Acrylic fiber, staple yarn comprising same, and knitted fabric

A technology of acrylic fibers and knitted fabrics, applied in knitting, fiber treatment, weft knitting, etc., can solve the problems of reduced commerciality and damage to appearance, and achieve excellent anti-pilling, ultraviolet shielding performance and excellent anti-pilling , Excellent UV shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

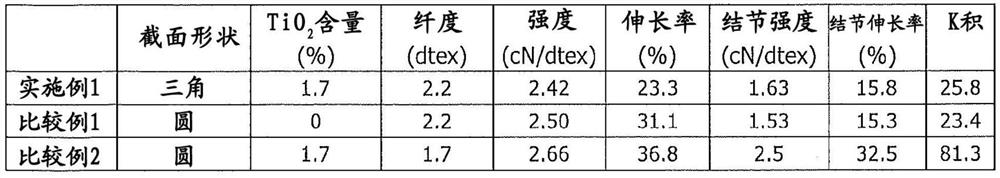

Embodiment 1

[0097] A copolymer composed of 93% by mass of acrylonitrile units and 7% by mass of vinyl acetate units was obtained by aqueous suspension polymerization. The reduced viscosity at 25° C. of a 0.5% by mass dimethylformamide solution of this copolymer was 2.0.

[0098] This copolymer was dissolved in dimethylacetamide to obtain an acrylonitrile copolymer solution having a copolymer concentration of 24% by mass. A dispersion containing and dispersing 20% by mass of titanium hexoxide with an average particle diameter of 0.6 μm in dimethylacetamide was added to the acrylic fiber so that the content of titanium oxide in the final acrylic fiber was 1.7% by mass. Nitrile copolymer solution to make spinning dope.

[0099] The above-mentioned spinning stock solution was adjusted to 75°C, and extruded from an equilateral triangle-shaped discharge hole of 80 μm on one side into a coagulation solution of 35% by mass of dimethylacetamide and a temperature of 40°C for wet spinning, follow...

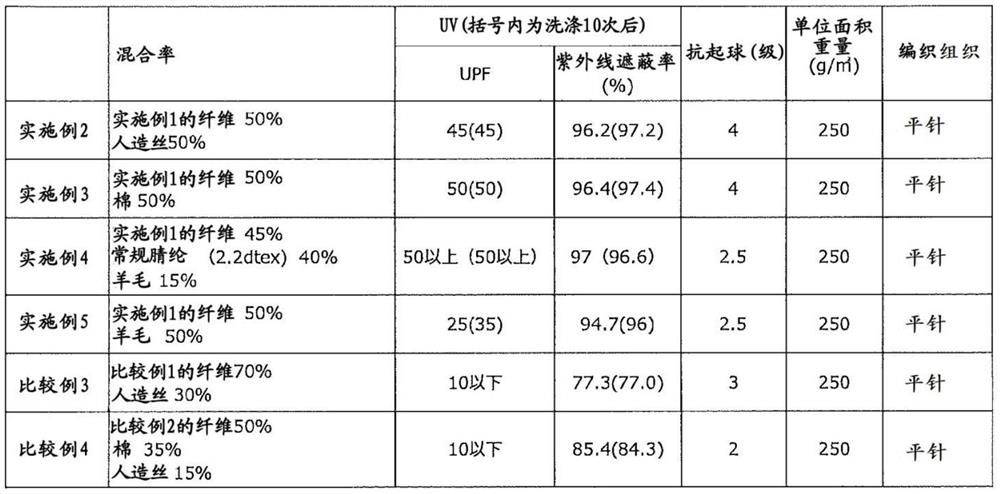

Embodiment 2~5

[0110] The fiber obtained in Example 1 is cut into 38mm, and according to the mixing ratio recorded in Table 2, it is spun into 30 / 2 spun yarn in terms of cotton yarn count by spinning through 2 inches, and it is braided using a 14-gauge circular knitting machine After forming a plain stitch, it is dyed with off-white by conventional methods, and the weight per unit area is 250g / m 2 of knitted fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com