Mesoporous calcium magnesium silicate/polylactic acid composite material as well as preparation method and use thereof

A technology of mesoporous calcium magnesium silicate and composite materials, which is applied in the field of mesoporous calcium magnesium silicate/polylactic acid composite materials and its preparation and application, can solve the problem that bone repair materials are difficult to have both biodegradable osseointegration effects and mechanical Performance and other issues, to achieve good biocompatibility and degradation performance, moderate mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

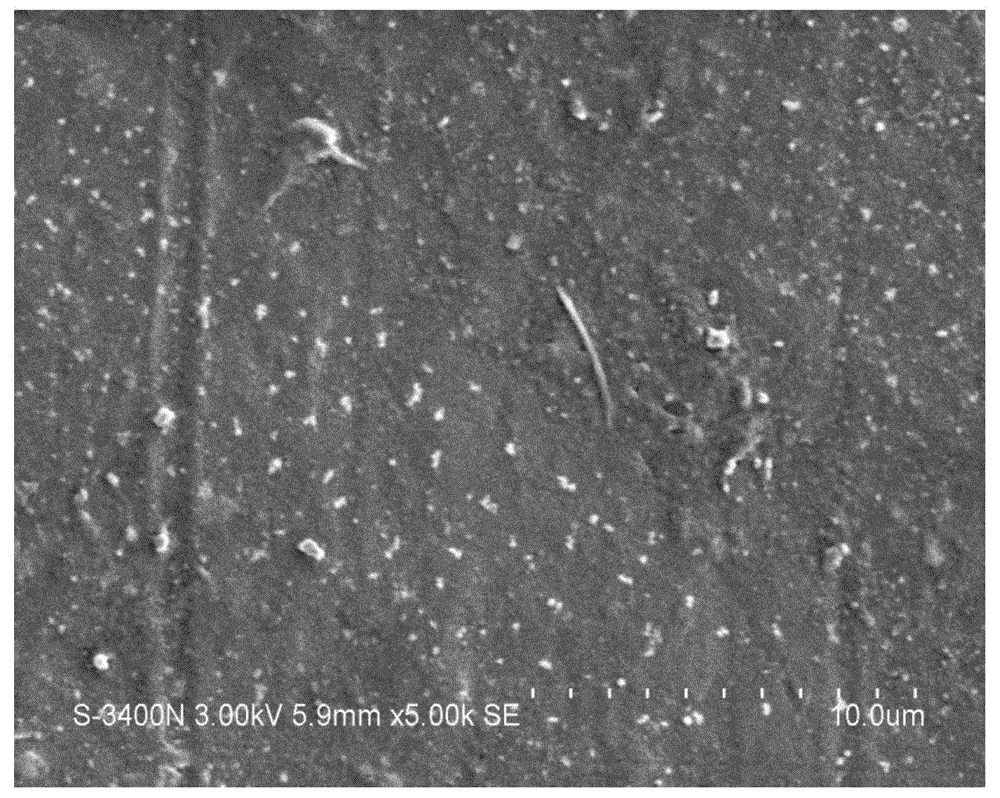

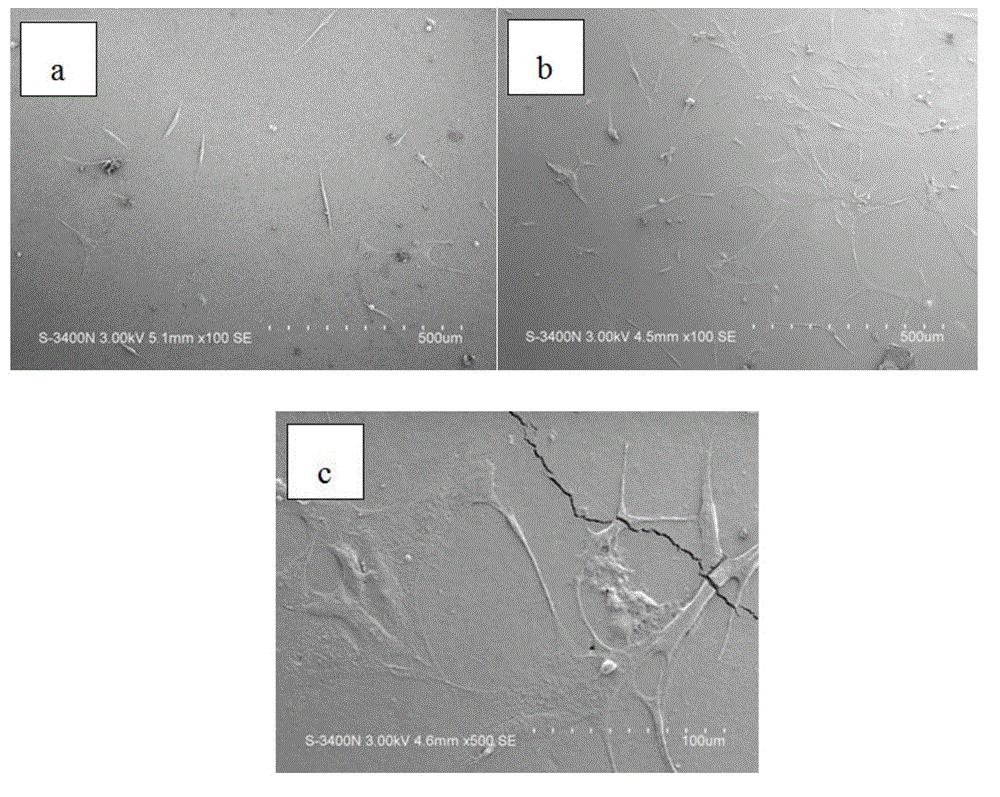

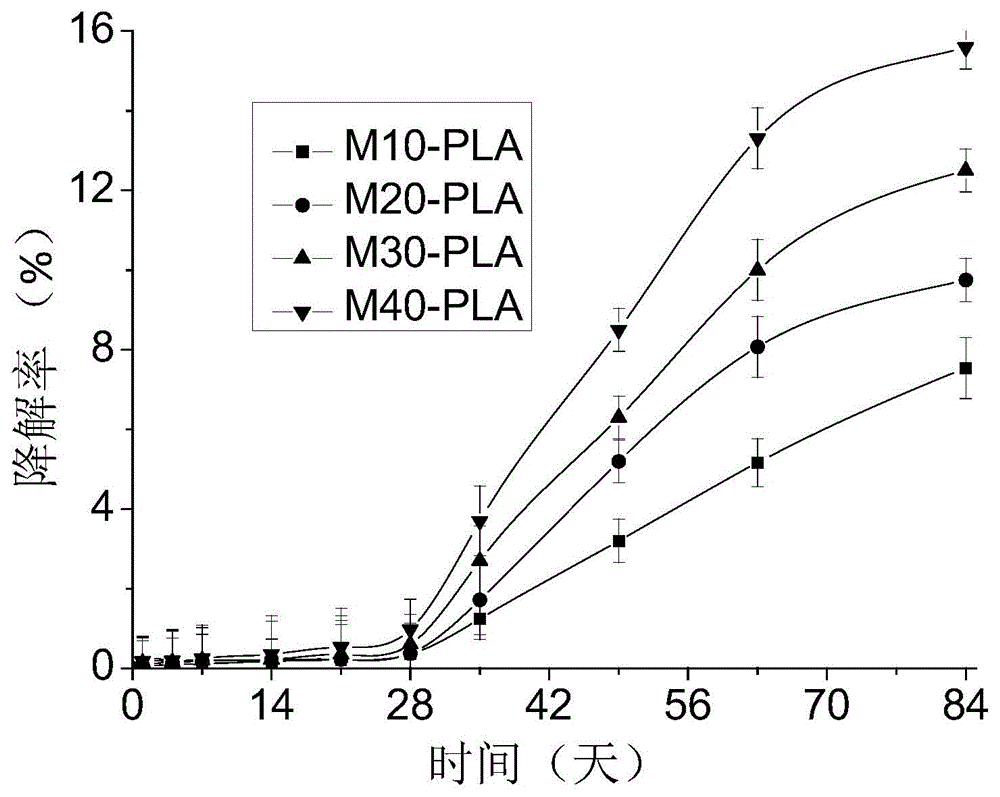

[0029] A method for preparing a mesoporous calcium magnesium silicate / polylactic acid composite material, comprising the steps of: drying 90 parts by weight of L-polylactic acid and 10 parts by weight of mesoporous calcium magnesium silicate at 90°C for 6 hours , mixed evenly in a high-speed mixer, melt-blended with an open mill, and formed, and then ready; wherein, the opening temperature is 180° C., and the opening time is 15 minutes.

Embodiment 2

[0031] A method for preparing a mesoporous calcium magnesium silicate / polylactic acid composite material, comprising the following steps: drying 80 parts by weight of D-polylactic acid and 20 parts by weight of mesoporous calcium magnesium silicate at 120°C for 6 hours , mixed evenly in a high-speed mixer, melted and blended with an internal mixer, and formed; wherein, the internal mixer temperature is 180°C, the internal mixer time is 10 minutes, and the internal mixer speed is 60rpm.

Embodiment 3

[0033] A method for preparing a mesoporous calcium magnesium silicate / polylactic acid composite material, comprising the steps of: drying 70 parts by weight of L-polylactic acid and 30 parts by weight of mesoporous calcium magnesium silicate at 100°C for 6 hours , mixed uniformly in a high-speed mixer, melt blended by a twin-screw extruder, and formed; wherein, the barrel temperature of each section of the extruder is 140-200 ° C, and the speed of the extruder is 100 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com