Multilayer film and its manufacturing method

A manufacturing method and multi-layer film technology, which can be used in chemical instruments and methods, layered products, flat products, etc., can solve the problems of insufficient heat and humidity resistance of triacetyl cellulose, and performance degradation of polarizing plates, and achieve excellent Excellent effect of UV shielding performance, mechanical strength, and surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

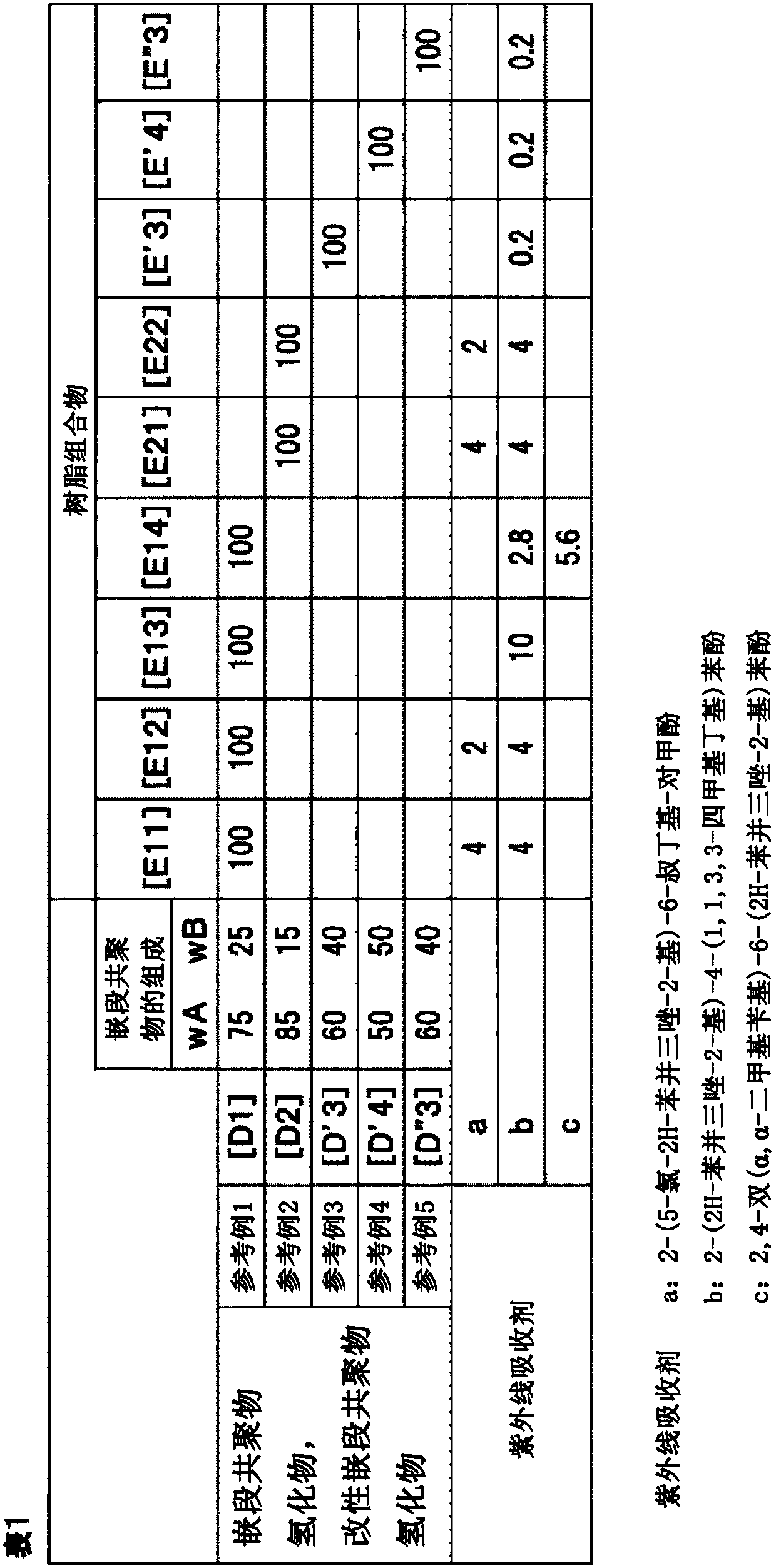

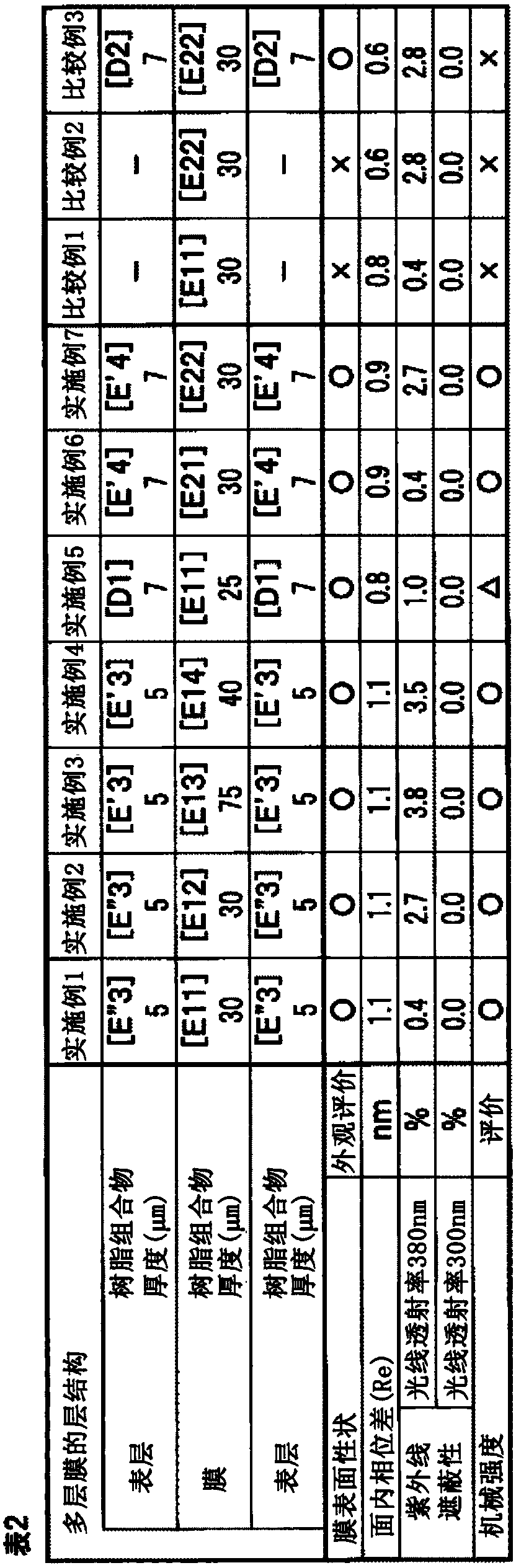

[0121] The present invention will be described in more detail while showing examples, but the present invention is not limited to the following examples. In addition, unless otherwise specified, "part" and "%" are based on weight.

[0122] The evaluation of this Example was performed by the following method.

[0123] (1) Weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn)

[0124] The molecular weights of the block copolymer and the hydrogenated product of the block copolymer were measured at 38° C. by GPC using THF as an eluent as a value in terms of standard polystyrene. As a measuring device, HLC8020GPC manufactured by TO SOH Co., Ltd. was used.

[0125] (2) Hydrogenation rate

[0126] Determination of hydrogenation rate of main chain, side chain and aromatic ring of hydrogenated block copolymer 1 H-NMR spectrum was calculated.

[0127] (3) Membrane surface properties

[0128] The surface appearance of the extruded film was observed and eval...

reference example 1

[0136] ・Manufacture of hydrogenated block copolymer [D1]

[0137] (Manufacture of block copolymer [C1])

[0138] 550 parts of dehydrated cyclohexane, 37.5 parts of dehydrated styrene, and 0.475 parts of di-n-butyl ether were placed in a reactor equipped with a stirring device whose interior was sufficiently replaced with nitrogen. While stirring the entire contents at 60°C, 0.72 parts of a 15% cyclohexane solution of n-butyllithium was added to initiate polymerization. After completion of the dropwise addition of the n-butyllithium solution, the entire contents were further stirred at 60° C. for 60 minutes. The polymerization conversion rate at this time measured by gas chromatography was 99.5%.

[0139] Next, 25.0 parts of dehydrated isoprene was added to the reaction liquid, and stirring was continued for 30 minutes. At this point, the polymerization conversion rate was 99.5%.

[0140] Then, 37.5 parts of dehydrated styrenes were further added, and it stirred for 60 minu...

reference example 2

[0147] ・Manufacture of hydrogenated block copolymer [D2]

[0148] (Manufacture of block copolymer [C2])

[0149] Divide styrene and isoprene into 5 times, sequentially add 30.0 parts of styrene, 7.5 parts of isoprene, 25.0 parts of styrene, 7.5 parts of isoprene and 30.0 parts of styrene, except Except that, the polymerization reaction was performed in the same manner as in Reference Example 1, and the reaction was terminated. The obtained block copolymer [C2] had a weight average molecular weight (Mw) of 61600, a molecular weight distribution (Mw / Mn) of 1.06, and wA:wB=85:15.

[0150] (Manufacture of hydrogenated block copolymer [D2])

[0151] Next, the above polymer solution was hydrogenated in the same manner as in Reference Example 1. The weight average molecular weight (Mw) of the hydrogenated block copolymer [D2] after the hydrogenation reaction was 65300, and the molecular weight distribution (Mw / Mn) was 1.07.

[0152] After the completion of the hydrogenation react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com