Manufacturing method of laminated ceramic capacitor, and laminated ceramic capacitor

一种陶瓷电容器、制造方法的技术,应用在电容器制造、叠层电容器、固定电容器电介质等方向,能够解决电介质陶瓷介电常数降低、Re偏析增多、可靠性降低等问题,达到抑制飞散、抑制孔隙和间隙、抑制收缩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

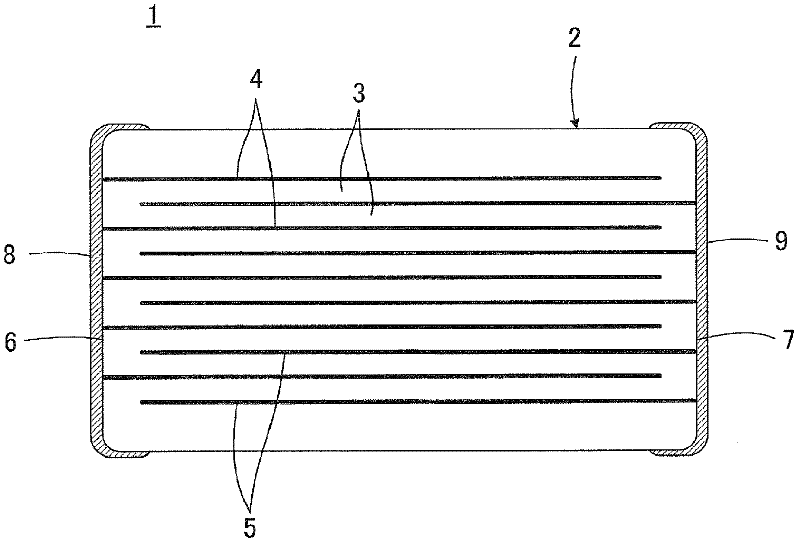

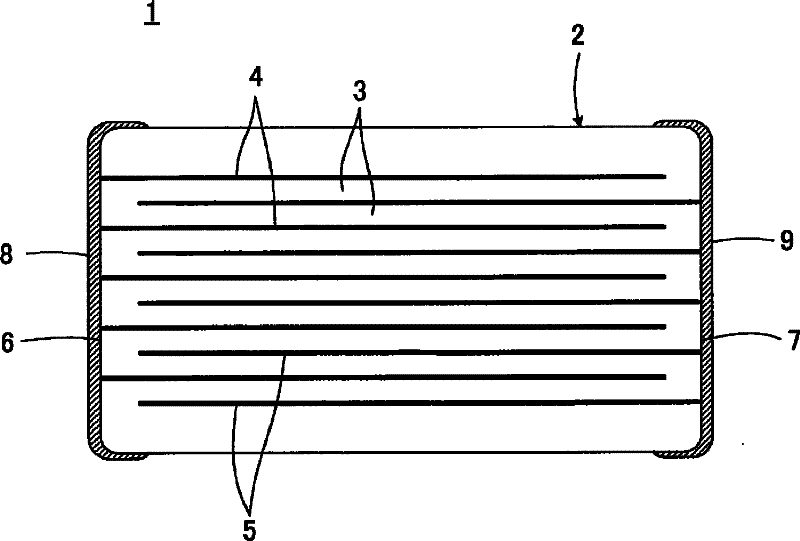

[0035] refer to figure 1 , the structure of the multilayer ceramic capacitor 1 used in the present invention will be described.

[0036]The multilayer ceramic capacitor 1 includes a laminated body 2 as a component main body. The laminated body 2 includes a plurality of stacked dielectric ceramic layers 3 and a plurality of internal electrodes 4 and 5 formed along specific interfaces between the dielectric ceramic layers 3 . The respective ends of the plurality of internal electrodes 4 and 5 are respectively exposed on one and the other end faces 6 and 7 of the laminated body 2, and the respective ends of these internal electrodes 4 and the respective ends of the internal electrodes 5 are electrically connected to each other, respectively. The external electrodes 8 and 9 are formed in a manner.

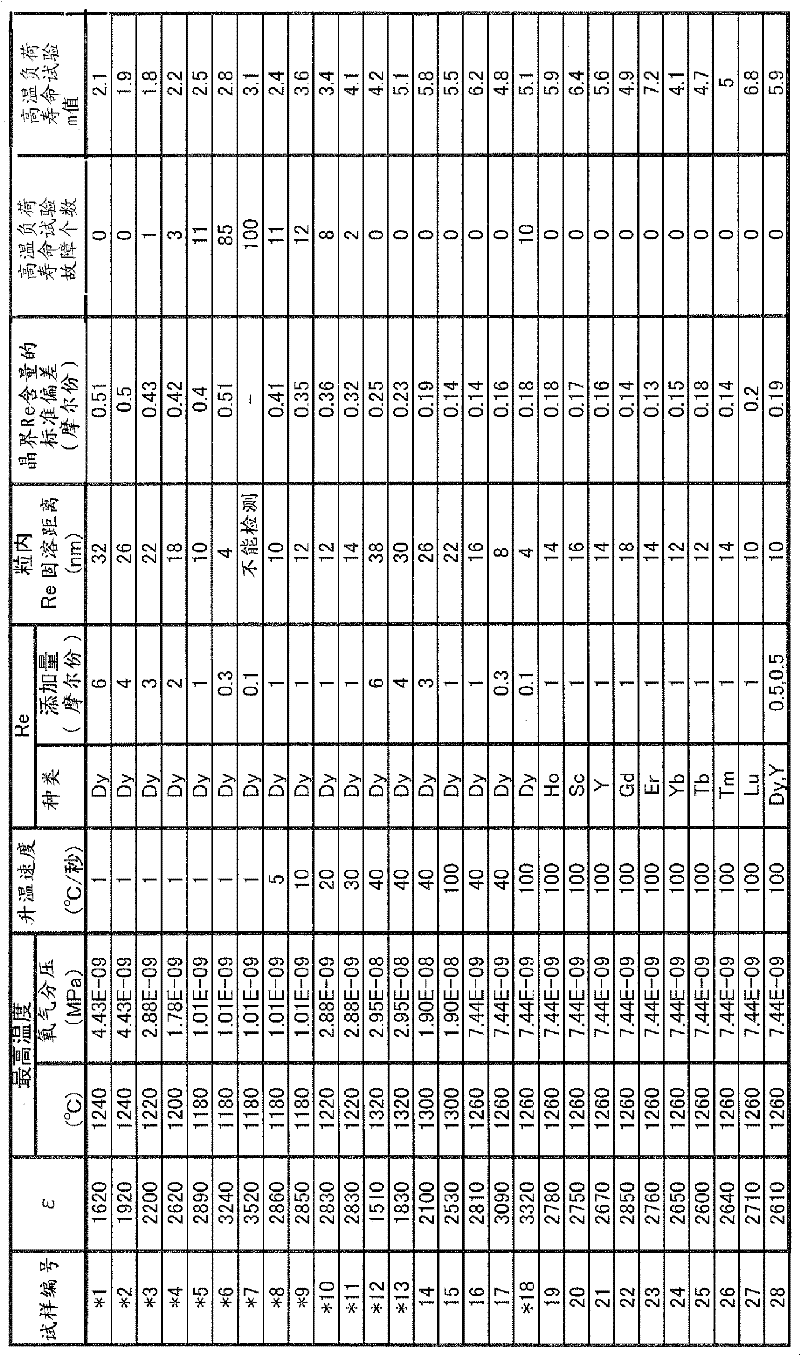

[0037] When manufacturing such a laminated ceramic capacitor 1 , first, a laminated body 2 in an unprocessed state is produced by a well-known method of laminating and printing ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com