Patents

Literature

302results about "Gas discharge sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS20100180934A1Flow on effectReduce softeningAddress electrodesConductive layers on insulating-supportsTe elementAntimony

Owner:RESONAC CORP

Glass composition, glass frit containing same, glass paste containing same, and electrical/electronic component obtained using same

ActiveUS20140145122A1Improve thermal stabilityGood chemical stabilityCathode-ray/electron-beam tube leading-in arrangementsSemiconductor/solid-state device detailsFritThermal stability

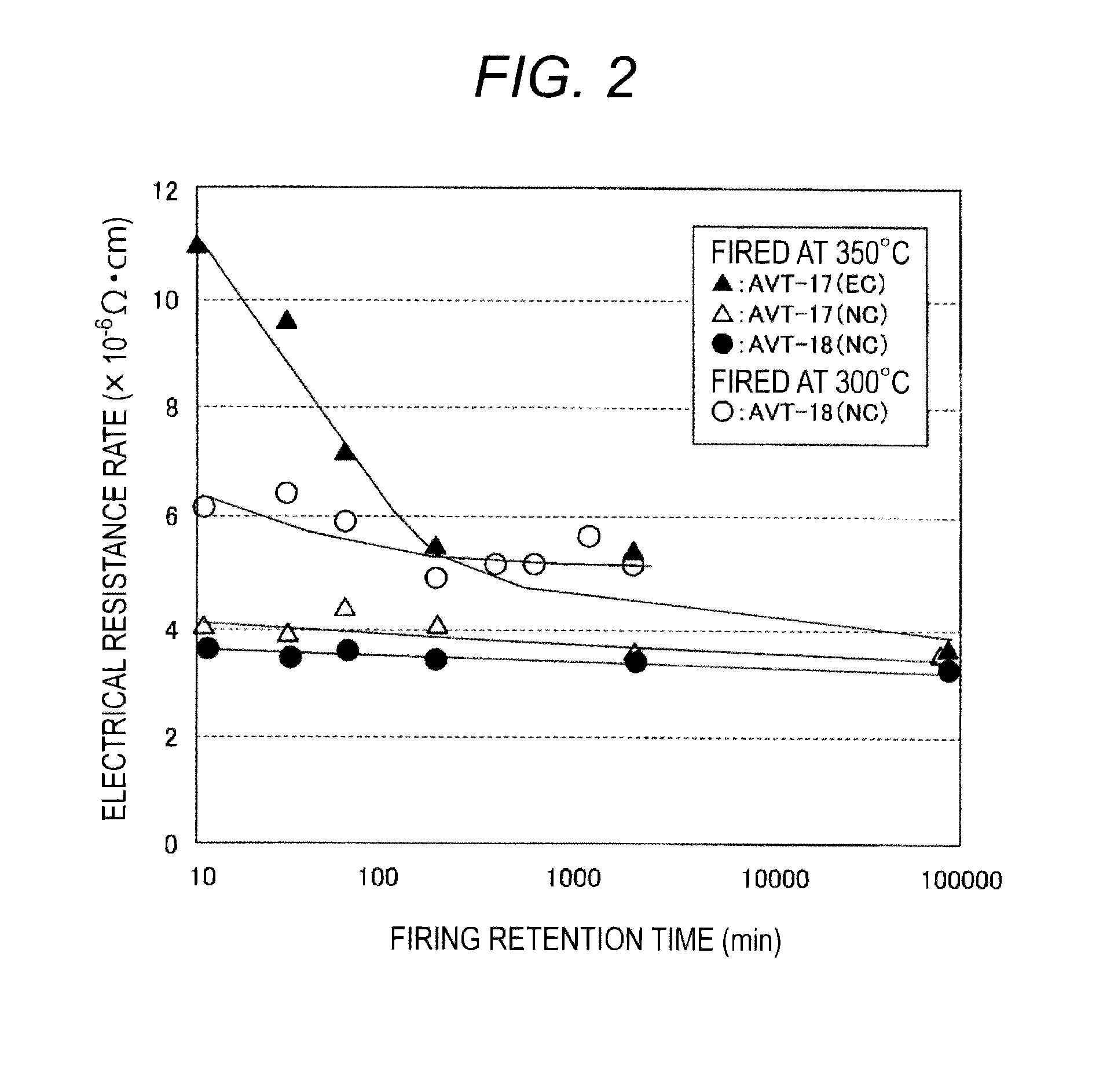

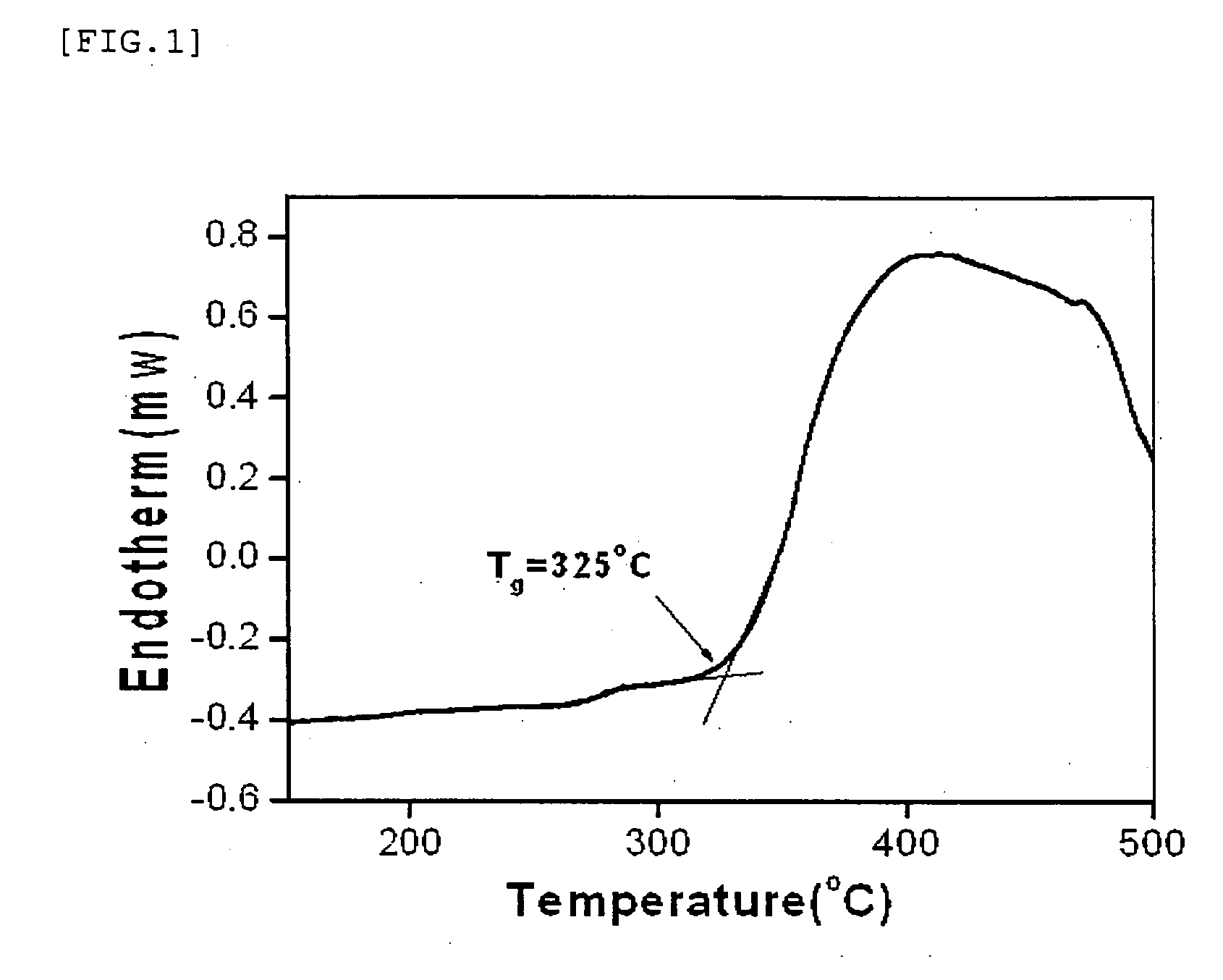

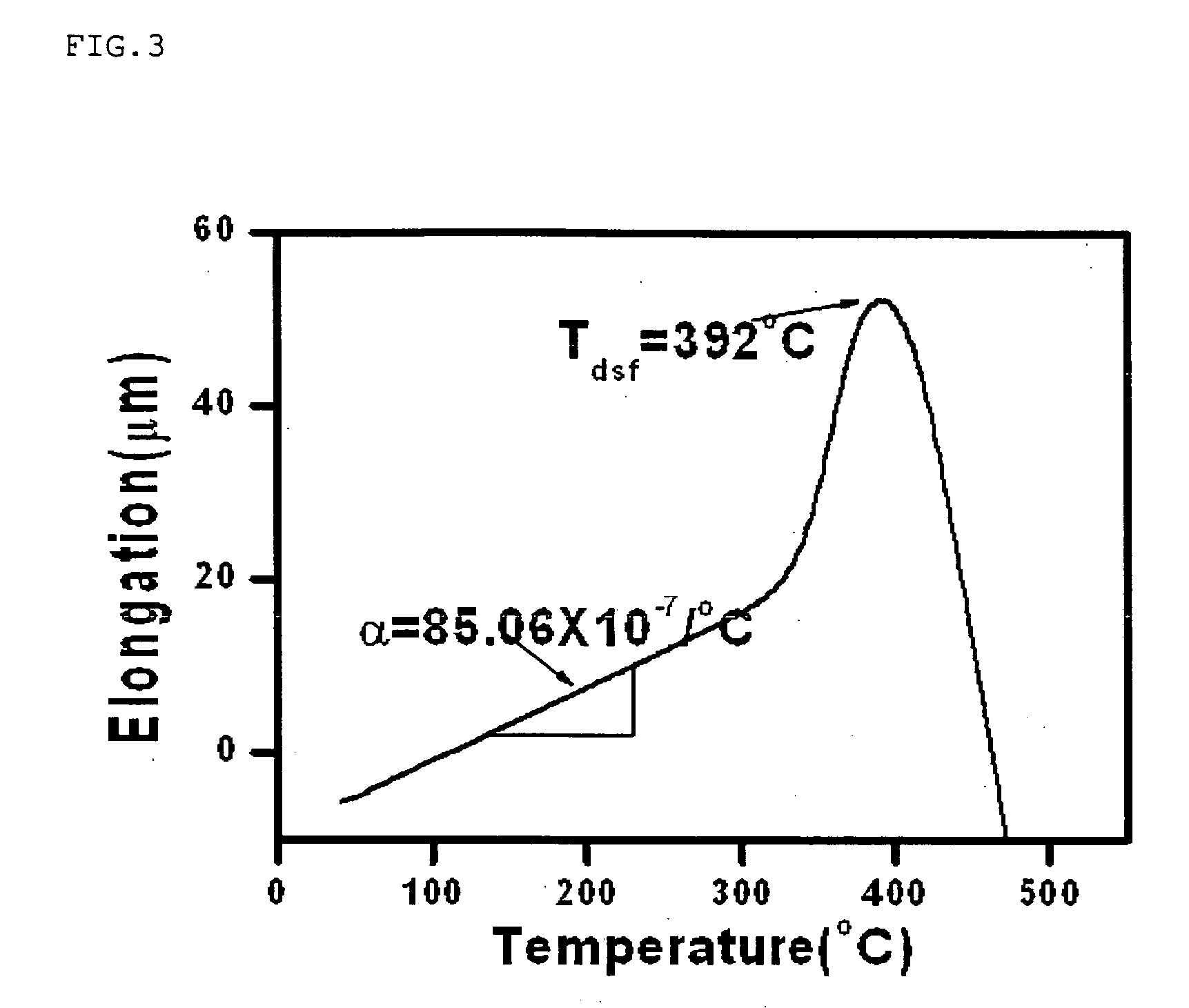

The present invention aims at providing a lead-free glass composition that can be soften and flowed at a firing temperature that is equal to or lower than that of conventional low melting point lead glass. Furthermore, the present invention aims at providing a lead-free glass composition having fine thermal stability and fine chemical stability in addition to that property. The lead-free glass composition according to the present invention is characterized by comprising at least Ag2O, V2O5 and TeO2 when the components are represented by oxides, wherein the total content ratio of Ag2O, V2O5 and TeO2 is 75 mass % or more. Preferably, the lead-free glass composition comprises 10 to 60 mass % of Ag2O, 5 to 65 mass % of V2O5, and 15 to 50 mass % of TeO2.

Owner:HITACHI LTD

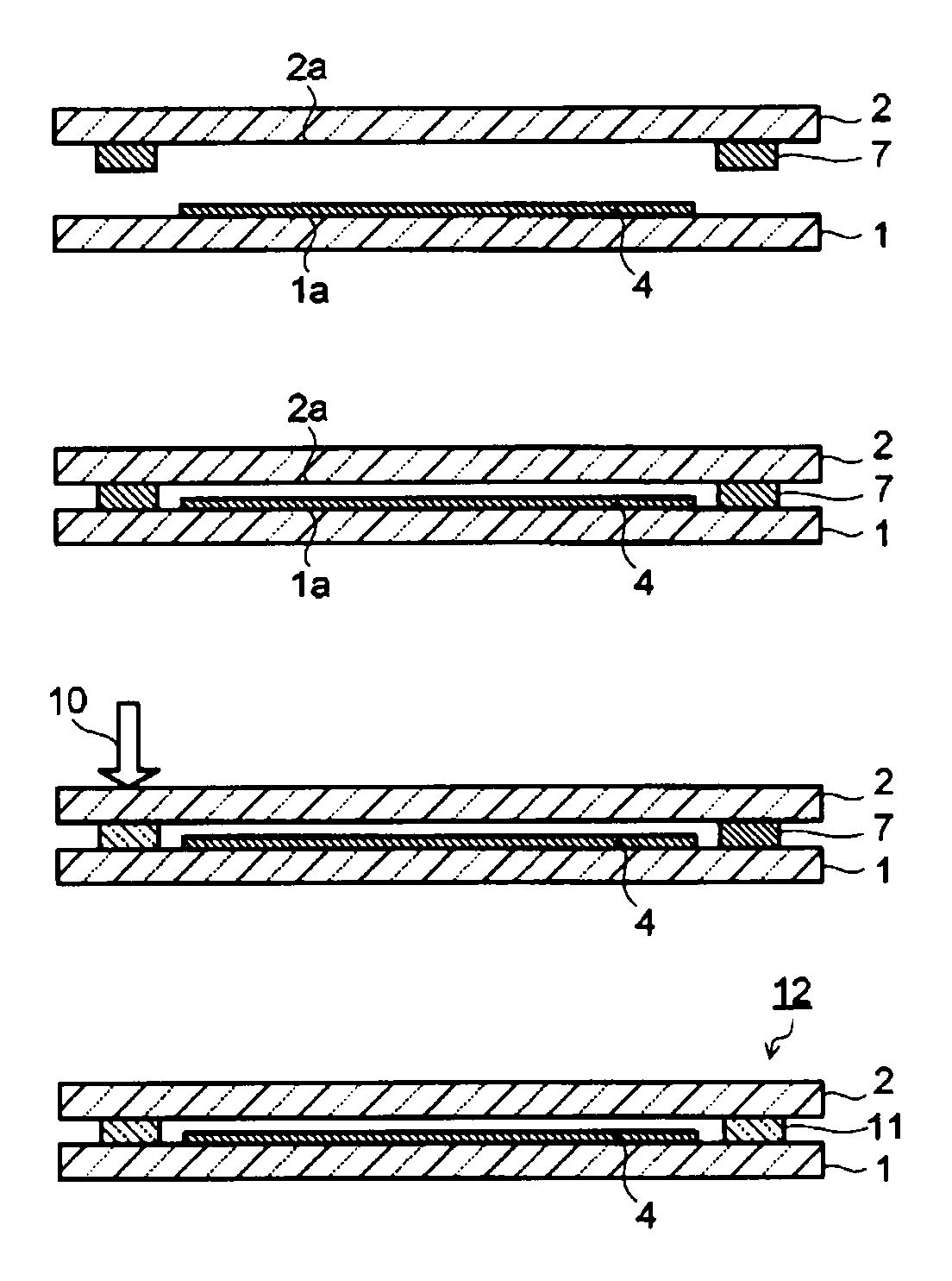

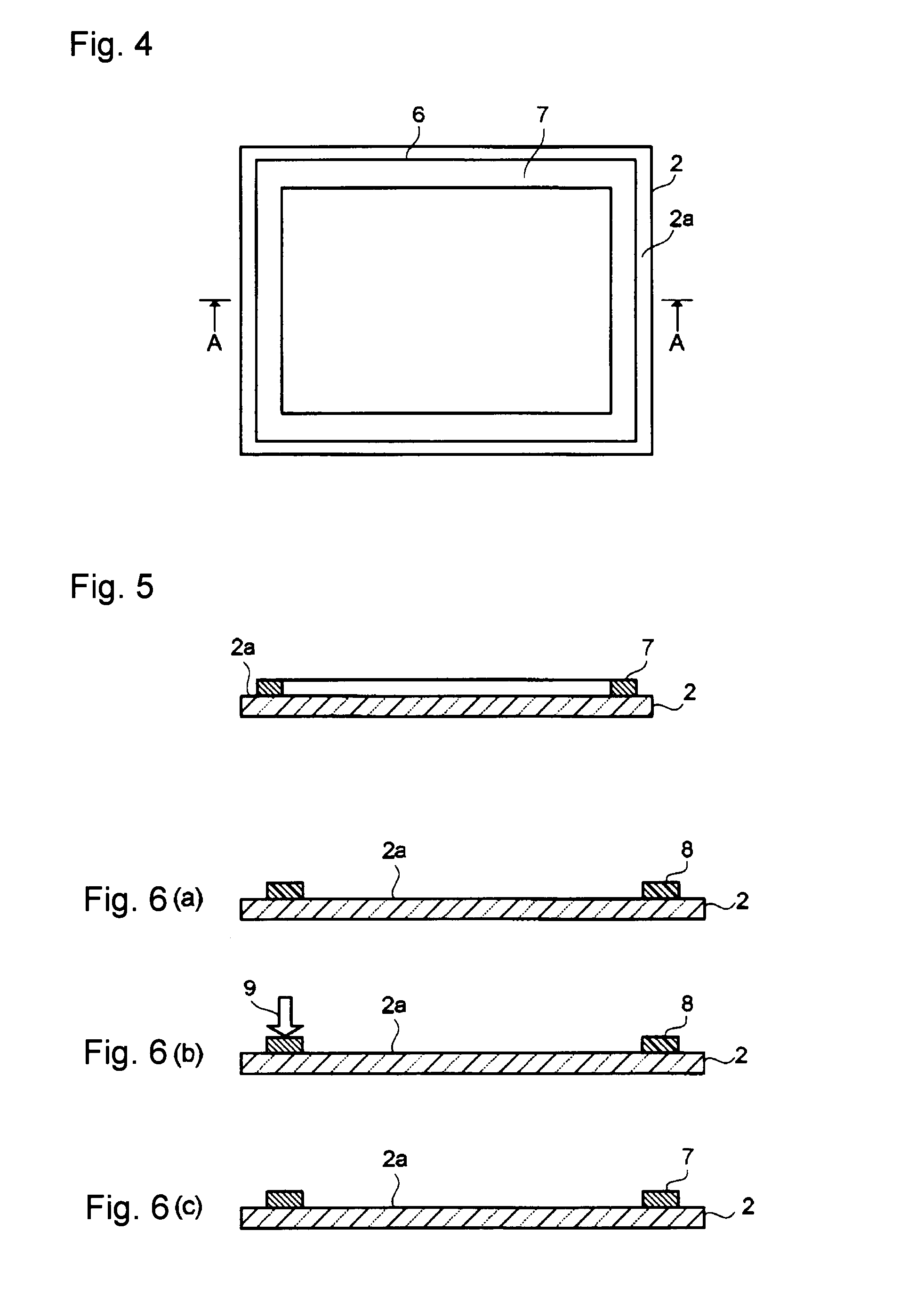

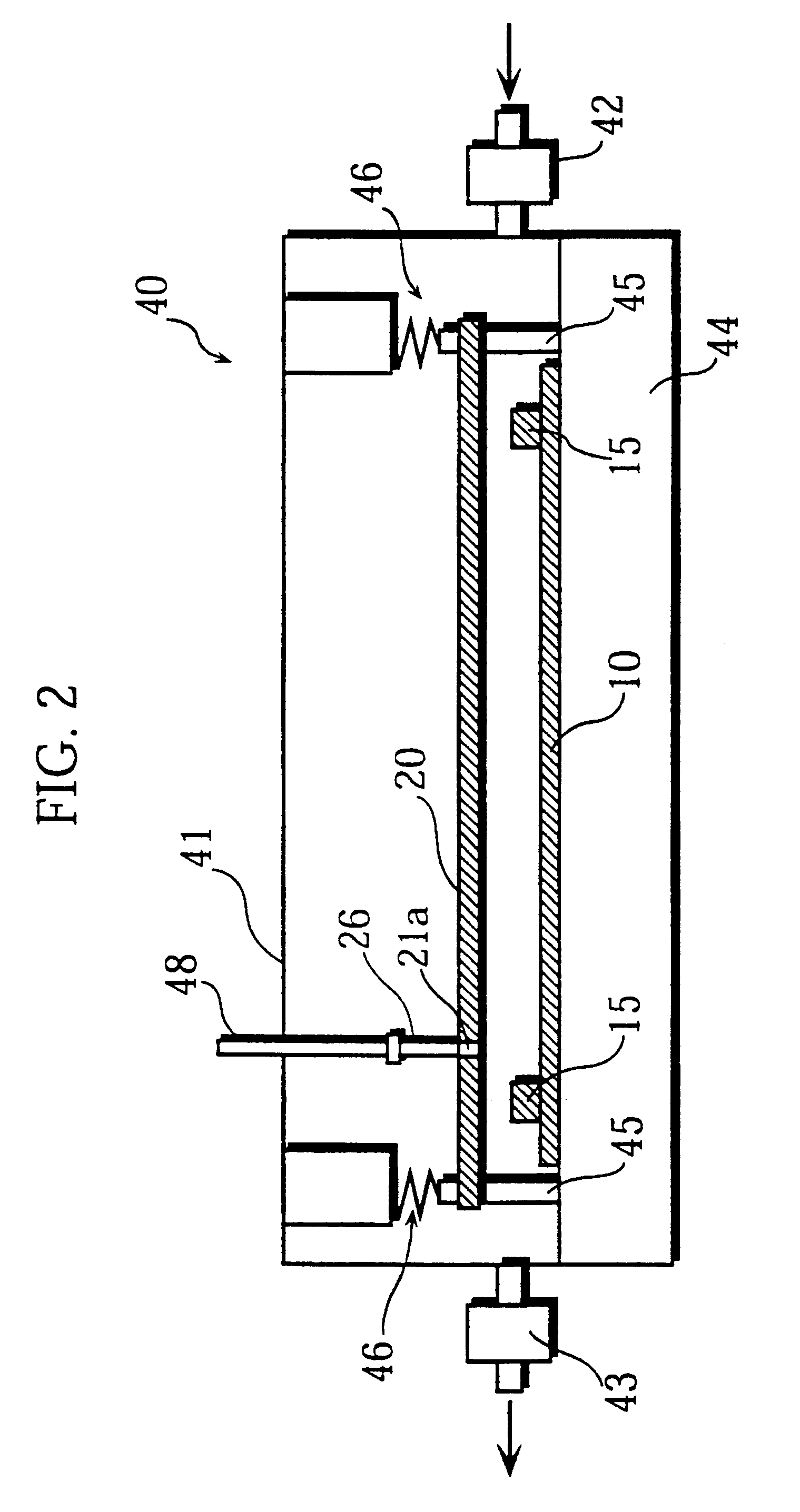

Process and apparatus for producing glass member provided with sealing material layer and process for producing electronic device

InactiveUS20120111059A1FavorableGood reproducibilityRadiation applicationsAlternating current plasma display panelsLaser lightIrradiation

To provide a process for producing a glass member provided with a sealing material layer, capable of favorably forming a sealing material layer even in a case where the entire glass substrate cannot be heated.A sealing material paste prepared by mixing a sealing material containing a sealing glass and a laser absorbent with an organic binder is applied to a sealing region of a glass substrate 2 in the form of a frame. The frame-form coating layer 8 of the sealing material paste is selectively heated by irradiation with a laser light 9 along the coating layer 8 to fire the sealing material while the organic binder in the coating layer 8 is burnt out to form a sealing material layer 7. Using such a sealing material layer 7, a space between two glass substrates is sealed.

Owner:ASAHI GLASS CO LTD

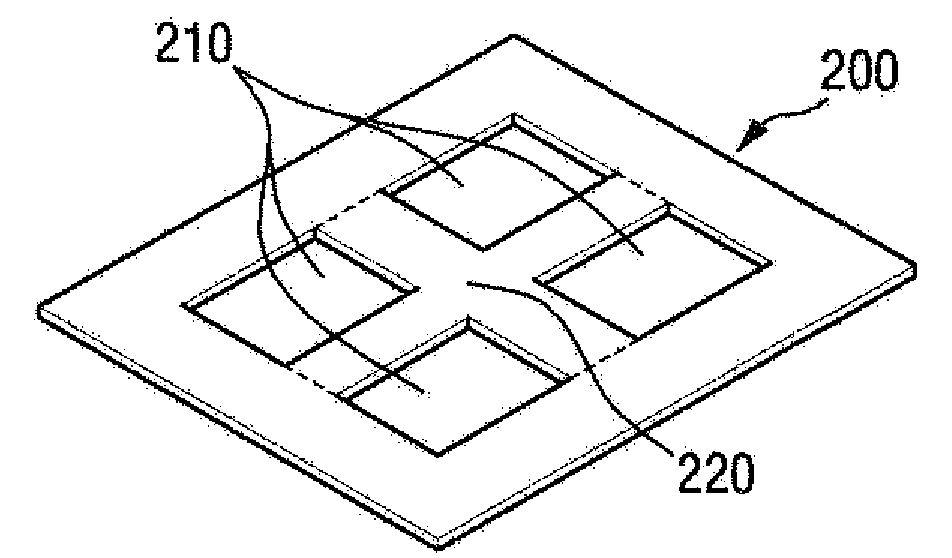

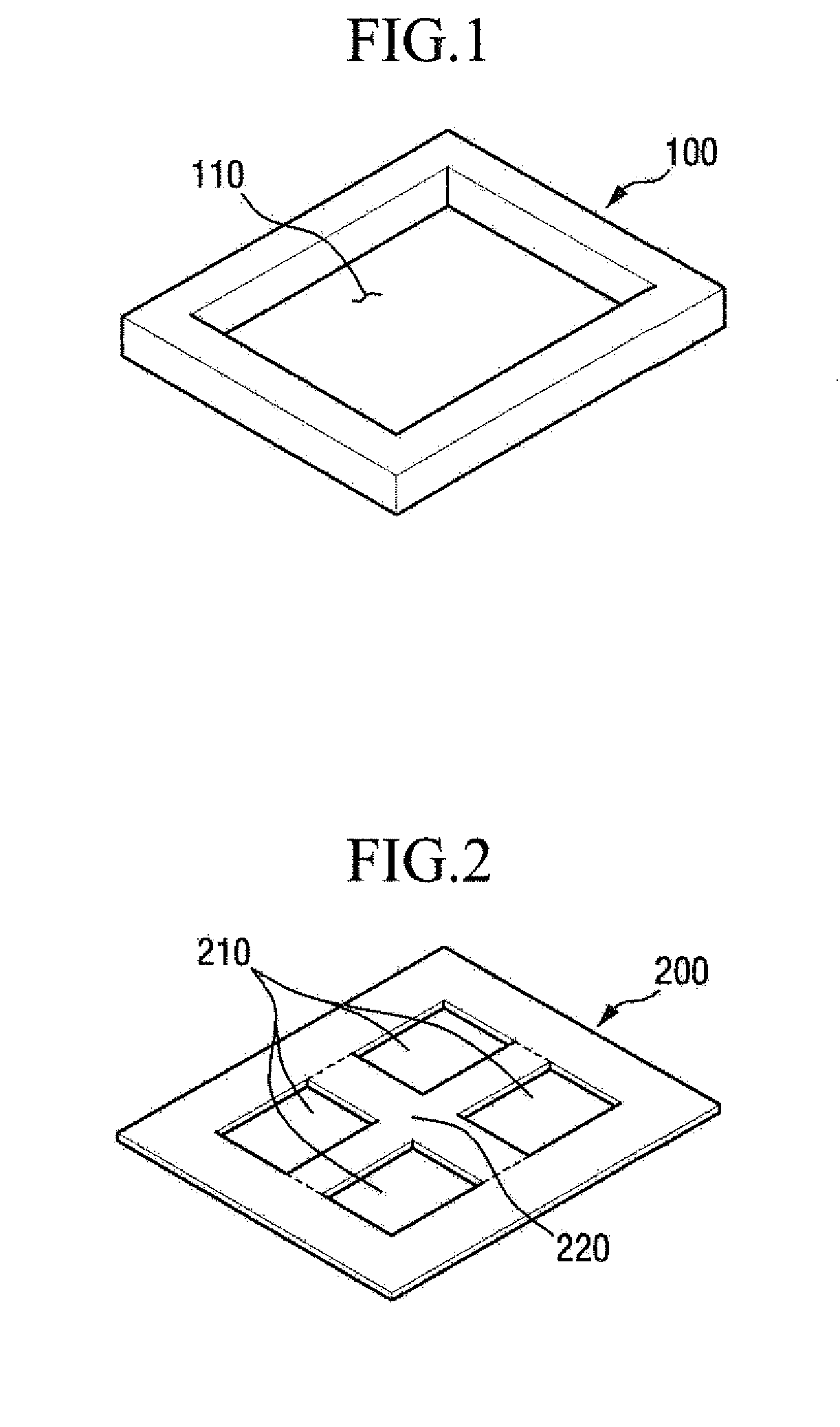

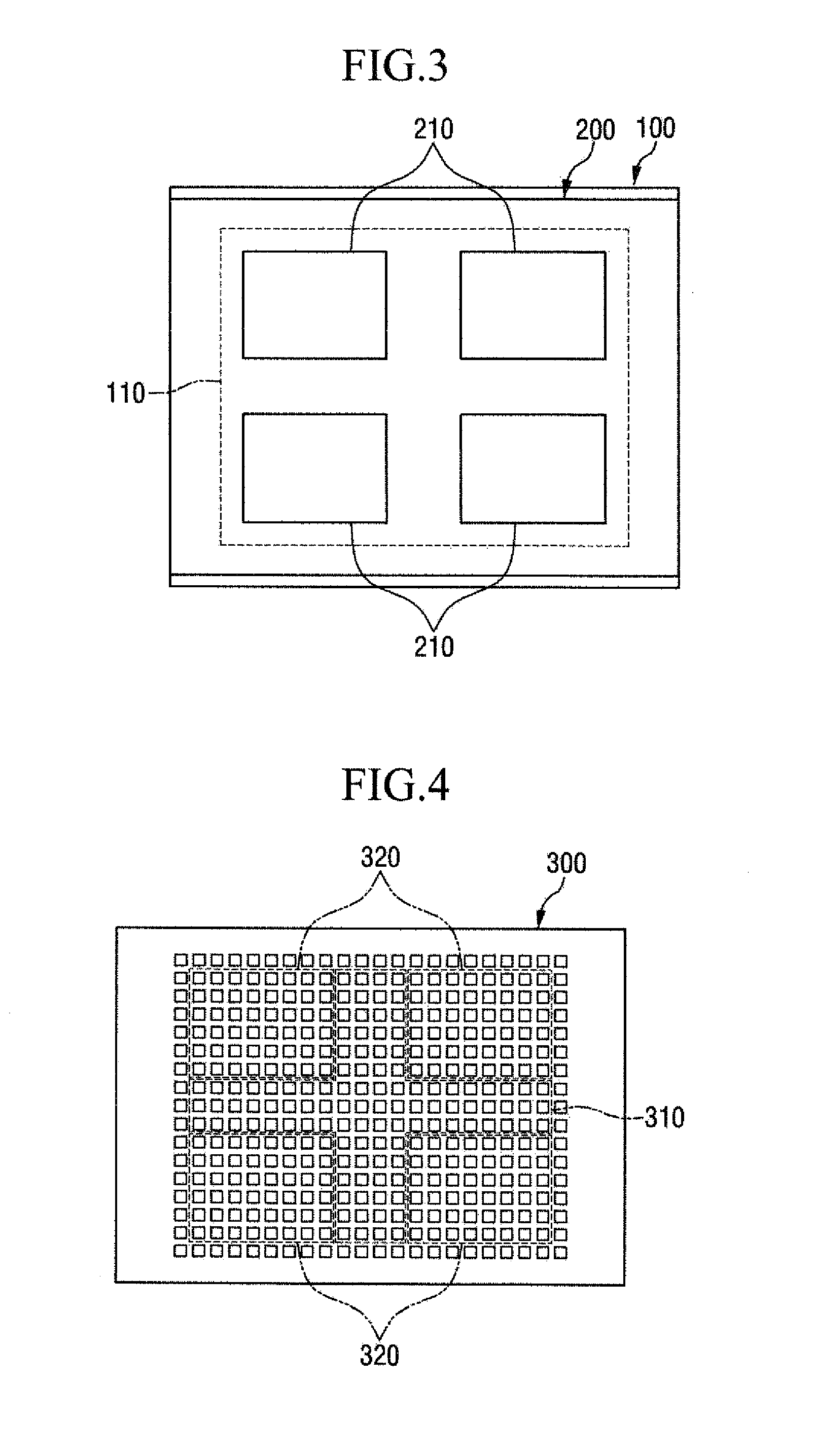

Deposition Mask and Method of Manufacturing the Same

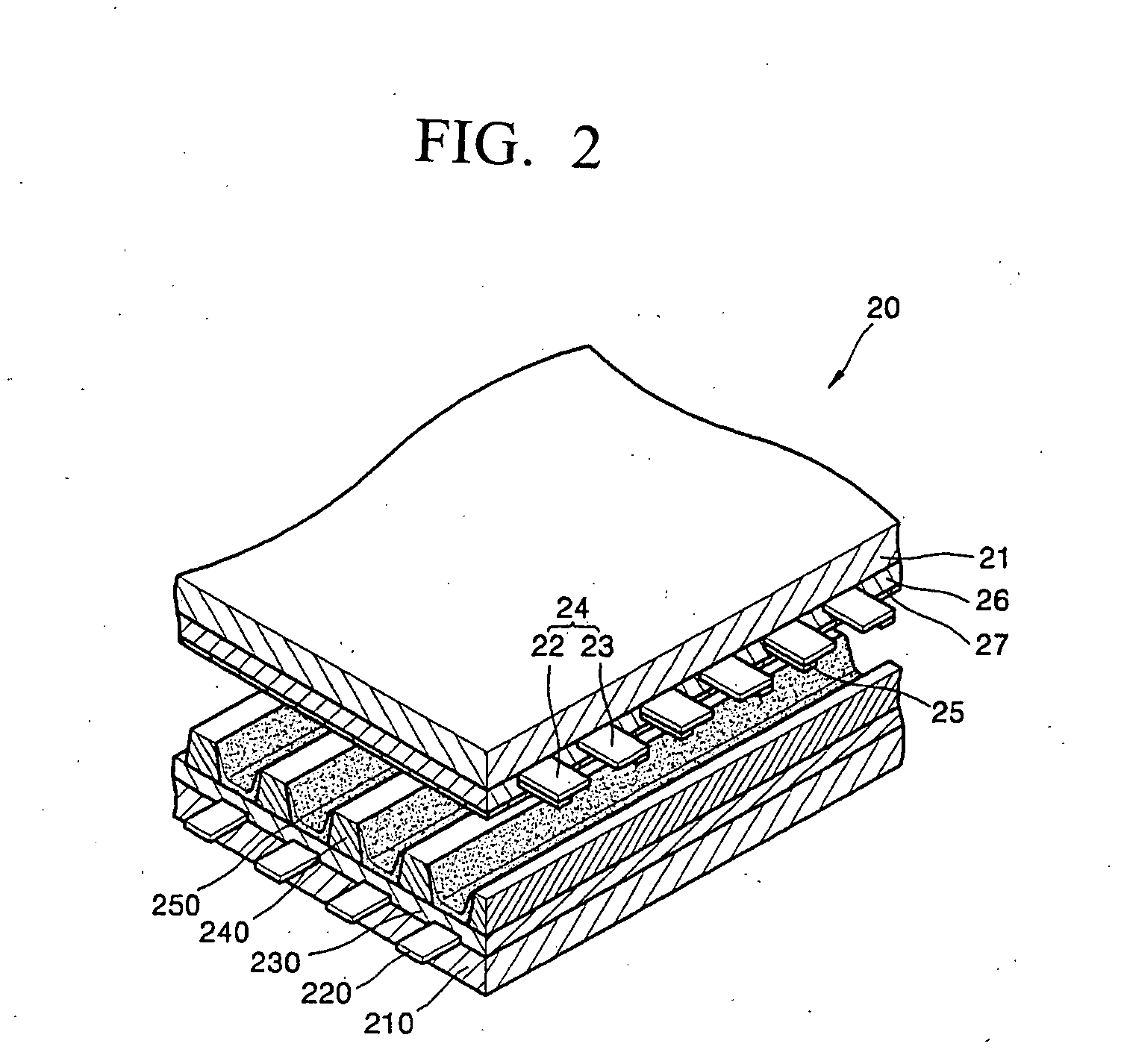

A deposition mask comprises a mask frame having an open window defined in a center thereof, a first mask sheet placed on the mask frame and including a plurality of open regions and a separation region which separates the open regions, and a second mask sheet placed on the first mask sheet and including a first aperture portion in a region which contacts the separation region of the first mask sheet.

Owner:SAMSUNG DISPLAY CO LTD

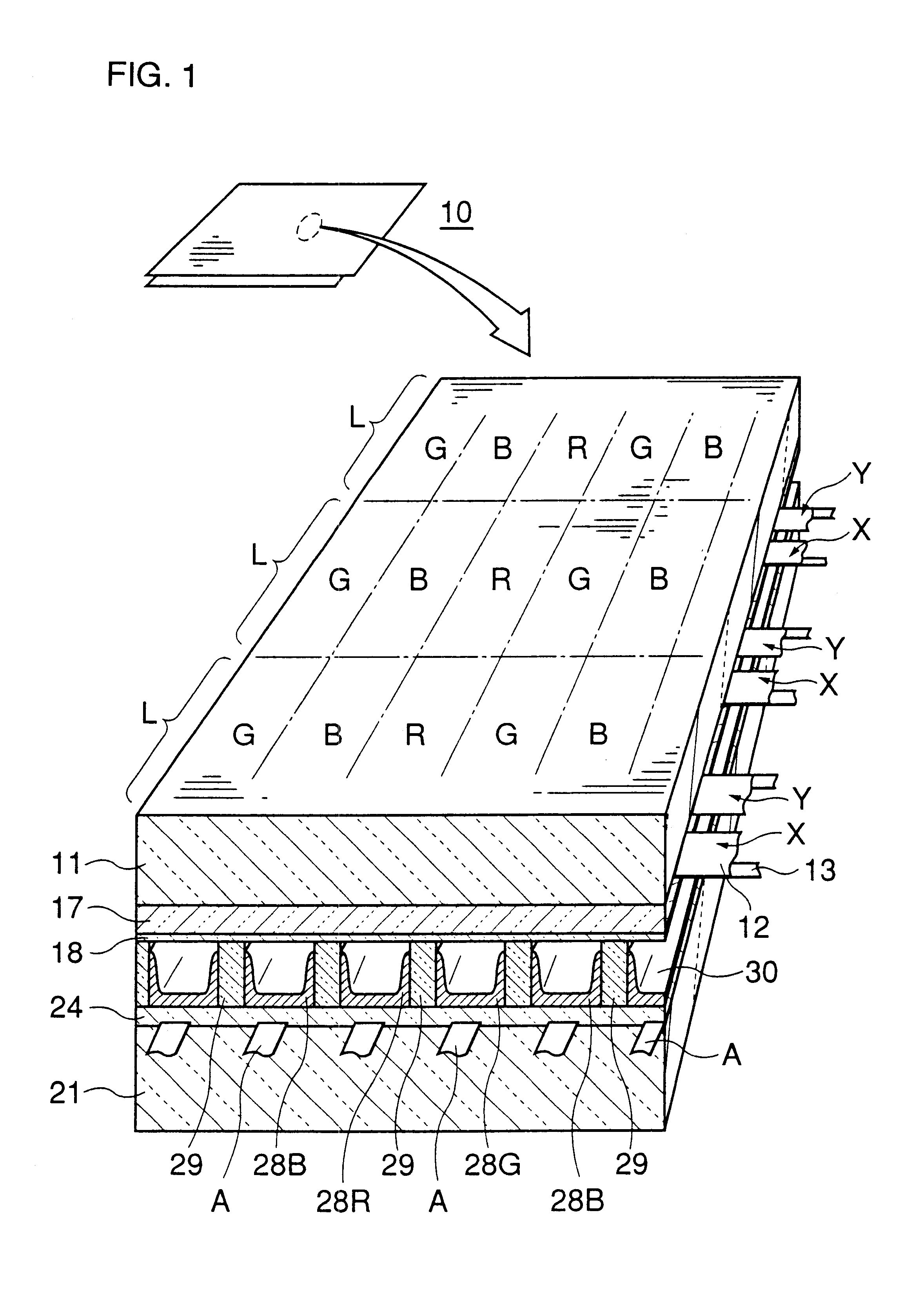

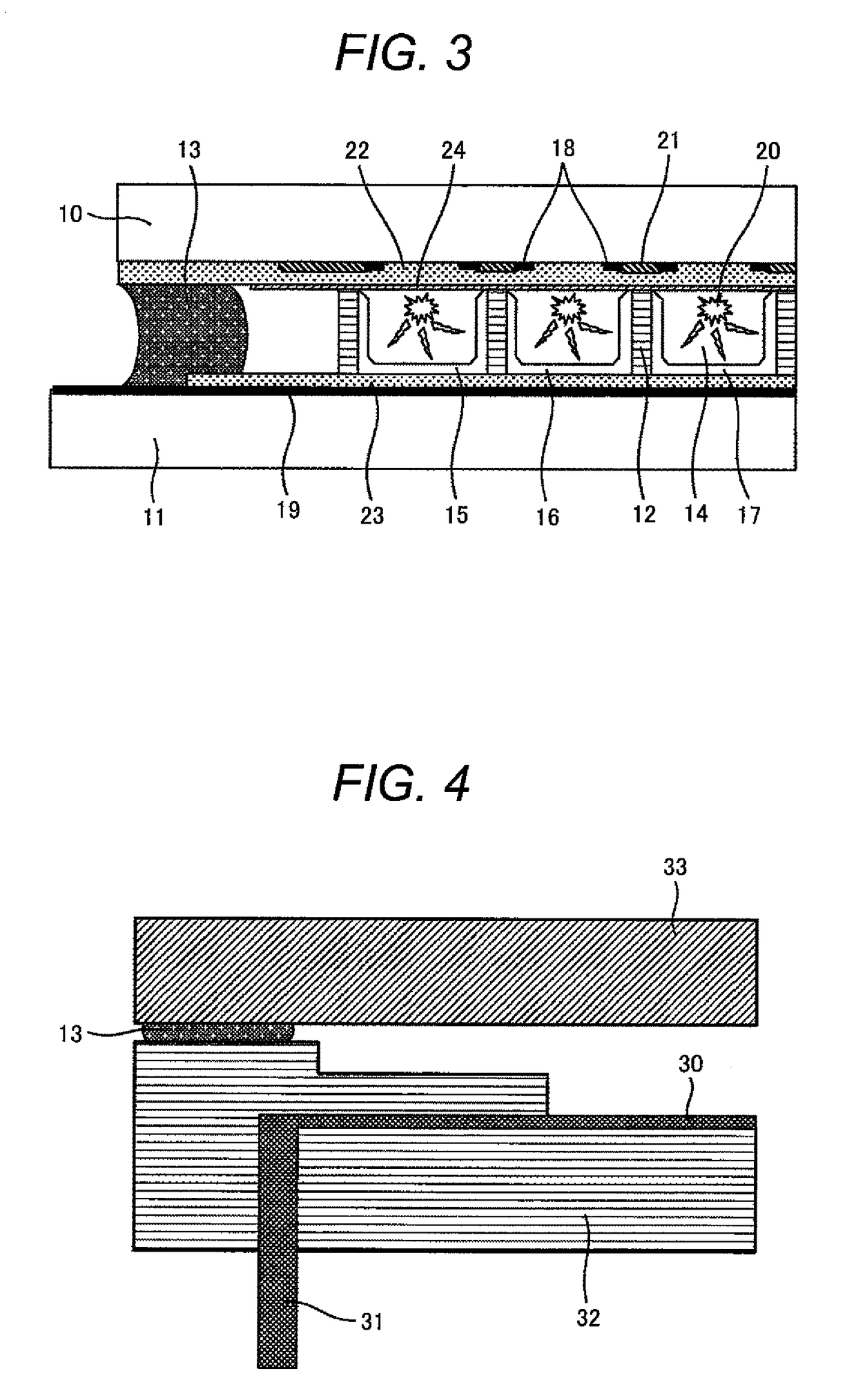

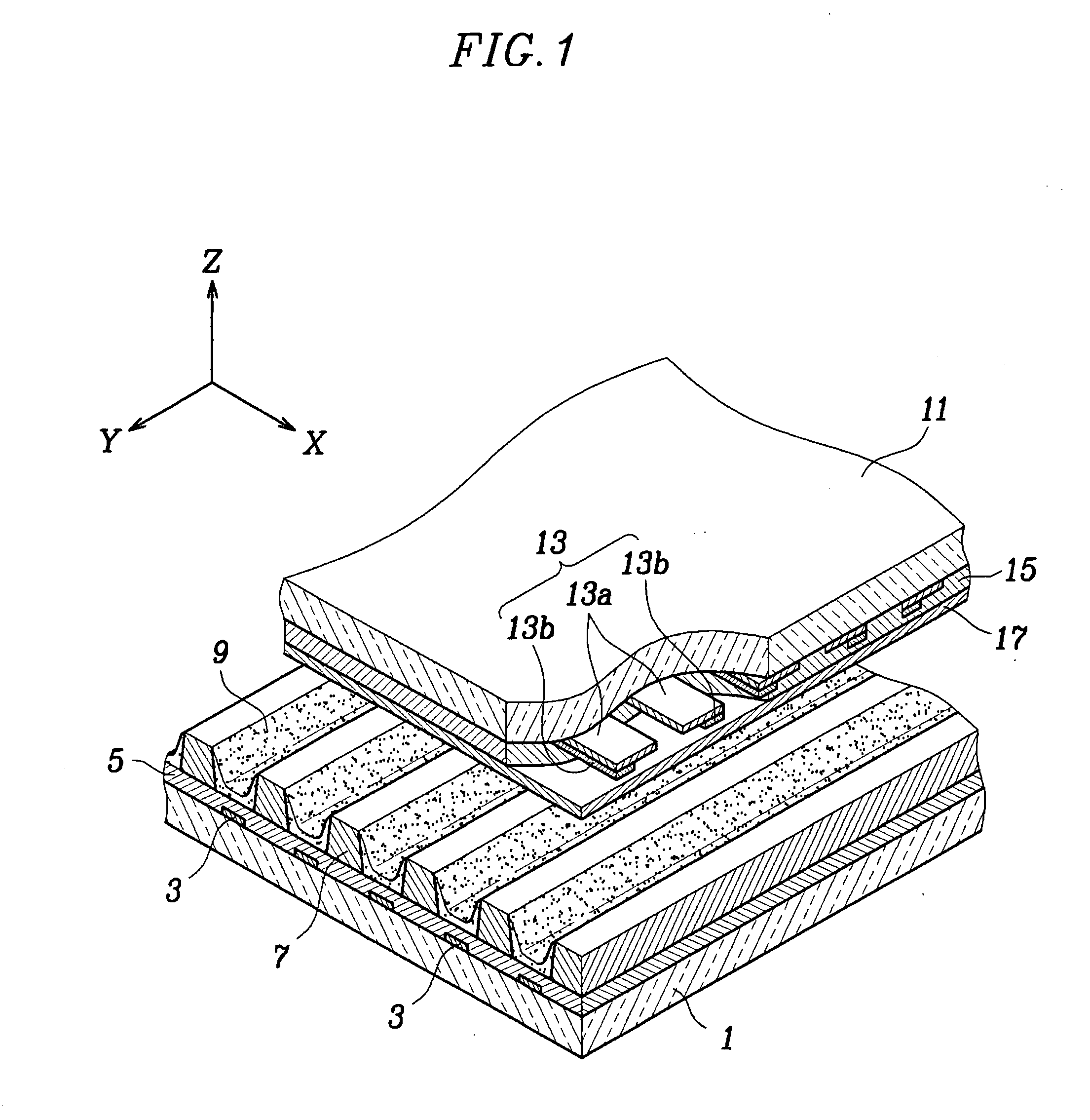

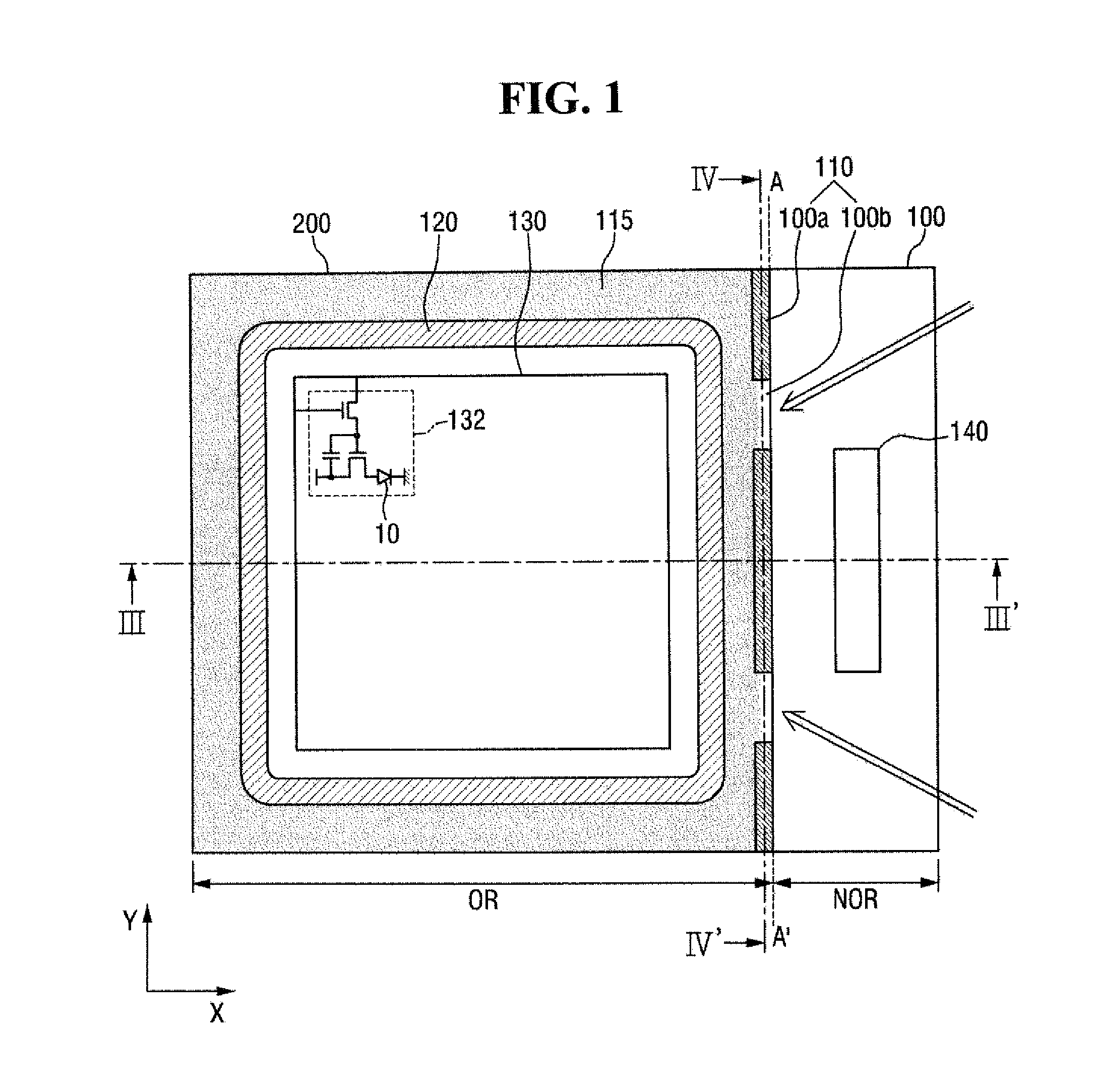

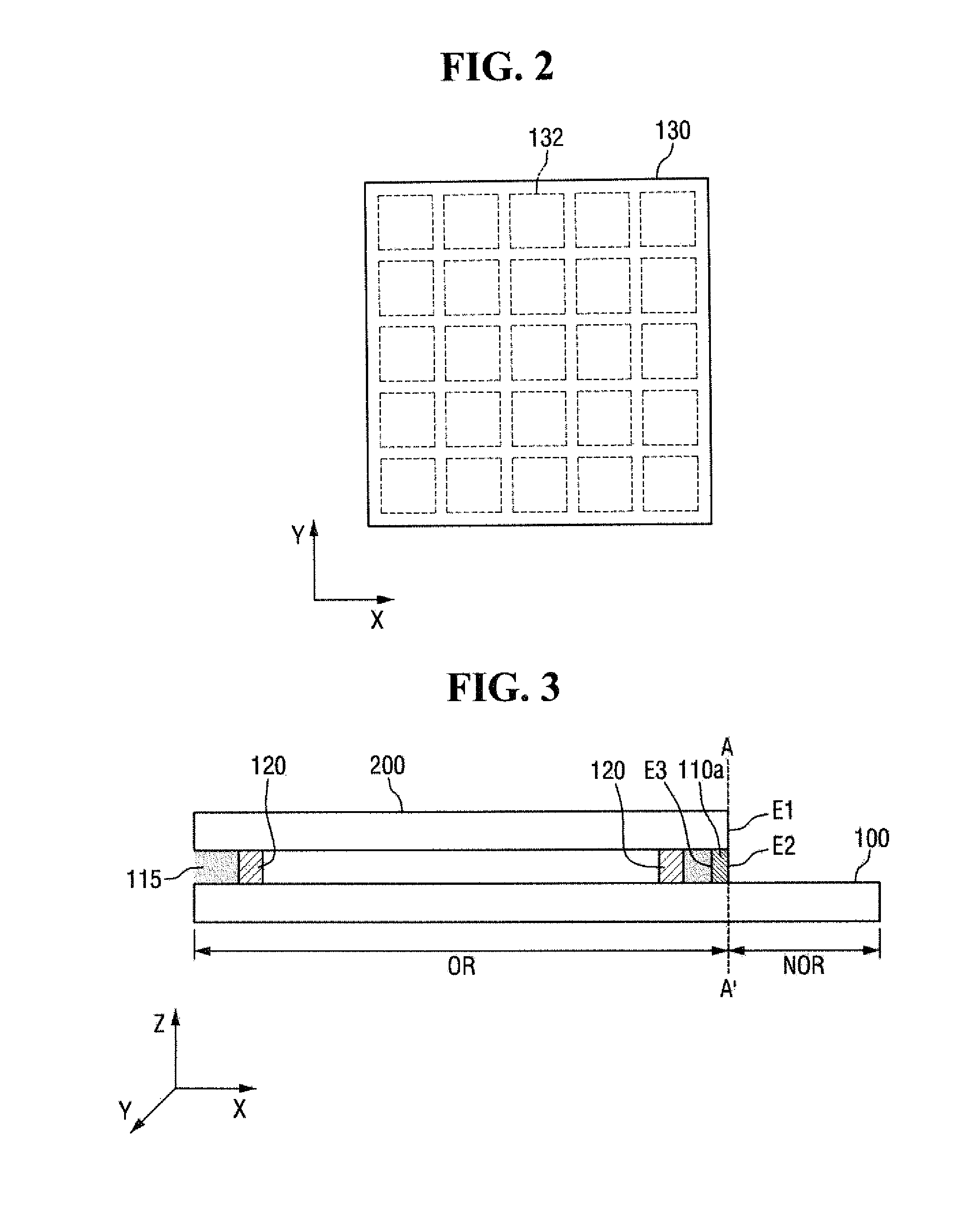

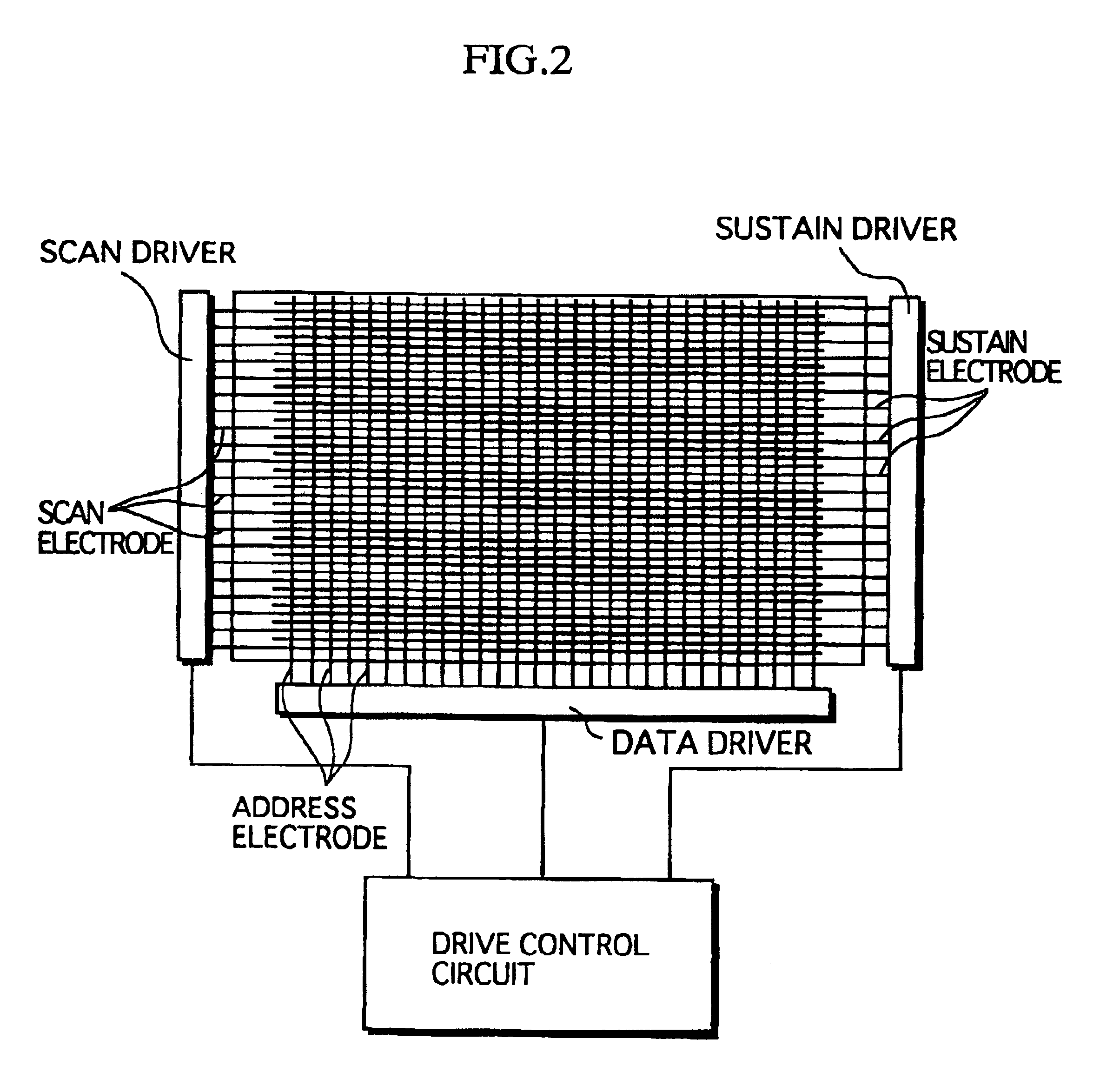

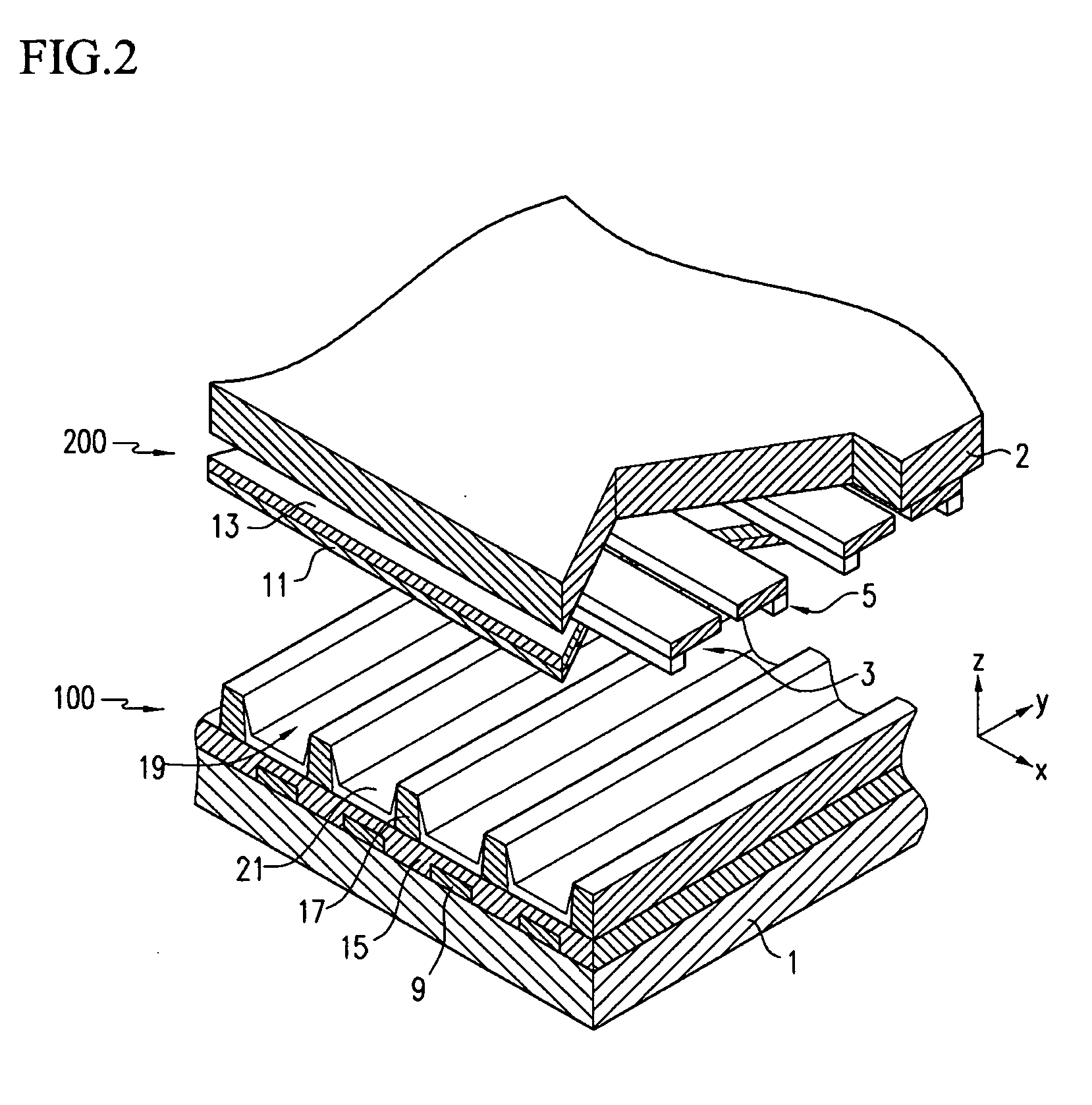

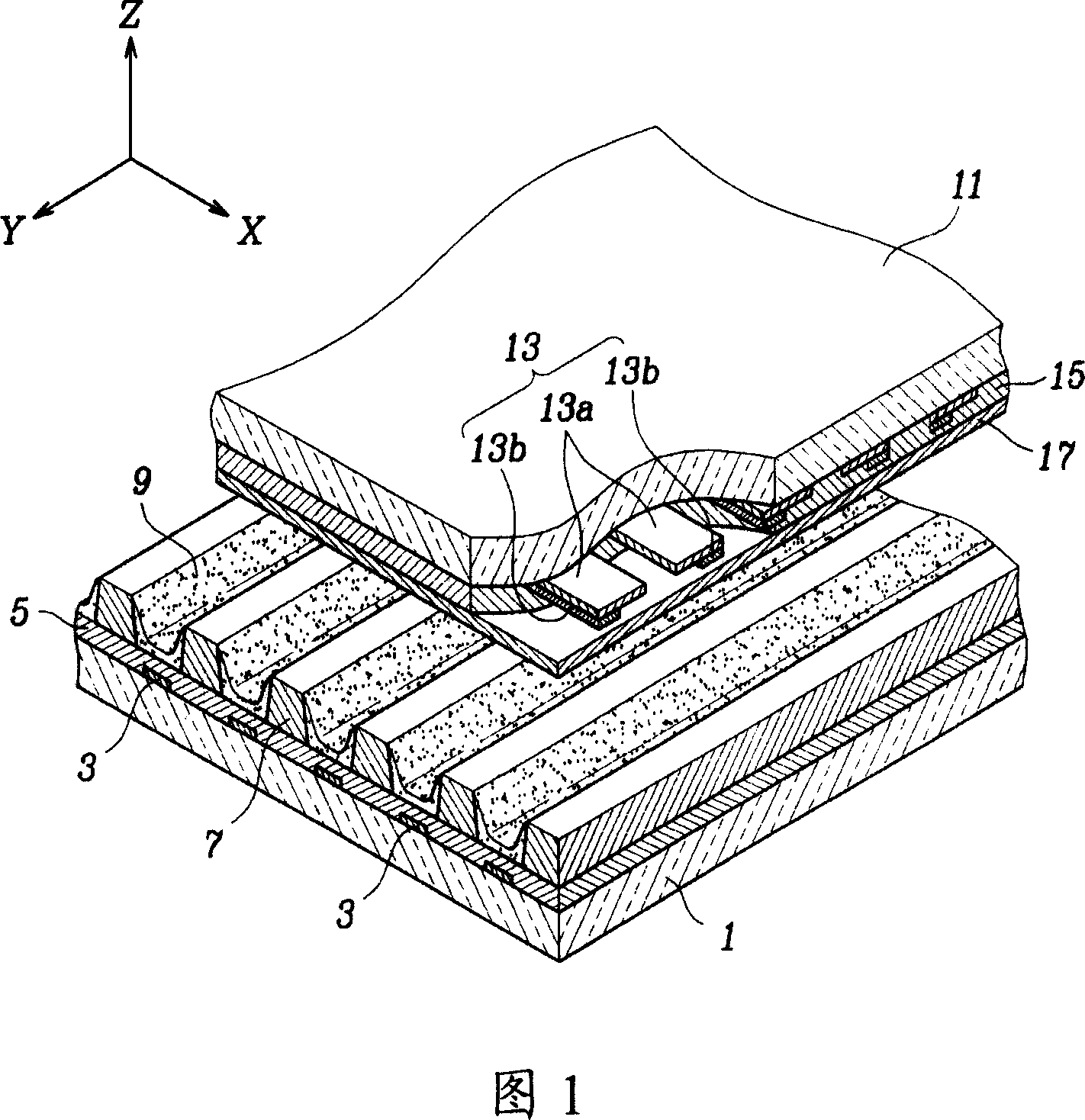

Plasma display panel and method for fabricating the same

InactiveUS7002296B2Improve efficiencyLess power consumptionAddress electrodesSustain/scan electrodesEngineeringPlasma display

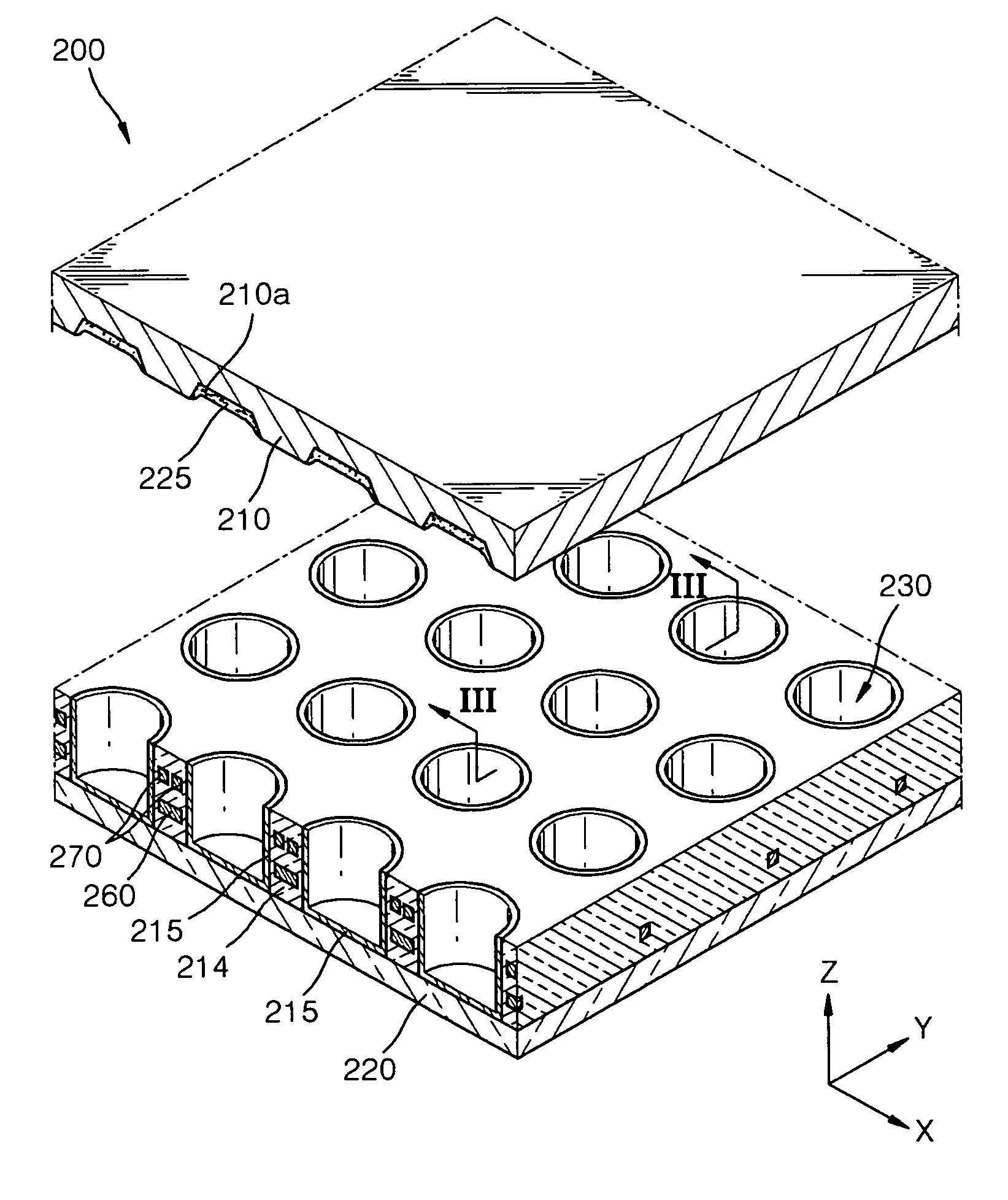

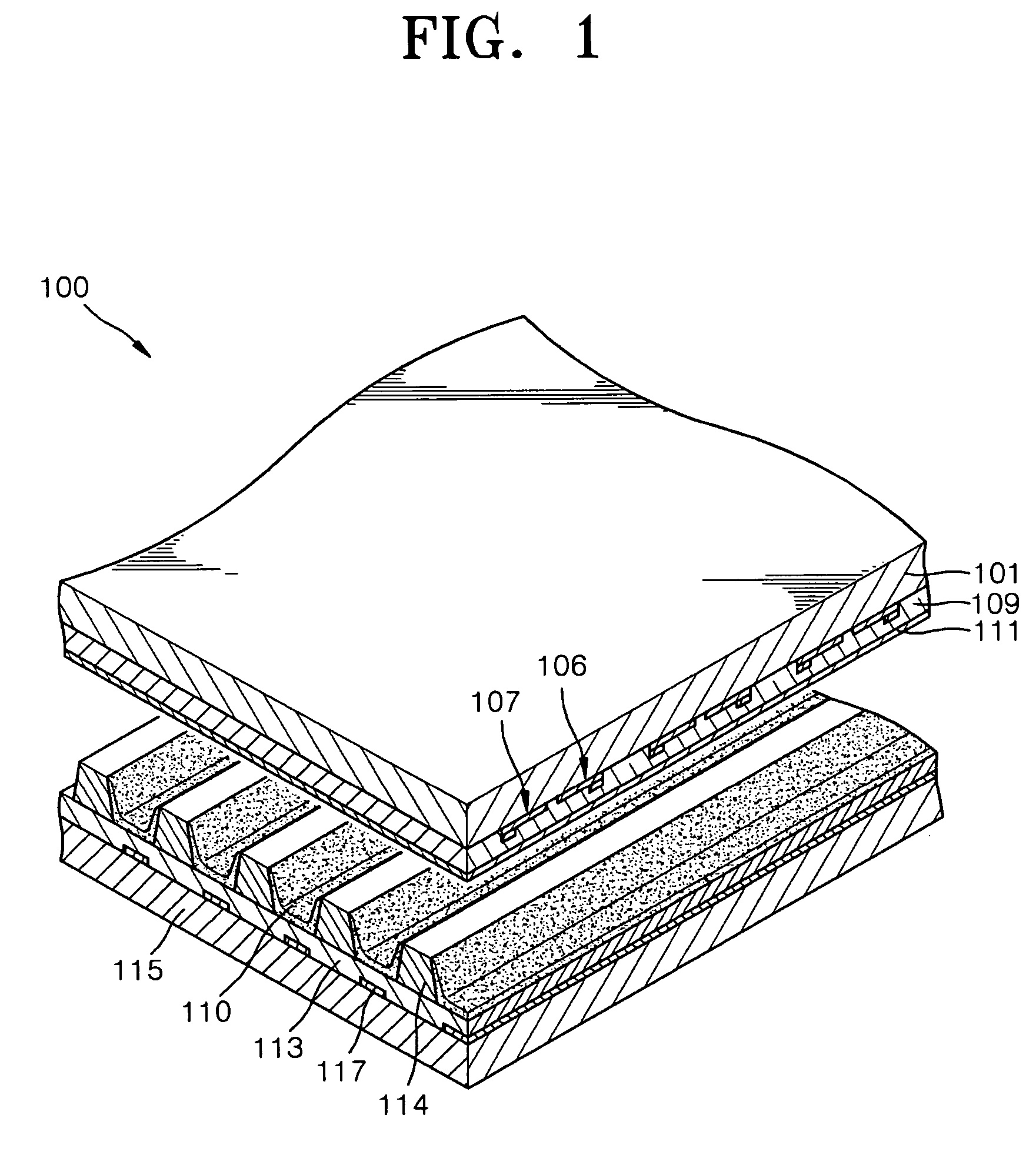

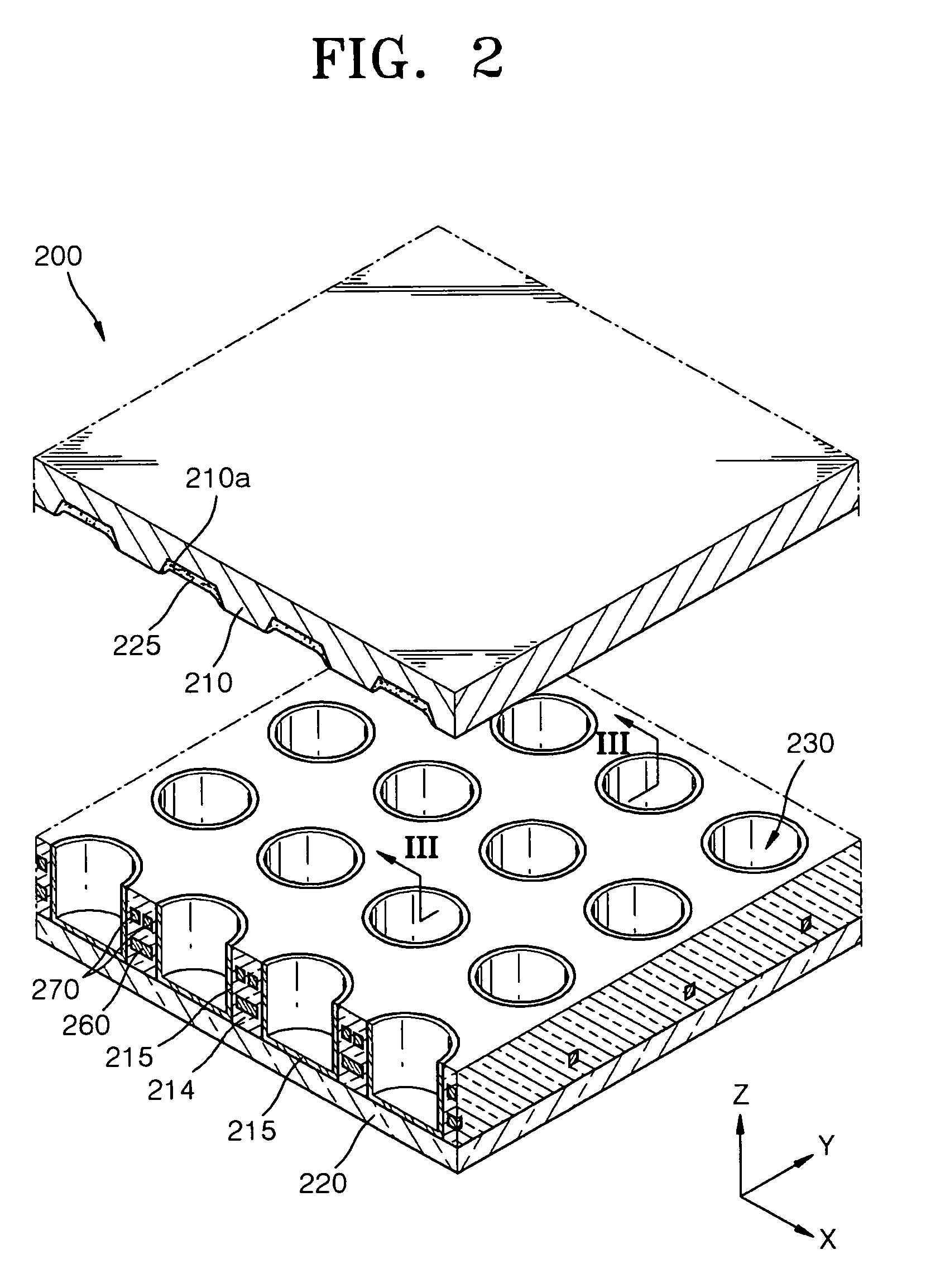

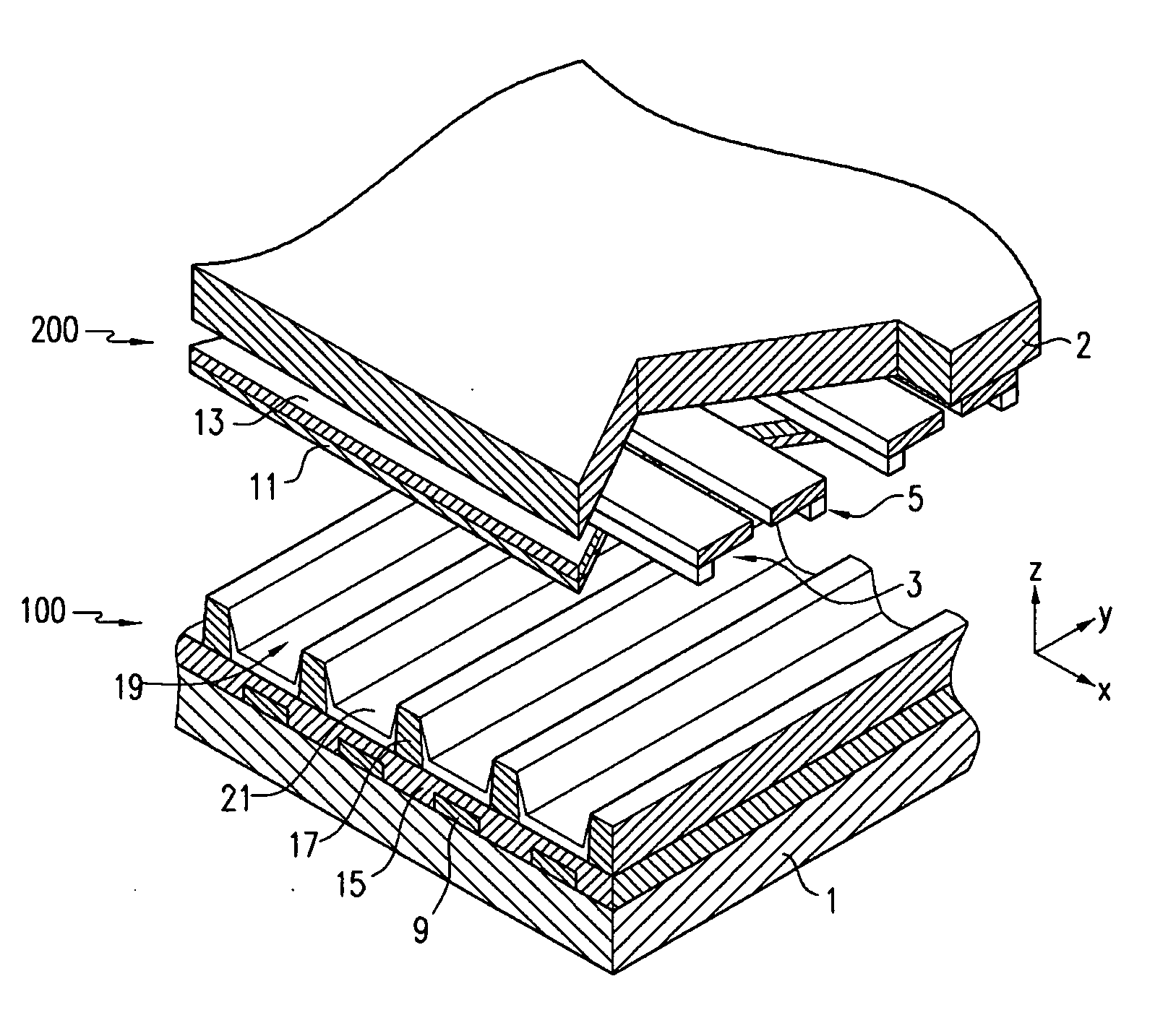

Ribs for defining pixel cells are formed in the shape of a lattice, and sustain electrodes and scan electrodes are disposed near the ribs. The electrodes are spaced apart in each pixel cell, and the sustain electrode and the scan electrode are each cut away between pixel cells arranged in the row direction to provide each pixel cell with individually separated electrodes. In addition, between pixel cells adjacent to each other in the row direction, the sustain electrodes and the scan electrodes are connected to each other by means of a sustain-side bus electrode and a scan-side bus electrode, respectively. This makes it possible to provide a high luminous efficiency.

Owner:PANASONIC CORP

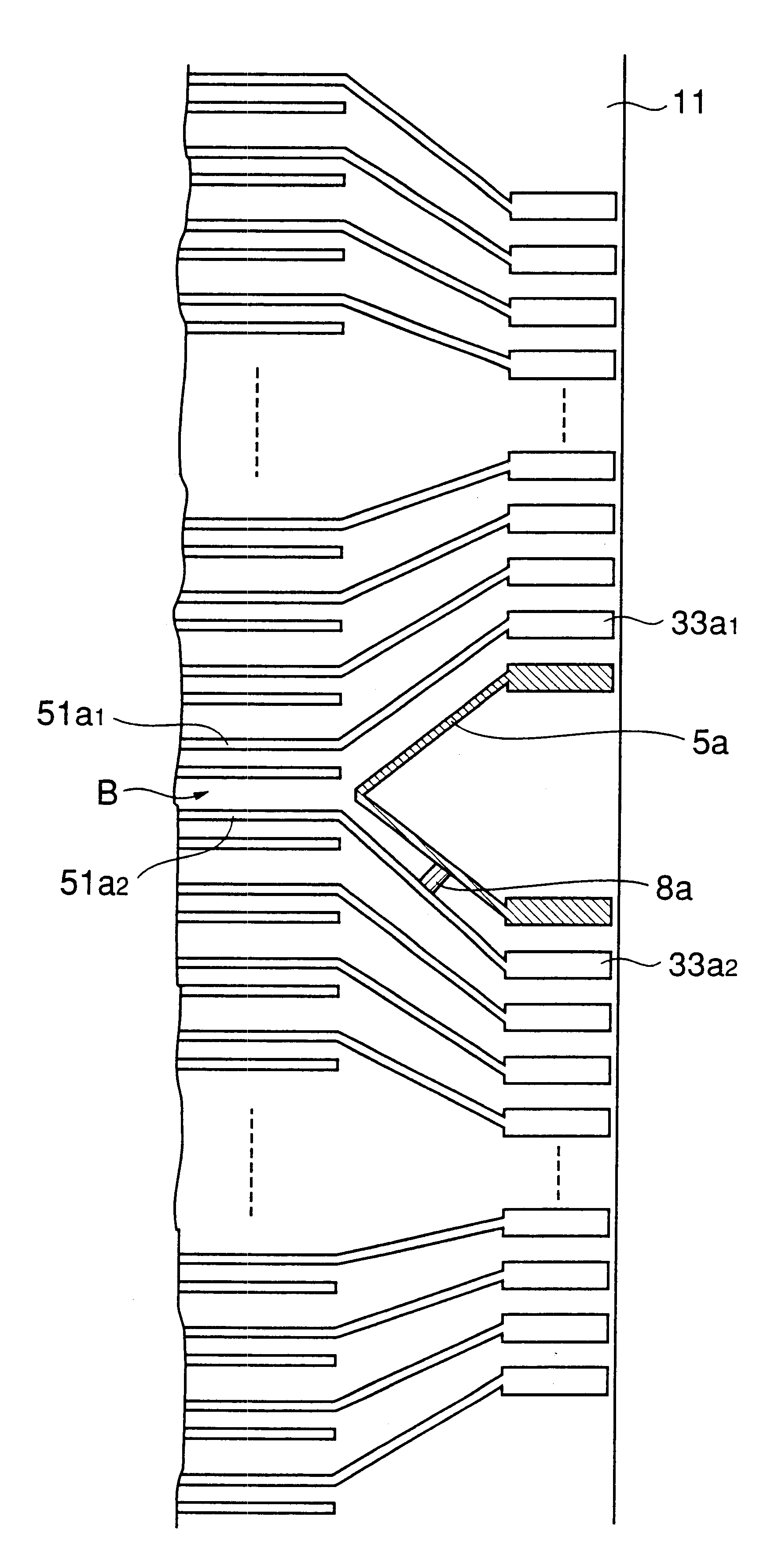

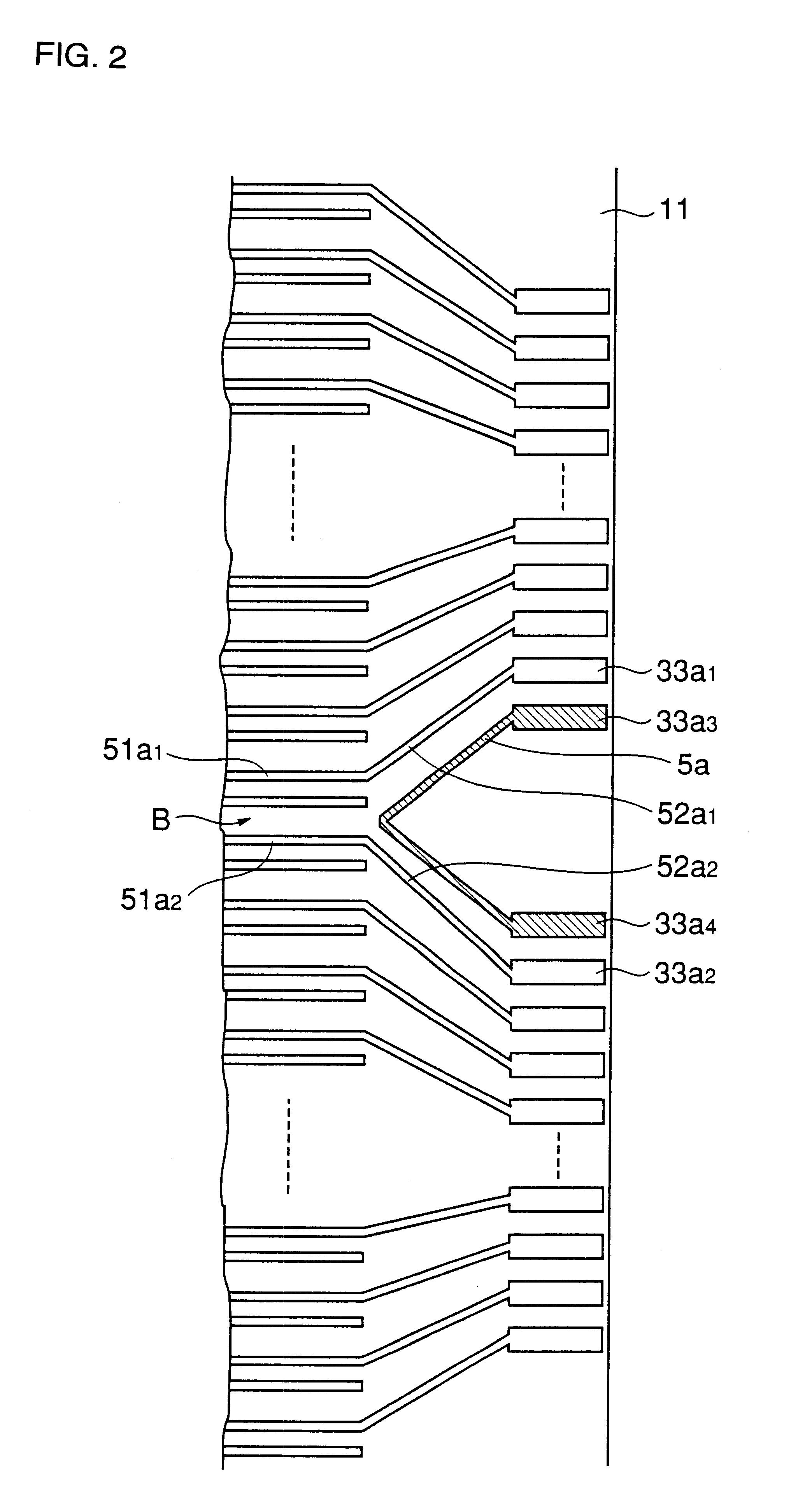

Electrode structure of display panel and electrode forming method using dummy electrode

InactiveUS6680759B2Eliminate unevennessControl flowAddress electrodesSustain/scan electrodesEngineeringLead electrode

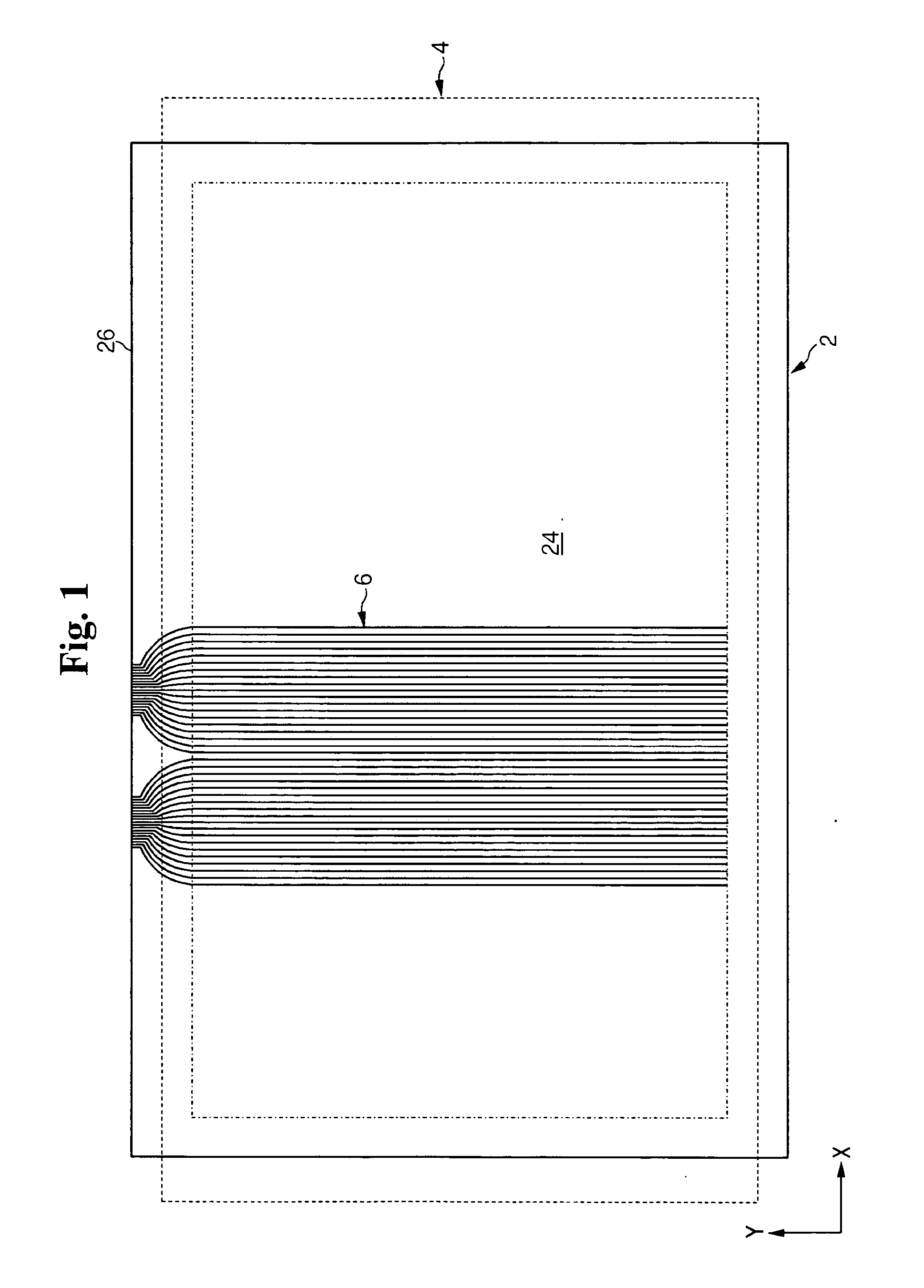

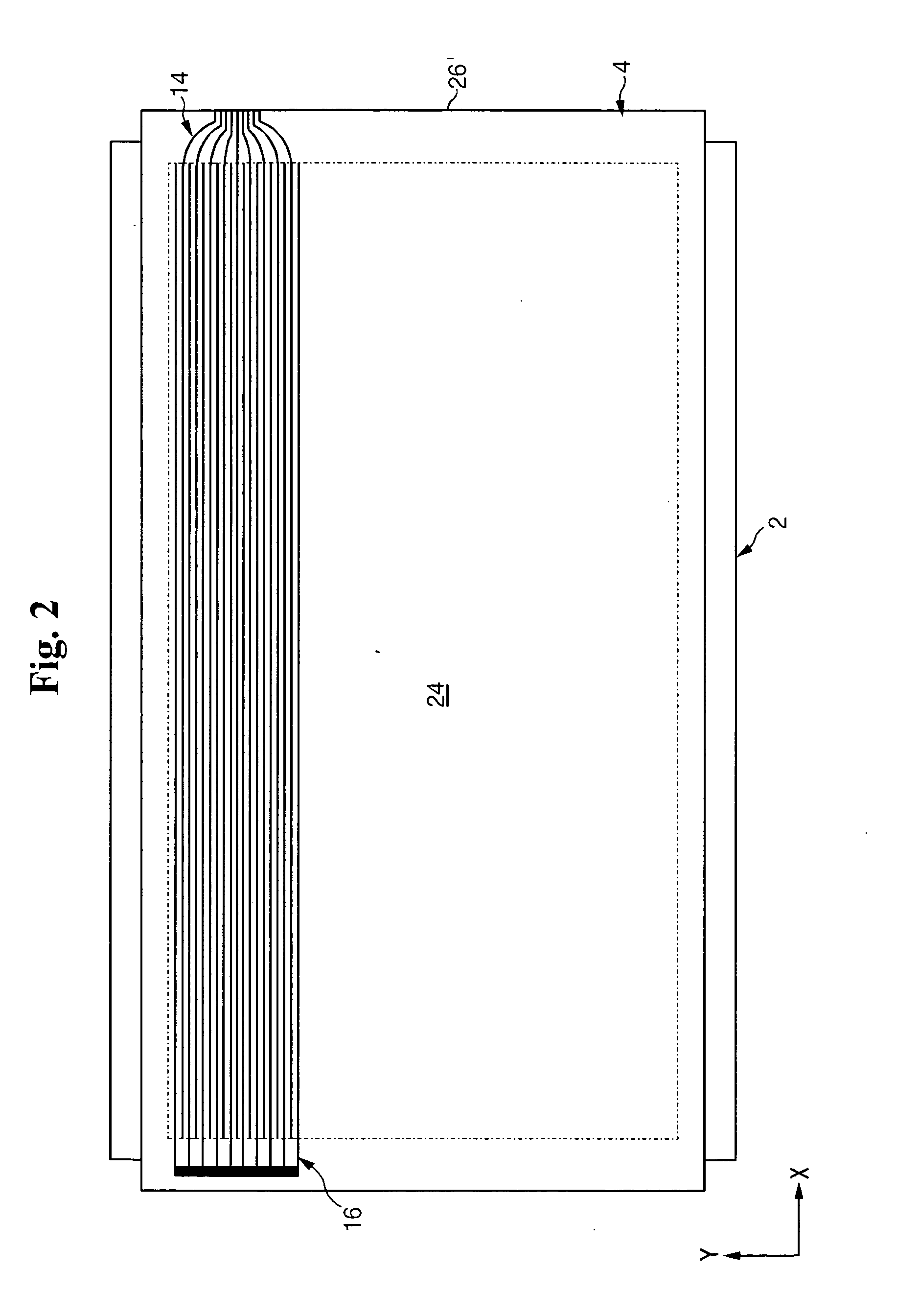

An electrode structure of a display panel includes a plurality of electrodes formed on a substrate constituting the display panel, the electrodes including display electrode portions provided in almost parallel in a central part of the substrate and oblique lead electrode portions converged in a predetermined number for each block from the display electrode portions to reach terminal portions at an end of the substrate, and a dummy electrode provided between two oblique lead electrode portions extending in different directions in a block boundary portion for limiting a flow of an etching solvent into the block boundary portion during etching when the electrodes are formed.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

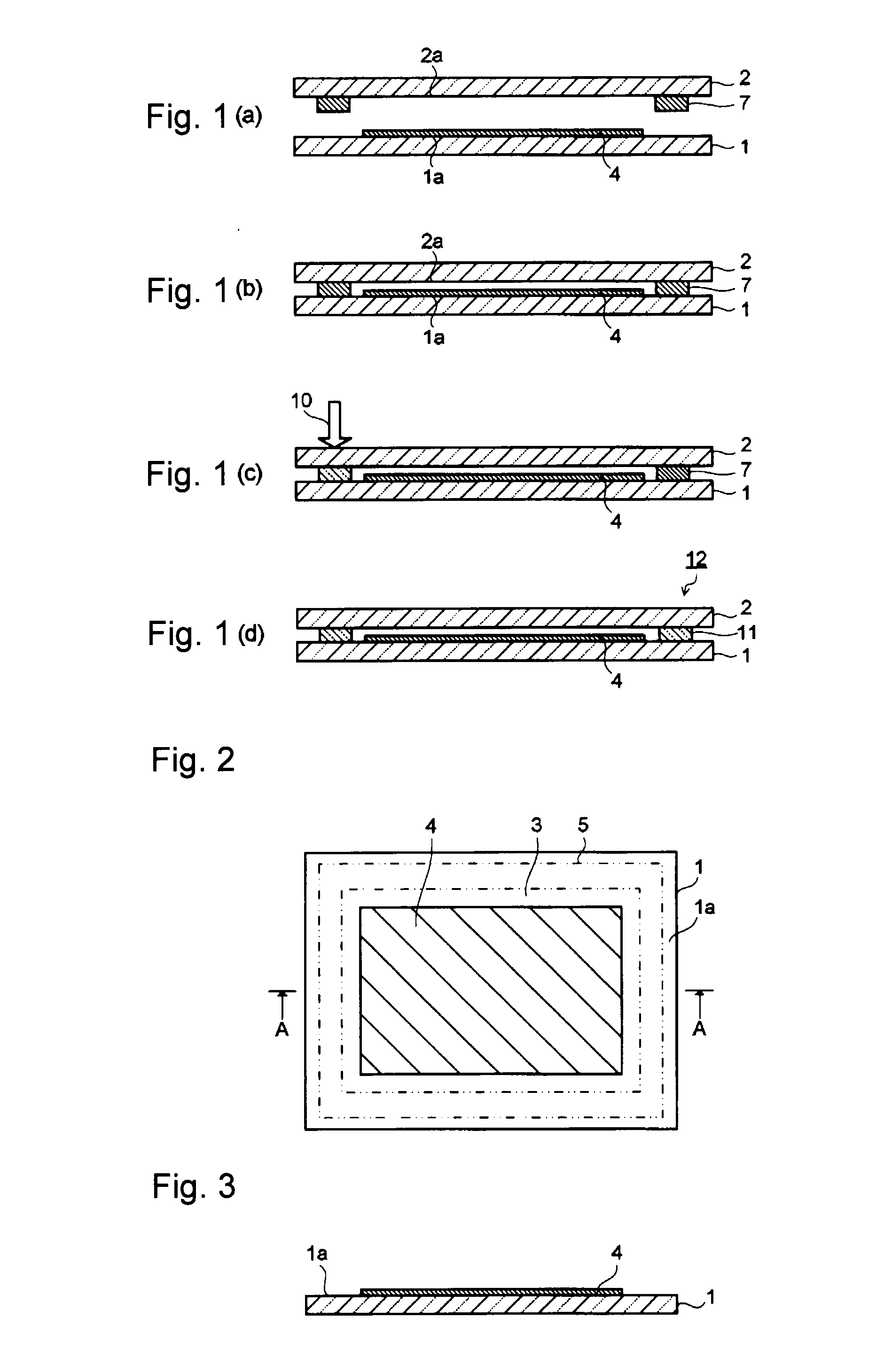

Highly productive method of producing plasma display panel

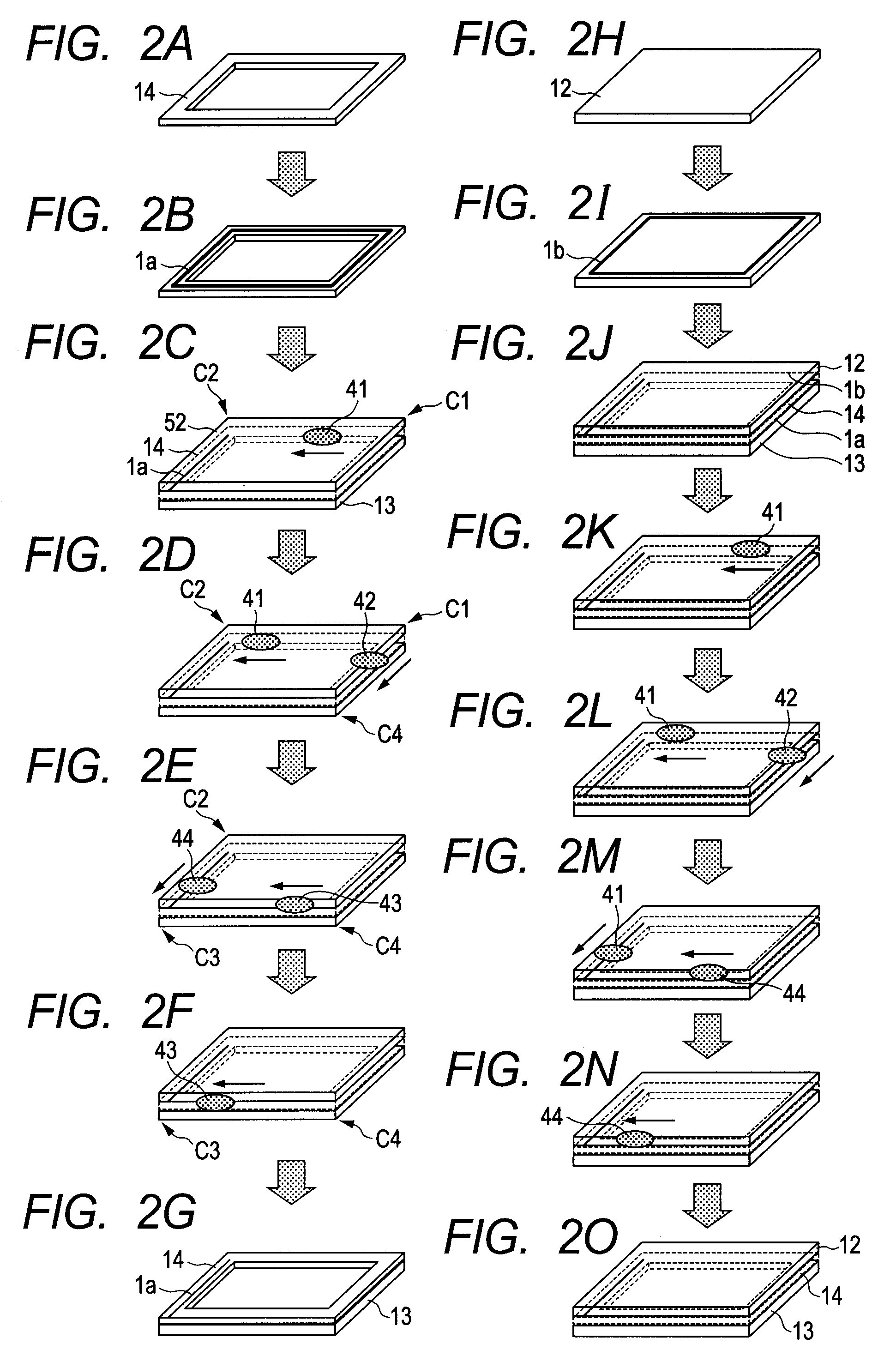

InactiveUS6860780B2Inhibit deteriorationHigh light-emitting efficiency and color purityAddress electrodesSustain/scan electrodesPhosphorEngineering

A method for producing a plasma display panel that has a front substrate and a back substrate disposed to face each other. A pre-baking phosphor layer containing a phosphor and an organic binder is formed on at least one of surfaces of the front substrate and the back substrate that are to face each other. A sealing material that softens with heat is applied to the peripheral region of at least one of the surfaces of the front and back substrates that are to face each other. The front and back substrates are disposed to face each other in a stack. The front and back substrates are heated to burn out the organic binder while supplying a dry gas containing oxygen to an internal space that is formed between the front and back substrates.

Owner:PANASONIC CORP

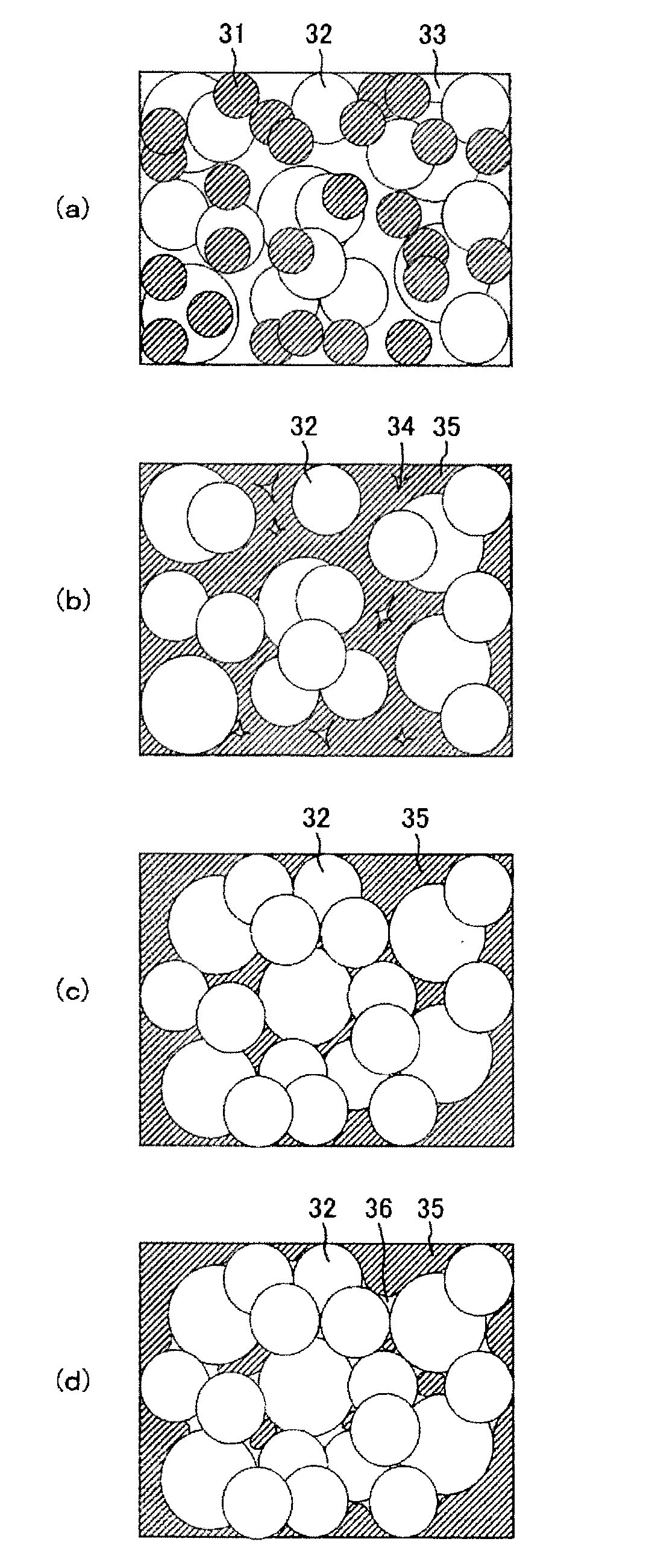

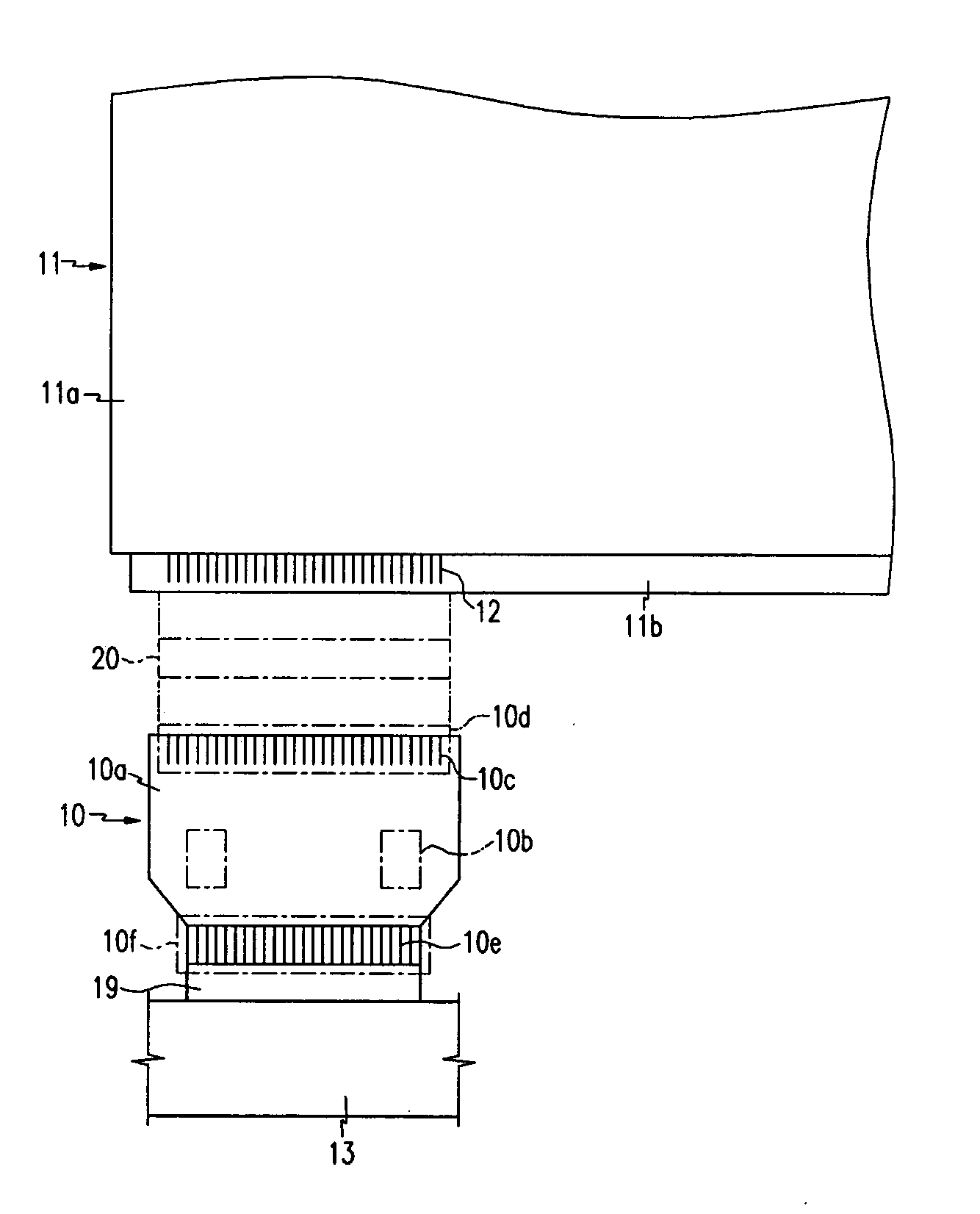

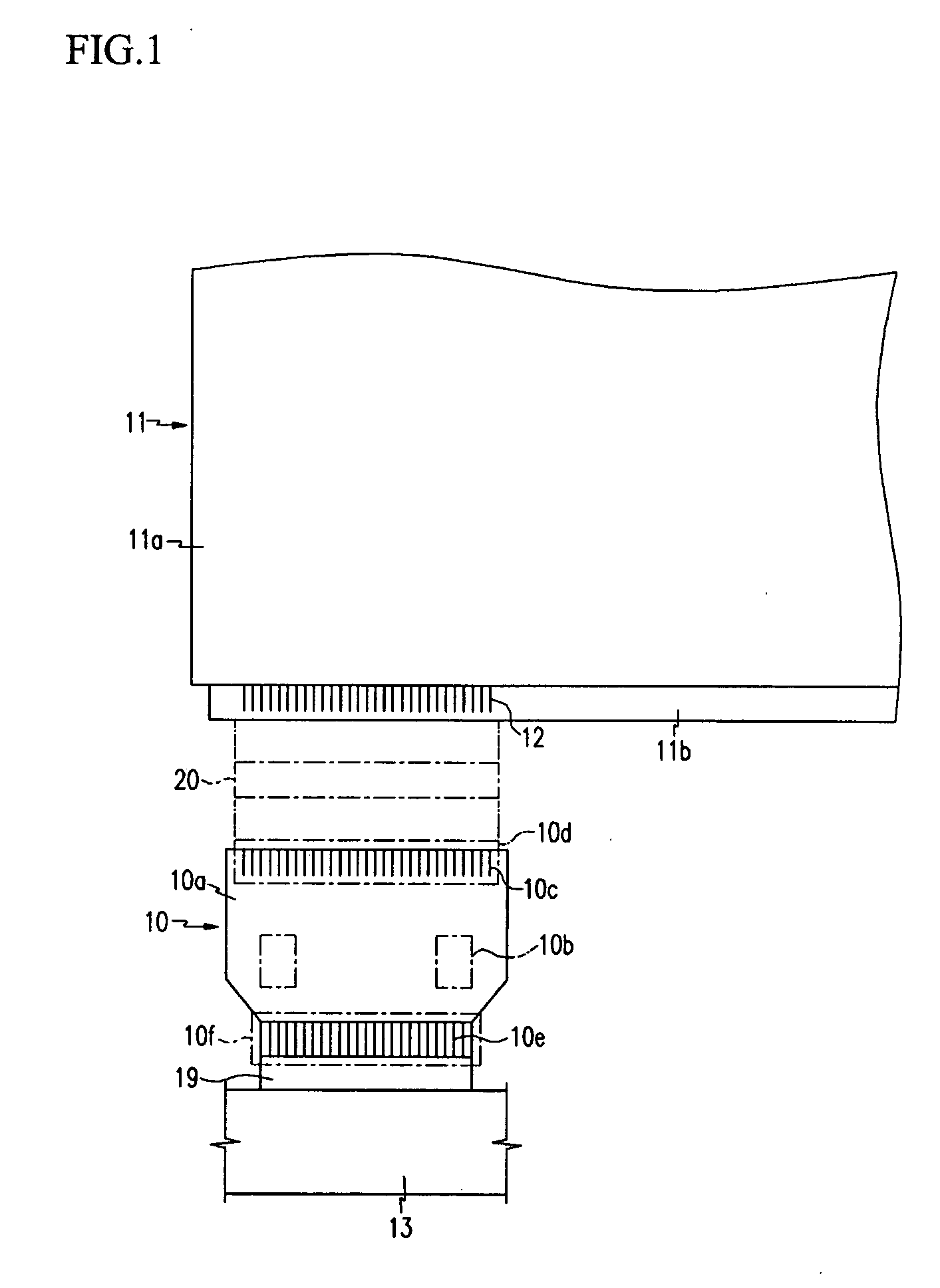

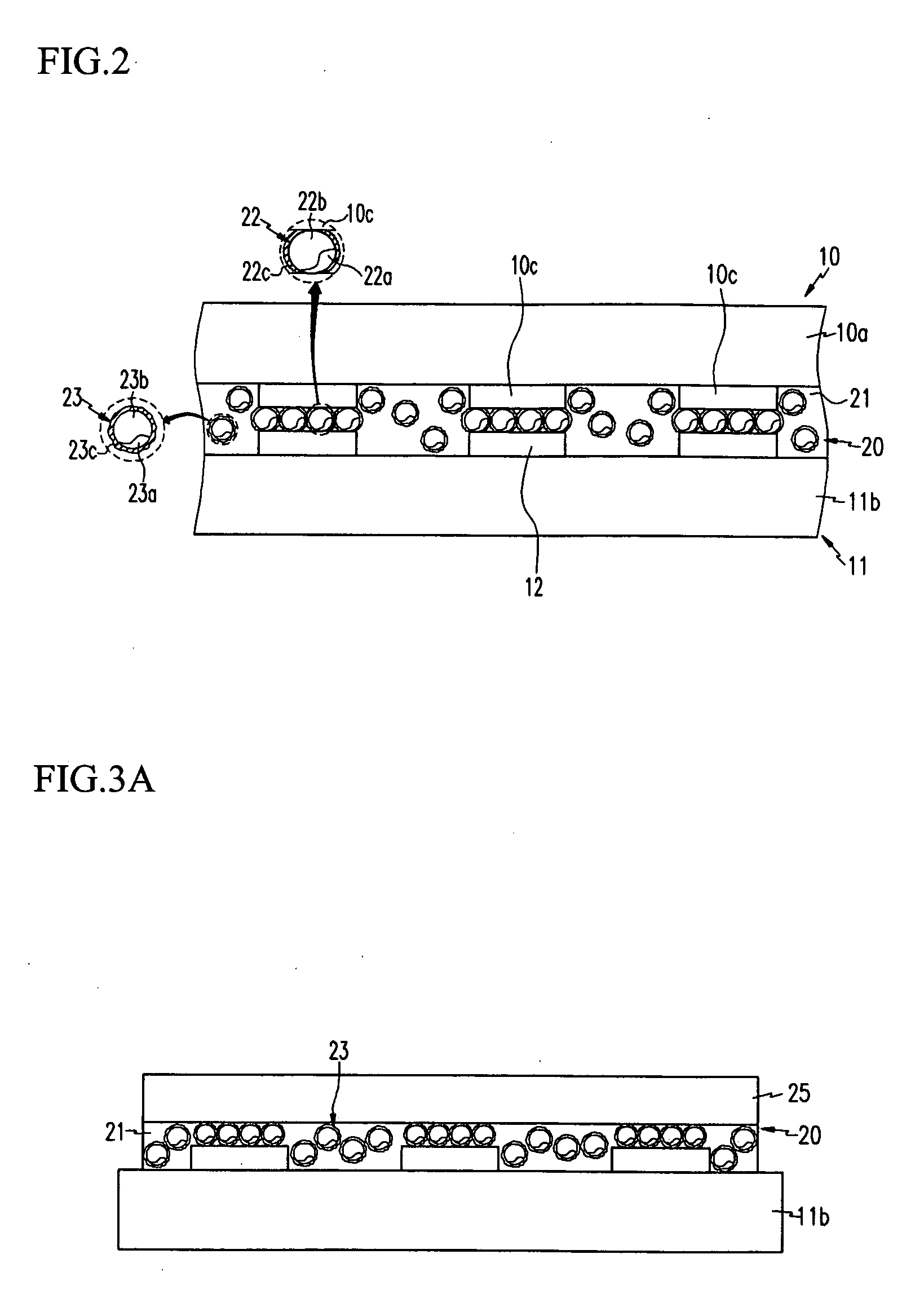

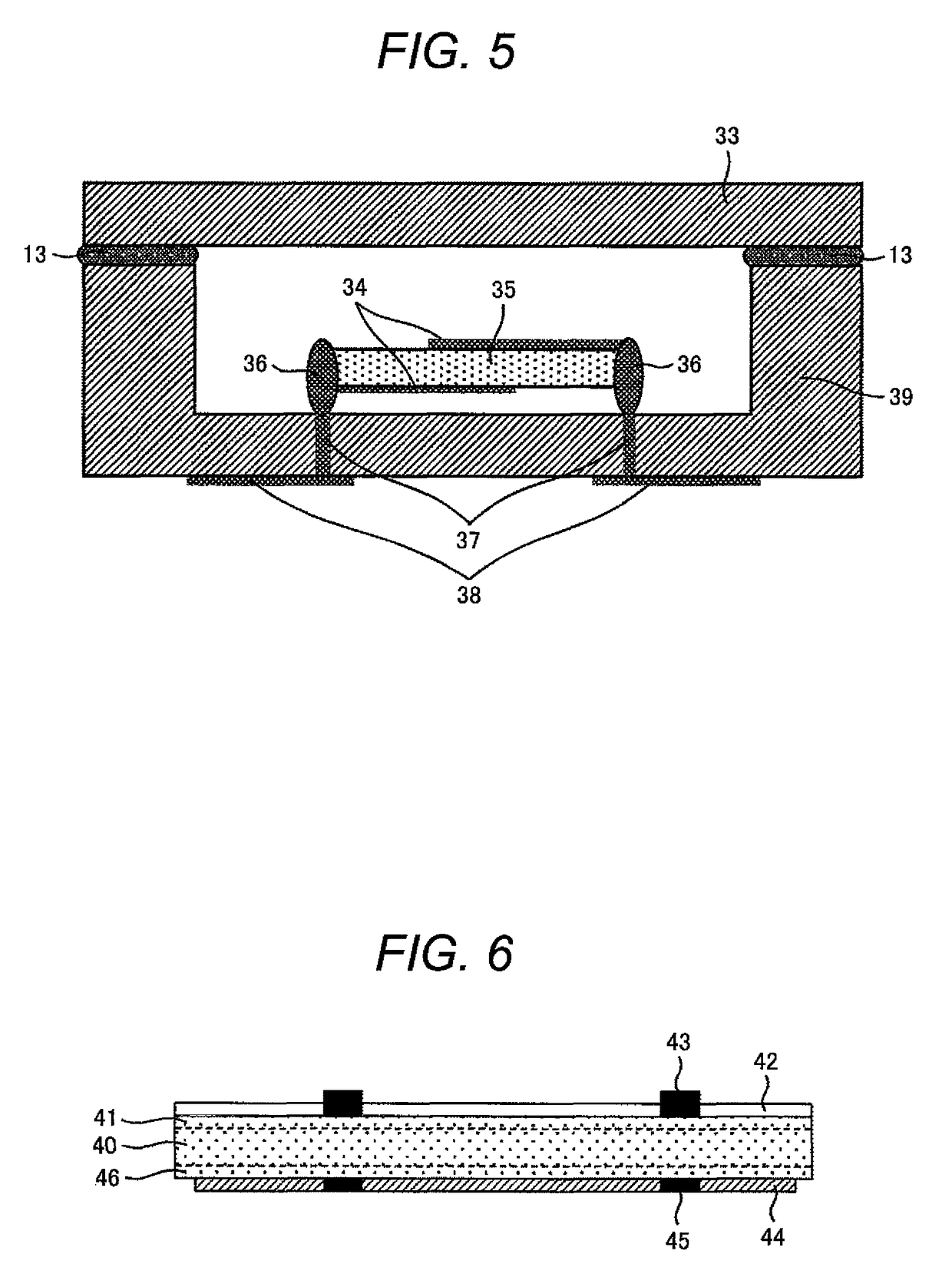

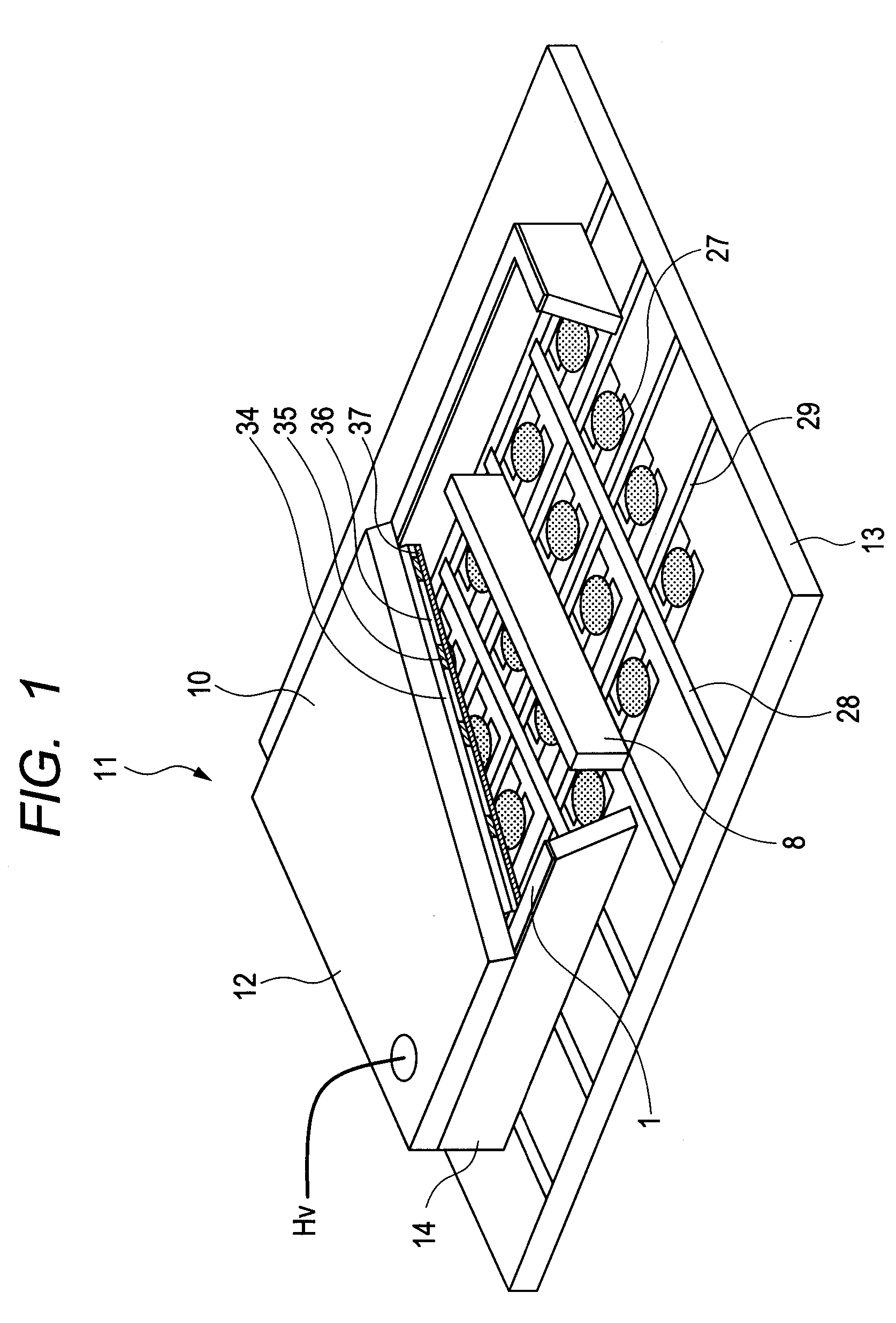

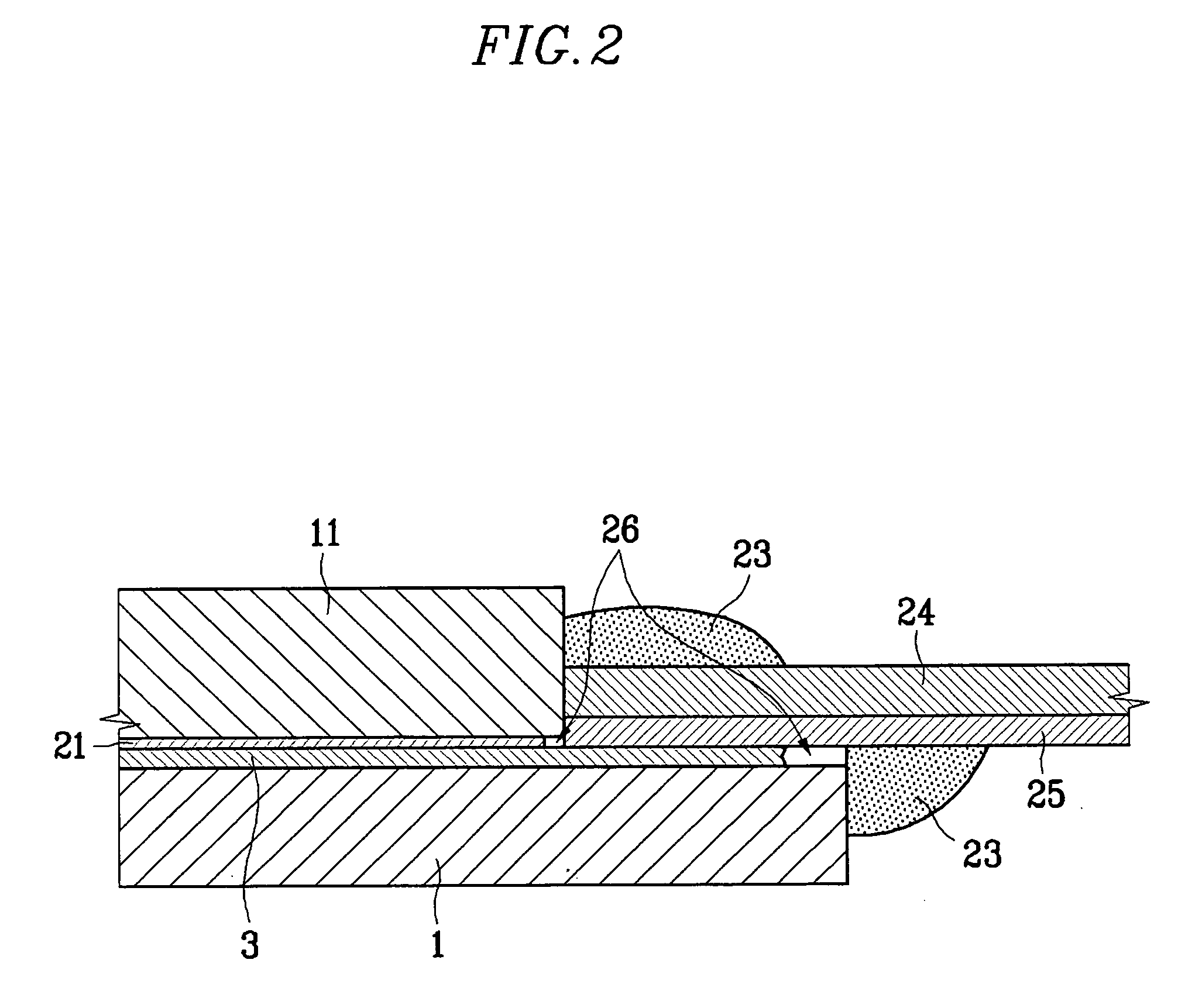

Interconnector, method for manufacturing a plasma display device using the same, and a plasma display device with the same

InactiveUS20050110406A1Strengthen interconnectionAlternating current plasma display panelsPrinted circuits structural associationsInterconnectorEngineering

A plasma display device may include a plasma display panel, a driving circuit portion for driving the plasma display panel, a connecter for electrically connecting electrodes of the plasma display panel with the driving circuit portion, and an interconnecter for electrically connecting the connecter with the plasma display panel. The interconnecter may include an adhesive layer, a plurality of conductive pellets, and a plurality of non-conductive pellets dispersed in the adhesive layer. The conductive pellets may be positioned substantially within a first region where the wiring of the connecter overlaps the electrodes of the plasma display panel. The non-conductive pellets may be positioned substantially at least at a second region other than the first region in the adhesive layer.

Owner:SAMSUNG SDI CO LTD

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS8470723B2Reduce softeningAddress electrodesConductive layers on insulating-supportsBismuthAntimony

Owner:RESONAC CORP

Manufacturing method of hermetic container and image display apparatus

InactiveUS20110265518A1Low viscosityReduce the differenceCathode-ray/electron-beam tube vessels/containersGas discharge vessels/containersViscosityElectrical and Electronics engineering

A manufacturing method of a hermetic container includes the steps of sandwiching a frame-like sealing material between a first glass substrate and a second glass substrate, irradiating first local heating light to a first region of the sealing material, and sealing the first glass substrate and the second glass substrate to each. The sealing is performed by irradiating, on a boundary between the first region of the sealing material and a second region of the sealing material which is adjacent to the first region and on which the first local heating light is not irradiated, second local heating light to heat and melt a portion of the second region adjacent to the boundary, during a period that viscosity of the sealing material at a portion of the first region adjacent to the boundary is equal to or lower than 1018 Pa·sec.

Owner:CANON KK

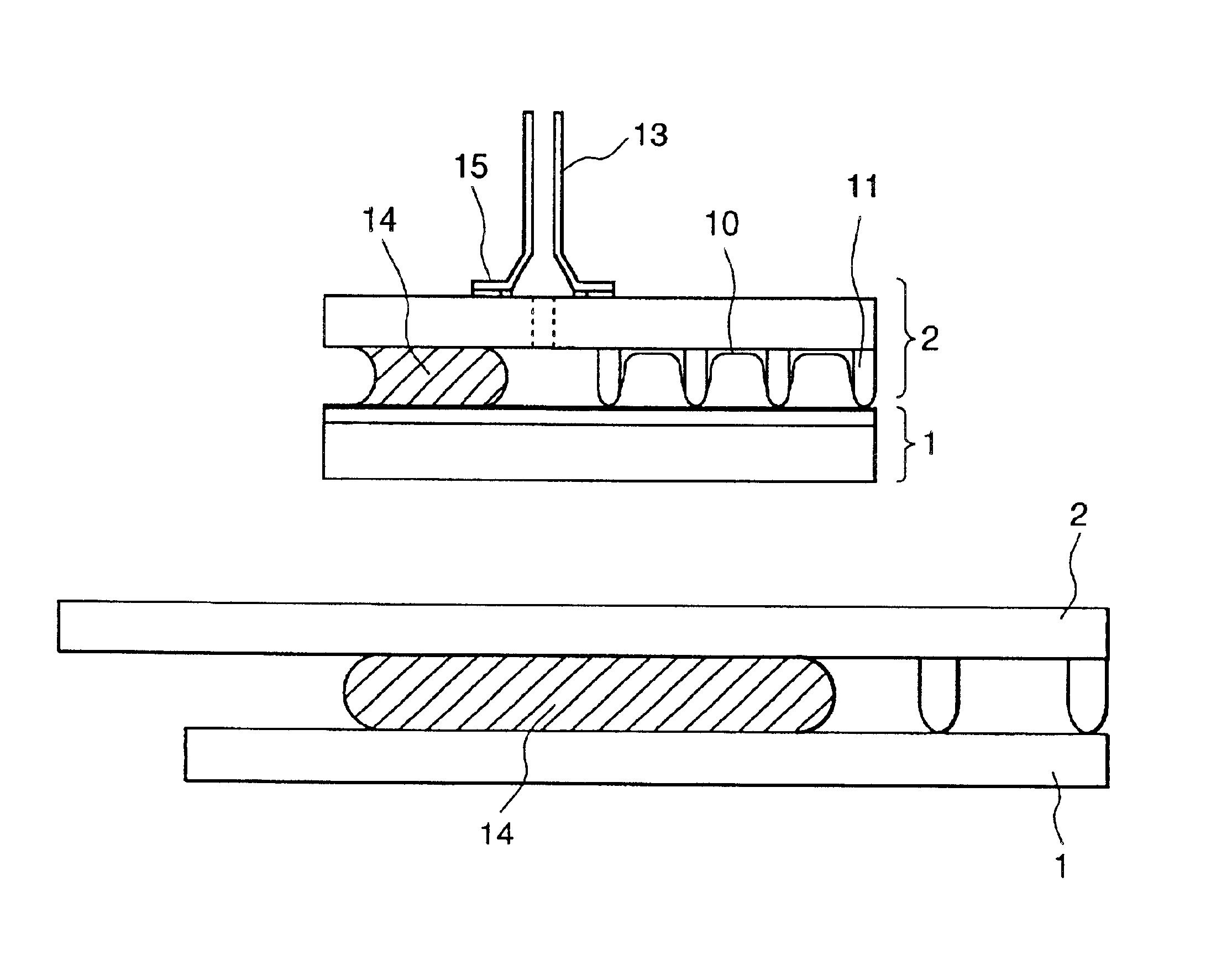

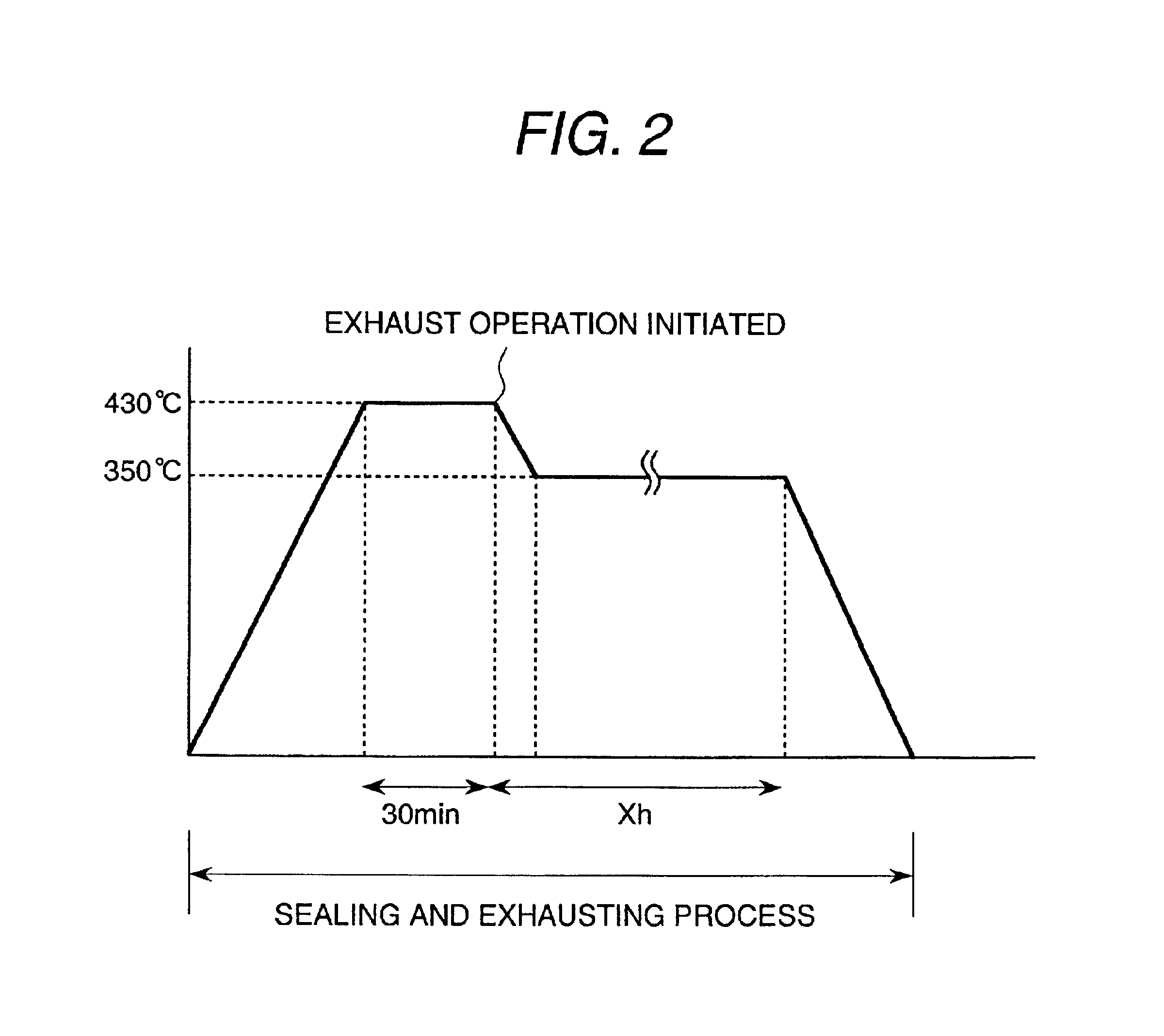

Plasma display panel manufacturing method for achieving luminescence characteristics

InactiveUS6666738B1Avoid flowInhibit deteriorationTube/lamp vessel degassingAlternating current plasma display panelsFluorescenceEngineering

The object of this invention is to provide a plasma display panel in which an aging process essential to the manufacturing process generates minimal phosphor deterioration, enabling a relatively high luminous efficiency and high quality color production to be produced. To achieve this object, the aging process takes place while gas generated inside the panel is evacuated. Alternatively, after completion of the aging process, the phosphor of the whole panel is heated to restore heat deterioration.

Owner:PANASONIC CORP

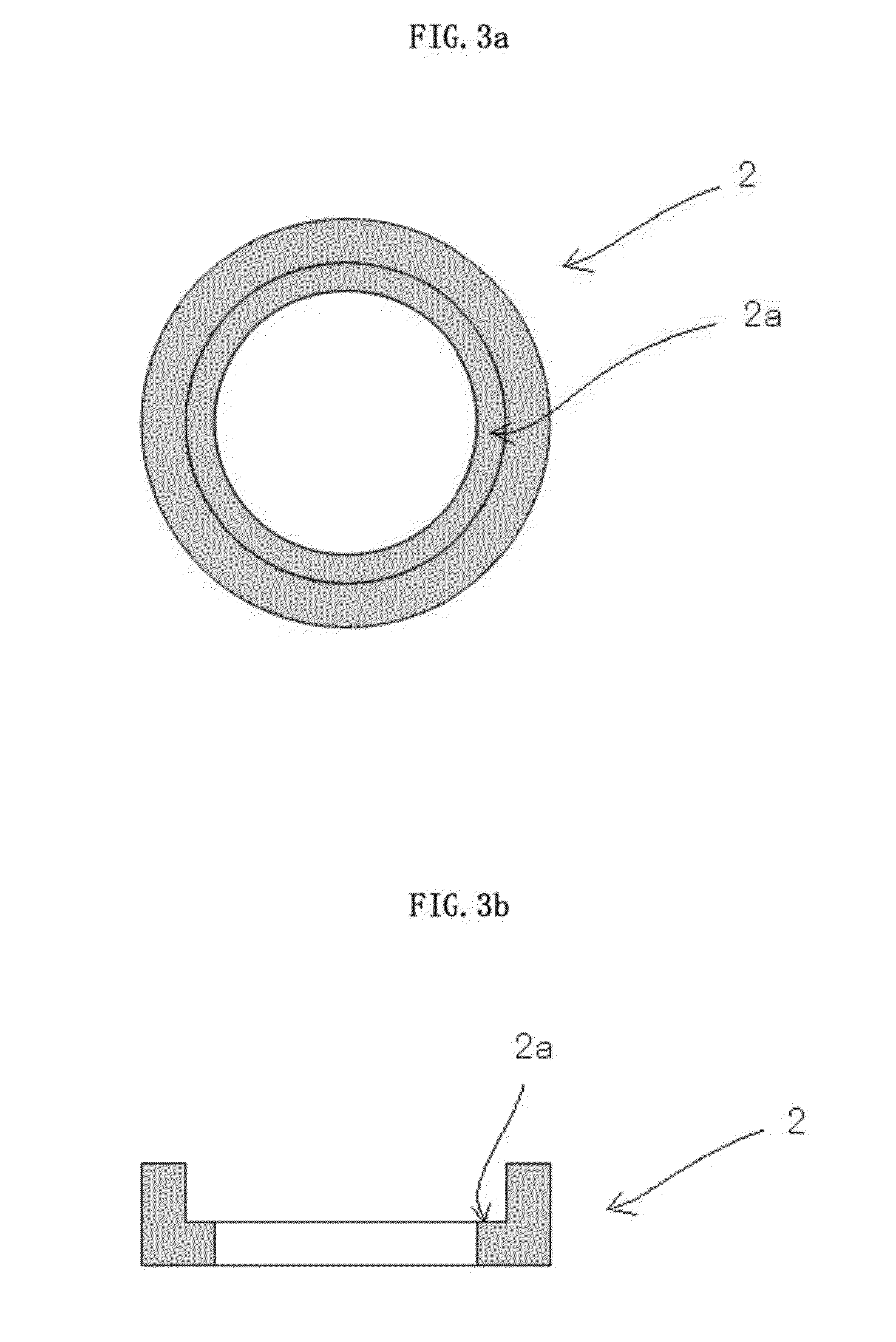

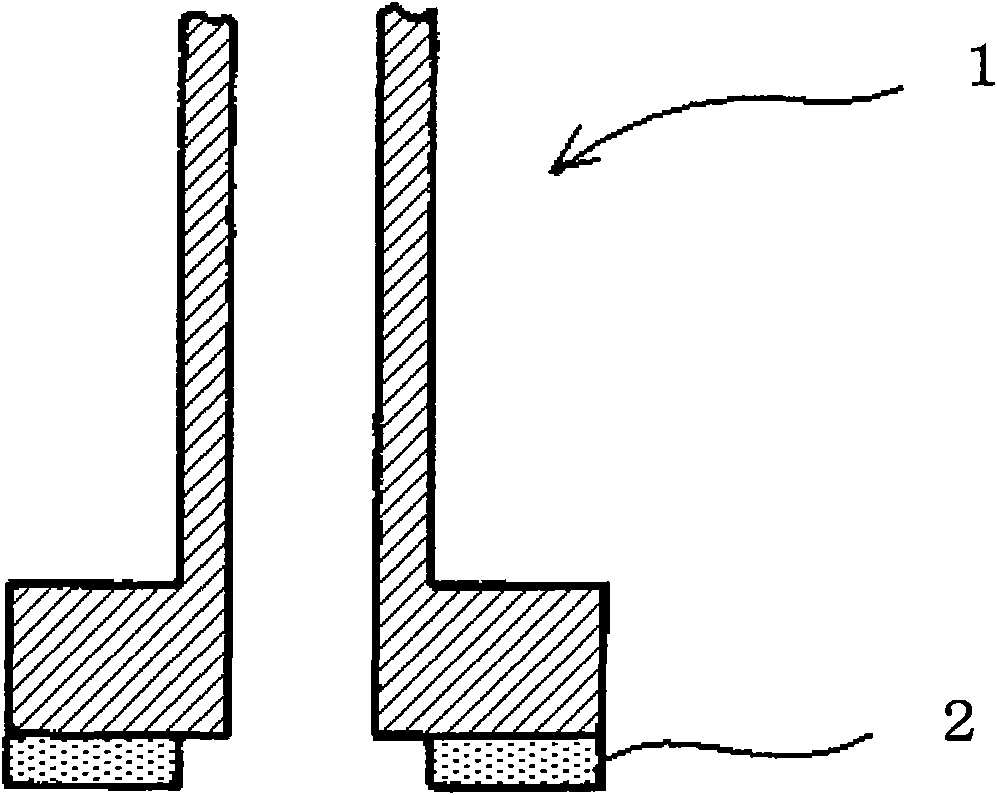

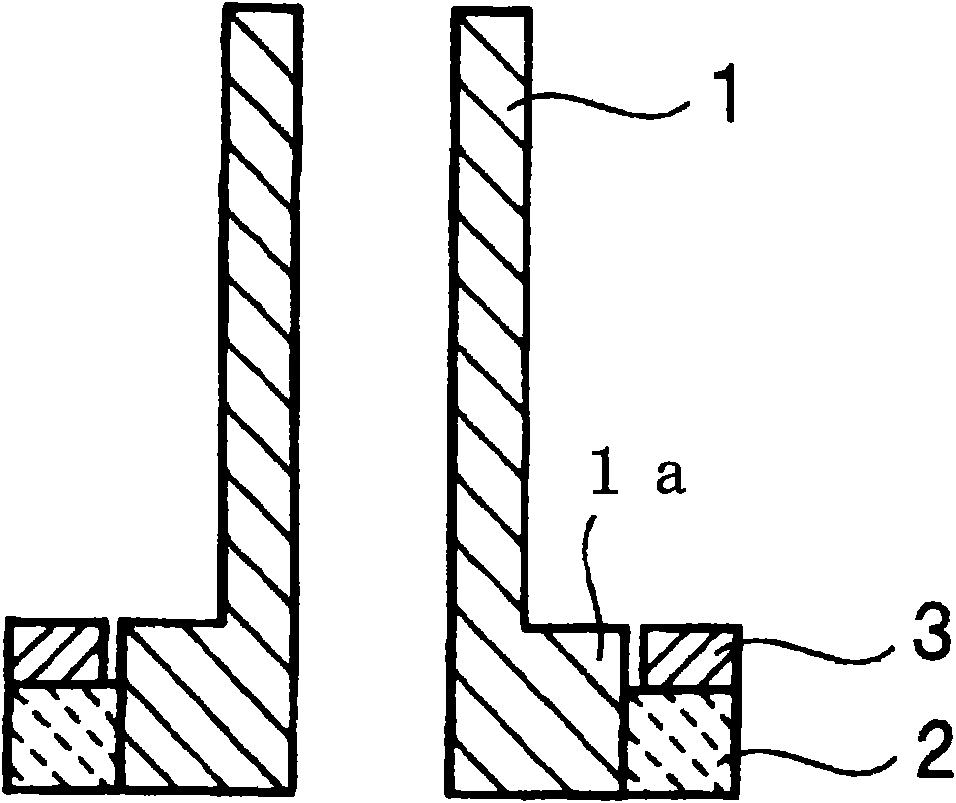

Tablet and exhaust pipe integrated with tablet

InactiveUS20120128904A1Increase productivityDegree of improvementGas filling substance selectionCathode-ray/electron-beam tube vessels/containersFilling ratioBismuth

A tablet comprises a bismuth-based glass and a refractory filler, wherein: (1) the bismuth-based glass comprises, as a glass composition, in terms of mass %, 70 to 90% of Bi2O3, 2 to 12% of B2O3, 0 to 5% of Al2O3, 1 to 15% of ZnO, 0 to 10% of BaO, and 0 to 8% of CuO+Fe2O3; (2) the tablet comprises 1 to 25 vol % of alumina as the refractory filler; and (3) the filling ratio of the tablet is 71% or more.

Owner:NIPPON ELECTRIC GLASS CO LTD

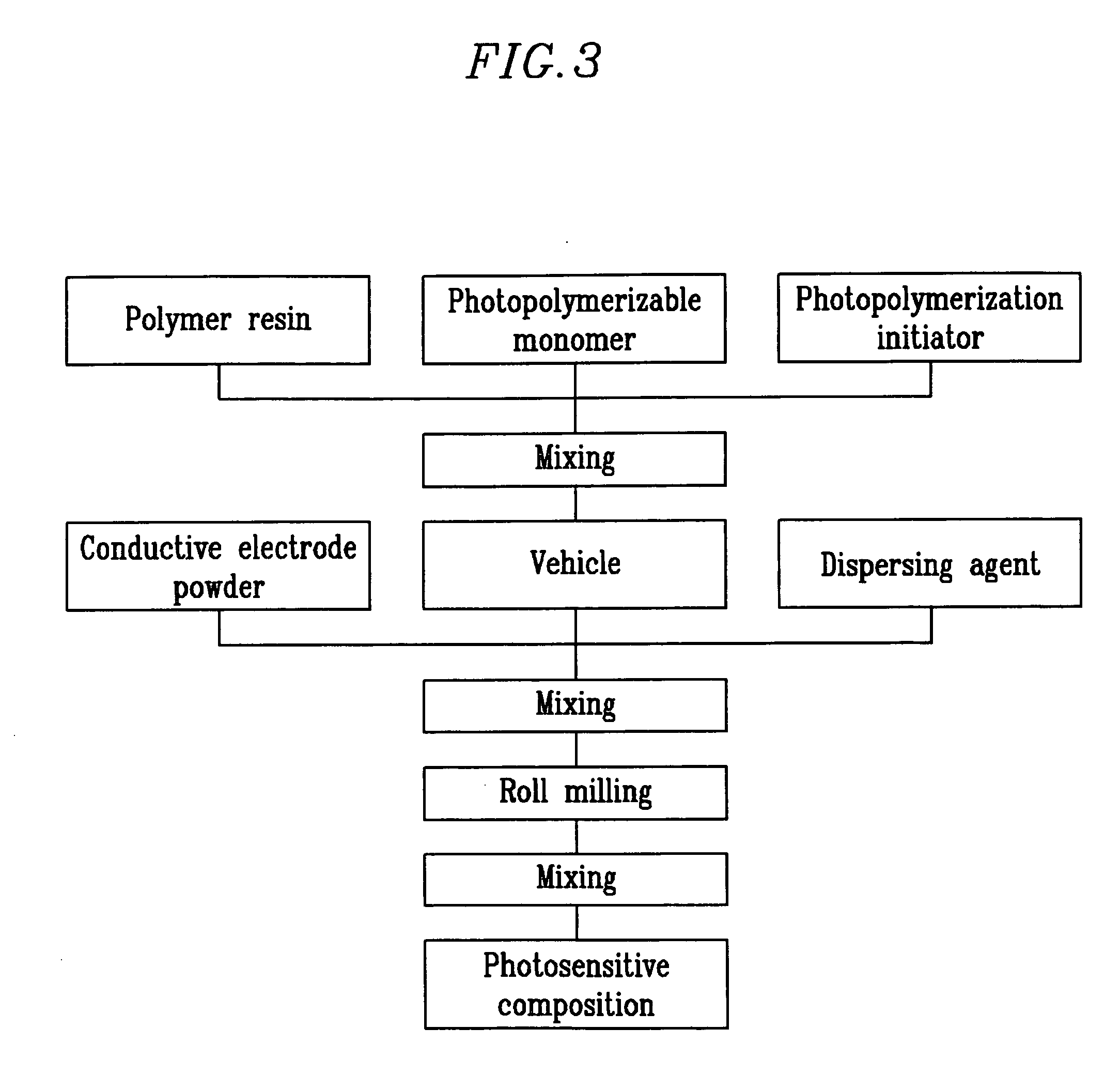

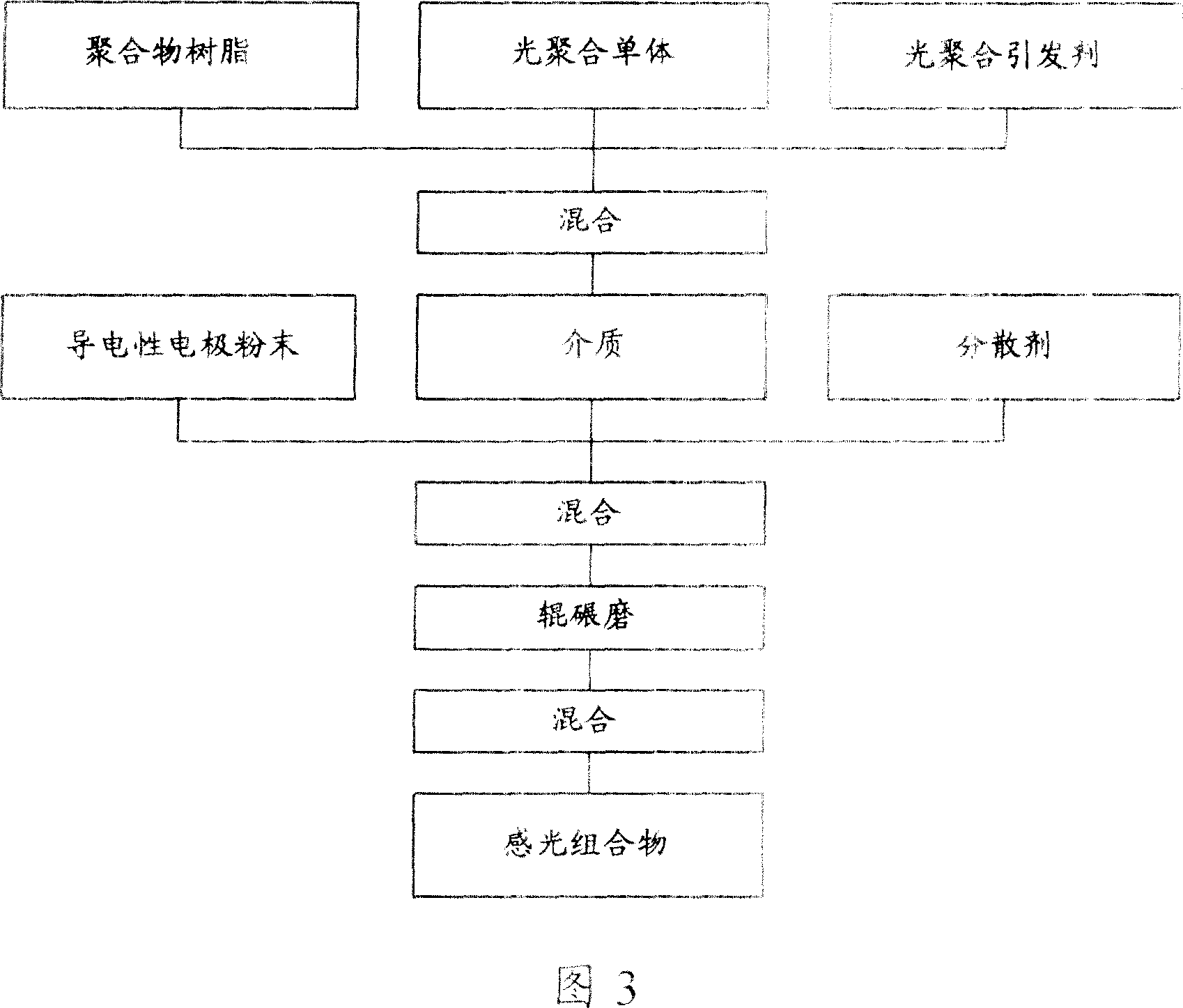

Conductive electrode powder, a method for preparing the same, a method for preparing an electrode of a plasma display panel by using the same, and a plasma display panel comprising the same

InactiveUS20070092987A1Display of display panel is improvedAddress electrodesSustain/scan electrodesMetal particleIonization

The present invention provides a conductive electrode powder which includes electroconductive metal particles, and an inorganic oxide coating layer covering the surface of the electroconductive metal particles. By using a conductive electrode powder, the corrosion, the ionization, the migration such as ionization, and yellowing of the electrode such as colloidalization can be prevented, while simultaneously maintaining electrical conductivity of an electrode.

Owner:SAMSUNG SDI CO LTD

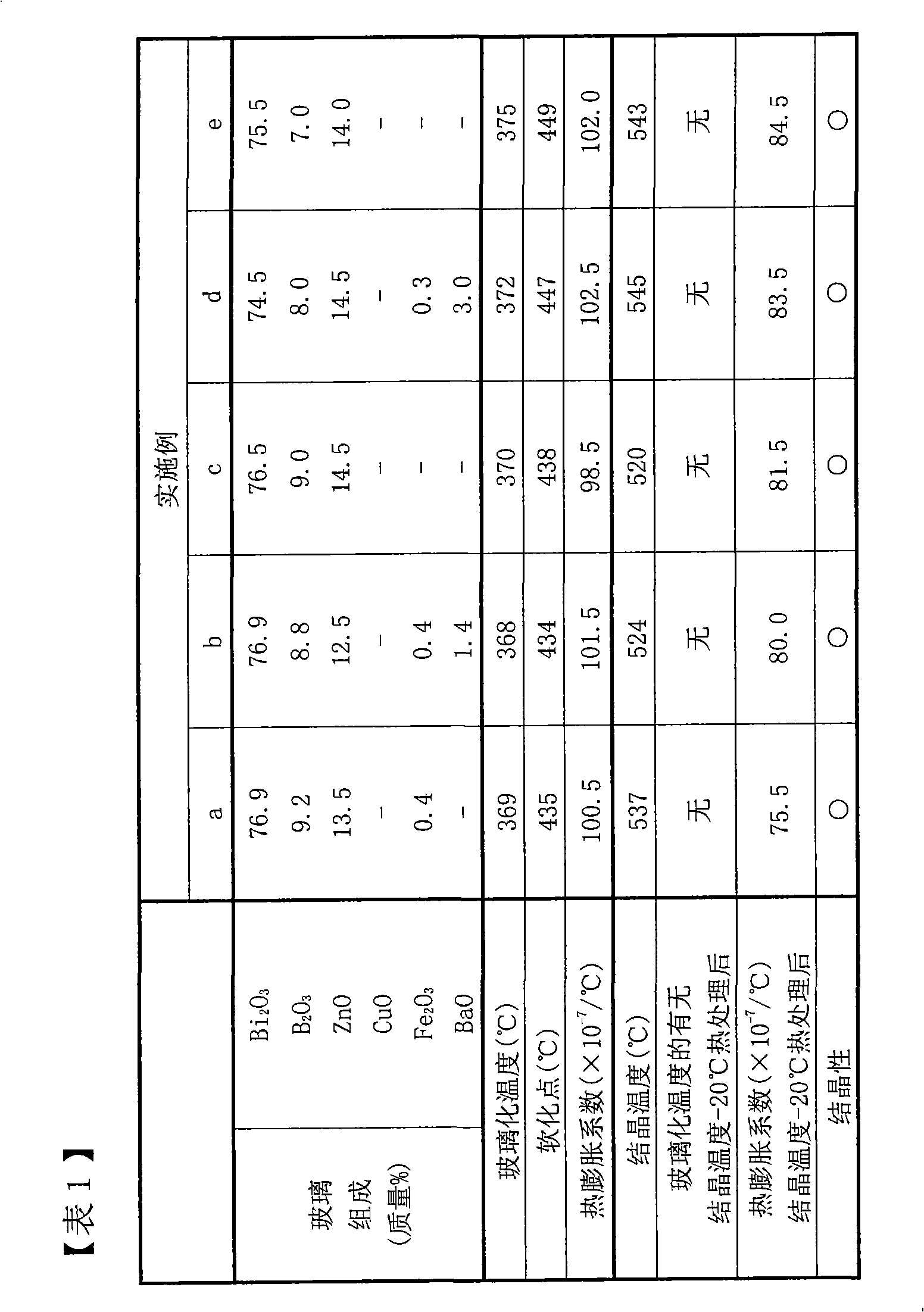

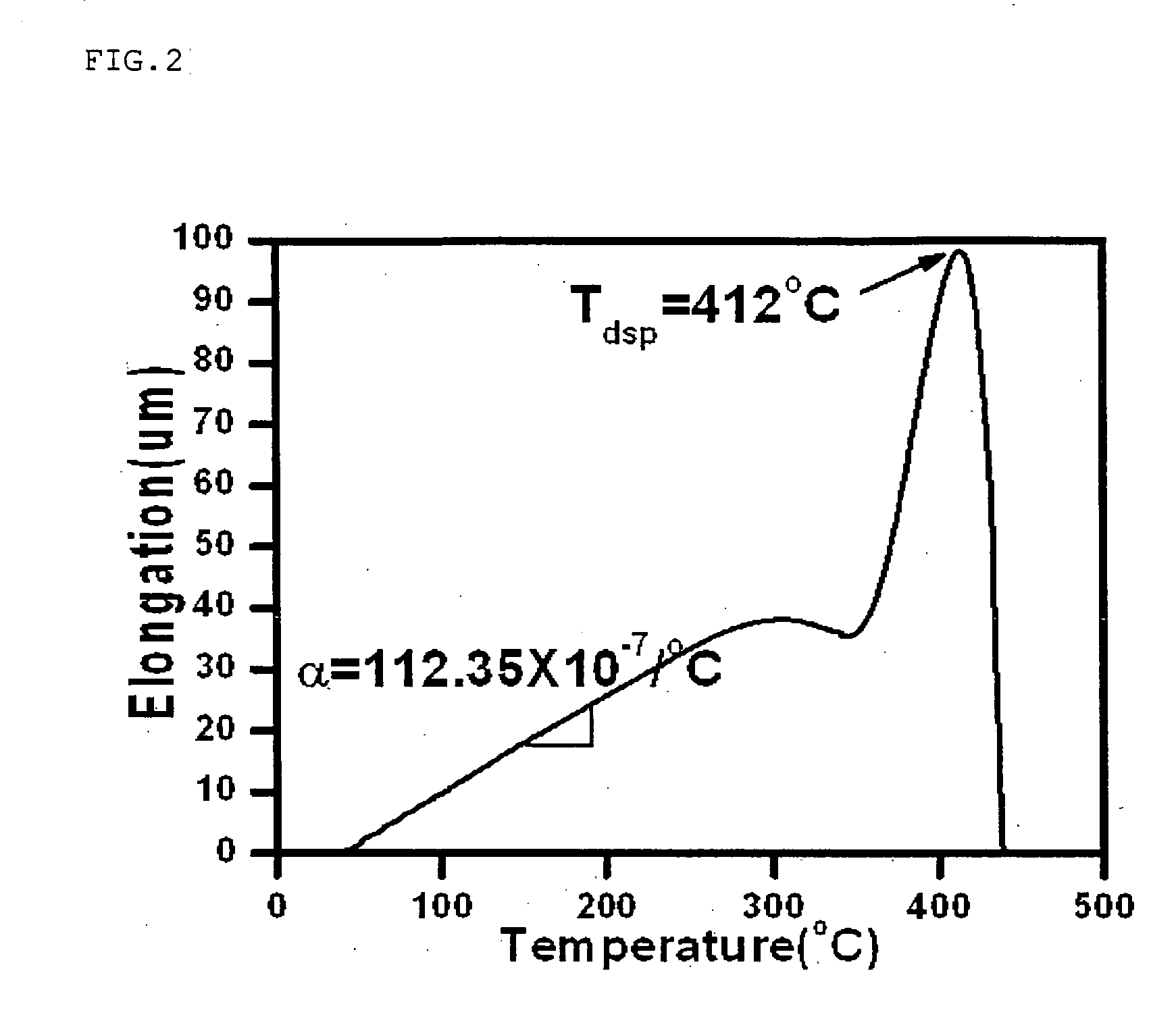

Bismuth-base glass composition and bismuth-base material

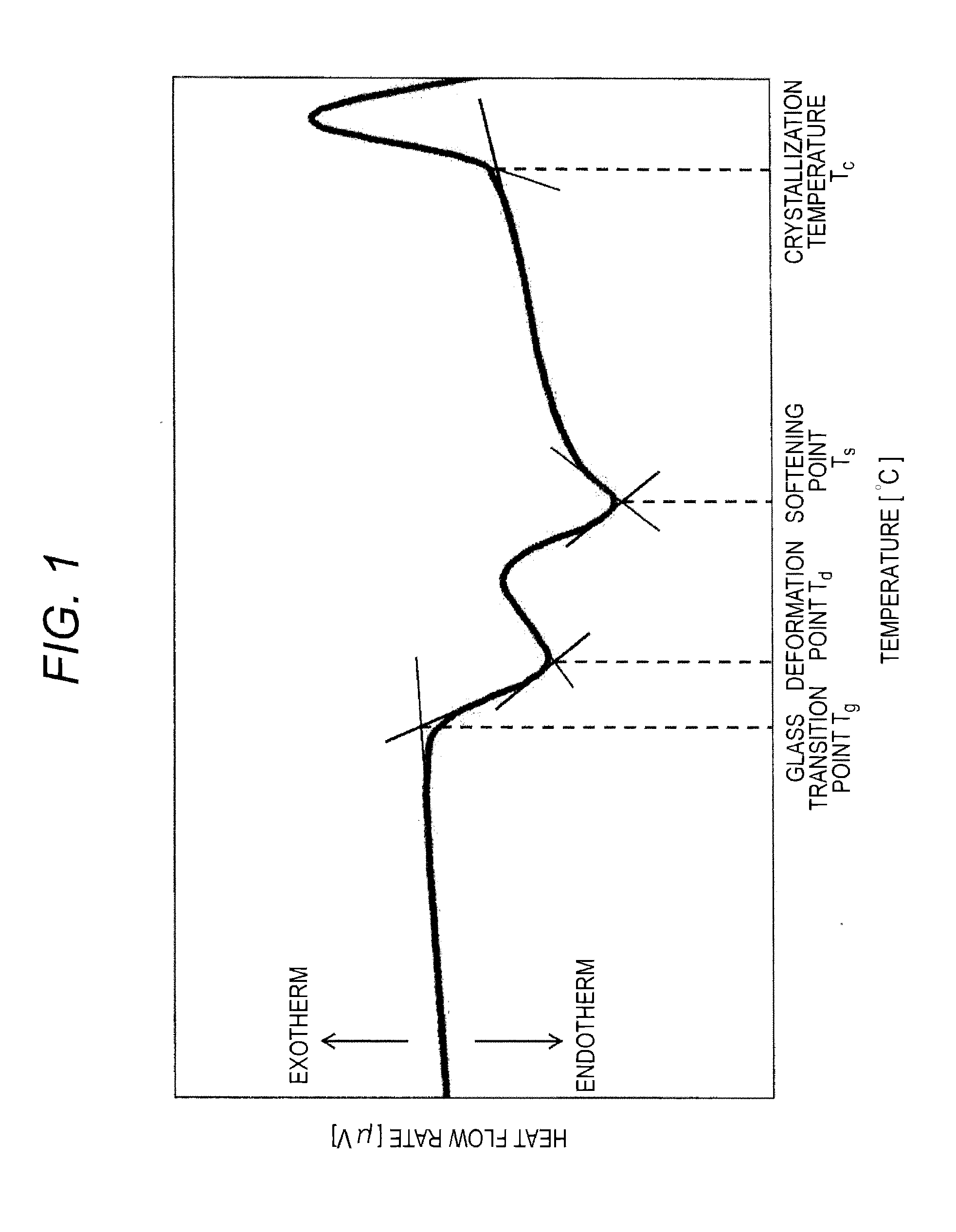

InactiveCN101528621AImprove liquidityGood sealingCathode-ray/electron-beam tube vessels/containersGas discharge vessels/containersMaterials scienceHeat treated

The invention provides a bismuth-base glass composition which can be well softened in heat treatment such as sealing and can crystallize satisfactorily after being softened and which is little re-softened after crystallization in heat treatment such as evacuation. A bismuth-base glass composition characterized by having a composition which comprises by mass 60 to 84% of Bi2O3, 5.4 to 15% of B2O3, 10 to 27% of ZnO, 0 to 7% of CuO, and 0 to 5% of Fe2O3 and contains BaO, SrO, MgO and CaO in a total amount of 0 to 10% and SiO2 and Al2O3 in a total amount of 0 to 5% and being substantially free from PbO.

Owner:NIPPON ELECTRIC GLASS CO LTD

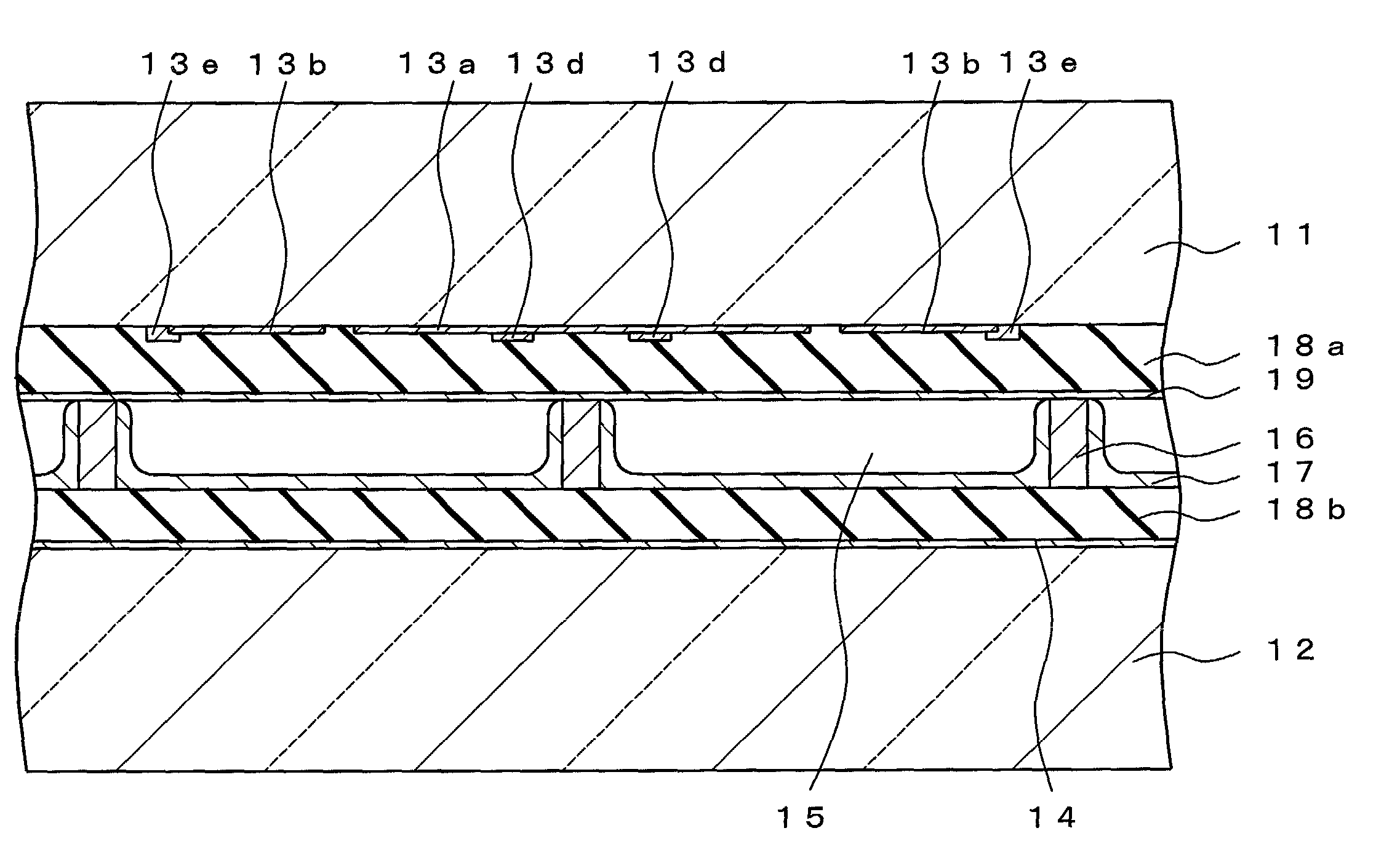

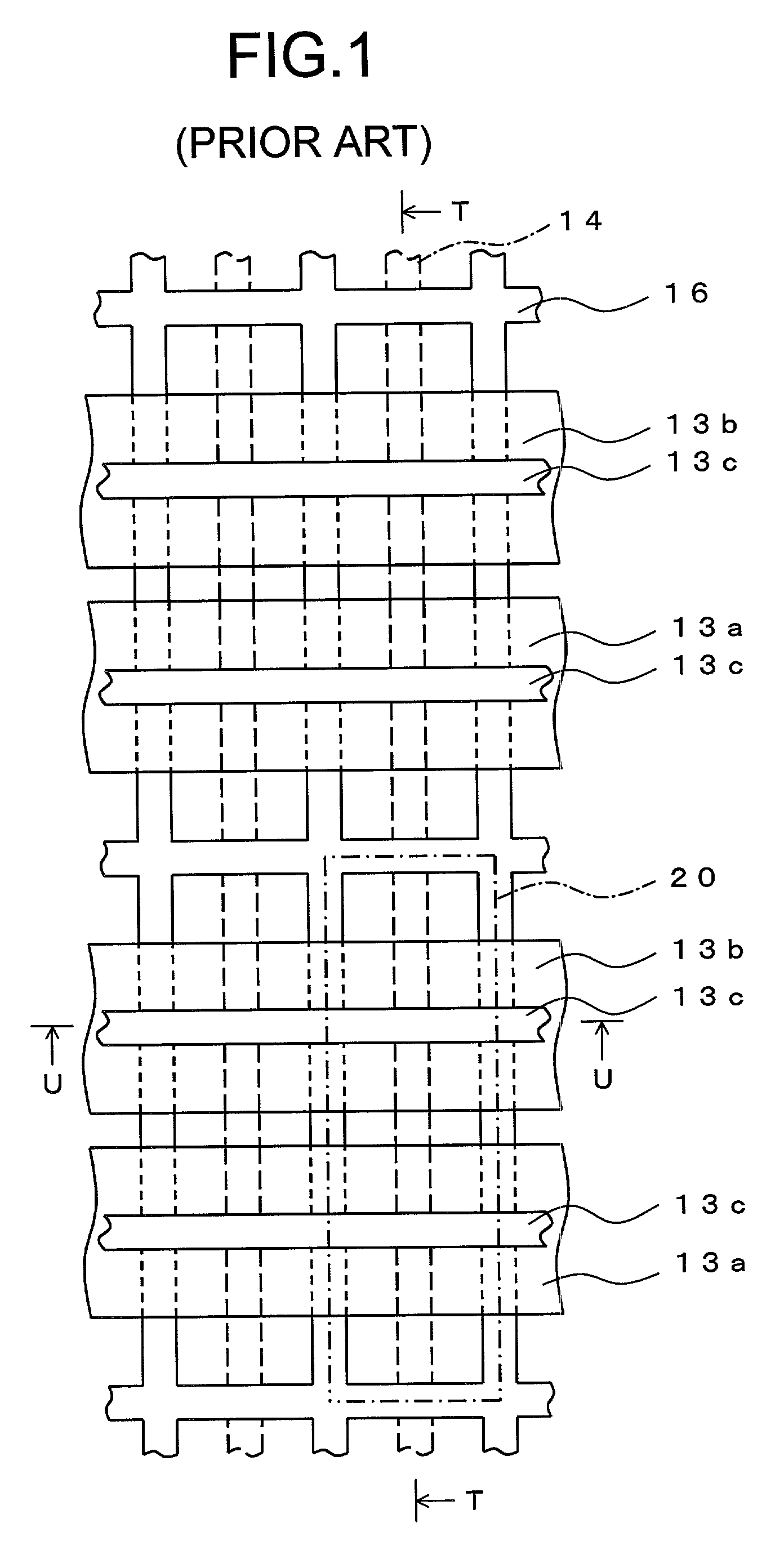

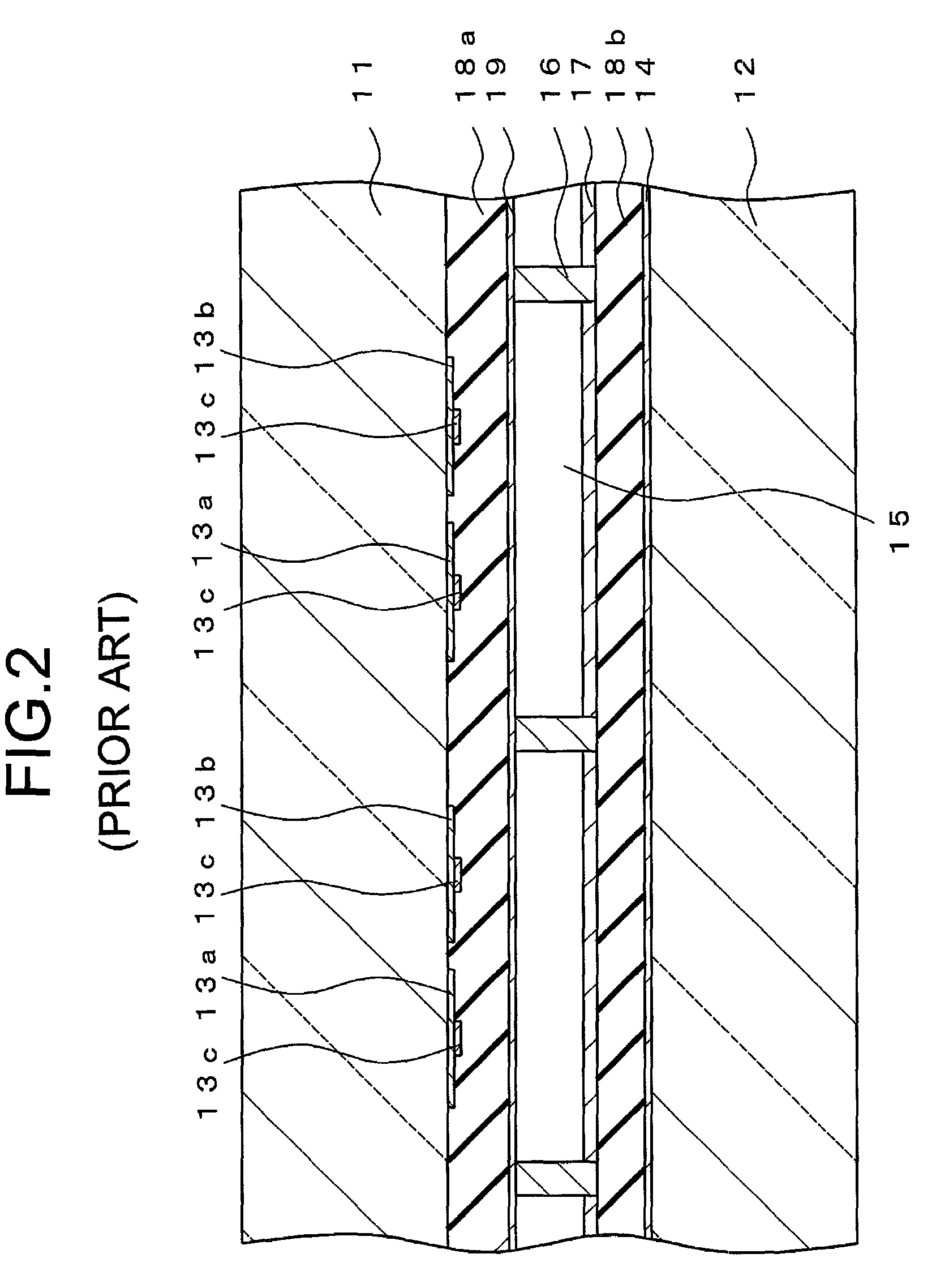

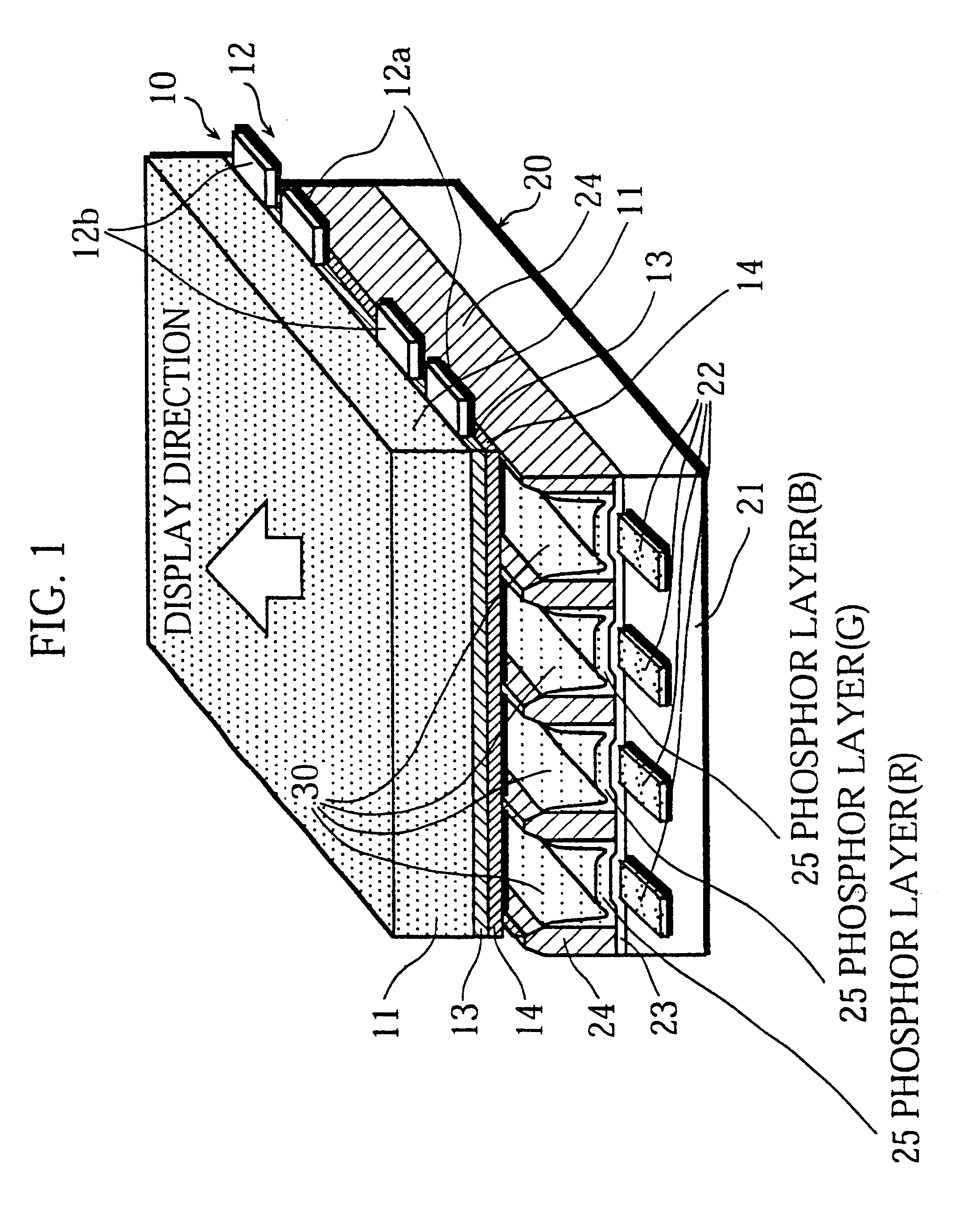

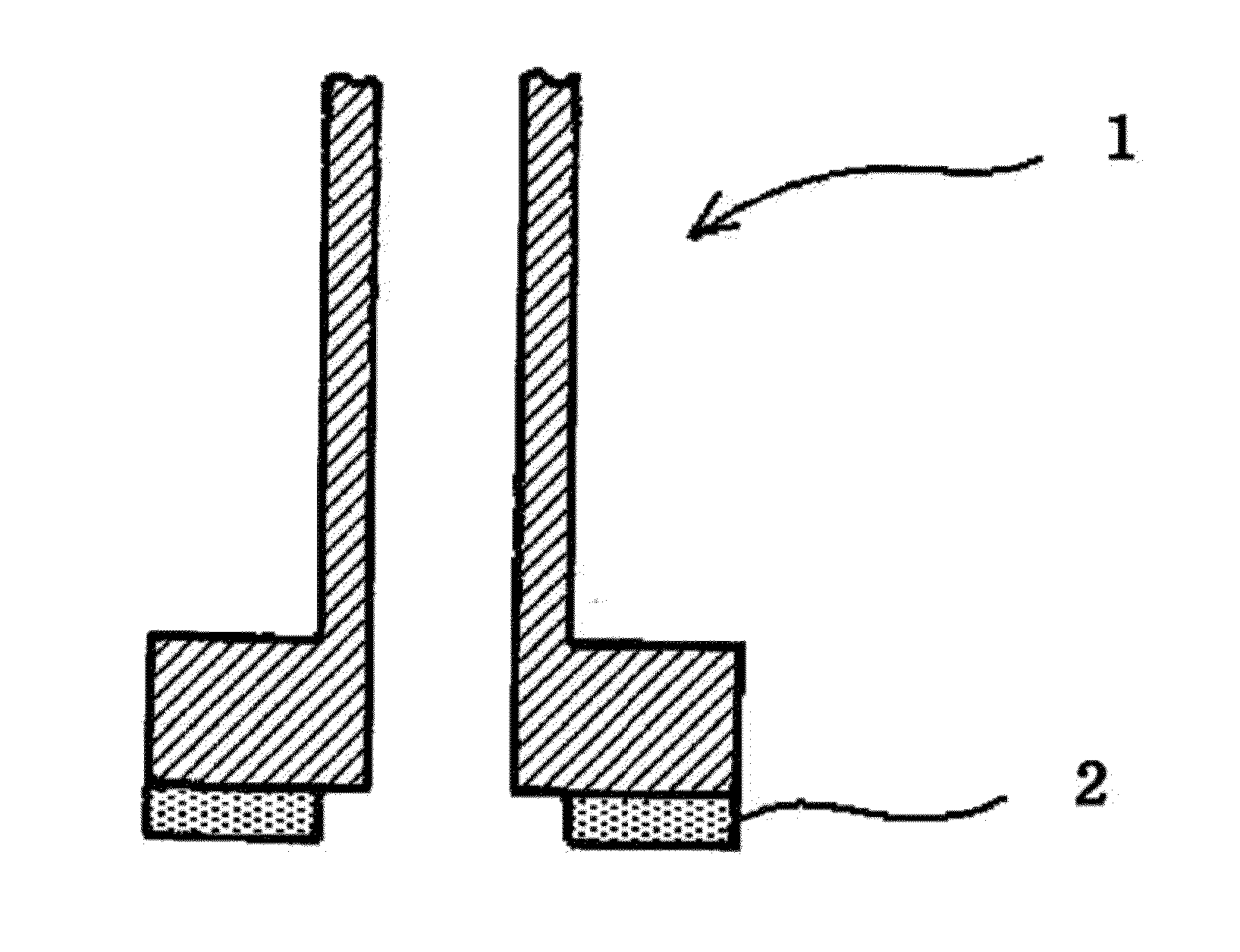

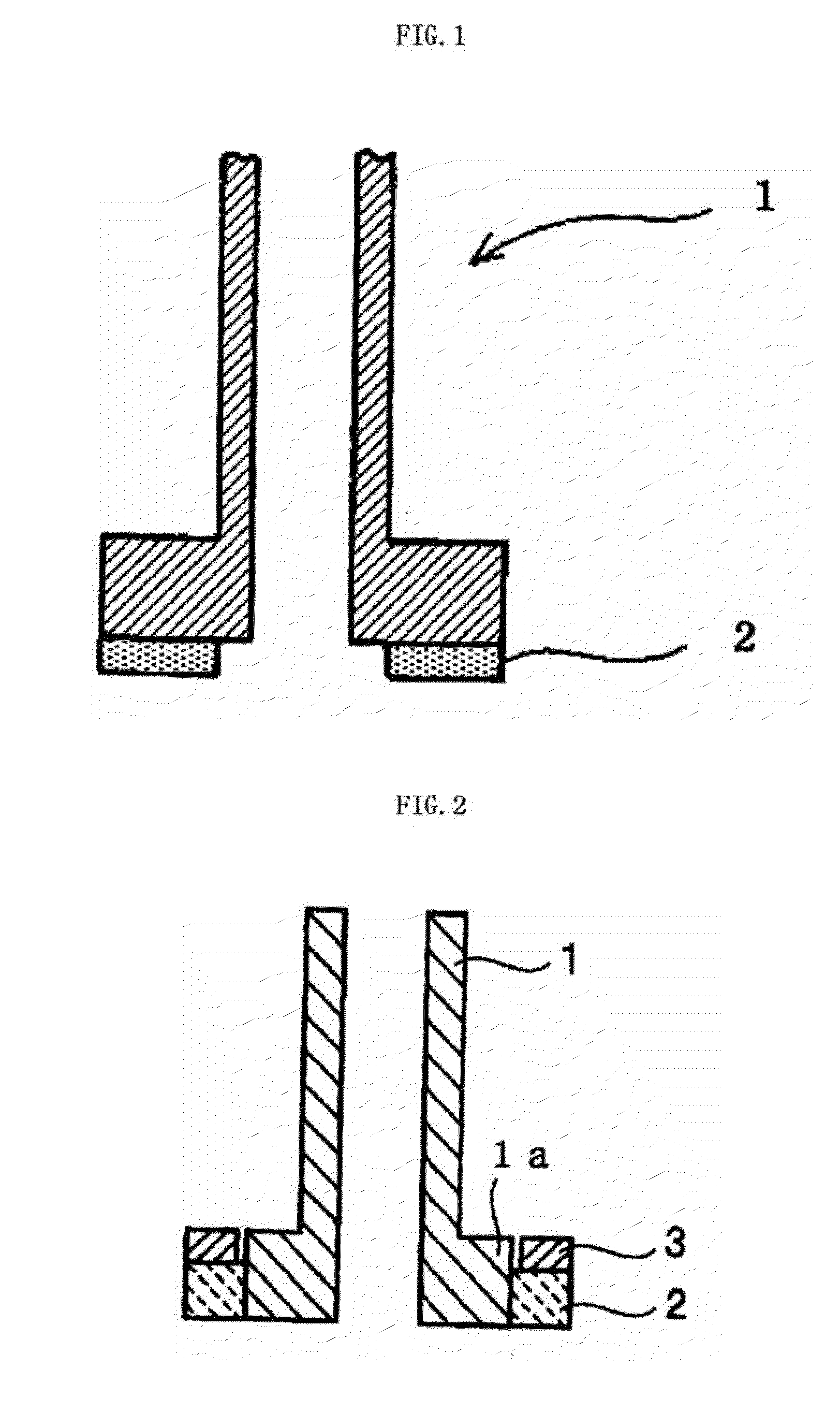

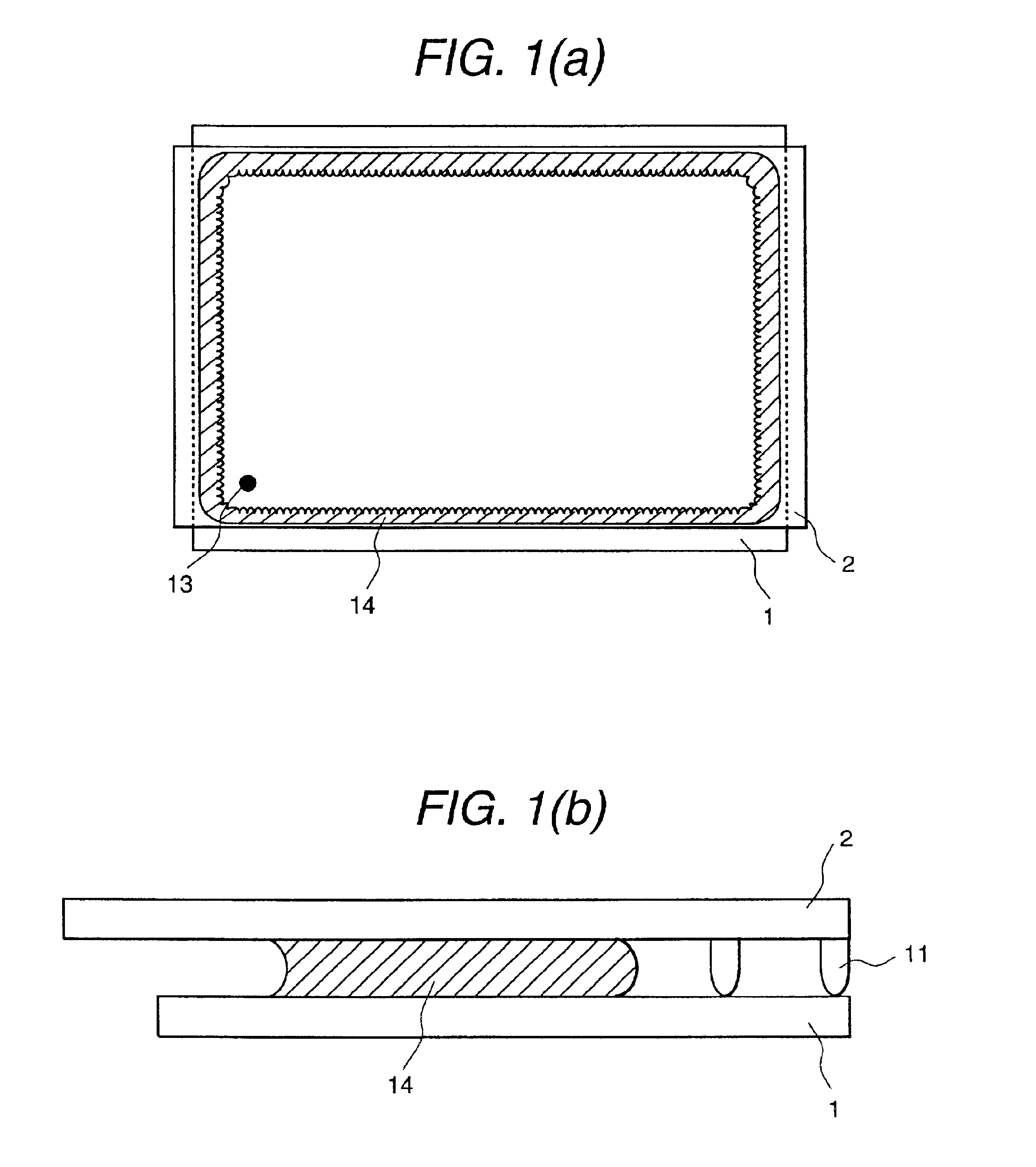

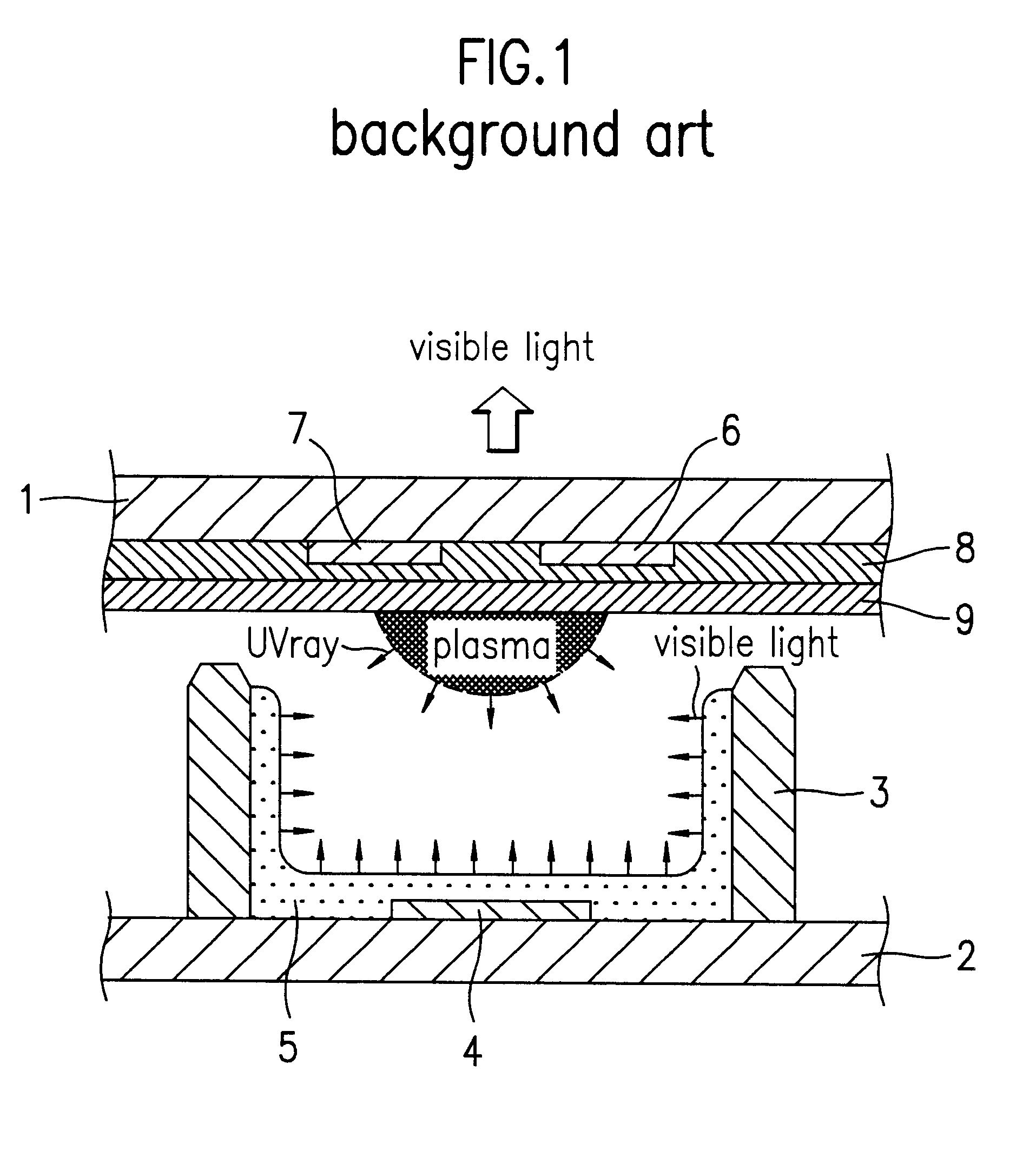

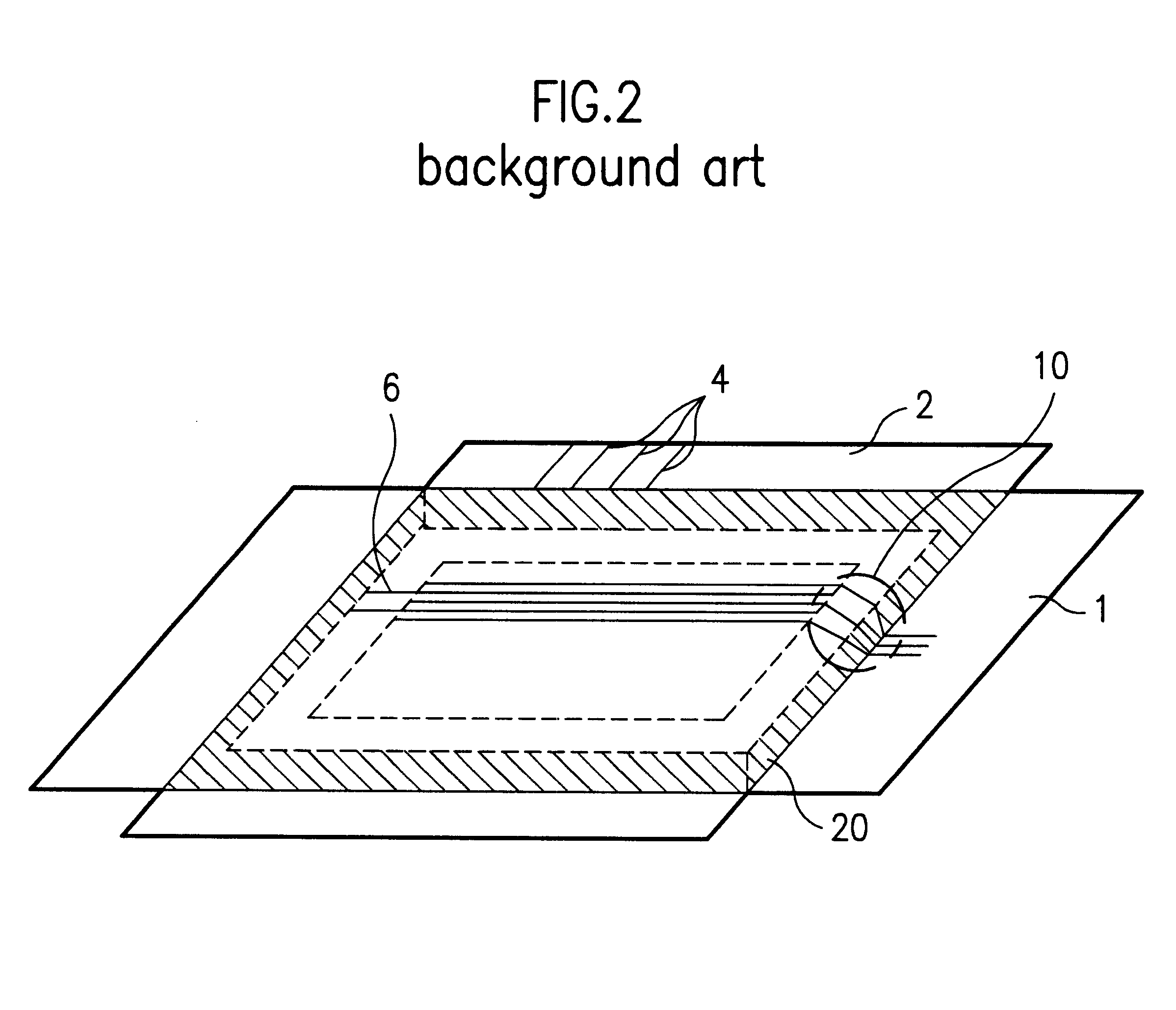

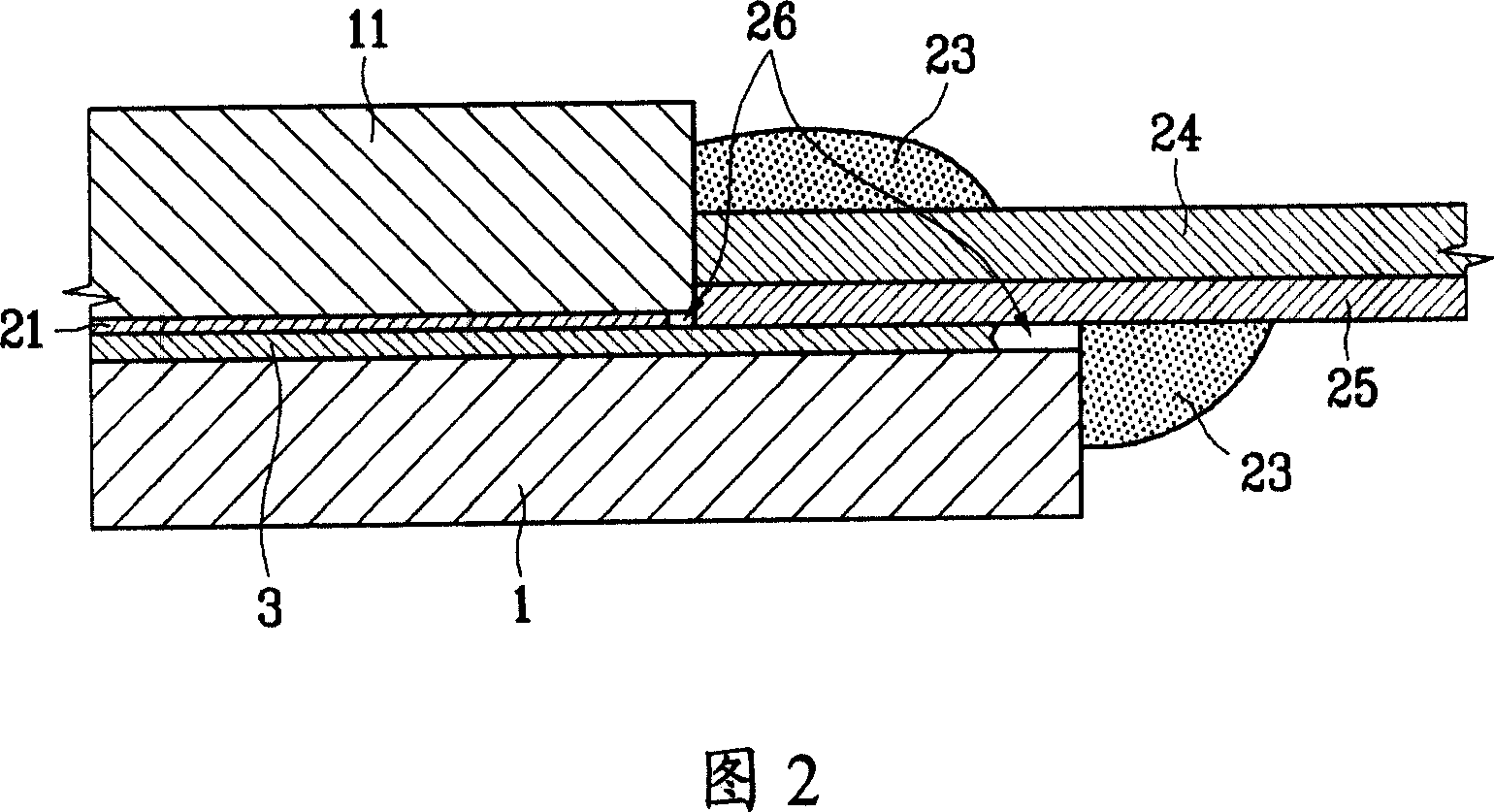

Gas discharge type display panel and production method therefor

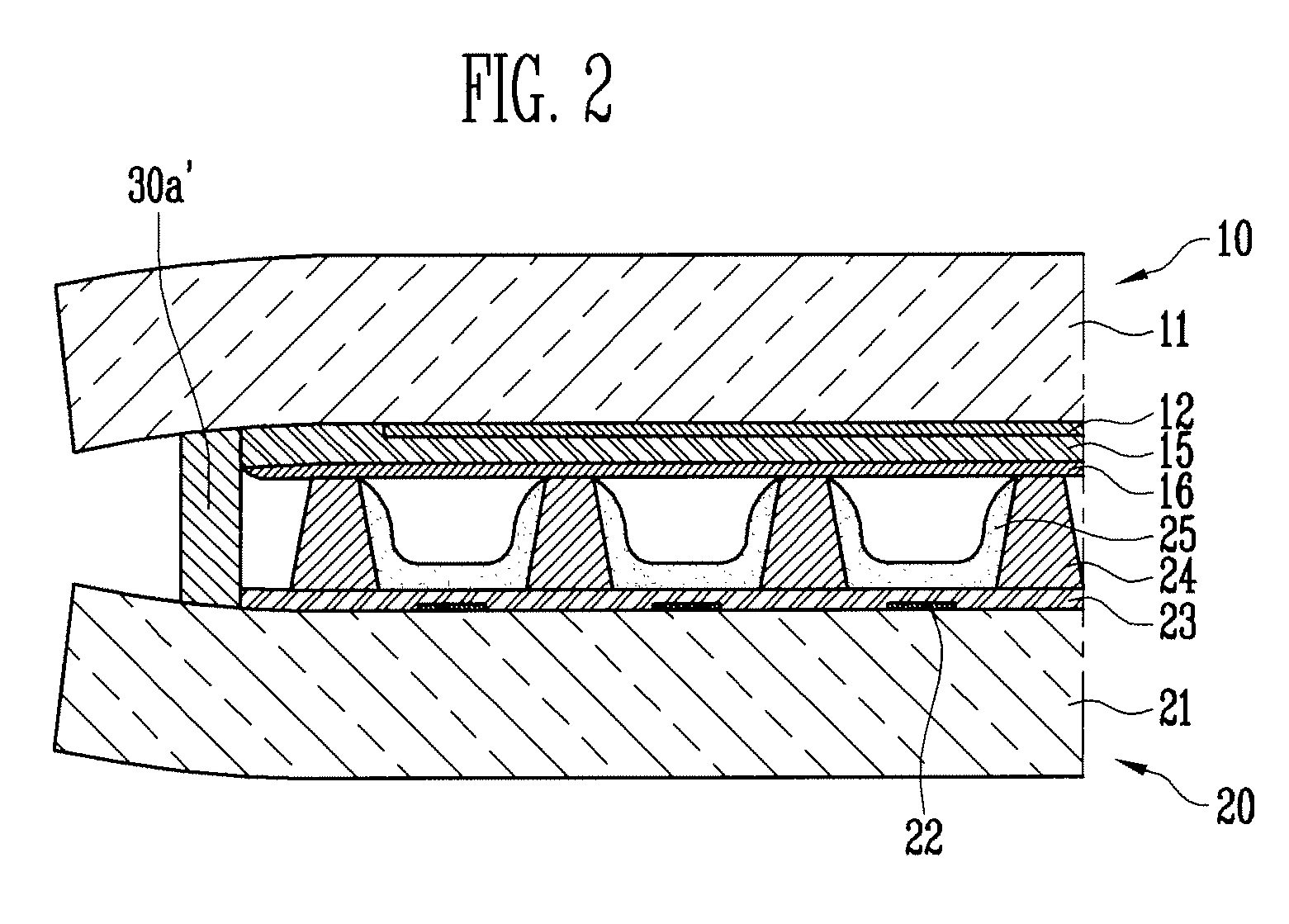

InactiveUS6840833B1Point becomes highLow pour pointGas discharge connecting/feedingGas discharge sealingPressure differenceElectrical and Electronics engineering

In the manufacture of a gas discharge type display panel, by applying a sealing operation along with an exhausting operation, the sealing glass 14 is broken down by a pressure difference between the inside and outside of the panel, and thus, the clearance gap between the substrates can be controlled as desired. In addition, the gaseous component that is unnecessary for the discharge operation is exhausted by setting the temperature of the amorphous sealing glass to exceed its softening-point and be no more than its working point. In the structure of the gas discharge type display panel, a protruding portion having a radius of curvature between 0.1 mm and 1 mm is formed on the sealing glass to reduce the dispersion in the thickness direction of the sealing glass, or the cross-sectional shape of the sealing glass is made convex both at its inside end part and its outside end part.

Owner:HITACHI LTD

Display Apparatus and Method of Fabricating the Same

ActiveUS20120235170A1Low mechanical strengthHigh mechanical strengthLiquid surface applicatorsSpraying apparatusOptoelectronics

Owner:SAMSUNG DISPLAY CO LTD

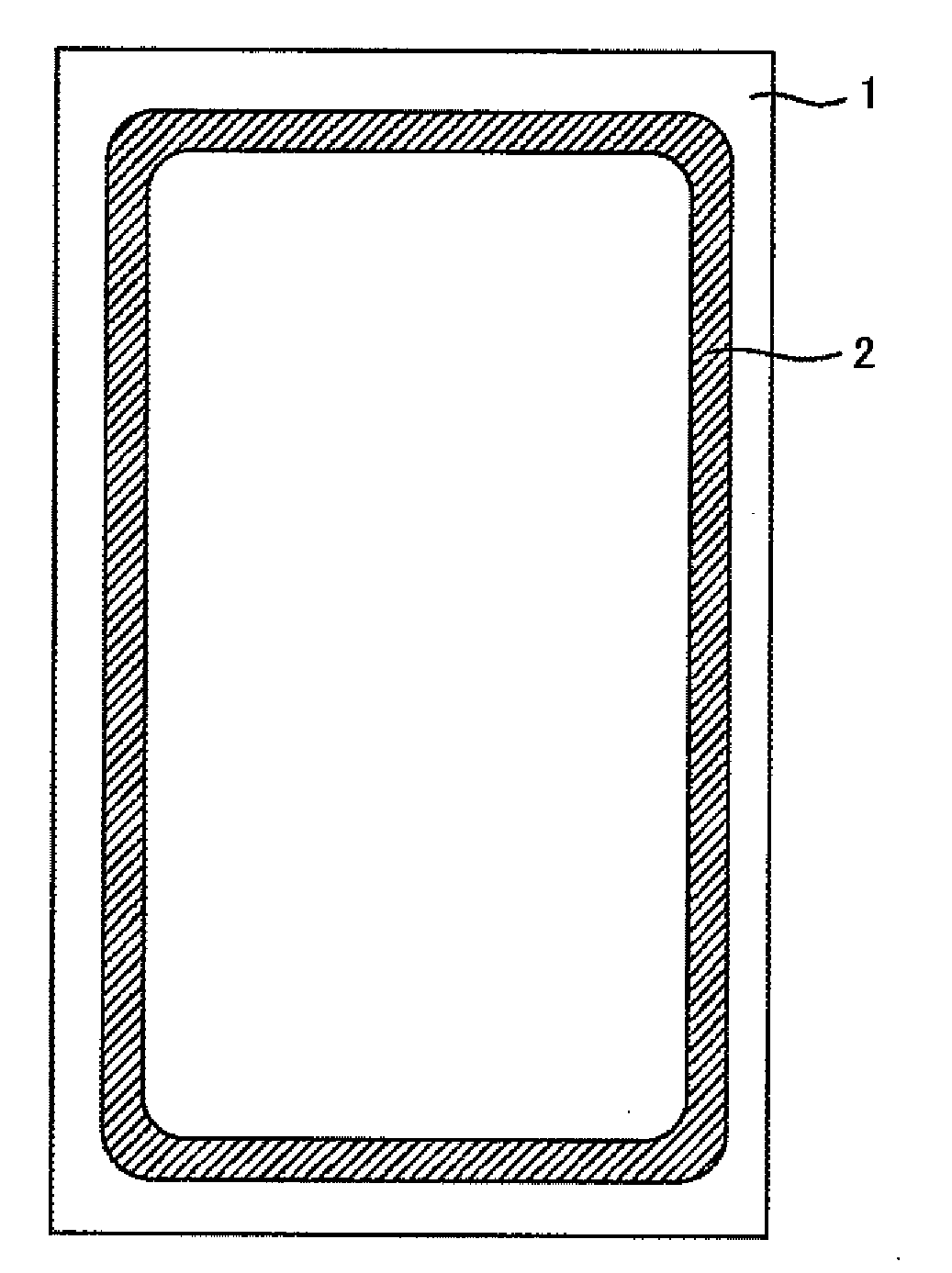

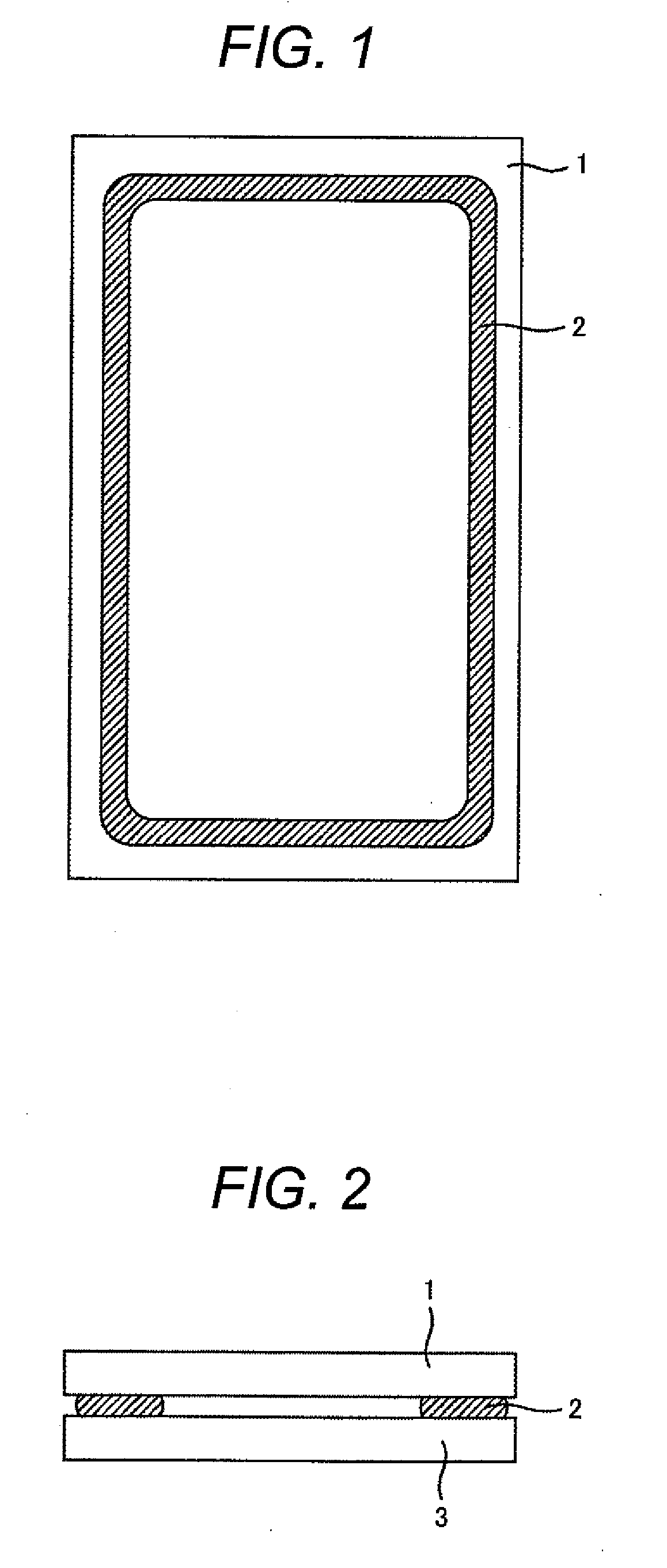

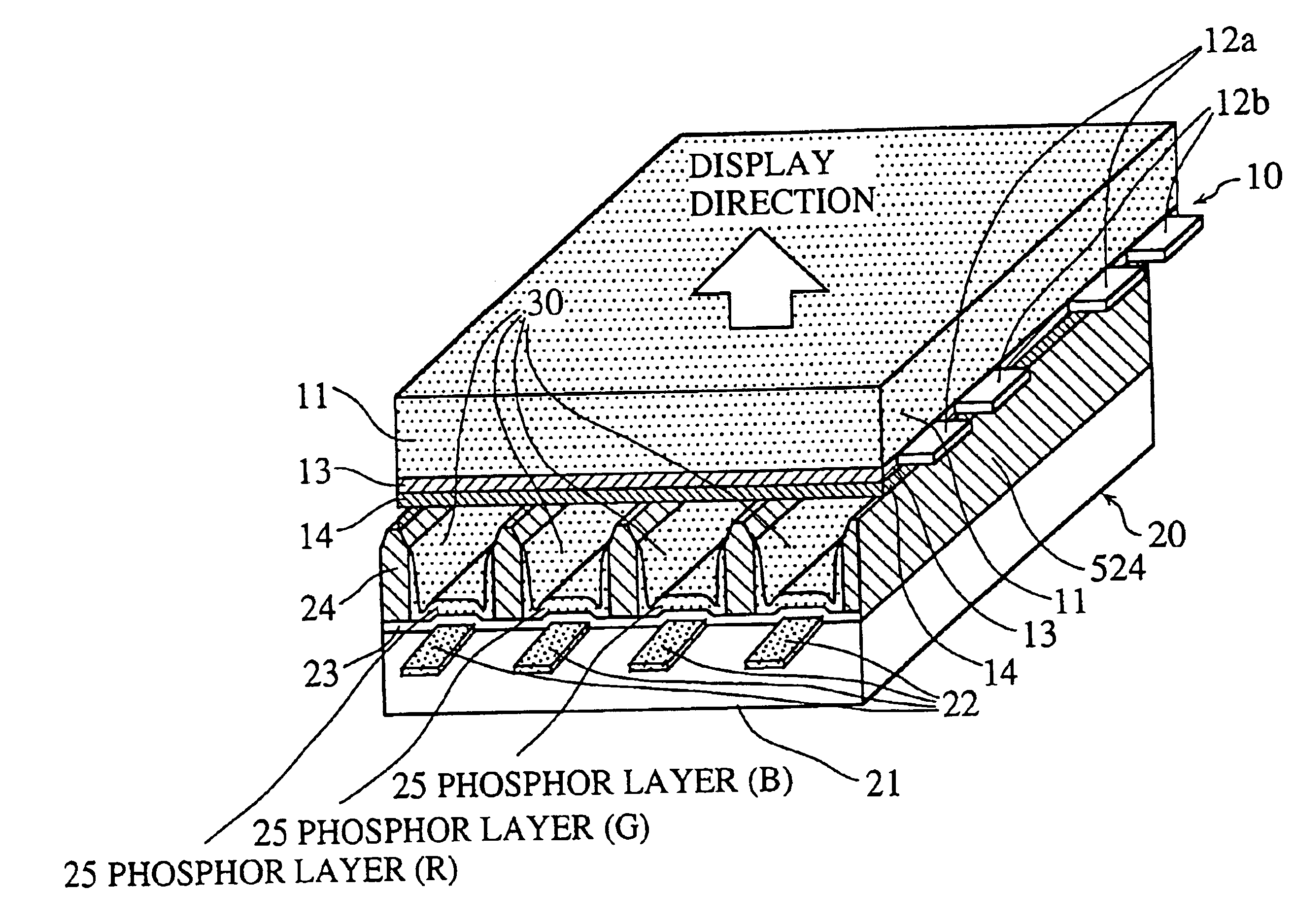

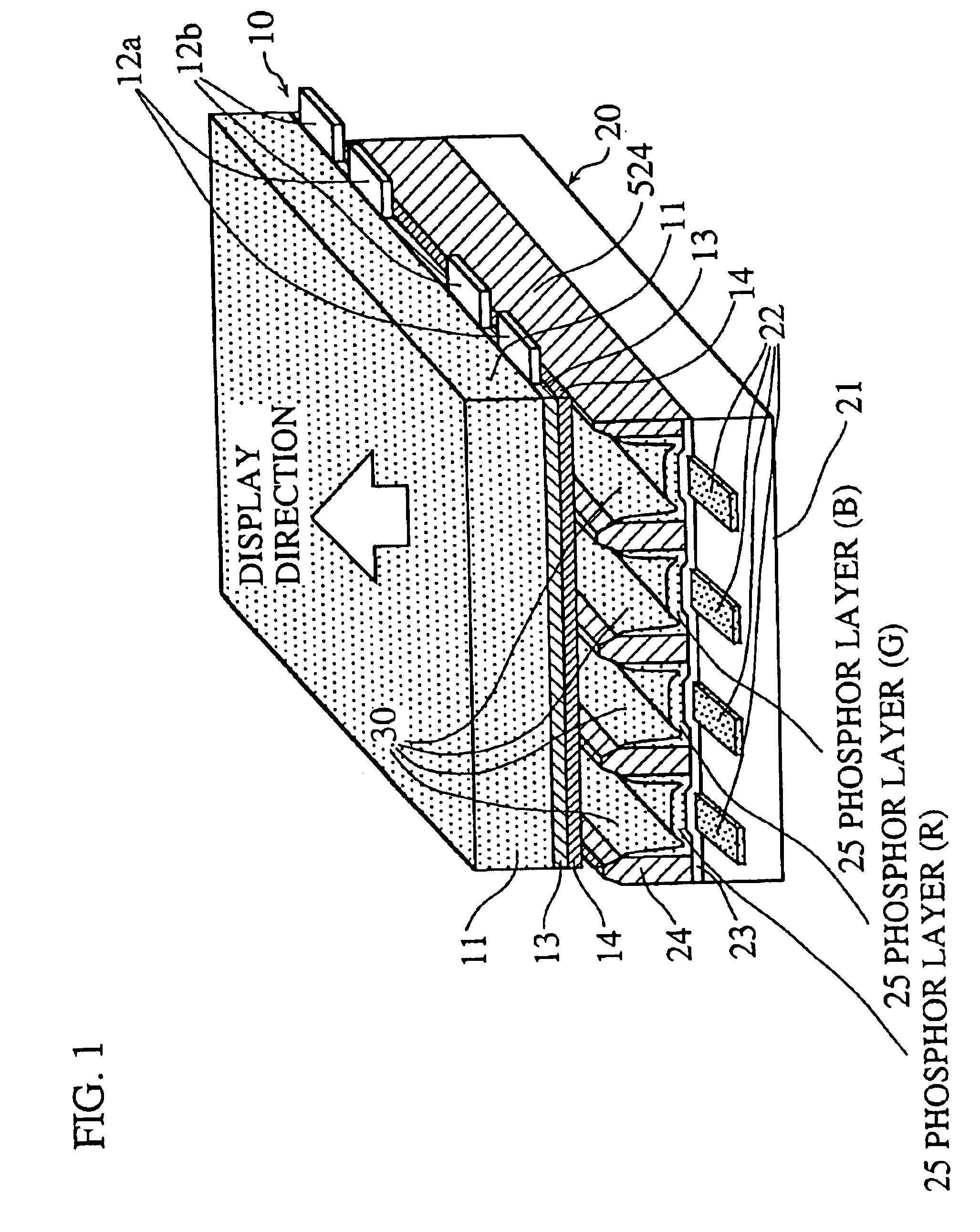

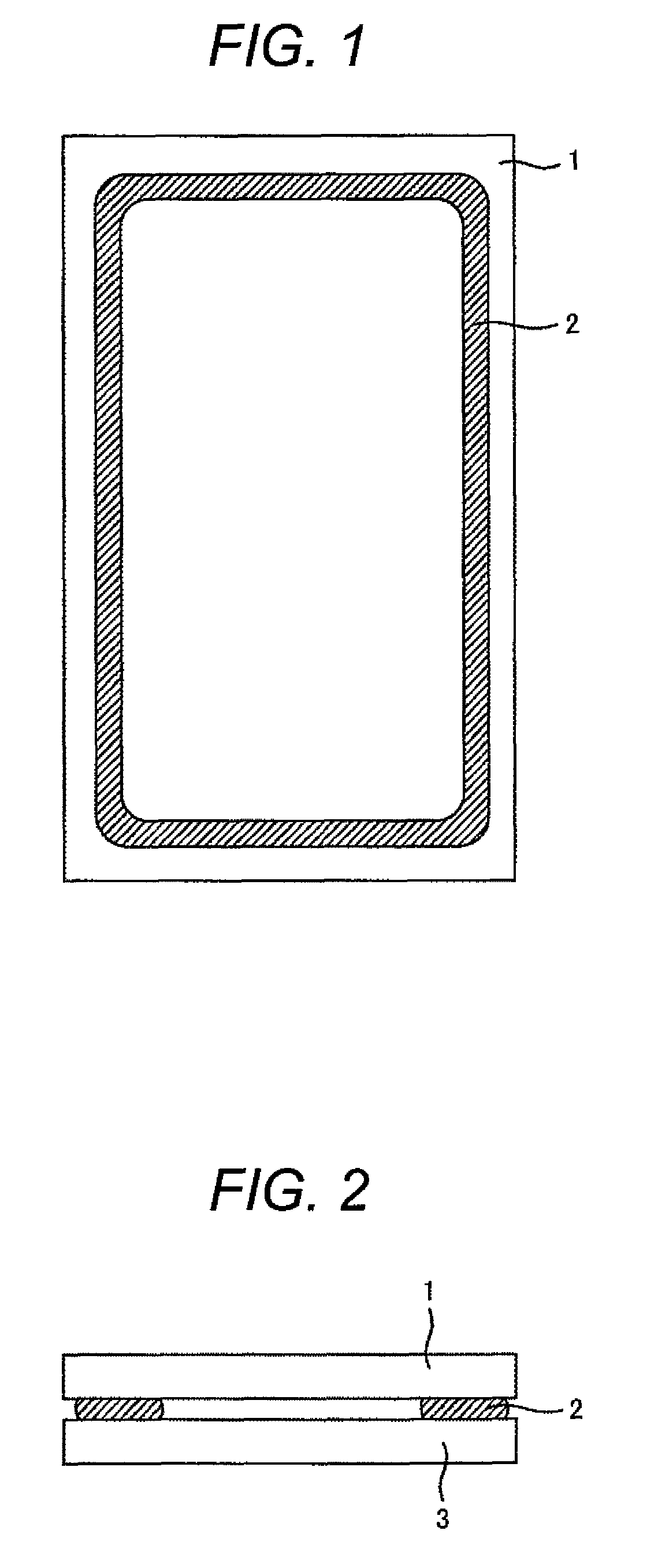

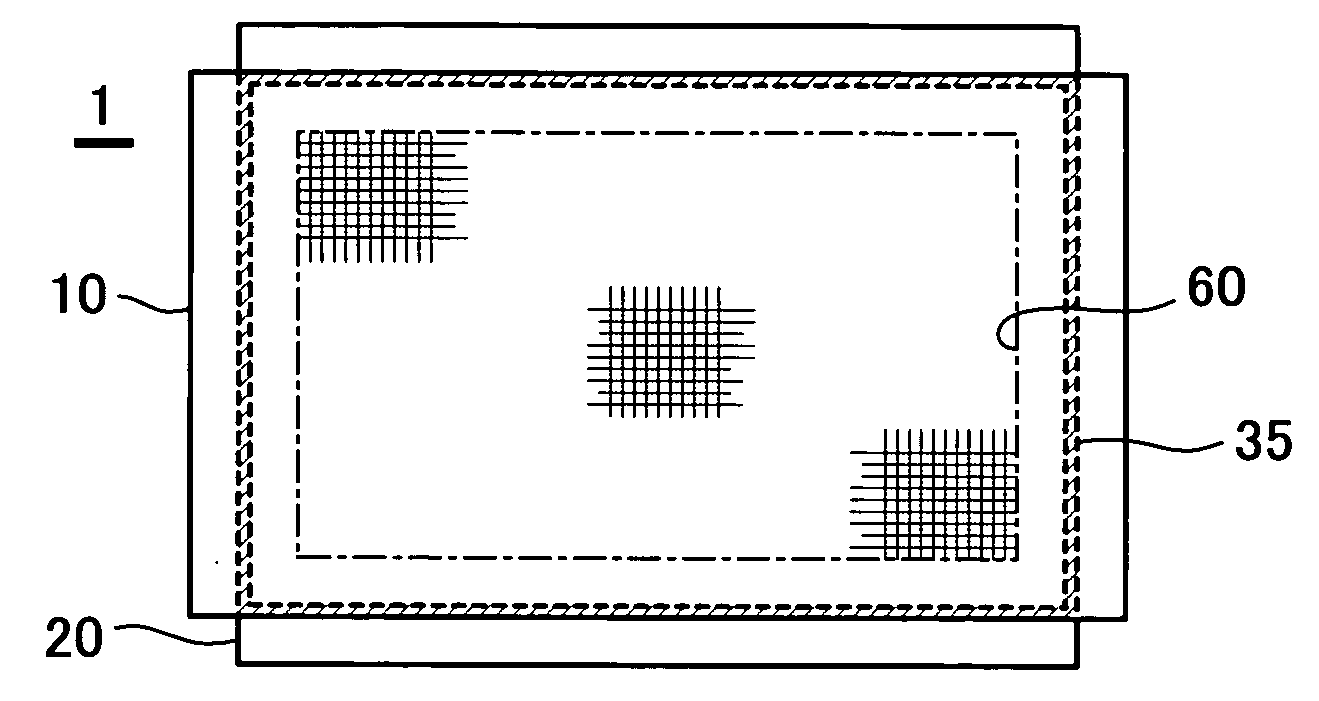

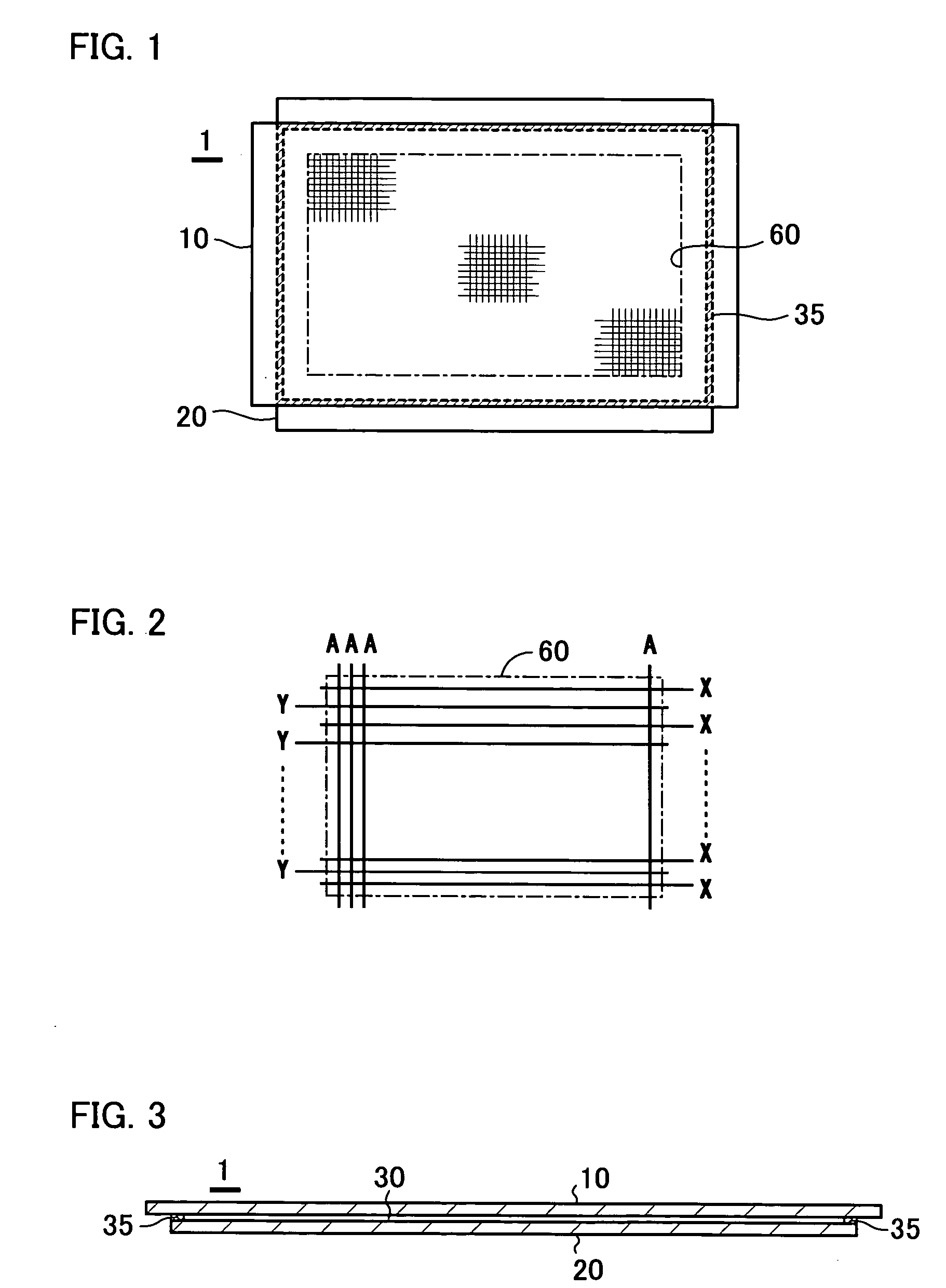

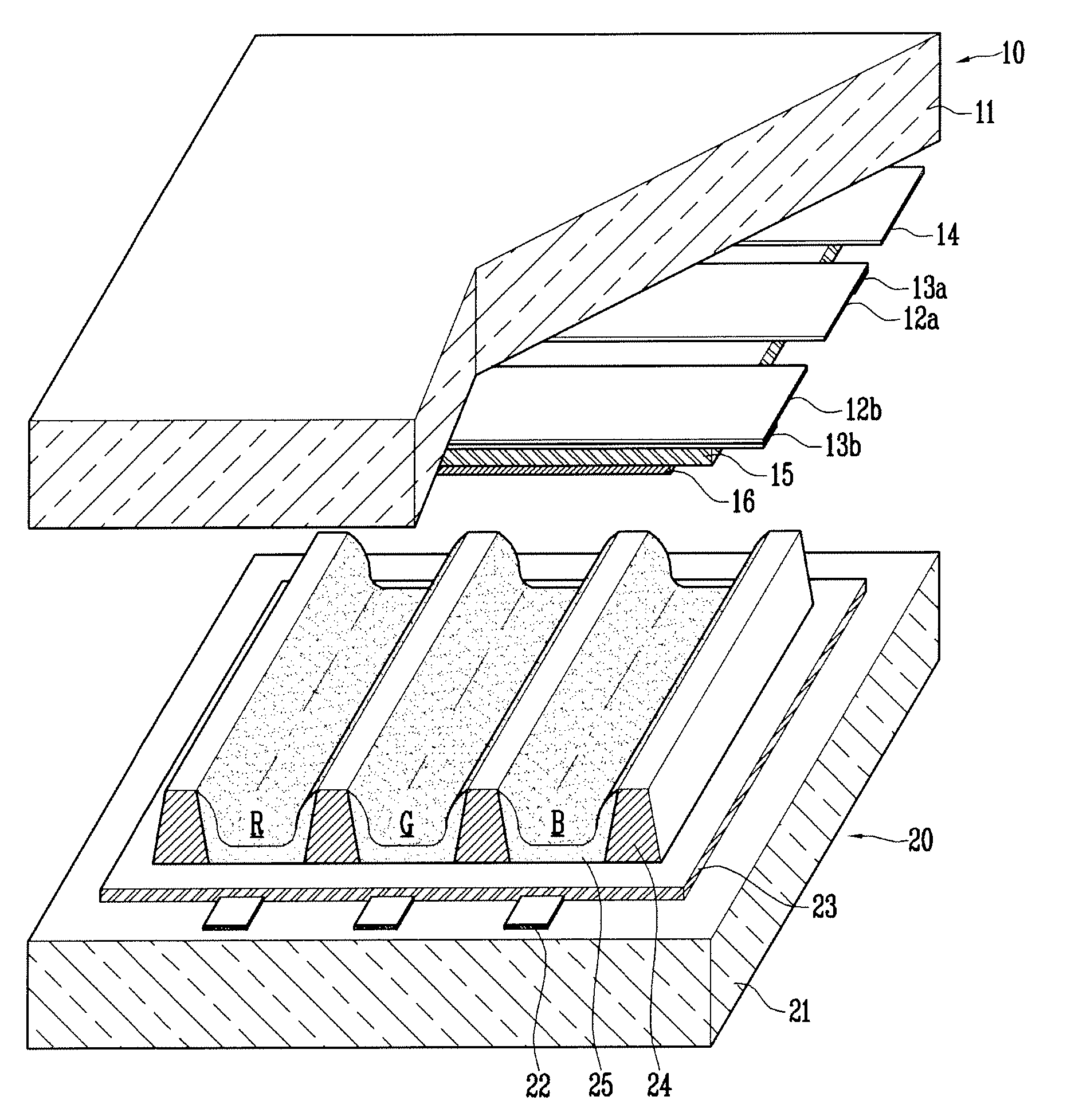

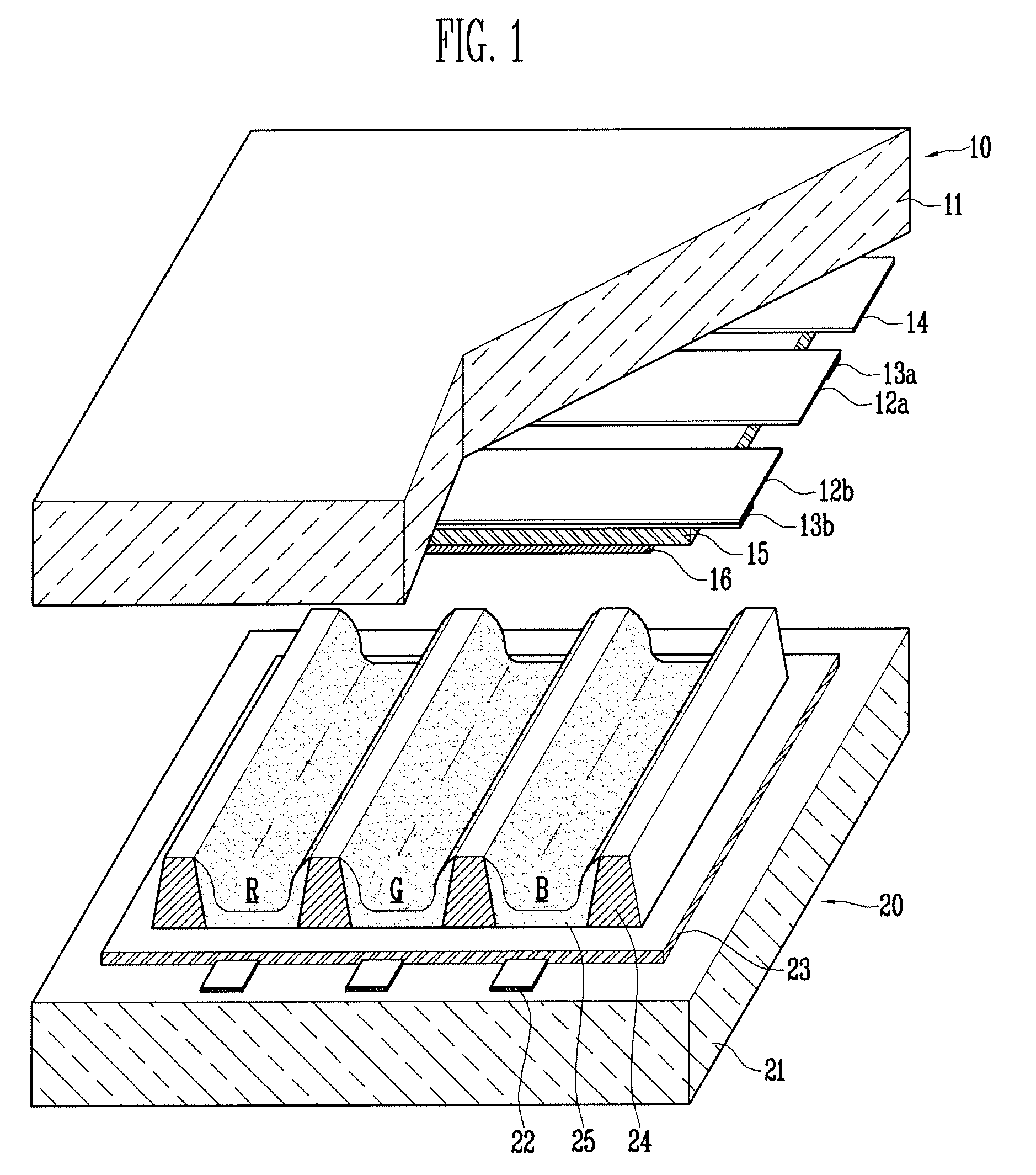

Plasma display panel

InactiveUS20060001373A1Avoid noiseUniform thicknessSustain/scan electrodesGas discharge connecting/feedingEngineeringPlasma display

A plasma display panel includes a front substrate and a rear substrate that are opposed to each other with a discharge gas space between them, and a sealing material for sealing the front substrate and the rear substrate at their peripheral portions. The sealing material contains an appropriate quantity of spacers so that a thickness of the plasma display panel is uniform along the entire perimeter of the sealing portion between the front substrate and the rear substrate. The sealing material contains non-porous beads as the spacers, preferably at a ratio within the range of 0.05-2.0 wt %.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

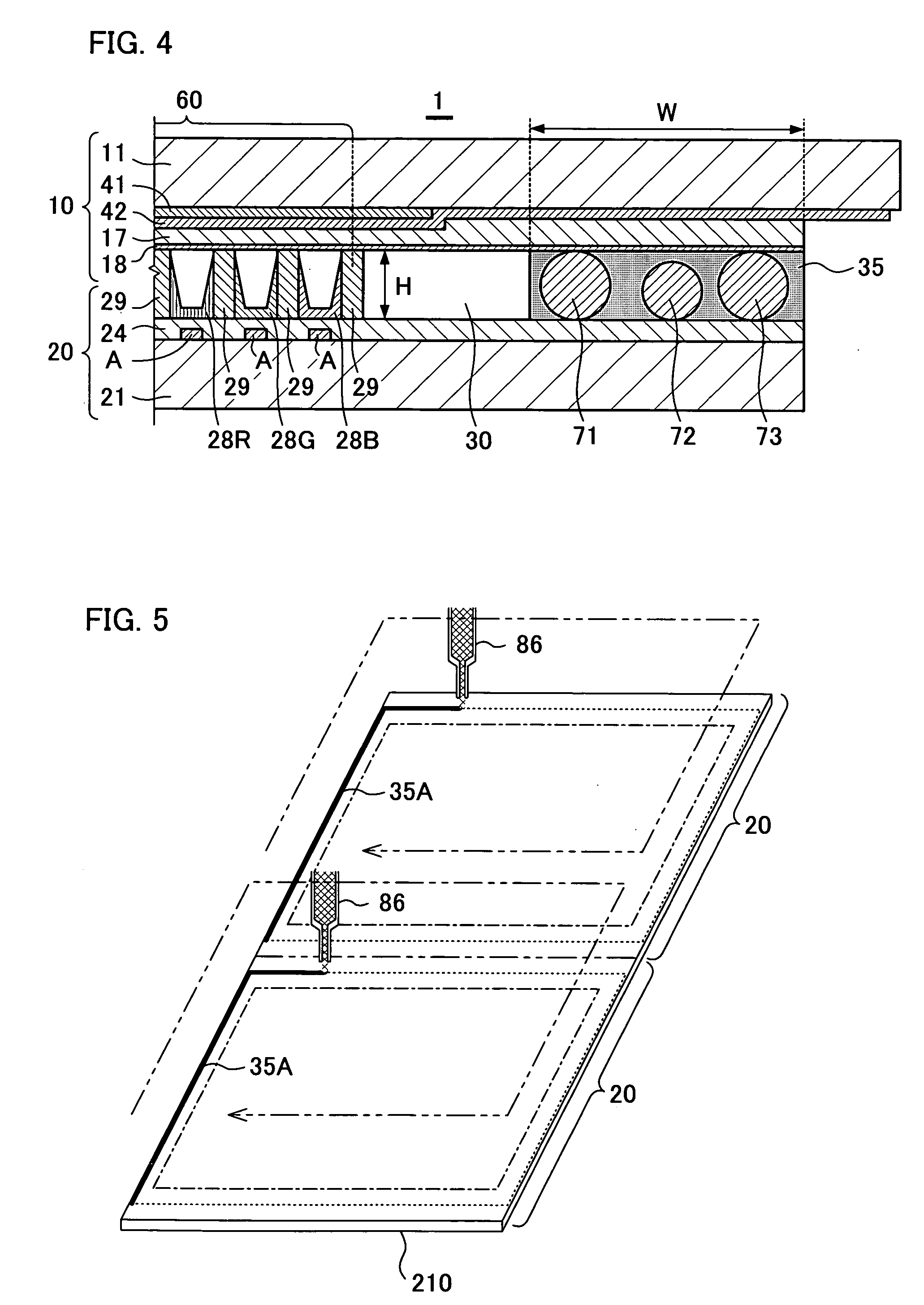

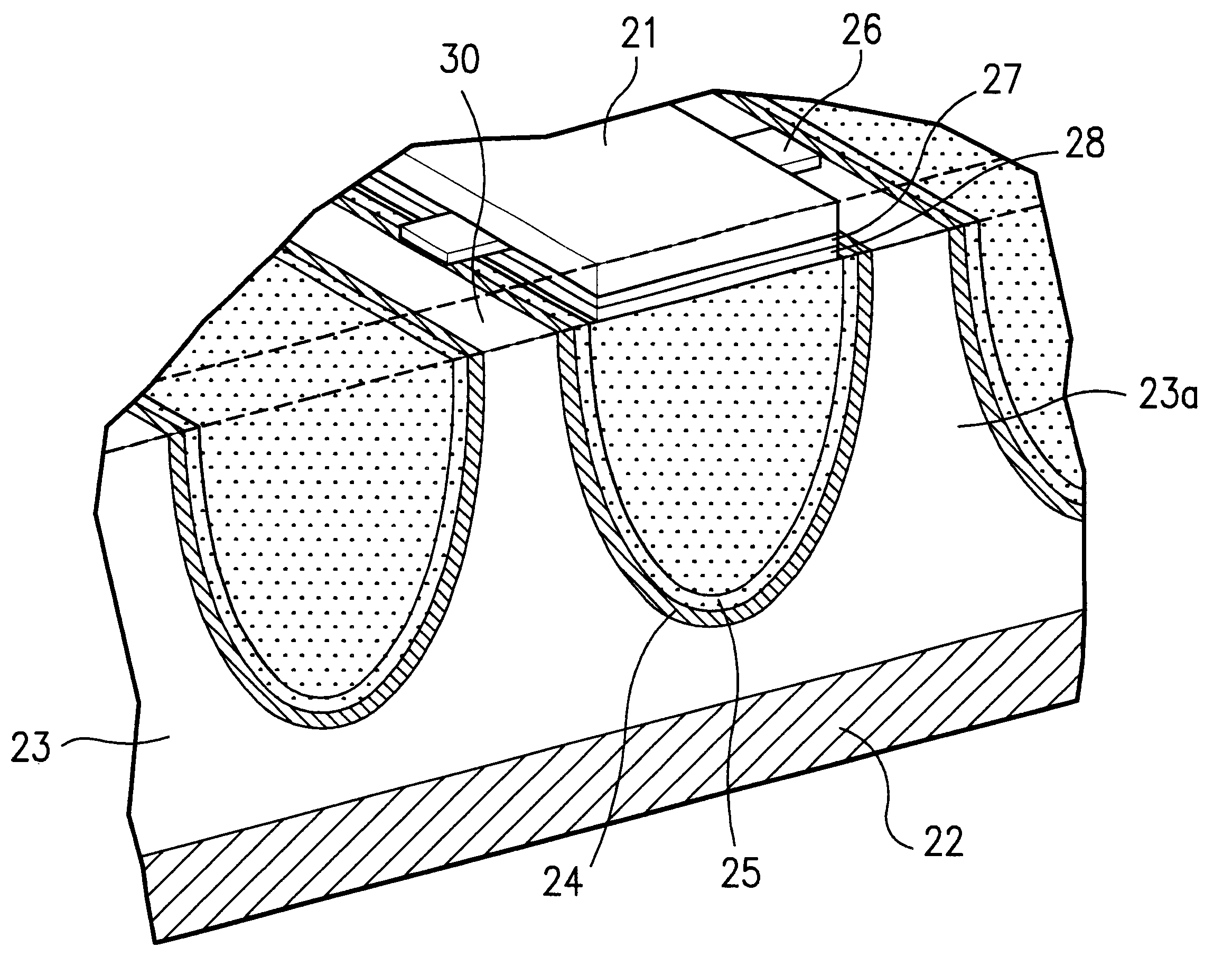

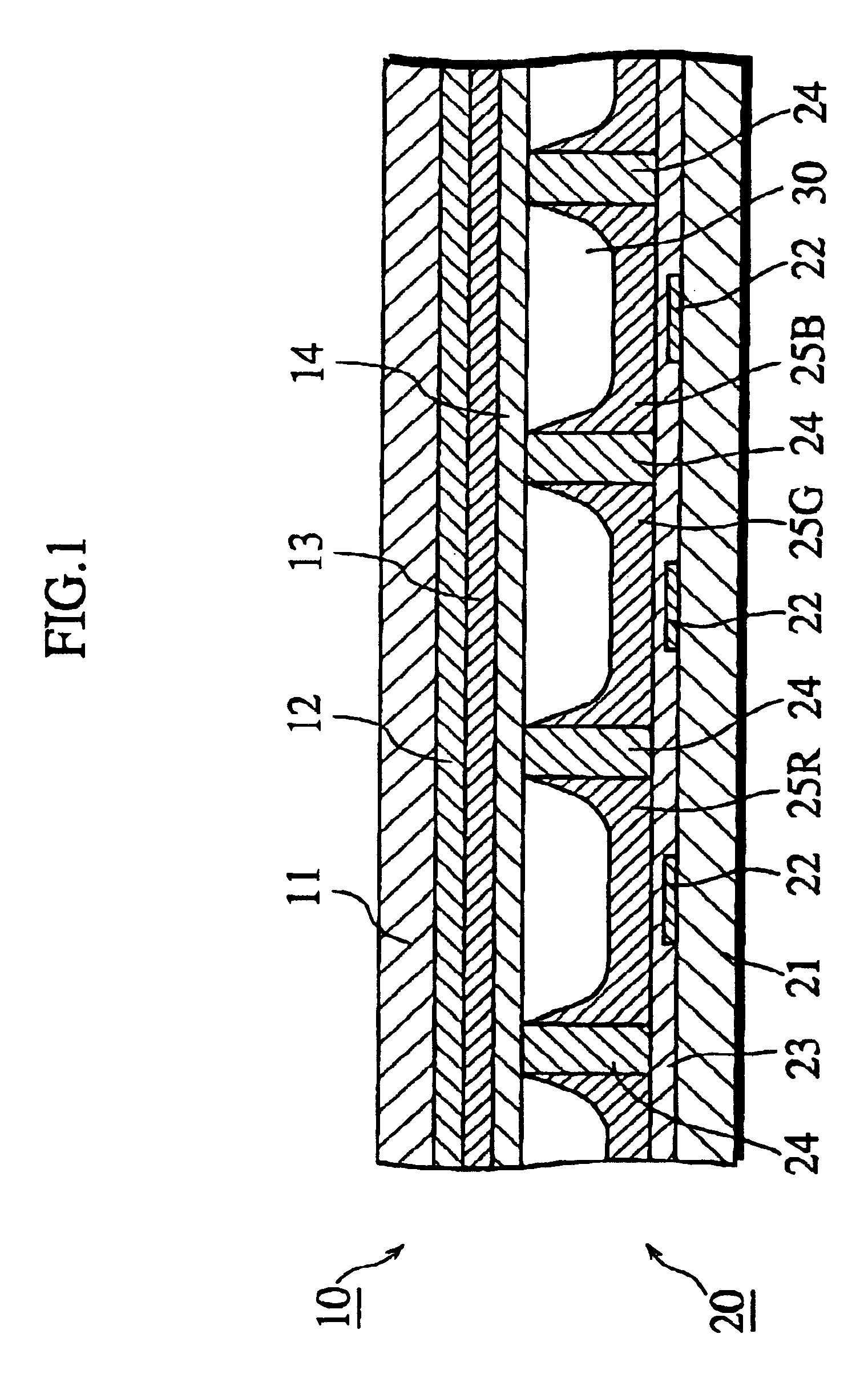

Hollow cathode type color PDP

Hollow cathode type color PDP, is disclosed, including a front panel having an electrode formed on a front substrate, and a first dielectric film and a protection film formed in succession on an entire surface of the electrode, and a rear panel having a second dielectric film formed on a rear substrate to a thickness opposite to the front panel, a well region formed by etching the second dielectric film to a depth, and an address electrode and a fluorescent material film stacked in succession on an inside surface of the well, thereby allowing a larger discharge area in the discharge cell compared to the related art PDP, which improves a luminance.

Owner:LG ELECTRONICS INC

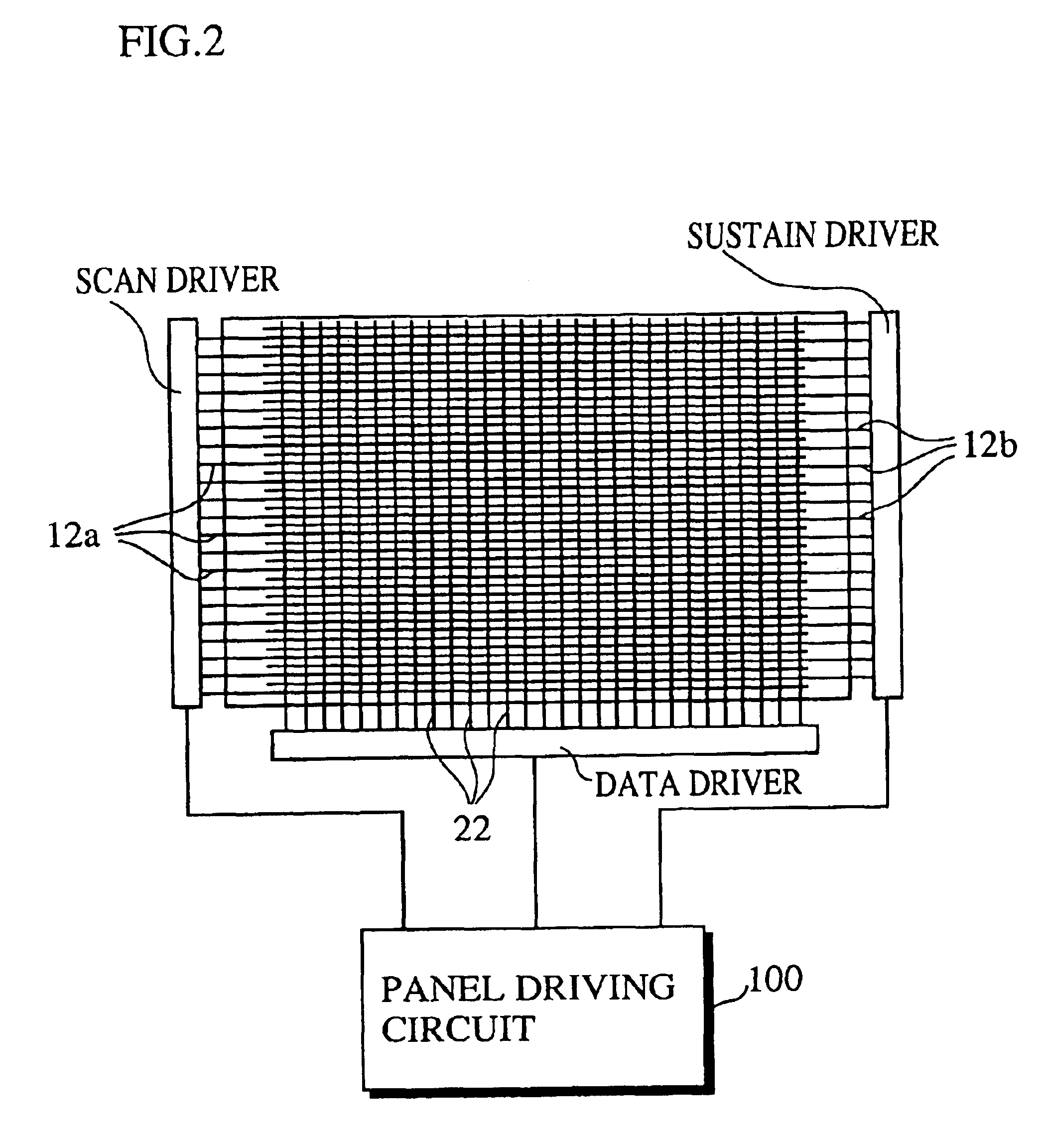

Plasma display apparatus and driving method thereof

InactiveUS20060290257A1Liquid crystal compositionsCathode-ray/electron-beam tube electrical connectionFlat panel displayPlasma display

The present invention relates to a sealing glass composition that excludes Pb, i.e., an environmentally harmful material, and a flat panel display apparatus using the same. A sealing glass composition of the present invention comprises Sb2O3 of 20 mol % to 50 mol %, B2O3 of 30 mol % to 70 mol %, SiO2 of 5 mol % to 15 mol % and Al2O3 of 0 mol % to 15 mol %. The flat display apparatus of the present invention has a front panel and a rear panel, which are combined together with a sealing glass composition with a predetermined distance therebetween.

Owner:LG ELECTRONICS INC

Plasma display panel (PDP) and plasma display apparatus including the PDP

InactiveUS20070108906A1Reduce weight and costAvoid temperatureAddress electrodesSustain/scan electrodesPhosphorTransmittance

A plasma display panel (PDP) that improves a transmittance rate of visible rays, prevents address electrodes from producing a lot of heat, and reduces the occurrence of afterimages from the PDP, and a plasma display apparatus using the PDP are provided. The PDP includes: a substrate through which visible rays displaying an image are transmitted; a plurality of electrode buried walls arranged below the substrate and defining discharge cells; a plurality of pairs of discharge electrodes spaced apart from each other in the electrode buried walls and performing a discharge in the discharge cells; a sealing member arranged below the electrode buried walls, sealing a discharge gas together with the substrate, and formed of a material having a higher thermal conductivity than that of the substrate; and phosphor layers arranged in the discharge cells.

Owner:SAMSUNG SDI CO LTD

Plasma display device

InactiveUS20080101002A1Improve adhesionImproved sealing propertyStatic indicating devicesDigital data processing detailsAnisotropic conductive filmInsulation layer

A plasma display device includes a plasma display panel (PDP) having electrodes between front and rear substrates, a chassis base on an outer surface of the PDP, a printed circuit board assembly (PBA) on the chassis base, a flexible printed circuit (FPC) connecting the PBA to the electrodes of the PDP, an anisotropic conductive film between terminals of the electrodes and a terminal of the FPC, and a sealing member surrounding the terminals of the electrodes and the terminal of the FPC, the sealing member including a surface hydrophobic modifying layer and an insulation layer.

Owner:SAMSUNG SDI CO LTD

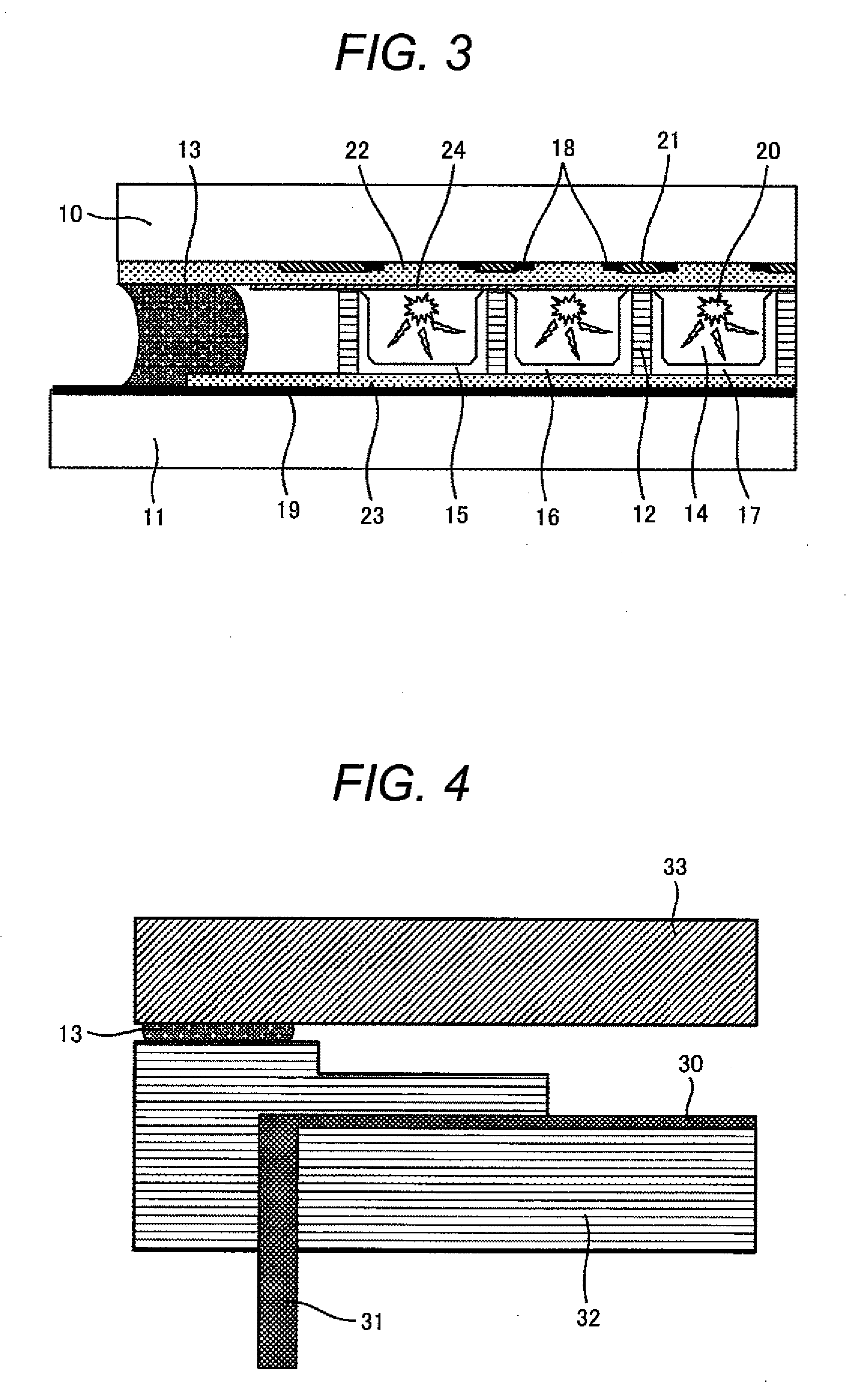

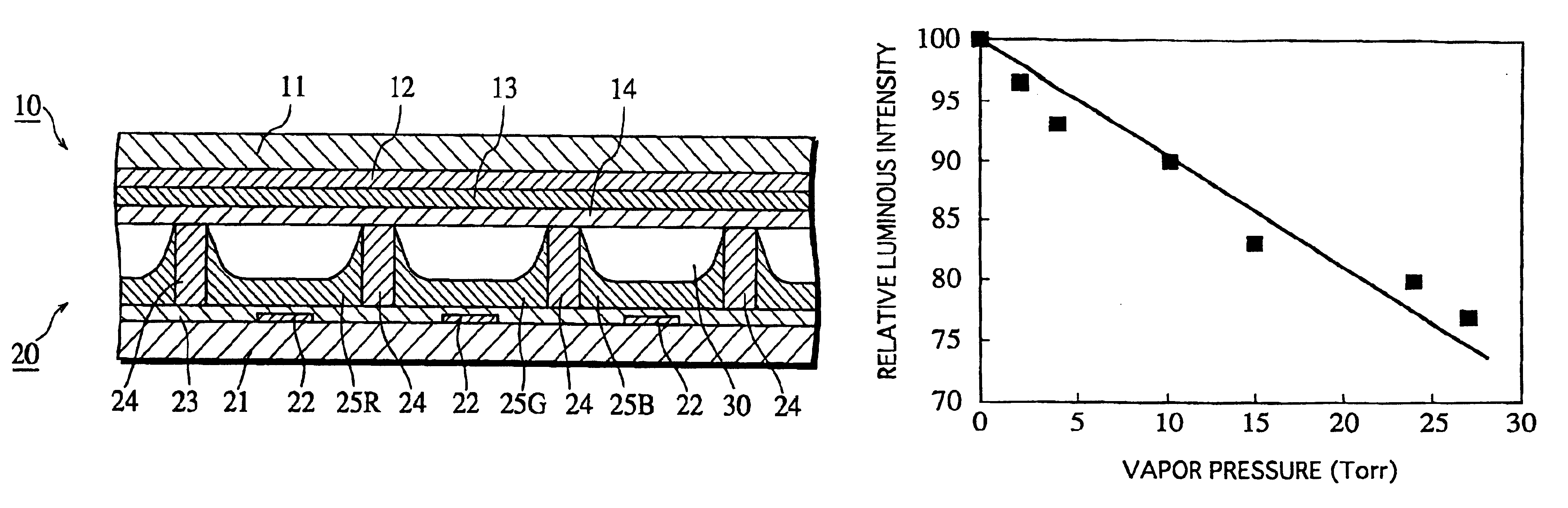

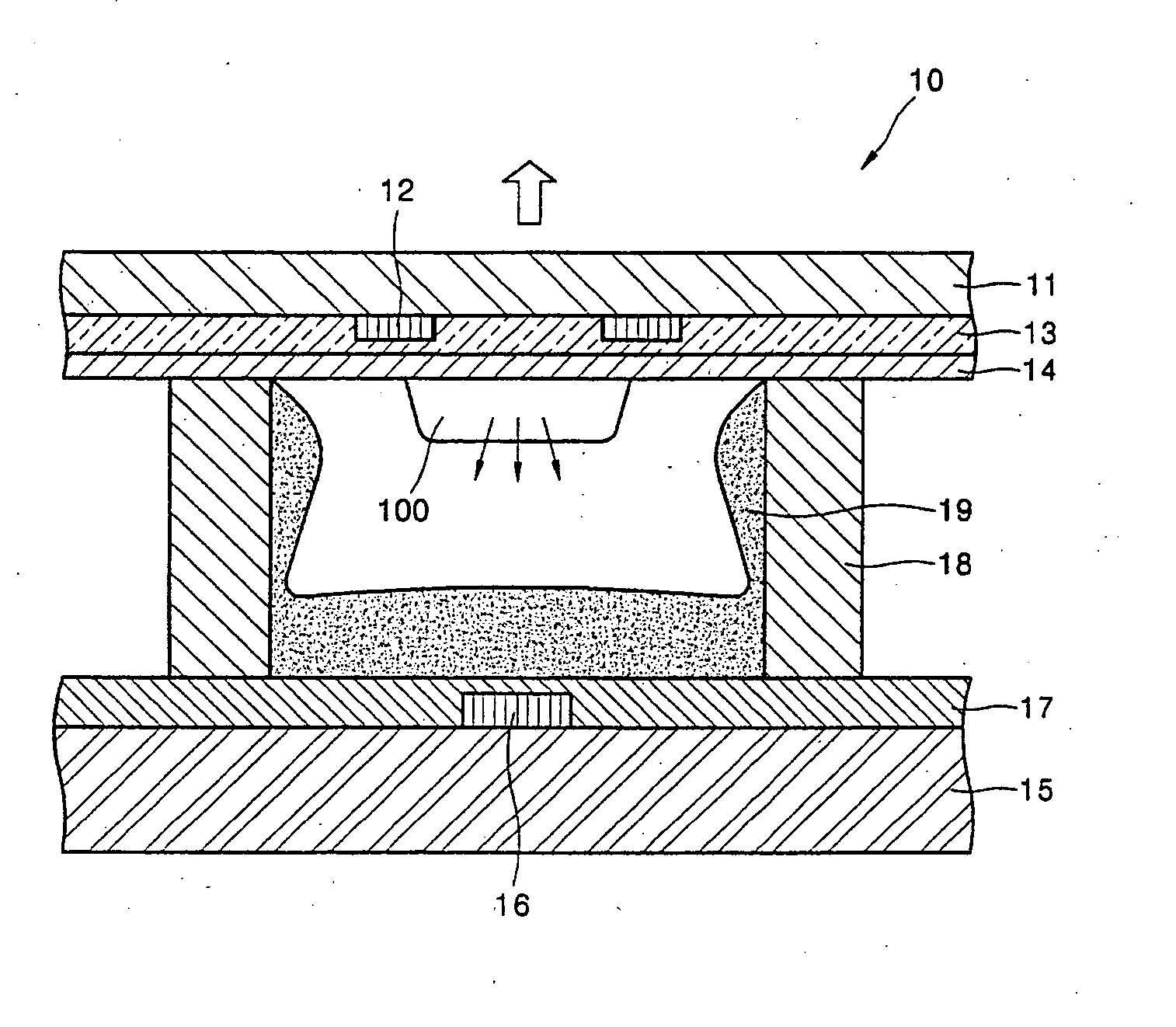

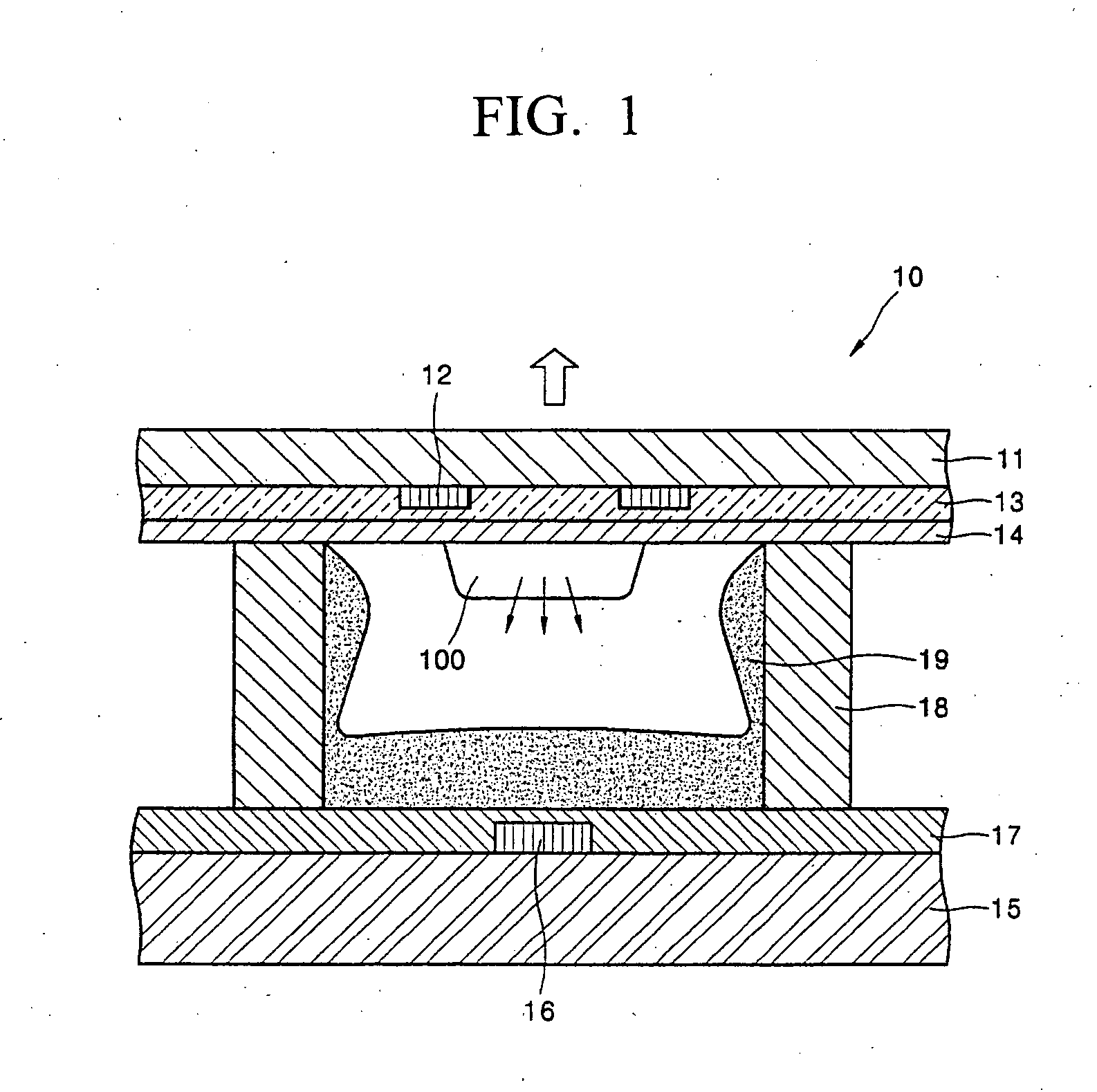

Discharge light-emitting device and method manufacture thereof

InactiveUS6744208B2Reduce voltageEasy dischargeTube/lamp vessel fillingAlternating current plasma display panelsElectric dischargeWater vapor

A discharge light-emitting device includes a gas-filled discharge spaces (30) to use electric discharge in the gas. The gas contains at least 0.01-1% water vapor by volume. The specified amount of water vapor decreases discharge voltage markedly. Water vapor is introduced between a sealing step and an evacuation step so that the gas-filled discharge spaces can finally contain a desired amount of water vapor.

Owner:PANASONIC CORP

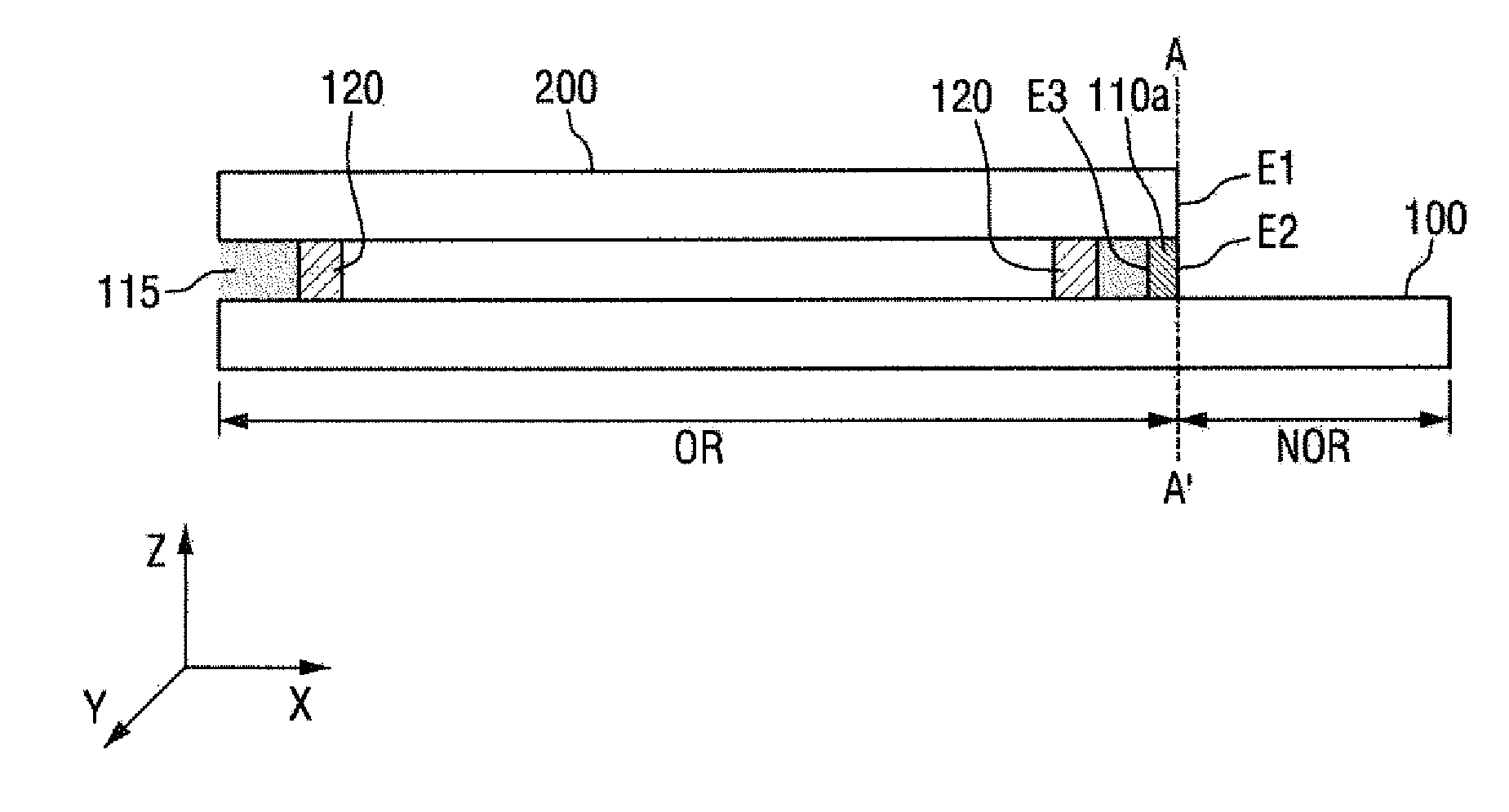

Plasma display panel and method of manufacturing the plasma display panel

InactiveUS20050104520A1Increase contrastIncrease brightnessSustain/scan electrodesGas discharge vessels/containersPhosphorEngineering

A Plasma Display Panel (PDP) includes: a front substrate, a common electrode and a scan electrode arranged on a lower surface of the front substrate, a bus electrode electrically connected to the common electrode and the scan electrode, a front dielectric layer covering the common electrode, the scan electrode, and the bus electrode, a rear substrate facing the front substrate, an address electrode arranged on an upper surface of the rear substrate to cross the bus electrode, a barrier rib arranged between the front and rear substrates, and a phosphor layer arranged on a discharge space defined by the barrier rib. The bus electrode includes a display unit bus electrode arranged on a display area that displays pixels, and a non-display unit bus electrode arranged on a non-display area electrically connected to the display unit bus electrode and connected to an external terminal. The display unit bus electrode and the non-display unit bus electrode have different structures. The non-display unit bus electrode arranged on the non-display area is a single-layered structure while the display unit bus electrode arranged on the display area is a double-layered structure.

Owner:SAMSUNG SDI CO LTD

Plasma display panel

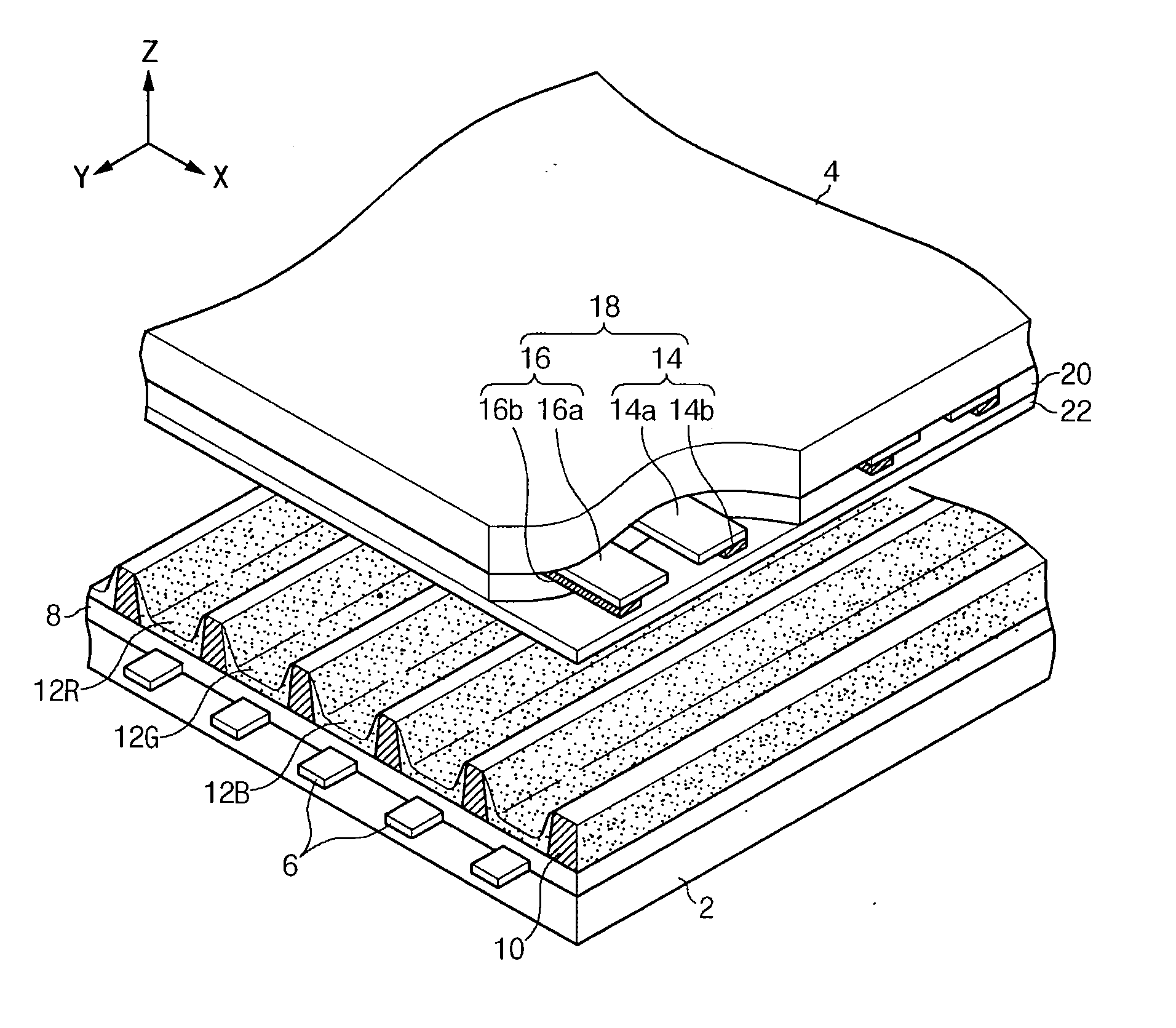

A plasma display panel includes first and second substrates provided opposing one another with a predetermined gap therebetween. Address electrodes are formed on the first substrate. Barrier ribs defining discharge cells are mounted in a display region between the substrates. Further, discharge sustain electrodes are formed on the second substrate substantially perpendicular to the address electrodes. The electrodes are formed into groups of a predetermined number, and the electrodes include effective segments positioned in the display region, terminal segments positioned in a terminal region outside the display region and having a smaller pitch than that of the effective segments, and intermediate segments interconnecting these segments. In at least one group, lengths of elements of the terminal segments increasingly decrease as a distance from a center of the group is increased.

Owner:SAMSUNG SDI CO LTD

Structure for connecting terminal parts of electrodes of plasma display panel and plasma display panel having the same

InactiveUS20060284558A1Reliably and efficiently connectedAddress electrodesSustain/scan electrodesConductive pasteDisplay board

A structure for connecting terminal parts of electrodes of a plasma display panel (PDP) includes a pair of substrates, barrier ribs arranged between the pair of substrates, a dielectric layer arranged between the pair of substrates, discharge electrodes, each having a discharge part arranged inside the barrier ribs, and an exposed part arranged at an end of the discharge part and outside the barrier ribs, terminal electrodes arranged on the dielectric layer, connection parts including conductive paste electrically connecting the exposed parts with the terminal electrodes, blocking partition walls arranged between the connection parts, and signal transmitting members electrically connected with the terminal electrodes.

Owner:SAMSUNG SDI CO LTD

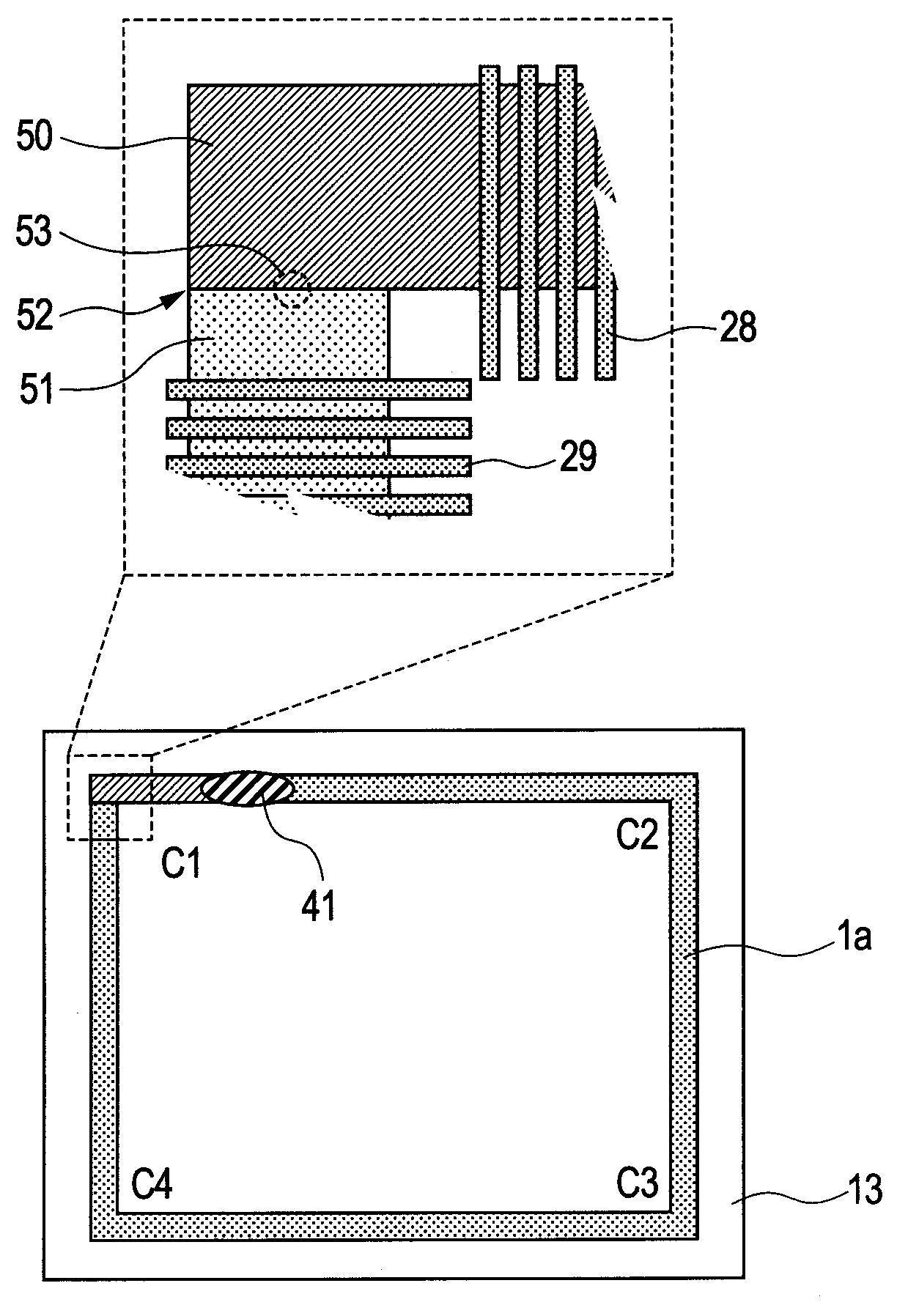

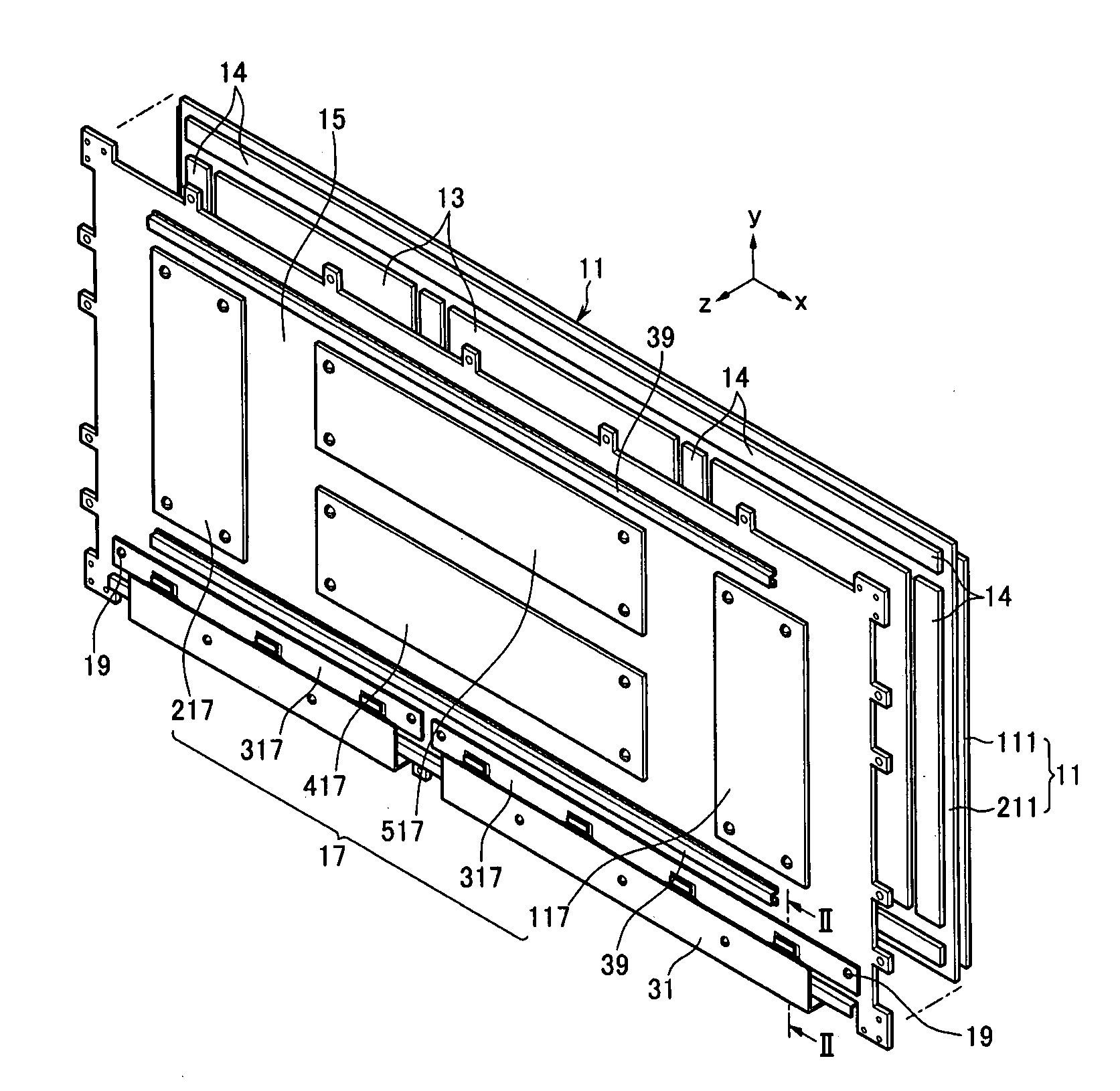

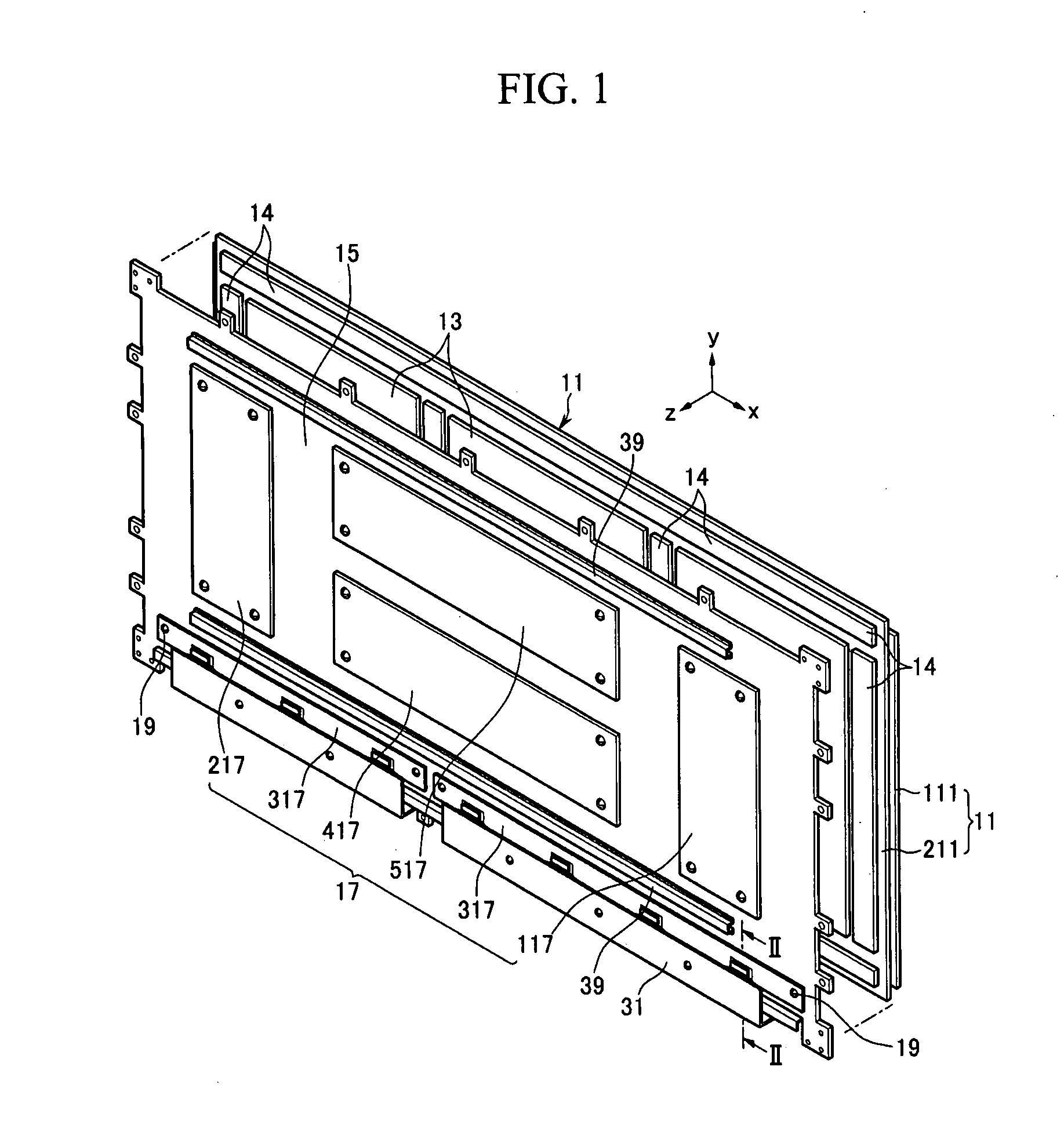

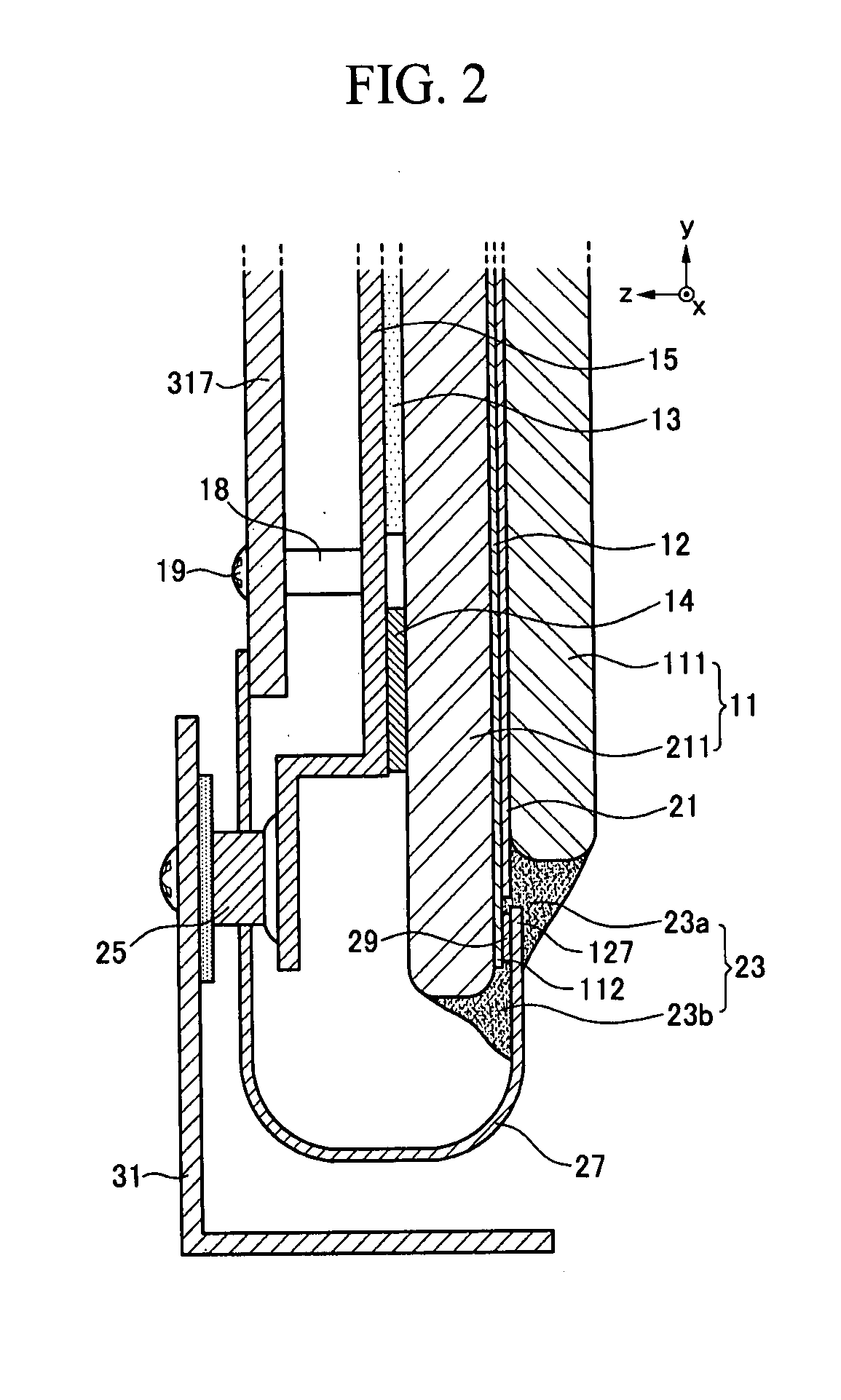

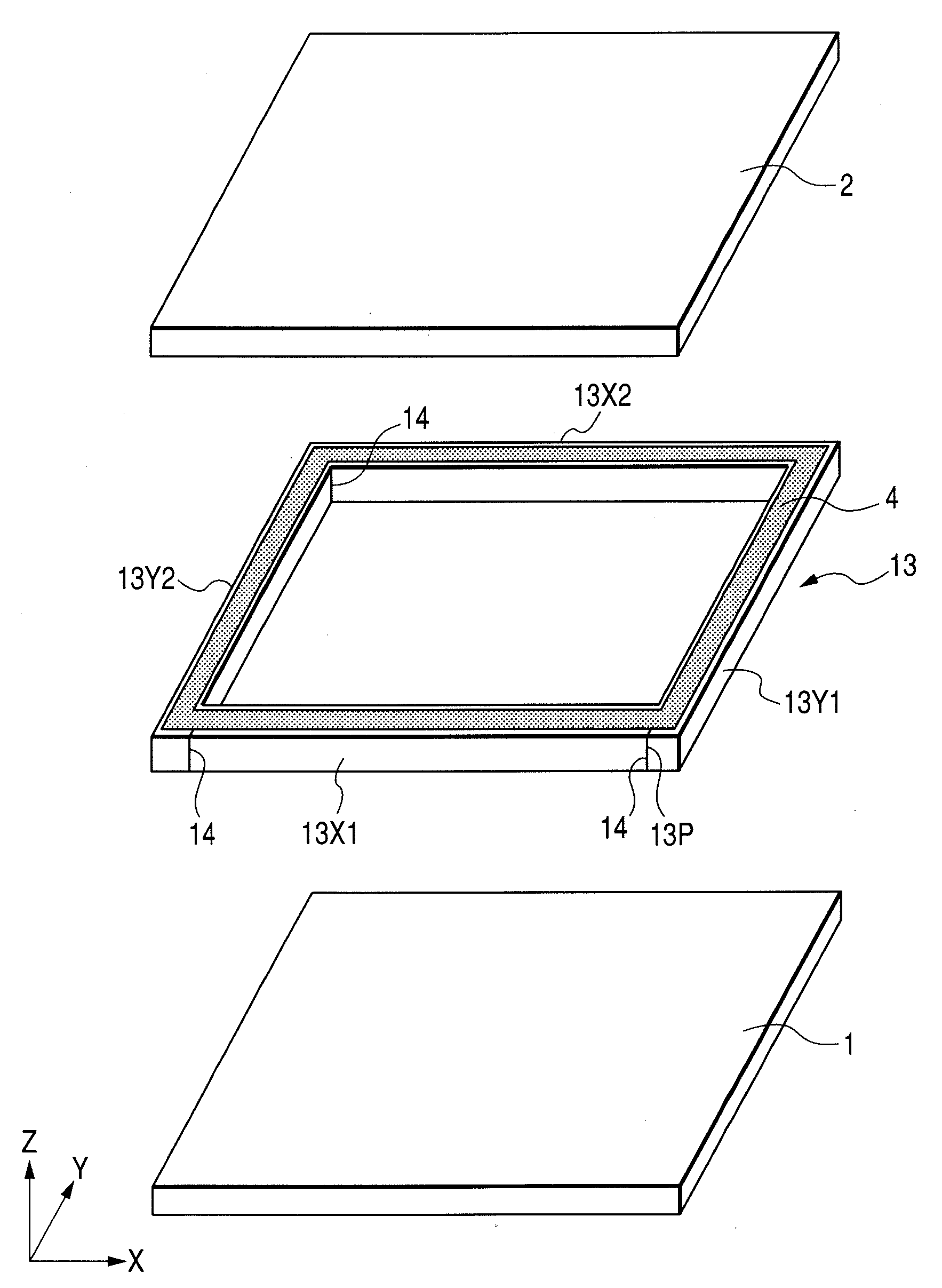

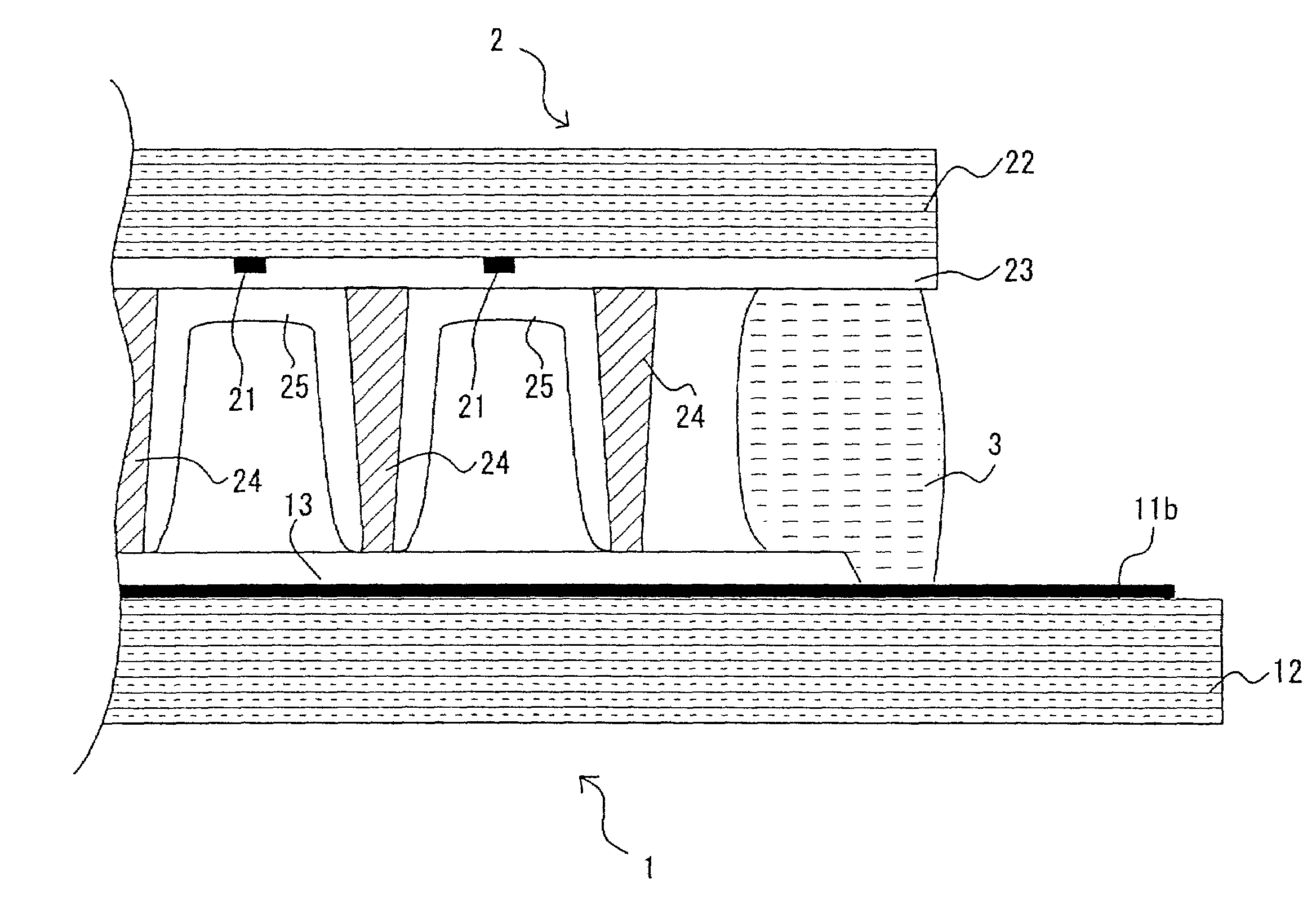

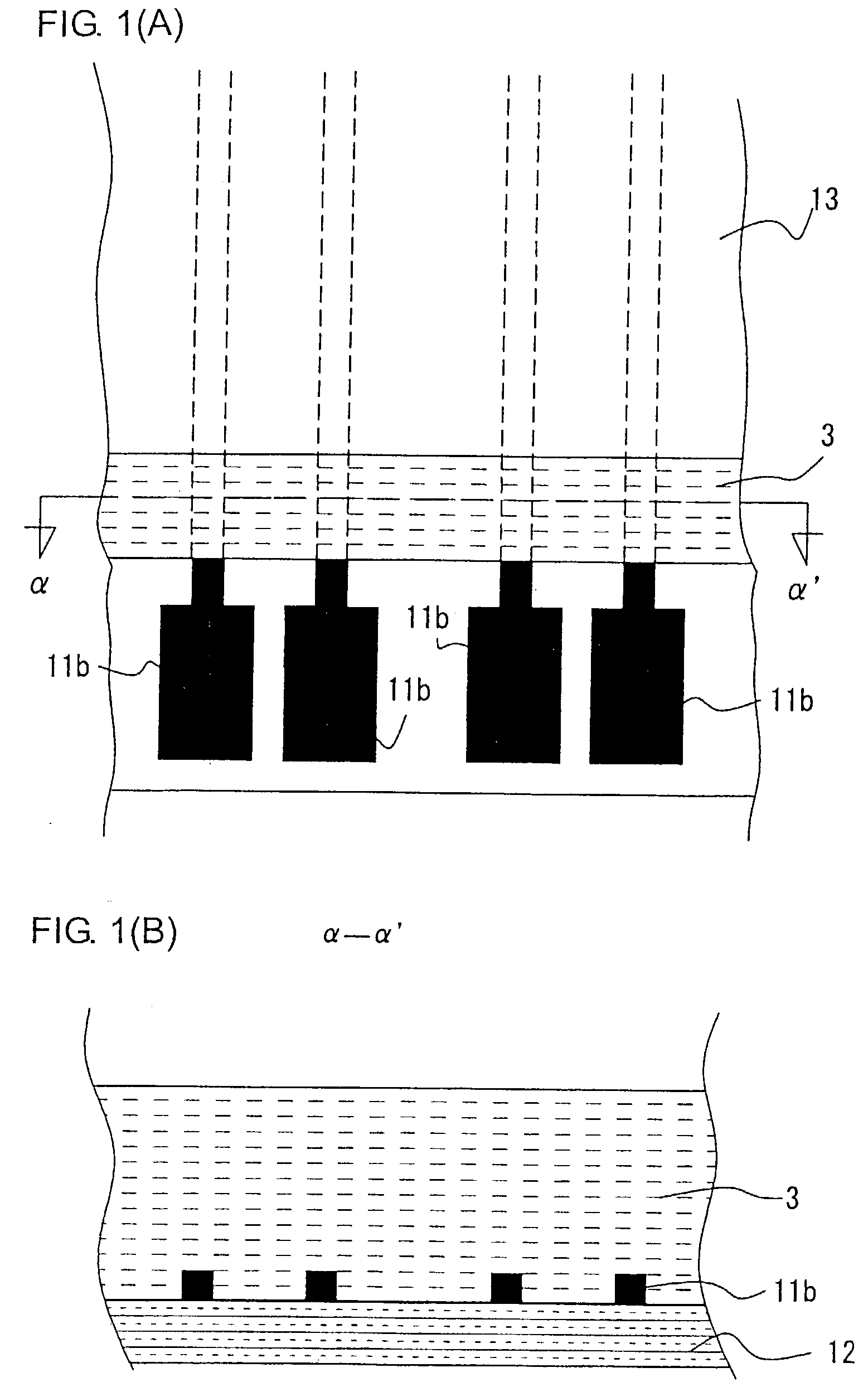

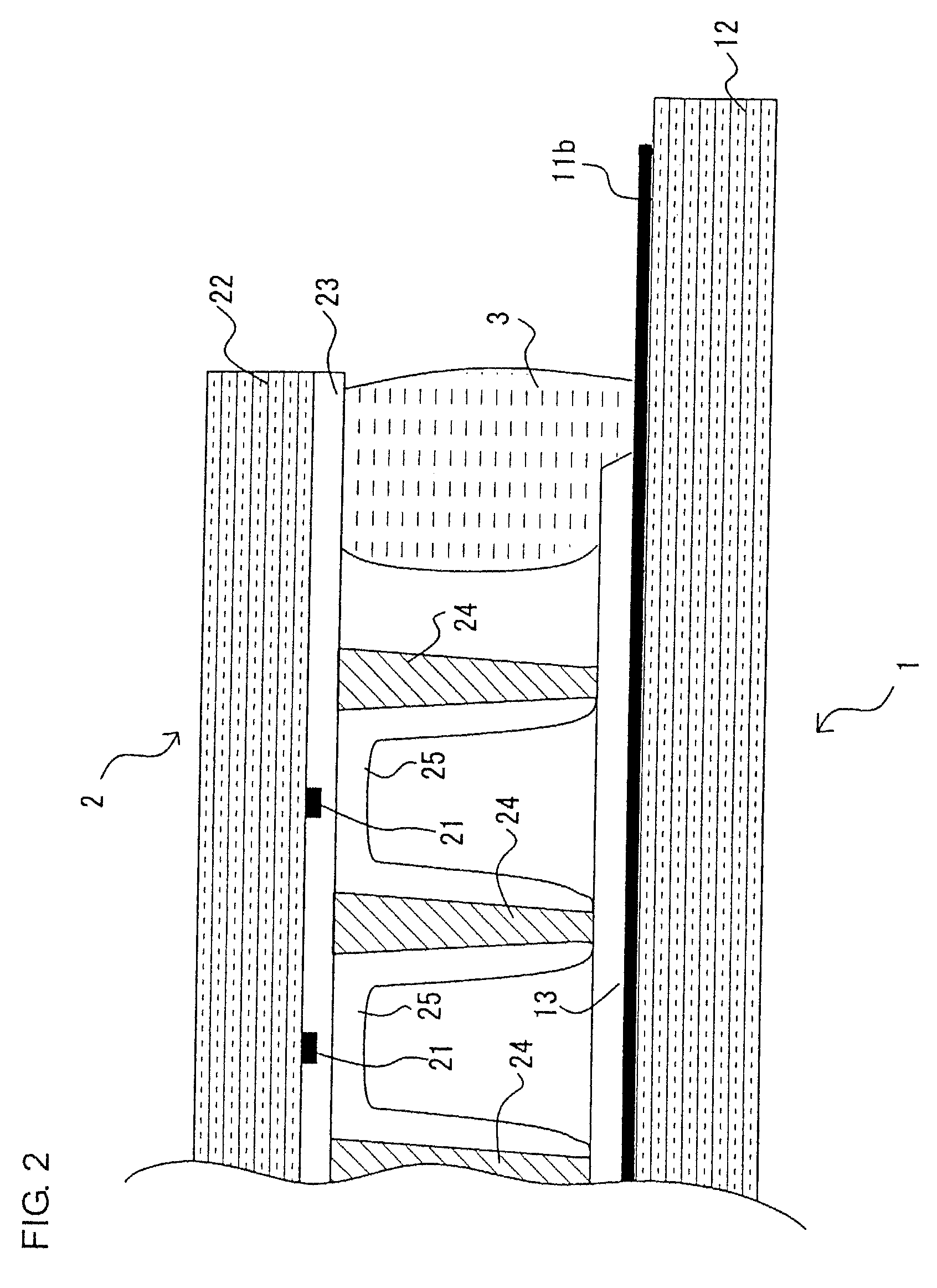

Display device

InactiveUS20070200476A1Improve quality and reliabilityInhibitionControl electrodesDischarge tube luminescnet screensCooking & bakingDisplay device

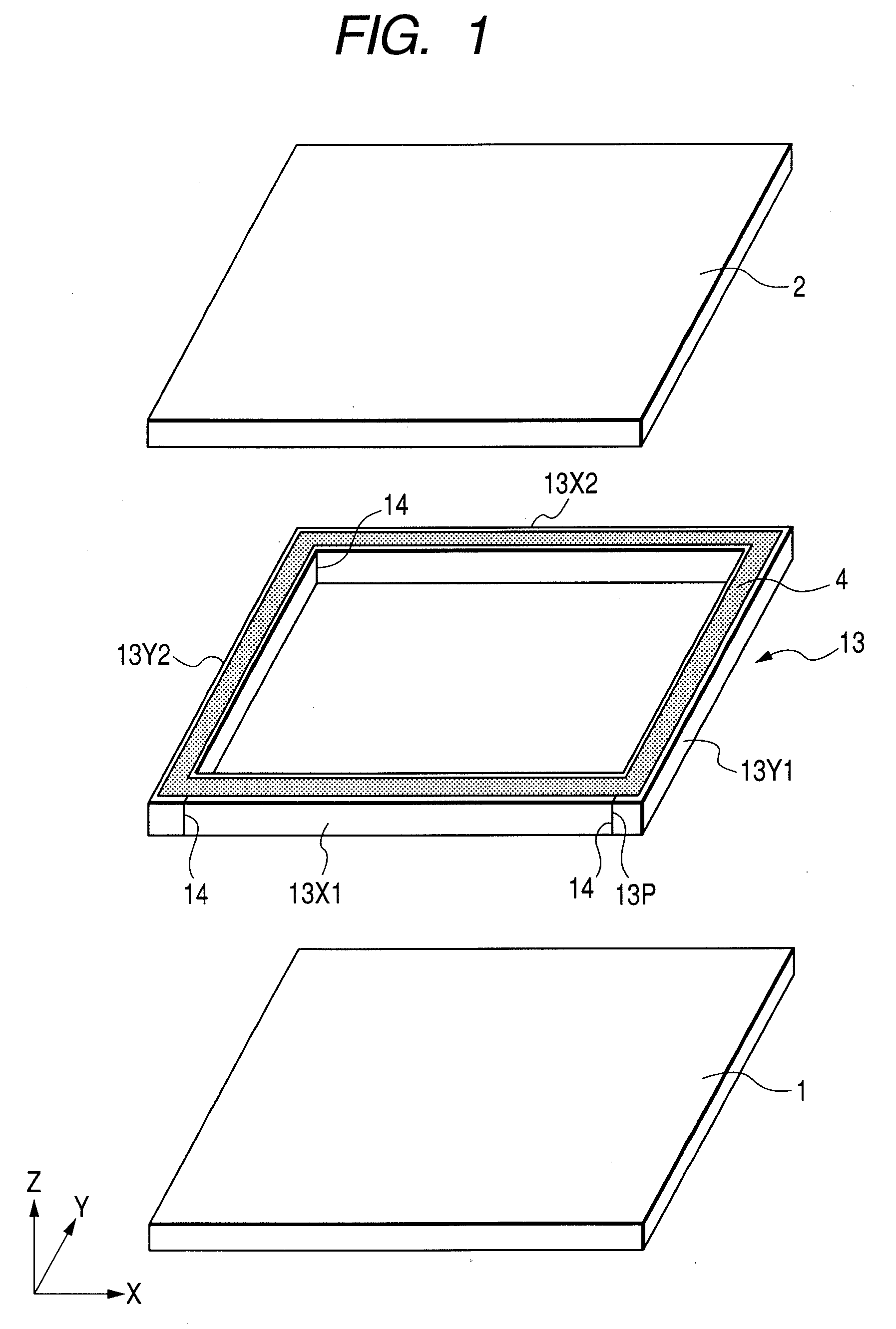

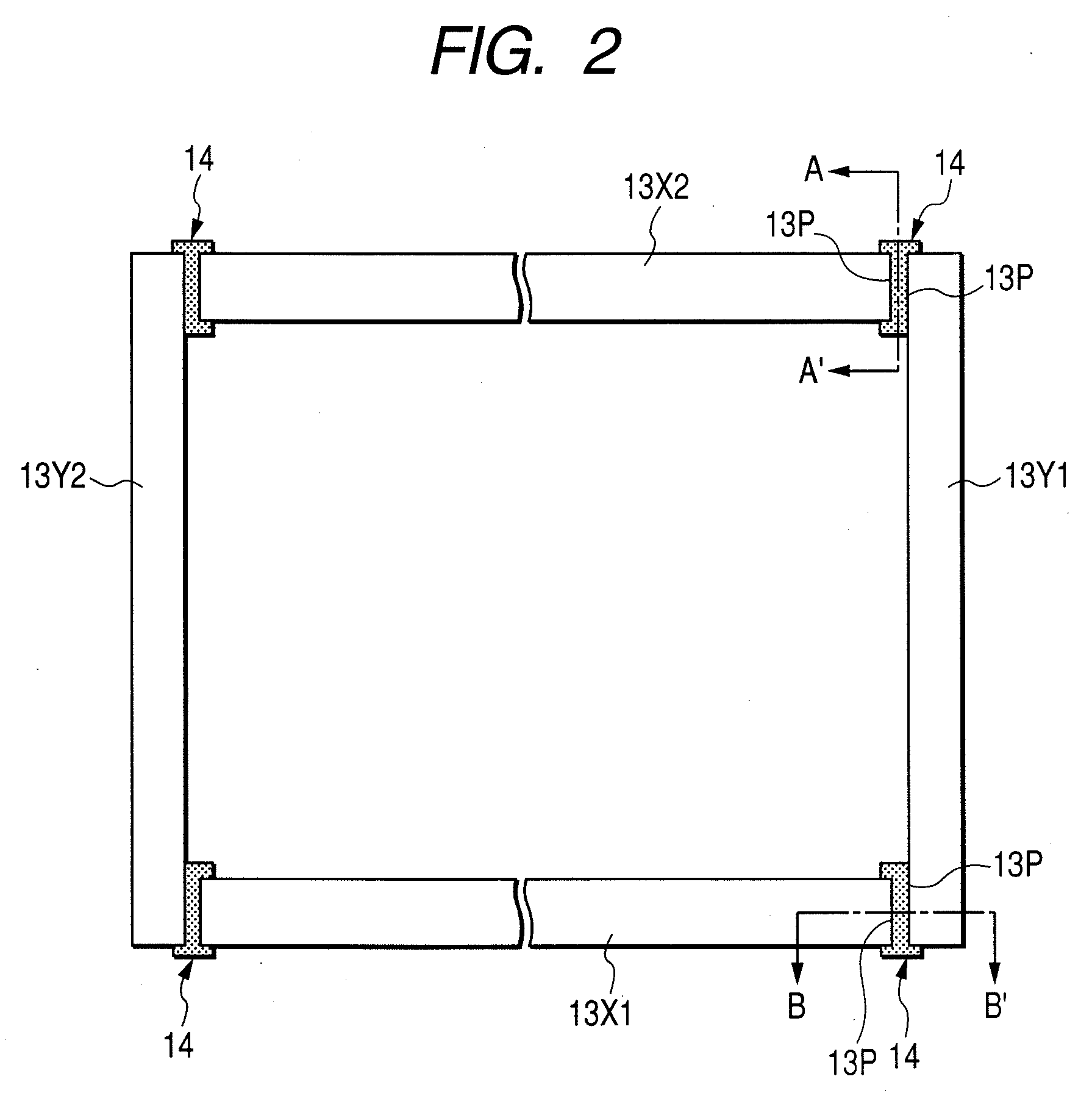

The present invention provides a display device allowing the quality and reliability to be improved by preventing the occurrence of vacuum leak attributable to dislocation which may be caused by preliminary baking and panel sealing.A display device in which the end surfaces of a support body 13 are hermetically bonded to a front substrate 2 and a rear substrate 1 by sealing members 4. In the display device, the support body 13 is formed by bonding together a plurality of support body members 13X1, 13X2, 13Y1 and 13Y2, and adjacent support body members are bonded by using a first bonding member 141 for bonding a central area of each bonding surface and a second bonding member 142 for bonding a marginal area around the central area. The softening temperature of the first bonding member is set higher than the softening temperature of the second bonding member.

Owner:KIJIMA YUUICHI +4

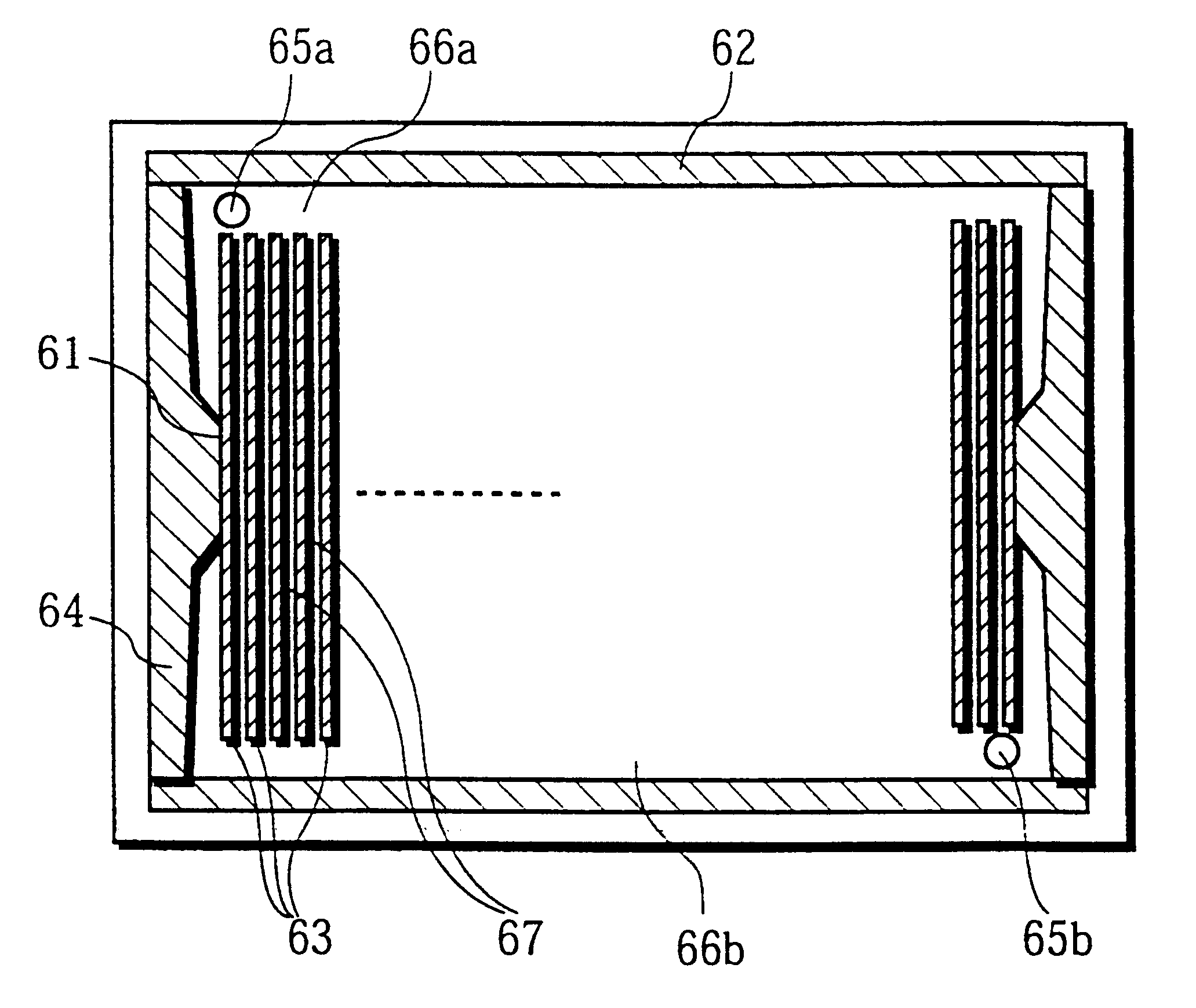

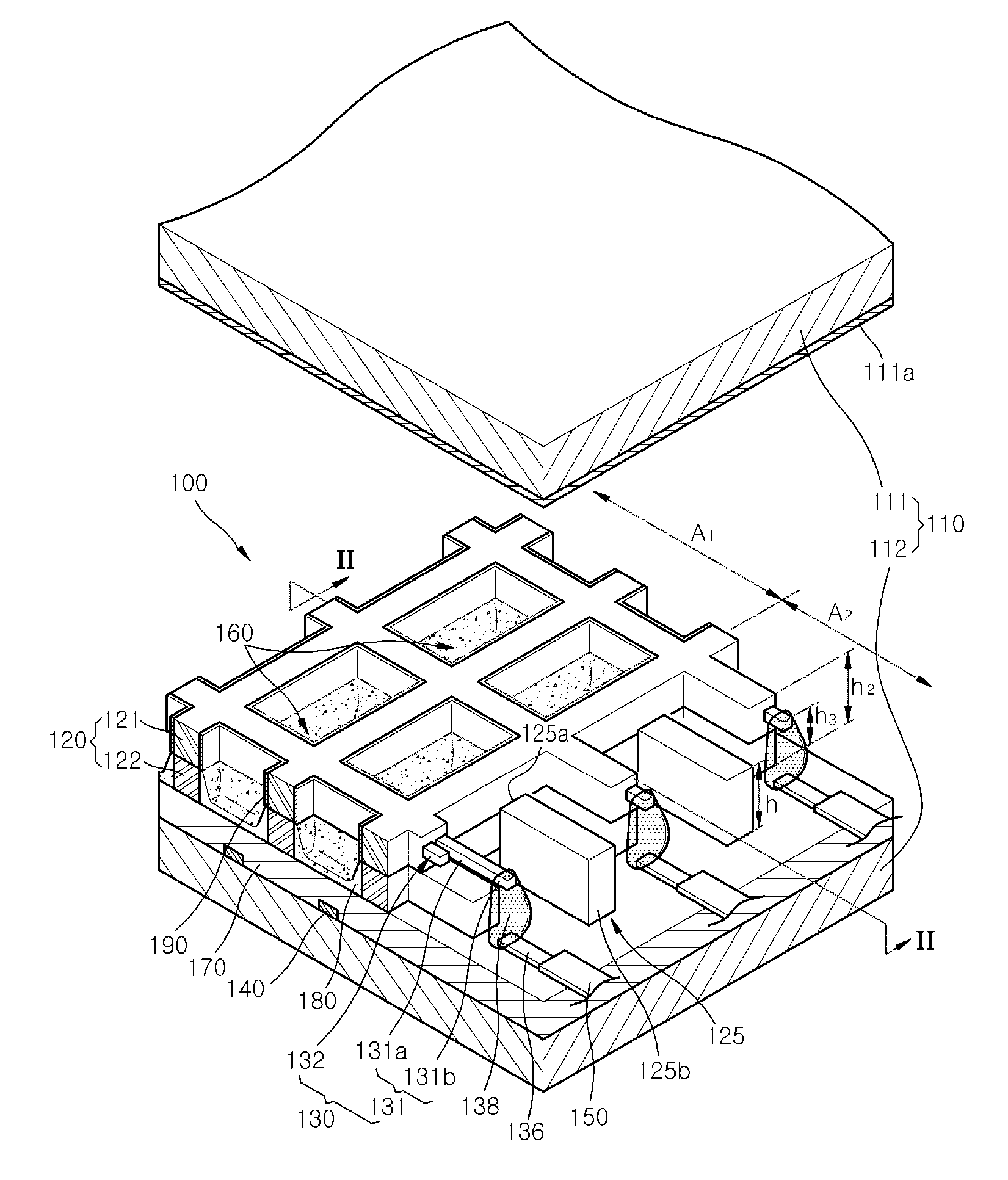

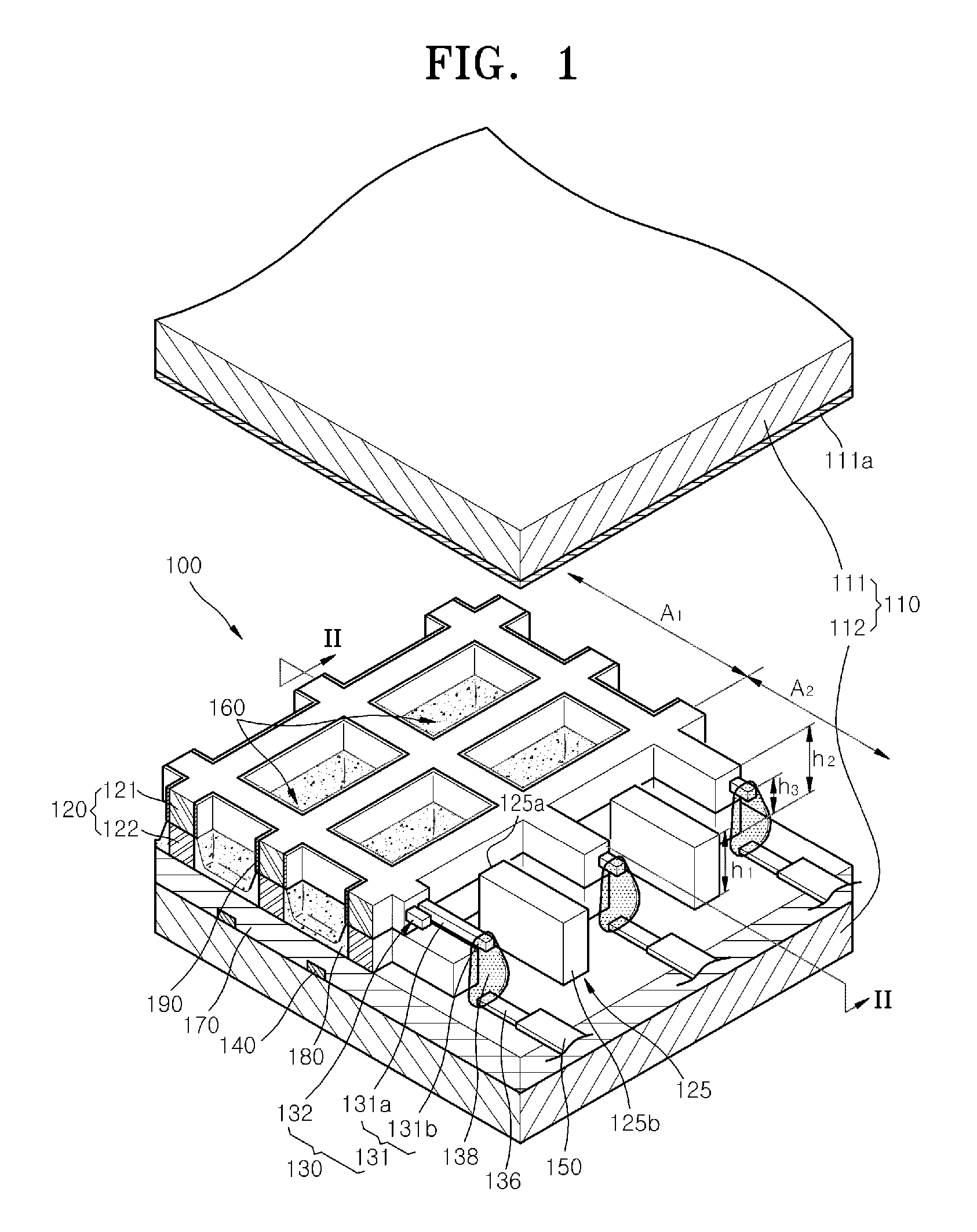

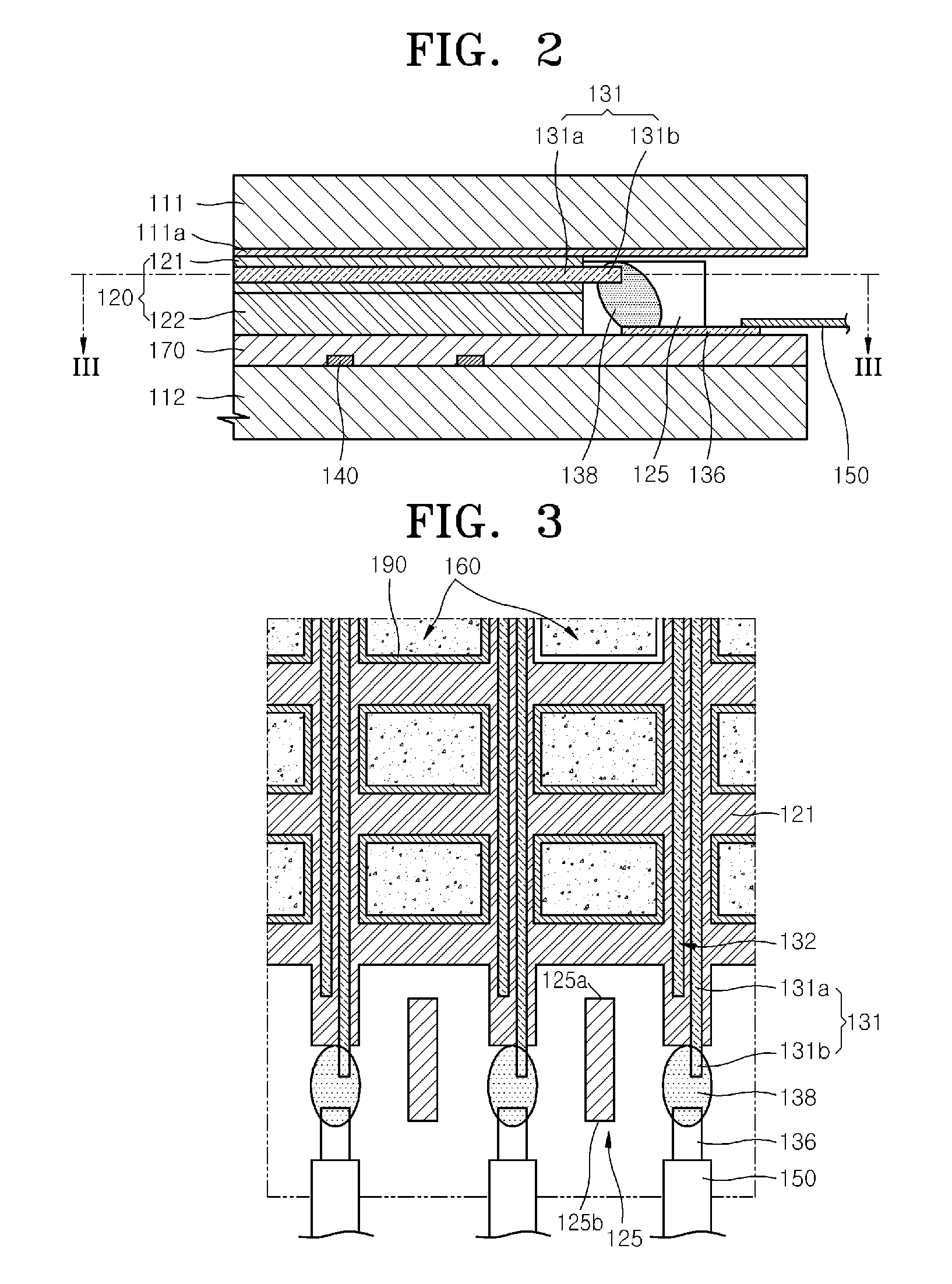

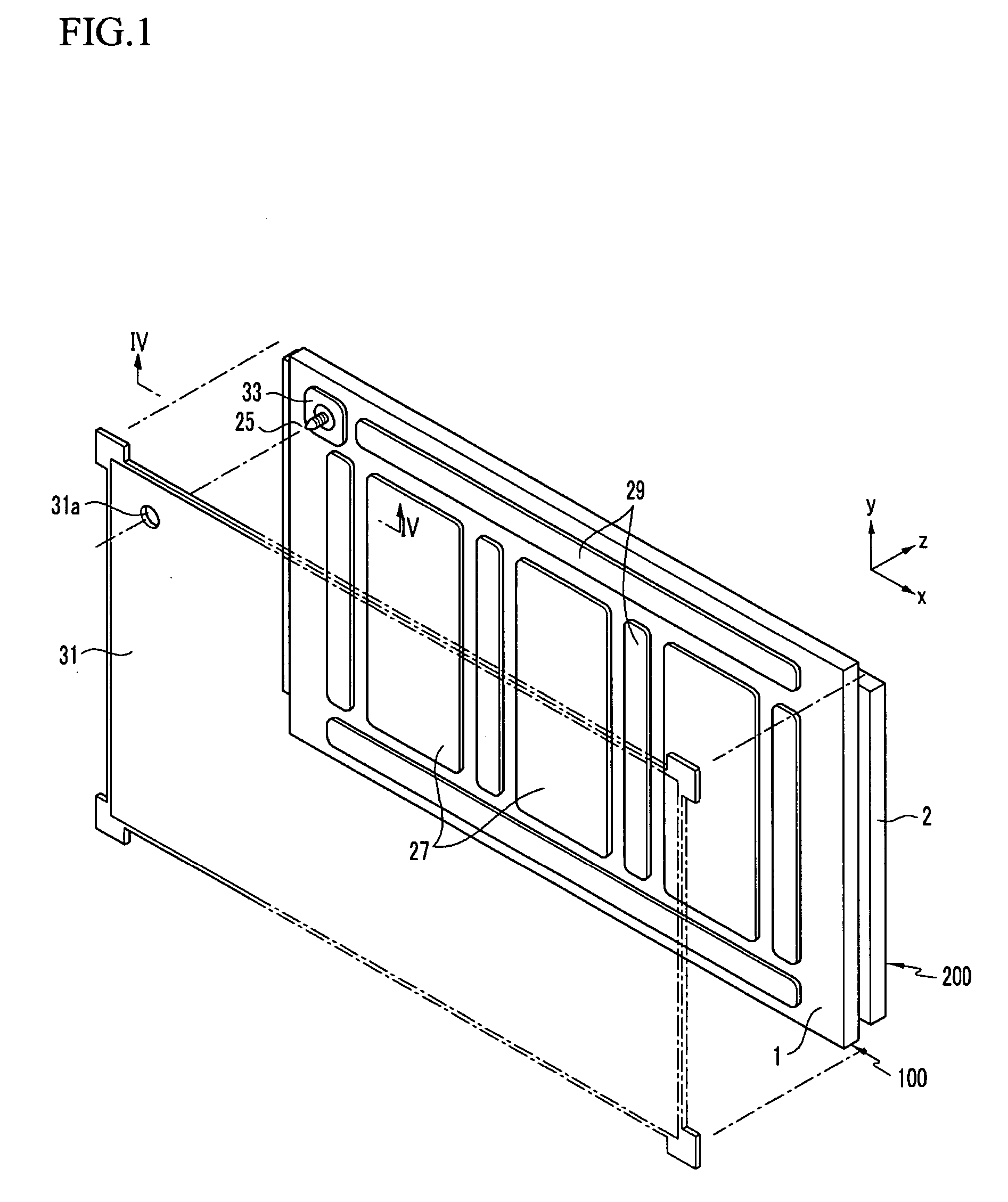

Plasma display panel and plasma display device

InactiveUS20060066238A1Effective absorptionEffectively blocking pathAddress electrodesSustain/scan electrodesEngineeringPlasma display

A plasma display panel that includes a first plate and a second plate that are sealed to each other to form discharge cells. The discharge cells generate images by gas discharge. The plates include an exhaust port that is formed along an edge of the first plate to define a path to connect to the discharge cells, an exhaust tube on the outside of the first plate that is connected to the discharge cells through the exhaust port, and a pad that is formed around the exhaust port and the exhaust tube of the first plate. This structure effectively blocks a noise path around the exhaust port and the exhaust tube formed in the rear plate.

Owner:SAMSUNG SDI CO LTD

A conductive electrode powder, a method for preparing the same, preparing method of electrode of plasma display and plasma display

The present invention provides a conductive electrode powder which includes electroconductive metal particles, and an inorganic oxide coating layer covering the surface of the electroconductive metal particles. By using a conductive electrode powder, the corrosion, the ionization, the migration such as ionization, and yellowing of the electrode such as colloidalization can be prevented, while simultaneously maintaining electrical conductivity of an electrode.

Owner:SAMSUNG SDI CO LTD

Plasma display panel and manufacturing method therefor

InactiveUS20090066215A1Reduce noiseReduce adverse effectsDischarge tube luminescnet screensLamp detailsSealantPlasma display

A plasma display panel includes a front plate and a back plate spaced from and facing each other with a barrier rib therebetween, the front plate and the back plate each having a long side and a short side. A first sealant is at the long side between the front plate and the back plate and a second sealant is at the short side between the front plate and the back plate to seal a discharge space divided by the barrier rib between the front plate and the back plate. A first spacer is in the first sealant and a second spacer is in the second sealant, the second spacer having a smaller volume than the first spacer.

Owner:SAMSUNG SDI CO LTD

Plasma display panel having sealing structure

InactiveUS7019461B2Smooth dischargeAccurate displayAddress electrodesSustain/scan electrodesEngineeringDielectric layer

An AC plasma display panel has a pair of panels disposed in spaced opposed relation, and each having a plurality of electrodes formed on an opposed surface thereof and mostly covered with a dielectric layer; and a sealing member which seals the periphery of the pair of panels. The electrodes each has a portion uncovered with the dielectric layer, and the sealing member is disposed in contact with the uncovered portions of the electrodes. With this arrangement, the discharge space can be kept gas-tightly sealed by the sealing member without communication with the outside of the display panel which may otherwise occur due to the presence of voids on opposite sides and surfaces of the electrodes.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com