Optical film, and preparation method

An optical film and manufacturing method technology, applied in optics, optical components, instruments, etc., can solve problems such as visual obstruction, high water absorption and moisture permeability, and unusable optical films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Here, the present invention will describe some embodiments in detail. It is to be noted, however, that the invention may be practiced in a wide range of other embodiments than those expressly described, and that the scope of the invention is not limited to the above-described embodiments, which should be determined by the scope of the claims. .

[0023] The optical film of the present invention comprises: at least one PMMA, PMMA or PMMA blending of substituted functional groups; and the above-mentioned PMMA, PMMA or PMMA blending of substituted functional groups can be uniformly mixed in any proportion according to the required properties In the above solvent, the above mixed solution forms the base material of the optical film after heat treatment.

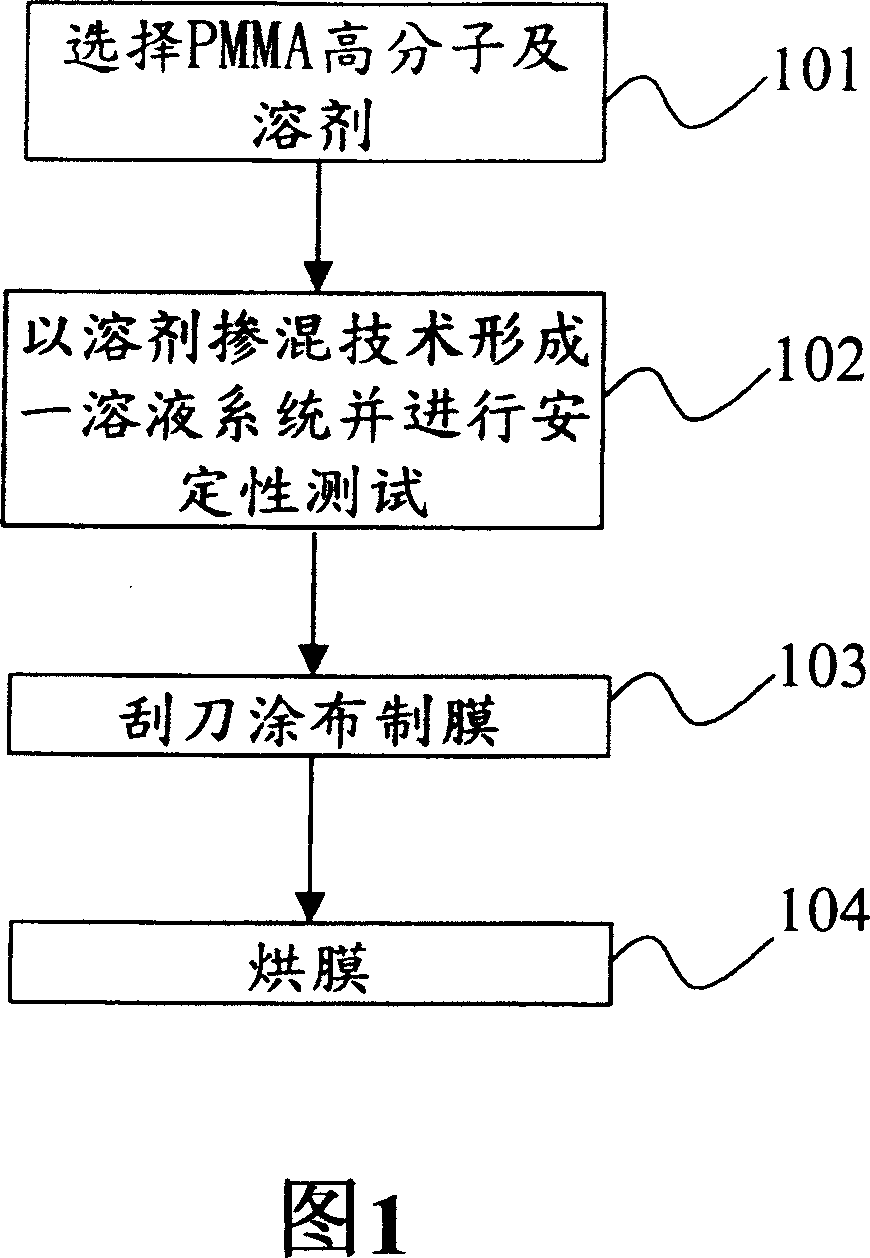

[0024]Please refer to FIG. 1 , which shows the flow chart of the optical film of the present invention. The manufacture method of the optical film of the present invention, at first, select PMMA polymer and solvent in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com