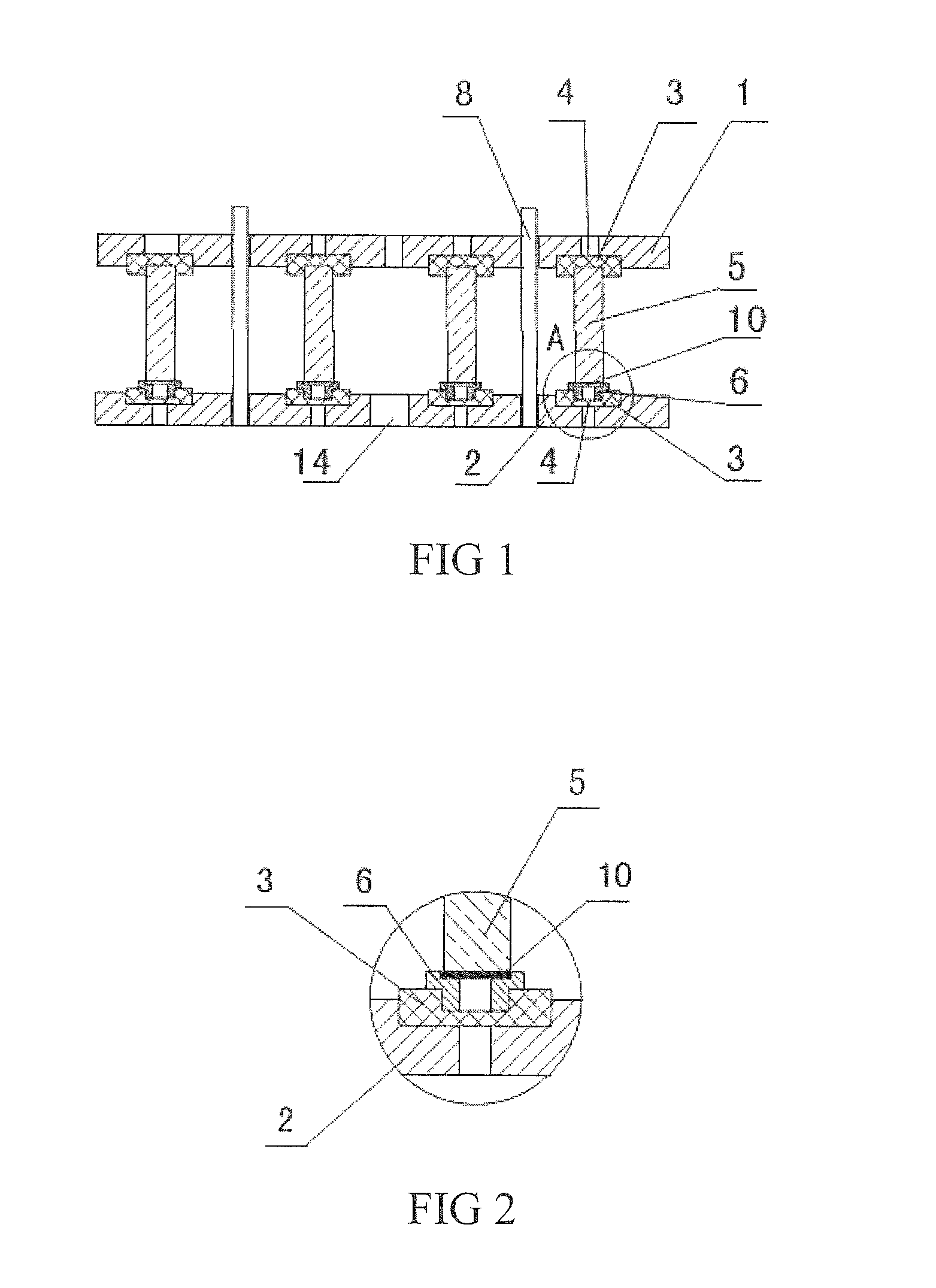

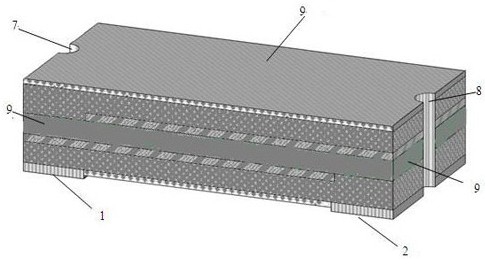

Manufacturing method of laminated ceramic capacitor, and laminated ceramic capacitor

ActiveCN102473523AInhibition of segregationUniform solid solutionFixed capacitor dielectricStacked capacitorsDielectricRoom temperature

Provided is a laminated ceramic capacitor, wherein reliability is not lost even when dielectric ceramic layers and internal electrodes are made to be thinner layers. Heat treatment is conducted with a temperature profile starting from room temperature and ending at maximum temperature, and having an average temperature-rising rate of 40 DEG C / second or more, when firing, in a raw-state, a laminated body (2), which is provided with laminated ceramic layers (3) that contain dielectric ceramic raw-material powder, and internal electrodes (4 and 5), and which is for the laminated ceramic capacitor (1). BaTiO3 is the main ingredient of the dielectric ceramic raw-material powder, and Re (Re is at least one type selected from the group consisting of Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu) is contained as an accessory ingredient, with the Re content made to be 0.3-3 parts by mole for 100 parts by mole of the main ingredient.

Owner:MURATA MFG CO LTD

Method for Reliably Soldering Microwave Dielectric Ceramics with Metal

InactiveUS20130062398A1Improve environmental reliabilitySave soldering costSoldering apparatusGas flame welding apparatusElectricityPorosity

A method for reliably soldering microwave dielectric ceramics with metal adopting the way of vapor soldering, a strict process of heating up, then soldering under heat preservation and finally cooling is provided. Therefore, thermal stress generated during the soldering of dielectric ceramics and metal material is reduced, reliability of a solder structure is ensured, porosity of the soldering side is effectively lowered, soldering quality is improved, soldering cost is reduced, and the demand of large-scale production can be met.

Owner:CHENGDU TIGER MICROWAVE TECH

Liquid ejection head and manufacturing method of liquid ejection head

ActiveCN105269964AInhibition of ruptureImprove environmental reliabilityPrintingEngineeringMechanical engineering

The invention provides a liquid ejection head and a manufacturing method of the liquid ejection head. The liquid ejection head with high environmental reliability which suppresses a crack of a Si substrate and peeling-off of an ejection port forming member by relaxing a residual stress in a printing element substrate and a manufacturing method of a liquid ejection head are provided. For that purpose, after the printing element substrate is bonded and fixed to a support member, the support member is screwed and fixed through an elastic member.

Owner:CANON KK

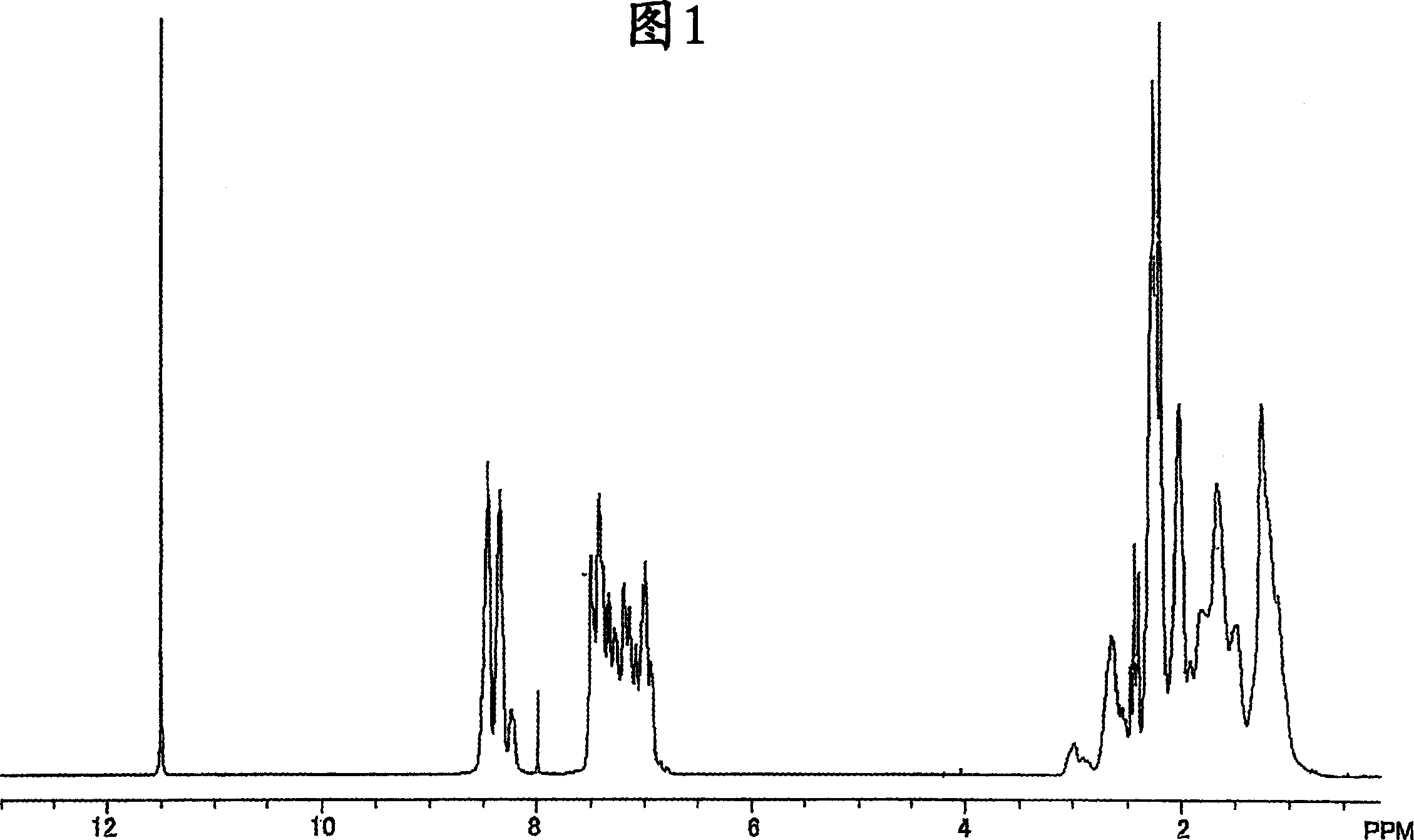

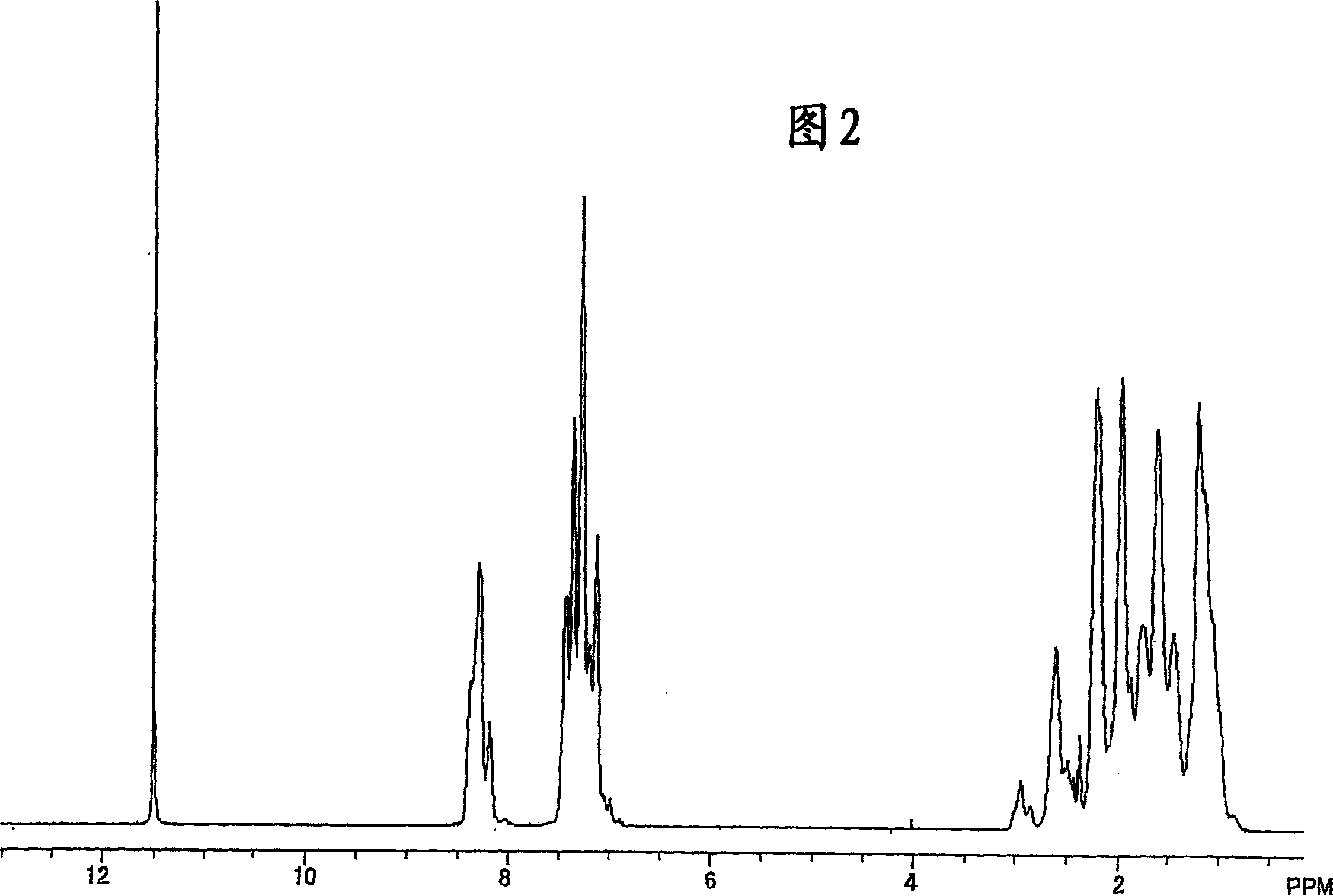

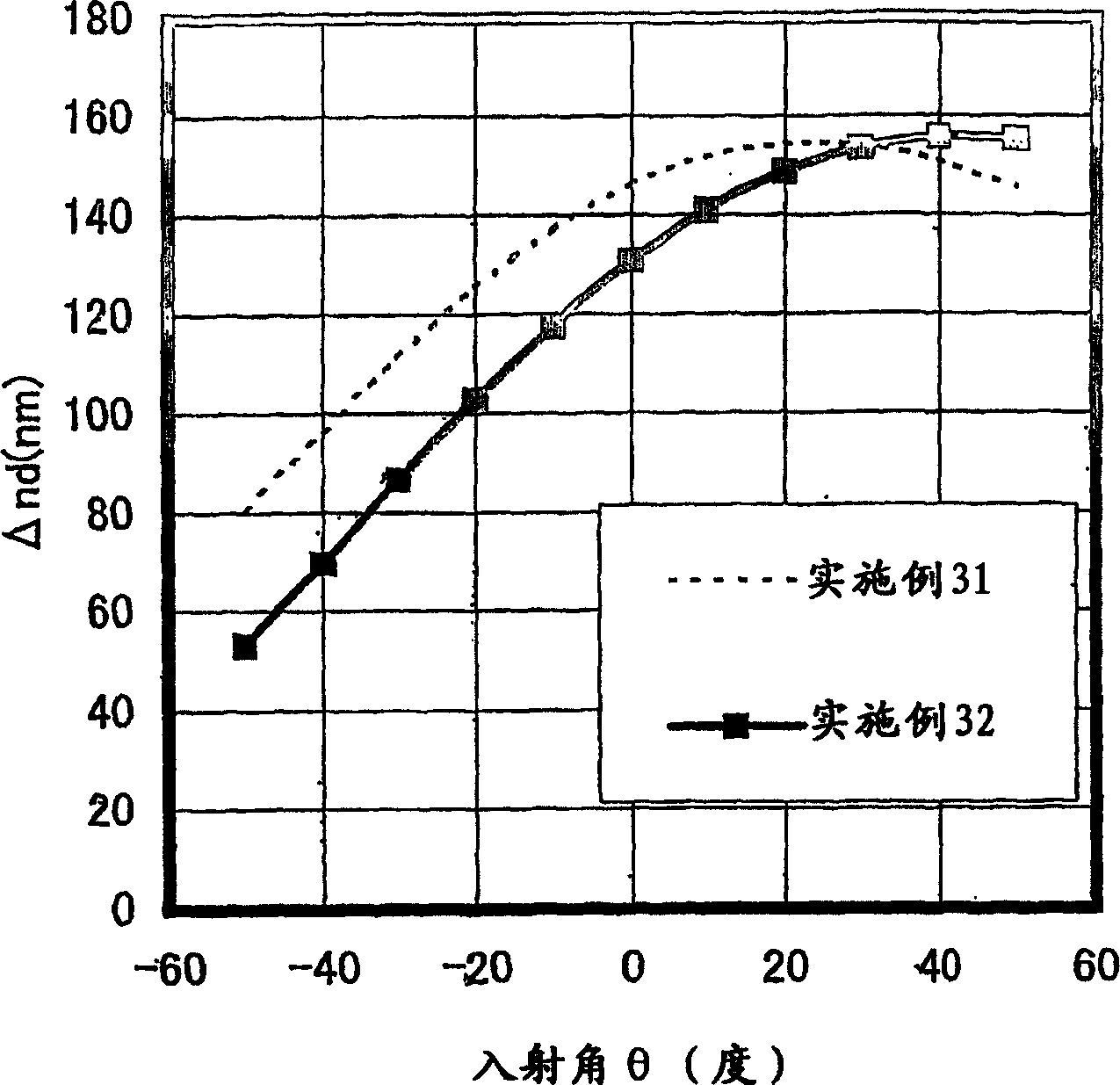

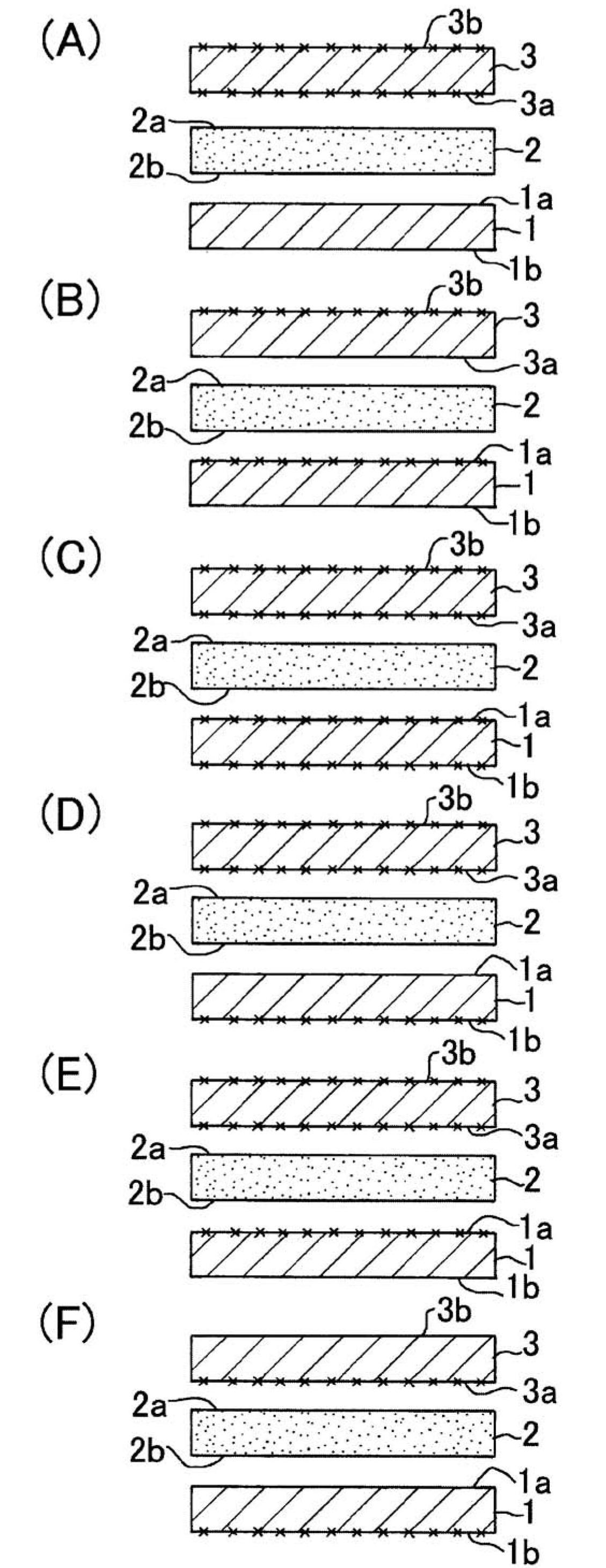

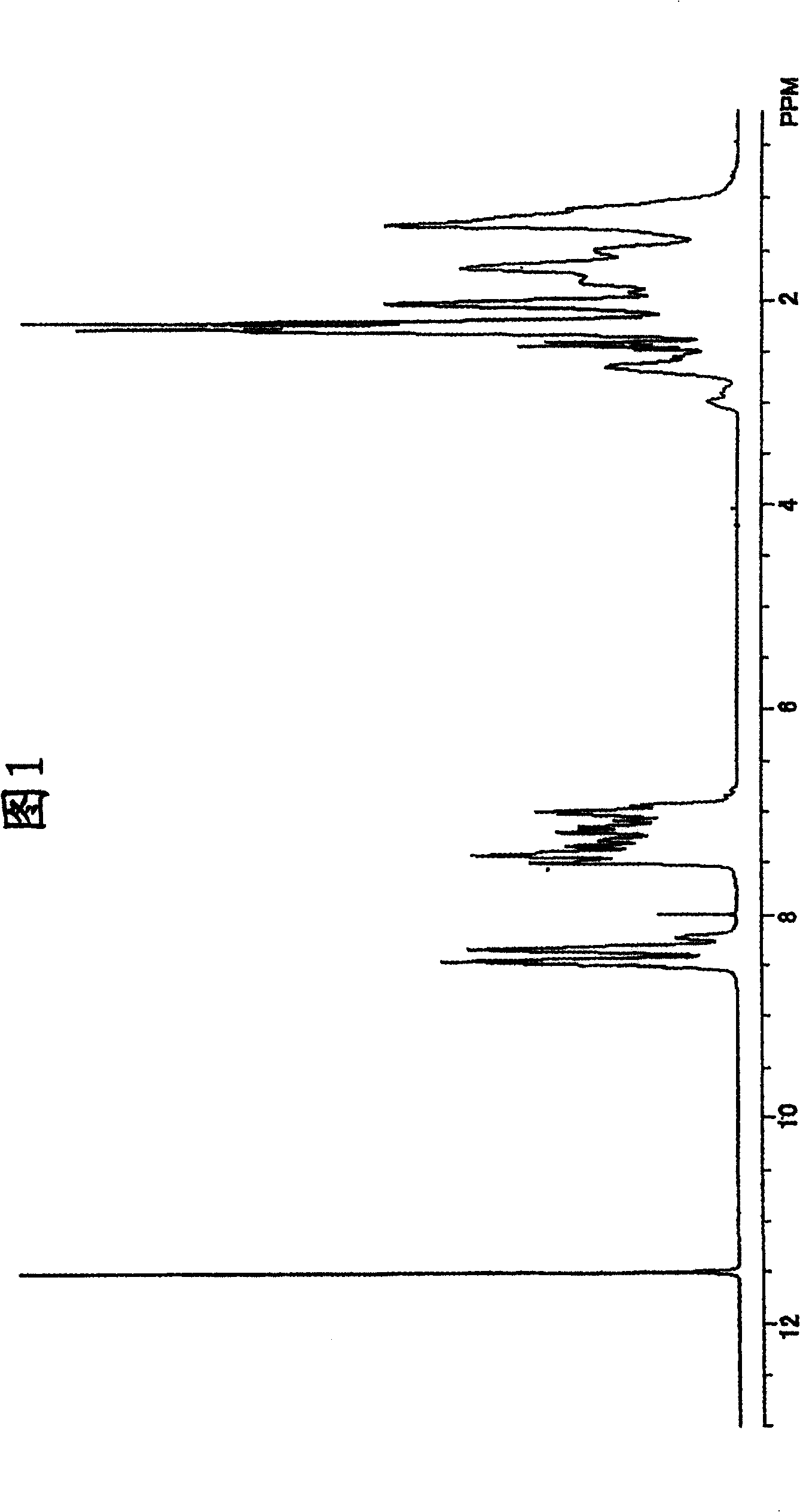

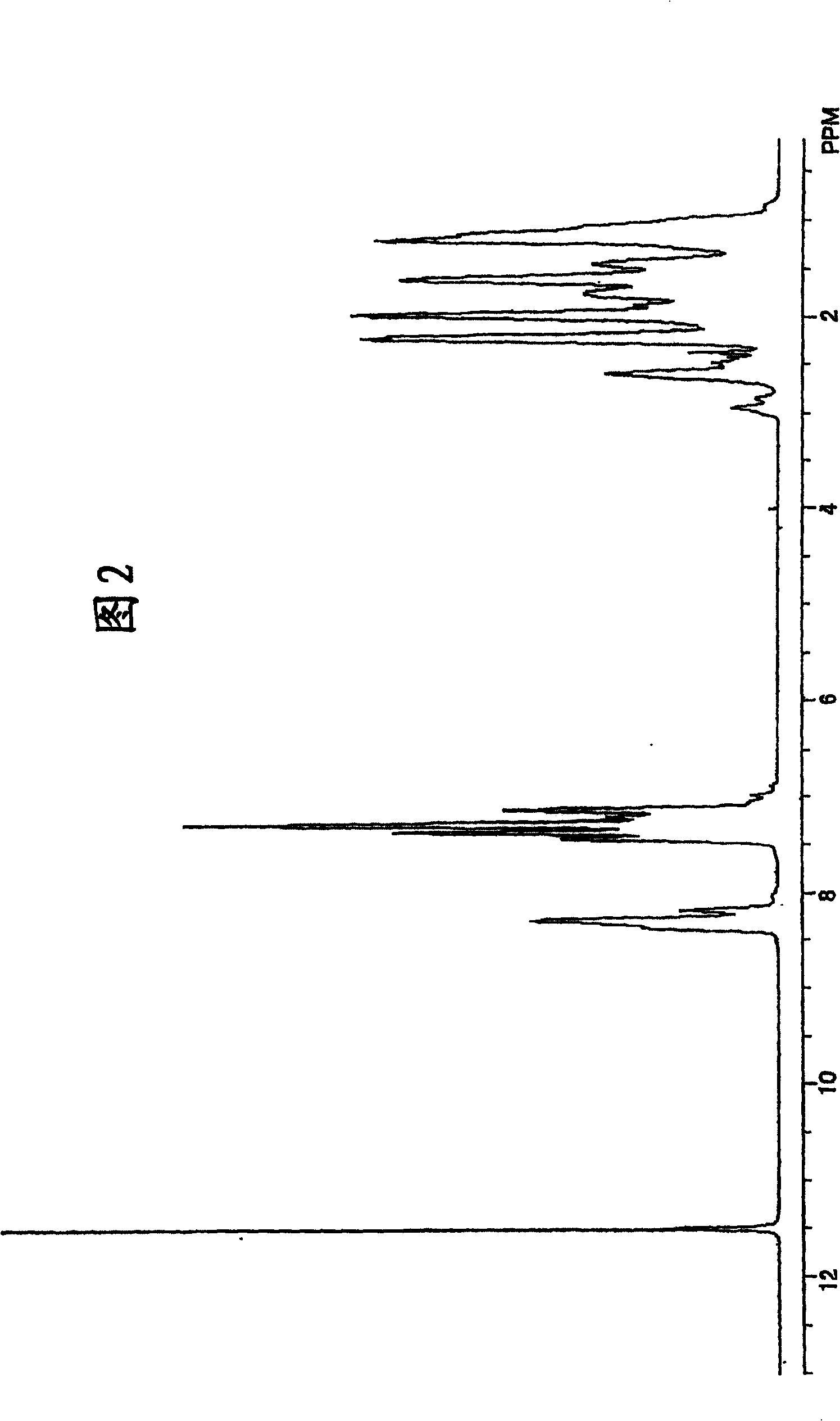

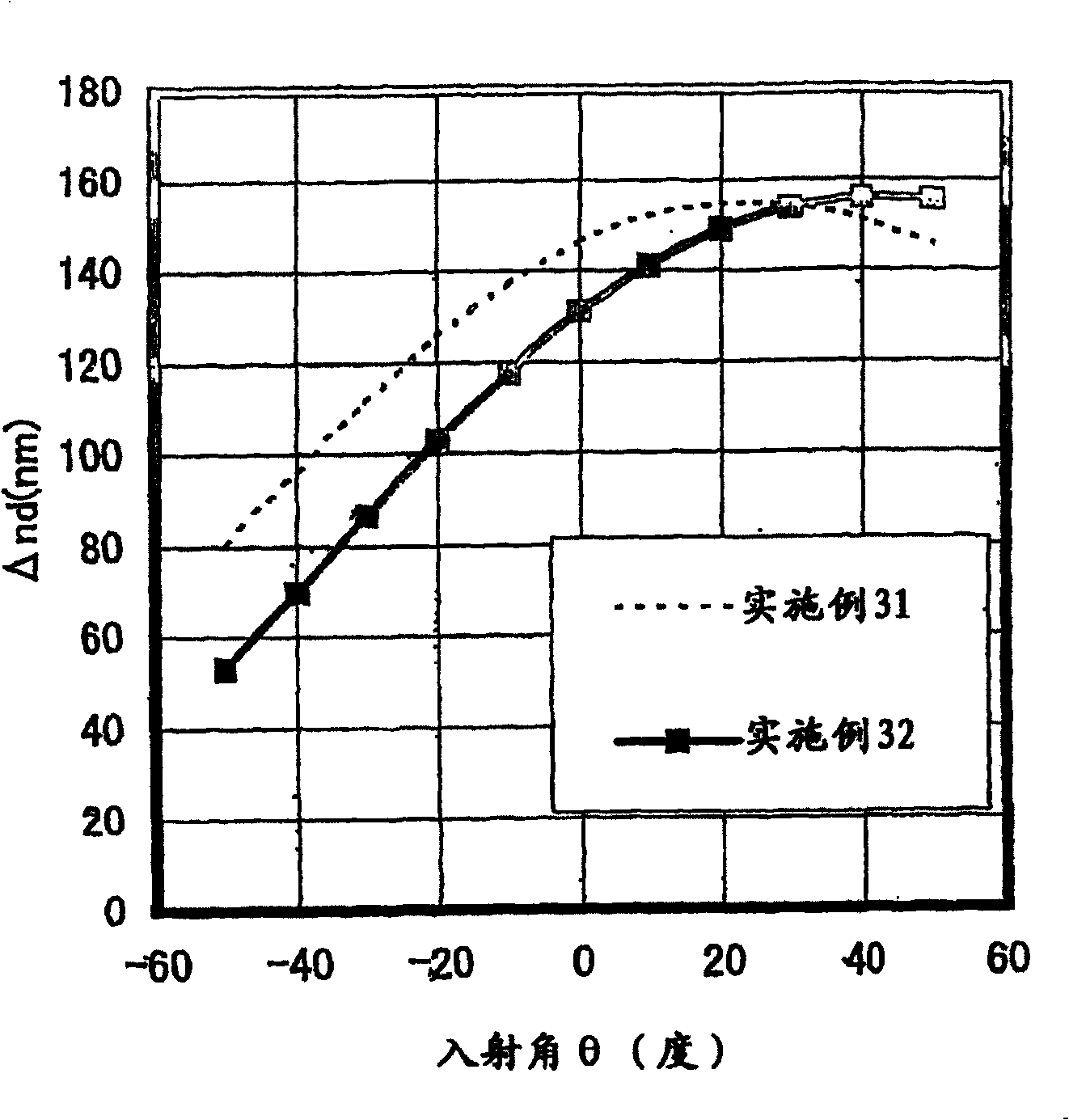

Optical film and liquid crystal display device

InactiveCN1759333AHigh strengthImprove environmental reliabilityPolarising elementsNon-linear opticsPolyesterOptical thin film

The present invention provides an optical film which facilitates the immobilization of liquid crystal orientation, can realize the wavelength dispersion of small birefringence, can be easily manufactured at a low cost in industrial view and can also be exactly regulated in optical characteristics, such as wavelength dispersion of the birefringence, is immobilized with the desired orientation state and can be made uniform and larger in area. The optical film is composed of polyester including a structural unit derived from 1,1'-bicyclohexyl-4,4'-dicarboxylic acid and a structural unit derived from an aromatic diol-based compound of an ortho body and is obtained by cooling the orientation state formed during the thermal orientation of the polyester to its glass transition temperature or below so as to immobilize the orientation state.

Owner:NIPPON OIL CO LTD

Double-sided pressure-sensitive adhesive sheet with release sheets

InactiveCN102597144ANo static electricityImprove environmental reliabilityFilm/foil adhesivesSynthetic resin layered productsEngineeringPressure sensitive

Provided is a double-sided pressure-sensitive adhesive sheet with release sheets, which is not charged with static electricity even when wound, cut, or stacked, more specifically, a sheet which comprises a pressure-sensitive adhesive layer and two release sheets provided on both surfaces thereof, wherein the surface on the pressure-sensitive-adhesive-layer side of at least one release sheet and the surface on the non-pressure-sensitive-adhesive-layer side of at least one release sheet are configured so as to exhibit electroconductivity.

Owner:MITSUBISHI PLASTICS INC

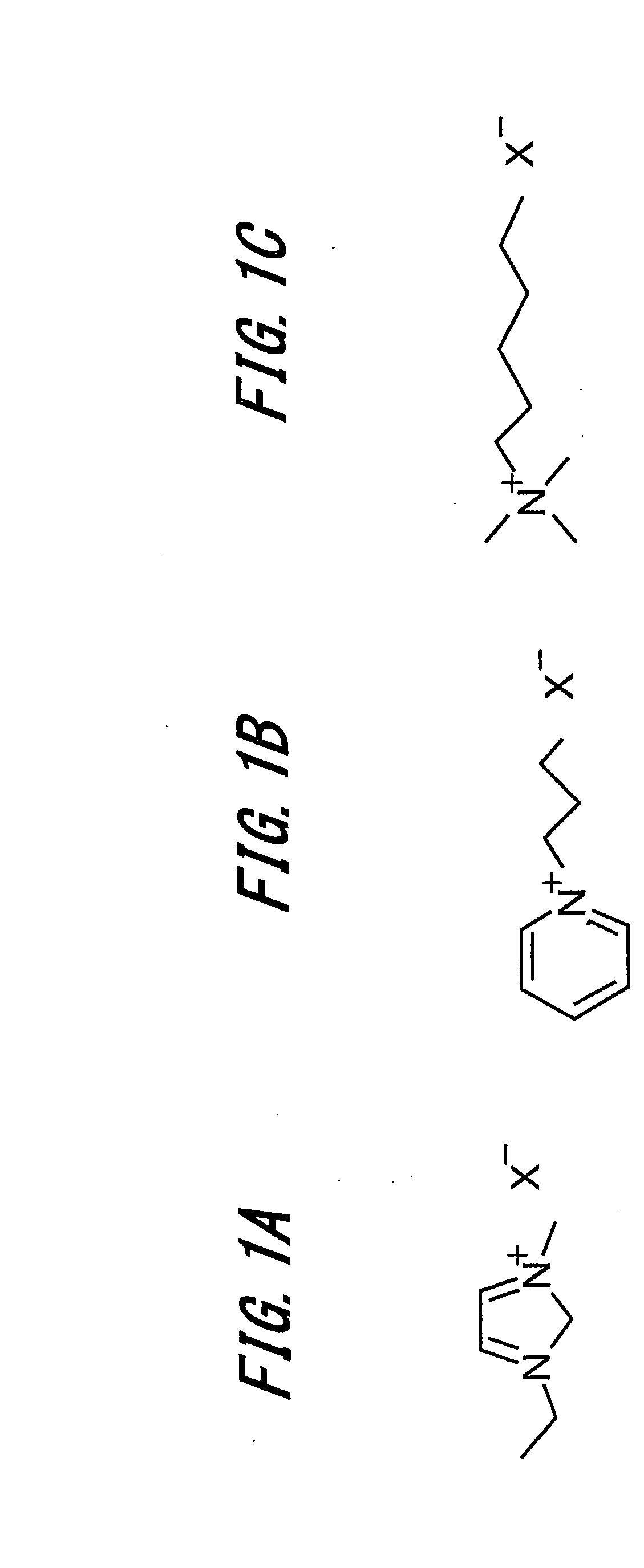

Electromagnetic-wave suppressing material, electromagnetic-wave suppressing device, and electronic apparatus

InactiveUS20090175021A1Good chemical stabilityExcellent in nonflammabilityOther chemical processesMagnetic/electric field screeningIonic liquidElectron

An electromagnetic-wave suppressing material is provided. The electromagnetic-wave suppressing material includes an ionic liquid and nanometer-order particles mixed with the ionic liquid, where 10 wt % or more of the nanometer-order particles is mixed with respect to 100 wt % of the ionic liquid.

Owner:SONY CORP

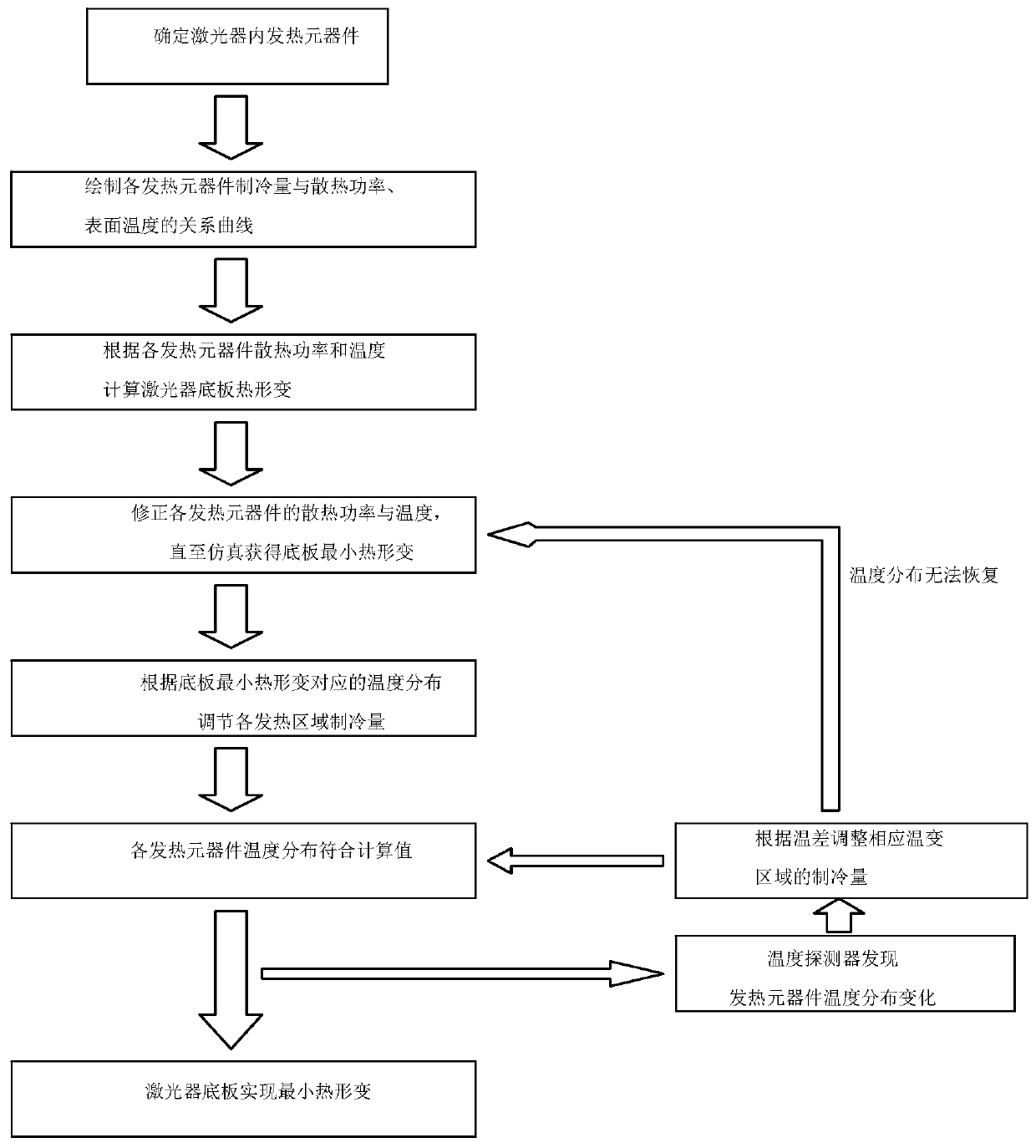

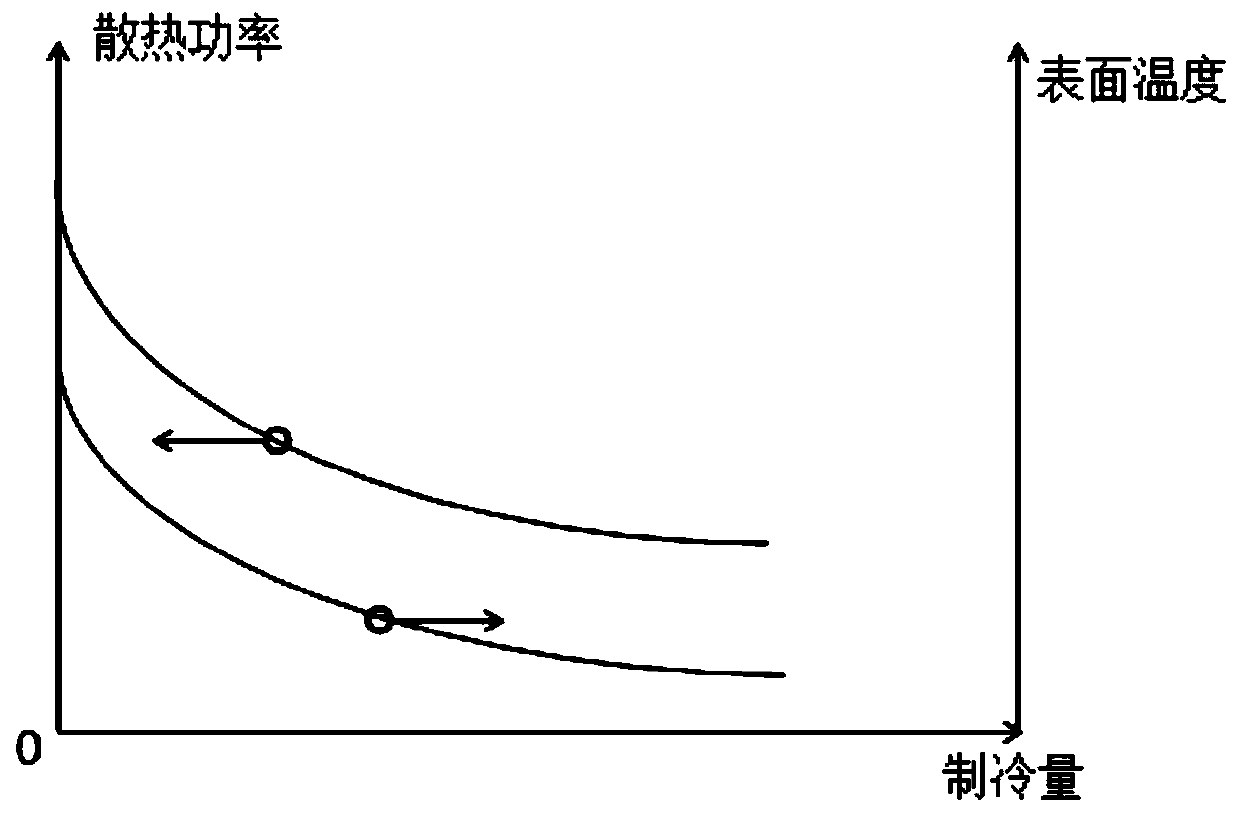

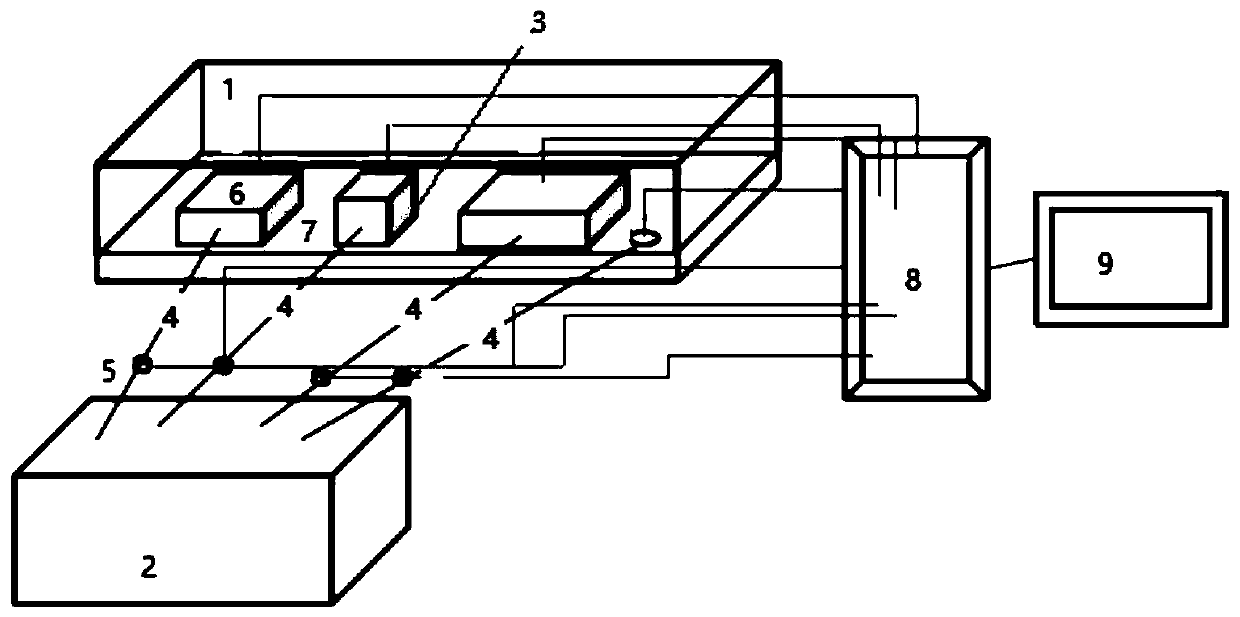

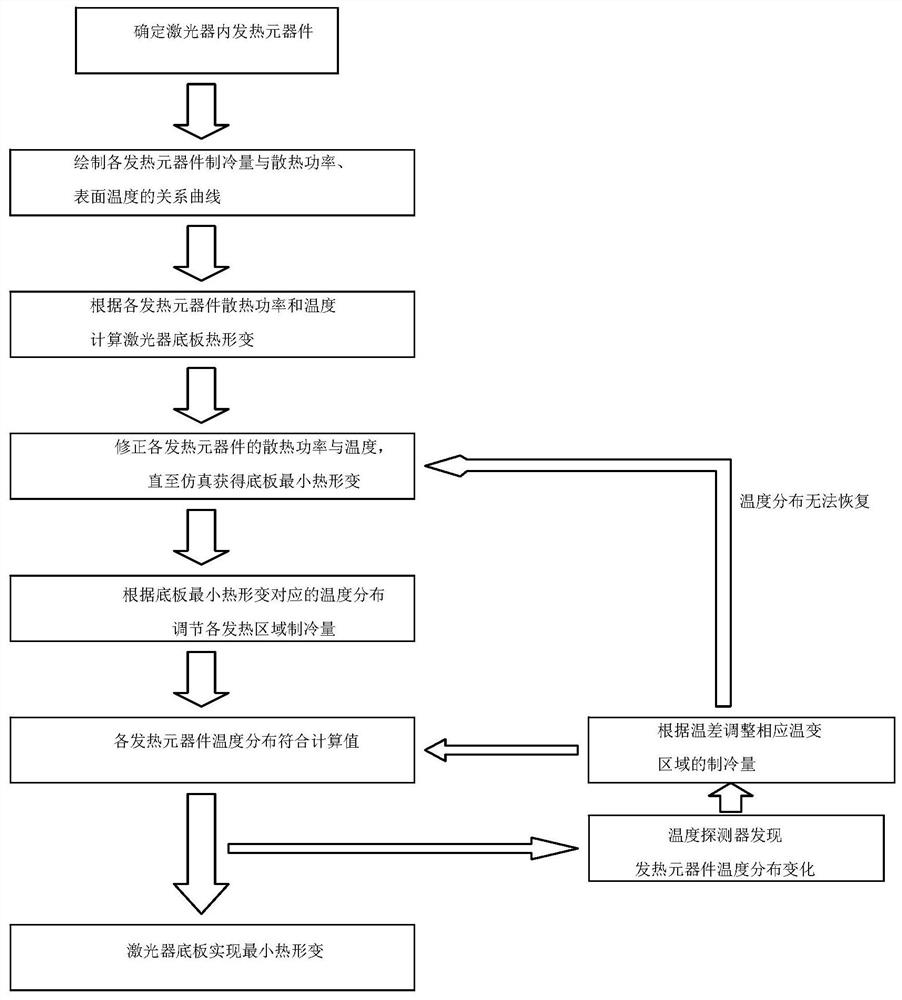

Method for realizing stable output of laser device, and laser device system

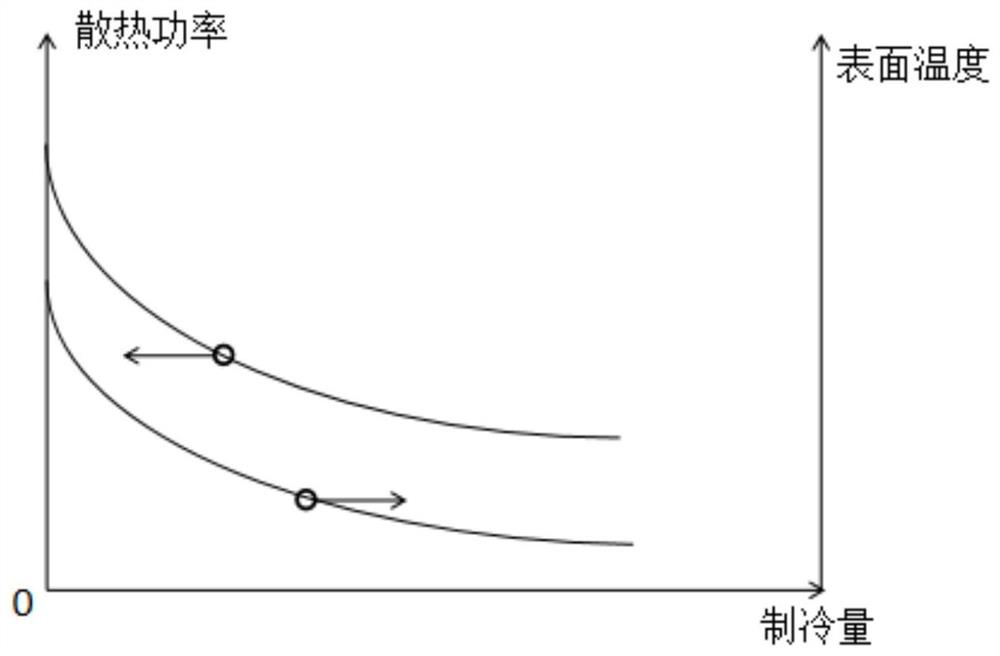

ActiveCN111509551AImprove output laser stabilityImprove reliabilityLaser cooling arrangementsLight beamErbium lasers

The invention discloses a method for realizing stable output of a laser device, and a laser device system. According to the invention, the heat regenerating condition of each heat regenerating component in a laser device is calculated through measurement and analysis, the refrigerating capacity required to be kept in the optimal working state of the laser device is simulated, and the temperature of each heat regenerating component in the laser device is detected in real time while the refrigerating capacity of each heat regenerating component in the laser device in a cooling scheme is corrected in time according to the comparison of the detected real-time temperature and the temperature in an optimal cooling scheme, so that the purpose of finally realizing the optical-mechanical heat balance of the laser device starting from the global domain is achieved. With the method and the system, the laser device has the product performances of strong environment self-adaptive capability, good output light beam quality and excellent long-time working stability.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

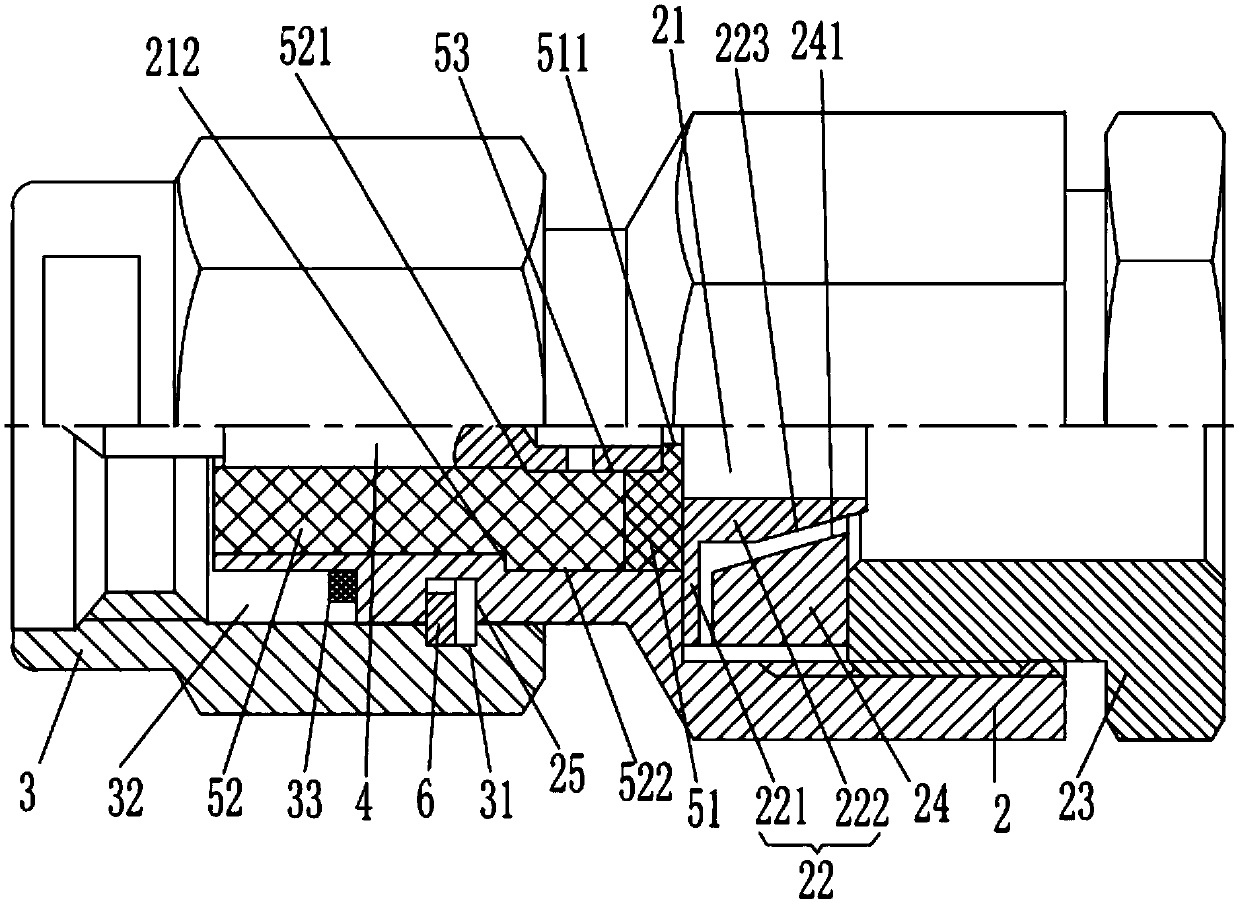

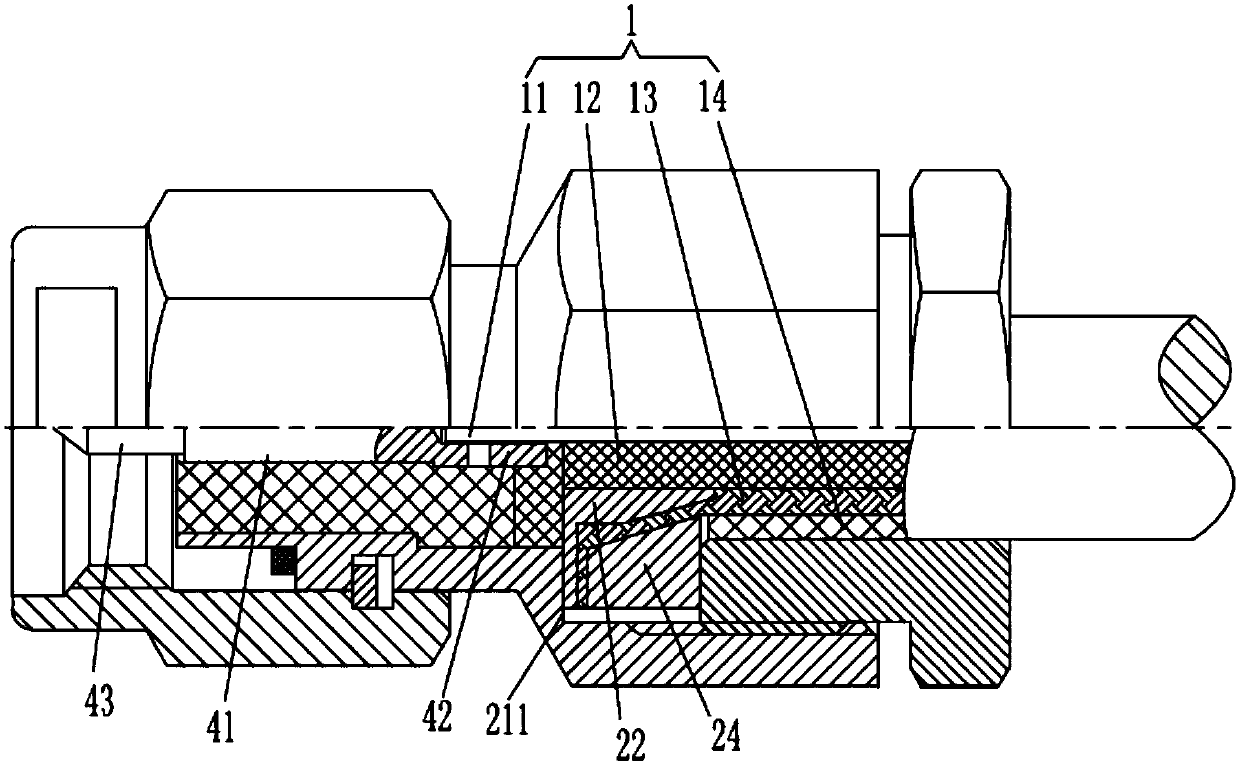

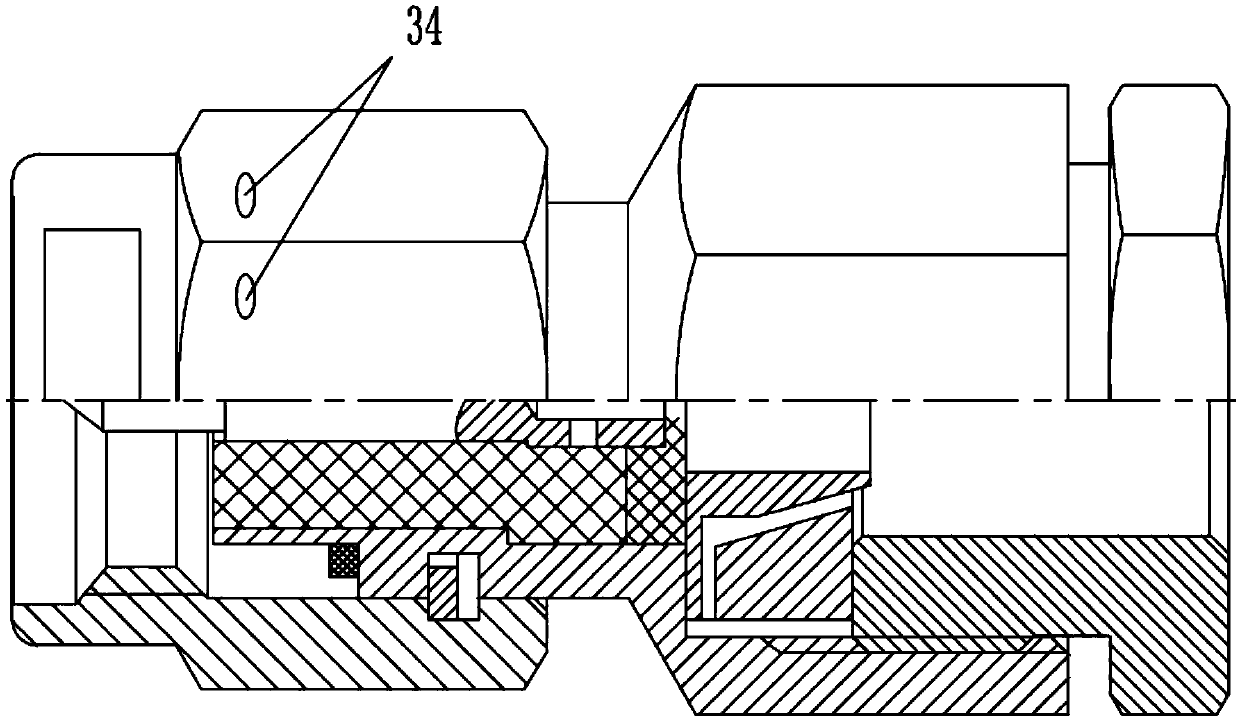

SMA type radio frequency coaxial connector with novel structure

PendingCN110299633AGuaranteed interface sizeStable and reliable signal transmissionRelieving strain on wire connectionSecuring/insulating coupling contact membersRelative displacementElectrical conductor

The invention discloses an SMA type radio frequency coaxial connector with a novel structure. The SMA type radio frequency coaxial connector comprises a casing for connecting a cable and a connectingscrew which sleeves an outer side of a front end of the casing. The casing is provided with a threading hole penetrating through the front and the back of the casing, an insulator is engaged at a front end of the threading hole, an inner conductor is engaged in the insulator, a bushing and a screw are orderly set from the inside to the outside at a back end of the threading hole, a front end of the bushing abuts against the insulator, a back end outer side of the bushing is sleeved with a pressing sleeve, and the bushing, the pressing sleeve and the insulator are pressed in the threading holeby screws. The SMA type radio frequency coaxial connector of the invention has the characteristics of compact structure and convenient installation, that an inner conductor does not have relative displacement when the connector is assembled into a cable component to be used and tested can be ensured, and the reliable signal transmission is ensured.

Owner:CHANGZHOU WUJIN FENGSHI COMM EQUIP

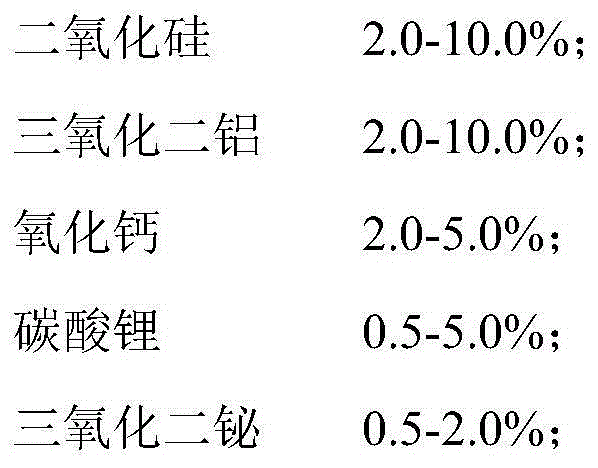

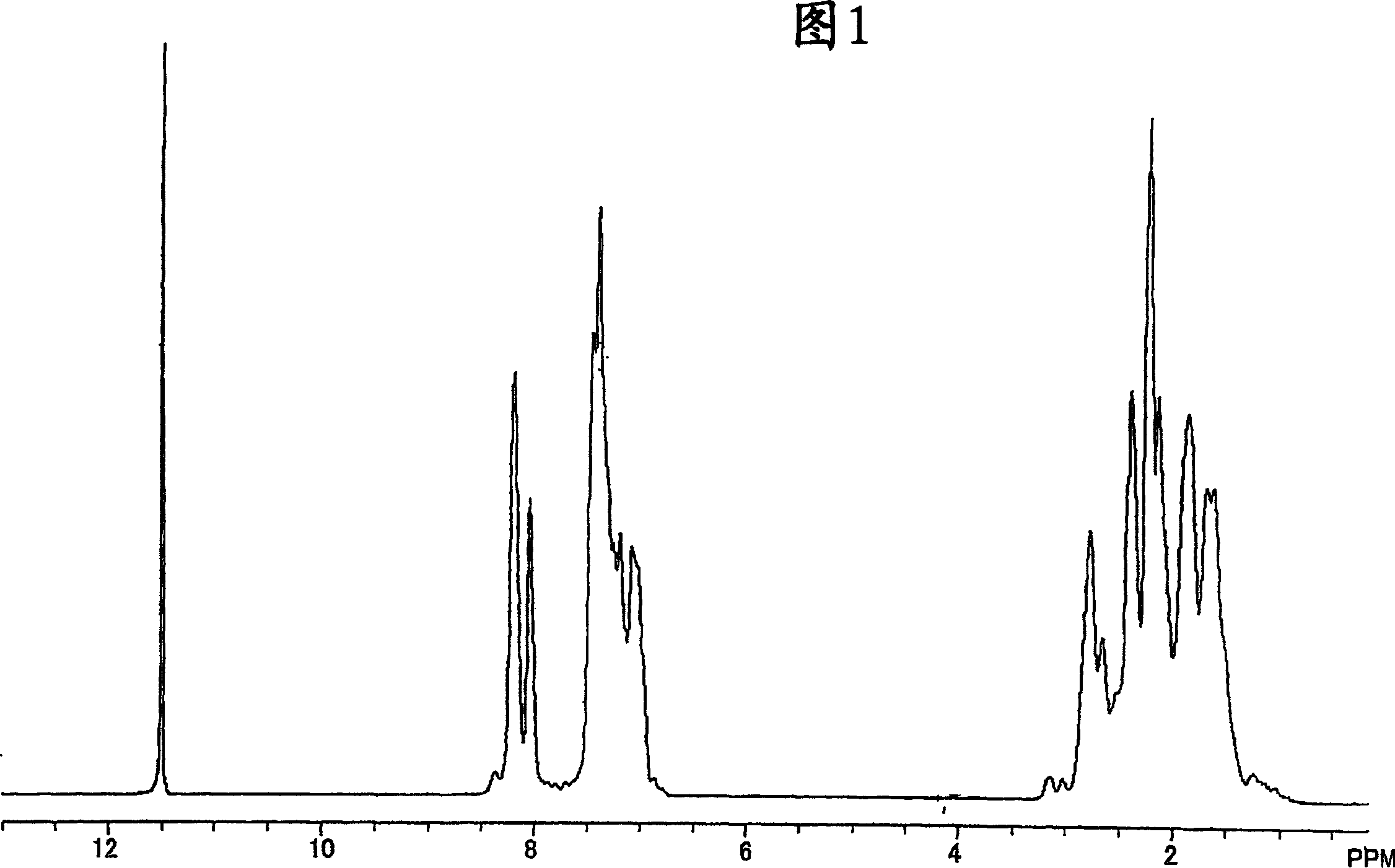

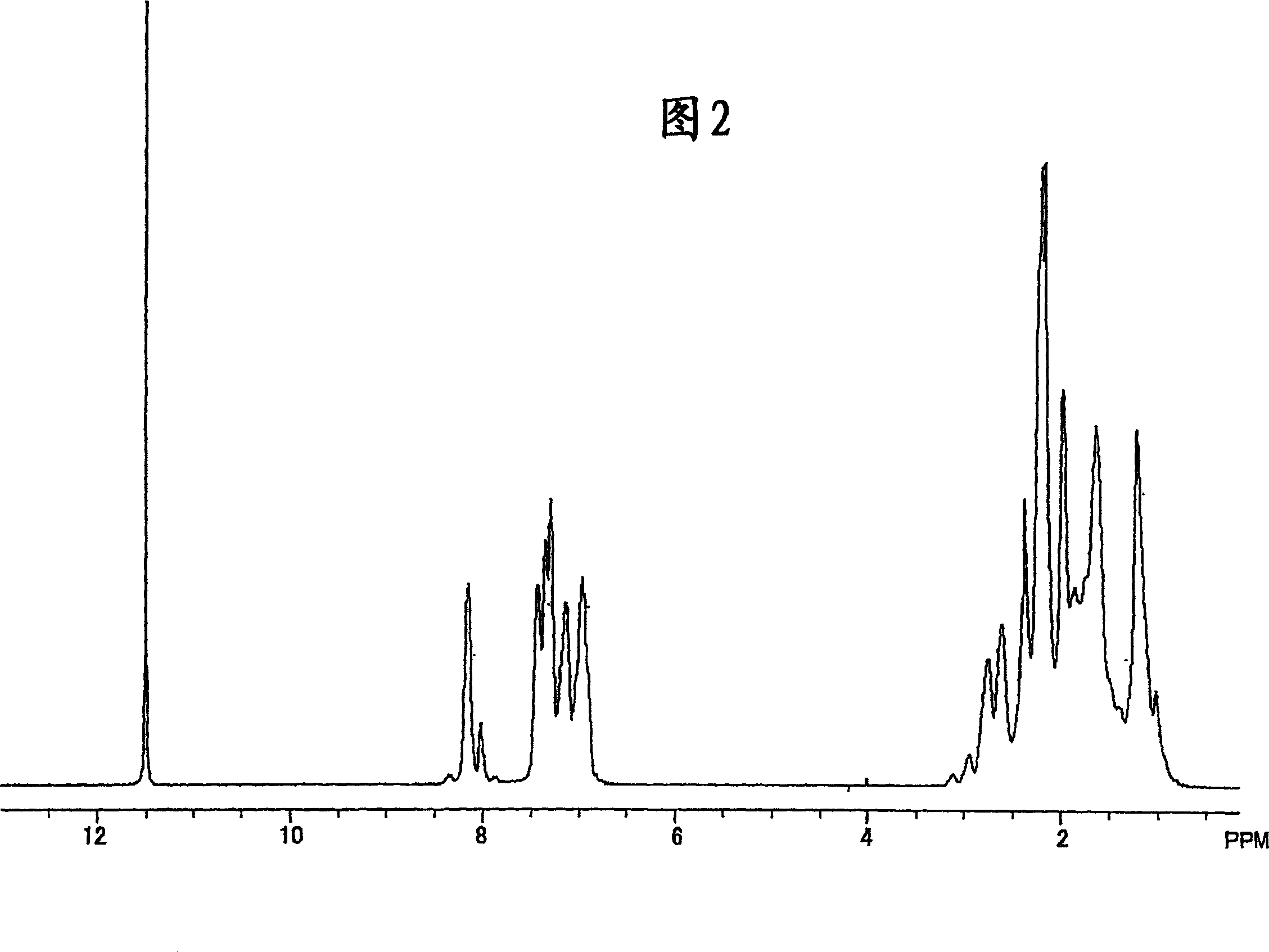

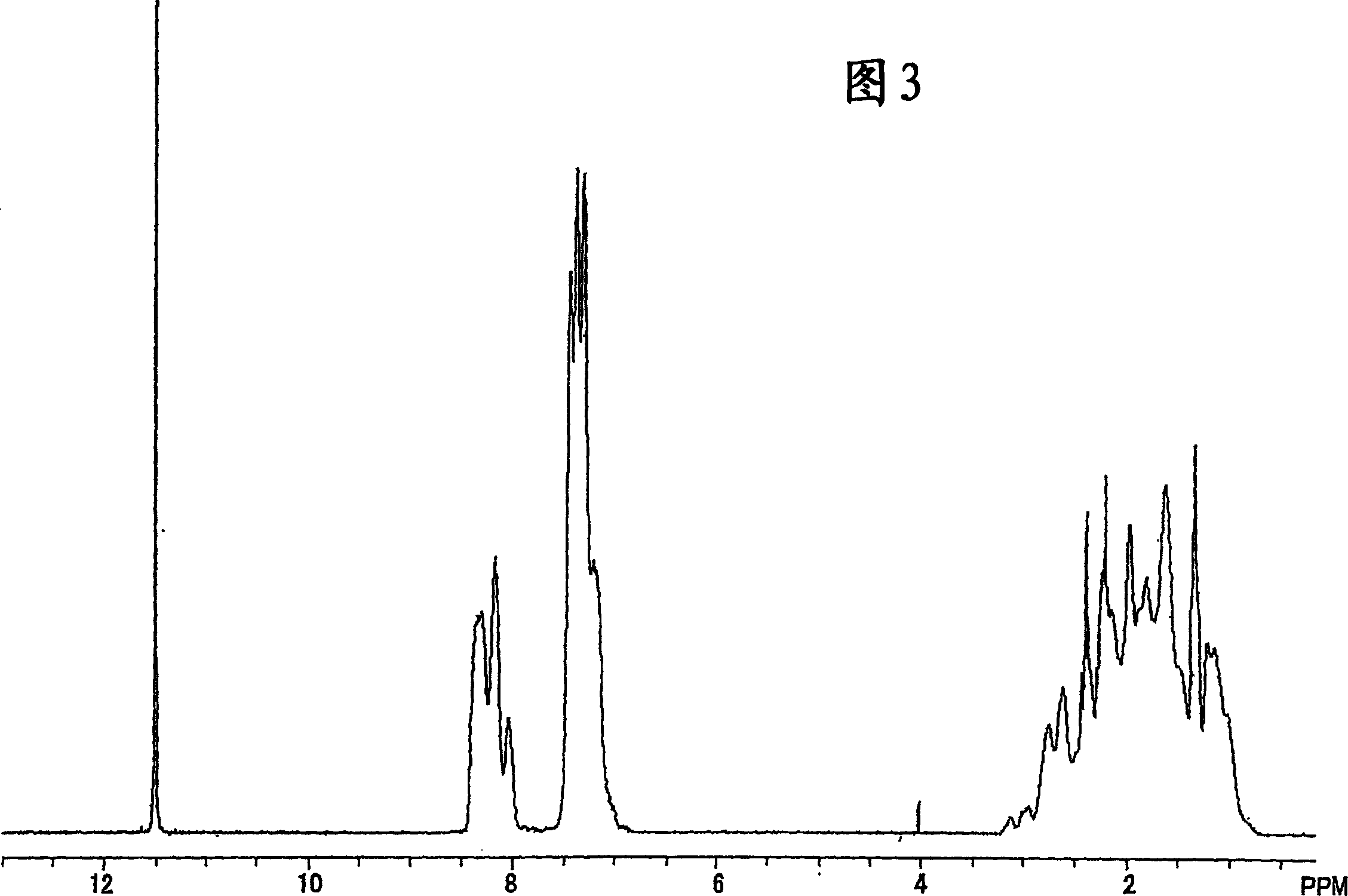

Method for preparing chip ceramic PTC thermistor surface protection layer

ActiveCN104529434AImprove environmental reliabilityImprove welding reliabilityBarium titanateAdhesive

The invention discloses a method for preparing a chip ceramic PTC thermistor surface protection layer. The method comprises the following steps: S1. mixing and ball-milling inorganic powder, an organic solvent and a dispersing agent according to a proportion of 100: (60-100): (0.6-1) to obtain a slurry precursor used for preparing the surface protection layer, wherein the inorganic powder comprises 70.0-90.0% of barium titanate, 2.0-10.0% of silicon dioxide, 2.0-10.0% of aluminum oxide, 2.0-5.0% of calcium oxide, 0.5-5.0% of lithium carbonate and 0.5-2.0% of bismuth trioxide; S2. adding an adhesive into the slurry precursor for mixing and ball-milling to obtain protection layer slurry, wherein the mass ratio of the adhesive to the inorganic powder is (6-10):100; S3. coating the protection layer slurry on the surface of a chip ceramic PTC thermistor blank, and sintering the chip ceramic PTC thermistor blank coated with the protection layer slurry at 1150-1250 DEG C to obtain the surface protection layer which is dense, high in insulation resistance and resistant to acid and alkali and is suitable for subsequent plating treatment of chip ceramic PTC.

Owner:SHENZHEN SUNLORD ELECTRONICS

Optical film and liquid crystal display device

InactiveCN1759334AHigh strengthImprove environmental reliabilityPolarising elementsNon-linear opticsBenzoic acidPolyester

The present invention relates to an optical film wherein fixing of liquid crystal alignment can be easily accomplished, which optical film can realize a wavelength dispersion of low birefringence and from the industrial point of view, is inexpensive and can be easily produced. The optical film enables accurate regulation of optical characteristics, such as wavelength dispersion of birefringence, to desired value and enables fixing of desired alignment state, being uniform and able to attain area expansion. In particular, an optical film comprising a polyester comprising structural units derived from 4-(4-carboxycyclohexyl)benzoic acid and structural units derived from an aromatic diol compound of ortho form, wherein the state of alignment created at thermal aligning of the polyester is fixed by cooling to temperature of not above the glass transition temperature.

Owner:NIPPON OIL CO LTD

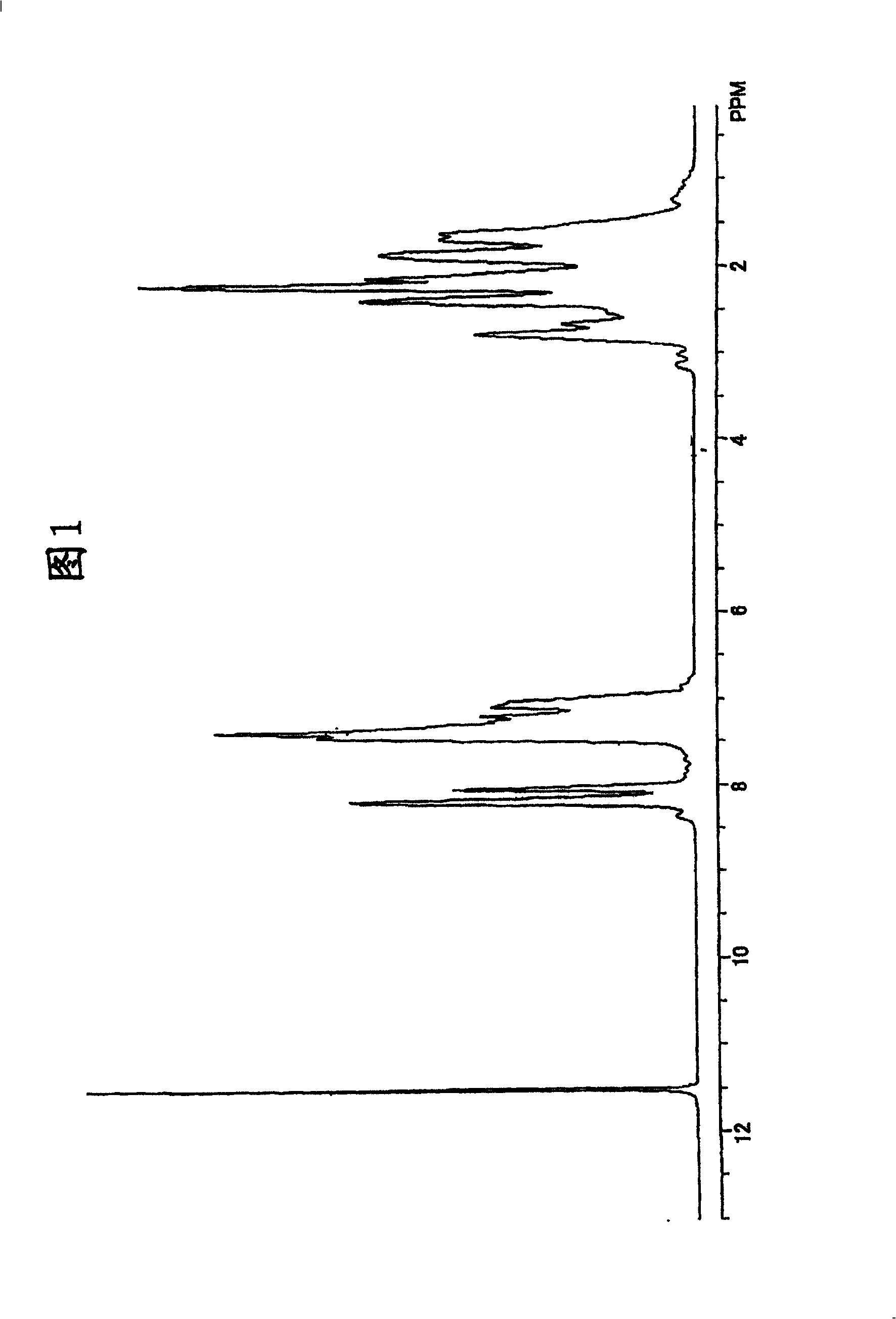

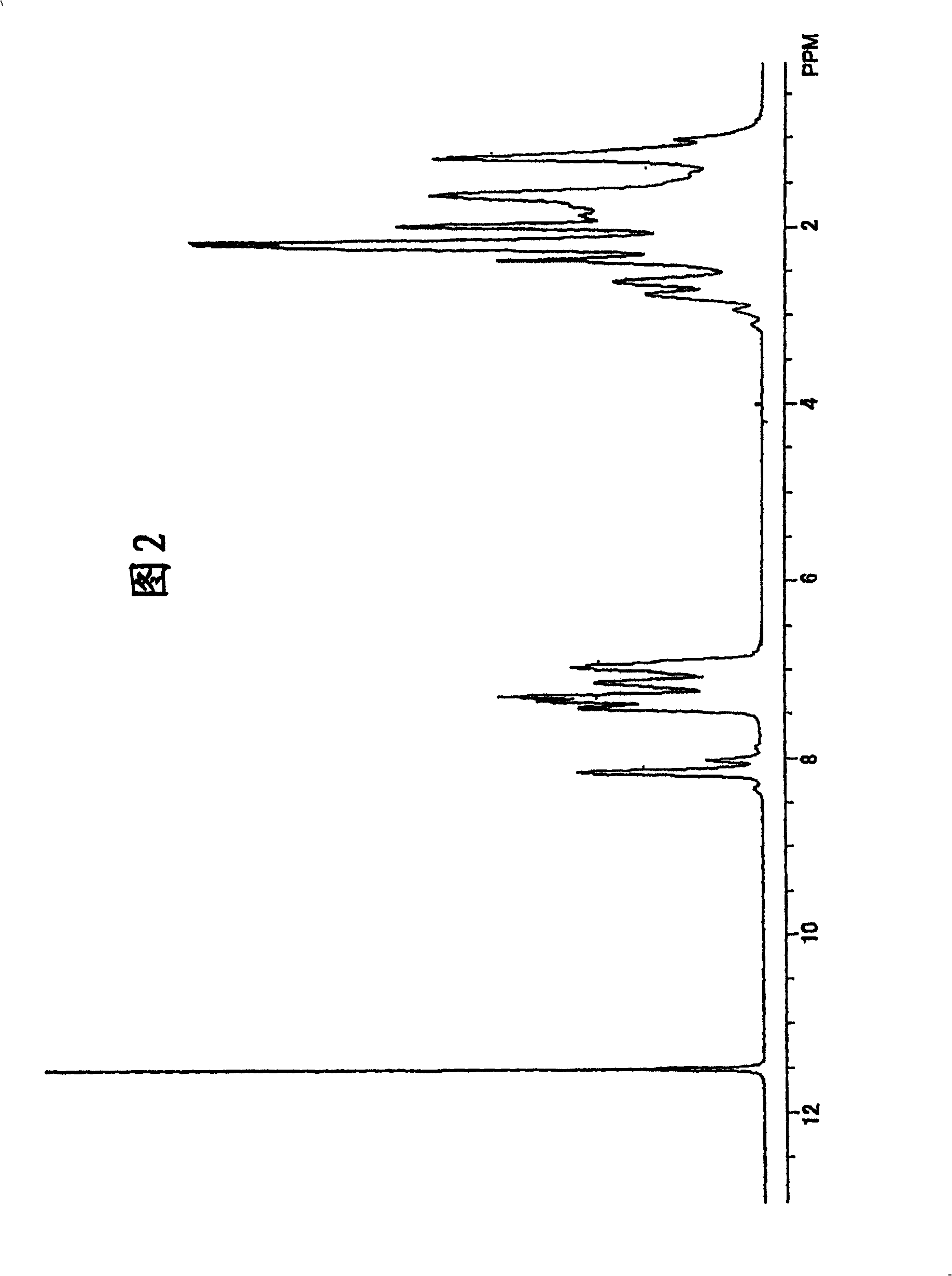

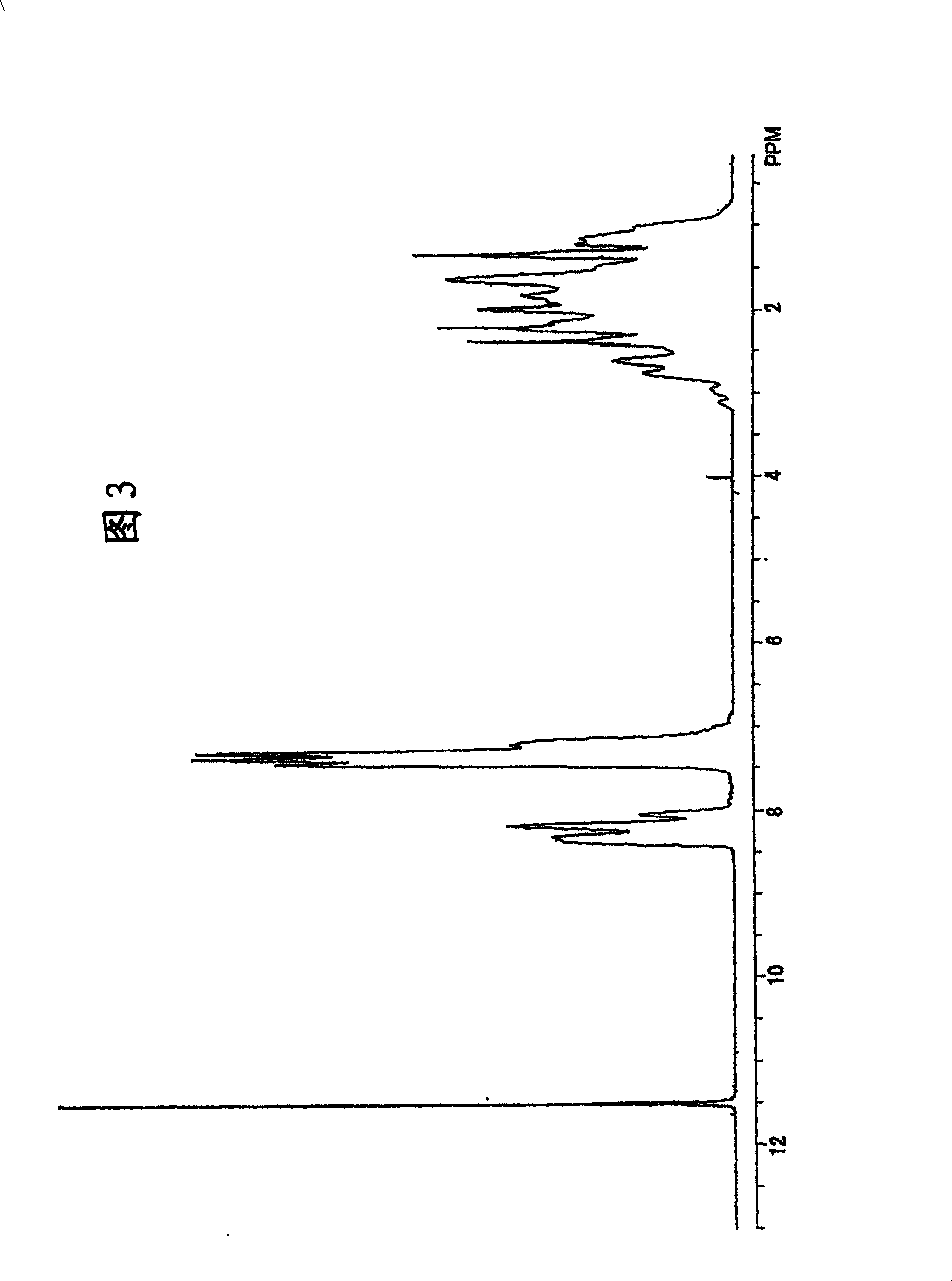

Optical information recording medium and recording/reproducing method therefor

ActiveUS8389098B2Improve responseHigh sensitivityLayered productsPhotomechanical apparatusManufacturing cost reductionRecording layer

Owner:SONY CORP

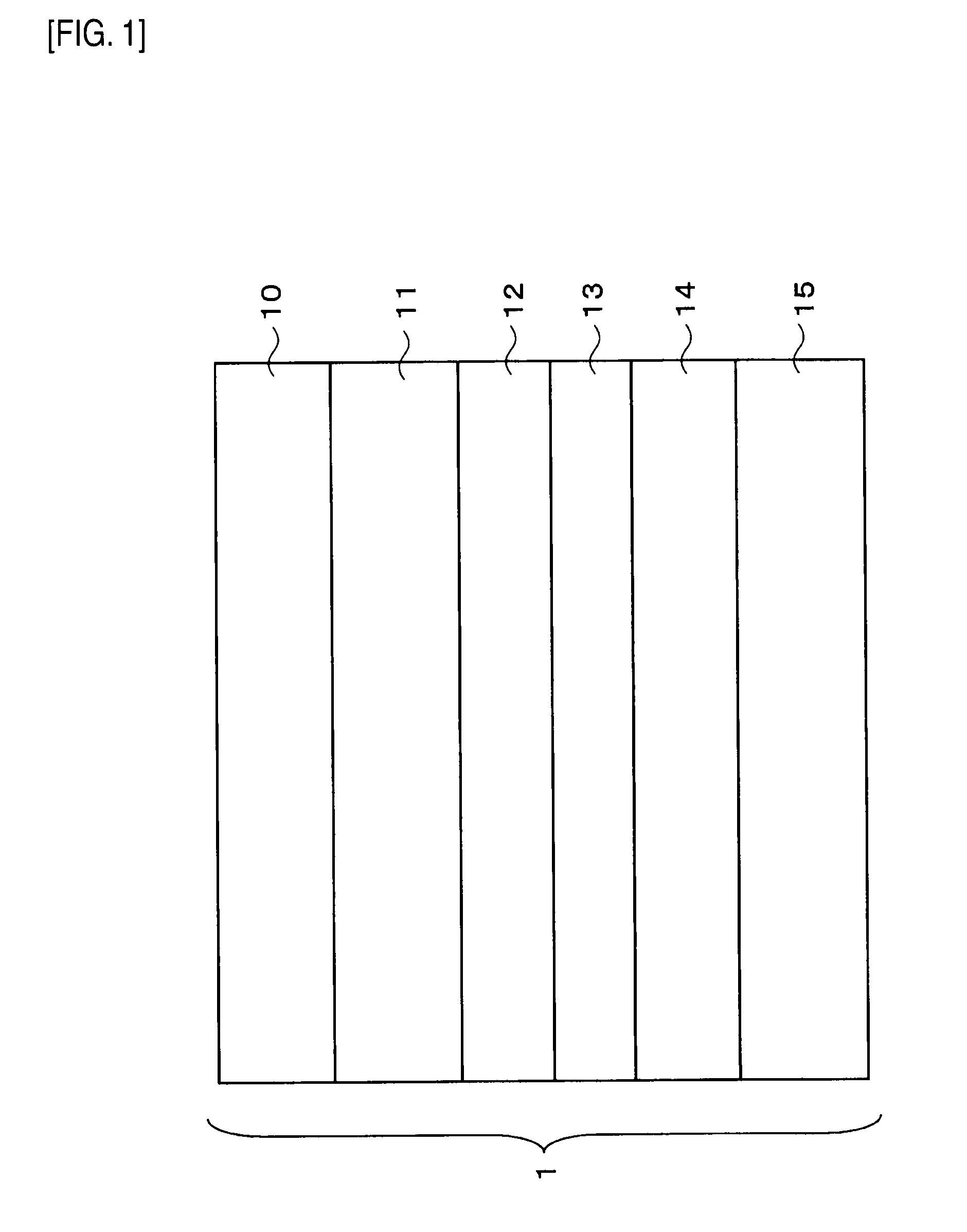

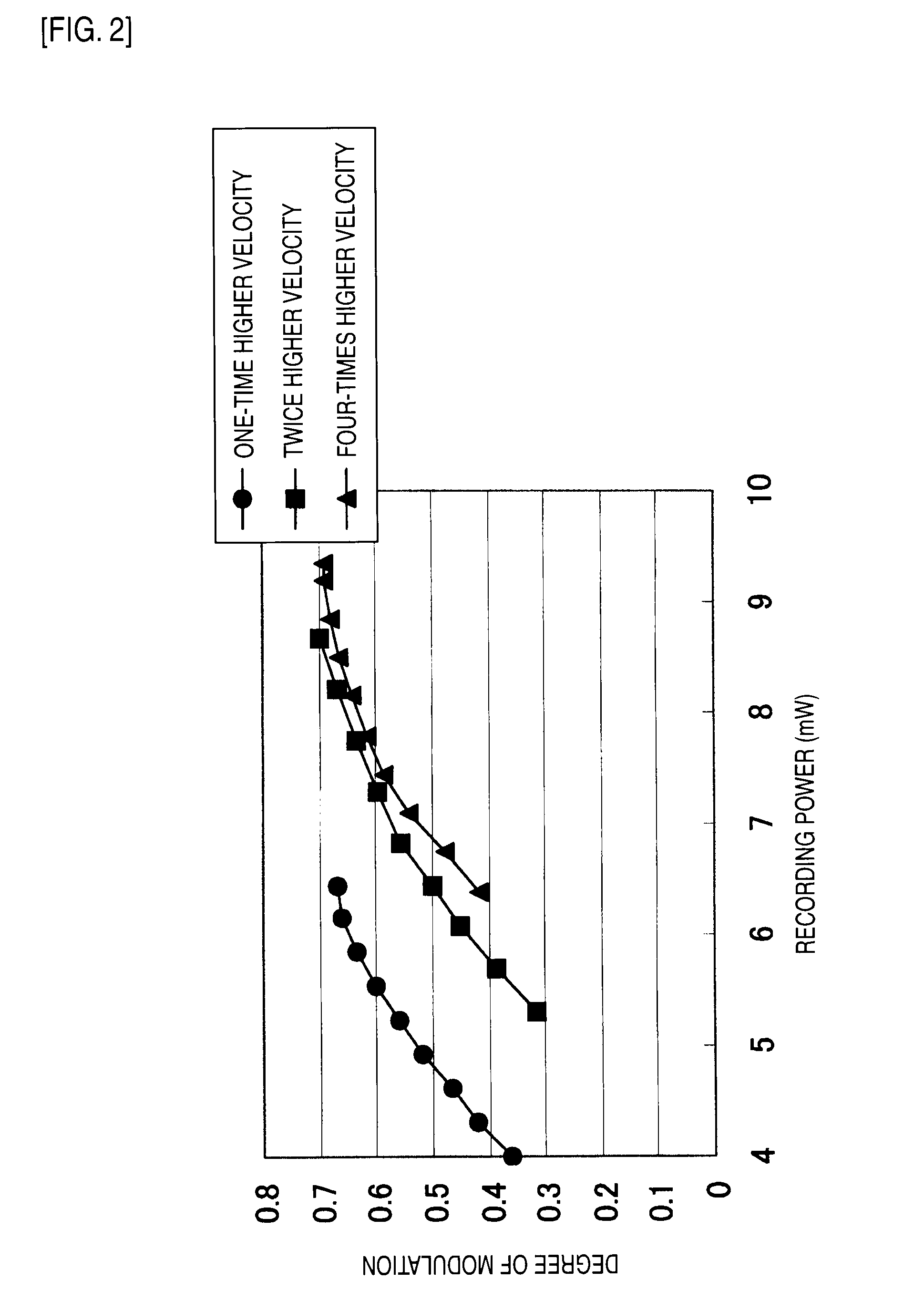

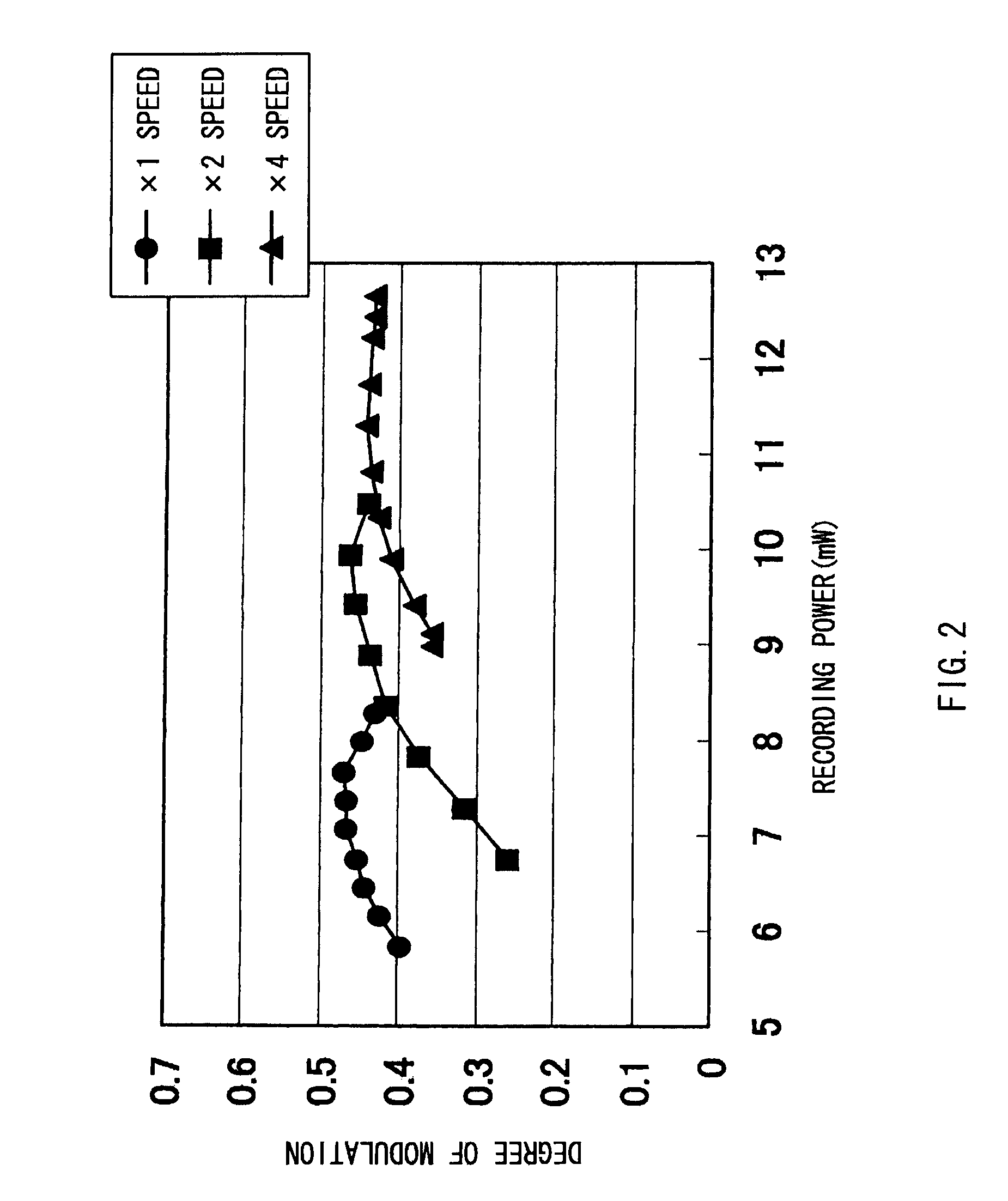

Optical information recording medium and recording/reproducing method therefor

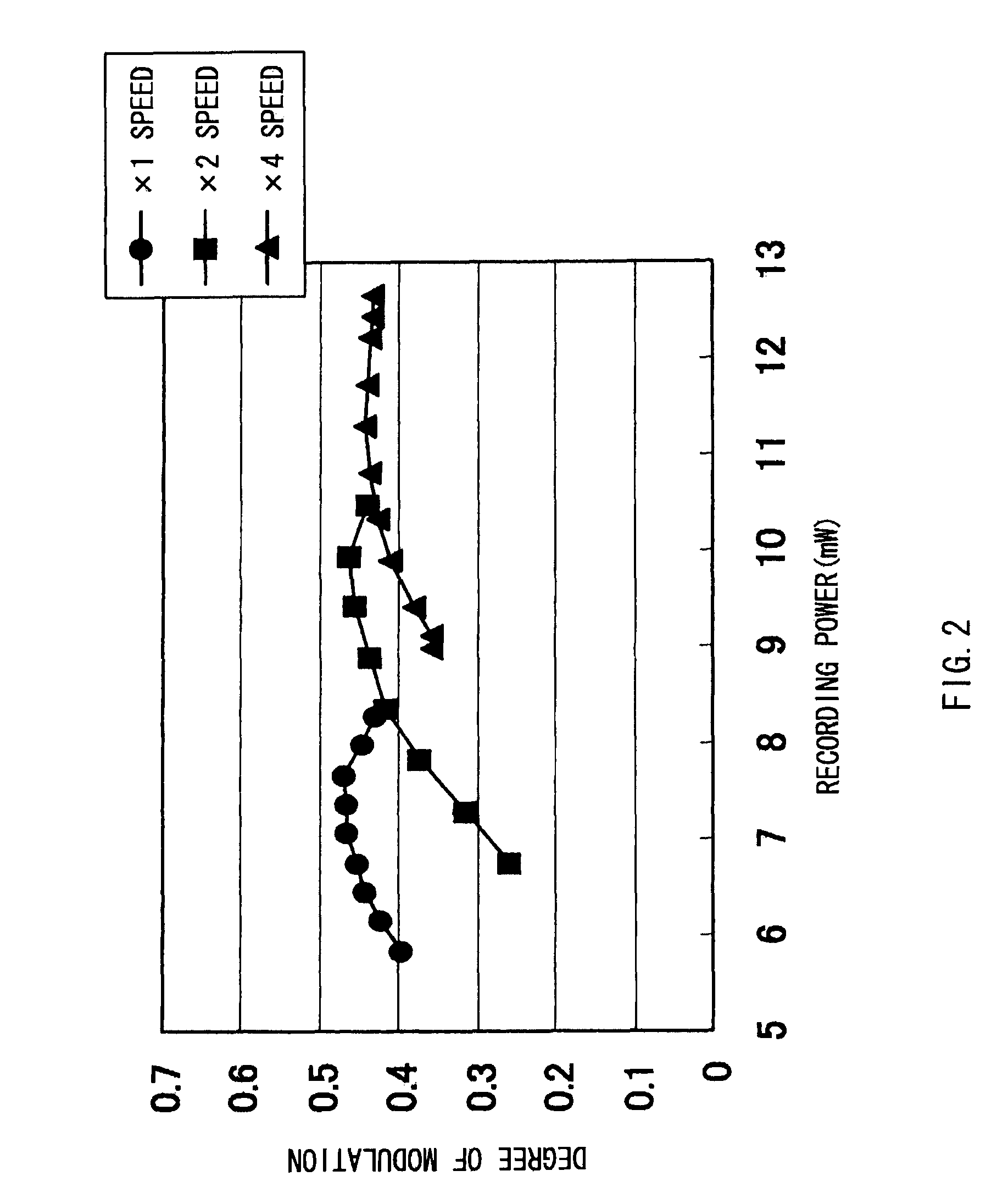

ActiveUS20100278032A1Improve responseHigh sensitivityMechanical record carriersRecord information storageInter layerRecording layer

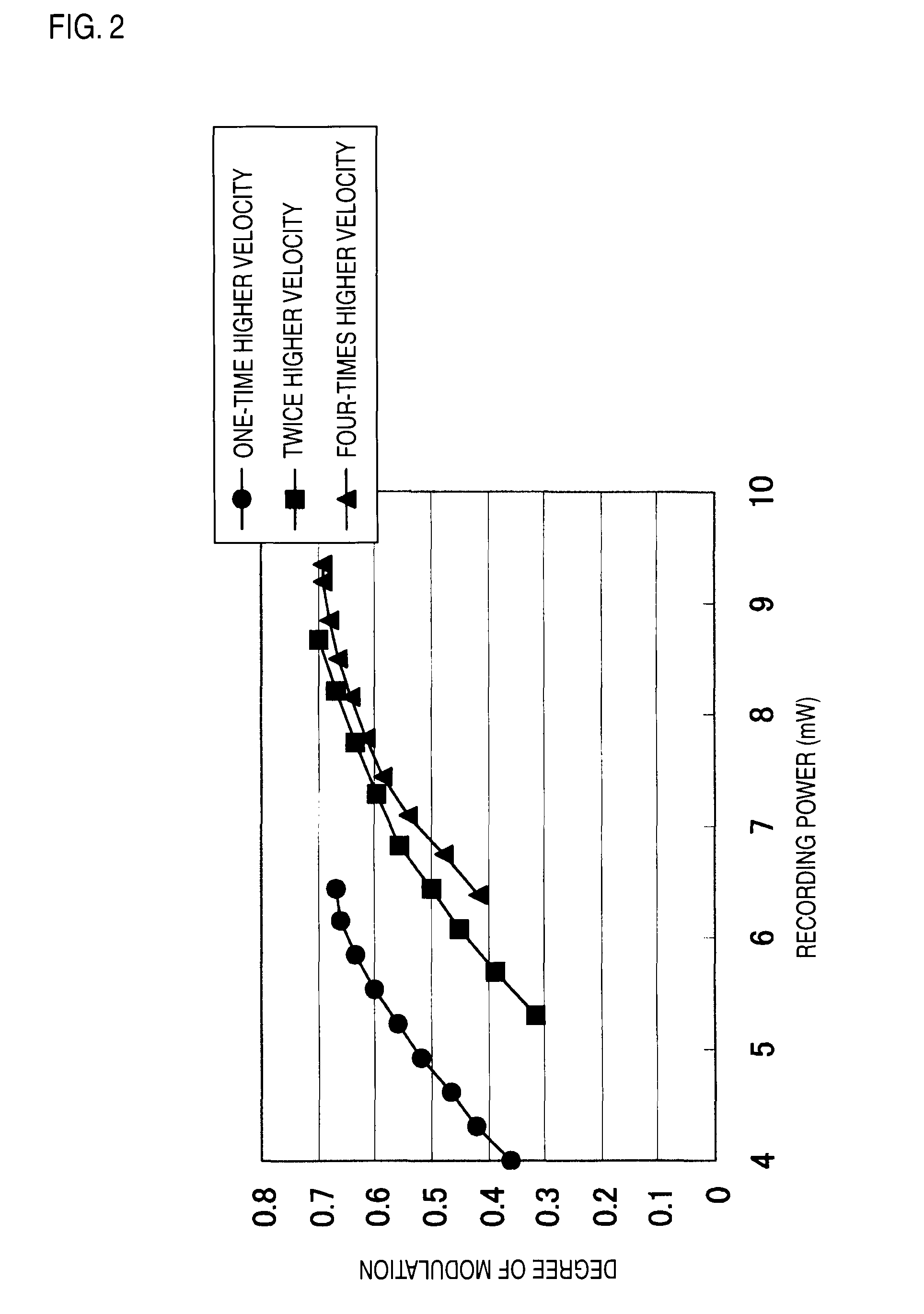

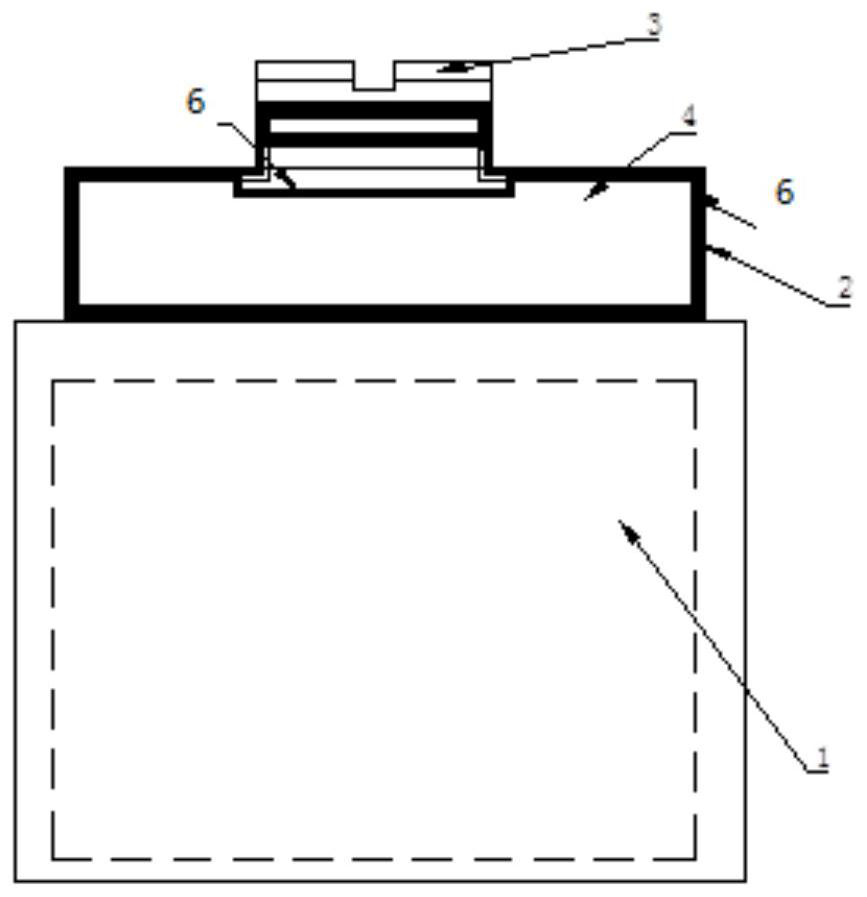

An optical information recording medium in which recorded information is stably stored for long time in the initial state, signals are not deteriorated by a laser beam for reproduction at the time of signal reproduction, the quality does not change in normal long-term storage, the write characteristic is held, a manufacturing cost is reduced, a margin in the manufacture process is assured, and excellent recording / reproducing characteristics are obtained in the wide range of linear speeds and recording powers is provided. An optical information recording medium 1 is formed by sequentially stacking a first information recording layer 11, an intermediate layer 12, a second information recording layer 13, and a protection layer 14 on a substrate 10. As a material of a recording layer 13b of the second information recording layer 13, a material having a composition expressed by [(ZnS)x(SiO2)1-x]y(SbzX1-z)1-y (where 0<x≦1.0, 0.3≦y≦0.7, 0.8≦z≦1.0, and X is at least one element selected from the group consisting of Ga, Te, V, Si, Zn, Ta, Sn, and Tb) is used.

Owner:SONY CORP

Method for improving circuitboard welding quality and air knife device therefor

InactiveCN100479634CIncrease spray volumeReduce ion residuePrinted circuit assemblingCleaning using gasesMetallurgySolderability

This invention discloses a method for improving solder quality of CB and a device, in which, the method includes: spraying scaling powder on the CB, blowing the scaling powder on the lower surface of the CB in the through--ole of the CB to increase the coating volume of the powder in the through-hole and wash out the OSP coating of the hole wall to increase the solder ability of the hole, removing the scaling powder coated on the solder resistant film of the lower surface of the CB to reduce residual ions of the welded CB, preheating the CB welding the CB by a wave crest welder.

Owner:HUAWEI TECH CO LTD

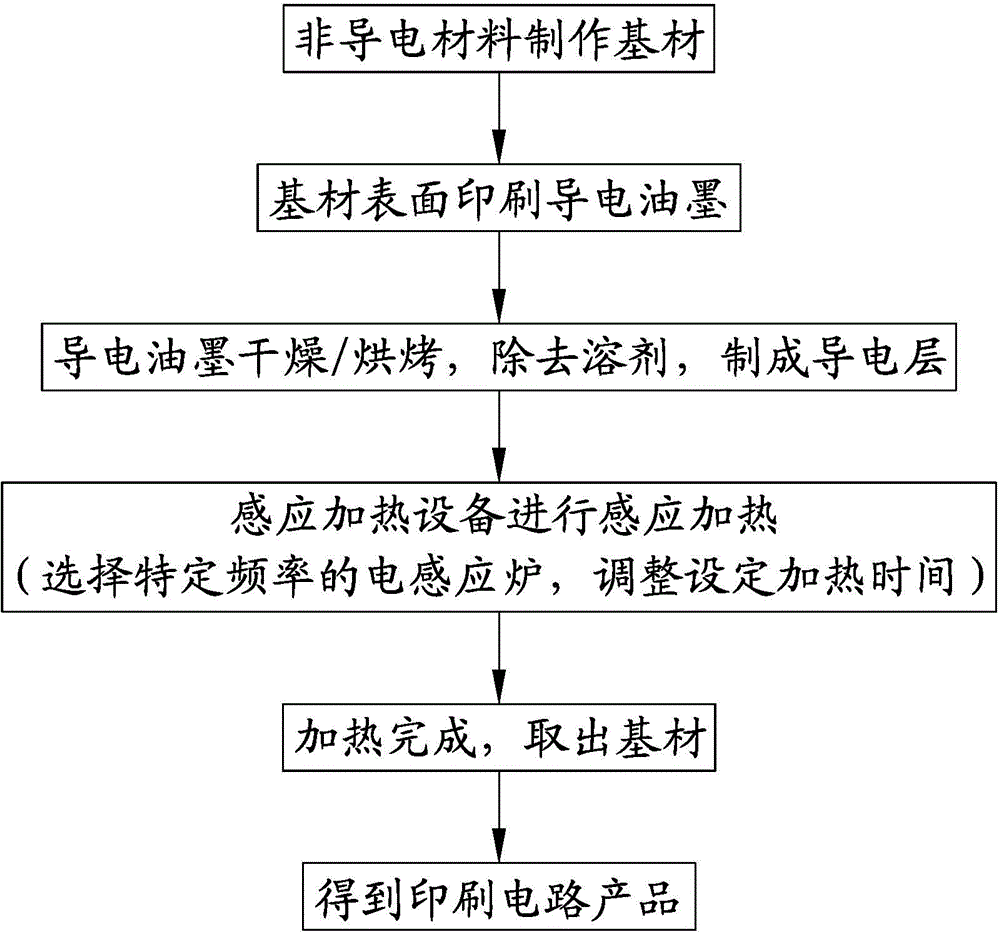

Selective sintering process of printed circuit

InactiveCN104582283AImprove conductivitySolve the deformationPrinted circuit manufactureHeating timeEngineering

The invention discloses a selective sintering process of a printed circuit. A non-conducting material is selected for manufacturing a base material; the surface of the base material is covered with conducting ink through a printing process; the base material covered with the conducting ink is placed aside so as to remove a solvent in the conducting ink after the conducting ink is dried, or the base material covered with the conducting ink is placed in a baking furnace to be baked at a temperature lower than the softening temperature or denaturation temperature of the base material so as to remove the solvent in the conducting ink; induction heating equipment is used for carrying out induction heating on the base material which has been dried or baked at the low temperature, namely, the base material which has been dried or baked at the low temperature is placed near an induction coil, an electric induction furnace of a specific frequency is selected according to the base material and the conducting ink material, power is adjusted, heating time is set, and heating is carried out; after heating is completed, the printed circuit product can be obtained. By means of the process, selective heating of the printed circuit is achieved, namely, heating is only carried out on the conducting material but not the non-conducting base material, and therefore high-temperature sintering of the printed circuit is achieved, and good electric conductivity is achieved.

Owner:XIAMEN PINGDA TRADING CO LTD

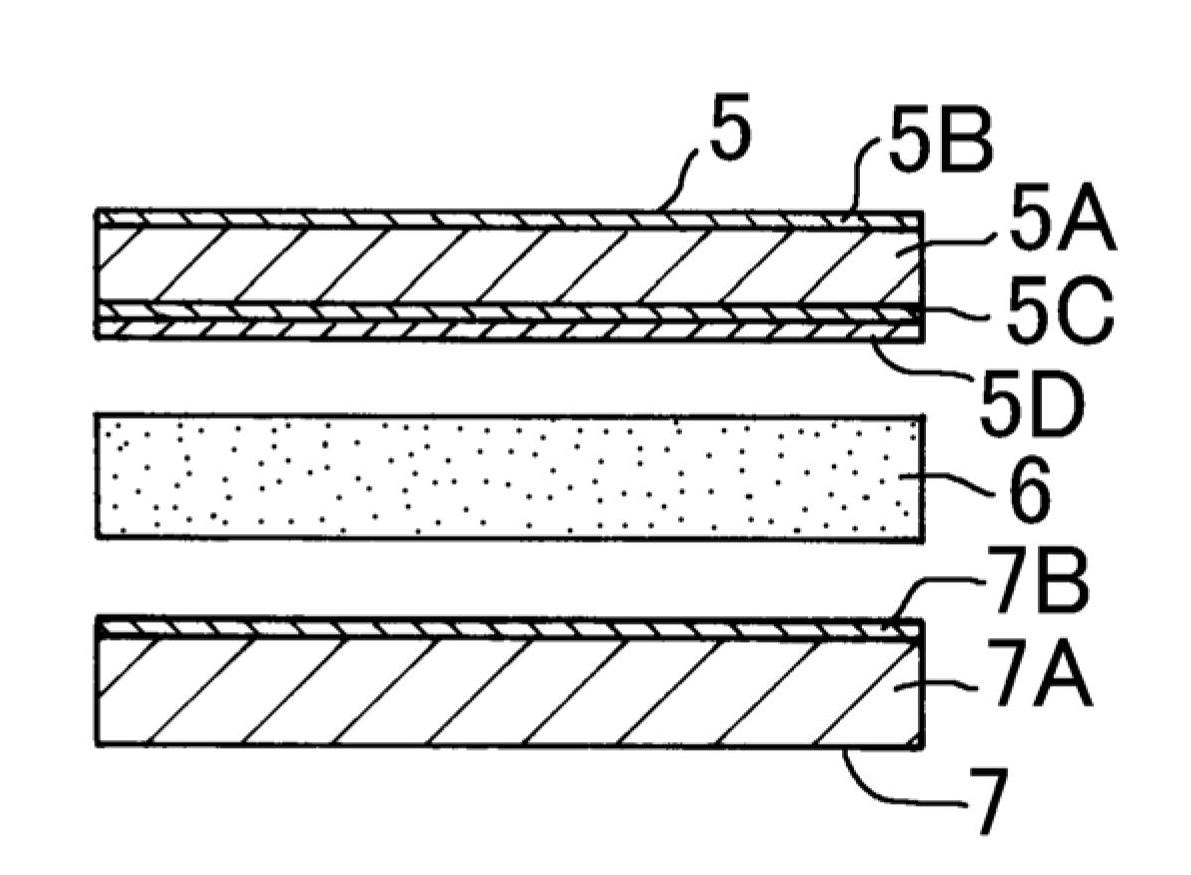

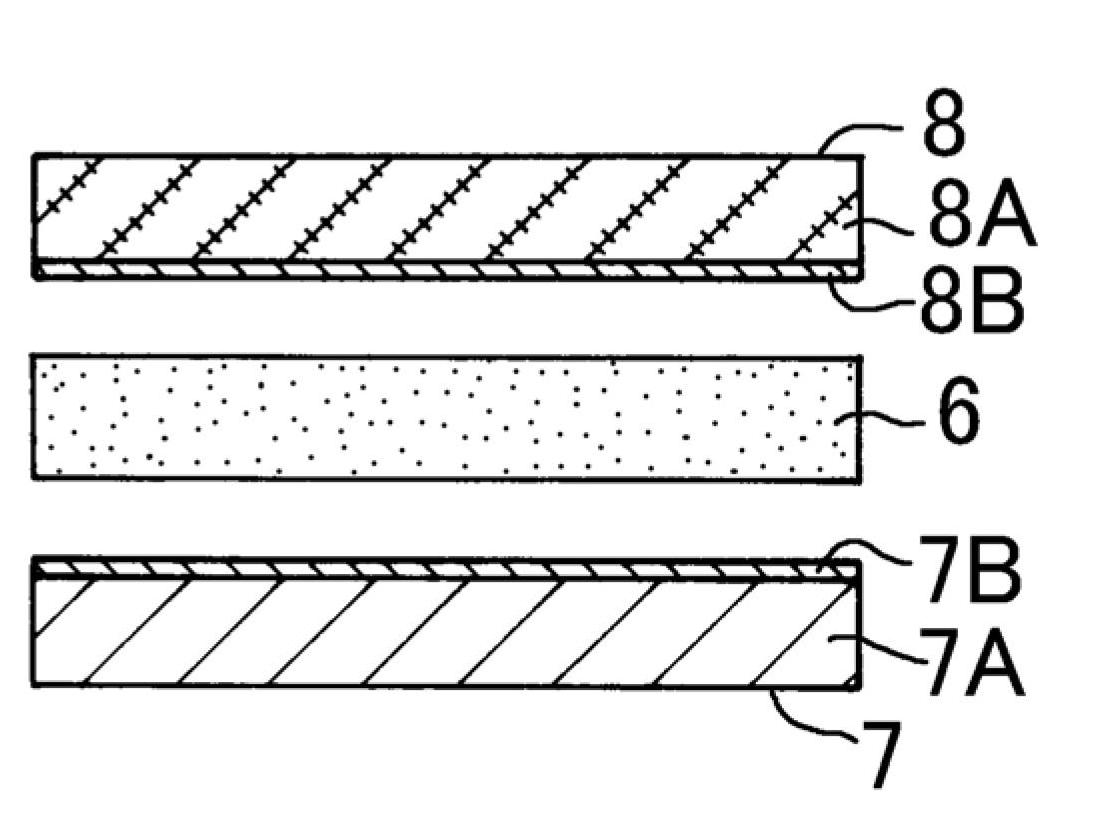

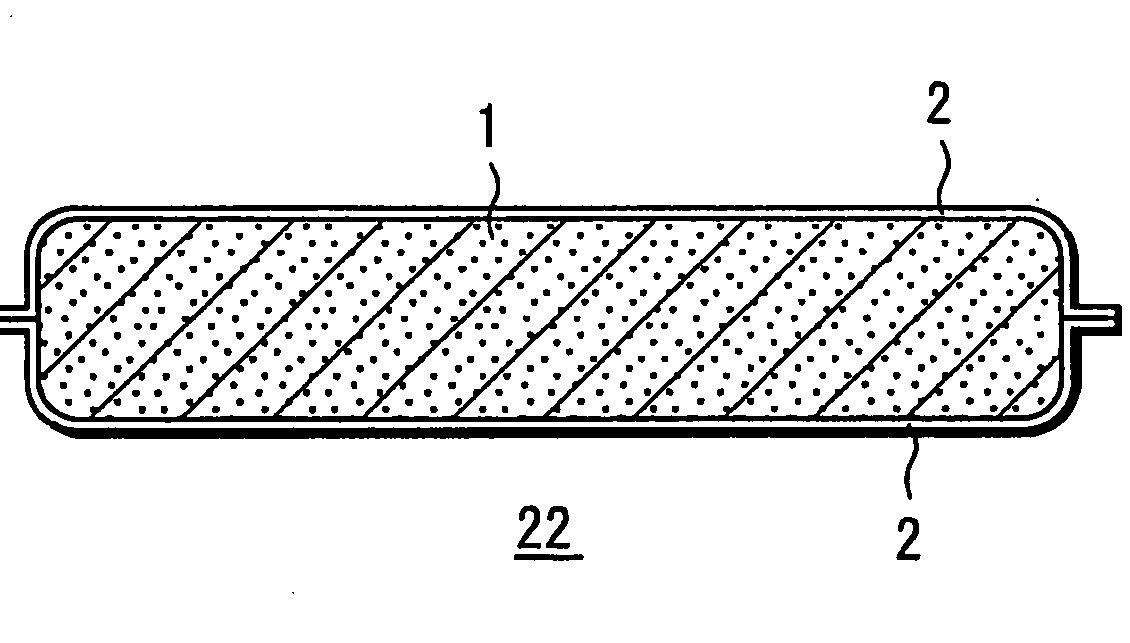

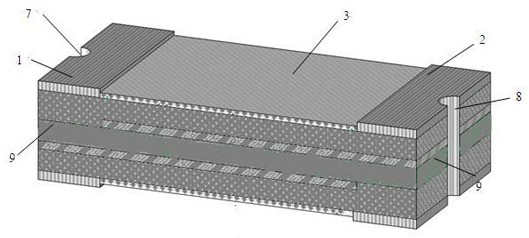

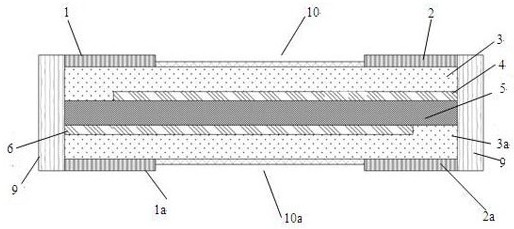

Low-resistance high-reproducibility PTC over-current protection element

PendingCN113674937AEnhanced environmental reliabilityImprove environmental reliabilityCurrent responsive resistorsPositive temperature coefficient thermistorsChemistryElectrical connection

The invention relates to a low-resistance high-reproducibility PTC over-current protection element, which has a function of effectively improving the environmental reliability of a product and is a low-resistance surface-mounted polymer PTC over-current protection element mainly made of a polymer PTC composite sheet and having excellent environmental stability. The side surface of theprotection element, or the side surface and the front surface of the protection element is provided with a coating layer or a plating layer, so that the conductive composite material base layer is isolated from the external environment. The low-resistance high-reproducibility PTC over-current protection element has the following characteristics that 1, any combination surface of the four side surfaces of the element is coated with a coating layer or a plating layer, and one front surface can be coated with or not coated with the coating layer, so that the polymer PTC composite sheet of the element is isolated from the environment, and the resistance reproducibility of the product is improved; 2, the conductive holes playing a role in electrical connection are positioned on two sides of the element, so that the element has good welding performance; and 3, the structure of the existing product is not changed, and the existing assembly mode can be completely adopted.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

High-precision circuit board and manufacturing method thereof

InactiveCN110972391AHigh densityHigh graphic precisionPrinted circuit aspectsCircuit susbtrate materialsFlat glassLithography process

The invention discloses a high-precision circuit board and a manufacturing method thereof. The circuit board comprises a supporting bottom plate and a conductive circuit arranged on the supporting bottom plate, the supporting bottom plate is a polyimide film formed on a flat glass mother plate; the conductive circuit is a metal layer, the metal layer is provided with a pattern corresponding to theconductive circuit, and the forming conditions of the metal layer comprise that the supporting bottom plate is located on the flat glass mother plate, the metal layer is deposited on the supporting bottom plate in a magnetron sputtering mode, and the metal layer forms a pattern corresponding to the conductive circuit through a photoetching process. The polyimide film is formed on the flat glass mother board to serve as the supporting bottom plate, the supporting base plate is flatter and smoother, when the supporting base plate is located on the flat glass mother plate, the metal layer with very high uniformity is plated on the supporting base plate in the magnetron sputtering mode, the circuit precision can reach the level of 10 micrometers or above through patterning of the photoetchingprocess, and the circuit density can also be remarkably improved.

Owner:SHANTOU GOWORLD DISPLAY TECH CO LTD +1

Optical information recording medium and method of recording and/or reproducing therein

InactiveUS8758980B2Stable storageSimple manufacturing processLayered productsMechanical record carriersRecording layerComputer science

An optical information recording medium 1 is constructed by sequentially layering a reflective layer 11, a protective layer 12, a recording layer 13, a protective layer 14, and a light transmissive protective layer 15 on a substrate 10. As the recording layer 13, a recording layer containing ZnS, SiO2, and Sb as principal components, or preferably, a recording layer expressed by a compositional formula [(ZnS)x(SiO2)1-x]y(SbzX1-z)1-y (where 0<x≦1.0, 0.3≦y≦0.7, and 0.8<z≦1.0 are met and X denotes at least one element selected from a group of Ga, Te, V, Si, Zn, Ta, and Tb) is adopted.

Owner:SONY CORP

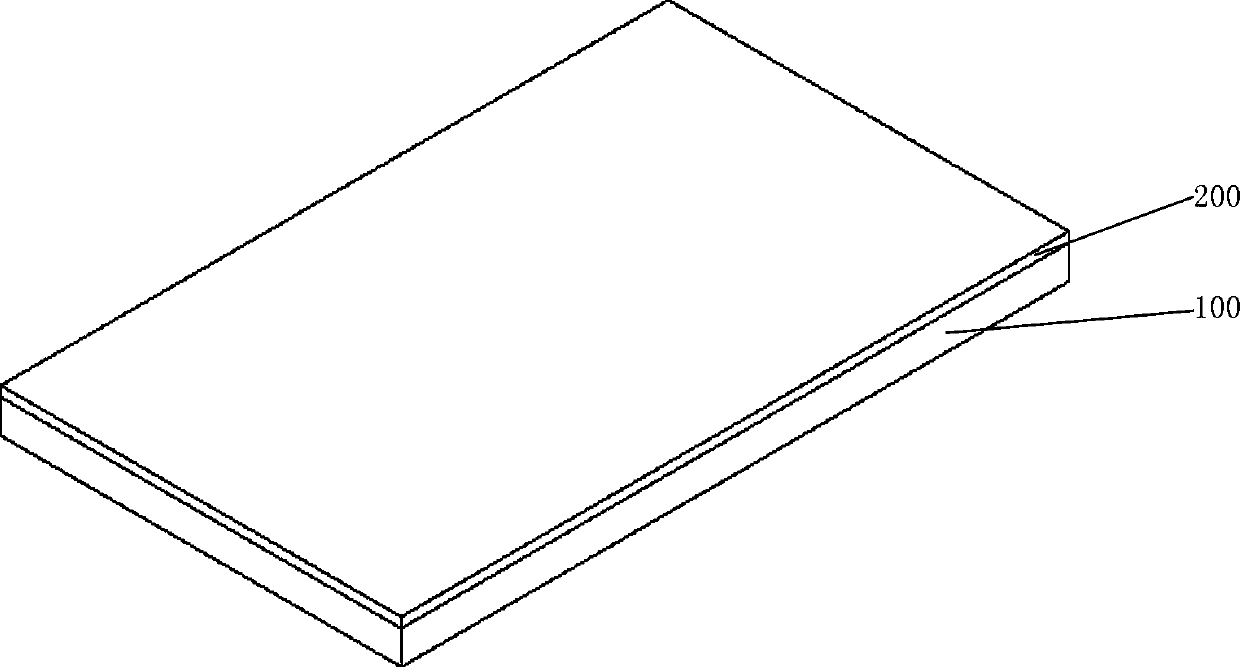

LCD screen signal transfer belt sealing method

ActiveCN109036171BImprove environmental reliabilitySimple structureCathode-ray tube indicatorsIdentification meansAdhesive beltMechanical engineering

The invention discloses a method for sealing a signal transfer belt of a liquid crystal screen. The method for sealing a signal transfer belt of a liquid crystal screen includes: step 1, connecting the FPC and the signal transfer belt through a heterosquare conductive adhesive film by hot pressing; Apply sealant to the hot-pressed position of the FPC and the signal transfer belt, and paste anti-static tape; step 3, after the sealant is cured, apply the sealant around the FPC and the signal transfer belt, and stick it again Cover with anti-static tape. The liquid crystal screen signal transfer belt sealing method solves the problems of blurred screen, black screen, white screen and the like that occur due to comprehensive environmental stress.

Owner:中航华东光电有限公司

Optical film and liquid crystal display device

InactiveCN100442092CHigh strengthImprove environmental reliabilityPolarising elementsNon-linear opticsBenzoic acidPolyester

PROBLEM TO BE SOLVED: To provide an optical film which facilitates the immobilization of liquid crystal orientation, can realize the wavelength dispersion of small birefringence, can not only be easily manufactured at a low cost in industrial view but also can be exactly regulated in optical characteristics, such as wavelength dispersion of the birefringence, to a desired value, is immobilized with the desired orientation state and can be made uniform and larger in area. SOLUTION: The optical film is composed of polyester including a structural unit derived from 4-(4-carboxycyclohexyl)benzoic acid and a structural unit derived from an aromatic diol-based compound of an ortho body and is obtained by cooling the orientation state formed during the thermal orientation of the polyester to its glass transition temperature or below so as to immobilize the orientation state.

Owner:NIPPON OIL CO LTD

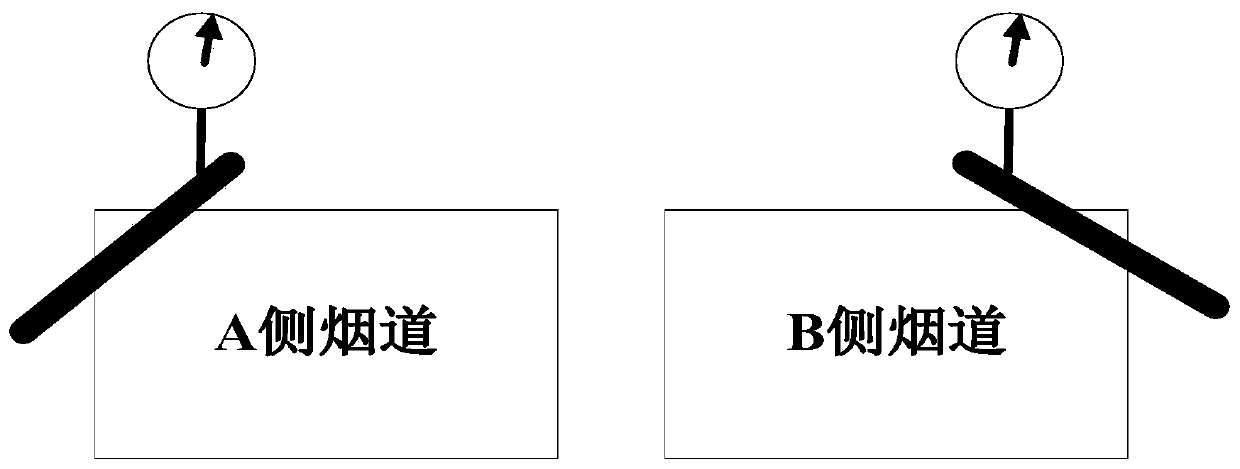

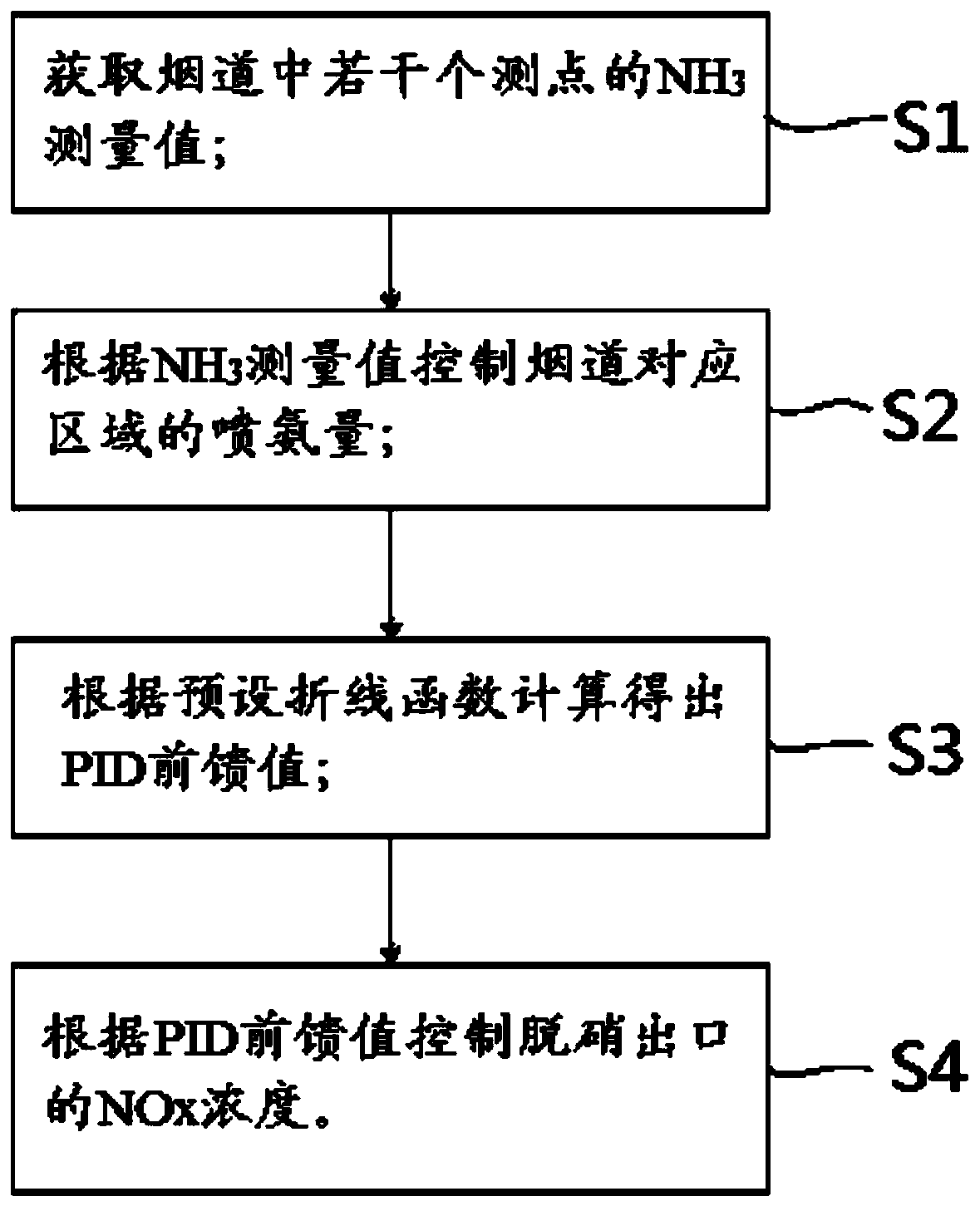

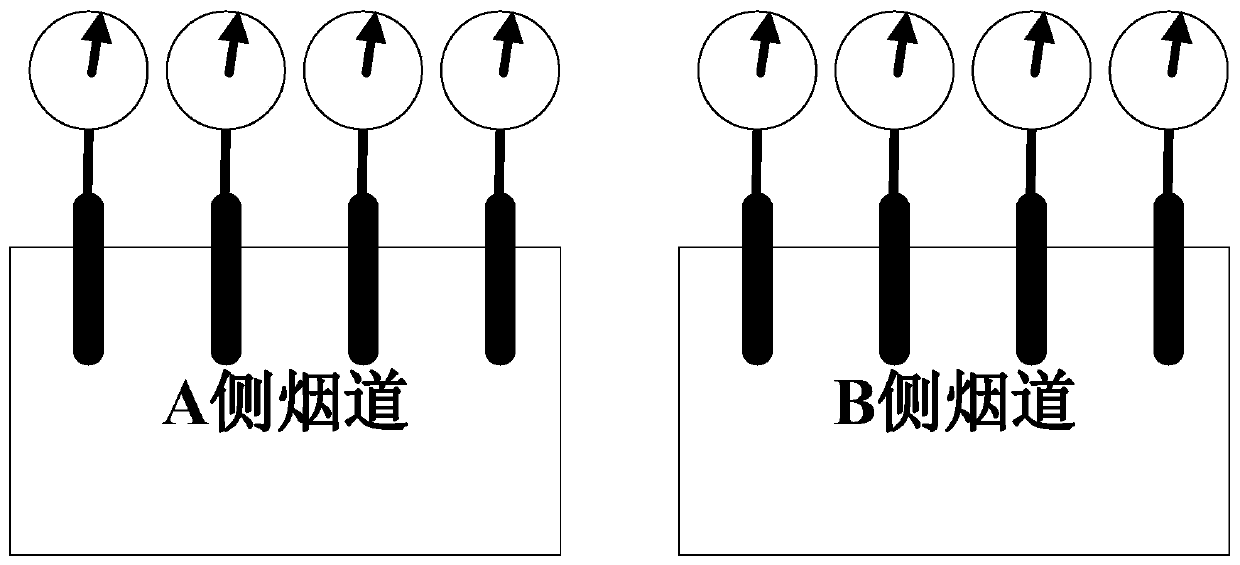

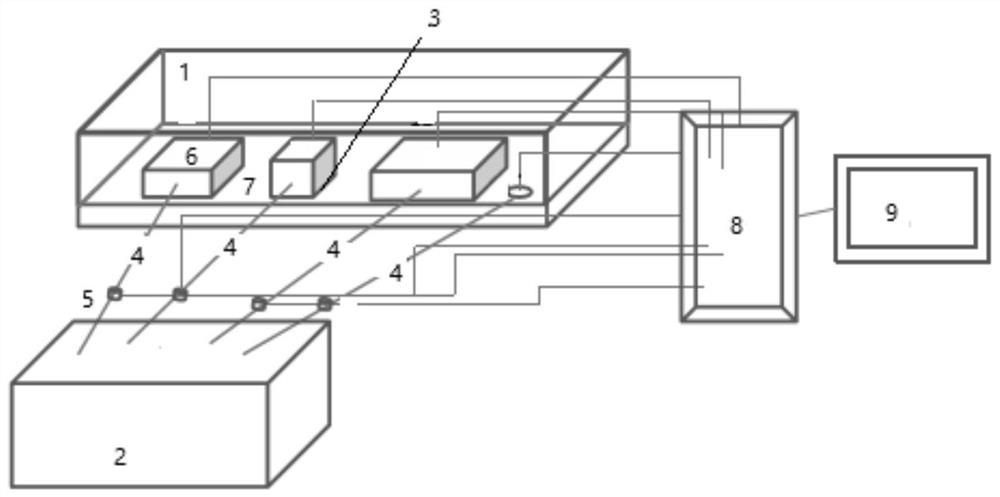

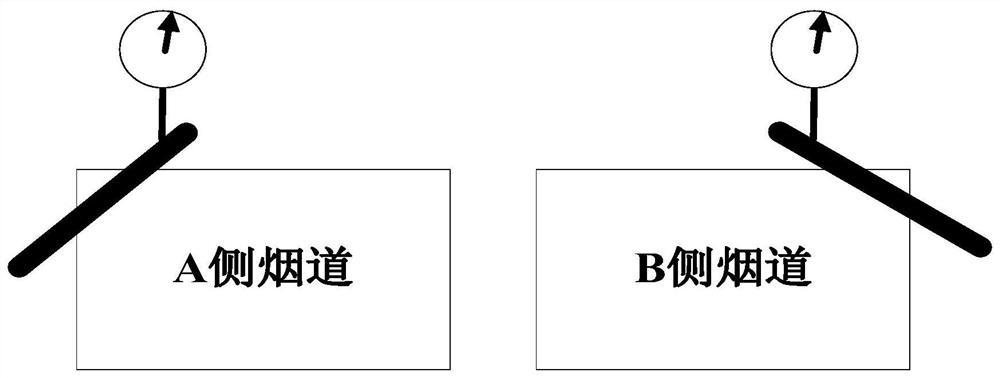

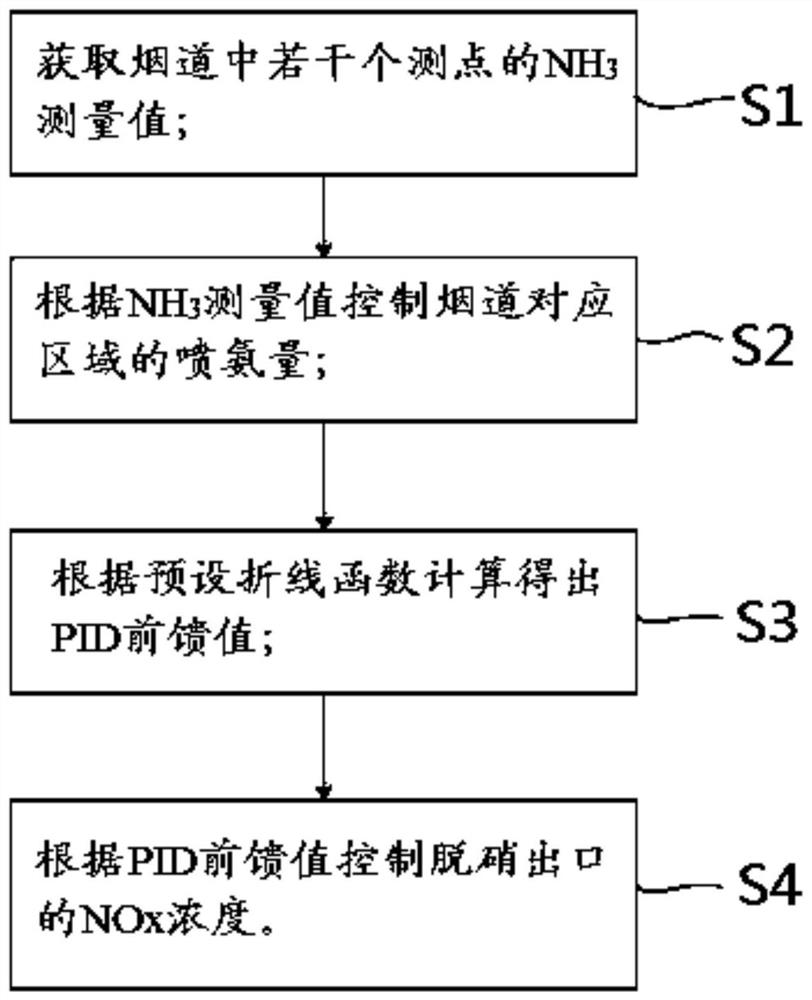

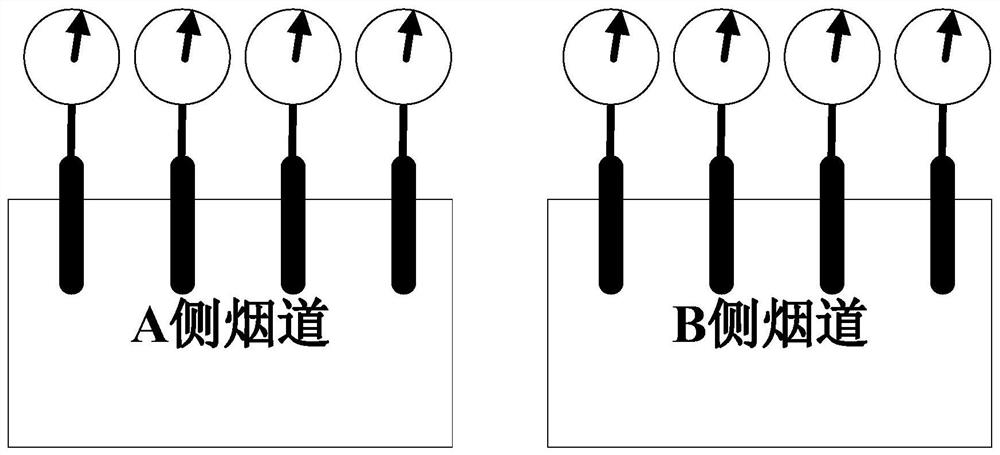

Thermal power generating unit and denitration control method and system based on NH3 measurement

ActiveCN111359411AImprove accuracyImprove representationGas treatmentDispersed particle separationAir preheaterControl system

The invention discloses a denitration control method based on NH3 measurement. The denitration control method comprises the following steps: acquiring NH3 measurement values of a plurality of measurement points in a flue, controlling an ammonia spraying amount of an area corresponding to the flue according to the NH3 measurement value, calculating a PID feedforward value according to a preset broken line function, and controlling an NOx concentration of a denitration outlet according to the PID feedforward value. The invention further discloses a denitration control system based on NH3 measurement and a thermal power generating unit comprising the denitration control system based on NH3 measurement. According to the denitration control method based on NH3 measurement, through multi-measuring-point NH3 parameter monitoring, a basis can be provided for an operator to adjust the opening degree of the ammonia spraying valve, so that the ammonia spraying amount of each area is more reasonable, the problem of excessive spraying or insufficient spraying of NH3 is effectively prevented, and the occurrence of blockage of an air preheater can be effectively reduced, meanwhile, the PID feedforward value is introduced into the denitration control system, so that the control reliability of the denitration control system can be effectively improved, and the environmental protection reliability is improved.

Owner:华润电力技术研究院有限公司

A method and laser system for realizing stable output of laser

ActiveCN111509551BImprove power stabilityImprove environmental reliabilityLaser cooling arrangementsLight beamProcess engineering

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Thermal power units and their nh-based 3 Measured denitrification control method and system

ActiveCN111359411BImprove accuracyImprove representationGas treatmentDispersed particle separationControl systemControl engineering

The invention discloses a NH-based 3 Measured denitrification control method, including: obtaining NH at several measuring points in the flue 3 measured value; according to the NH 3 The measured value controls the amount of ammonia injection in the corresponding area of the flue; the PID feedforward value is calculated according to the preset broken line function; the NOx concentration at the denitrification outlet is controlled according to the PID feedforward value. The invention also discloses a NH-based 3 Measurement of the denitrification control system and including the above NH-based 3 Measurement of the denitrification control system of the thermal power unit. The above is based on NH 3 Measured denitrification control method through multi-measuring point NH 3 Parameter monitoring can provide operators with a basis for adjusting the opening of the ammonia injection valve, making the amount of ammonia injection in each area more reasonable and effectively preventing NH 3 The problem of overspray or underspray can effectively reduce the occurrence of air preheater clogging; at the same time, by introducing the PID feedforward value into the denitration control system, the reliability of the denitration control system can be effectively improved, and the reliability of environmental protection can be improved.

Owner:华润电力技术研究院有限公司

Optical film and liquid crystal display device

InactiveCN100442091CHigh strengthImprove environmental reliabilityPolarising elementsNon-linear opticsPolyesterCarboxylic acid

PROBLEM TO BE SOLVED: To provide an optical film which facilitates the immobilization of liquid crystal orientation, can realize the wavelength dispersion of small birefringence, can be easily manufactured at a low cost in industrial view and can also be exactly regulated in optical characteristics, such as wavelength dispersion of the birefringence, is immobilized with the desired orientation state and can be made uniform and larger in area. SOLUTION: The optical film is composed of polyester including a structural unit derived from 1,1'-bicyclohexyl-4,4'-dicarboxylic acid and a structural unit derived from an aromatic diol-based compound of an ortho body and is obtained by cooling the orientation state formed during the thermal orientation of the polyester to its glass transition temperature or below so as to immobilize the orientation state.

Owner:NIPPON OIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com