Optical film and liquid crystal display device

A technology of optical film and liquid crystallinity, applied in optics, polarizing elements, nonlinear optics, etc., can solve problems such as amorphous, non-liquid crystallinity of polymers, and difficulty in fixing liquid crystal orientation structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] Put 40mmol of 1,1'-dicyclohexyl-4,4'-dicarboxylic acid, 60mmol of terephthalic acid, 50mmol of methyl hydroquinone diacetate and 50mmol of catechol diacetate in 200ml of acetic acid The outflow was carried out in a flask with a cooling tube under a nitrogen stream at 270°C for 6 hours, and then deacetate polymerization was carried out at this temperature under a nitrogen stream of 30 ml / min for 2 hours. The obtained polymer was dissolved in tetrachloroethane, and a large amount of methanol was added to refine the polymer. The polyester has an intrinsic viscosity of 0.23 dL / g, has a nematic phase as a liquid crystal phase, an isotropic phase-liquid crystal phase transition temperature of 270°C or higher, and a glass transition point of 80°C. In addition, it was found from the results of polarizing microscope observation that the orientation of the nematic liquid crystal phase is completely fixed below the glass transition temperature.

[0130] Next, a phenol / tetrachloro...

Embodiment 2~18 and comparative example 1

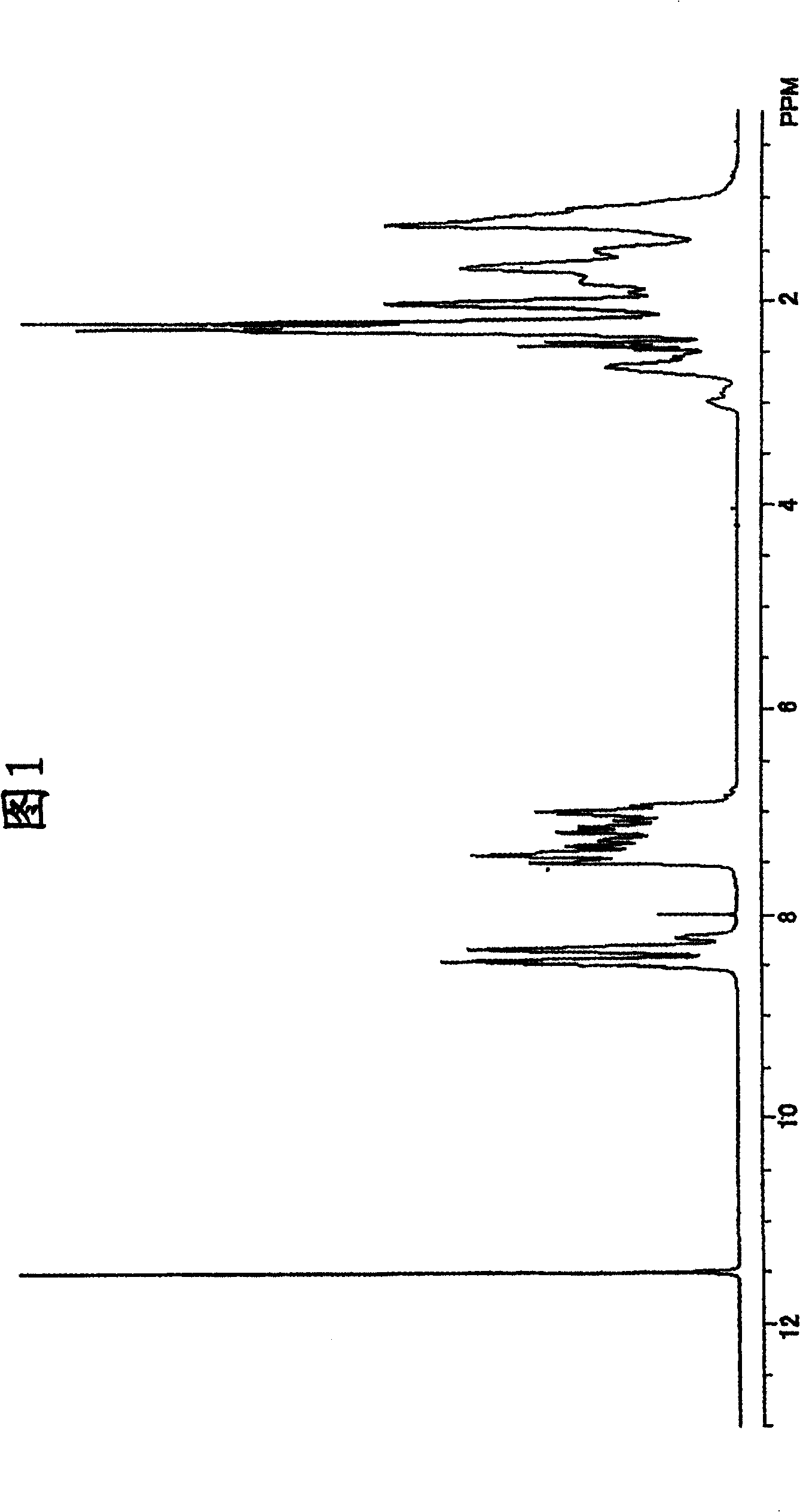

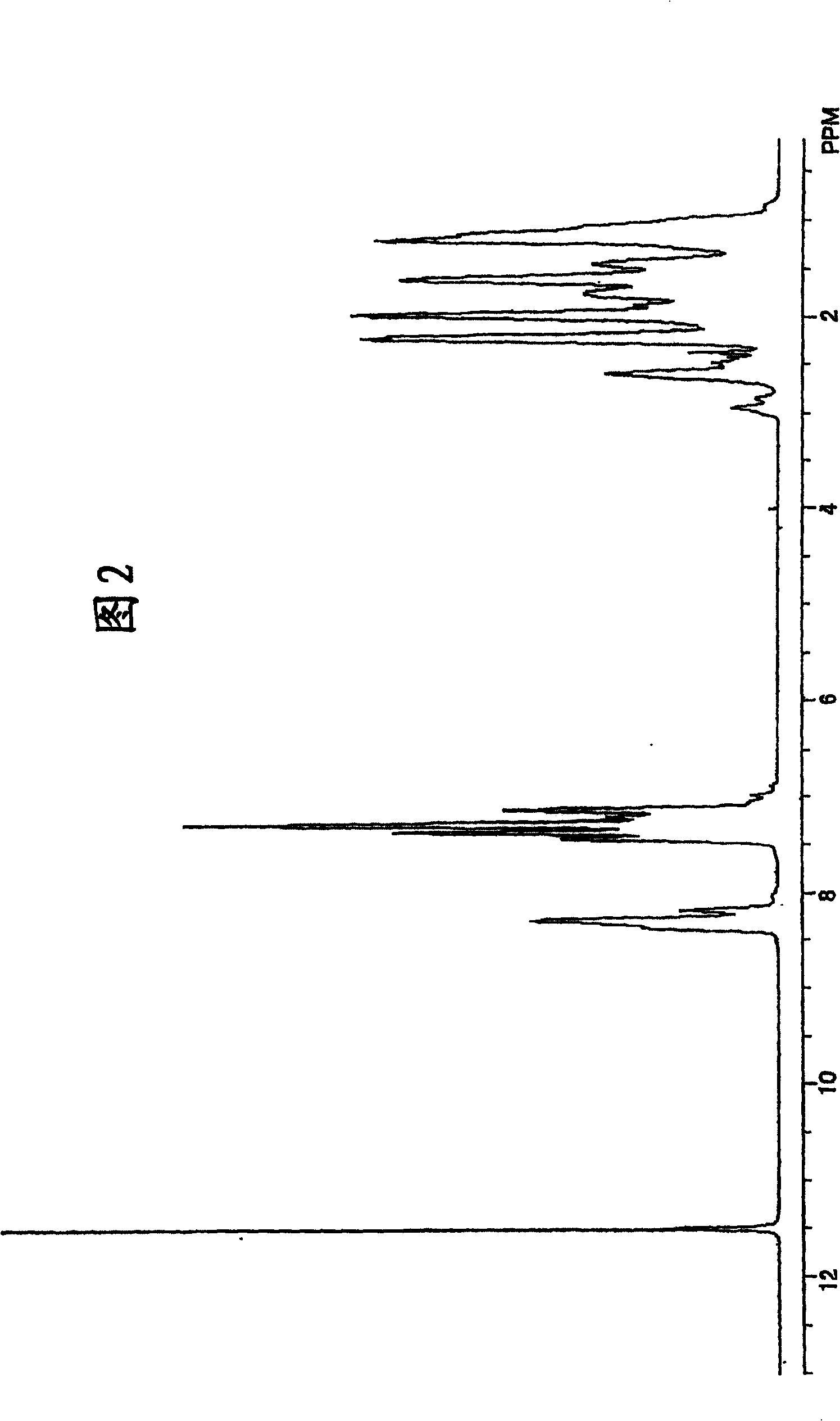

[0132] The research was carried out in the same manner as in Example 1, except that the types of monomers and the addition ratio were changed. The results are shown in Table 1. In addition, the polymer of Example 2 1 H-NMR spectrum is shown in Fig. 1, the polymkeric substance of embodiment 10 1 The H-NMR spectrum is shown in FIG. 2 . All of these polyesters show a uniform nematic liquid crystal phase above the glass transition temperature, and even when cooled to below the glass transition temperature, no transition to the nematic crystal phase is confirmed, and the orientation state formed in the nematic liquid crystal phase is fixed. .

Embodiment 19

[0134]An 8% by weight phenol / tetrachloroethane (60 / 40 weight ratio) mixed solvent solution of the polyester obtained in Example 7 was prepared. This solution was spin-coated on plain glass, and dried on a hot plate at 55°C for 20 minutes. After heat-treating in a clean oven at 220° C. for 20 minutes, it was taken out from the clean oven and cooled in natural air to obtain an optical film in which the orientation state of the nematic phase was fixed. The obtained optical film was transparent and uniform without orientation defects. As a result of observing the optical film under a crossed Nicol, no in-plane retardation was observed when viewed from the front, but a retardation occurred when viewed obliquely. As a result of interferometer observation with a polarizing microscope, a cross shape was observed, and as a result of observation with a 1 / 4 wavelength plate inserted, the second and fourth quadrants were observed to be black. From the above results, it can be seen that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com