Bioactive antioxidant polysalicylic acid hydrogel as well as preparation method and application thereof

A polysalicylic acid, bioactive technology, applied in the direction of organic active ingredients, drug combinations, pharmaceutical formulations, etc., can solve problems such as unfavorable clinical applications, complex multi-component compositions, etc. The effect of preventing damage to the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention is committed to preparing a biocompatibility and functional properties, biocompatibility, ultraviolet shielding performance and anti-oxidation performance. The preparation method comprises the following steps:

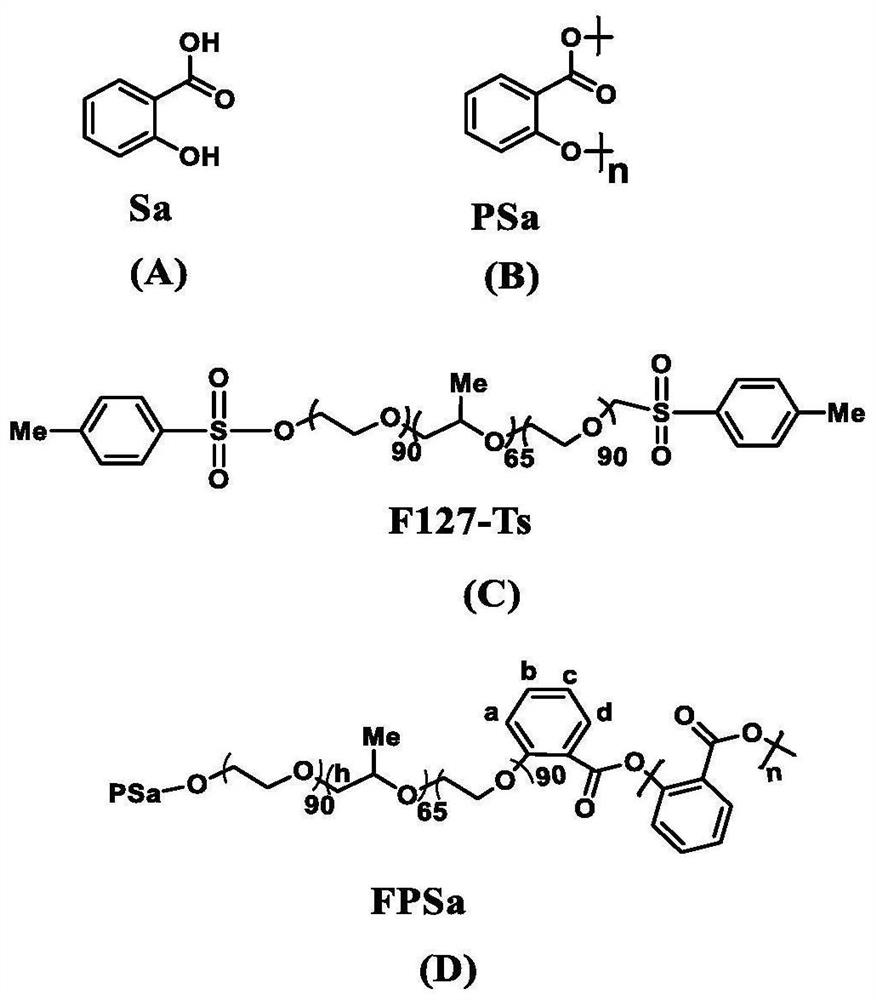

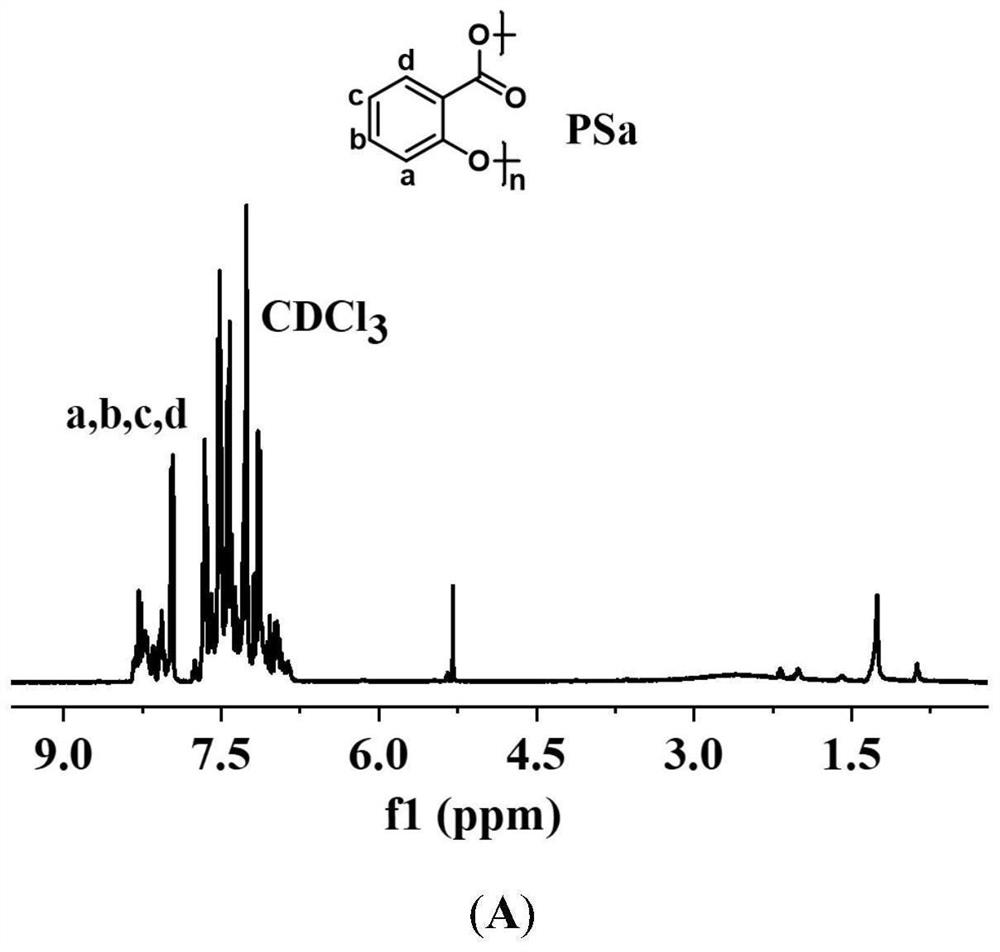

[0034] 1) Preparation of PSa polymer: Dissolving salicylic acid (Sa) in dichloromethane, reacting with thionyl chloride and pyridine as a catalyst to obtain PSa polymer, the structural formula is as follows:

[0035]

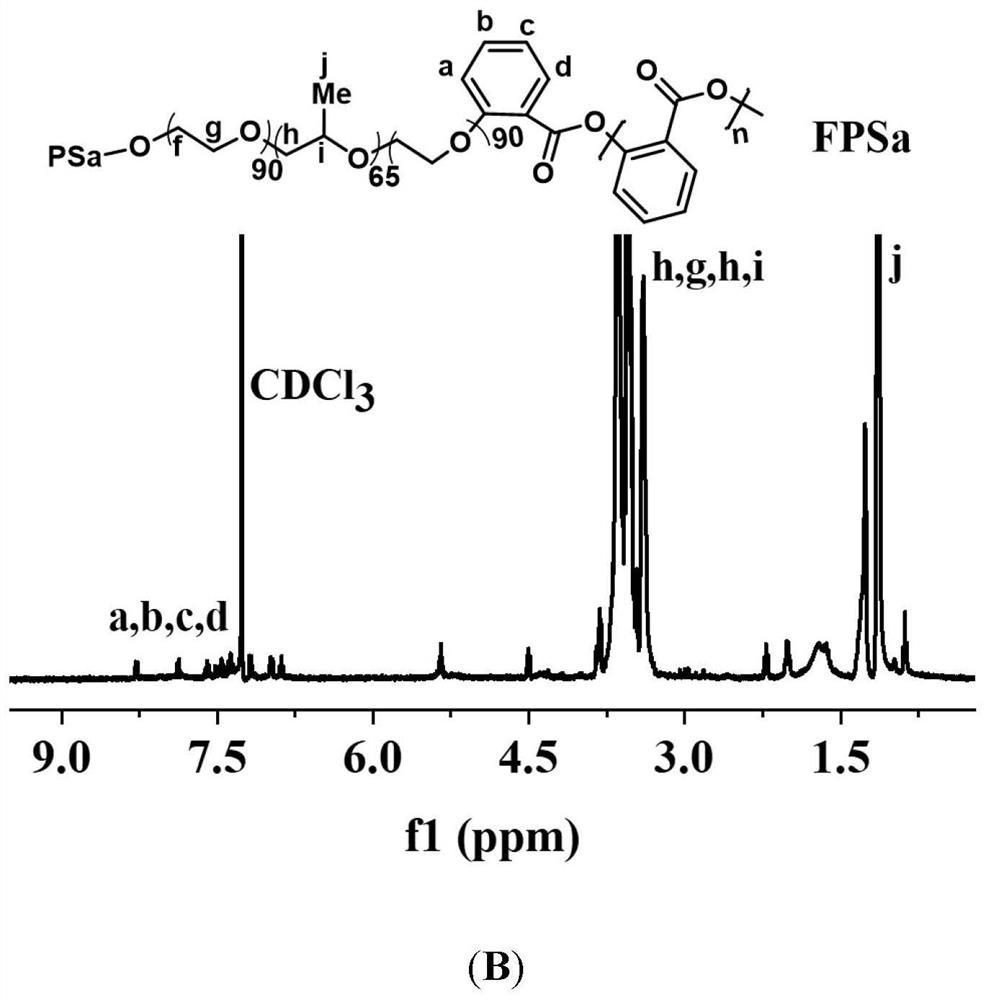

[0036] 2) Preparation of FPSa polymer: dissolve the above-mentioned synthesized PSa polymer and formylated poloxamer polymer (F127-Ts) in N,N-dimethylformamide, and use K 2 CO 3 React as catalyst, obtain FPSa polymer, structural formula is as follows:

[0037]

[0038] 3) Preparation of FPSa hydrogel: dissolve the FPSa polymer synthesized by the appeal in deionized water with a mass fraction of 20-50% at 0-10°C, and stir at this temperature for 2-5 hours to completely dissolve FPSa in In deionized water, after stirri...

Embodiment 1

[0041] 1) Preparation of PSa polymer: Dissolve 10 mmol of salicylic acid monomer in dry dichloromethane, add 10 mmol of dry thionyl chloride and stir at room temperature for 5 min, then add 10 mmol of dry pyridine and react at 30°C for 12 h, finally The product was extracted with 10% dilute hydrochloric acid (3*100 mL), washed with saturated brine, and finally rotated to obtain a polymer.

[0042] 2) Preparation of FPSa polymer: dissolve the formylated poloxamer polymer (F127-Ts) and PSa polymer synthesized above in DMF at a molar ratio of 1:2, and finally add F127-Ts polymer and K 2 CO 3 The molar ratio of 1:3 was used as a catalyst, and the reaction was carried out at 80°C for 36 hours. The final product was purified by dialysis and freeze-dried to obtain a polymer.

[0043] 3) Preparation of FPSa hydrogel: Dissolve the FPSa polymer synthesized above in deionized water at 4°C with a mass fraction of 20%, and stir at this temperature for 3 hours to completely dissolve FPSa i...

Embodiment 2

[0045]1) Preparation of PSa polymer: Dissolve 10 mmol of salicylic acid monomer in dry dichloromethane, add 20 mmol of dry thionyl chloride and stir at room temperature for 5 min, then add 20 mmol of dry pyridine and react at 3°C for 12 h, finally The product was extracted with 10% dilute hydrochloric acid (3*100 mL), washed with saturated brine, and finally rotated to obtain a polymer.

[0046] 2) Preparation of FPSa polymer: dissolve the formylated poloxamer polymer (F127-Ts) and PSa polymer synthesized above in DMF at a molar ratio of 1:2, and finally add F127-Ts polymer and K 2 CO 3 The molar ratio of 1:3 was used as a catalyst, and the reaction was carried out at 80°C for 36 hours. The final product was purified by dialysis and freeze-dried to obtain a polymer.

[0047] 3) Preparation of FPSa hydrogel: Dissolve the FPSa polymer synthesized above in deionized water at 4°C with a mass fraction of 20%, and stir at this temperature for 3 hours to completely dissolve FPSa i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com