Zeolite film and process for producing zeolite film

A manufacturing method, zeolite membrane technology, applied in the direction of separation methods, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of not being able to provide large membranes, membrane defects, and high separation performance, and achieve improved yields and reduced The effect of high defect and separation performance

Active Publication Date: 2012-11-21

NGK INSULATORS LTD

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, for practical use, it is necessary to form a film on a large substrate in the shape of a monolith with a large film area. A difference occurs, and the film will have defects when the structure directing agent is removed from the thicker film

Therefore, it is not possible to provide a membrane with a small amount of defects in the entire large membrane and high separation performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1~4)

Embodiment 5、6)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Login to View More

Abstract

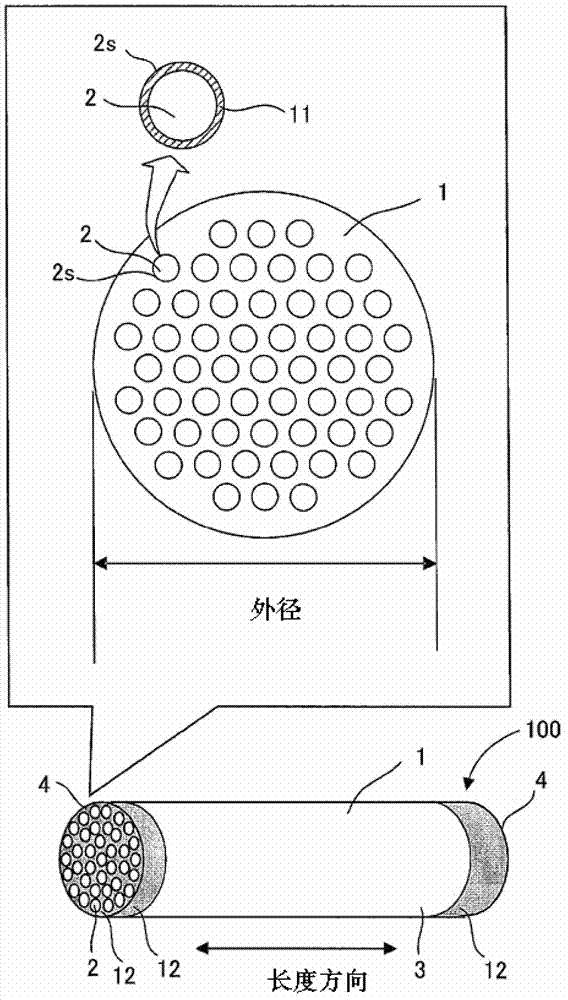

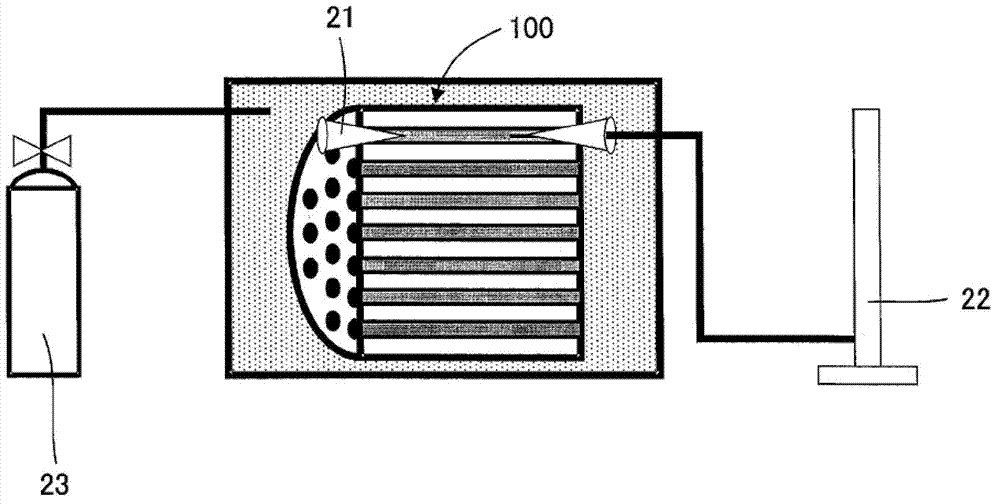

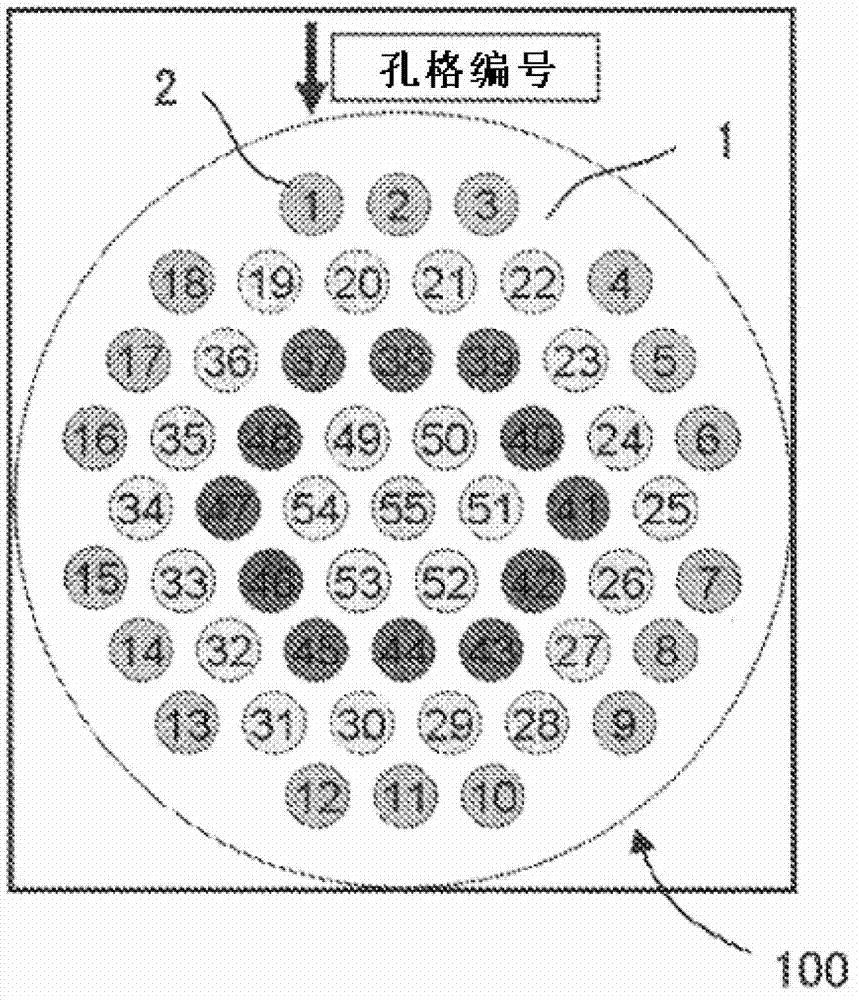

Provided are a process for producing a zeolite film which, even when large, has few defects and which has higher separation performance than conventional zeolite films, and a zeolite film obtained by the process. In the process, a zeolite film containing a structure-directing agent and formed on a substrate through hydrothermal synthesis is heated in an atmosphere having an O2 concentration of 22.0 vol% or higher, thereby removing the structure-directing agent. The process includes: a particle adhesion step in which a slurry containing, dispersed therein, zeolite particles serving as seeds is caused to flow down the surface of a substrate by means of the weight of the slurry itself, thereby adhering the zeolite particles to the substrate; and a film formation step in which the substrate to which the zeolite particles have been adhered is immersed in a sol and subjected to hydrothermal synthesis, thereby forming a zeolite film on the substrate.

Description

technical field [0001] The present invention relates to a zeolite membrane and a method for producing the zeolite membrane. Background technique [0002] Zeolites are used as catalysts, catalyst supports, adsorbents, etc. In addition, zeolite membrane devices formed on the surface of porous substrates made of metal or pottery can be used as gas separation membranes or pervaporation membranes by utilizing the molecular sieve function of zeolites. [0003] Among zeolites, there are many types (types) with different crystal structures, such as LTA, MFI, MOR, FER, FAU, and DDR. For example, it is known that the main component of DDR (Deca-Dodecasil 3R) type zeolite is silica, and it is formed of microporous polyhedrons composed of oxygen 8-membered rings with a micropore diameter of 4.4×3.6 angstroms. Due to the small pore size in DDR zeolite, it is used as carbon dioxide (CO 2 ), methane (CH 4 ), ethane (C 2 h 6 ) and other low molecular gas molecular sieve membrane applic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D71/02B01D69/04B01D69/10B01D69/12C01B39/04

CPCB01D53/228B01D69/02C01B39/48B01D67/0051B01D63/066B01D71/028B01D61/362B01D2325/02B01D2325/02833B01D71/0281

Inventor 内川哲哉谷岛健二新野真纪子

Owner NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com