Selective sintering process of printed circuit

A printed circuit, selective technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of poor electrical conductivity, etc., and achieve the effect of high line environment reliability, improved circuit electrical conductivity, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

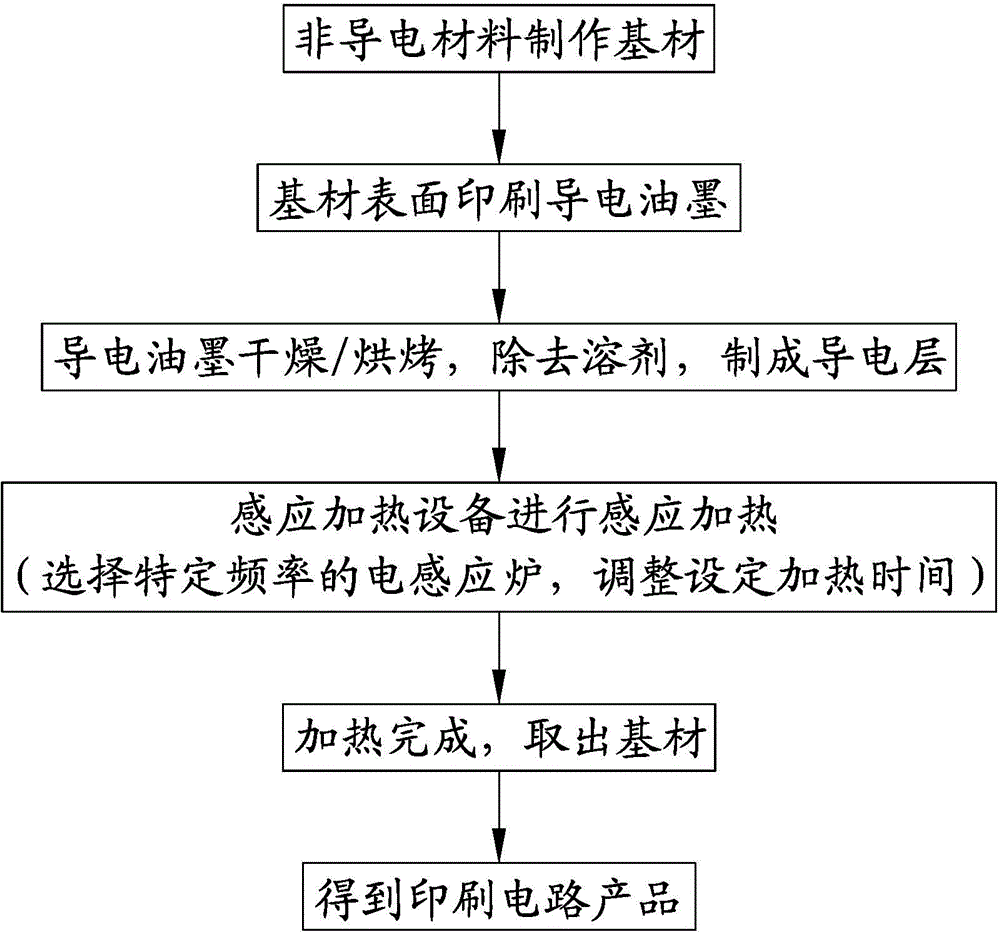

Image

Examples

example 1

[0031] When the substrate is plastic, conductive ink containing Ag is printed on the plastic surface to form a circuit, and it is first preheated:

[0032] ink material Substrate material heating time Sintering temperature / oven temperature Conductive Silver Ink nylon 30min 60℃ Conductive Silver Ink polycarbonate 3 hours room temperature

[0033] After preheating, sintering by induction heating:

[0034] ink material ink thickness Induction Furnace Frequency / Power heating time The highest temperature of the conductive layer Conductive Silver Ink 8 microns 13.65MHZ / 100W 10S 450℃ Conductive Silver Ink 6 microns 13.65MHz / 80W 15S 500℃

[0035] After sintering, the appearance and size of the substrate did not change. For PC substrates, the conductivity of the sintered metal film layer is 3 to 6 times that of the sintered one hour at 120°C. For some high-temperature nylon substrates, the conductivit...

example 2

[0037] When the base material is wood, brush a layer of conductive nickel ink on the surface of the base material, and the thickness of the ink is 30-40 microns.

[0038] Preheat the sample at 80°C for 20 minutes.

[0039] After preheating, the sample was heated by induction at 2M Hz with a power of 800W for 30S. The instantaneous maximum temperature of the conductive layer is 450°C.

[0040] After sintering, the appearance and size of the substrate remained unchanged, and the electrical conductivity was 4 to 5 times that of the sample sintered at 150°C for 1 hour.

example 3

[0042] Take the eggshell as the base material, and use a syringe to dispense glue to print conductive copper lines on the eggshell. The thickness of the ink is 10-20 microns.

[0043] Let the samples dry naturally for 1 hour.

[0044] The sample is heated at 13.65MHz, 1000W, for 5S. The instantaneous maximum temperature of the conductive layer is 500°C.

[0045] After the sintering was completed, no burning loss was observed in the eggshell inner membrane. The line is on. The electrical conductivity is equivalent to sintering at 150 degrees for 1 hour. However, the burning of local organisms is avoided. Suitable for biological sensing monitoring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com