Polyvinyl chloride compound for industrial pipeline and preparation method thereof

A technology for polyvinyl chloride and industrial pipes, applied in the field of polymer compound modification, can solve the problems of poor long-term stability and decreased mechanical properties of PVC pipes, and achieve the effects of prolonging service life, good ultraviolet shielding and reducing aging rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation of modified calcium-zinc stabilizers:

[0028] KH570 was dissolved in anhydrous acetone and stirred evenly to form a KH570-acetone solution with a concentration of 35wt.%, and then added a hydrotalline calcium-zinc stabilizer powder (trade name QF180) and ultrasonically dispersed for 15-20min, and the silanized calcium-zinc stabilizer powder was obtained by vacuum filtering and low temperature drying (30-40 °C); among which the mass ratio of the hydrotalline calcium-zinc stabilizer powder to KH570 was 1:5.

[0029] The calcium silylated calcium zinc stabilizer powder was placed in a part of the toluene solvent (60wt.% of the total amount of toluene solvent, and the amount of toluene solvent was 4 times the total amount of the silylated calcium zinc stabilizer powder and the total amount of hydroxyl functional monomers) and stirred to form a silylated calcium zinc stabilizer-toluene mixture, and then the heat initiator (the heat initiator is AIBN, the dosage is 1...

specific Embodiment

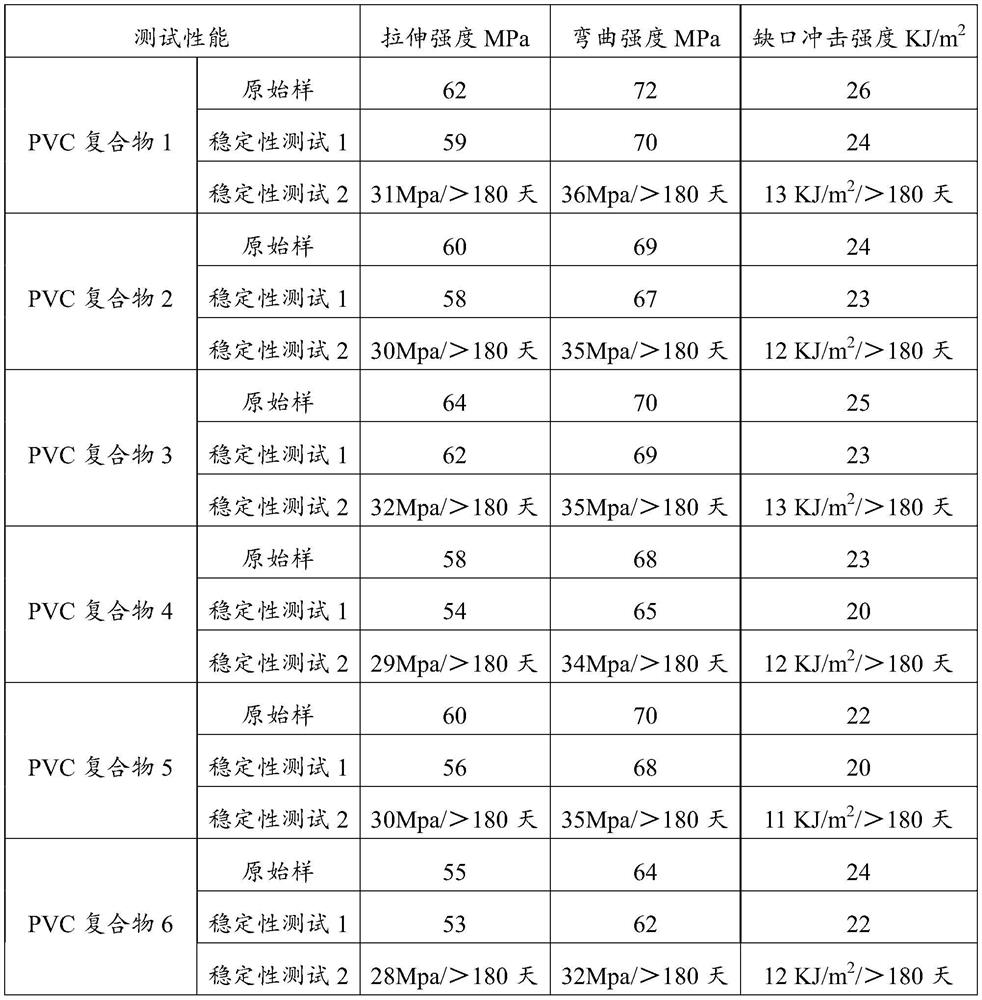

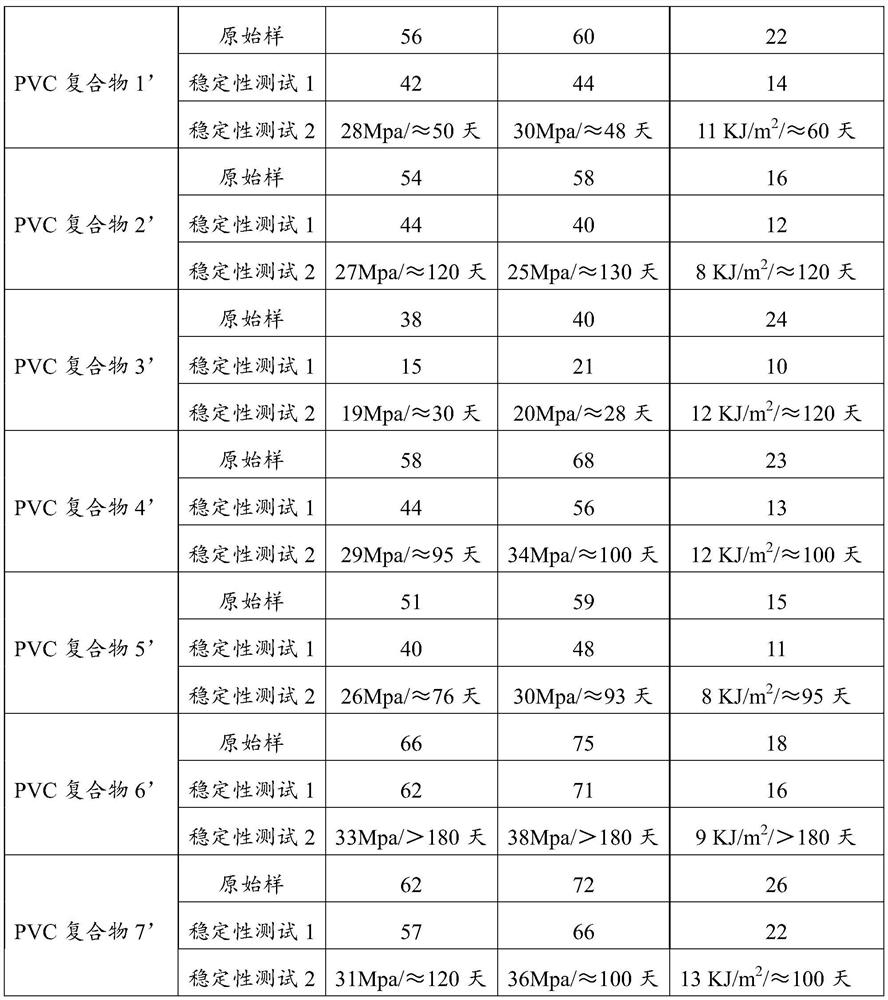

[0033] Specific embodiments: preparation of polyvinyl chloride composite 1-7.

[0034]According to the dosage of the formula described in Table 1 below, the polyvinyl chloride composite is prepared by the following preparation process.

[0035] Preparation process A: according to the ratio described in Table 1 to weigh each component, and then the polyvinyl chloride resin, chlorinated polyvinyl chloride resin and modified calcium and zinc stabilizer was added to the high-speed mixer, and then the hot mixing was uniform at 50-60 °C; then the calcium carbonate and modified titanium dioxide type additives were added to it at 80 °C-85 °C after hot mixing uniformly for 1-2h; finally, when the material was cooled to room temperature, lubricants, antistatic agents, pigments, antioxidants and PVC processing aids were added and mixed evenly, The polyvinyl chloride composite for industrial pipelines was obtained.

[0036] The following specific embodiments and proportional polyvinyl chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com