Vertical connected plate type unballasted track cement emulsified bitumen mortar

A technology of cement emulsified asphalt and slab ballastless track, which is applied in the field of cement emulsified asphalt mortar, can solve the problems of complex environment and climatic conditions, and German technology cannot fully adapt to the environment and climatic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

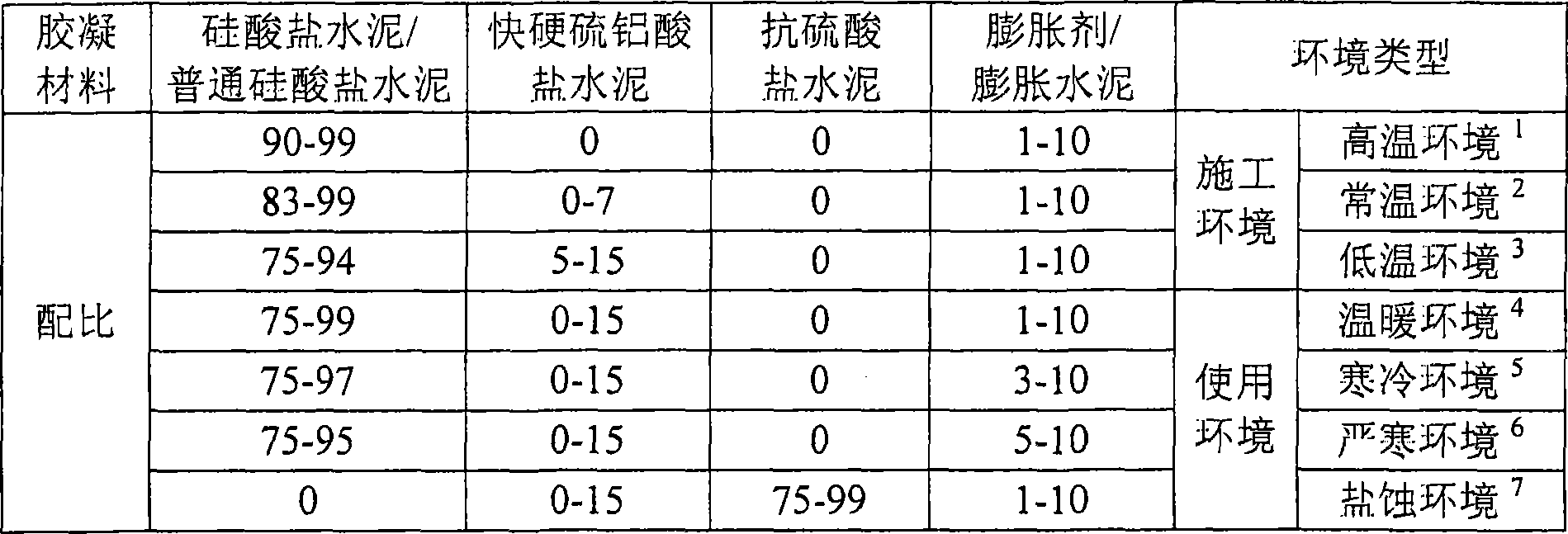

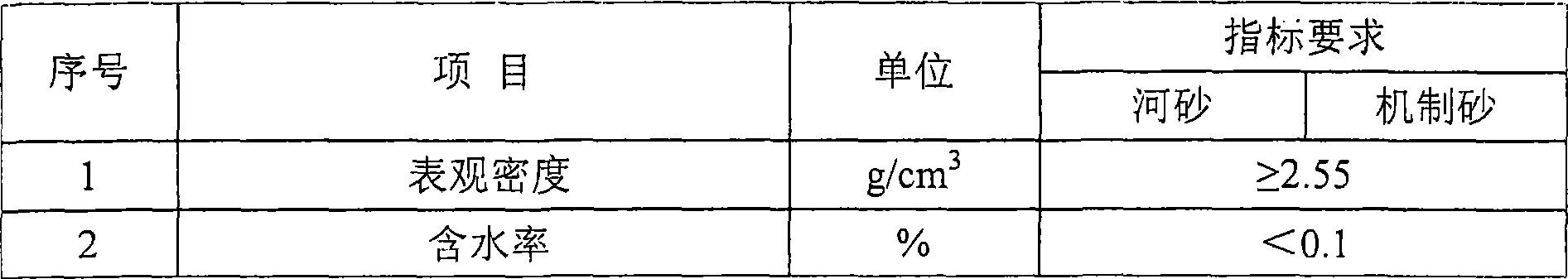

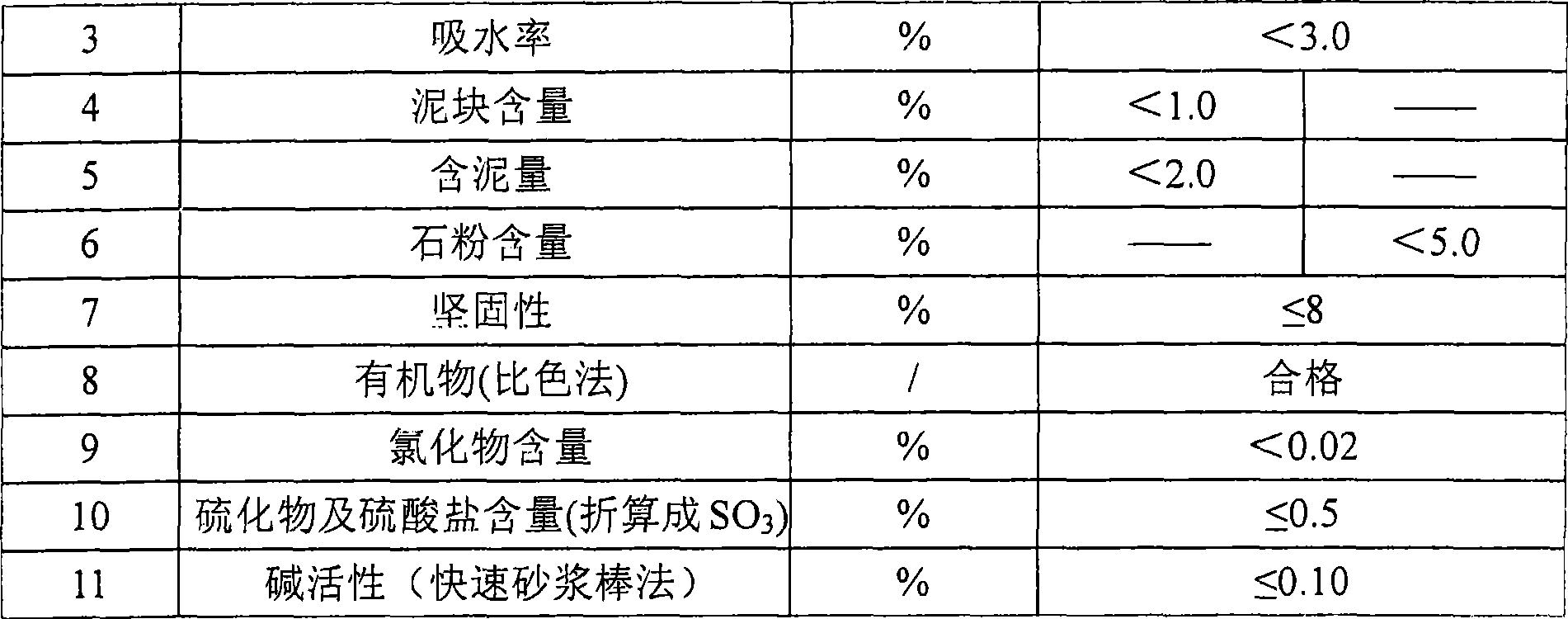

[0057] The proportioning of the cement emulsified asphalt mortar of embodiment 1-3, the composition and proportioning of dry material adopted, the composition and proportioning of emulsified asphalt adopted are shown in table 6, table 7, table 8 and table 9 respectively .

[0058] The preparation method of the cement emulsified asphalt mortar of embodiment 1-3 is as follows:

[0059] Add the emulsified asphalt into the propeller mixer with adjustable speed, stir at a low speed (20rpm) for 5s, then add water, water reducer and defoamer in turn, stir at a low speed (20rpm) for 5s, then add the dry material, and then With the increase of the amount of dry material added, the rotation speed of the agitator was gradually increased to 700rpm.

[0060] After all the dry materials are added, stir rapidly (rotating speed 700rpm) for 60s, then stir at low speed (rotating speed 100rpm) for 120s to obtain cement emulsified asphalt mortar.

[0061] The dry material used can be prepared b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com