Patents

Literature

98results about How to "Moderate mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-ceramic composite brake disc and preparation method thereof

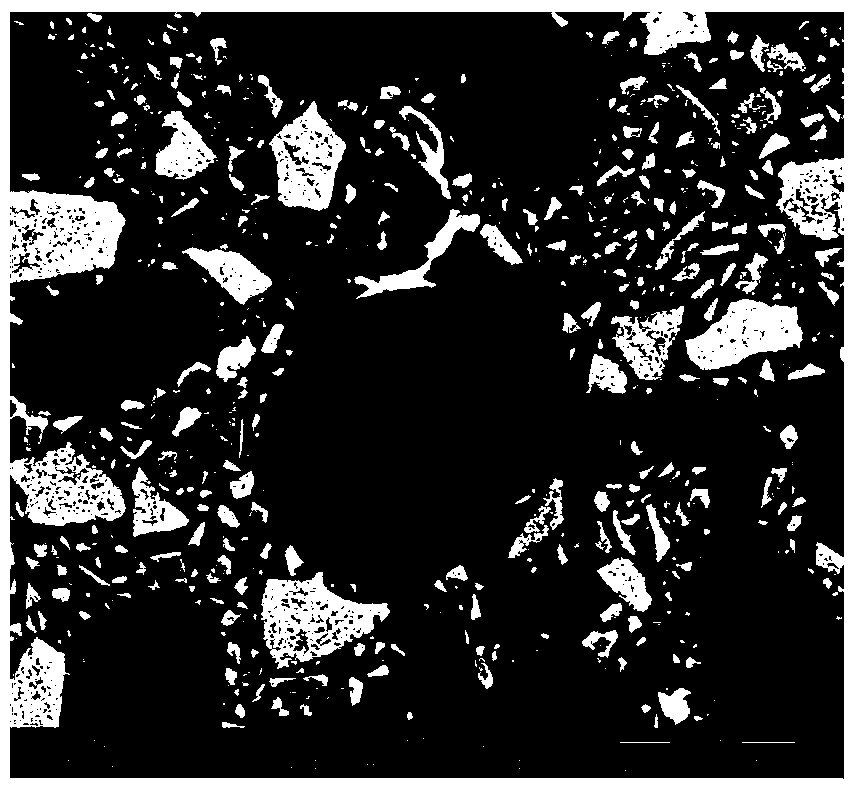

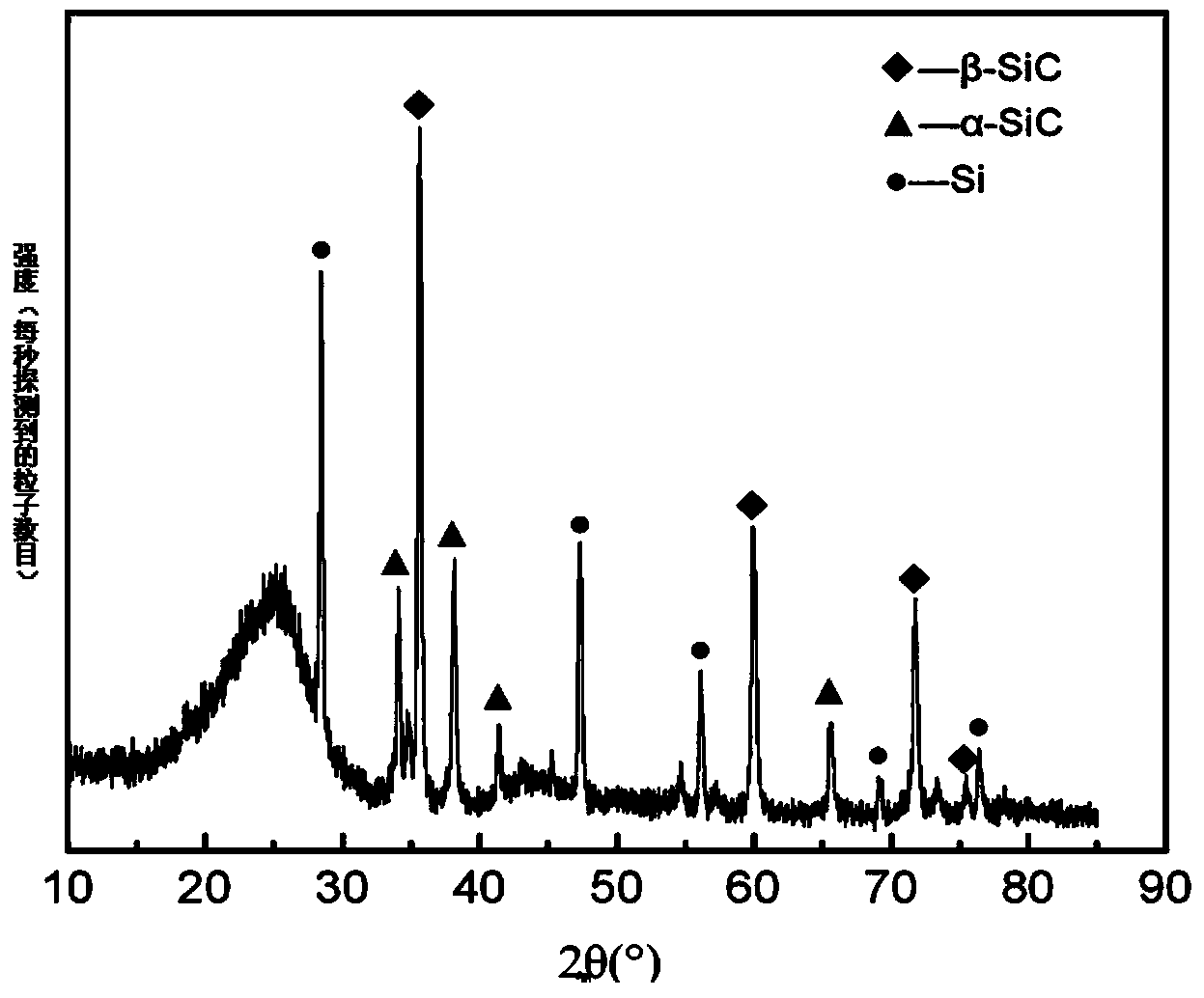

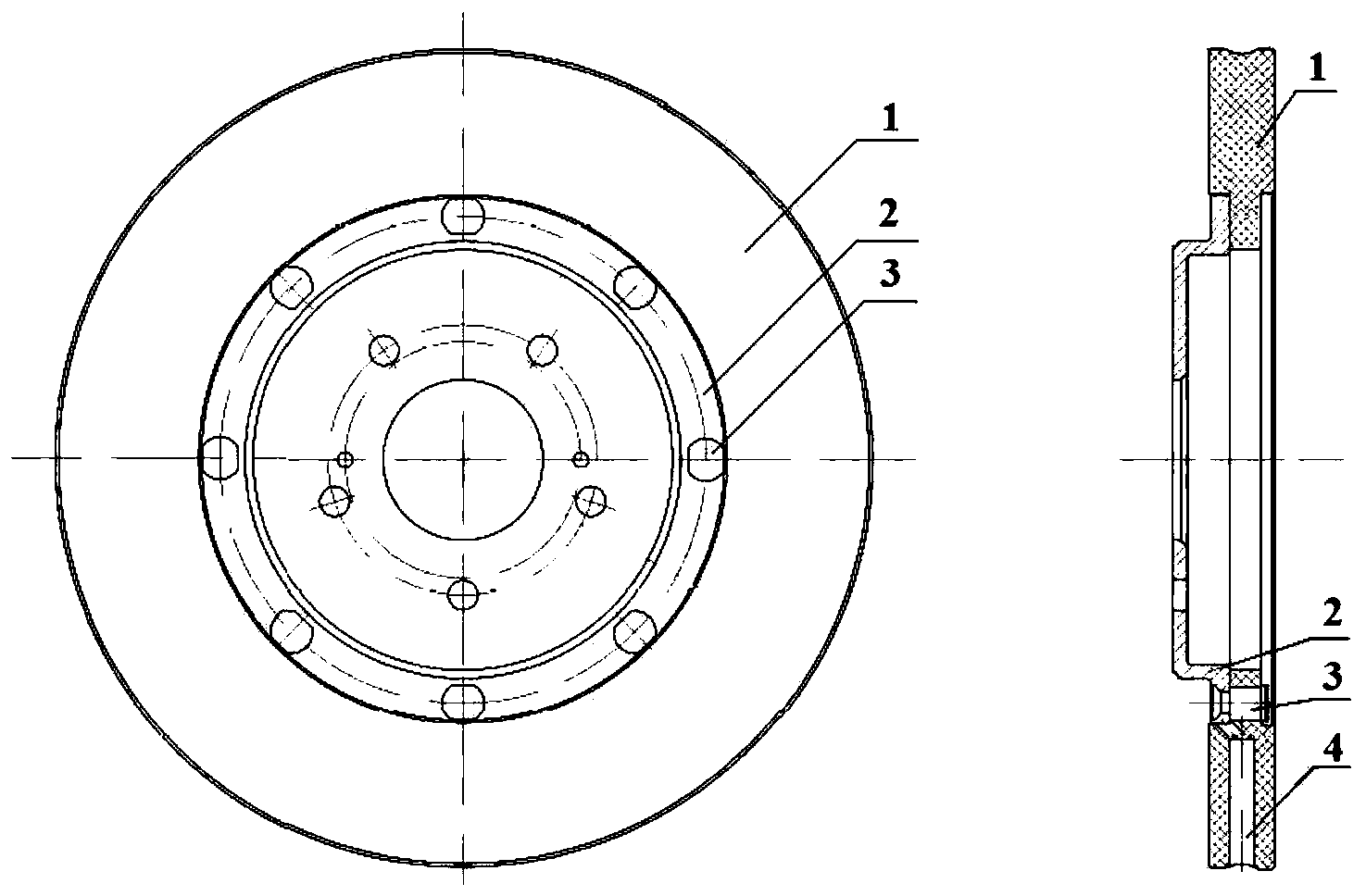

The invention relates to a carbon-ceramic composite brake disc and a preparation method thereof and belongs to the technical field of preparation of carbon-ceramic composites and brake discs. The carbon-ceramic composite brake disc comprises the following components by mass percent: 12% to 20% of short carbon fiber, 20% to 45% of matrix carbon, 30% to 55% of SiC and 2% to 6% of Si, wherein the short carbon fiber is 15-30mm in length. The method comprises the following steps: carbonizing a carbon fiber-reinforced blank body with the density of 0.9g / cm<3> to 1.3g / cm<3> so as to obtain a porous carbon / carbon (C / C) body; then performing dipping on the porous C / C body, cross-linking solidification and splitting decomposition so as to generate a SiC base body on the matrix carbon; performing the dipping, the cross-linking solidification and the splitting decomposition again until the density of an obtained C / C-SiC composite blank body reaches 1.6-1.9g / cm<3>; and performing silicon leaching treatment on the C / C-SiC composite blank body and anti-oxidation treatment and assembling, thus obtaining the carbon-ceramic composite brake disc. According to the method provided by the invention, the difficult problem that a metal brake disc is poor in thermal dissipation and abrasion resistance and heavy in weight in the prior art is effectively solved. The preparation method is simple; and the obtained carbon-ceramic composite brake disc is high in thermal stability, light in weight and resistant to abrasion, and cannot generate thermal vibration.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Method for preparing medical porous NiTi shape memory alloy by microwave sintering

The invention relates to a method for preparing a medical porous NiTi shape memory alloy by microwave sintering. The method comprises the following steps of: (1) compounding powder: compounding titanium powder, nickel powder and pore-forming agent powder according to certain mass percentage; (2) performing ball milling: putting the compounded powder body into a stainless steel ball milling pot for ball milling; (3) pressing billets: performing mold pressing on the powder materials after the ball milling at the pressure of between 50 and 500 MPa into pressed billets; (4) charging in a furnace:putting the obtained pressed billets and a microwave auxiliary heating material into a polycrystalline mullite fiber heat insulation barrel, and putting the heat insulation barrel into a microwave sintering furnace; and (5) performing microwave sintering. The method has the advantages that: the preparation method is simple and convenient, the sintering cycle is short, the energy consumption is low, the method is suitable for industrialized production, the porous NiTi shape memory alloy obtained by sintering has good mechanical properties, a pore structure is in three-dimensional communication, the pore ratio is controllable between 20 and 80 percent, the pore sizes are uniform and are controllable between 30 and 600 mu m, and the medical porous NiTi shape memory alloy can be used as materials for repairing and replacing hard tissues such as bones, joints, artificial tooth roots and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

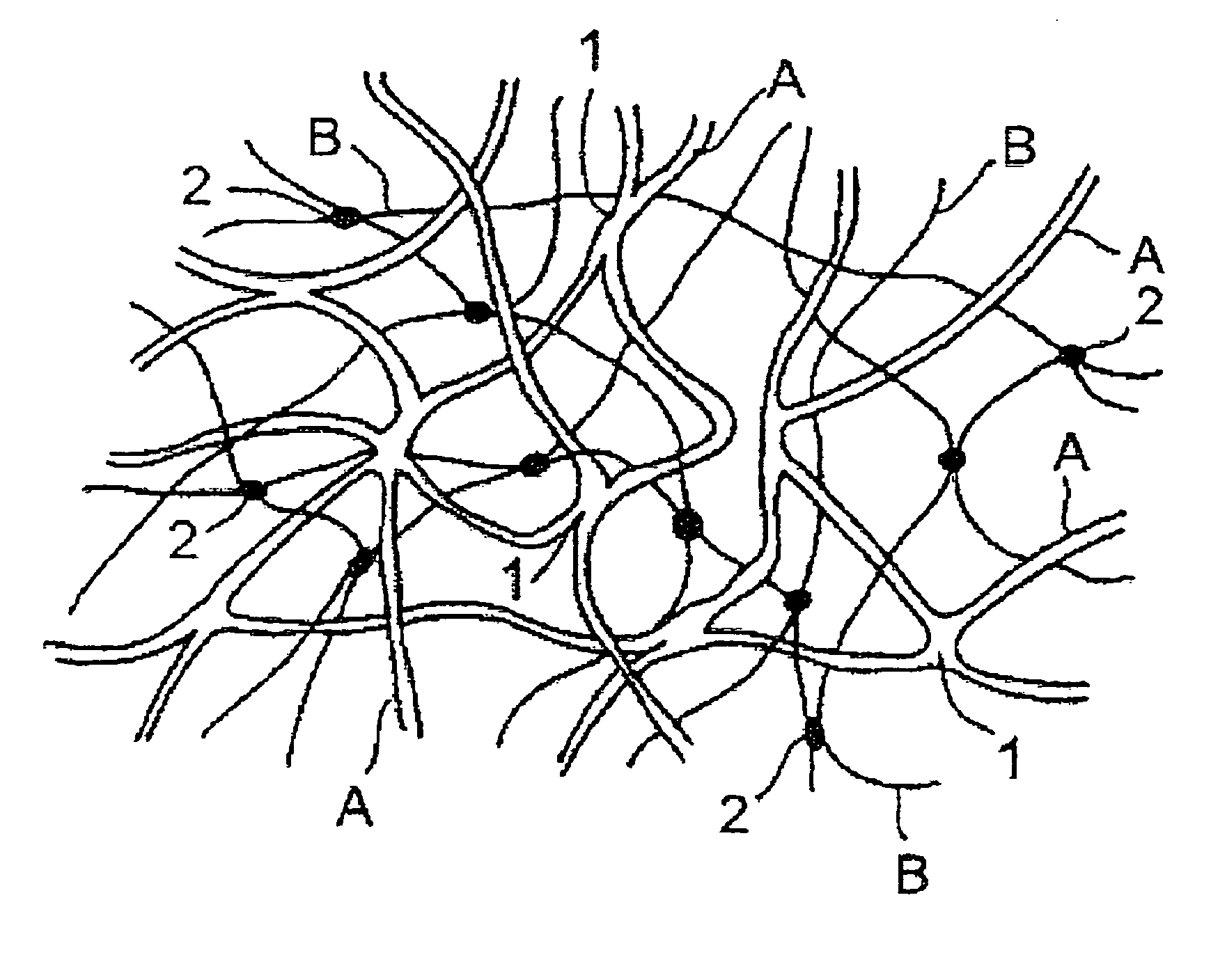

Artificial Meniscus

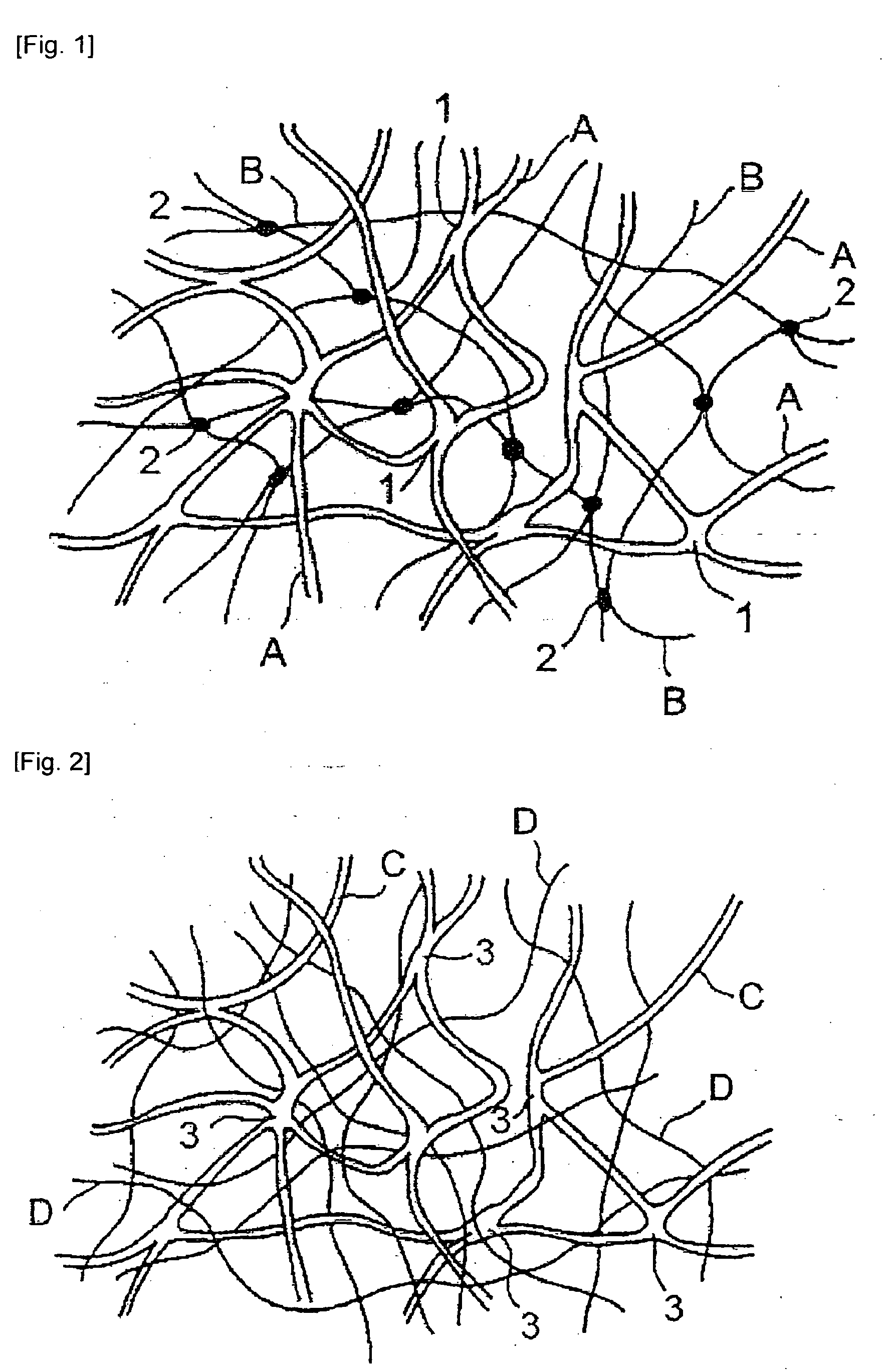

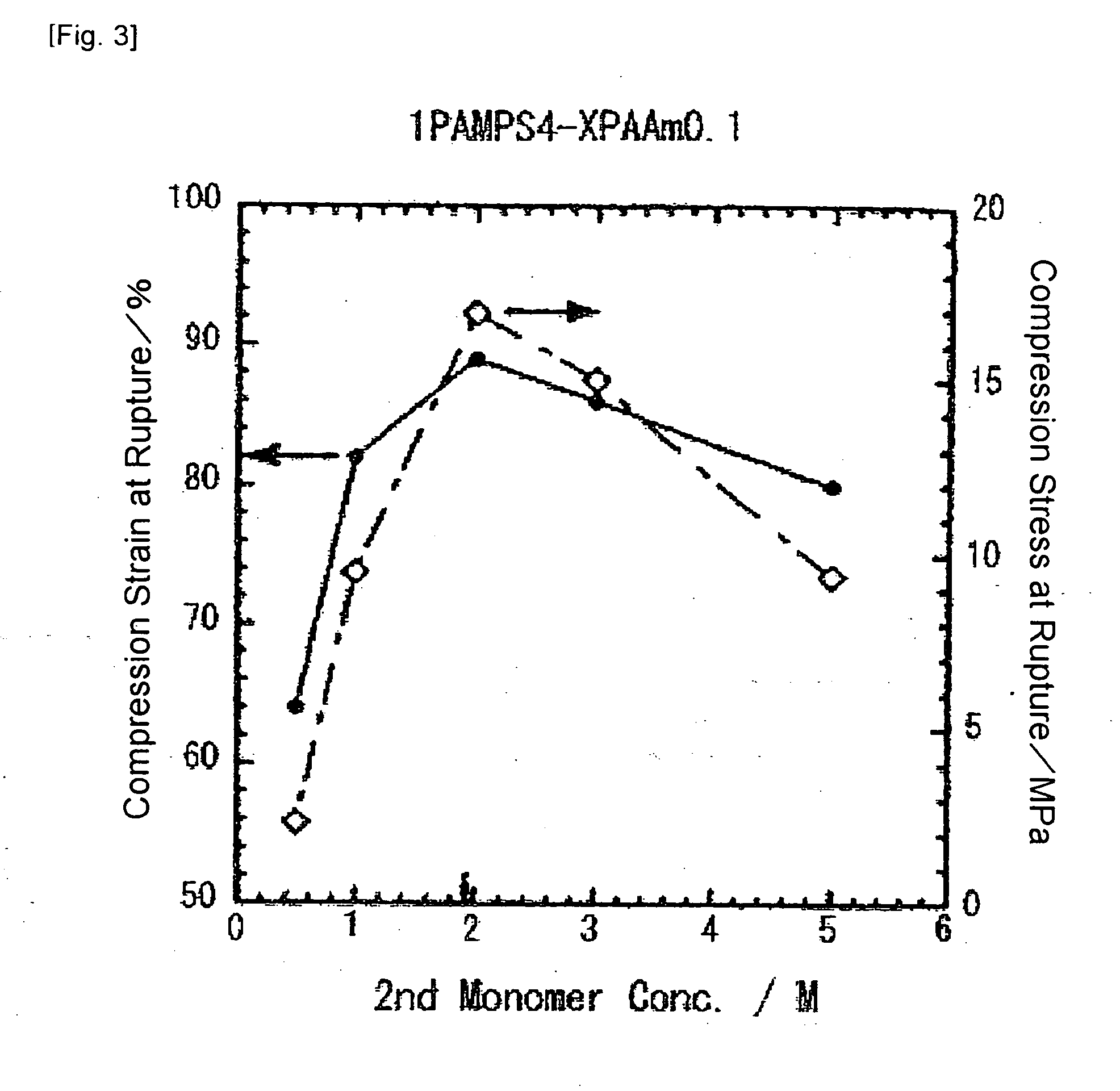

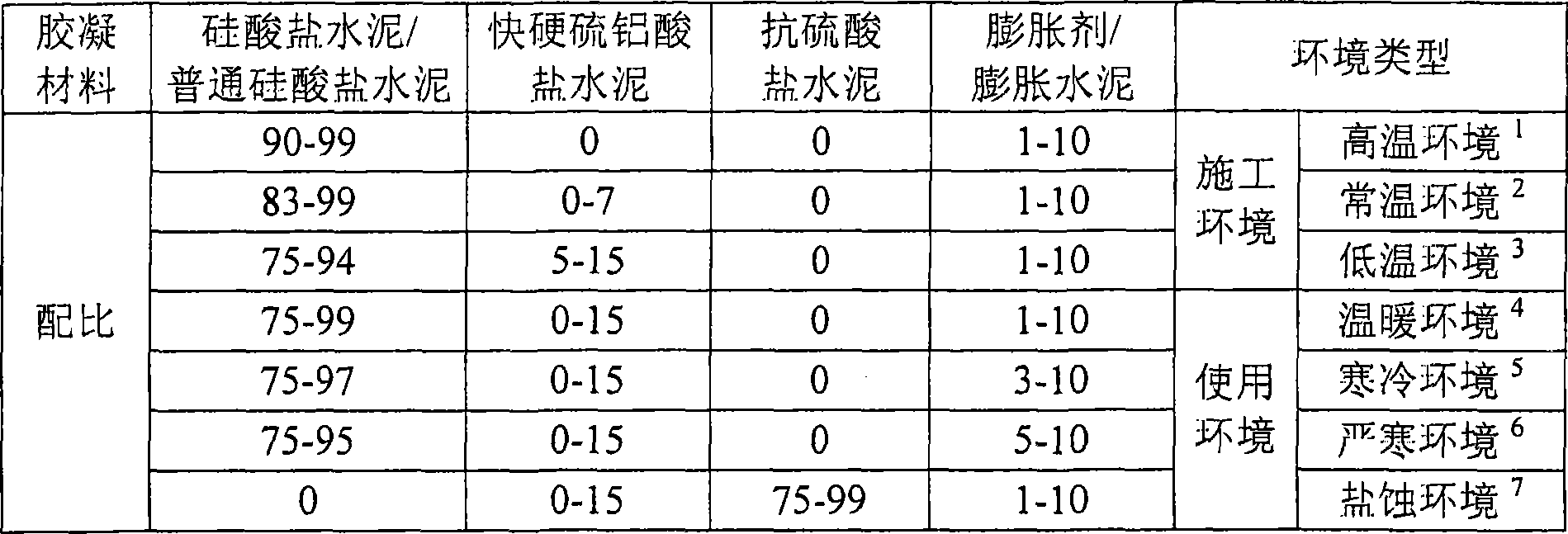

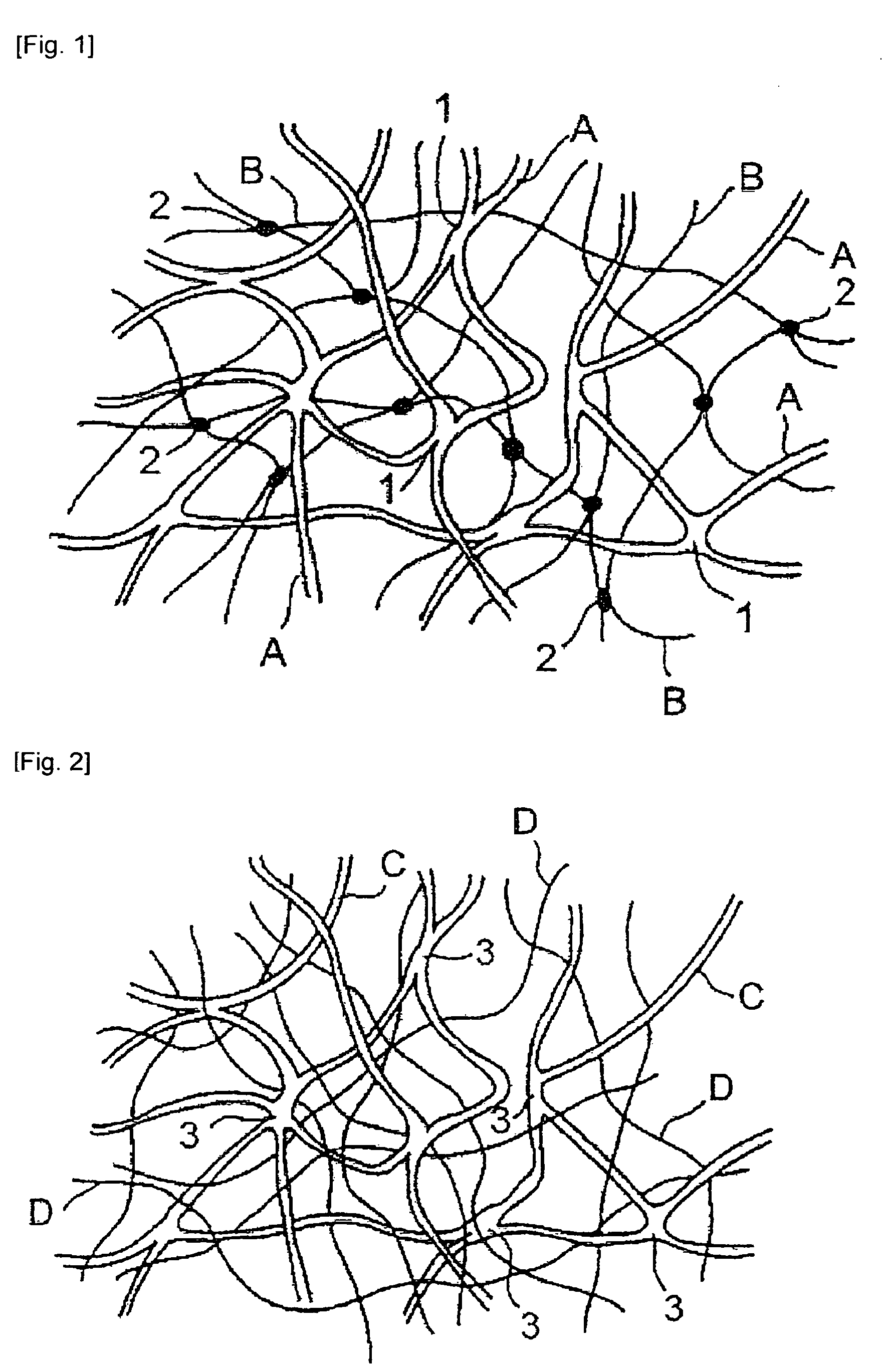

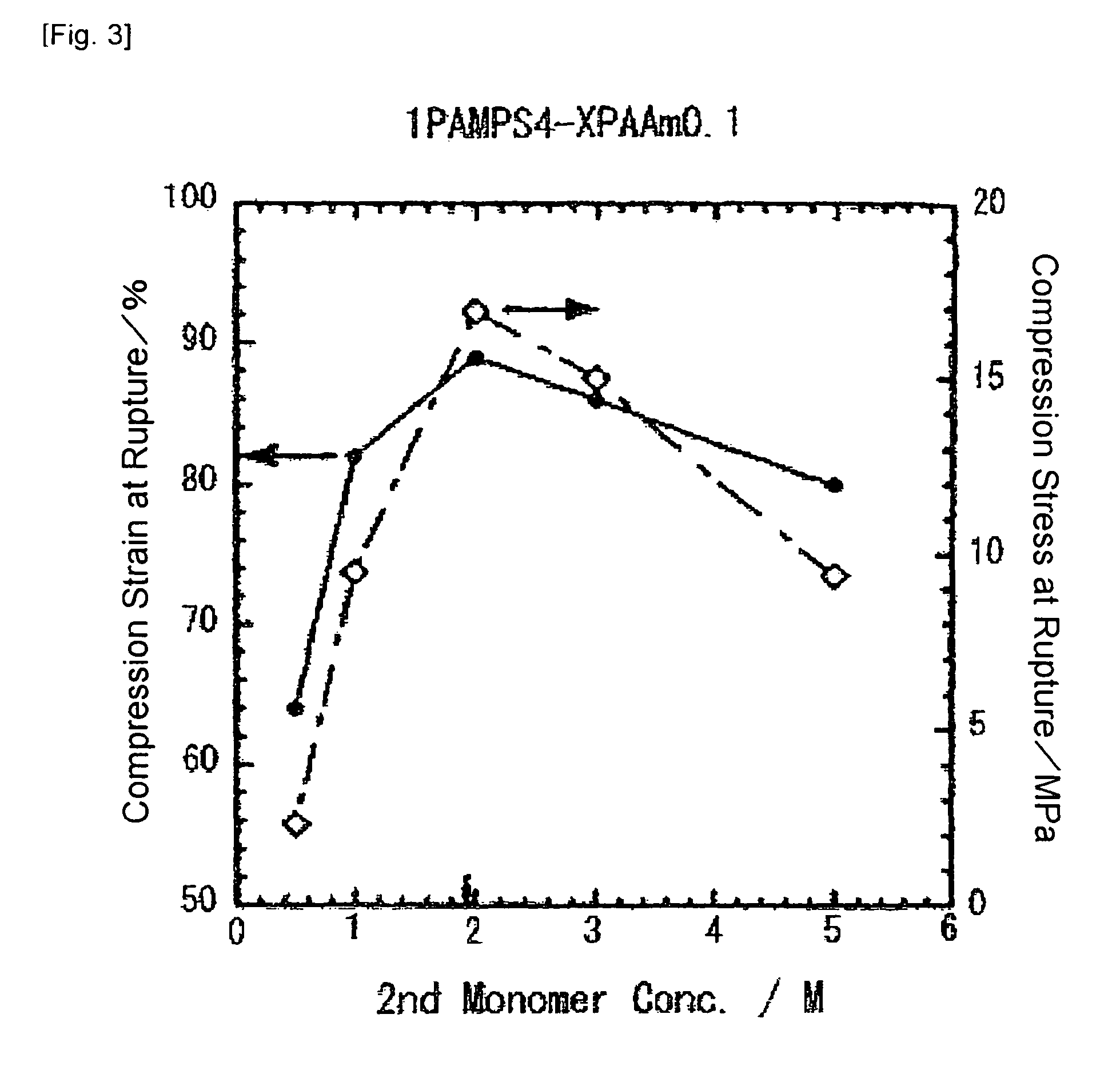

ActiveUS20080119930A1Not induce any osteoarthritisModerate mechanical propertiesSurgical adhesivesLigamentsBiological bodyNetwork structure

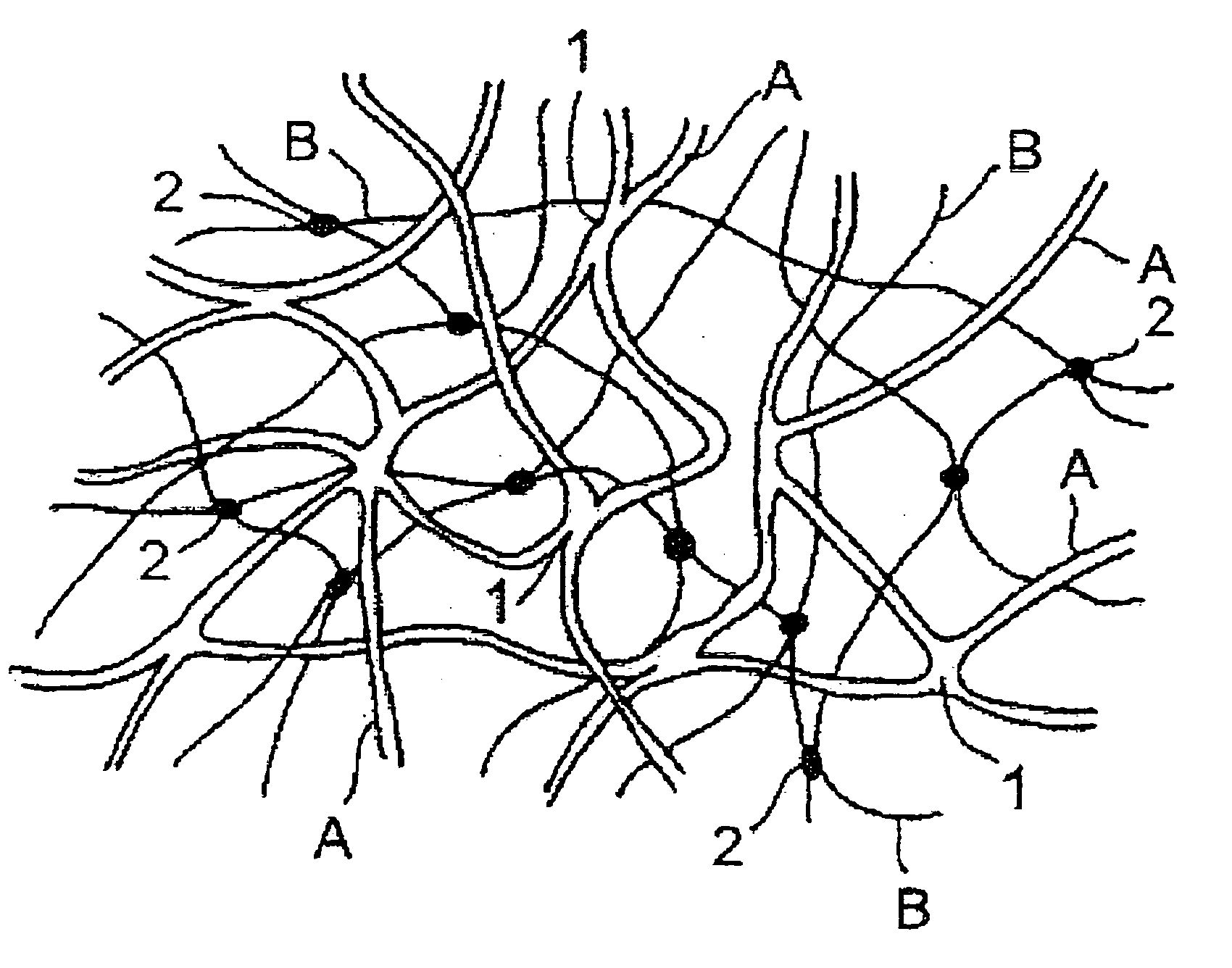

An artificial meniscus, a base material of which is a hydrogel having a semi-interpenetrating network structure or an interpenetrating network structure (e.g., a linear polymer or a network structure composing the hydrogel is a polymer of an electrically charged unsaturated monomer and / or an electrically neutral unsaturated monomer or a crosslinked product thereof or / and a naturally occurring macromolecule or a crosslinked product thereof.), which can maintain moderate mechanical properties even in the case of application for an extended period of time between the joints where the severest mechanical environment is found in an organism, and which has no fear of causing osteoarthritis.

Owner:HOKKAIDO UNIVERSITY

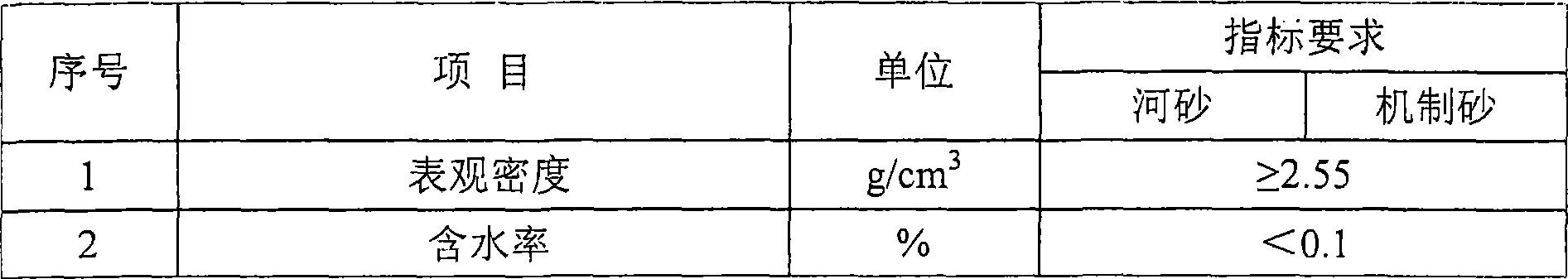

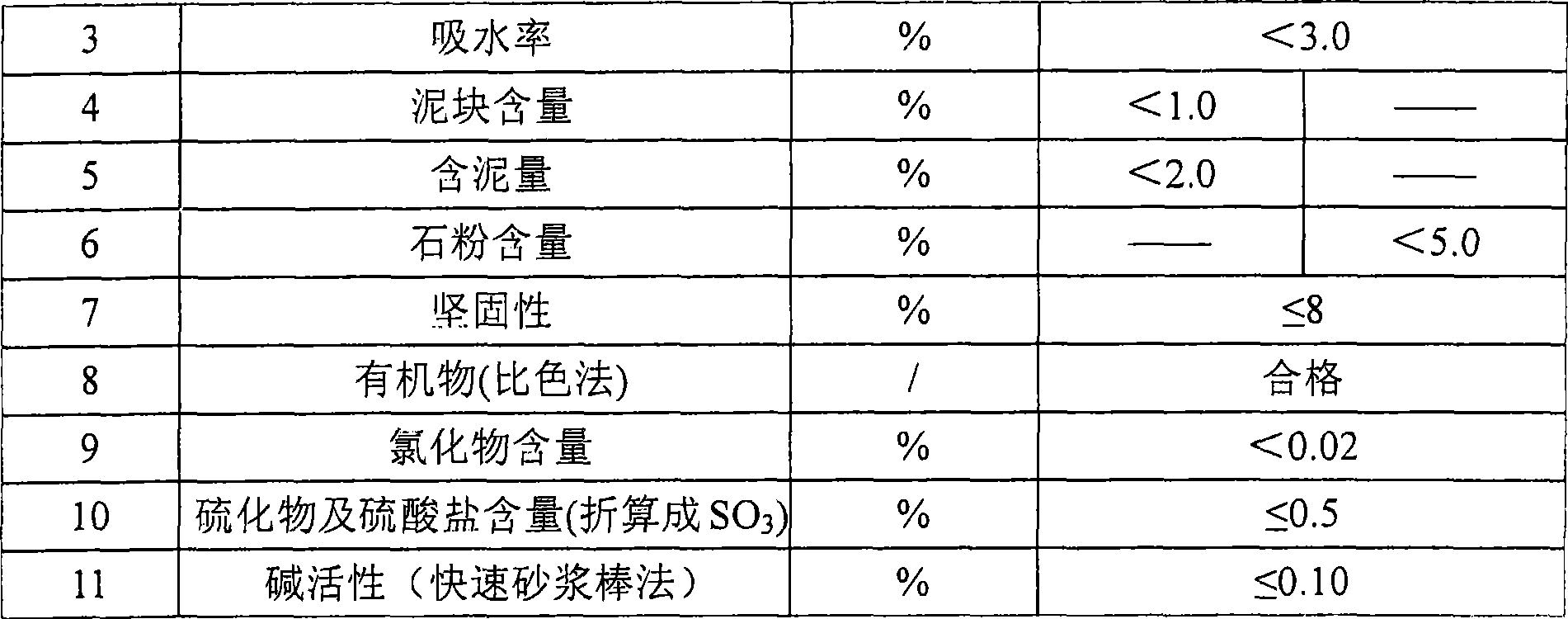

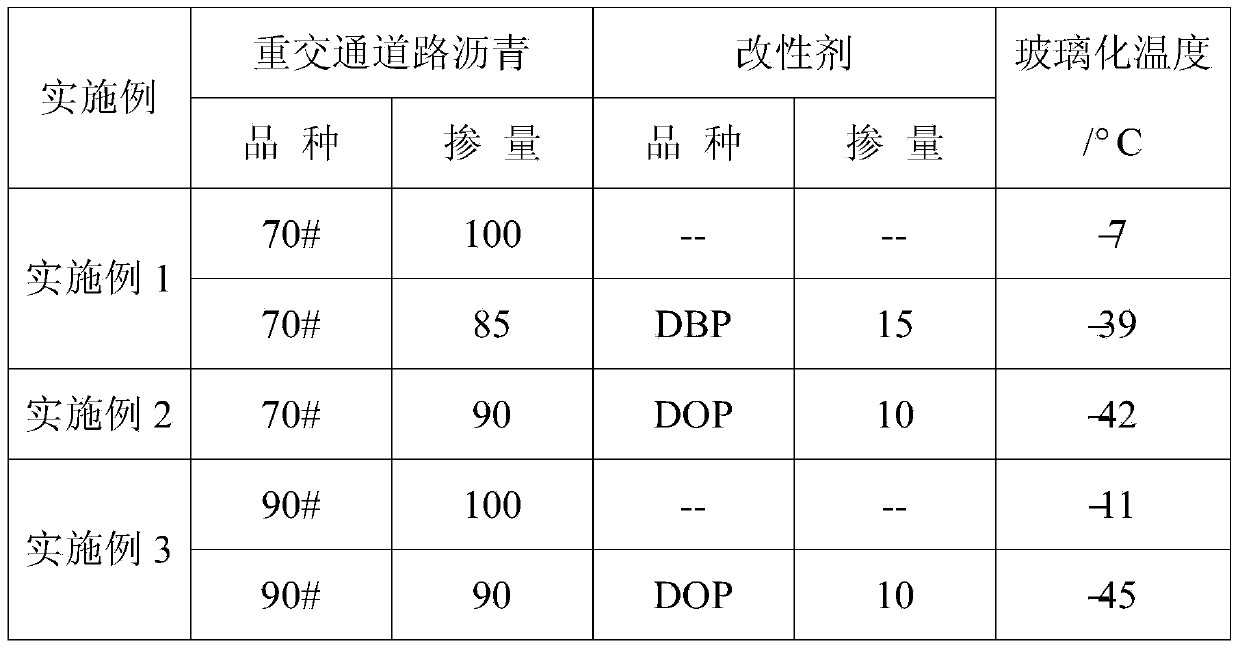

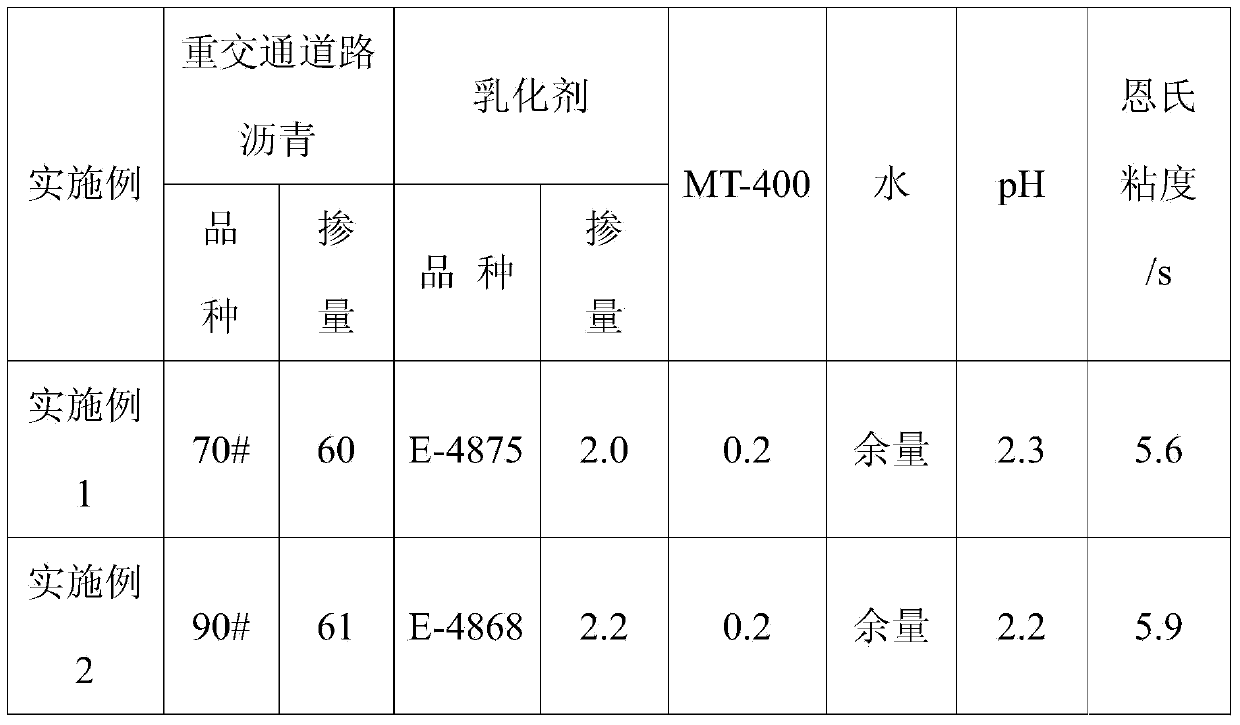

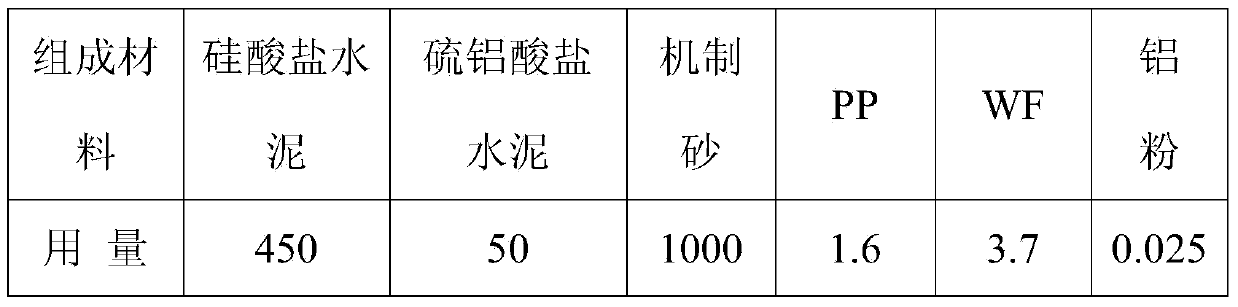

Vertical connected plate type unballasted track cement emulsified bitumen mortar

ActiveCN101475349AImprove environmental adaptabilityConvenience to workSolid waste managementCeramicwareCrack resistanceDedicated line

The invention relates to a cement emulsified bitumen mortar for vertical connecting plate type ballastless rails, which comprises the following components in portion by weight: 1,370 to 1,516 portions of dry material, 230 to 270 portions of emulsified bitumen, 0 to 68 portions of polymer emulsion, 162 to 210 portions of water, 0.5 to 5 portions of water reducing agent, and 0 to 4 portions of antifoaming agent. The cement emulsified bitumen mortar has the advantages of good environment adaptability and working performance, agreeable mechanical property, small shrinkage, good crack resistance and superior lasting quality, is the cement emulsified bitumen mortar with high elasticity modulus, and can satisfy the requirements on different construction and use environmental conditions of the vertical connecting plate type ballastless rails for high speed railways and passenger dedicated lines in China.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

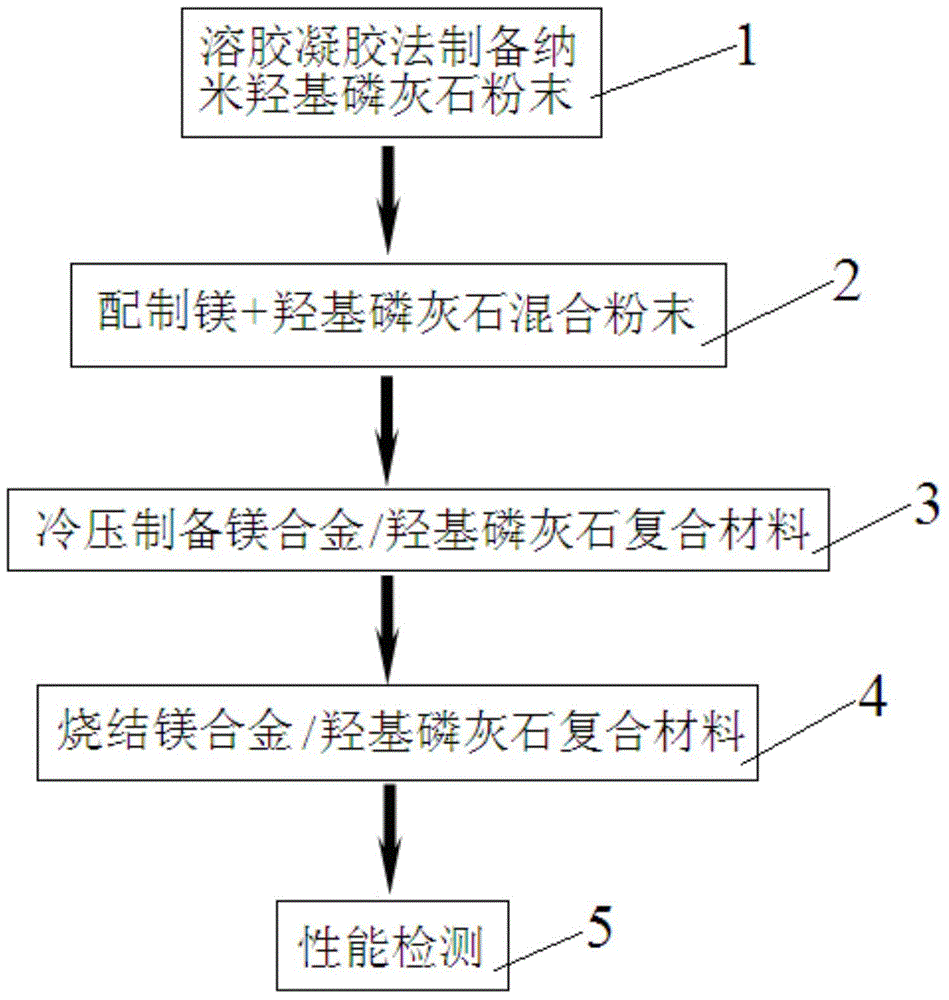

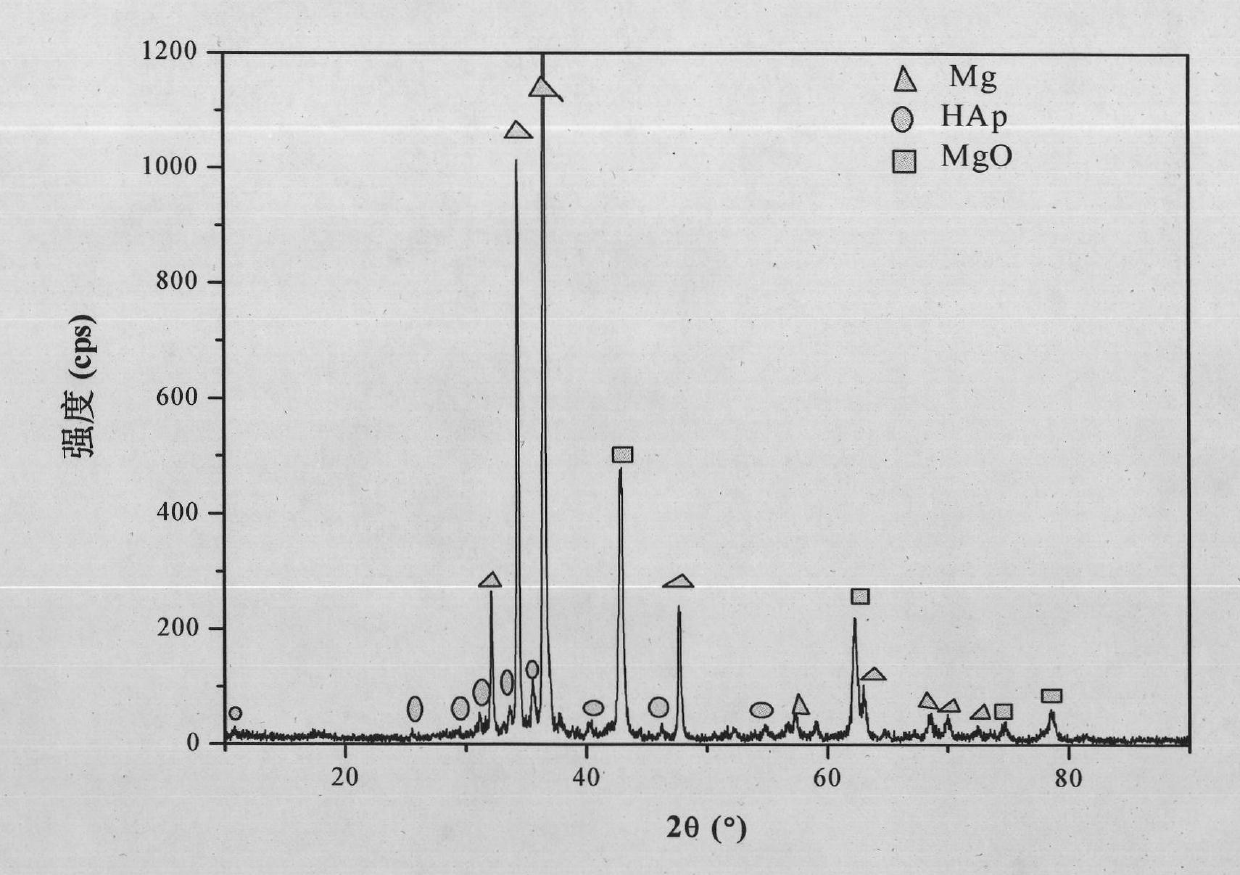

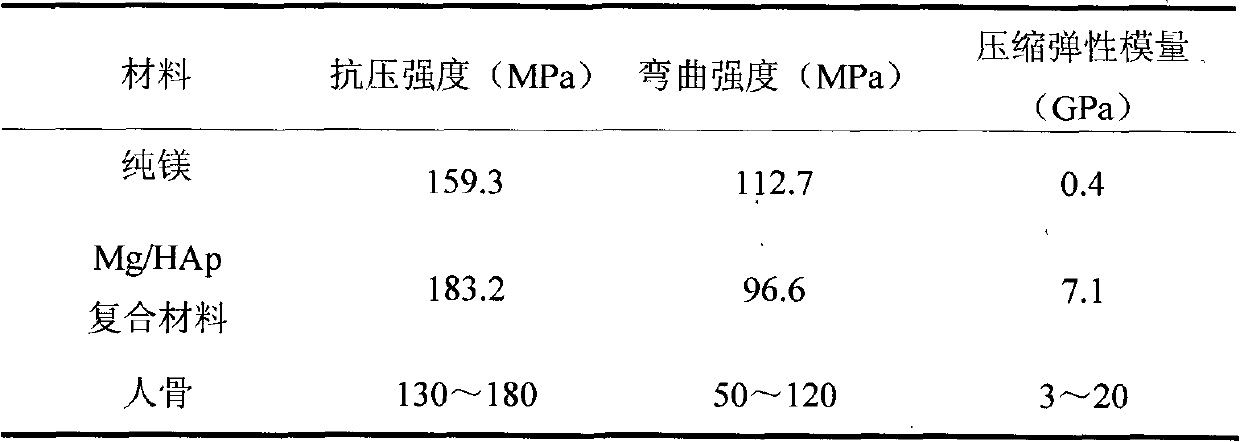

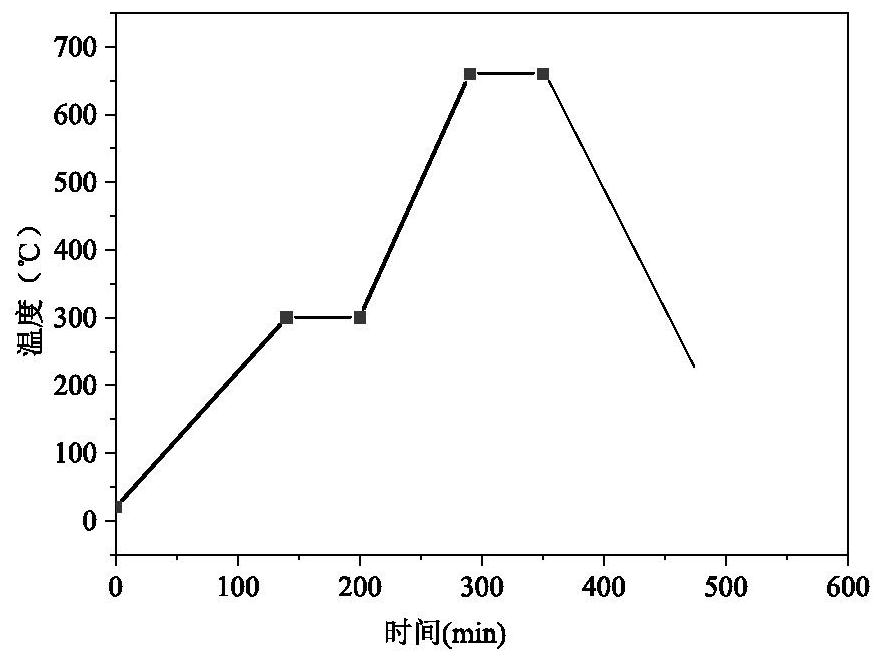

Preparation method of magnesium alloy/hydroxyapatite composite

InactiveCN103599561ADegradability adjustableDegradative regulationSurgical adhesivesProsthesisSolubilityCardiovascular stent

The invention relates to a preparation method of a magnesium alloy / hydroxyapatite composite, which comprises the steps of firstly preparing nano hydroxyapatite powder by a sol-gel process, and then uniformly mixing the magnesium powder with the nano hydroxyapatite powder; putting the mixture into a mould and performing cold pressing; putting the cold-pressing formed sample into a vacuum heat treatment furnace for sintering to obtain the magnesium alloy / hydroxyapatite composite. Compared with the prior art, in the method provided by the invention, the magnesium alloy is used as a metal matrix, the hydroxyapatite with the same chemical composition as the human skeleton and having low solubility in the human body environment is used as a reinforcing body, and the method aims at preparing a magnesium alloy / calcium phosphate composite biomedical material by use of a powder metallurgical process; the material is mainly applied to clinical medicine as a degradable endosteal fixing material, a porous bone repair material, a dental implantation material, an oral repair material, a cardiovascular stent and the like, and has broad prospects in terms of bone tissue defect repair.

Owner:TONGJI UNIV

Hot rolling method for wide and thin size high-strength cold-rolled base plate for automobile

InactiveCN105478472AGuaranteed MicrostructureGuaranteed mechanical propertiesMetal rolling arrangementsStructure propertySheet steel

The invention discloses a hot rolling method for a wide and thin size high-strength cold-rolled base plate for an automobile. After continuous casting billets are assembled in a heating furnace in a hot state, the Cu accumulation amount of iron oxide scales and steel substrates is reduced by adopting high-temperature preheating and high-temperature rapid heating technologies; after rough rolling, the thickness of an intermediate billet is reduced, a heat holding cover is used for reducing temperature drop and temperature differences of all parts, so that the finish rolling entry temperature of the intermediate billet is increased; and loads of all racks for finish rolling are reduced, and the stability of finish rolling is improved. In the process from finish rolling to steel belt coiling, a controlled rolling and controlled cooling technology is adopted, so that the cold-rolled base plate has excellent uniformity between the shape and the structure property. According to the method, the cold-rolled base plate with the thickness of 1.5-2.5 mm and the width of 1650-2000 mm can be obtained; the convexity degree of a steel belt is controlled to be in a range between 45-15 mu m and 45+15 mu m; the straightness is controlled to be 30I; the thickness accuracy is in a range between -30 mu m and +30 mu m; the structure property of different edges of the head, the middle, the tail of the steel belt is uniform; and the yield and the production efficiency of the wide and thin size high-strength cold-rolled base plate can be increased and improved, so that the cold-rolled base plate meeting the requirements of the actual product quality and the performance is provided for steel plates with the grade of 450-590 MPa for automobile covering parts.

Owner:ANGANG STEEL CO LTD

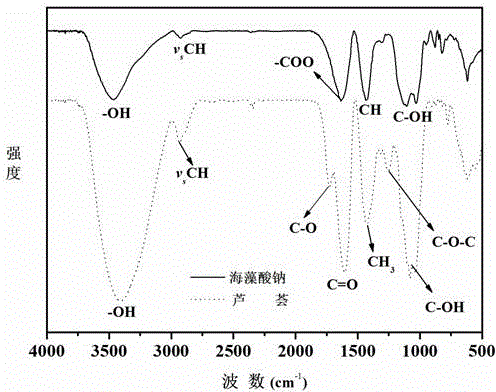

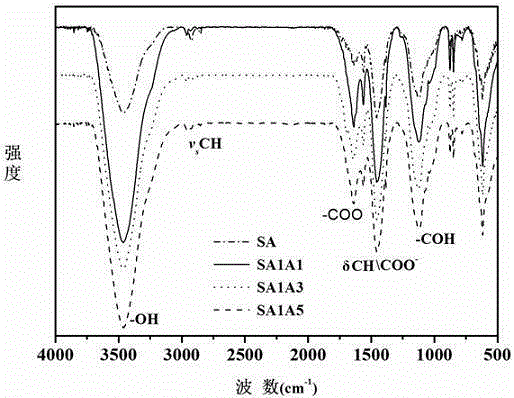

Preparation method of aloe/sodium alginate double-layer hydrogel dressing

InactiveCN105079863AGood light transmissionNo light transmissionAbsorbent padsBandagesIrritationChemistry

The invention discloses a preparation method of aloe / sodium alginate double-layer hydrogel dressing. The method includes: adding plasticizer glycerol into sodium alginate aqueous solution, stirring, performing ultrasonic treatment, standing at room temperature to obtain sodium alginate gel, dripping the sodium alginate gel into a culture dish, and drying to obtain a sodium alginate substrate layer; adding aloe aqueous solution into the sodium alginate aqueous solution, stirring, performing ultrasonic treatment, and standing at room temperature to obtain aloe / sodium alginate mixed gel; dripping the aloe / sodium alginate mixed gel on the surface of the sodium alginate substrate layer, and drying; soaking the double-layer hydrogel film into CaCl2 solution for 5-20 minutes, then washing with distilled water, and drying to obtain the aloe / sodium alginate double-layer hydrogel dressing. The method has the advantages that the hydrogel dressing with high transparency and swelling rate is prepared through the simple method, and the prepared dressing has excellent antibacterial performance, can promote fibroblast proliferation ability, and has weak sensitization and no irritation to the skin.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

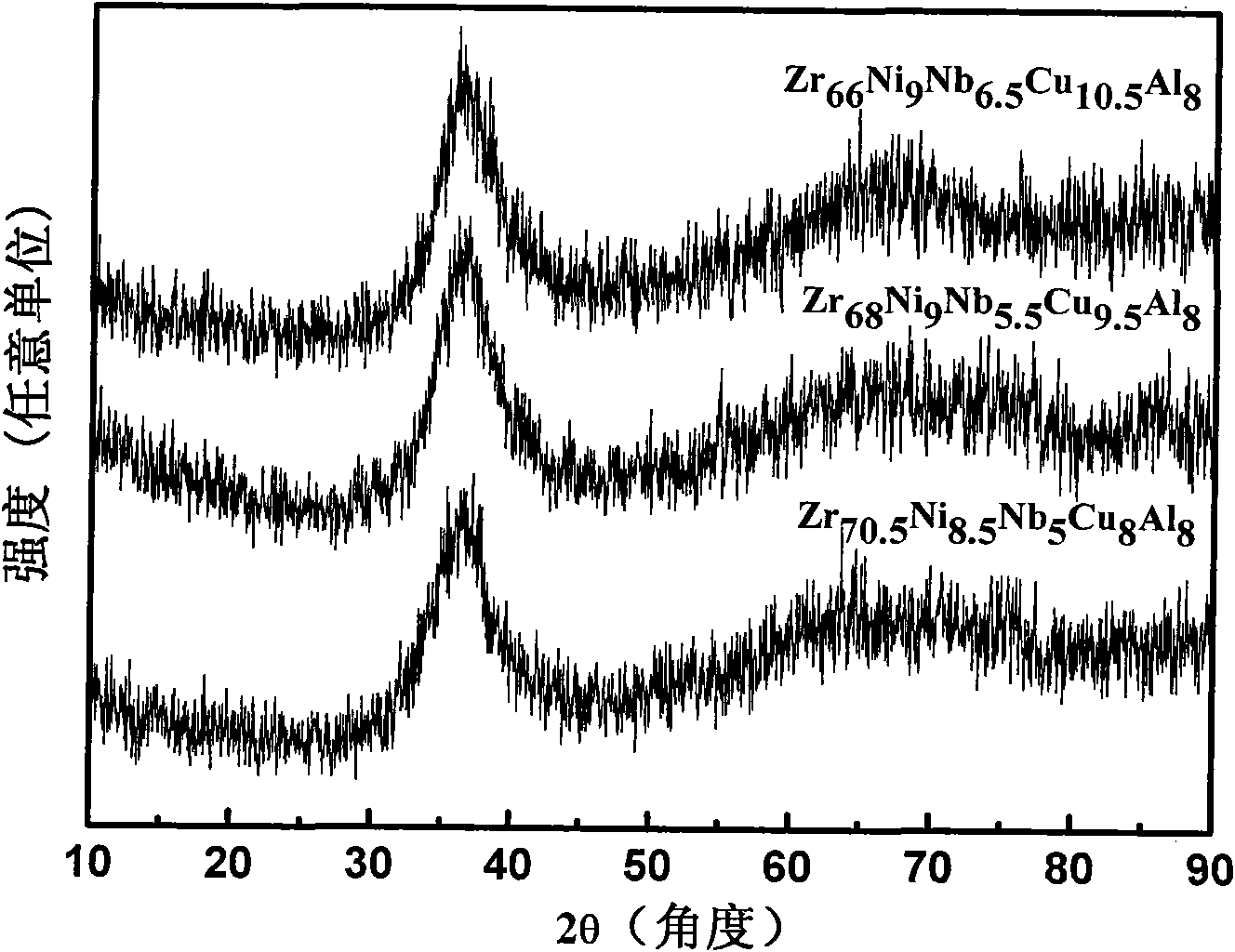

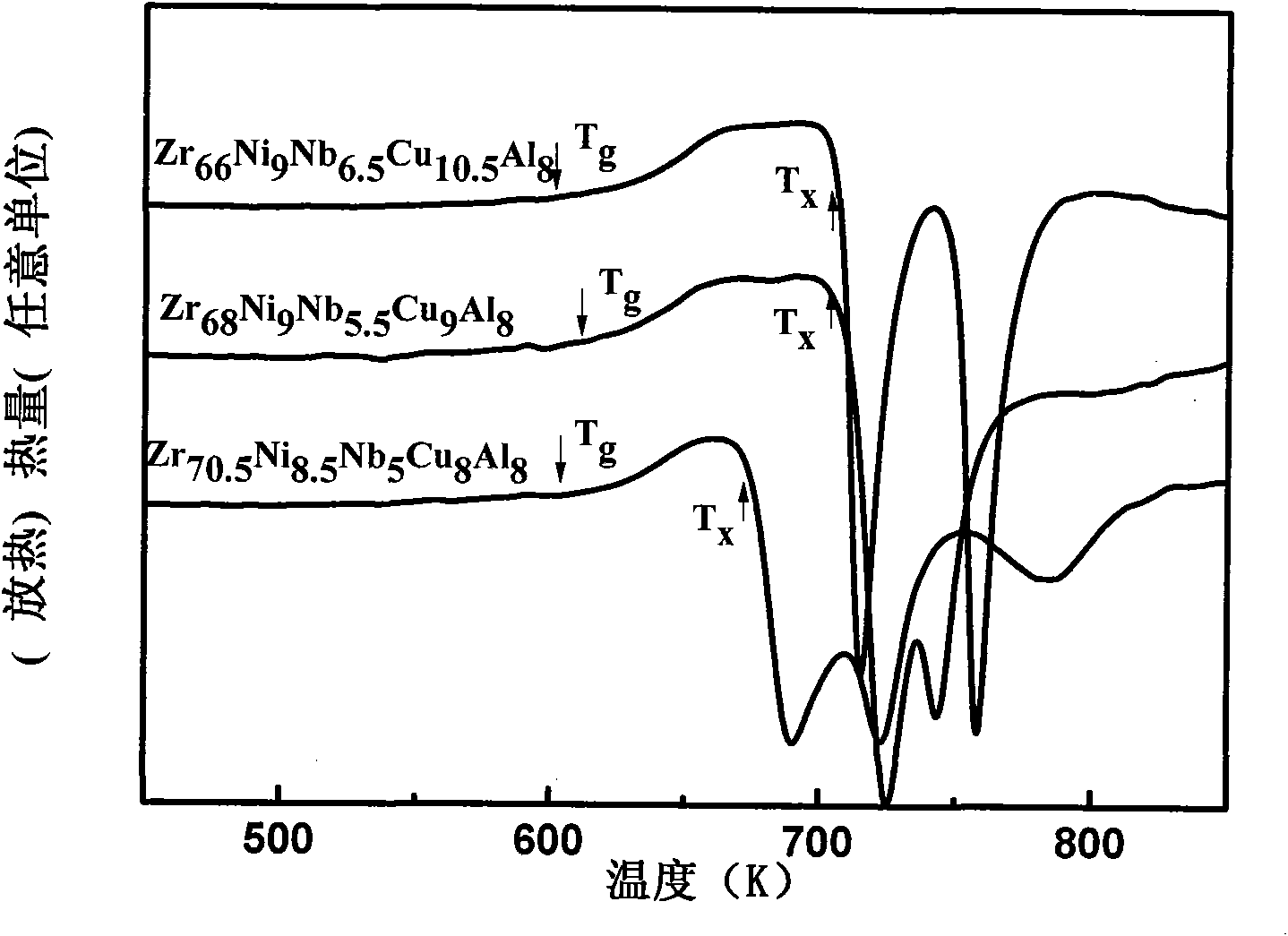

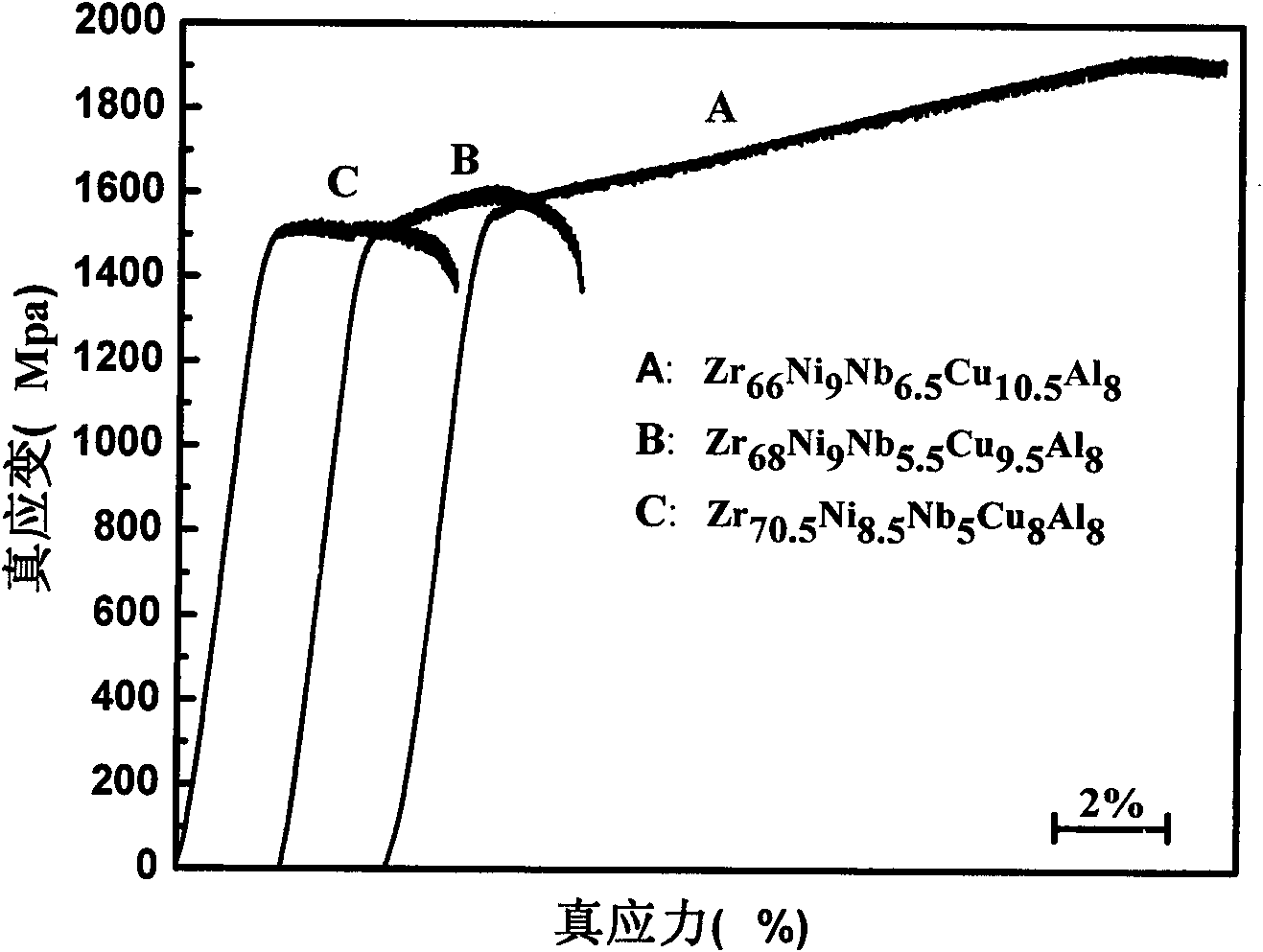

Zr-Cu-Ni-Al-Nb bulk amorphous alloy with high zirconium content

The invention relates to a Zr-Cu-Ni-Al-Nb bulk amorphous alloy with high zirconium content. The Zr-Cu-Ni-Al-Nb bulk amorphous alloy includes the following chemical components (atom percent): 66-72 Zr, 7.0-10.0 Ni, 3.0-7.0 Nb, l6.0-10.0 Al and 8.0-12.0 Cu. The material can form a bulk amorphous alloy under the ordinary casting condition, the required critical cooling rate is low, the thermal stability is good and a wide surfusion phase region is provided; under the condition that the atom percent of Zr is not lower than 66 percent, the corrosive resistance of the bulk amorphous alloy to various acid, alkali and salt is enhanced and the specific weight of the alloy is reduced; the plastic deformation property of the bulk amorphous alloy is enhanced by adding a proper amount of Nb elements, and the compression plastic deformation amount at the room temperature is higher than 7 percent; and meanwhile, the alloy has good corrosive resistance in high-temperature and high pressure water at 300-400 DEG C and in steam, proper mechanical property and lower atomic heat neutron absorption cross section.

Owner:UNIV OF SCI & TECH BEIJING

Artificial meniscus and process of making thereof

InactiveUS8025696B2Not induce any osteoarthritisModerate mechanical propertiesSurgical adhesivesLigamentsPolymer scienceNetwork structure

An artificial meniscus, a base material of which is a hydrogel having a semi-interpenetrating network structure or an interpenetrating network structure (e.g., a linear polymer or a network structure composing the hydrogel is a polymer of an electrically charged unsaturated monomer and / or an electrically neutral unsaturated monomer or a crosslinked product thereof or / and a naturally occurring macromolecule or a crosslinked product thereof.), which can maintain moderate mechanical properties even in the case of application for an extended period of time between the joints where the severest mechanical environment is found in an organism, and which has no fear of causing osteoarthritis.

Owner:HOKKAIDO UNIVERSITY

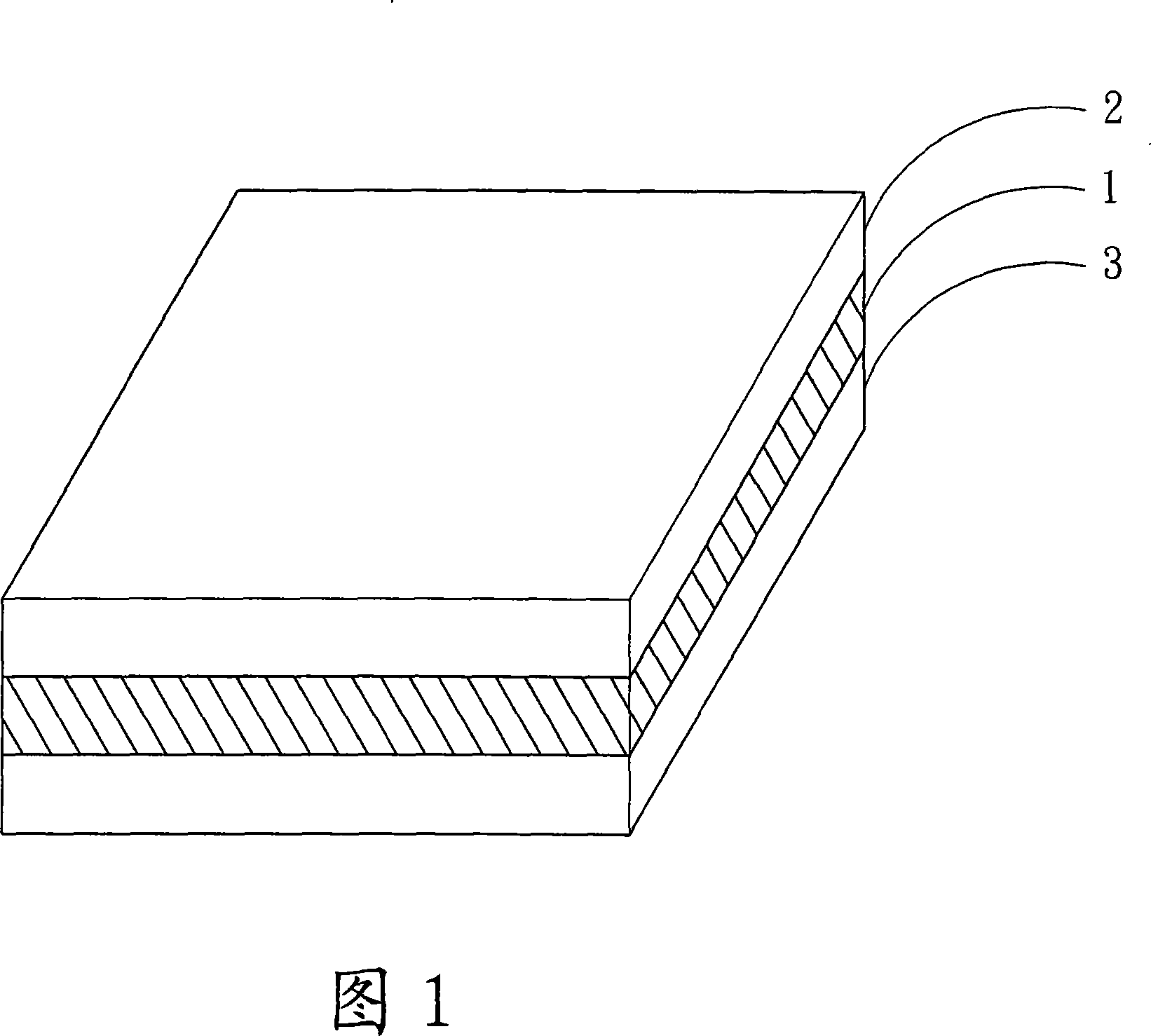

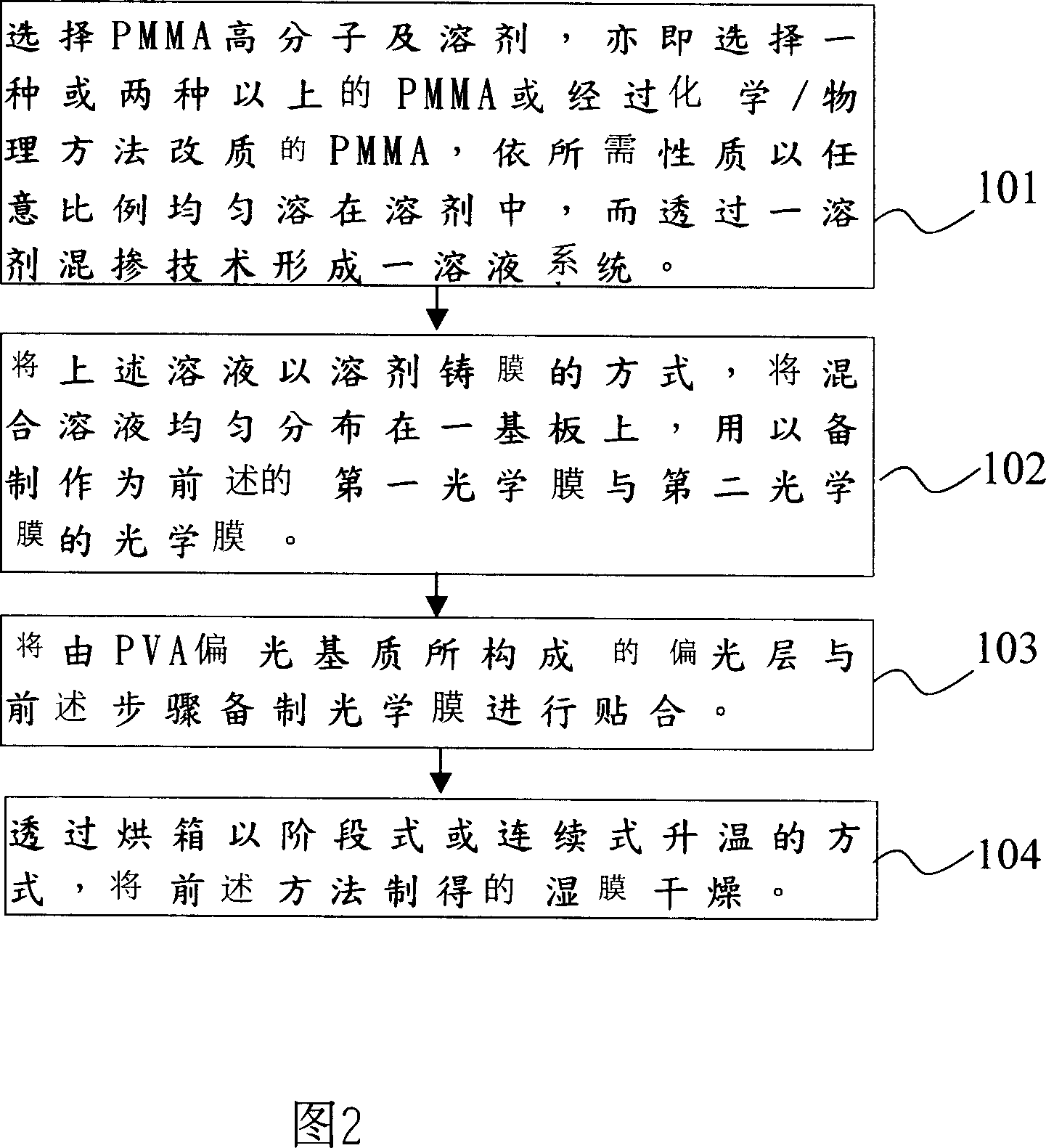

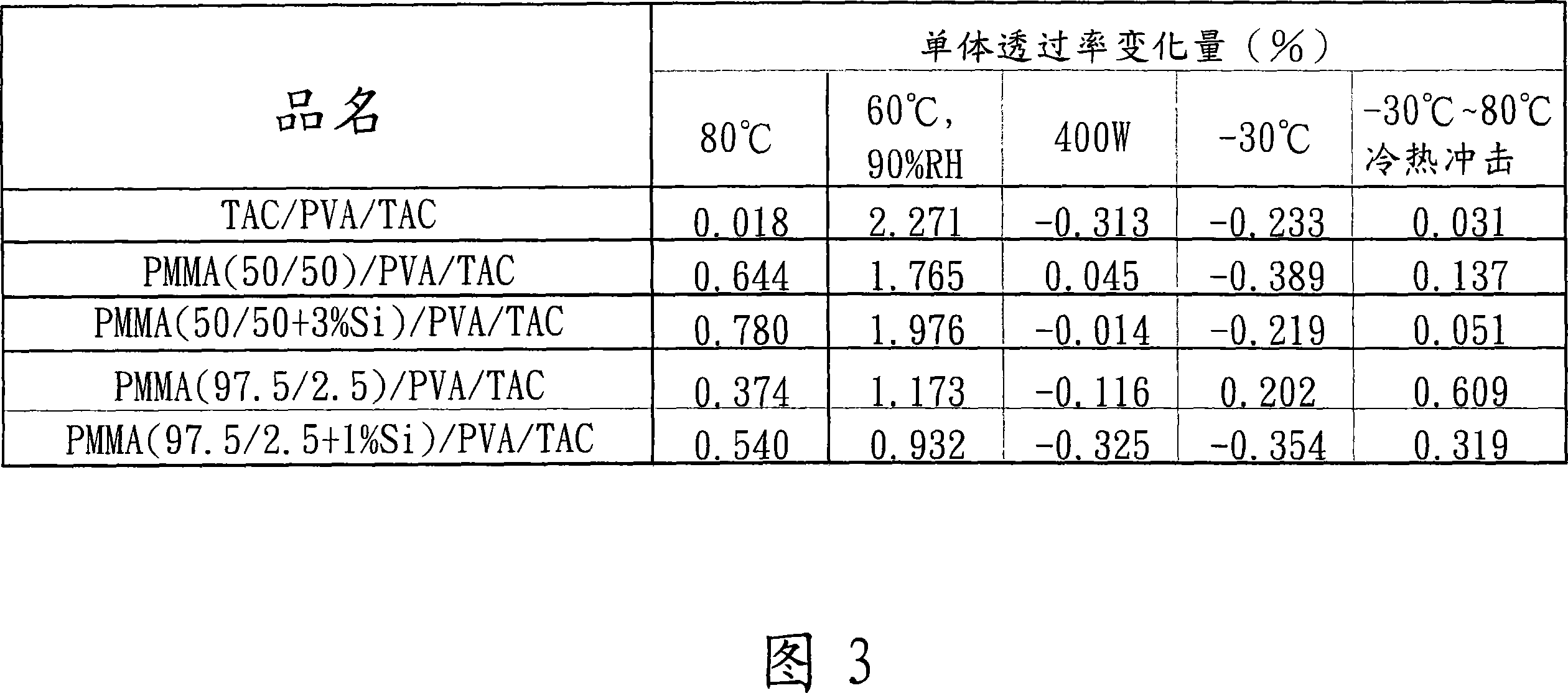

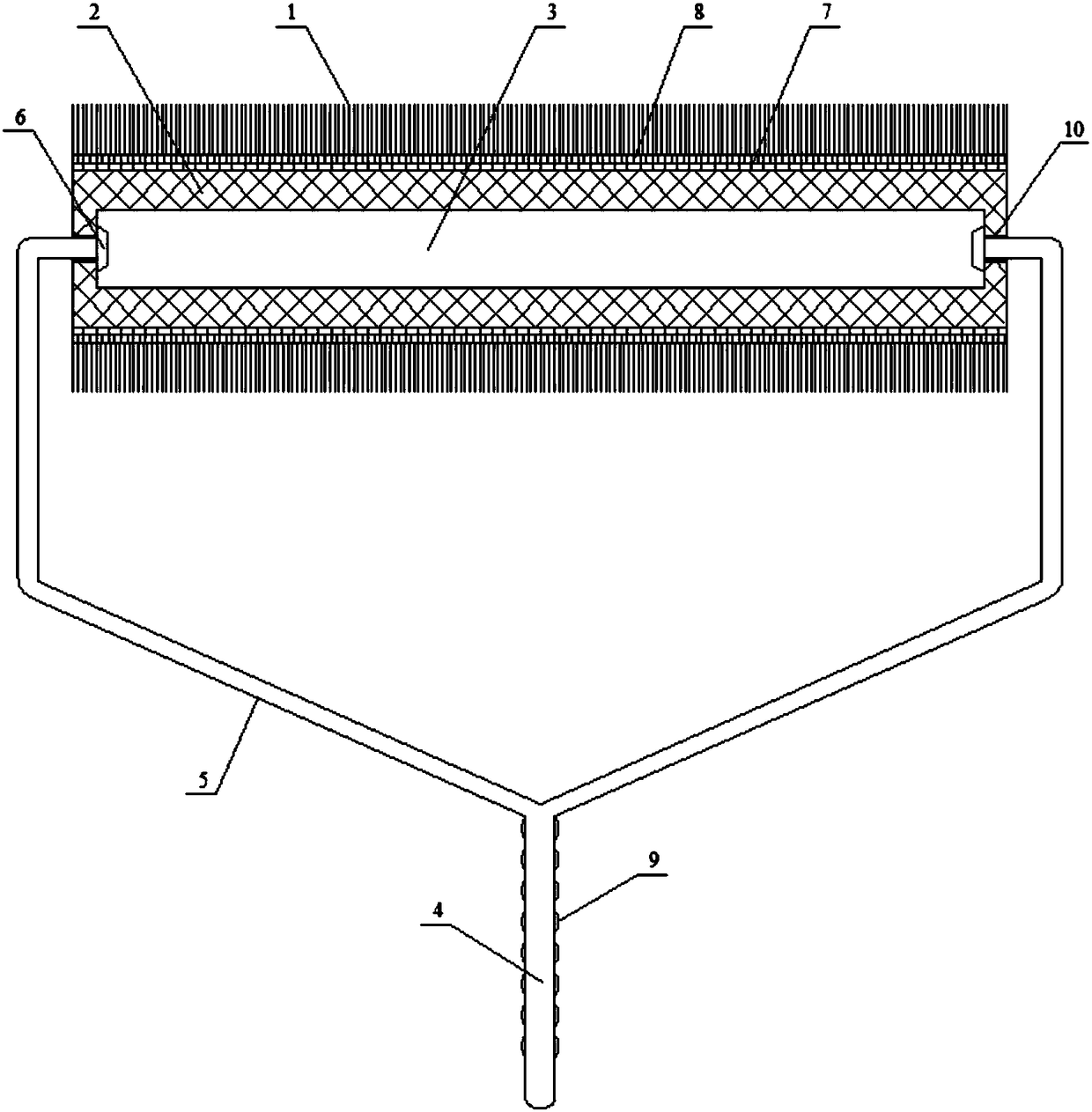

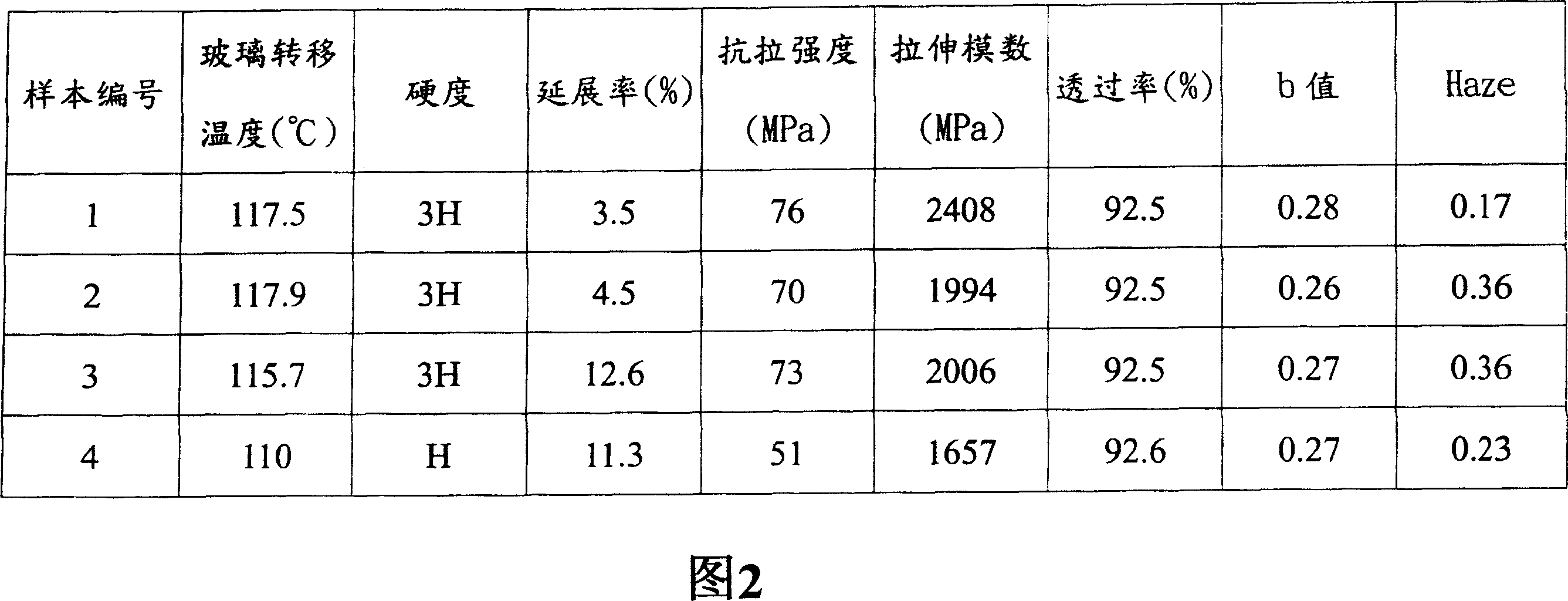

Polarized plate structure

InactiveCN101097269AGood heat resistanceModerate mechanical propertiesPolarising elementsBoard structureOptical film

The present invention relates to a polarized light board structure which is provided with a polarized light layer, a first optical film and a second optical film, the first optical film is formed above the polarized light layer and the second optical film is formed below the polarized light layer, wherein, at least one optical film selected from the first optical film and the second optical film is polymethyl methacrylate optical film. Into the bargain, the optical film is formed by pasting the mixed solution to the polarized light board and doing heat treatment when penetrating the mixed solution and distributing on the substrate to prepare for making have finished, or the optical film is formed by penetrating the mixed solution and distributing on the substrate and doing thermal treatment.

Owner:OPTIMAX TECHNOLOGY CORPORATION

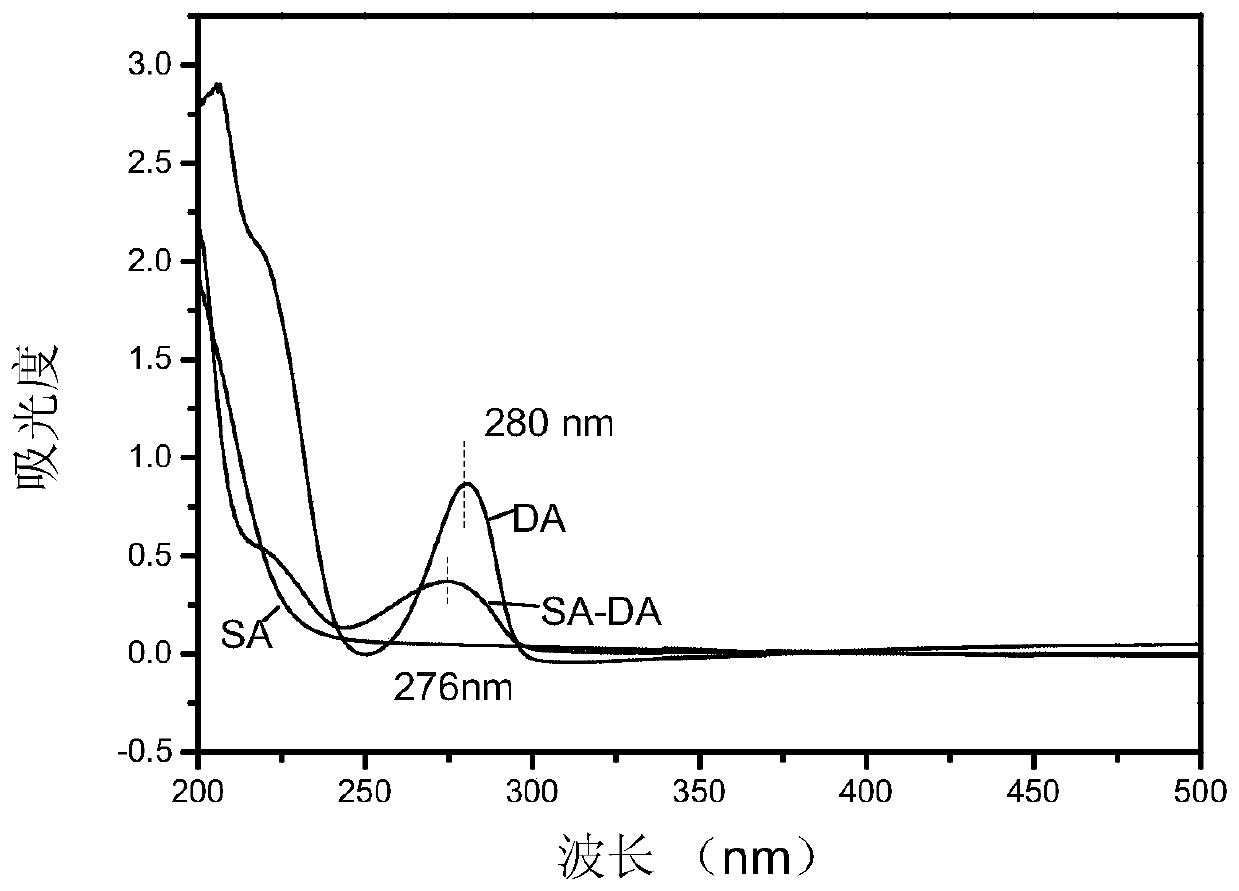

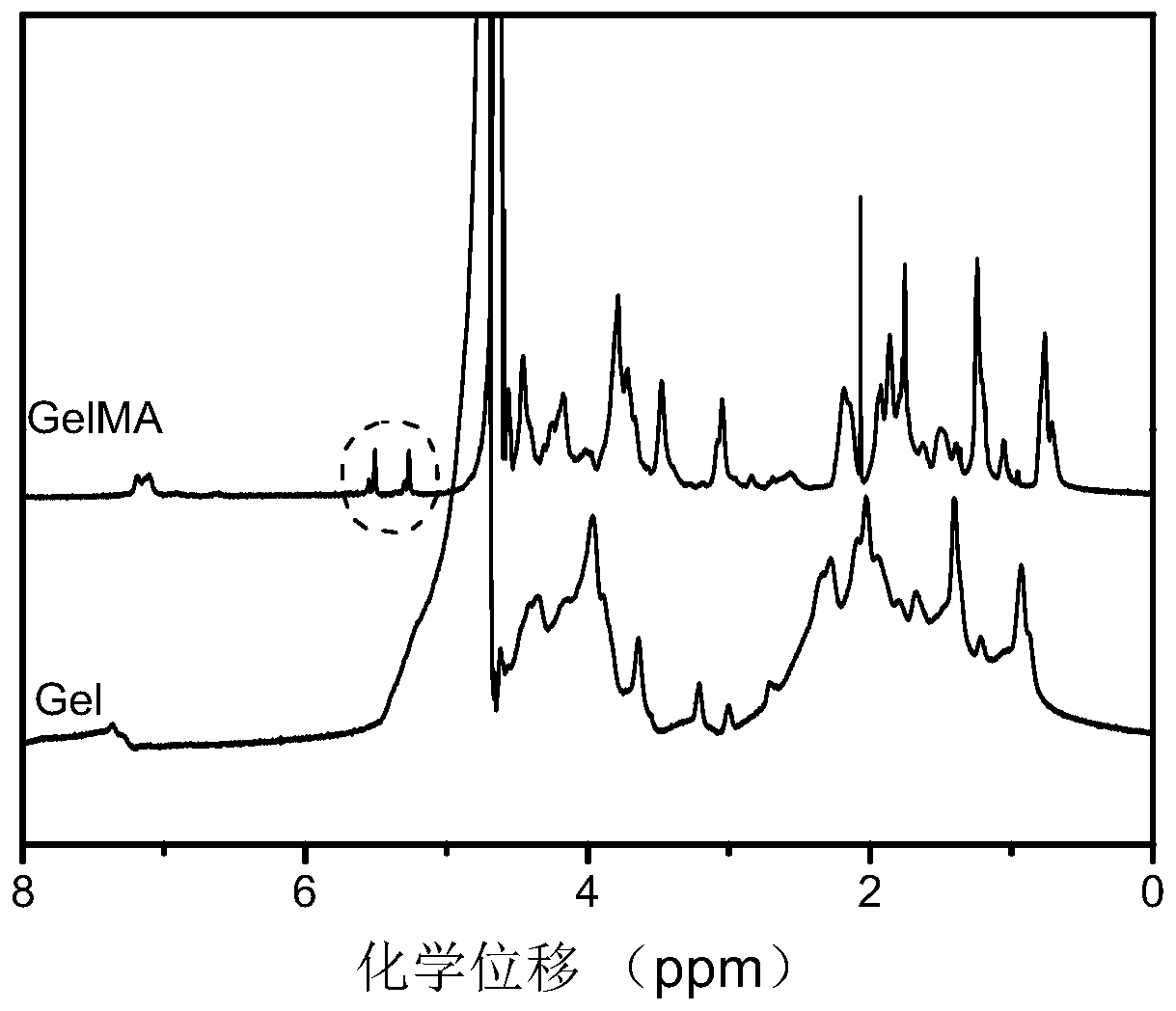

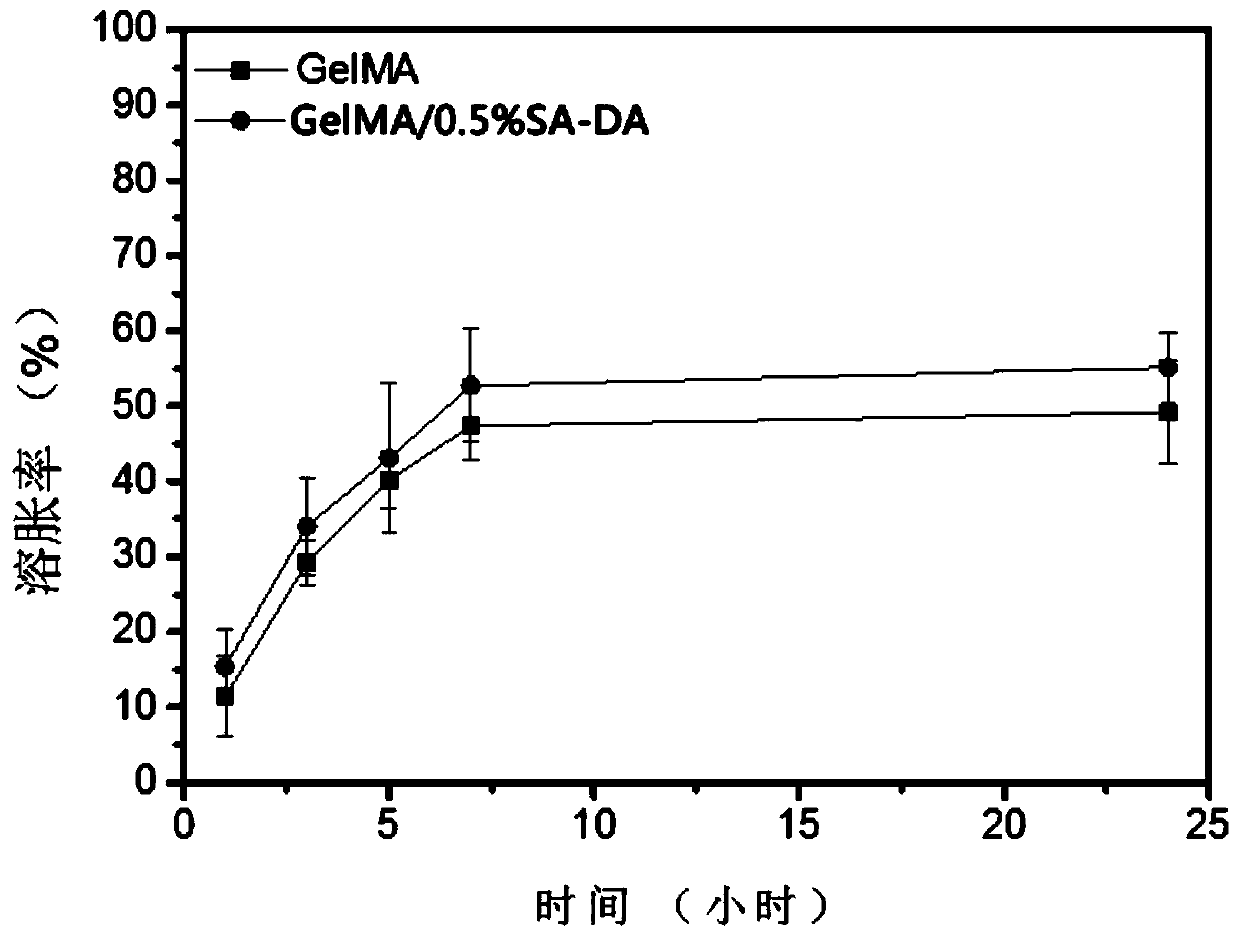

Composite hydrogel for promoting bone repair and preparation method and application of composite hydrogel

PendingCN111569148AImprove mechanical propertiesImprove adhesionTissue regenerationProsthesisPharmaceutical SubstancesBiology

The invention discloses a composite hydrogel for promoting bone repair. The composite hydrogel is prepared from the following components; methacrylic acid modified gelatin and dopamine modified sodiumalginate. In the composite hydrogel, the content of the methacrylic acid modified gelatin is 8-12% w / v, and the content of the dopamine modified sodium alginate is 0.5% w / v-2% w / v. A molecular structure of the dopamine modified sodium alginate contains a catechol structure, and the adhesion property is excellent. The composite hydrogel uses the methacrylic acid modified gelatin as a substrate ofthe hydrogel, and the mechanical properties and adhesion properties of the hydrogel are improved by incorporating the dopamine modified sodium alginate, so that the viscosity is excellent, the softness degree and elasticity are suitable, and the composite hydrogel is suitable for bone repair treatment. The results of in vitro experiments show that the composite hydrogel can load and slowly releasebiologically active factors and / or drugs that promote bone repair, good repair effect can be presented in bone defect models, and the healing of bone defect wounds can be significantly promoted.

Owner:ZHEJIANG MEDICAL COLLEGE

Cationic modified emulsified asphalt and application thereof in slab ballastless track

ActiveCN104151844AExcellent low temperature elasticity and toughnessImprove liquidityBuilding insulationsCrack resistancePetroleum

The invention relates to cationic modified emulsified asphalt which is composed of low-molecular modified petroleum asphalt, a cationic emulsifier, a stabilizer and water. The application of the cationic modified emulsified asphalt in a slab ballastless track provided by the invention means that the cationic modified emulsified asphalt is contained in cement emulsified asphalt mortar poured in a gap between a track slab of the CRTS I type slab ballastless track and a base plate. The cationic modified emulsified asphalt provided by the invention has excellent low-temperature elastic resilience; the cement emulsified asphalt mortar for the CRTS I type slab ballastless track, which is prepared from the cationic modified emulsified asphalt provided by the invention, has the advantages of good fluidity and stability, proper mechanical property and excellent low-temperature elasticity and toughness and crack resistance and is particularly suitable for a mortar filling layer in the CRTS I type slab ballastless track of a high-speed railway or a railway passenger dedicated line in severe cold areas; the dynamics of the CRTS I type slab ballastless track of the high-speed railway and the railway passenger dedicated line in the severe cold areas and the requirement for six years of service life in China can be met.

Owner:CENT SOUTH UNIV

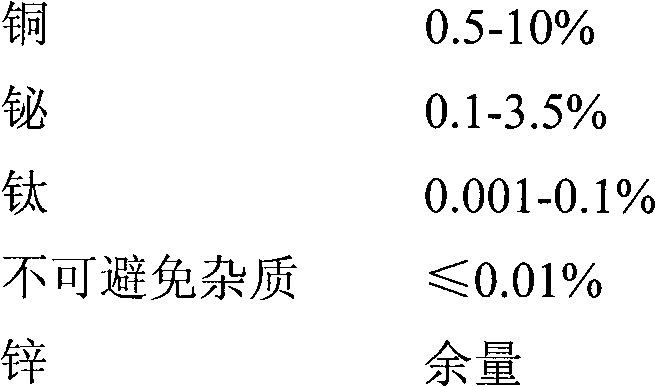

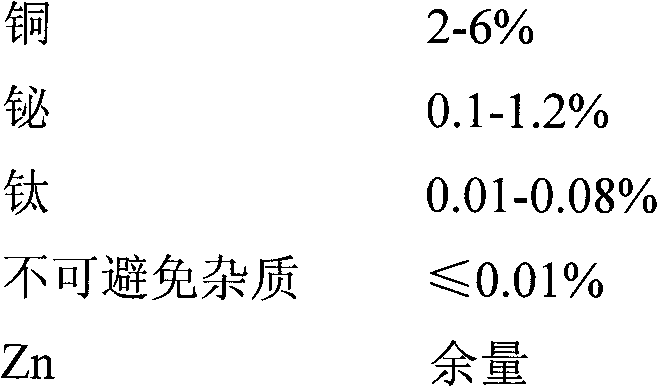

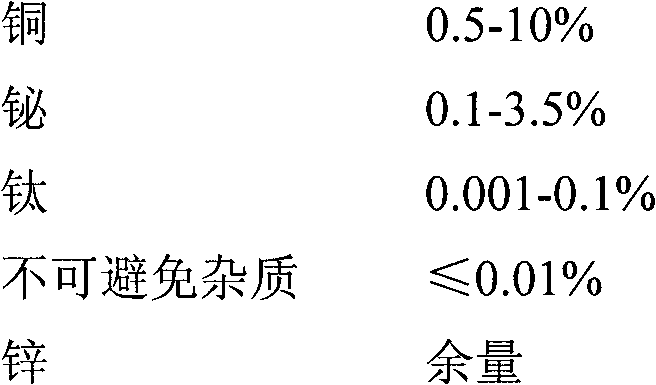

Easy-cutting zinc-copper-base wrought zinc alloy and preparation method thereof

The invention relates to an easy-cutting zinc-copper-base wrought zinc alloy and a preparation method thereof. The easy-cutting zinc-copper-base wrought zinc alloy is characterized by comprising the following components in percentage by weight: 0.5-10% of copper, 0.1-3.5% of bismuth, 0.001-0.1% of titanium, at most 0.01% of inevitable impurity and the balance of zinc. The alloy fusion casting technique comprises the following steps: smelting in a line frequency furnace, intermediate frequency or reverberatory furnace, and carrying out continuous casting or metal mold casting to obtain a casting blank; and carrying out hot extrusion at 180-400 DEG C, and finally carrying out cold drawing to obtain various sizes of rods, wires and section products. The obtained products can be used in the fields of automatic lathes, drill presses, instrument lathes and the like. Compared with the prior art, the alloy provided by the invention has the characteristics of favorable cutting property, moderate mechanical properties and the like, and is easy for processing and electroplating.

Owner:NINGBO POWERWAY ALLOY MATERIAL

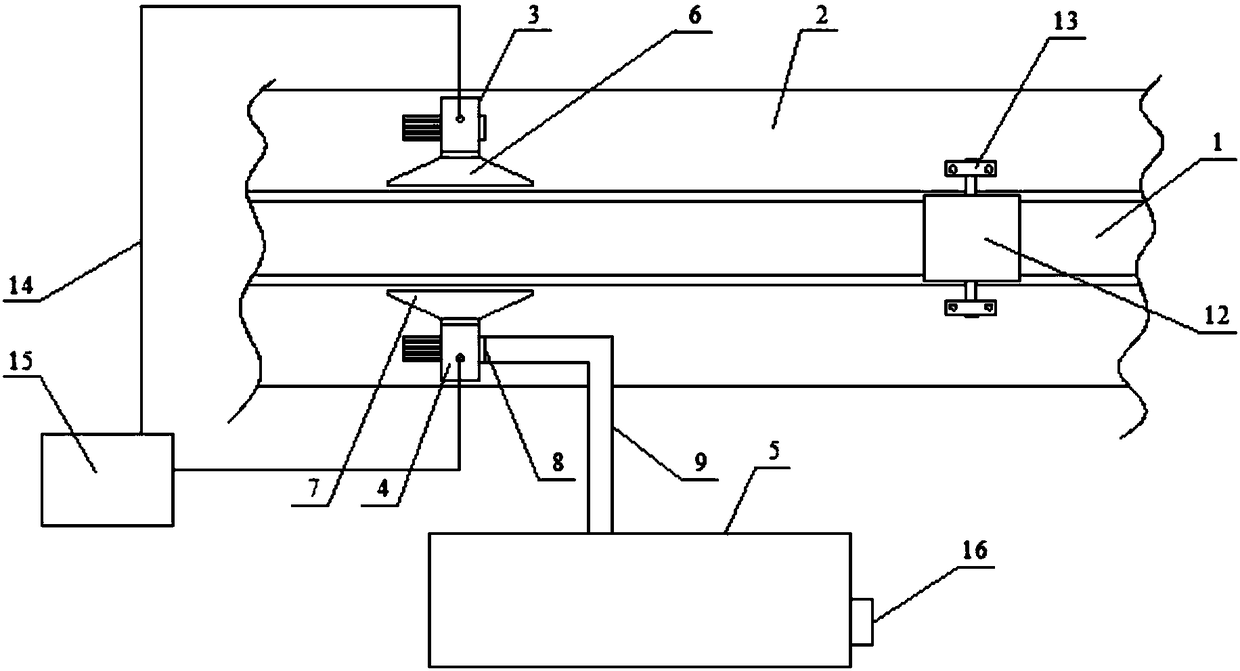

Device for removing dust on papers before printing of printed matters

InactiveCN108176675AEfficient removalAffect normal printingPlastic/resin/waxes insulatorsBristlePositive pressurePulp and paper industry

The invention discloses a device for removing dust on papers before printing of printed matters and relates to the technical field of printing. The device comprises a paper conveying table, a primarydust removing mechanism, a secondary dust removing mechanism and dust removing mechanism installing platforms, wherein the dust removing mechanism installing platforms are symmetrically arranged at two sides of the paper conveying table; the primary dust removing mechanism comprises a positive-pressure air blower, a negative-pressure induced draft fan and a settling chamber; a trumpet-shaped air outlet is formed in the positive-pressure air blower; a trumpet-shaped air inlet is formed in the negative-pressure induced draft fan; both the positive-pressure air blower and the negative-pressure induced draft fan face toward the upper surfaces of the papers; the negative-pressure induced draft fan is connected with the settling chamber through an air supply pipe; the secondary dust removing mechanism comprises a roll shaft, a roller sleeving on the roll shaft and a dust removing brush cylinder sleeving on the roller; two ends of the roll shaft are arranged on the dust removing mechanism installing platforms through supports; and the outer edge of the dust removing brush cylinder is in contact with the upper surfaces of the papers. The device disclosed by the invention has the advantagesthat the dust on the papers can be effectively removed and the removing rate is up to more than 99%, so that the normal printing of the papers is prevented from being influenced by the dust.

Owner:马斌祥

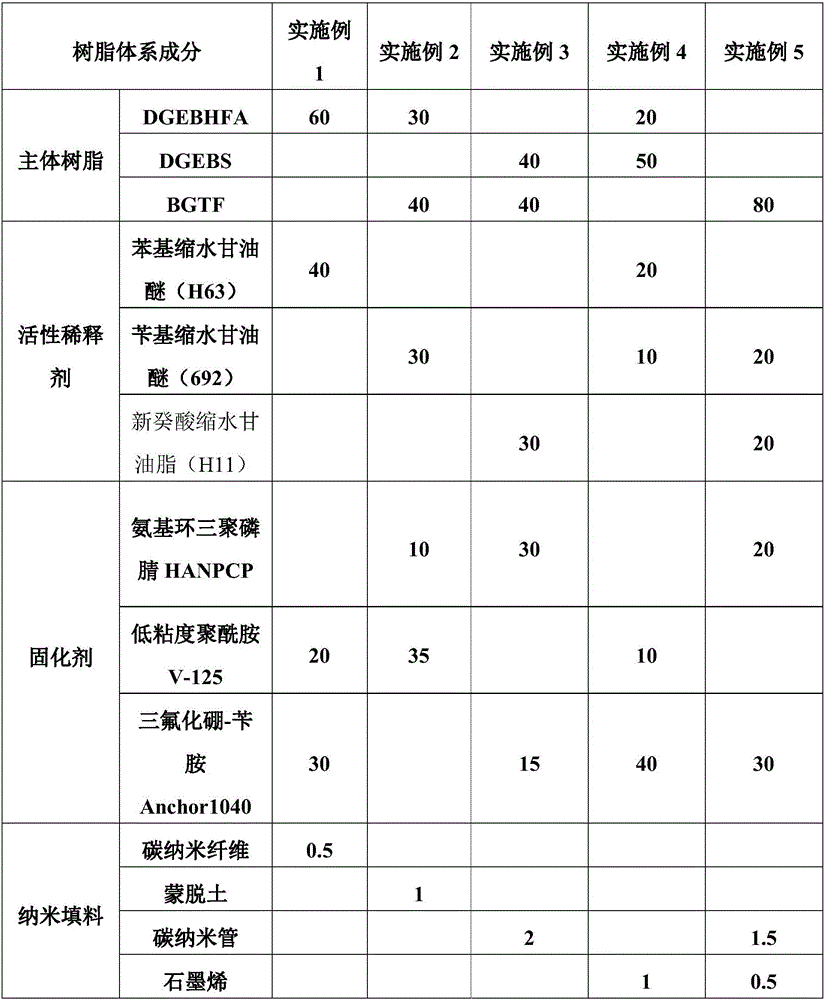

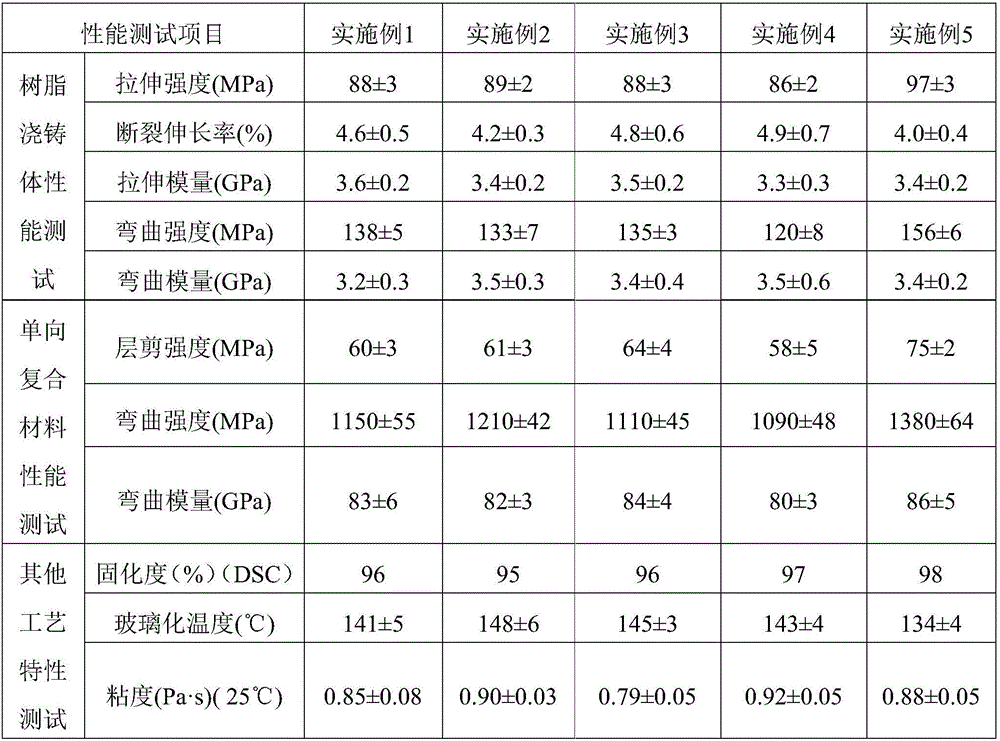

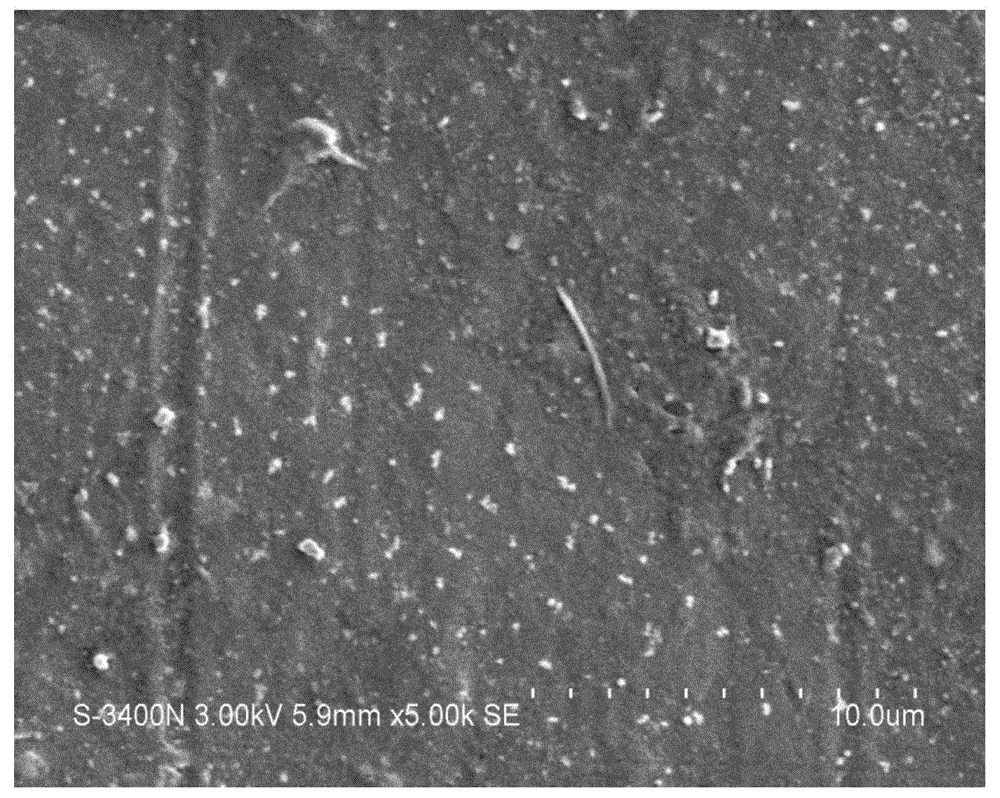

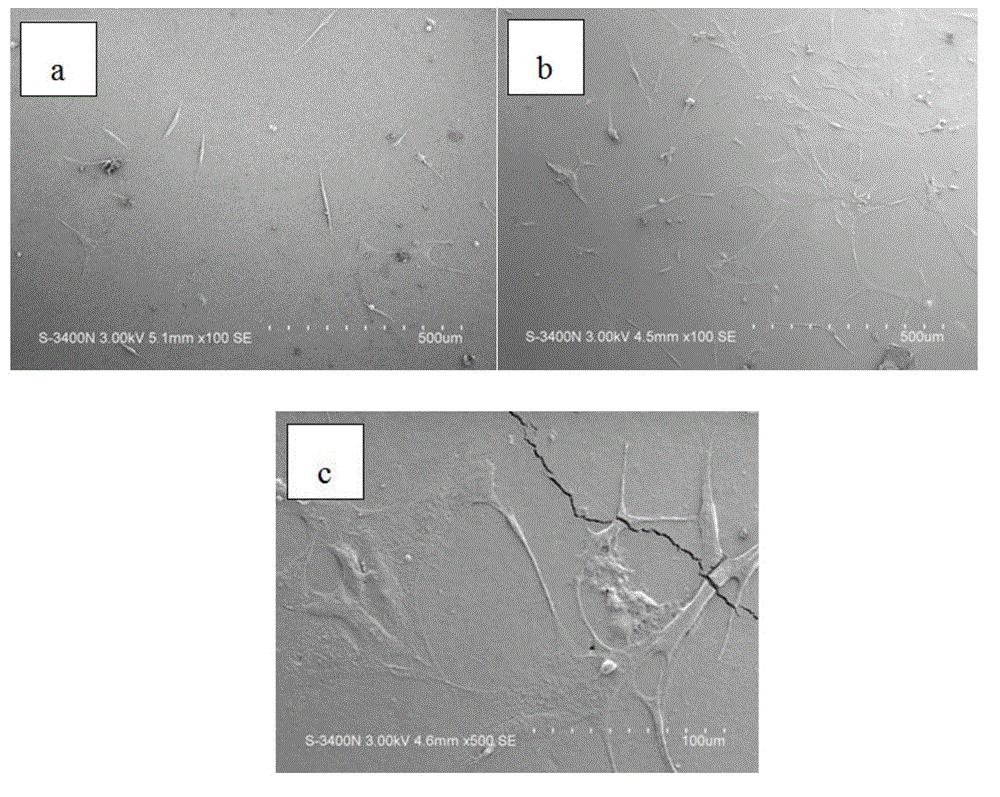

Resin matrix applicable to microwave curing and preparation method of resin matrix

The invention discloses a resin matrix applicable to microwave curing and a preparation method of the resin matrix, and belongs to the field of preparation of composite materials. Polar mulfunctional high-performance epoxy resin is used as main body resin; an active diluent is added to adjust the viscosity of a resin system so as to enable the resin to adapt to liquid forming processes such as winding; a novel compound curing agent is selected to adjust the curing activity of the resin matrix, and nanofiller is added to improve the microwave responsiveness of the resin matrix and realize the mechanical property, the heat resistance and the size stability of the resin matrix; by the adjustment of the structures and the proportions of components such as the main body resin, the curing agent, the diluent and the nanofiller, the resin system which is proper in microwave responsiveness and curing activity, excellent in comprehensive mechanical property, high in heat resistance, high in size stability and low in viscosity and is applicable to microwave curing is developed, has a great guidance significance for preparation of a fiber composite material, and can be widely applied to the field of aerospaces and the like.

Owner:BEIJING UNIV OF CHEM TECH

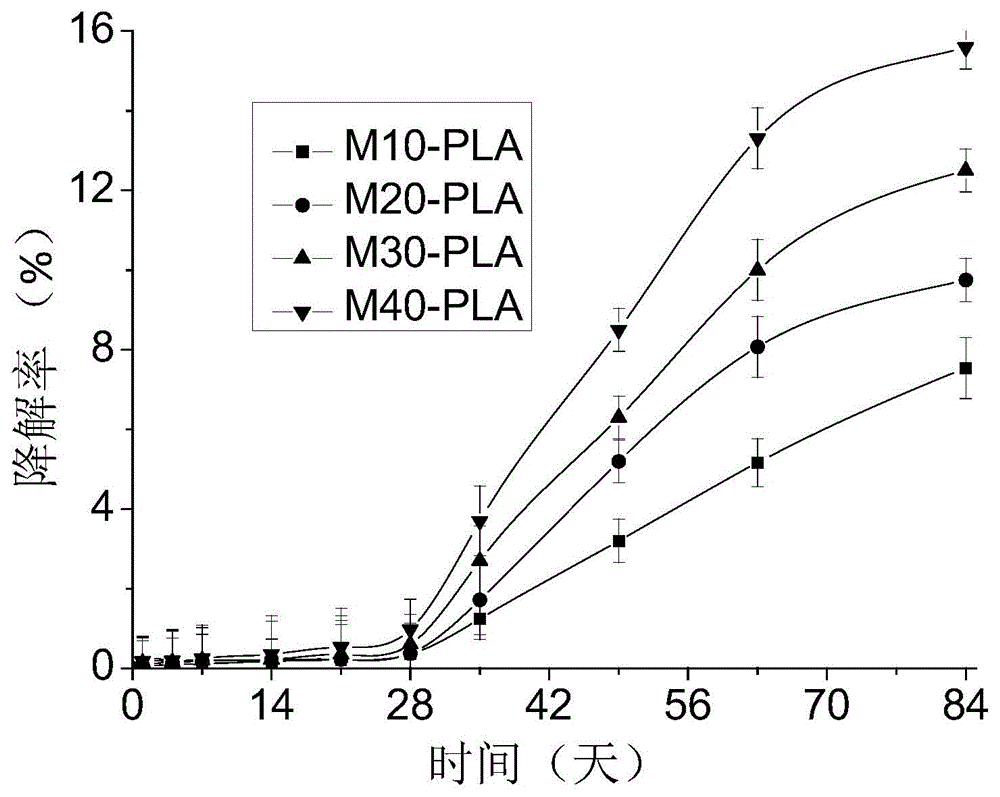

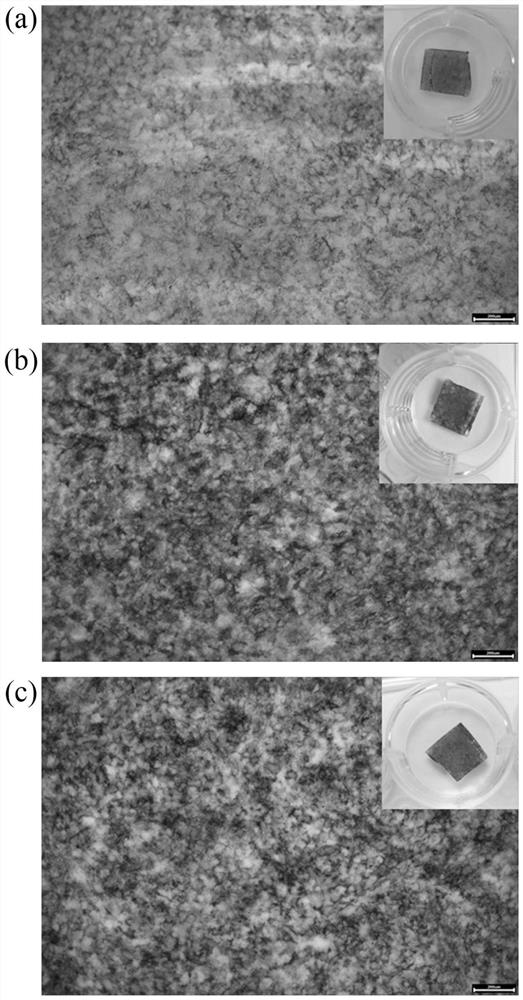

Mesoporous calcium magnesium silicate/polylactic acid composite material as well as preparation method and use thereof

InactiveCN104086962AGood biocompatibility and degradabilityModerate mechanical propertiesProsthesisImplant materialCalcium magnesium

The invention discloses a mesoporous calcium magnesium silicate / polylactic acid composite material as well as a preparation method and a use thereof. The preparation method comprises the steps of drying raw materials, evenly mixing, carrying out melt blending and then molding, wherein the raw materials include 1-50wt% of mesoporous calcium magnesium silicate and 50-99wt% of polylactic acid. The preparation method of the mesoporous calcium magnesium silicate / polylactic acid composite material is simple in process, and the obtained mesoporous calcium magnesium silicate / polylactic acid composite material contains no other toxic small molecules and impurities, and has excellent biological activity and compatibility and appropriate mechanical properties; besides, the ratio of the mesoporous calcium magnesium silicate to the polylactic acid in the mesoporous calcium magnesium silicate / polylactic acid composite material is adjusted to meet the requirement on different degradation velocities of implant materials in different bone repair environments.

Owner:EAST CHINA UNIV OF SCI & TECH

Tunable laser crystal chrome-mixing magnesium molybdate and preparation method thereof

InactiveCN102534792ARaw materials are easy to getModerate mechanical propertiesPolycrystalline material growthFrom melt solutionsSpace groupFluorescence

The invention provides a tunable laser crystal chrome-mixing magnesium molybdate and a preparation method thereof. A fused salt top-seeded method is adopted, 55-80at.%K2Mo2O7 serves as a fluxing agent, growth parameters include that cooling speed is 0.5-5 DEG C / day, growth temperature is 700-880 DEG C, rotation speed is 5-30 turns / minute, and high quality big-sized Cr 3+: MgMoO4 crystal is grown. The crystal belongs to a monoclinic system and has a C2 / m space group structure, and a=10.273, b=9.288, c=7.025, beta=106.96 degrees, z=8, V=641.14, and Dc=3.82 g / cm3. The crystal has the advantages of being moderate in mechanical performance, wide in tunable laser wave band, big in emission section, short in fluorescence service life and the like and is a good tunable laser crystal material.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

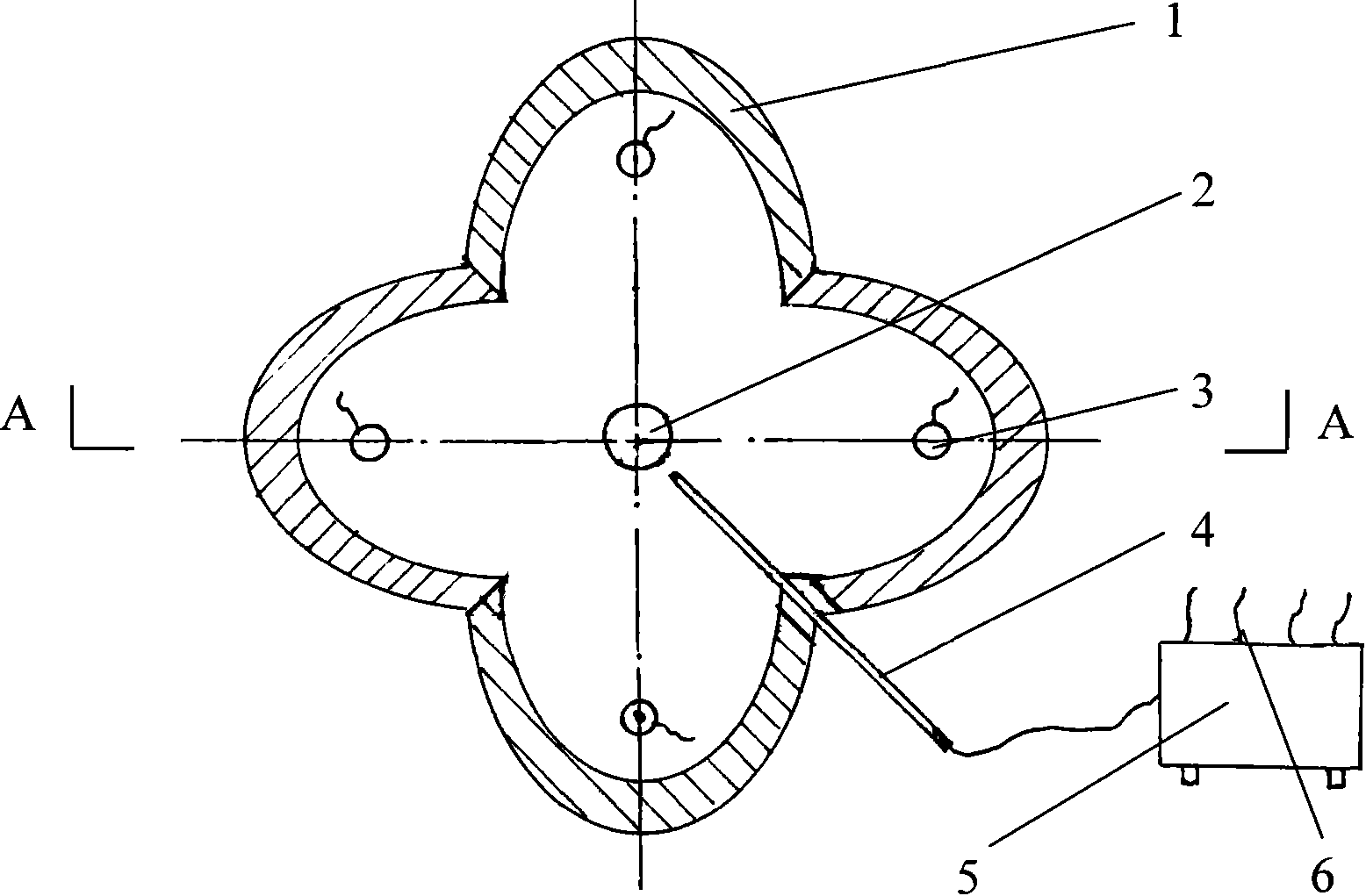

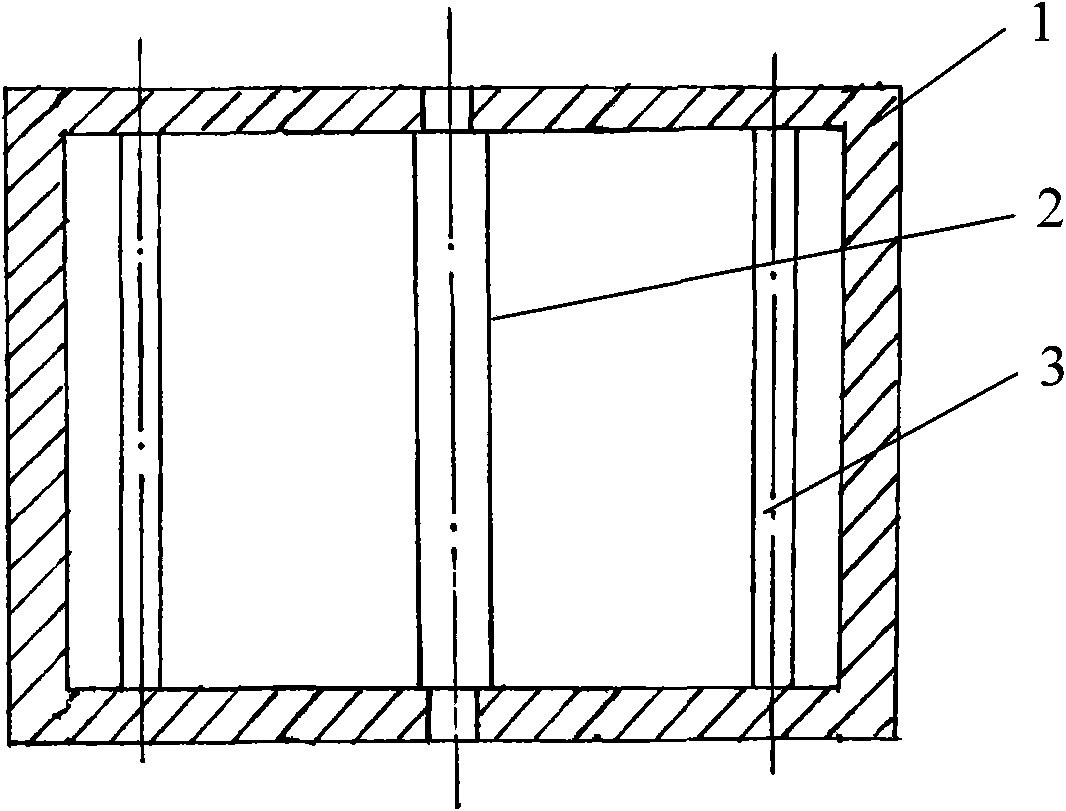

Infrared heating furnace device

InactiveCN101685052AHeating up fastRealize variable temperature testFurnace typesStrength propertiesTemperature controlStrength of materials

The invention belongs to the field of material mechanical property test, particularly relates to an infrared heating furnace device for heating a material sample in an infrared way, solves the problems that temperature change test is difficult to finish, the heating temperature of a low end is unstable, and the like, and is used for searching the material mechanical property under the conditions of constant temperature and changed temperature. The device is provided with furnace bodies with elliptical cylindrical reflection, infrared heating lamps and temperature controllers, wherein the focusof the elliptical cylindrical surface of each furnace body is provided with an infrared heating lamp; the input ends of the temperature controller are connected with temperature thermocouples extending into the furnace bodies, and the output ends of the temperature controllers are connected to all the infrared heating lamps. The invention is suitable for testing the mechanical properties of a material under different temperatures and continuous changed temperatures and realizes mechanical property test and thermal mechanical property test on the material sample through rapidly heating the material sample to the teat temperature so as to search a method for improving the material property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

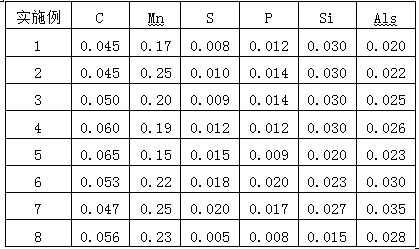

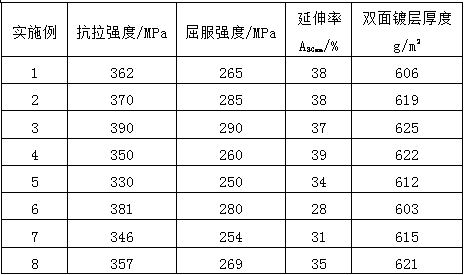

Ultra-thick coating hot galvanized steel strip for underground pipe gallery corrugated pipe and production method thereof

ActiveCN110684929AReduce the temperatureReduce core heatHot-dipping/immersion processesStrip steelAir knife

The invention discloses an ultra-thick coating hot galvanized steel strip for an underground pipe gallery corrugated pipe and a production method thereof. The hot galvanized steel strip comprises thefollowing chemical components of, in percentage by mass, 0.045%-0.065% of C, 0.15%-0.25% of Mn, less than or equal to 0.020% of S, less than or equal to 0.020% of P, less than or equal to 0.03% of Si,greater than or equal to 0.020% of Als, and balance iron and inevitable impurities; the production method comprises converter smelting, LF refining, continuous casting , hot rolling, cold rolling andgalvanizing processes. According to the ultra-thick coating hot galvanized steel strip for the underground pipe gallery corrugated pipe and the production method thereof, proper mechanical propertiesof the steel strip are guaranteed through reasonable component design and hot rolling and galvanizing annealing process design; and through reducing the height of an air knife, increasing the distance between a knife lip and the strip steel and sectional control measures of the opening degree of the air knife lip, the generation of zinc rhyolite and edge thickness defects is inhibited, the requirement of the underground pipe gallery industry on the ultra-thick coating hot galvanized steel strip is met, and remarkable economic benefits are achieved.

Owner:TANGSHAN IRON & STEEL GROUP +1

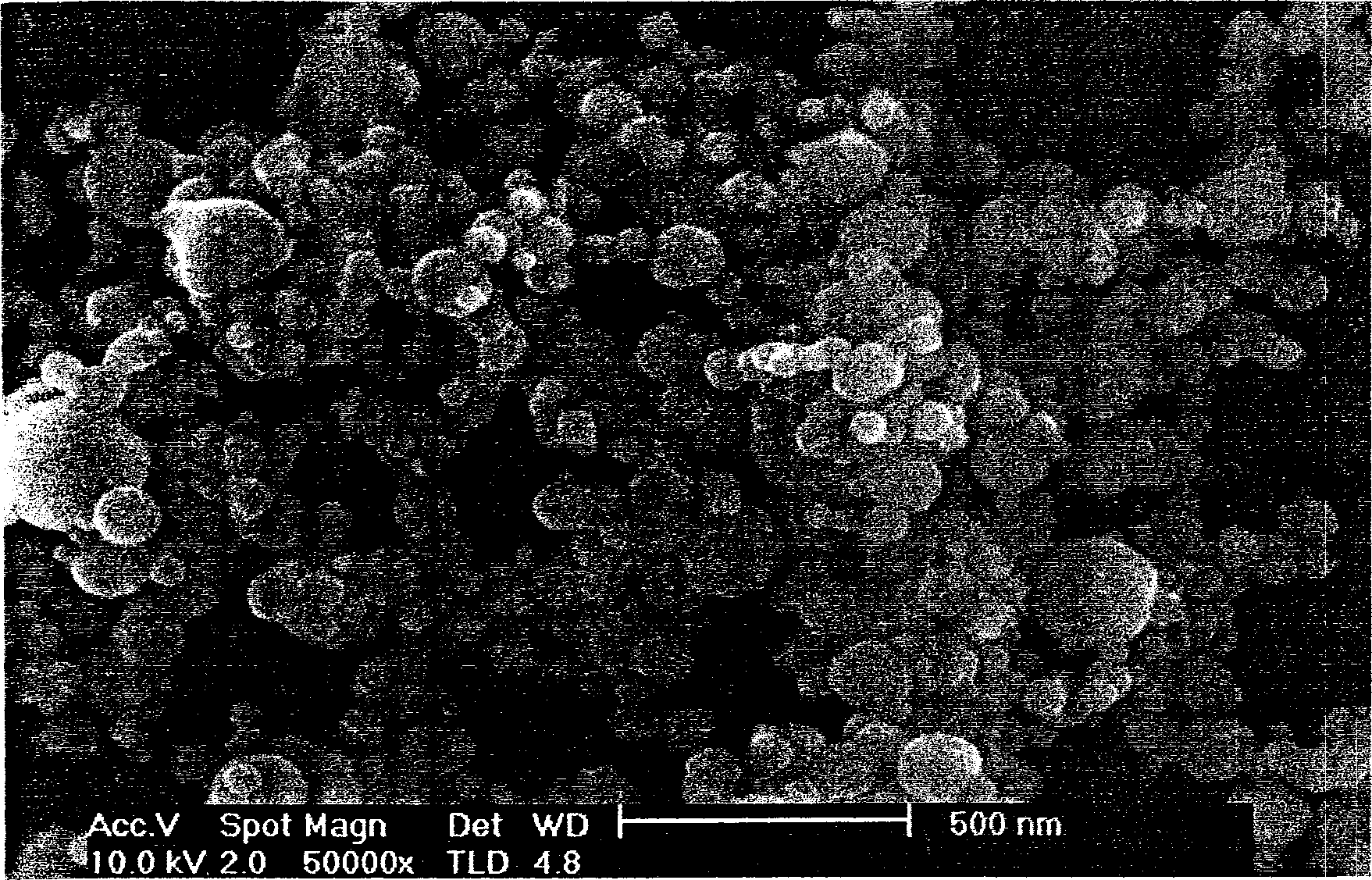

Cutting production technology of metal nanometer powder zero boundry particle

InactiveCN1911567AImprove product qualityEasy to shapeTransportation and packagingMetal-working apparatusIron powderGranularity

The present invention relates to preparation of nanometer metal powder, and is especially critical cutting nanometer metal powder producing process. The production process includes the steps of: setting iron powder at critical temperature of -10 deg.c to +10 deg.c, cutting iron powder particle at the speed of 4000-6000 times every minute, high frequency grinding at 4000-6000 rpm, physical reduction, surface treatment and final grading. By means of the technology of the present invention, may be produced nanometer level superfine iron powder with spherical form, homogeneous granularity, good flowability and high strength.

Owner:王惠民

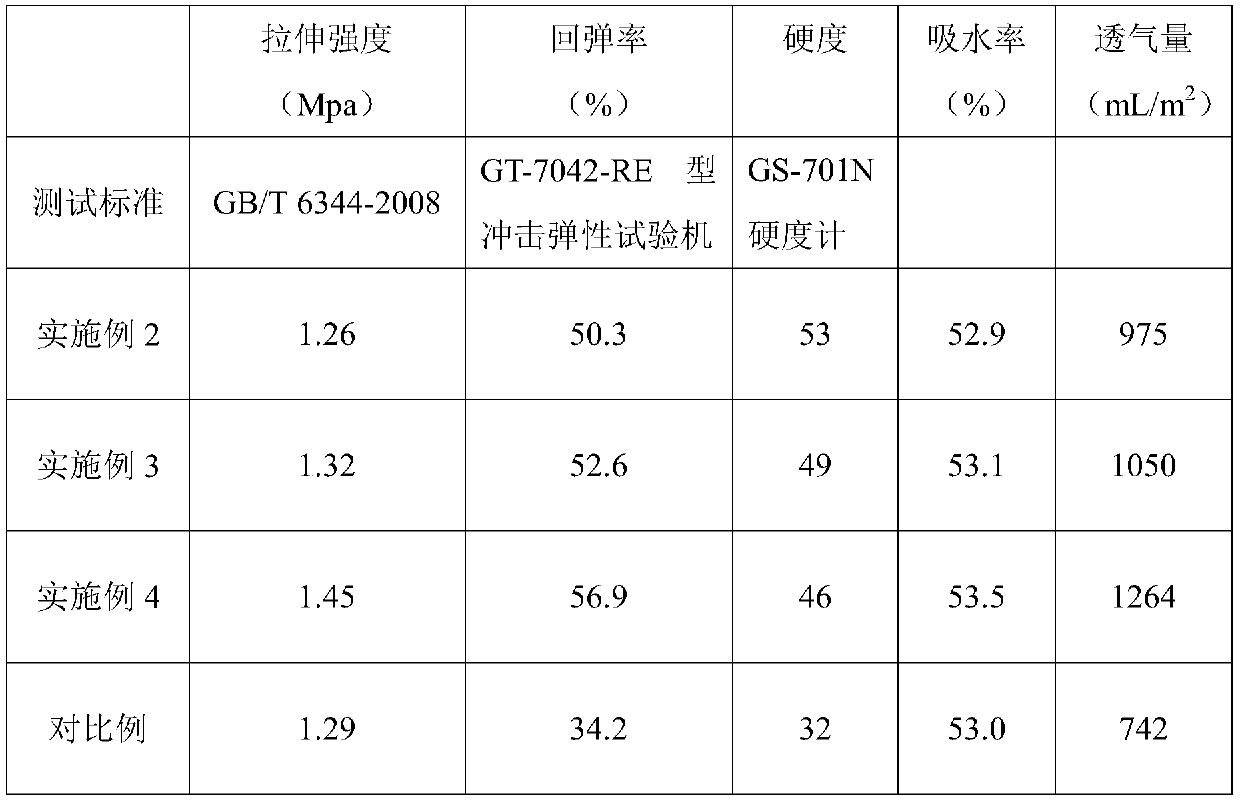

Graphene regenerated rubber-plastic foamed insole and preparation method thereof

The invention discloses a graphene regenerated rubber-plastic foamed insole and a preparation method thereof. The foamed insole is prepared by the following raw materials in parts by weight: 17-22 parts of an ethylene-vinyl acetate copolymer, 35-42 parts of an ethylene-vinyl acetate copolymer offcut grinding powder, 5-7 parts of ethylene propylene diene monomer rubber, 3-6 parts of oxidized polyethylene, 3.5-5.5 parts of graphene, 1-1.5 parts of carboxylated graphene, 30-37 parts of a thermoplastic polyester elastomer, 10-14 parts of a polyester-polyether block copolymer, 2-4 parts of fluorinated polyethylene, 1.2-2.3 parts of a foaming agent, 0.7-1.1 parts of a bridging agent, 2.5-4.5 parts of aluminum silicate fiber tubes, 2.5-4 parts of an antioxidant, and 3-4.5 parts of zinc stearate.The graphene regenerated rubber-plastic foamed insole has good mechanical properties such as high tensile strength and the like, the hardness is moderate, the air permeability is good, the service life as an insole material is long, the foamed insole is not easy to have excessive deformation, and the comfort degree is high. The recycling of EVA is realized, the utilization rate of EVA is improved,the raw material cost is reduced, and thus the foamed insole is more environment-friendly.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

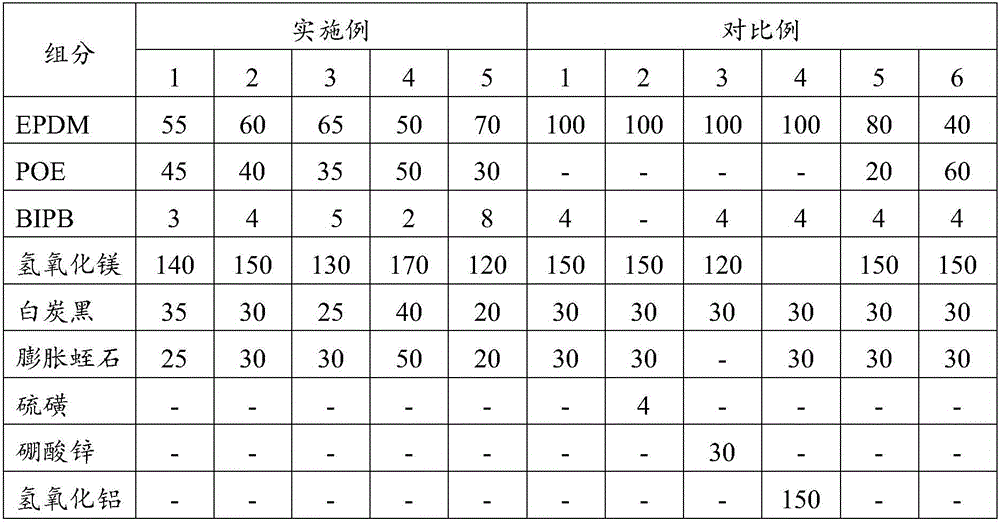

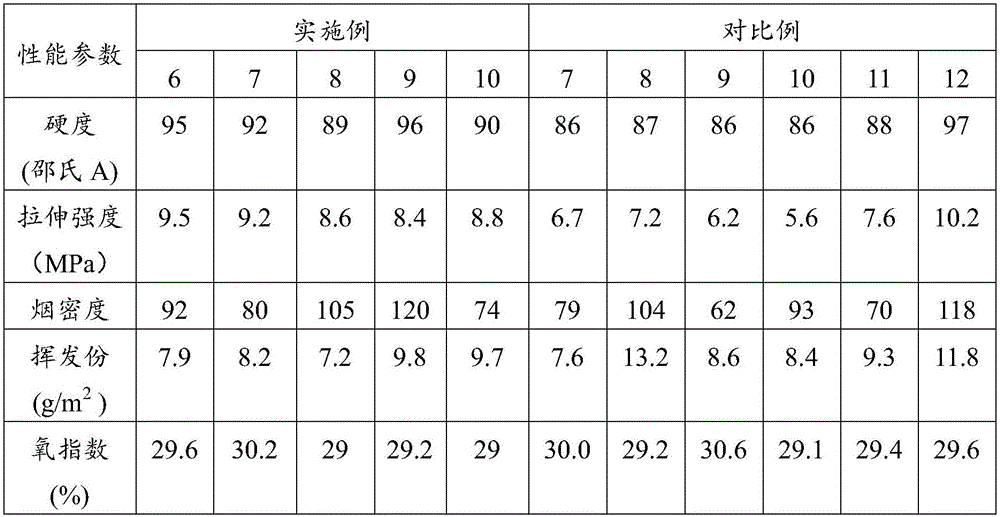

Rubber floor cloth composition, rubber floor cloth prepared from rubber floor cloth composition and applications of rubber floor cloth composition and rubber floor cloth

The invention provides a rubber floor cloth composition for preparation of rubber floor cloth. The composition is prepared from, by weight, 50-70 parts of EPDM (ethylene propylene diene monomer) rubber, 30-50 parts of POE (polyolefin elastomer), 2-8 parts of BIPB (Bis(tert-butylperoxy Isopropyl)benzene), 120-170 parts of silane modified magnesium hydrate, 20-50 parts of expanded vermiculite and 20-40 parts of silane modified white carbon black, wherein the sum of weight parts of the EPDM and the POE is 100. The invention further provides application of the composition to preparation of the rubber floor cloth, a preparation method of the rubber floor cloth with the composition serving as a raw material and application of the rubber floor cloth to railway vehicles. The rubber floor cloth has advantages of thickness uniformity, high strength, low volatile matter content, nontoxicity, safety and the like.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

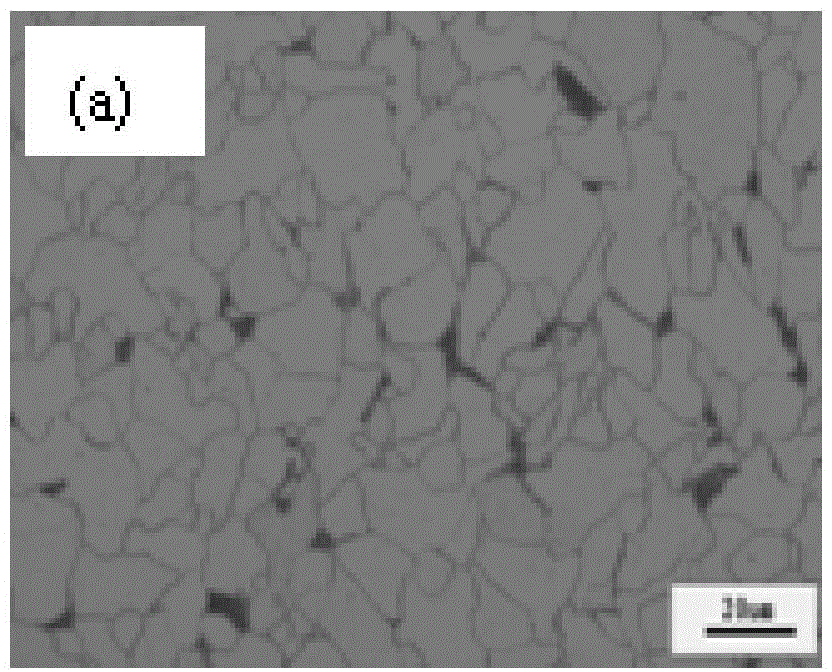

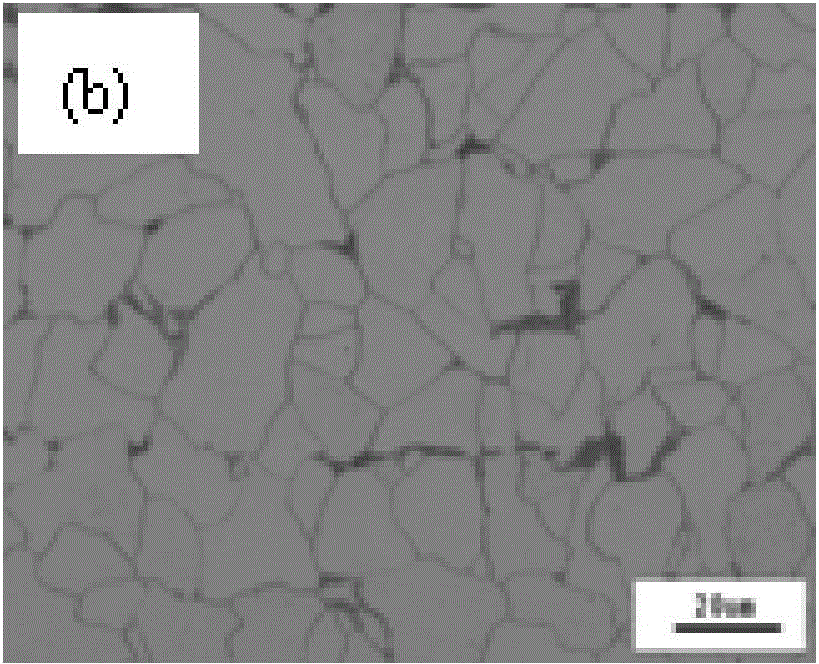

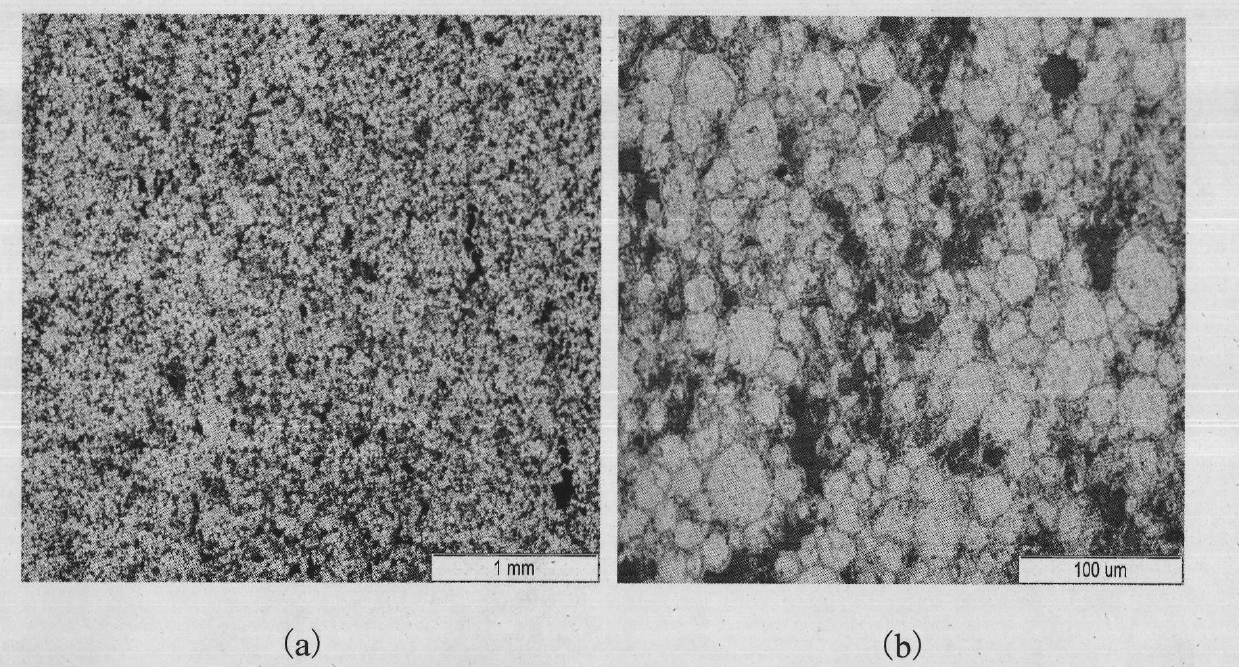

Magnesium/hydroxyapatite composite material and preparation method thereof

The invention relates to a magnesium / hydroxyapatite composite material and a preparation method thereof. The magnesium / hydroxyapatite composite material is prepared by mixing magnesium and hydroxyapatite serving as raw materials in a mass ratio of 80.5-99.9 percent: 0.1-19.5 percent for molding and sintering the mixture in a vacuum microwave sintering furnace. The composite material provided by the invention has proper mechanical property and can meet the requirements on human body bone tissue materials. A microwave sintering method is adopted, so the method has the advantages of high temperature rise speed, short sintering time, short preparation period, low energy consumption and no pollution.

Owner:TIANJIN UNIV

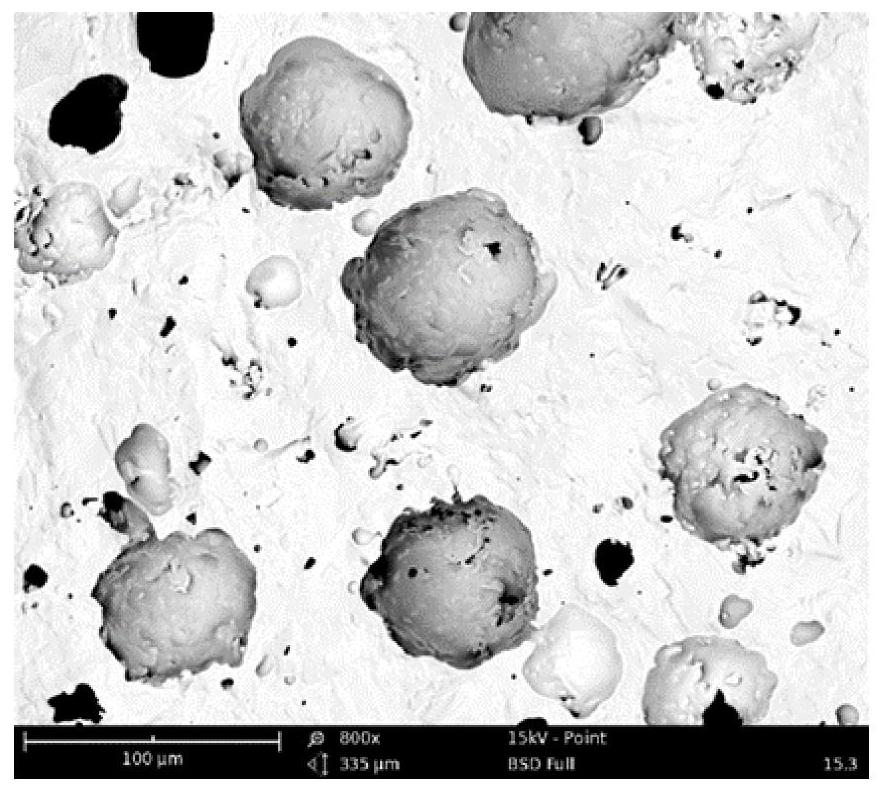

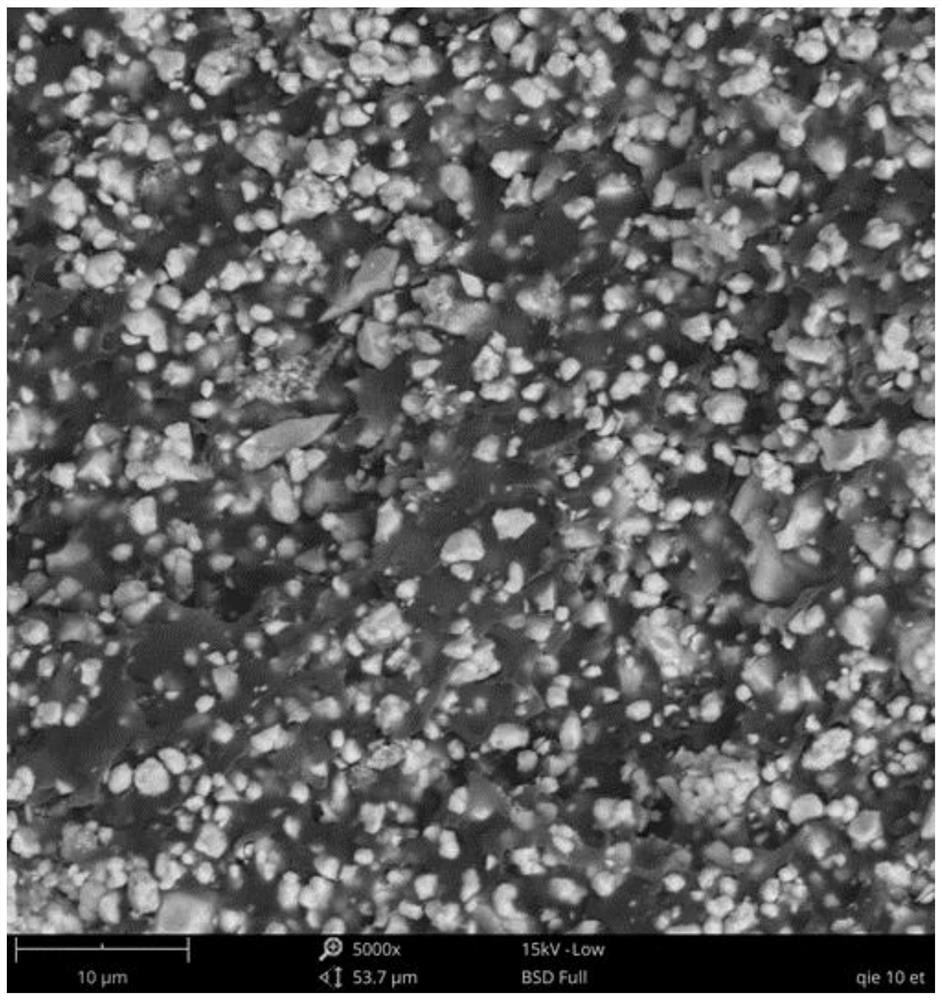

Slurry direct writing forming method of diamond tool

ActiveCN112723902APromote self-sharpeningUniform stomataAdditive manufacturing apparatusAbrasion apparatusPolymethyl methacrylateNanoceramic

The invention discloses a slurry direct writing forming method of a diamond tool, which comprises the following steps: (1) fully mixing nano ceramic powder, PMMA (polymethyl methacrylate) and diamond microparticles to obtain mixed powder; (2) fully dispersing xanthan gum in deionized water to obtain a xanthan gum solution; (3) uniformly mixing the mixed powder prepared in the step (1) with the xanthan gum solution obtained in the step (2) to obtain slurry; (4) adding the slurry prepared in the step (3) into a needle cylinder of slurry direct writing forming equipment, and printing into a designed shape in a layer-by-layer overlapping manner to obtain a green body; and (5) drying the green body prepared in the step (4) to constant weight, and then sintering to obtain the diamond tool. The diamond tool with a complex structure can be manufactured at a time through slurry direct writing forming, and the diamond tool has high consistency, proper mechanical property, controllable porosity and high shape precision.

Owner:HUAQIAO UNIVERSITY

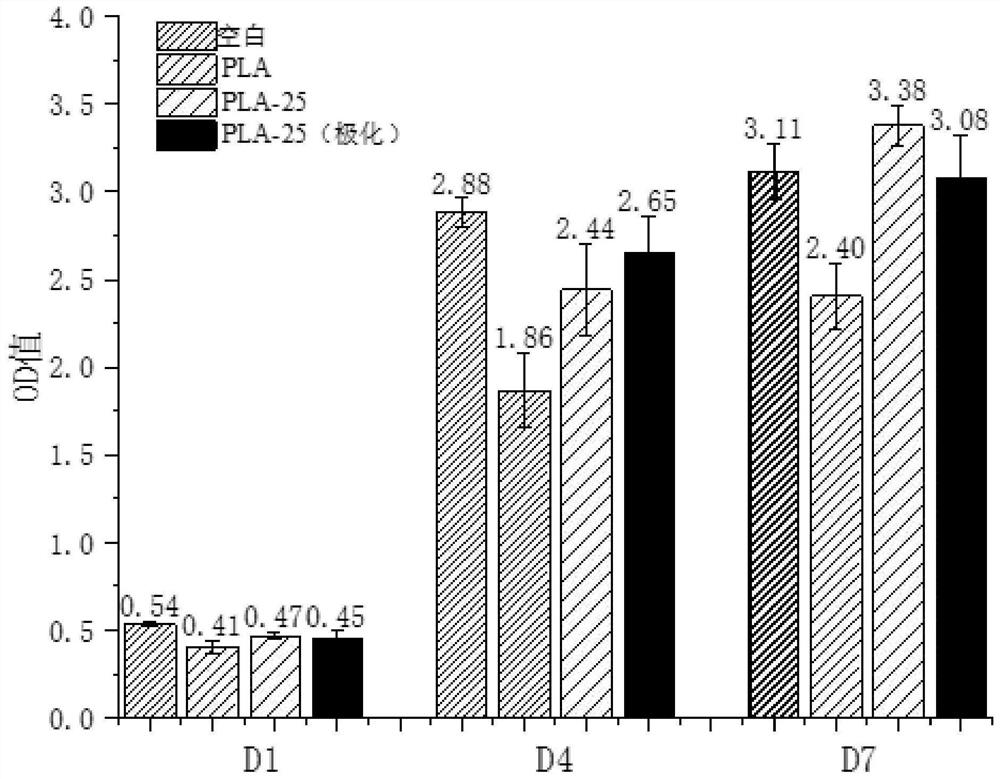

Reinforced biodegradable composite material

PendingUS20210388201A1Improve heat resistanceImprove mechanical propertiesGlass fiberPolymer science

The present disclosure relates to a composite material comprising glass fiber and a polymer blend comprising polylactic acid (PLA) and polybutylene succinate (PBS), wherein the composite material comprises about 10 wt-% to about 80 wt-% of glass fibre, and wherein the polymer blend comprises about 20 wt-% to about 60 wt-% of PLA and about 40 wt-% to about 80 wt-% of PBS. The disclosure also relates to an article comprising the reinforced composite material.

Owner:ARCTIC BIOMATERIALS OY

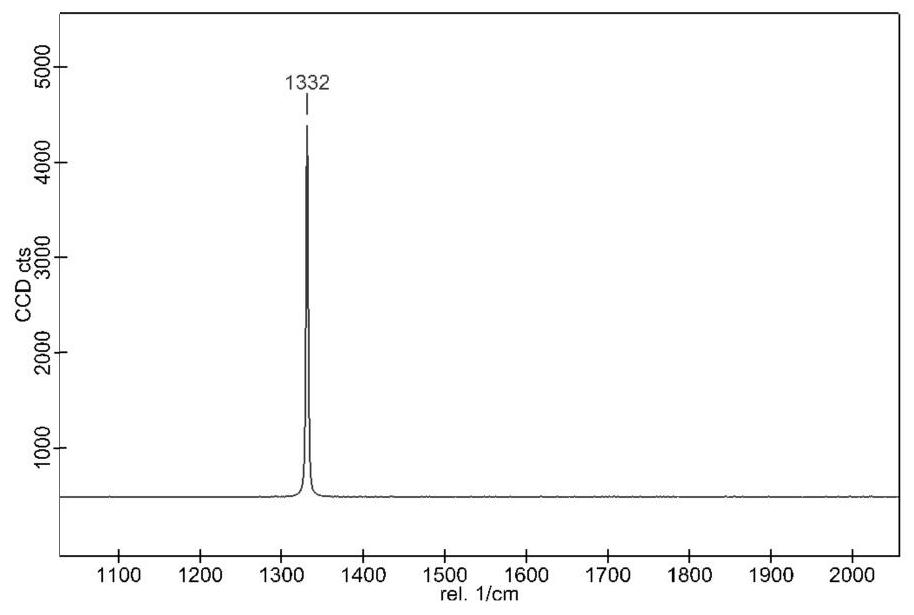

Piezoelectric composite material capable of being subjected to 3D printing/hot press molding and preparation method thereof

PendingCN114220912ASimple preparation processMild conditionsPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionBatch productionHot press

The invention discloses a piezoelectric composite material capable of being subjected to 3D printing / hot press molding and a preparation method thereof. The piezoelectric composite material comprises the following components: surface modified barium titanate and a polymer. The surface modified barium titanate provided by the invention has excellent biocompatibility, and the piezoelectric composite material which can be formed by the surface modified barium titanate and a polymer and can be subjected to 3D printing / hot press molding has moderate piezoelectric property and mechanical property; the piezoelectric composite material is obtained by mixing the surface-modified barium titanate with the polymer and then carrying out processing molding and electric polarization, and the piezoelectric composite material is simple in preparation process, mild in condition, low in cost and suitable for industrial batch production; the piezoelectric composite material can be widely applied to the field of biomedical materials.

Owner:INST OF MEDICINE & HEALTH GUANGDONG ACAD OF SCI

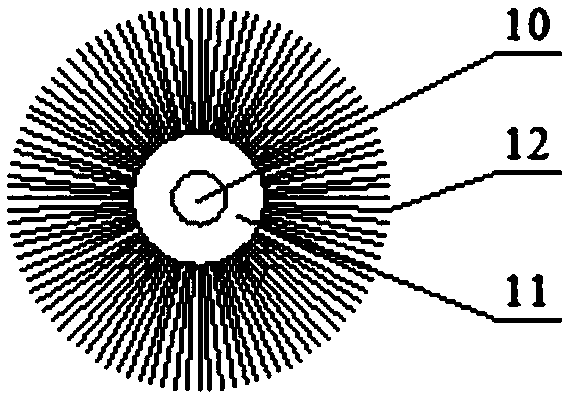

Electrostatic dust removal roller for sofa and carpet cleaning

The invention discloses an electrostatic dust removal roller for sofa and carpet cleaning, and relates to the technical field of a domestic dust removal roller. The electrostatic dust removal roller comprises a dust removal hairbrush, a roller and a clamping part, wherein a clamping part installing space of a hollow structure is axially formed inside the roller; the clamping part consists of a handle and a roller clamping rod; the roller clamping rod realizes rotatable connection with the roller through a clamping position limiting block arranged in the clamping part installing space; a sticking hook surface is arranged on the outer wall of the roller; a sticking loop surface matched with the sticking hook surface is arranged on the dust removal hairbrush; and the dust removal hairbrush isfixedly arranged on the roller in a sleeving way through the sticking loop surface and the sticking hook surface. Through the matched arrangement of the sticking hook surface and the sticking loop surface, the mounting and the dismounting of the dust removal hairbrush are convenient; meanwhile, the dust removal hairbrush can be easily replaced; the service life of the dust removal roller is prolonged; and non-woven fabrics, chemical fiber wires and insulation plastic wires are used for preparing the dust removal hairbrush, so that the dust clearing is realized through the electrostatic effect.

Owner:马斌祥

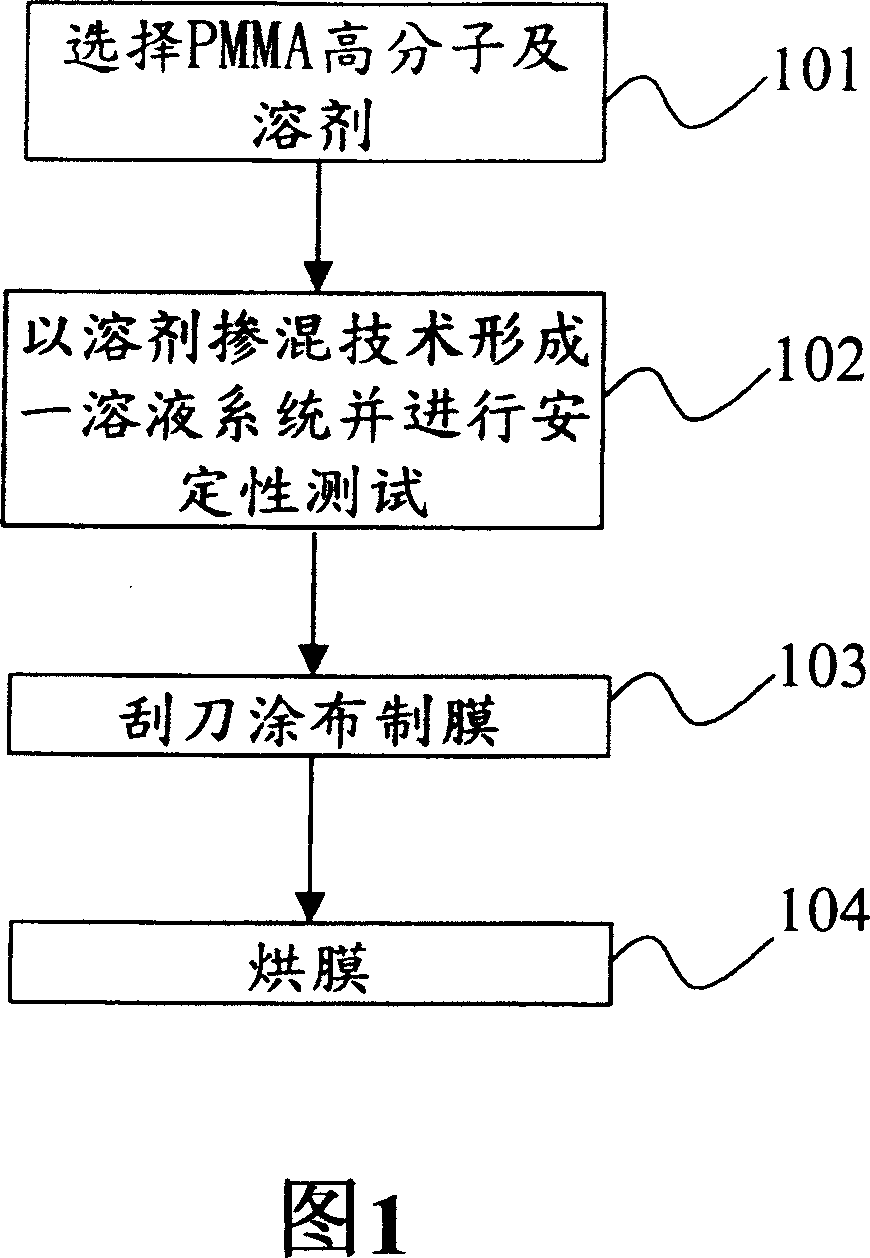

Optical film, and preparation method

InactiveCN1959440AAvoid harmSolve the problem of optical property variationOptical elementsSolventHeat treated

A method for preparing optical film includes mixing PMMA mixture with solvent uniformly to form a wet film, heating said wet film to form an optical dried film, enabling to mix PMMA mixture in any ratio as per required property with solvent to form a mixed solution then carrying out heat treatment on mixed solution to obtain optical film.

Owner:OPTIMAX TECHNOLOGY CORPORATION

Light-type structure composite material

InactiveCN105818397AModerate mechanical propertiesLightweight laminated structureSynthetic resin layered productsFiberVolumetric Mass Density

The invention provides a lightweight structural composite material, which relates to a layered composite lightweight composite material with relatively low uniform surface density and periodic or non-periodic modulation. The composite material includes: at least one layer of layers with uniform surface density and at least one layer of hollow fiber skeleton, and periodic or non-periodic lamination is adopted between the layer of uniform surface density and the hollow fiber skeleton. The main materials selected in the present invention all have relatively low surface density. Compared with common composite materials, the laminated composite materials in the present invention have ultra-light weight, and their mechanical structure design is relatively simple. This new type of composite material can be used in long-endurance solar unmanned aircraft, space vehicles and other occasions that do not bear too much mechanical load, but require lightweight applications.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High peeling resistance concrete surface protective coating and construction method thereof

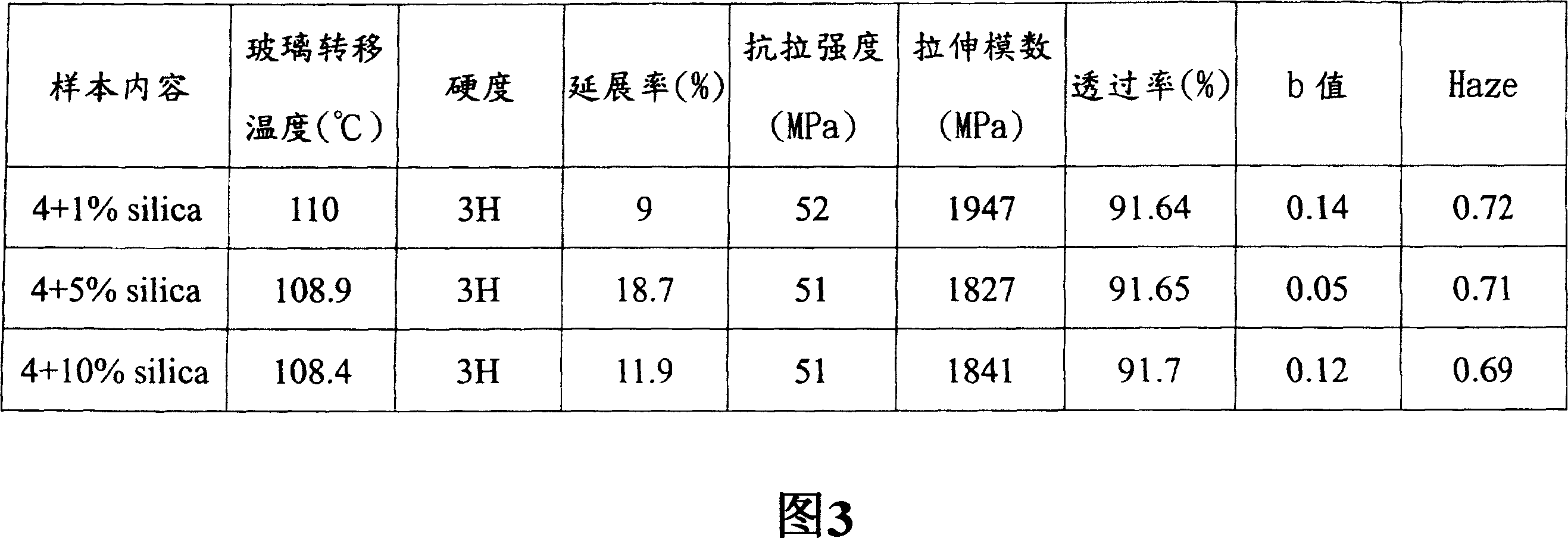

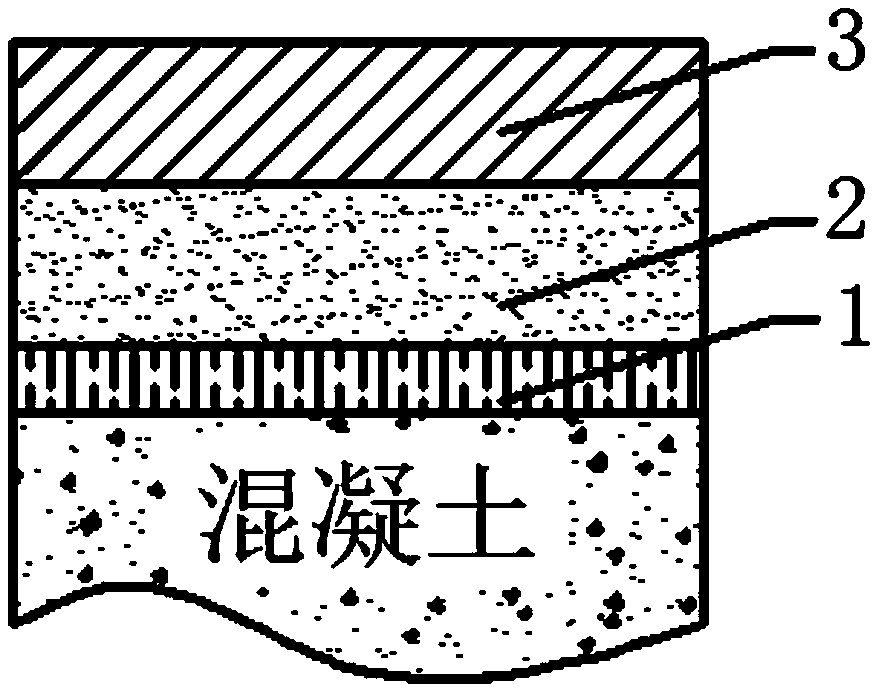

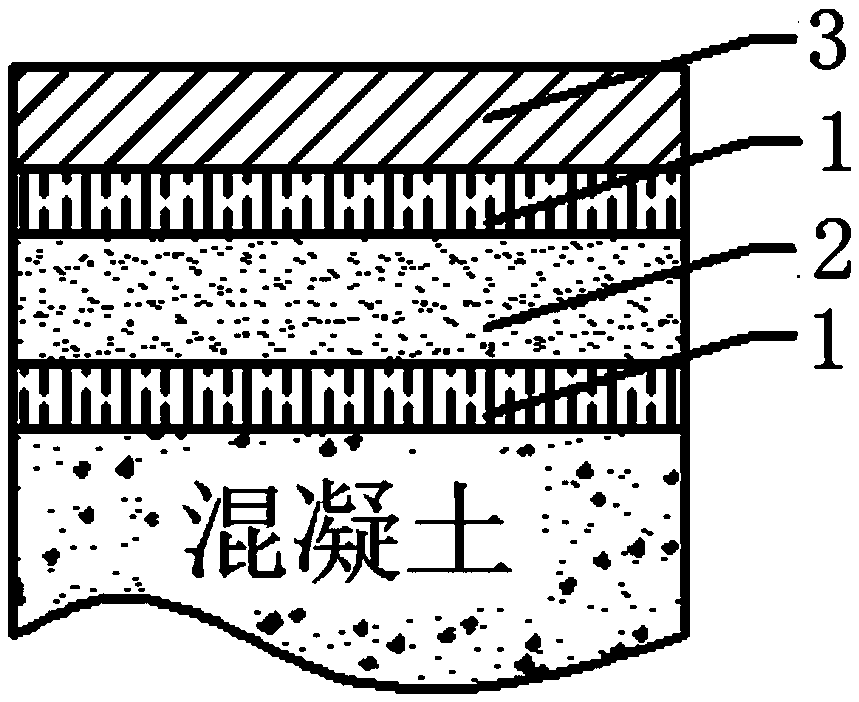

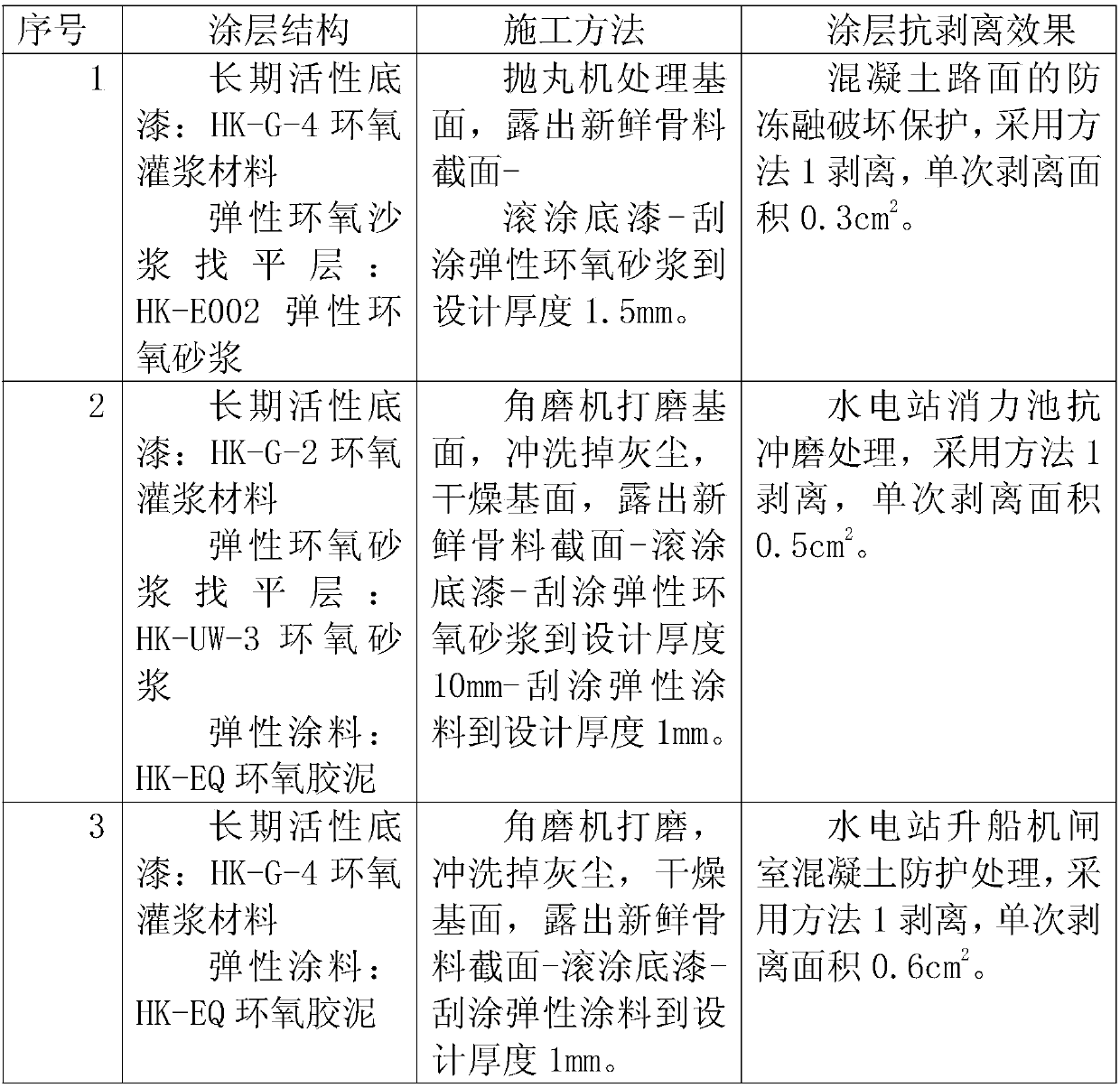

PendingCN109577279ASuitable mechanical propertiesModerate mechanical propertiesMarine site engineeringMaterials scienceCoating

The invention relates to a high peeling resistance concrete surface protective coating and a construction method thereof. The invention aims at providing the high peeling resistance concrete surface protective coating and the construction method thereof. The high peeling resistance concrete surface protective coating is characterized by comprising a long active primer layer, an elastic epoxy mortar layer and an elastic coating which are sequentially arranged on the surface of concrete. The coating is applicable to the field of concrete protection.

Owner:HANGZHOU GUODIAN DAM SAFETY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com