Preparation method of aloe/sodium alginate double-layer hydrogel dressing

A sodium alginate and hydrogel technology, used in medical science, bandages, absorbent pads, etc., can solve problems such as exogenous infection, affect wound healing, damage new tissue, etc., achieve excellent antibacterial properties, and promote fibroblasts. Proliferation and proliferation-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

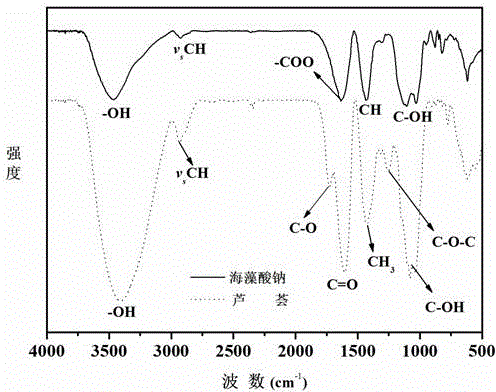

[0035] a Preparation of non-toxic base layer sodium alginate hydrogel film

[0036] Dissolve 0.5g of sodium alginate powder in 100mL of distilled water, stir at room temperature until completely dissolved, add 0.6mL of plasticizer glycerin during stirring, exhaust for 12h, and stand at room temperature. Afterwards, a certain amount of sodium alginate gel was dripped into a petri dish to a height of 0.5 cm, and dried at a temperature of 37°C and a relative humidity of 50% for at least 24 hours.

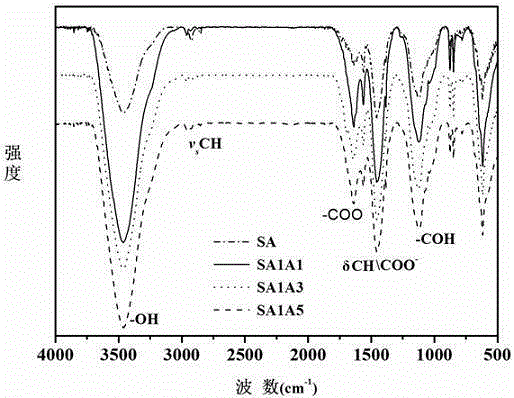

[0037] b Preparation of the upper hydrogel loaded with drugs

[0038] Dissolve 5g of aloe vera in 100mL of distilled water, stir at room temperature until completely dissolved; then add appropriate amount of aloe vera solution to sodium alginate according to different mass ratios (A / SA mass ratios: 1, 3, 5), In the solution, aloe / sodium alginate mixtures with different mass ratios were prepared respectively, stirred and reacted at room temperature for 2 hours, exhausted for 24 hours, ...

Embodiment 2

[0046] a Dissolve 2.5g of sodium alginate powder in 100mL of distilled water, stir at room temperature until completely dissolved, add 1.2mL of plasticizer glycerin during stirring, exhaust for 12h, and let stand at room temperature. Afterwards, a certain amount of sodium alginate gel was dripped into a petri dish to a height of 0.5 cm, and dried at a temperature of 37°C and a relative humidity of 50% for at least 24 hours.

[0047] b Preparation of the upper hydrogel loaded with drugs

[0048] Dissolve 15g of aloe vera in 100mL of distilled water, stir at room temperature until completely dissolved; then add appropriate amount of aloe vera solution to sodium alginate according to different mass ratios (A / SA mass ratios: 1, 3, 5), In the solution, aloe / sodium alginate mixtures with different mass ratios were prepared respectively, stirred and reacted at room temperature for 2 hours, exhausted for 24 hours, and left standing at room temperature for later use.

[0049] c Prepar...

Embodiment 3

[0056] a Dissolve 5g of sodium alginate powder in 100mL of distilled water, stir at room temperature until completely dissolved, add 6mL of plasticizer glycerin during stirring, exhaust for 12h, and stand at room temperature. Afterwards, a certain amount of sodium alginate gel was dripped into a petri dish to form a height of 0.5 cm, and dried at a temperature of 37°C and a relative humidity of 50% for at least 24 hours.

[0057] b Preparation of the upper hydrogel loaded with drugs

[0058] Dissolve 25g of aloe vera in 100mL distilled water, stir at room temperature until completely dissolved; then add appropriate amount of aloe vera solution to sodium alginate according to different mass ratios (A / SA mass ratios: 1, 3, 5), In the solution, aloe / sodium alginate mixtures with different mass ratios were prepared respectively, stirred and reacted at room temperature for 2 hours, exhausted for 24 hours, and left standing at room temperature for later use.

[0059] c Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com