Liquid ejection head and manufacturing method of liquid ejection head

一种液体喷出头、制造方法的技术,应用在印刷等方向,能够解决剥离、硅基板破裂、构件剥离等问题,达到抑制剥离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0030] A first embodiment of the present invention will be described below with reference to the drawings.

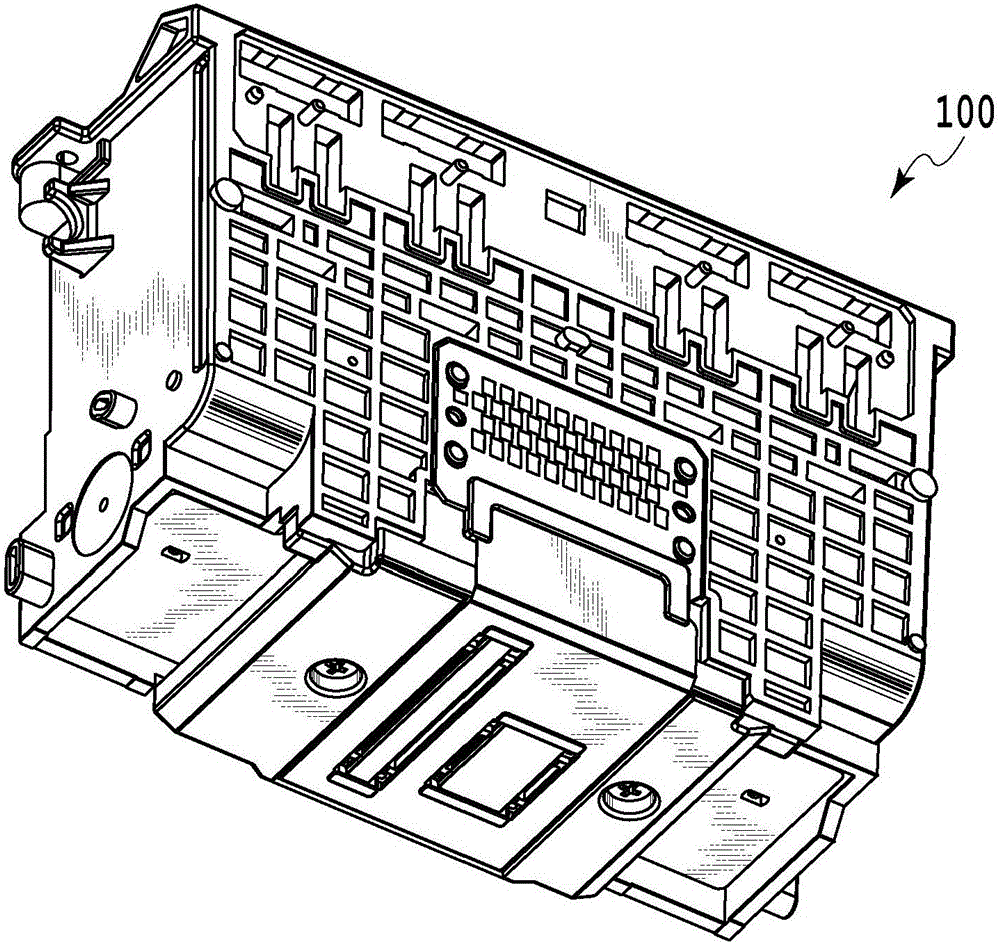

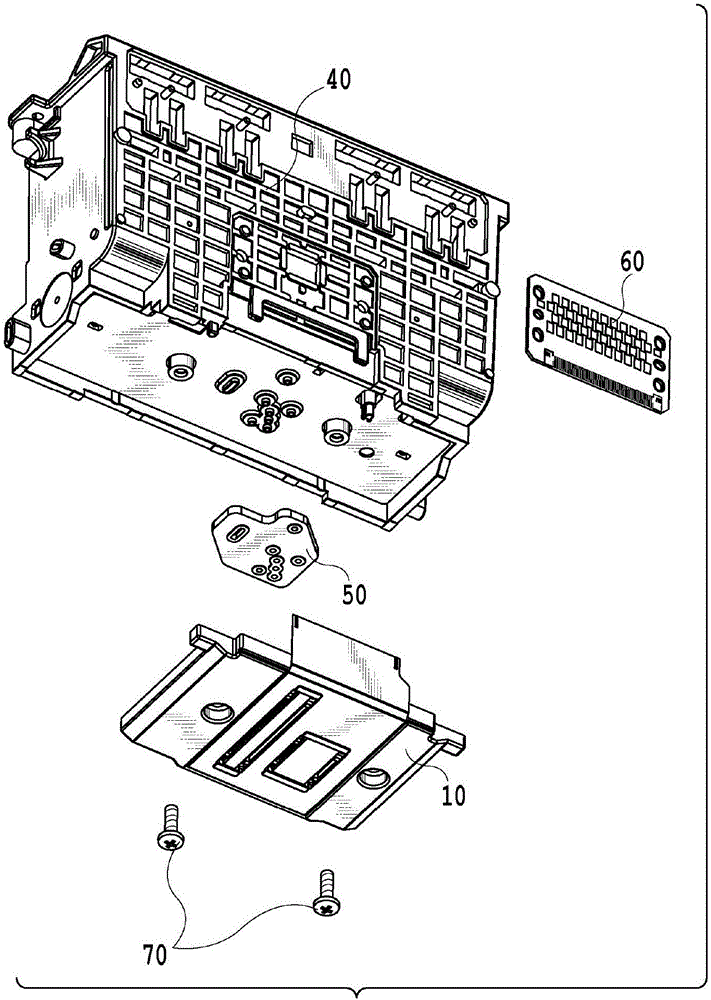

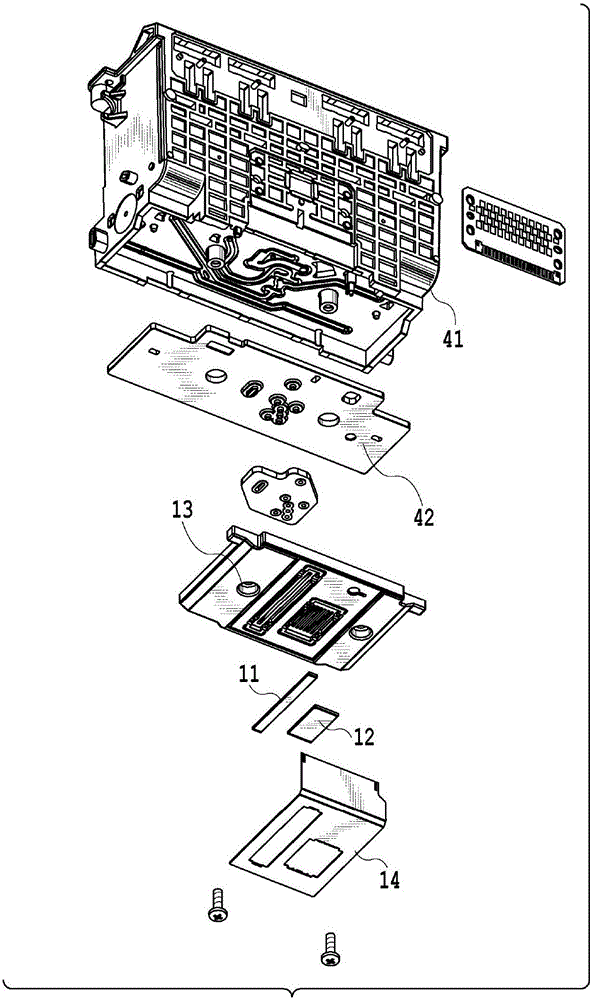

[0031] figure 1 is a schematic diagram showing the liquid ejection head of the first embodiment, figure 2 and image 3 It is an exploded view of the liquid ejection head. The liquid ejection head 100 has a printing element unit 10 , a flow path unit 40 , an elastic member 50 , an electric substrate 60 and screws 70 . The printing element unit 10 has printing element substrates 11 and 12 , a plate-shaped supporting member (first supporting member) 13 and an electric wiring substrate 14 , and the flow path unit 40 (second supporting member) has a casing 41 and a flow path plate 42 .

[0032] The flow path unit 40 has a flow path plate 42 fixed to the housing 41 by ultrasonic welding to form a liquid supply path for guiding liquid from an ink cartridge for storage (not shown) to a liquid introduction port. The housing 41 and the flow path plate 42 are formed of resin...

no. 2 approach

[0045] A second embodiment of the present invention will be described below by referring to the drawings. Since the basic configuration of the present embodiment is the same as that of the first embodiment, only the characteristic configuration will be described below.

[0046] Figure 10 It is a figure for demonstrating the printing element unit of 2nd Embodiment. Since the configurations other than the printing element unit are the same as those of the liquid ejection head of the first embodiment, description will be omitted. In the support member 13 , recesses 23 for accommodating the printing element substrates 11 and 12 in the thickness direction of the support member 13 are provided. The outer peripheries of the printing element substrates 11 and 12 (or at least a part of the printing element substrates 11 and 12 ) engaging and fixed to the concave portion 23 of the supporting member 13 are sealed with a sealing material 24 . Since the supporting member 13 is formed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com