A kind of highly transparent ultraviolet blocking polymer composition and its preparation method and application

A composition, a technology of transparent violet, applied in the field of highly transparent ultraviolet blocking polymer composition and preparation thereof, can solve the problems of uncontrollable melanin particle size, complicated operation, low transparency of functional film, etc. The effect of good transparency and excellent UV shielding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preparation of Hollow Polydopamine Nanoparticles

[0040] Preparation of hollow polydopamine nanoparticles 1: First, dopamine (provided by Aladdin Biochemical Technology Co., Ltd., specification: AR) was dissolved in water to form a solution (the concentration of dopamine was 50g L -1 ), and then polystyrene particles (BASF, with an average particle size of 100nm) were dispersed in the dopamine solution (the concentration of polystyrene was 150g·L -1 ), the mass ratio of dopamine and template agent is 1:3, adding NaOH solution to adjust the pH value of the solution to 8.5, stirring, separating and washing after 12 hours of reaction, and removing polystyrene by dissolving in tetrahydrofuran (Sinopharm Chemical Reagent Co., Ltd.) Nuclei were subsequently washed and dried under vacuum to obtain hollow poly Dopamine Nanoparticles 1 (The inner diameter is 100nm, the outer diameter is 110nm, and the polydopamine shell thickness is 5nm).

[0041] Preparation of hollow pol...

Embodiment 1

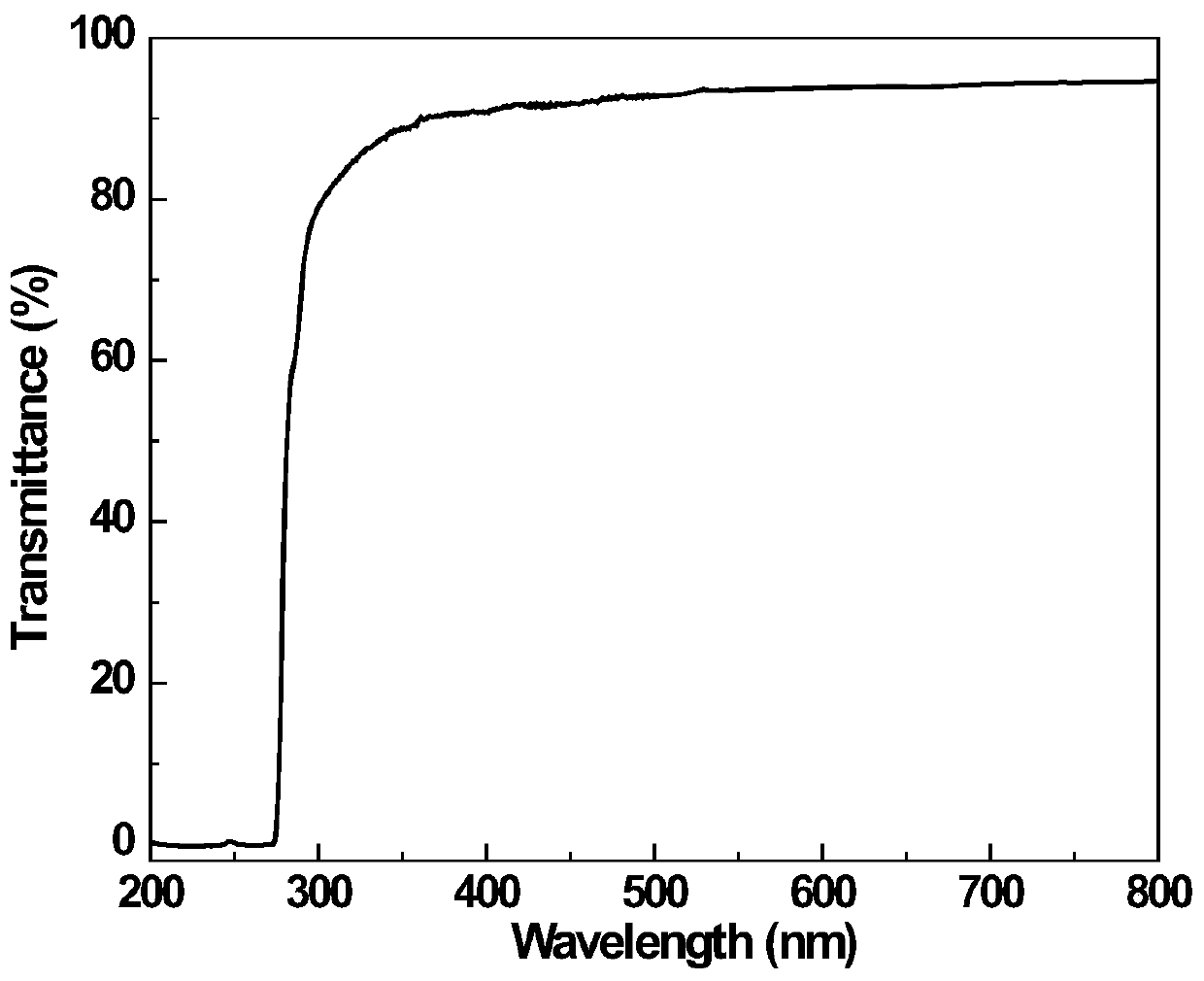

[0044] Take by weighing 1000g polycarbonate (Saudi Arabia Basic Plastics, model 141R-701), 5g hollow polydopamine rice grains 1 and 0.5g 4,4'-thiobis(6-tert-butyl-3-methylphenol) were first fully mixed in a high-speed mixer, and then the resulting premix was put into a twin-screw extruder for processing The temperature is controlled at 255° C., and the polycarbonate composition particles are obtained through melting, plasticizing and granulating. Subsequently, the composition was vacuum-dried at 80° C. for 6 hours, and then hot-pressed (mould temperature 250° C.) to obtain a sample sheet with a thickness of 1.0 mm. The optical properties of the prepared samples were measured by a UV-2501 ultraviolet-visible photometer. The optical performance test results of the samples prepared in Example 1 are shown in Table 1. The UV-Vis spectrum of the polymer composite is shown in figure 2 shown.

Embodiment 2

[0048] Weigh 1000g polystyrene (Taiwan Chi Mei, model PG-33) and 10g Hollow polydopamine nanoparticles 2 First, fully mix uniformly in a high-speed mixer, then put the obtained premixed material into a twin-screw extruder, control the processing temperature at 160°C, and obtain polystyrene composition particles through melting, plasticizing and granulating. Subsequently, the composition was vacuum-dried at 80° C. for 6 hours, and then hot-pressed (mould temperature 250° C.) to obtain a sample sheet with a thickness of 1.0 mm. The optical performance test results of the samples prepared in Example 2 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com