Magnesium/hydroxyapatite composite material and preparation method thereof

A technology for hydroxyapatite and composite materials, which is applied in the field of preparing magnesium/hydroxyapatite composite materials by microwave sintering, can solve the problems of slow heating rate, large energy consumption and high equipment requirements, and achieves fast heating rate, The effect of low energy consumption and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

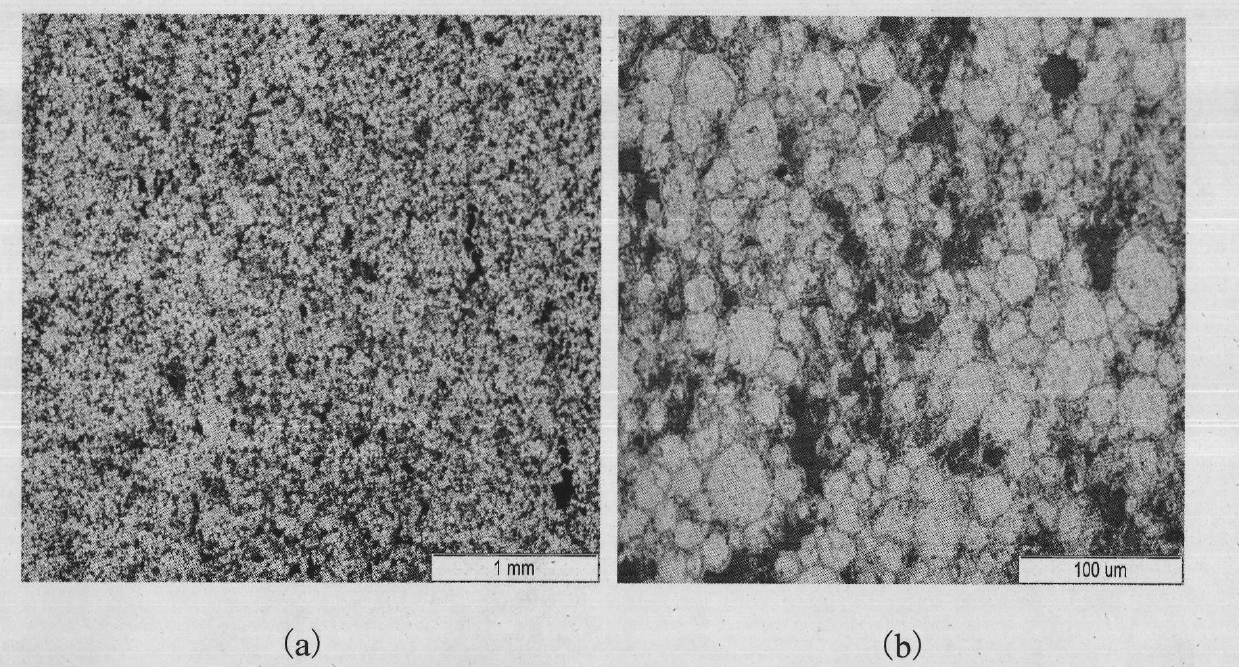

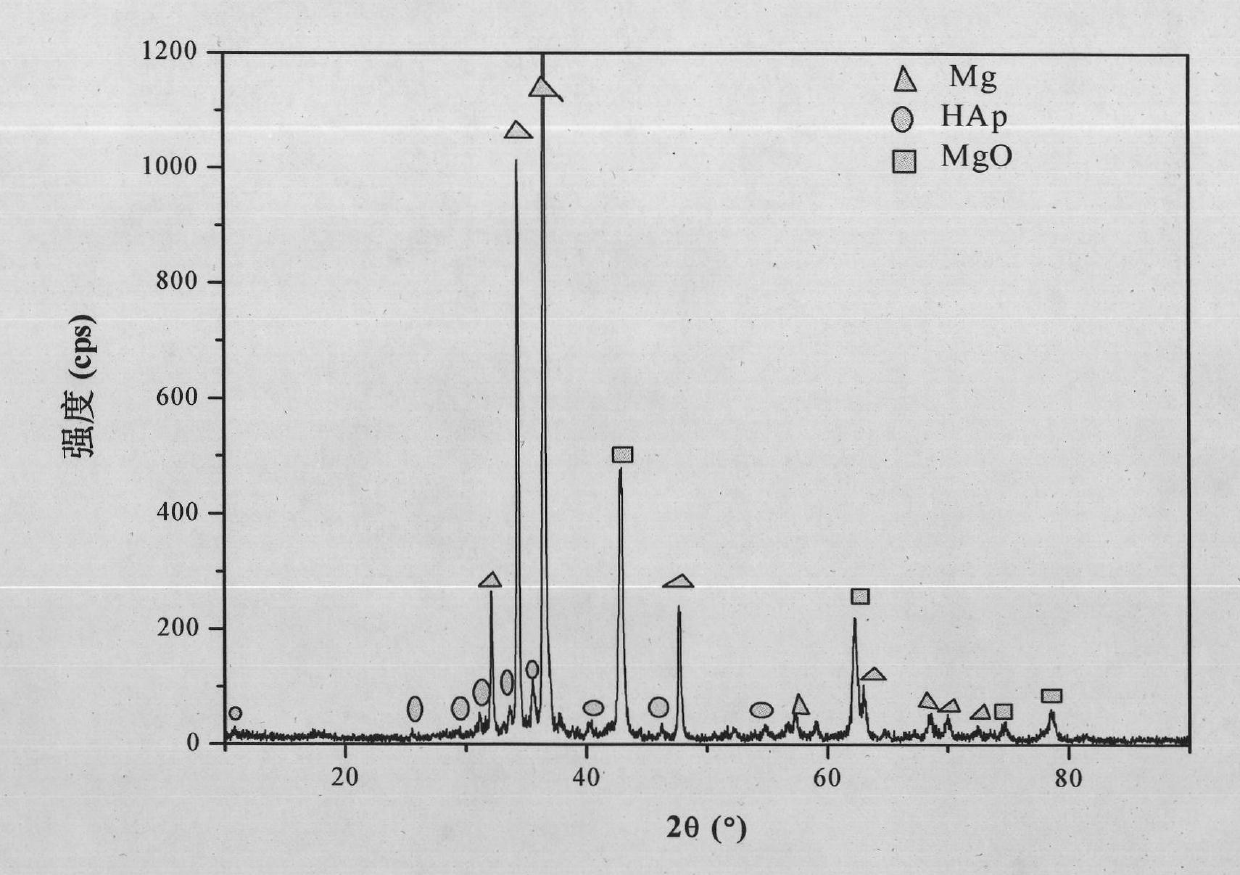

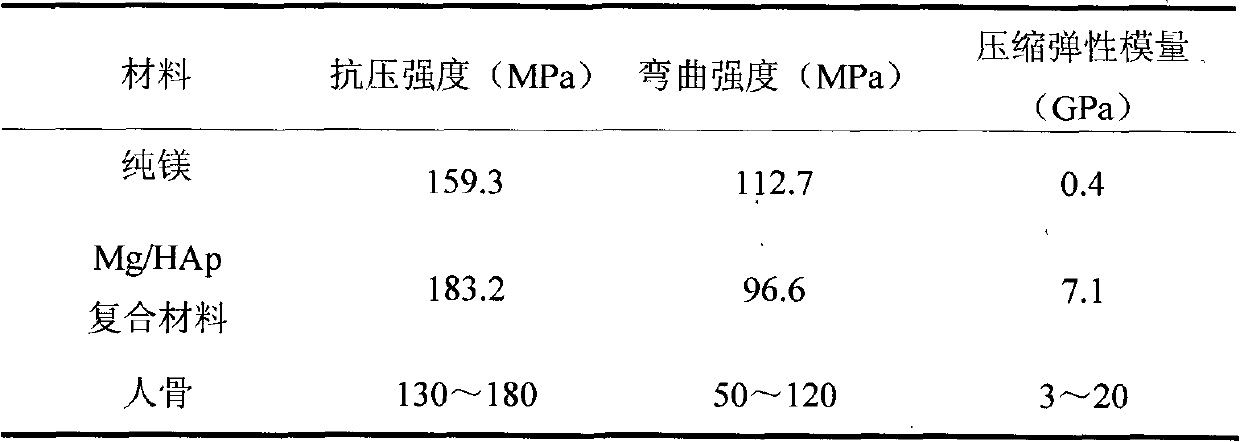

Embodiment 1

[0018] (1) The method of magnetic stirring is used to mix powder, the total mass of powder is 20g, the mass percentage of magnesium powder (purity 99.8%, particle size ≤ 80 μm), hydroxyapatite powder (purity 97.5%, particle size ≤ 80 μm) was 19.5%, the stirring speed was 1200 rpm, and magnetic stirring was performed for 4 hours.

[0019] (2) Dry the mixed powder in step (1) in a vacuum oven for 2 hours at a drying temperature of 60 degrees Celsius.

[0020] (3) The mixed powder in step (2) is cold-pressed into a mold, the size of the compressed sample is Φ11×12 mm, the size of the bent sample is 30×5×4 mm, and the pressure is 500 MPa.

[0021] (4) A ceramic tube is placed in the glass tube, silicon carbide is used as an auxiliary heating substance, and 5 grams of silicon carbide is placed between the ceramic tube and the glass tube. The sample is placed in a ceramic tube with an electrical insulating sheet at the bottom.

[0022] (5) Sinter the green body in step (3) in a va...

Embodiment 2

[0025] (1) The method of magnetic stirring is used to mix powder, the total mass of powder is 20g, the mass percentage of magnesium powder (purity 99.8%, particle size ≤ 80 μm), hydroxyapatite powder (purity 97.5%, particle size ≤ 80 μm) 5%, the stirring speed was 1200 rpm, and magnetic stirring was performed for 2 hours.

[0026] (2) Dry the mixed powder in step (1) in a vacuum oven for 2 hours at a drying temperature of 100 degrees Celsius.

[0027] (3) The mixed powder in step (2) is cold-pressed into a mold, the size of the compressed sample is Φ11×12 mm, the size of the bent sample is 30×5×4 mm, and the pressure is 450 MPa.

[0028] (4) A ceramic tube is placed in the glass tube, silicon carbide is used as an auxiliary heating substance, and 7 grams of silicon carbide is placed between the ceramic tube and the glass tube. The sample is placed in a ceramic tube with an electrical insulating sheet at the bottom.

[0029] (5) Sinter the green body in step (3) in a vacuum m...

Embodiment 3

[0032] (1) The method of magnetic stirring is used to mix powder, the total mass of powder is 20g, the mass percentage of magnesium powder (purity 99.8%, particle size ≤ 80 μm), hydroxyapatite powder (purity 97.5%, particle size ≤ 80 μm) 10%, the stirring speed was 1200 rpm, and magnetic stirring was performed for 2 hours.

[0033] (2) Dry the mixed powder in step (1) in a vacuum oven for 2 hours at a drying temperature of 100 degrees Celsius.

[0034] (3) The mixed powder in step (2) is cold-pressed into a mold, the size of the compressed sample is Φ11×12 mm, the size of the bent sample is 30×5×4 mm, and the pressure is 600 MPa.

[0035] (4) A ceramic tube is placed in the glass tube, silicon carbide is used as an auxiliary heating substance, and 7 grams of silicon carbide is placed between the ceramic tube and the glass tube. The sample is placed in a ceramic tube with an electrical insulating sheet at the bottom.

[0036] (5) Sinter the green body in step (3) in a vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com