Patents

Literature

99results about How to "Pure ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for porous nickel titanium/hydroxyapatite composite material

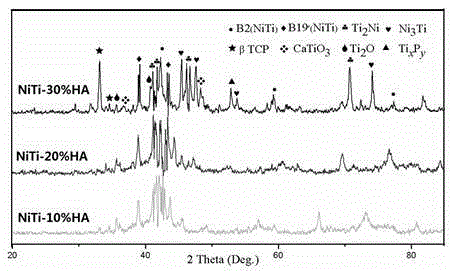

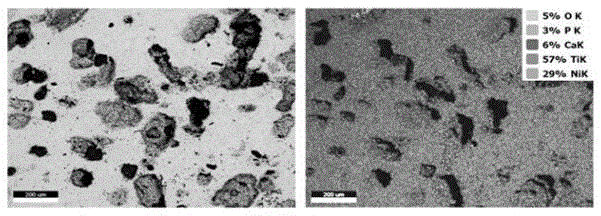

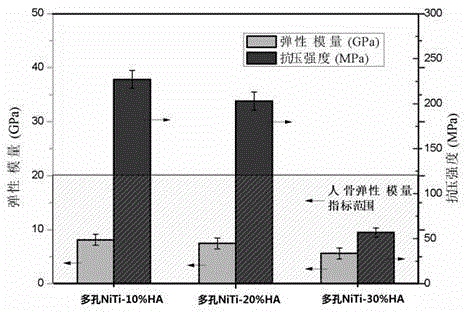

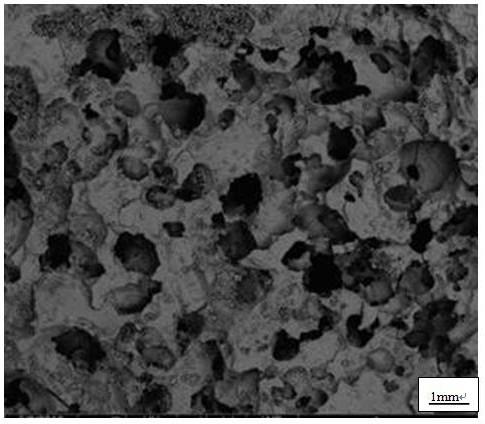

The invention relates to a preparation method for a porous nickel titanium / hydroxyapatite composite material, and belongs to the technical field of biomedical material preparing. The preparation method for the porous nickel titanium / hydroxyapatite composite material comprises the steps that firstly, nickel titanium mixed powder is obtained by mixing nickel metal powder and titanium metal powder evenly; secondly, the obtained nickel titanium mixed powder is mixed with hydroxyapatite powder, and nickel titanium / hydroxyapatite powder is obtained; thirdly, after the nickel titanium / hydroxyapatite powder is mixed with ammonium bicarbonate pore forming agent powder, a briquetted pressing blank is formed through mechanical compression and then put into a discharge plasma sintering furnace to be sintered; and fourthly, after sintering is completed, the briquetted pressing blank is cooled to the room temperature along the furnace, then the hyper-elastic porous nickel titanium / hydroxyapatite composite material is obtained. The porous nickel titanium / hydroxyapatite composite material prepared through the method has the advantages of being controllable in pore parameter, low in elasticity modulus, good in mechanical adaptability and the like; in addition, the porous nickel titanium / hydroxyapatite composite material is endowed with good biological activity and synosteosis capacity, so that the composite material is closer to the structure and functions of a human bone, and good biological adaptability is achieved; the material is particularly suitable for plastic surgery medical apparatus and instruments, marrow cavity implants and the like.

Owner:KUNMING UNIV OF SCI & TECH

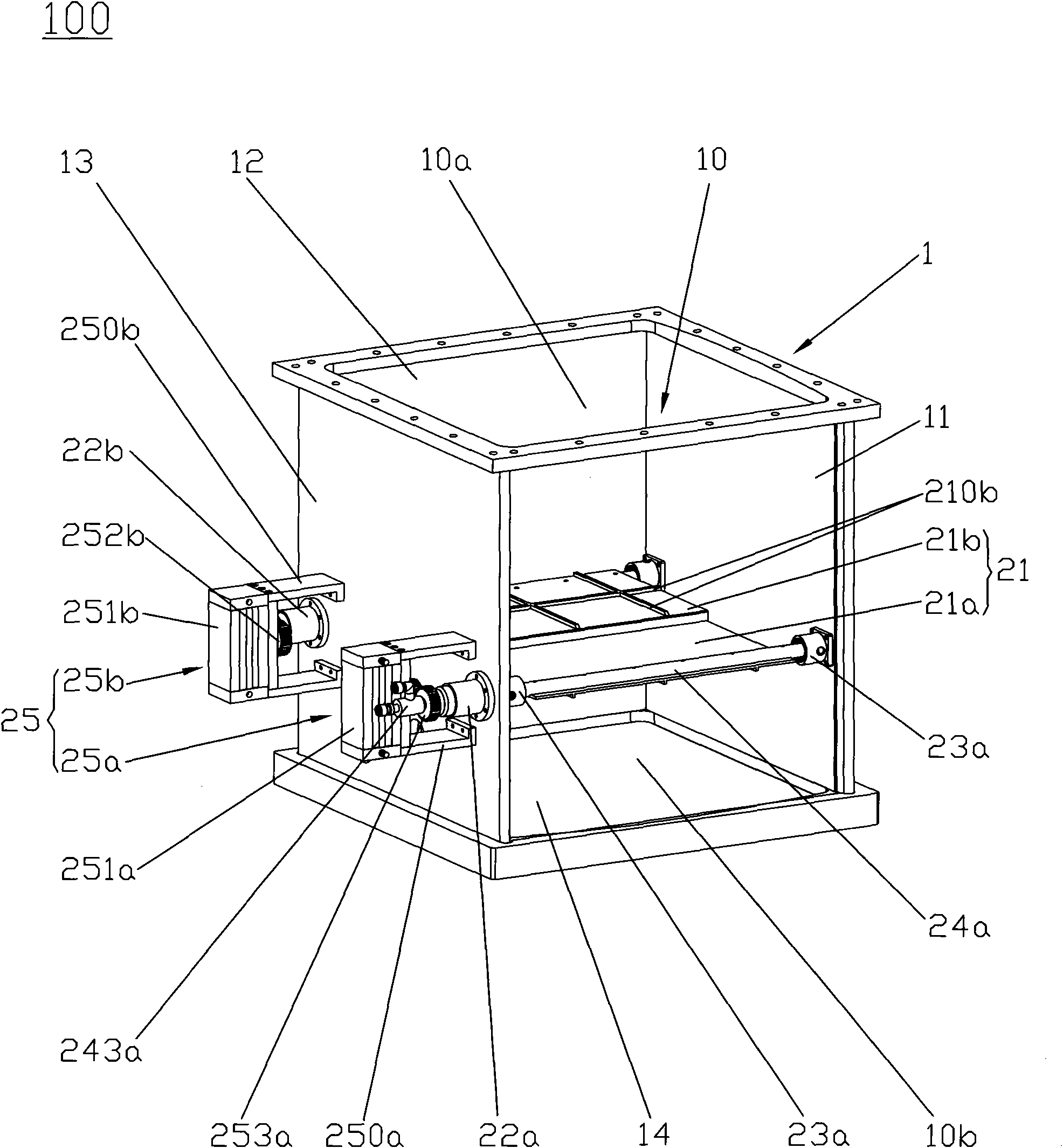

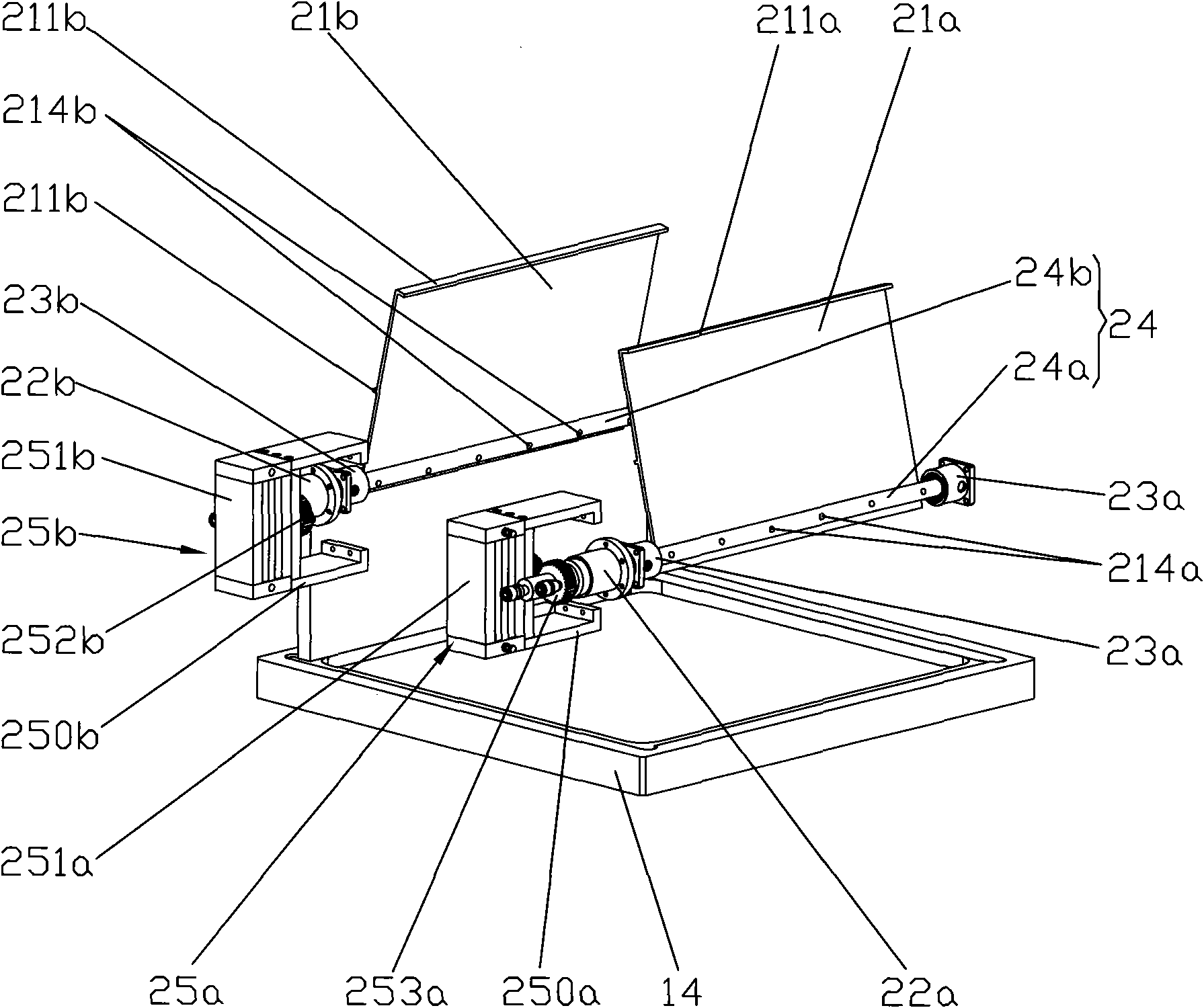

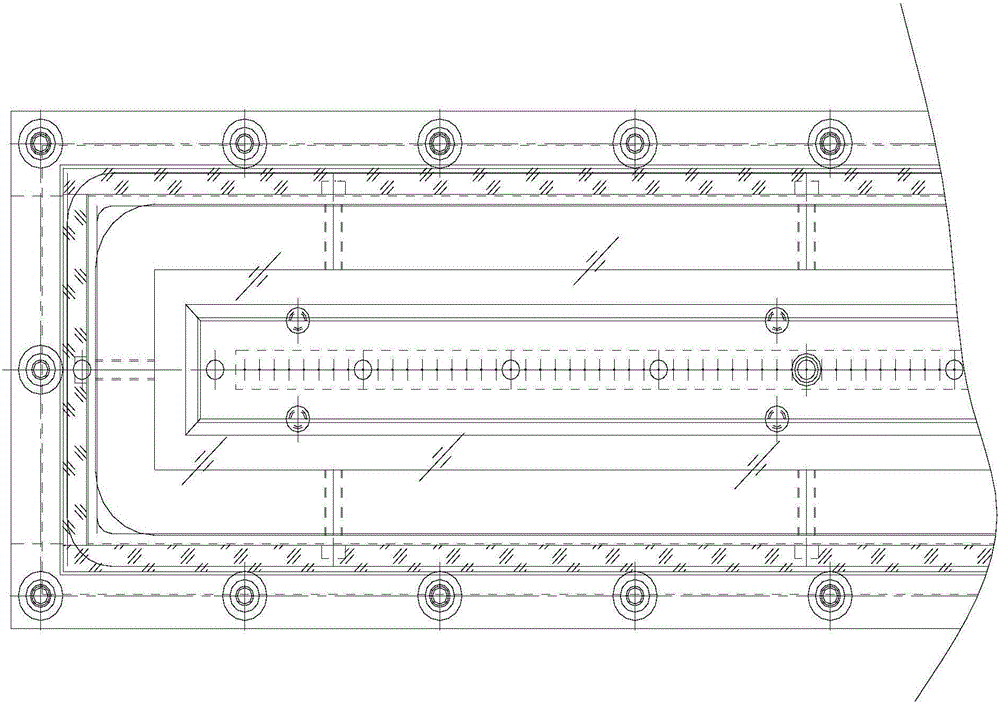

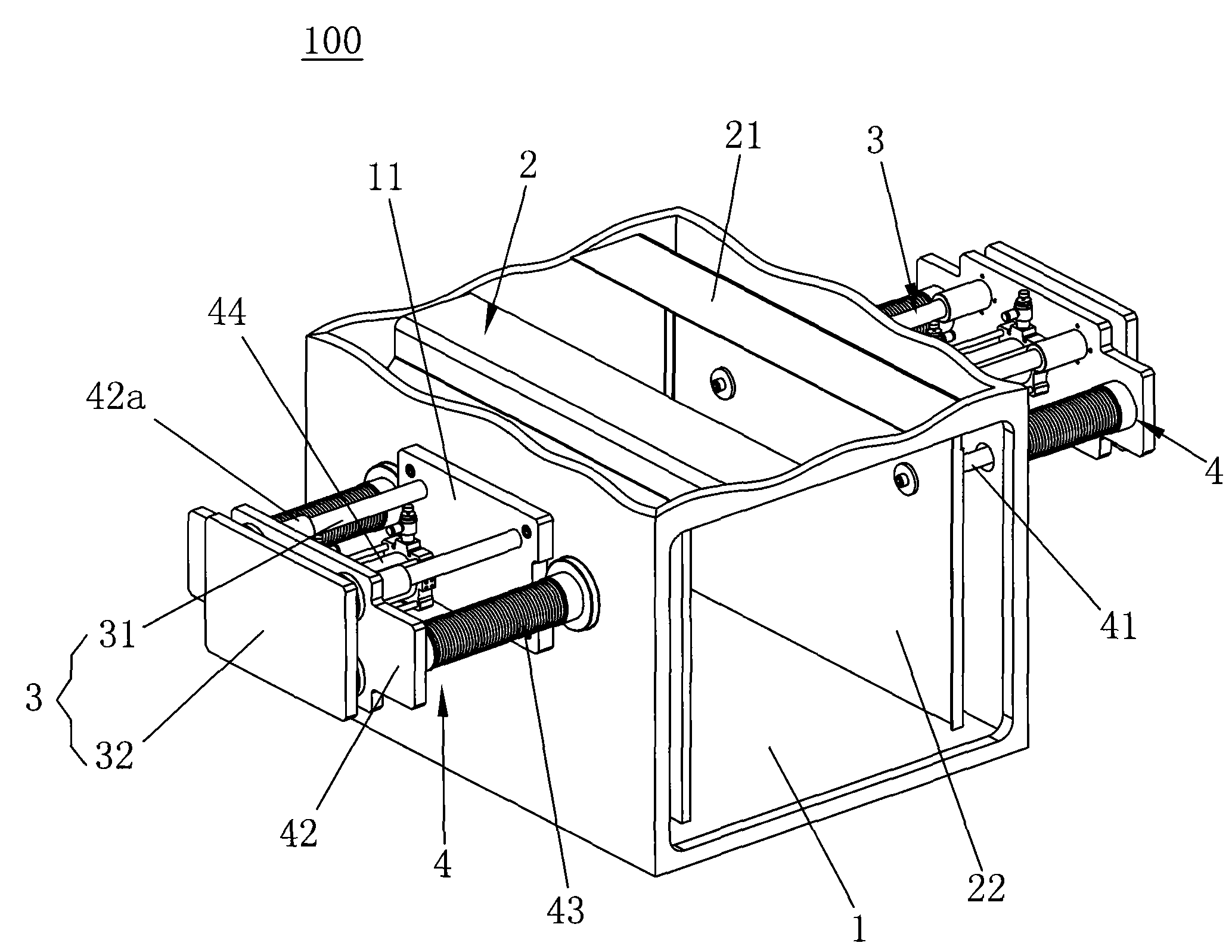

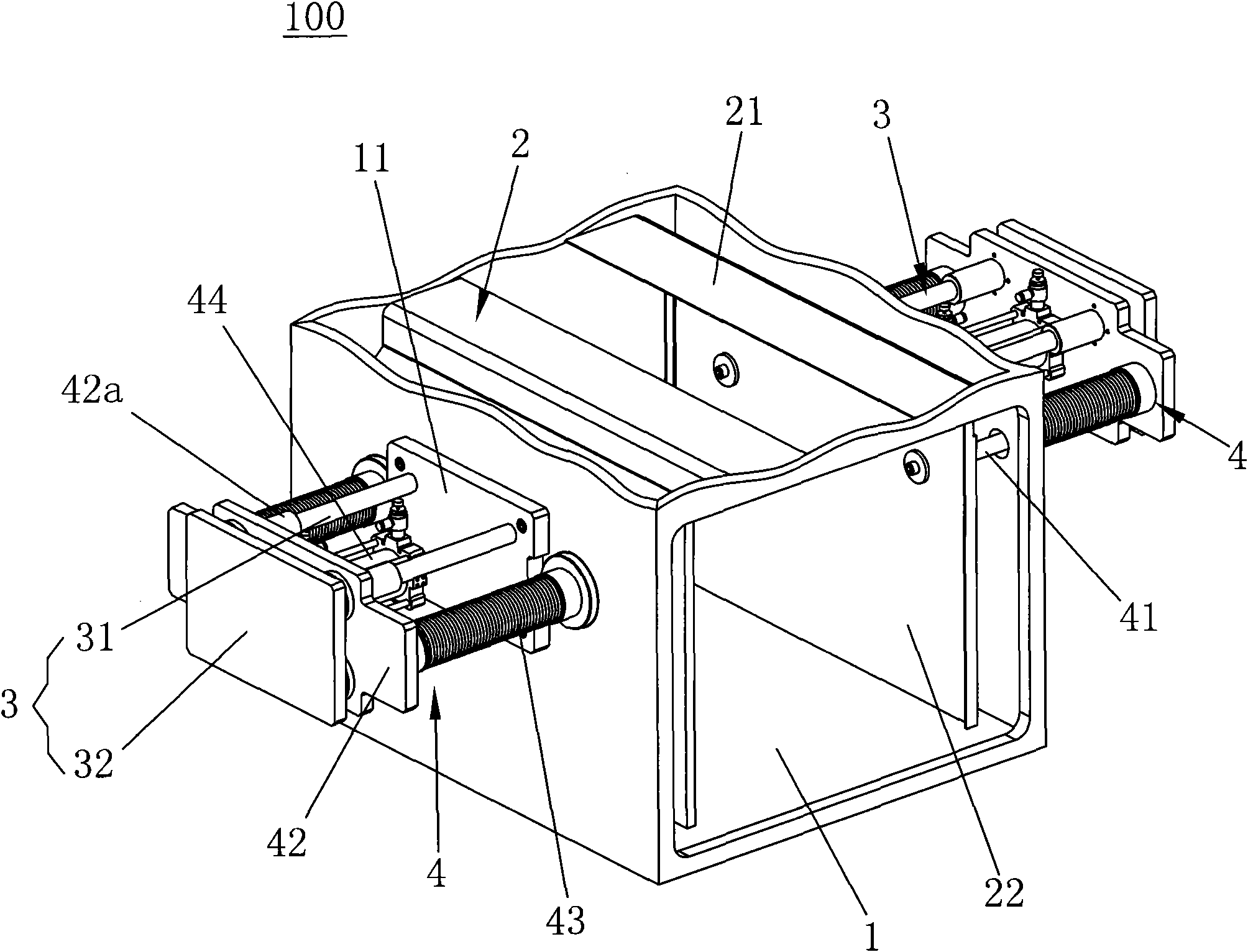

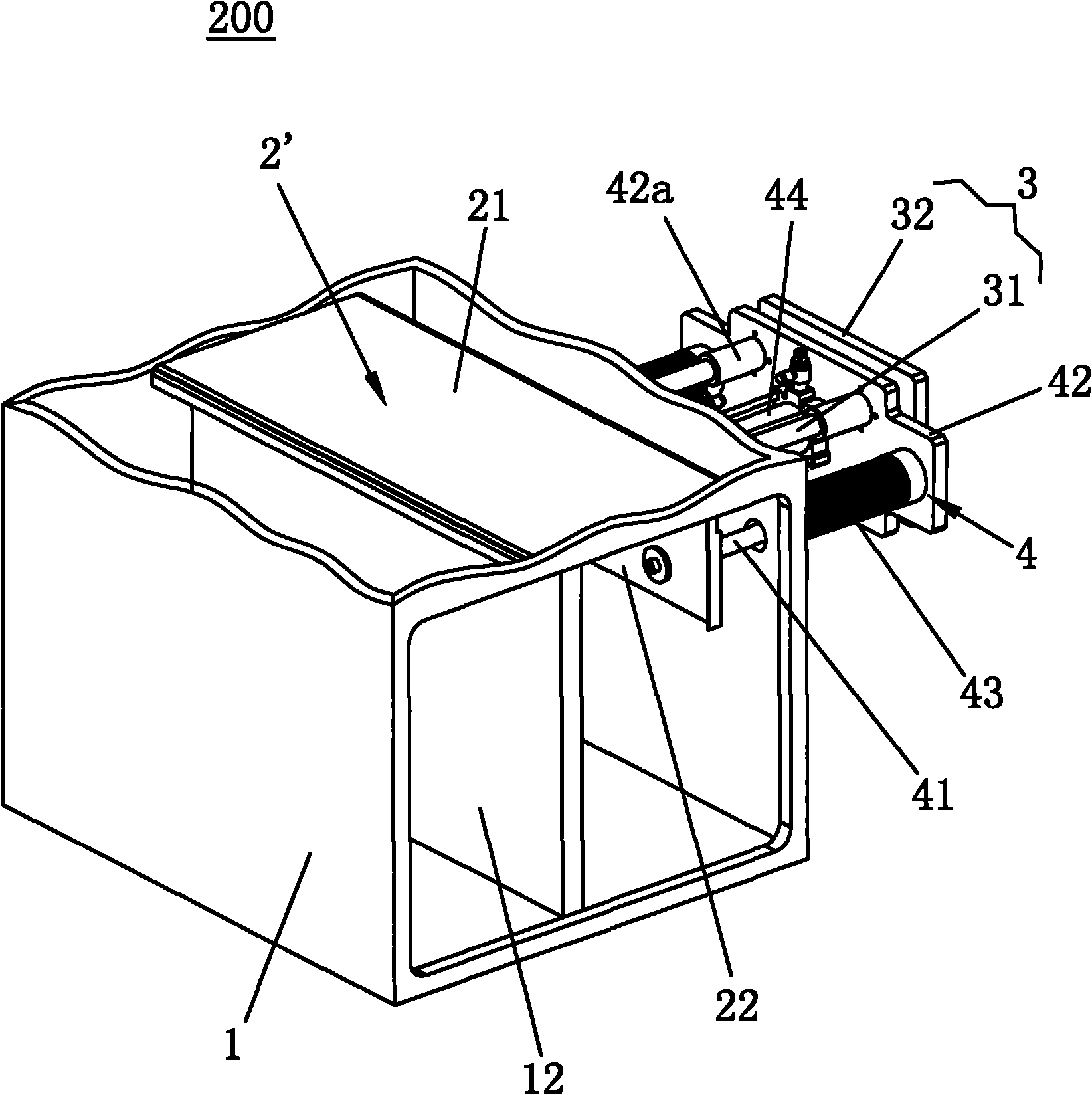

Processing device used for vacuum coating

InactiveCN101665913AGuaranteed to workAvoid pollutionVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention provides a processing device used for vacuum coating. The device comprises a cabinet body, a processing board and an evaporation source, wherein the cabinet body takes a hollow structurethat forms a sealing cavity; and the evaporation source and the processing board are arranged in the sealing cavity and the processing board is arranged above the evaporation source. Besides, the device also comprises a baffle mechanism and the baffle mechanism comprises a baffle, magnetofluid, a cooling shaft and a baffle driving mechanism, wherein the magnetofluid is arranged on the cabinet body; the baffle driving mechanism is arranged outside the cabinet body and connected with one end of the cooling shaft; the other end of the cooling shaft passes through the magnetofluid by pivotal connection and extends into the sealing cavity; the baffle is fixedly connected with the cooling shaft and arranged in the sealing cavity and between the evaporation source and the processing board, and isolates or opens the spatial join of the evaporation source and the processing board; and the baffle driving mechanism drives the cooling shaft and the cooling shaft drives the baffle to rotate. On the one hand, the processing device can improve the quality of a substrate coated layer to a maximum degree, and on the other hand, the normal service life of the processing device can be prolonged to amaximum degree.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

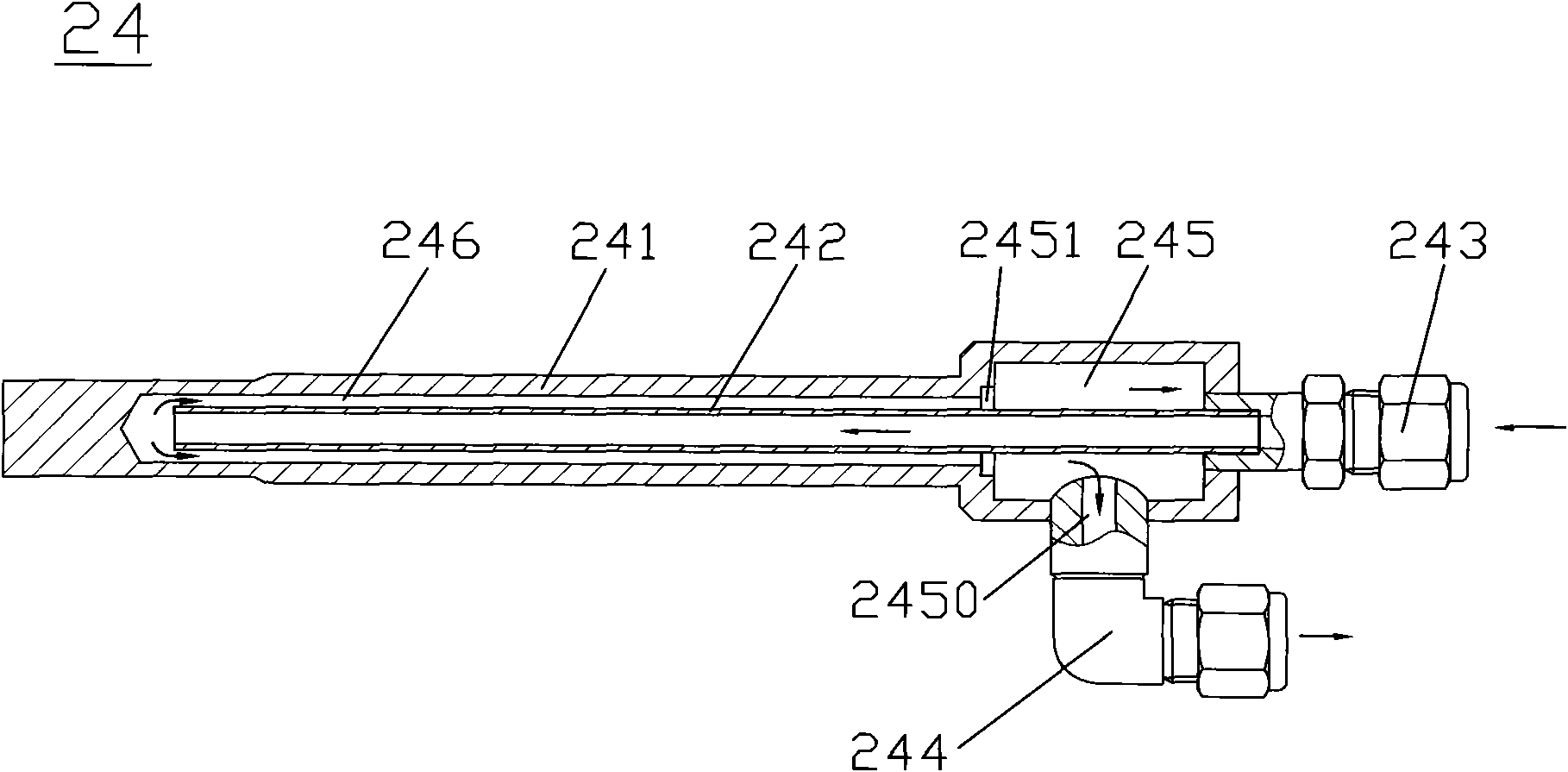

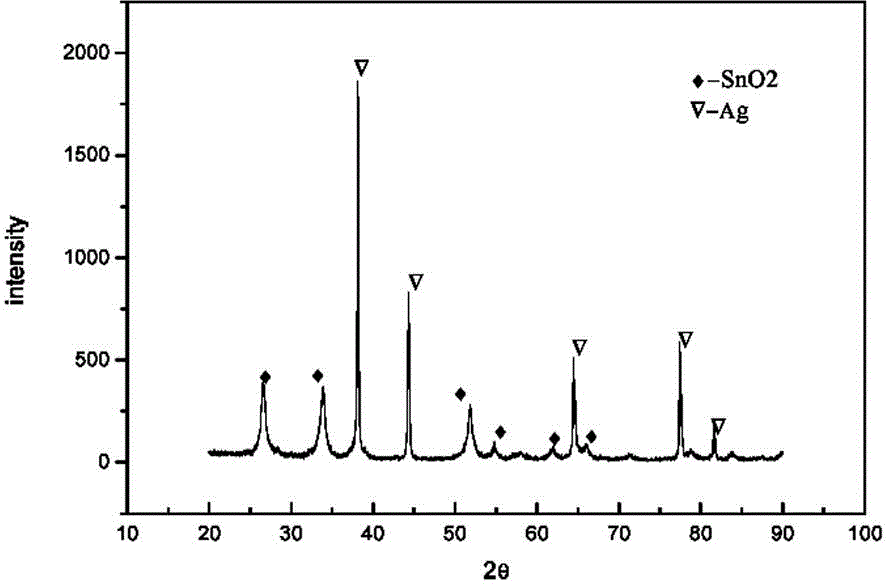

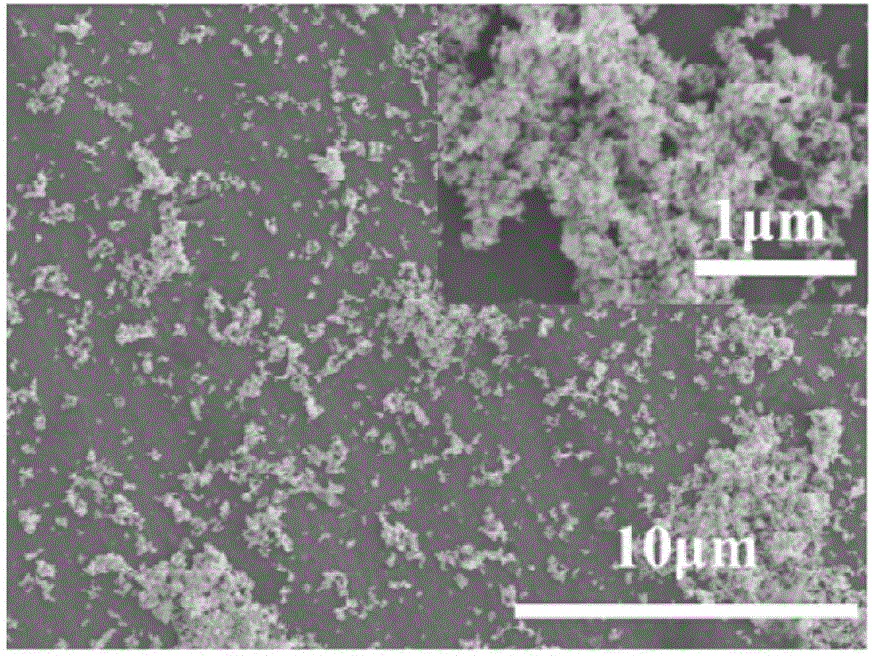

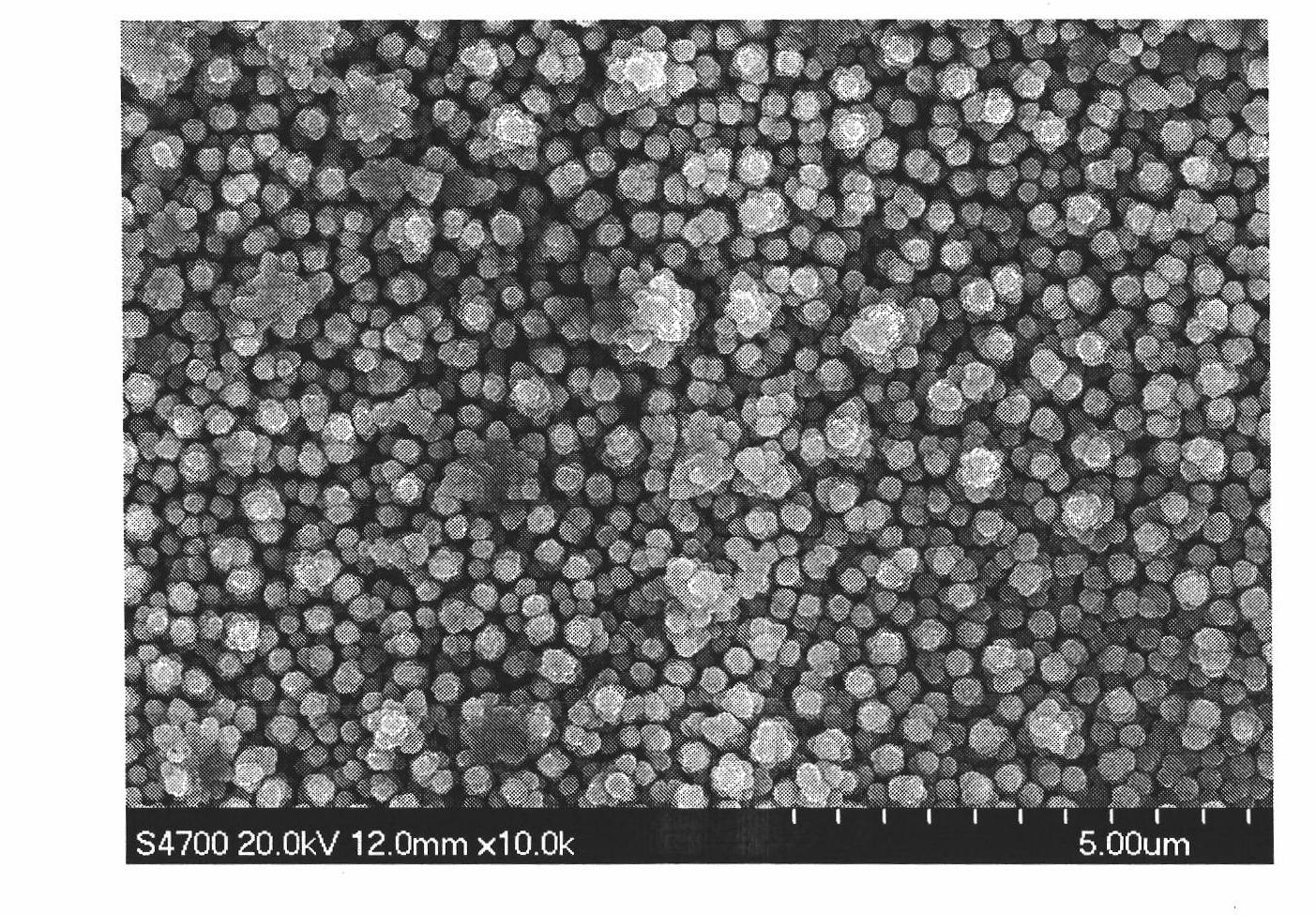

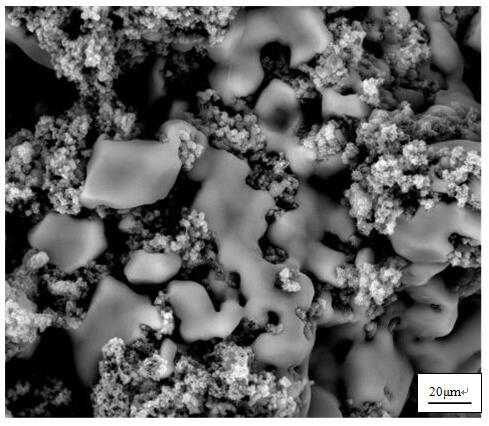

SnO2/Ag nanometer composite powder and preparation method thereof

InactiveCN104402041APure ingredientsHigh crystallinityMaterial nanotechnologyTransportation and packagingInorganic saltsFluid phase

The present invention relates to good-dispersity SnO2 / Ag nanometer composite powder and a preparation method thereof. The preparation method comprises: adopting soluble inorganic salts SnCl2.2H2O and AgNO3 as raw materials, respectively preparing solutions with a certain concentration, mixing according to a certain ratio to obtain milky white precipitate, adding ammonia water to the precipitate to adjust the pH value so as to obtain brown precipitate, and finally carrying out washing, drying and sintering on the obtained precipitate to obtain the SnO2 / Ag nanometer composite powder. According to the present invention, the diffused distribution of the nano-SnO2 in the composite powder is achieved through the liquid phase precipitation method, such that the problem of easy agglomeration of the nanoparticle in the conventional powder metallurgy method is avoided; and the method of the present invention has characteristics of simple process, energy saving, time saving, and broad application prospects, and is suitable for industrial production and promotion.

Owner:CHINA THREE GORGES UNIV

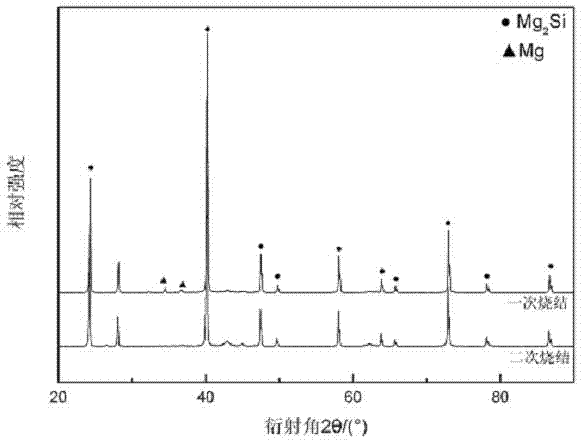

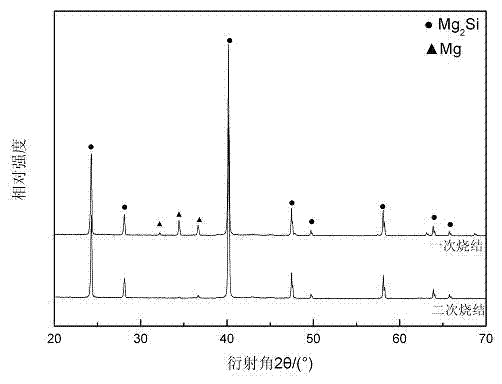

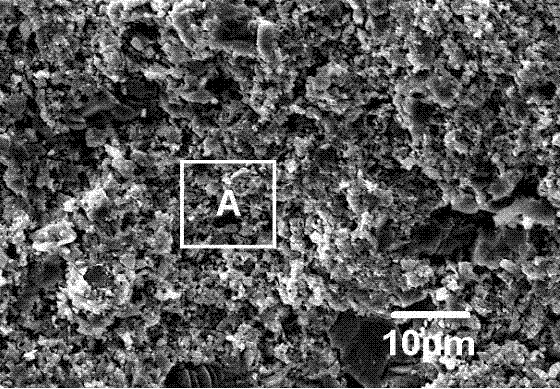

Preparation method for Mg2Si thermoelectricity material

InactiveCN102897768ASimple processEasy to operateMetal silicidesThermoelectric materialsThermal insulation

The present invention relates to a preparation method for an Mg2Si thermoelectricity material. The method comprises the following steps: (1) uniformly mixing Mg powder and Si powder under an Ar protection atmosphere to obtain a mixture; (2) placing the mixture in a glove box filled with Ar, and placing the glove box in a stainless steel vacuum ball milling tank to carry out intermittent ball milling to obtain uniformly-mixed powder; (3) carrying out tableting on the mixed powder to obtain a Mg-Si mixed powder tablet; (4) loading the Mg-Si mixed powder tablet into a graphite mold, and placing graphite mold in a tube furnace under an Ar atmosphere to carry out primary sintering and thermal insulation to obtain Mg2Si thermoelectricity material alloy powder; (5) carrying out tableting on the Mg2Si thermoelectricity material powder to obtain a Mg2Si alloy tablet; and (6) loading the Mg2Si alloy tablet into the graphite mold and placing the graphite mold in the tube furnace under an Ar atmosphere to carry out secondary sintering and thermal insulation to obtain the Mg2Si block thermoelectricity material. The preparation method has characteristics of simple process, easy operation and low cost. The obtained Mg2Si thermoelectricity material has characteristics of high product purity, small particle size and uniform distribution.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

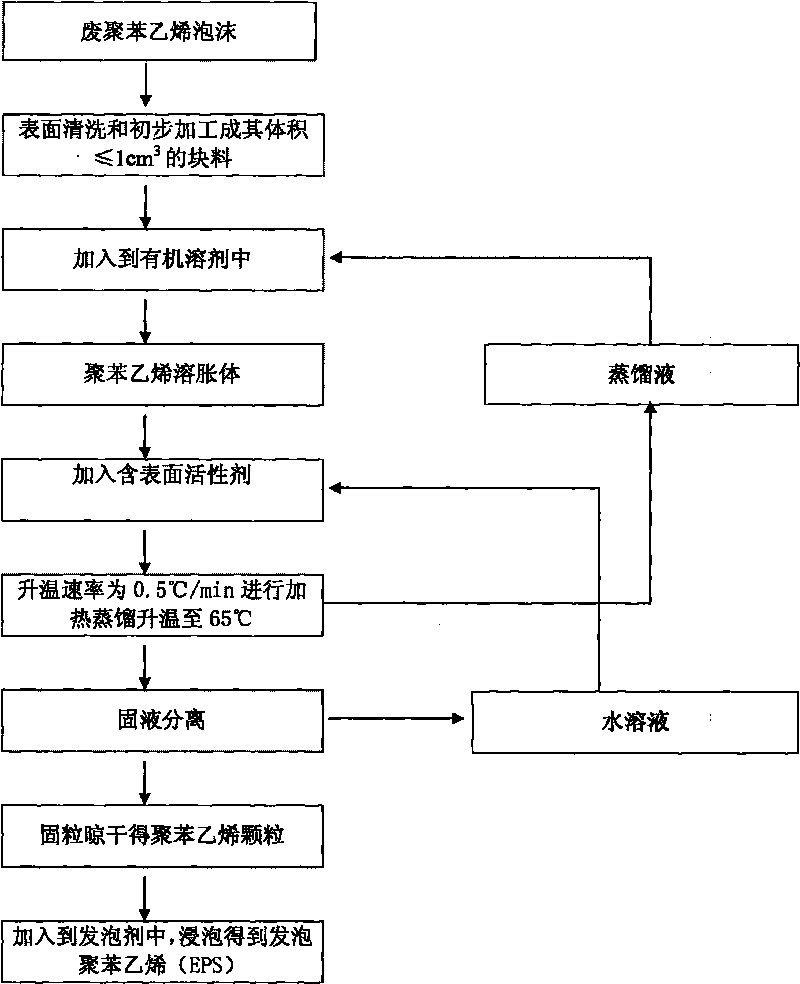

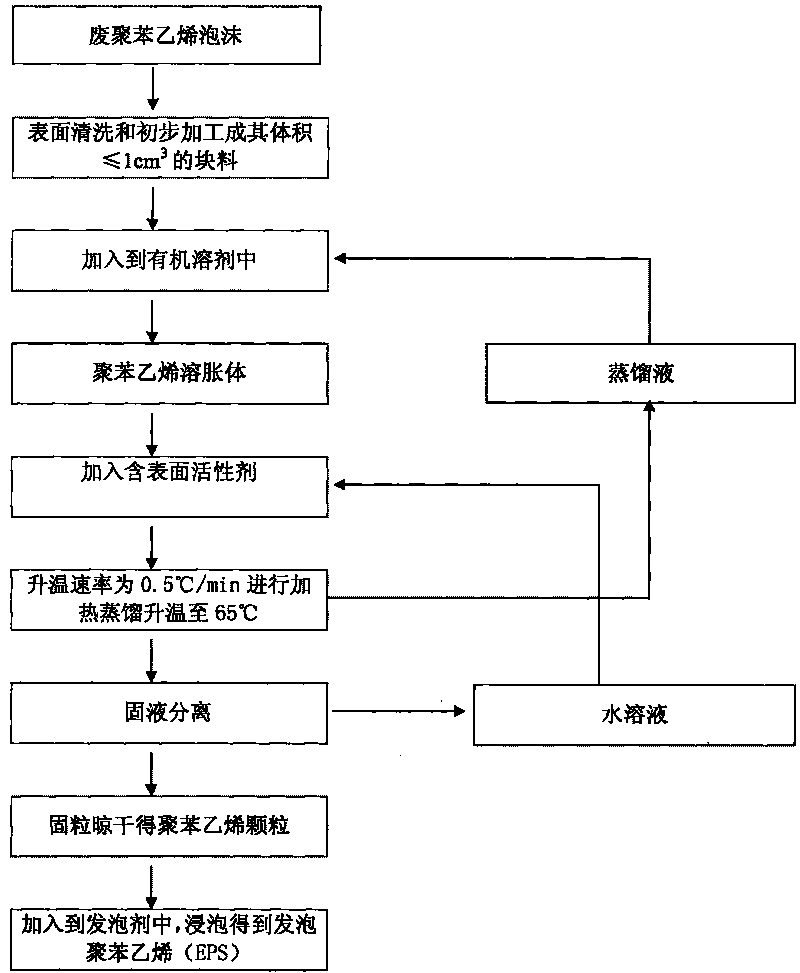

Method for functionally remolding waste polystyrene

InactiveCN101701073ASolve the pollution of the environmentSimple processPlastic recyclingOrganic solventFoaming agent

The invention relates to a method for functionally remolding waste polystyrene. The method includes the following steps of: preprocessing polystyrene foam, adding the preprocessed polystyrene foam to a water-fast organic solvent so as to dissolve the polystyrene foam into a polystyrene swelling body, adding the polystyrene swelling body to water containing a surface active agent, continuously stirring, heating, distilling and carrying out solid-liquid separation to obtain the finished product of polystyrene particle; and soaking the polystyrene particle in a foaming agent to obtain expandable polystyrene (EPS) particles. The used organic solvent is simple and is easy to recycle and reuse. The method not only can functionally remold the waste polystyrene, but also can conveniently prepare an antistatic black polystyrene particle and a magnetic polystyrene particle, overcomes the disadvantages of toxic solvent, high price, impure products, and the like of the traditonal method for functionally remolding the waste polystyrene and effectively solves the problem of environmental pollution caused by the waste polystyrene. The invention has the advantages of simple process of functionally remolding the waste polystyrene, low cost and high purity of product ingredients.

Owner:JILIN UNIV

Method for preparing nickel and nickel alloy one-dimensional superstructure nanometer functional materials by adopting hydrogen separation template method

InactiveCN102134732APure ingredientsLow costPolycrystalline material growthSingle crystal growth detailsBuffering agentElectrolyte

The invention relates to a method for preparing nickel and nickel alloy one-dimensional superstructure nanometer functional materials by adopting a hydrogen separation template method, which mainly comprises the following steps of adding an additive, metal salt of a first constituent element and a complexing agent in an aqueous solution containing a buffering agent with specific pH in sequence toform a solution, mixing the solution uniformly, and then adding one of a sulfur source, a phosphor source and a tin source commonly deposited in a second constitute element in the solution. The obtained mixture is uniformly mixed at certain temperature; a pH value is adjusted to stabilize an electrolyte; hydrogen is separated out on the surface of a nickel matrix quantitatively, directionally anduniformly through controlling current density by adopting a direct current or pulse electrolytic deposition method; and finally, lots of fine, dense and continuous air bubbles are formed in the mixedsolution. By adopting the method, as an actual template does not need to be used when an alloy nanometer wire is prepared, the problem of removing the template is not involved. By using the method, the preparation reaction period is short, the operation is simple and convenient, the conditions are easy to control, and the production efficiency is high. Simultaneously, the method further has the advantages that the cost is low, the maneuverability is strong, the yield is high, the mass production can be realized and the like, and has obvious practical value.

Owner:BEIJING UNIV OF CHEM TECH +1

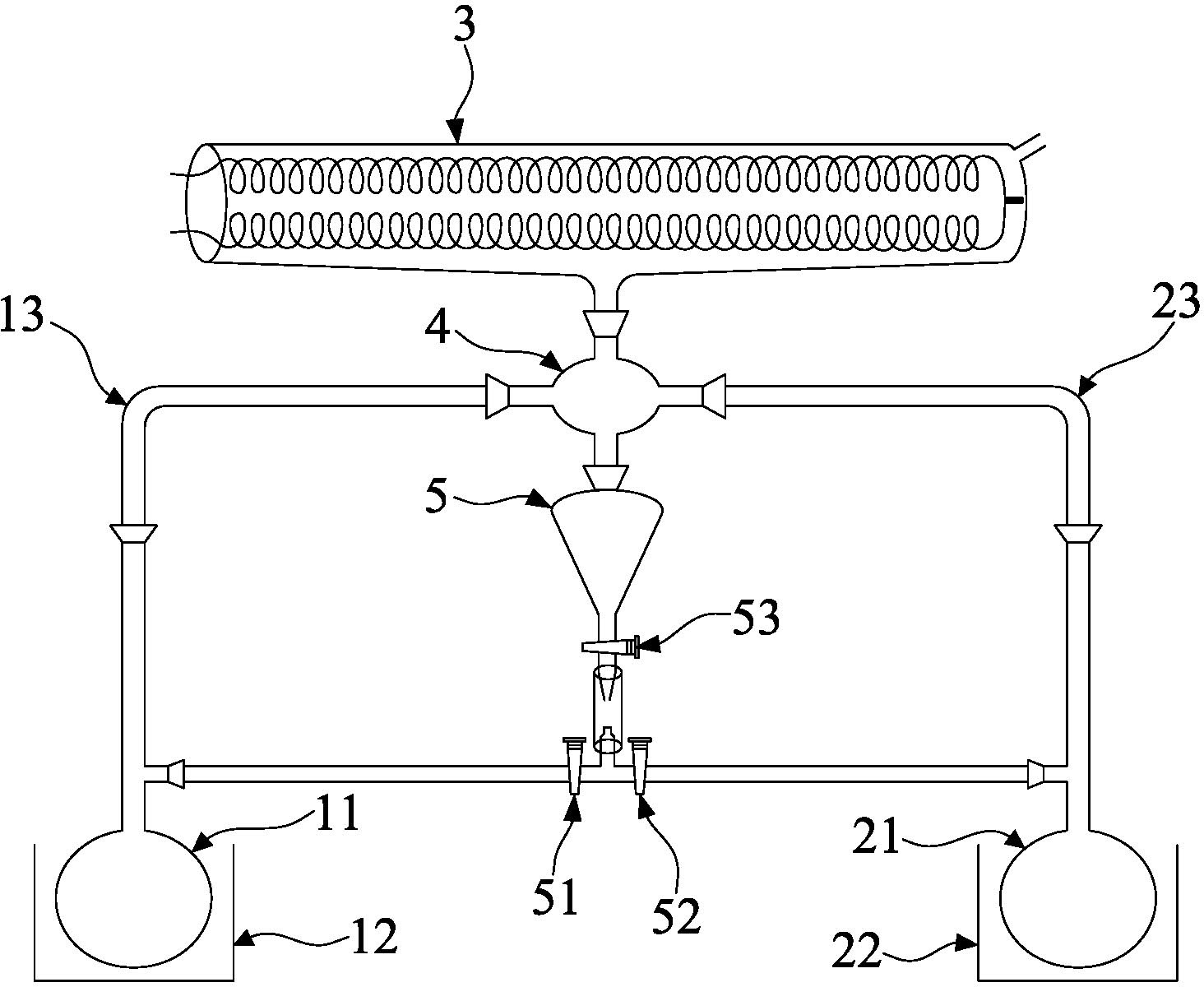

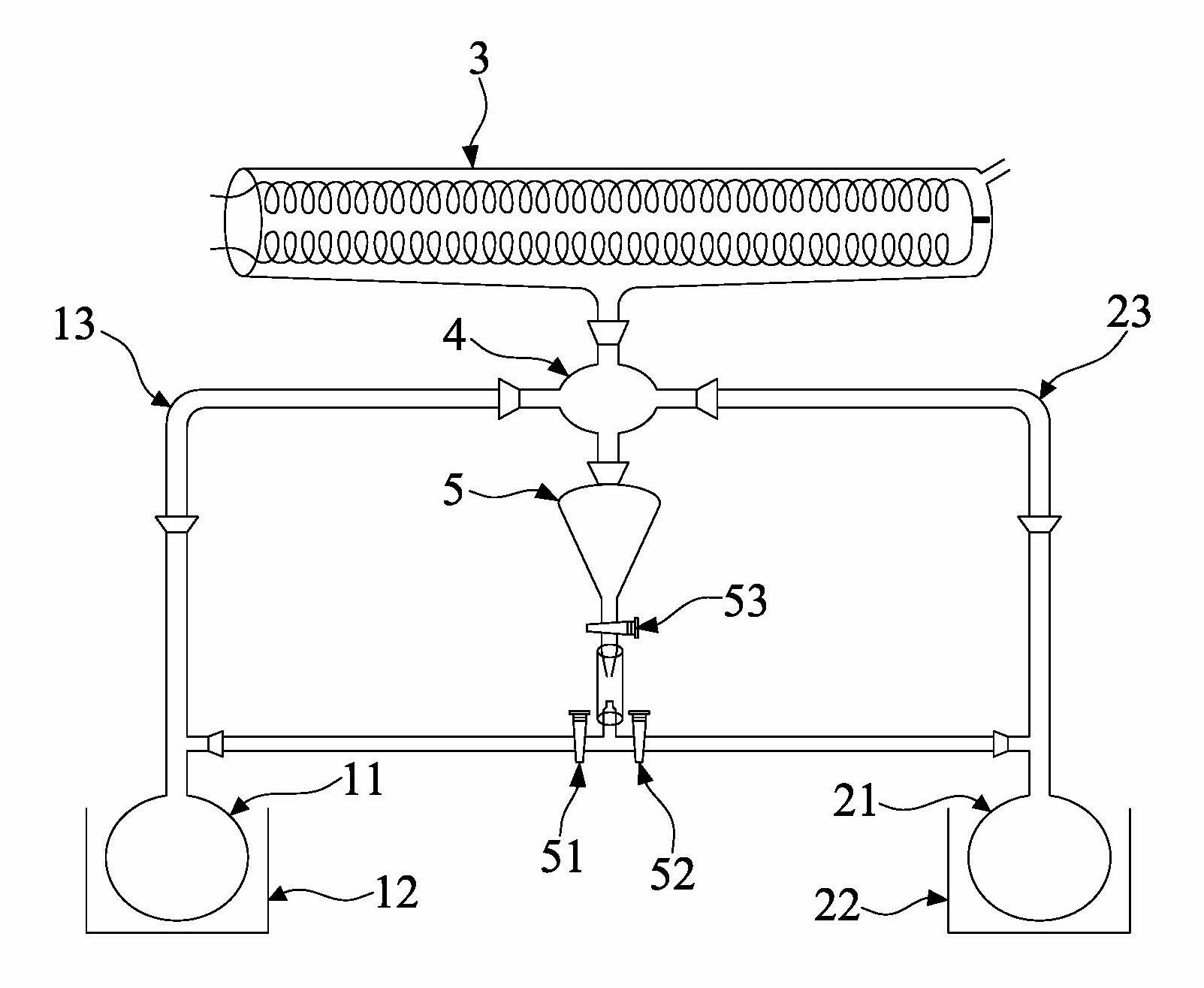

Method for extracting tea essential oil from oolong tea stalks

ActiveCN102504956ALow impurity contentImprove efficiencyEssential-oils/perfumesDistilled waterProcess engineering

The invention discloses a method for extracting tea essential oil from oolong tea stalks. The method comprises the following steps of: putting the oolong tea stalks serving as raw materials into a tea stalk distillation device, adding distilled water, and distilling; measuring petroleum ether, adding into a petroleum ether distillation device, and distilling; connecting the tea stalk distillation device and the petroleum ether distillation device through a glass guide pipe, fully mixing volatile gas distilled from the tea stalks and petroleum ether steam in a gas storage bag, introducing mixed steam into a condensation pipe, condensing to form oil-water mixed liquid, and refluxing the mixed liquid to a separating funnel; refluxing a water phase and an oil phase in the separating funnel to a first flask and a second flask respectively, so that the circular extraction process is finished once; repeating the process to fully extract the essential oil from the tea stalks; and taking the second flask with the petroleum ether out, concentrating a solution in the second flask, and collecting to obtain tea essential oil paste. By the method, the extraction cost of the tea essential oil can be reduced, and the economic benefit of tea processing is improved.

Owner:HUAXIANG YUAN TEA IND

Artemisia leaf nutritional chewable tablet and preparation method thereof

ActiveCN102090561ADispelling cold and relieving painWith warm meridians to stop bleedingFood preparationFlavorBanana powder

The invention relates to an artemisia leaf nutritional chewable tablet and a preparation method thereof. The artemisia leaf nutritional chewable tablet comprises the following raw materials in parts by weight: 2-6 parts of artemisia leaf powder, 1-2 parts of oligoisomaltose and 1-3 parts of nutrient substance, wherein the nutrient substance refers to skim milk powder or banana powder or hawthorn powder or orange powder. A preparation process comprises the following steps of: selecting materials, preparing soft materials, pelletizing, tableting and sterilizing. The artemisia leaf nutritional chewable tablet is rich in bioflavonoid and oligoisomaltose, has multiple health-care effects of eliminating cold to stop pain, warming meridian to stop bleeding, improving intestinal balance and the like, has a unique flavor, is convenient to eat, easy to carry and particularly suitable for the aged, women and sub-healthy people, and is a novel health-care food.

Owner:HEFEI UNIV OF TECH

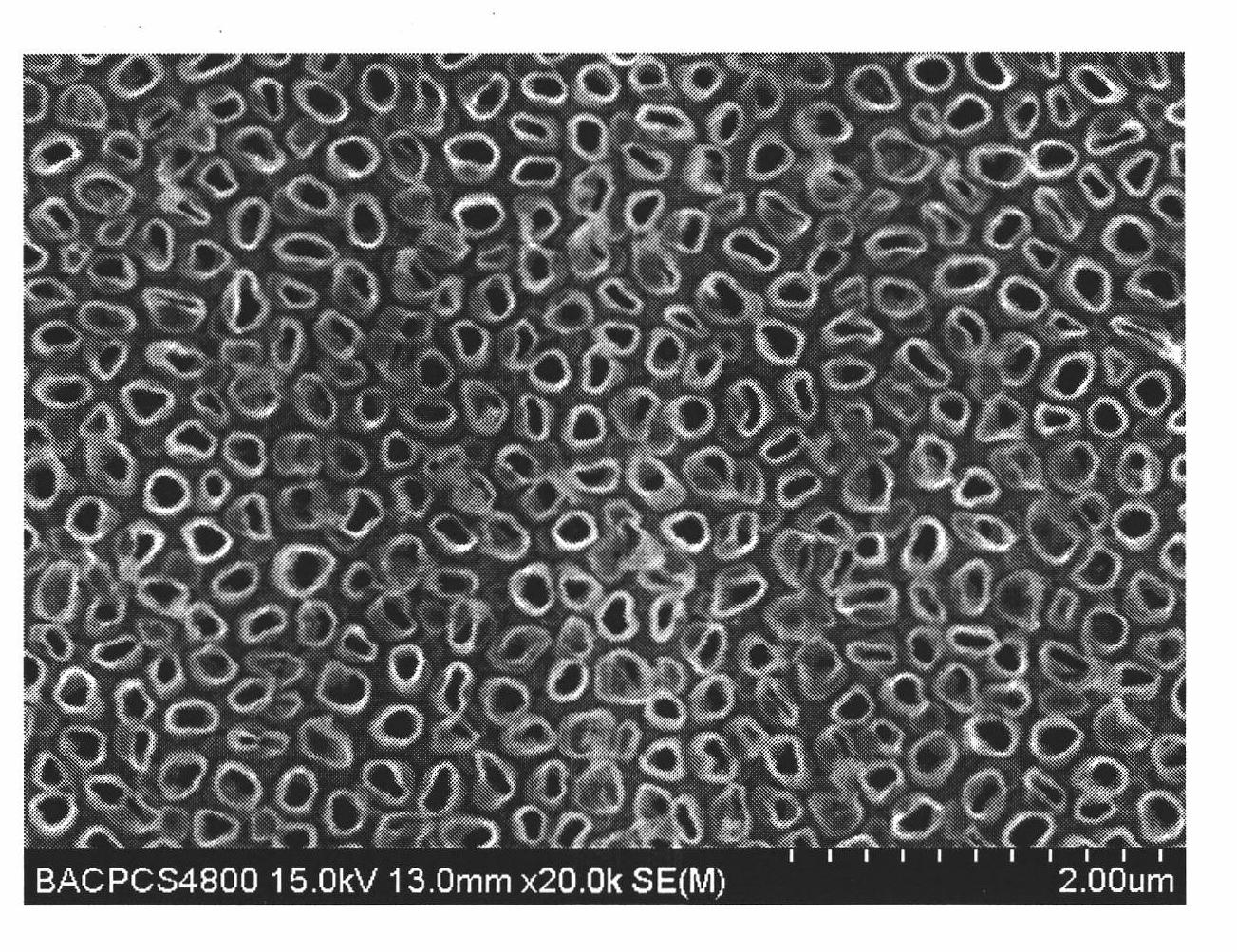

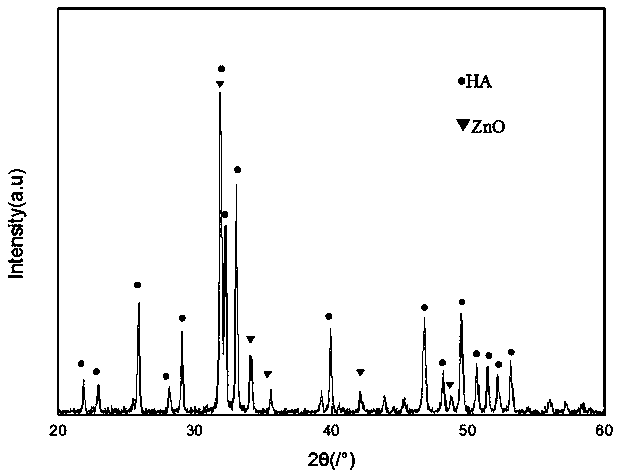

Preparation method of nano-zinc oxide-doped hydroxyapatite porous ceramic

ActiveCN110054491APure ingredientsAvoid churnPharmaceutical delivery mechanismTissue regenerationApatiteZno nanoparticles

The invention relates to a preparation method of a nano-zinc oxide-doped hydroxyapatite porous ceramic and belongs to the technical field of preparation of biomedical materials. The preparation methodtakes nano-zinc powder and hydroxyapatite powder as the raw materials and comprises weighing out ZnO and HA (hydroxyapatite) at a weight ratio of 1-7%:99%-93%, performing ball milling to obtain composite powder, uniformly mixing and pressing the composite powder and a pore forming agent of ammonium bicarbonate to obtain a blank, and then preparing the nano-zinc oxide-doped hydroxyapatite porous ceramic through a spark plasma sintering method. The prepared nano-zinc oxide-doped hydroxyapatite porous ceramic is pure in composition and achieves a controllable porosity of 40-70%, and added nano-zinc oxide can improve the osteogenic induction capacity of the nano-zinc oxide-doped hydroxyapatite porous ceramic and further improve the bone-forming capacity of parts around an implanted part; by controlling the porosity of the nano-zinc oxide-doped hydroxyapatite porous ceramic, the preparation method can prepare biological ceramics which meet different requirements and are applied to bone scaffold, filling and repair materials.

Owner:KUNMING UNIV OF SCI & TECH

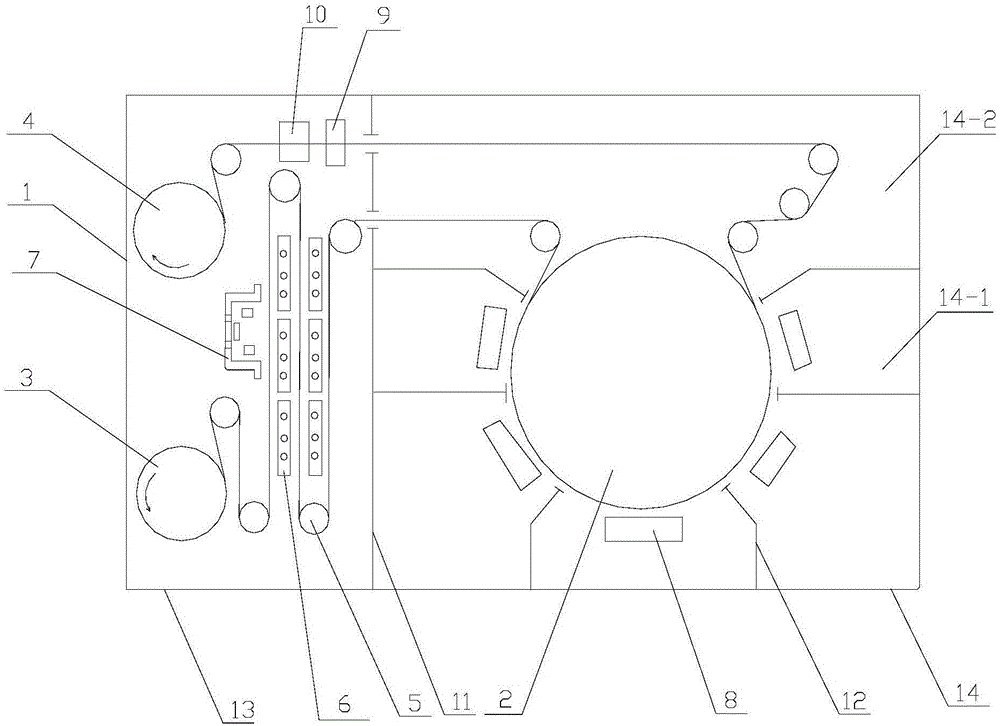

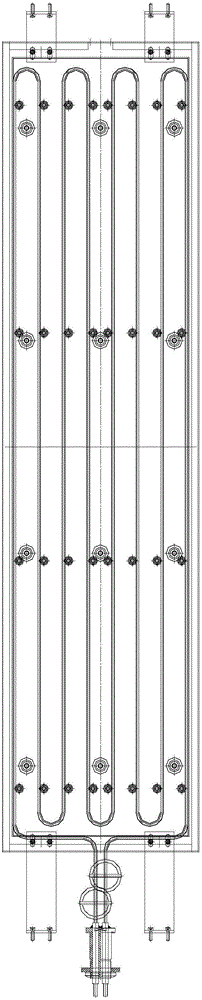

Compact type flexible substrate magneto-controlled sputter coating equipment and method

ActiveCN106048546ACompact structureOptimize layoutVacuum evaporation coatingSputtering coatingEngineeringConductor Coil

The invention discloses compact type flexible substrate magneto-controlled sputter coating equipment and method. According to the equipment, a partition clapboard is arranged in a vacuum chamber, space in the vacuum chamber is divided into a winding area and a coating area, the partition clapboard is provided with a through hole for a flexible substrate to pass through, the flexible substrate penetrates the whole vacuum chamber, a heater and an ion source are arranged in the winding area, a magneto-controlled sputter device is arranged in the coating area, multiple unit clapboards are arranged in the coating area, and space in the coating area is divided into one flexible substrate conveying unit and multiple coating units. According to the method, the winding area and the coating area in the vacuum chamber are vacuumized, and the flexible substrate unwound by an unwinding roller passes through the winding area firstly, and is subjected to ion treatment and preheating in the winding area, then conveyed into the coating area, subjected to sputter coating through the multiple coating units in sequence and finally conveyed to the winding area to be wound through a winding roller. The equipment is compact in structure, saves equipment cost and can effectively prevent work atmospheres of the different process stages from influencing one another.

Owner:ZHAOQING KERUN VACUUM EQUIP

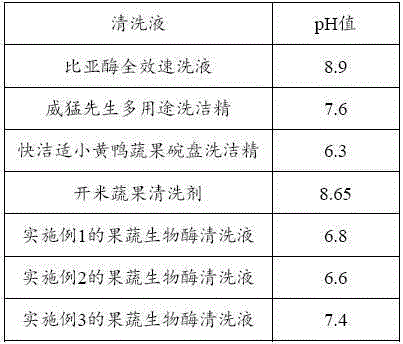

Fruit and vegetable bio-enzyme detergent as well as preparation method and application thereof

InactiveCN106833945APure ingredientsFragrance freeAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsPreservativeOrganophosphorus pesticides

The invention discloses a fruit and vegetable bio-enzyme detergent which consists of the following constituting components in percentage by weight: 15-25% of a surfactant, 0.2-0.5% of a chelating agent, 1-5% of an enzyme preparation, 0.1-0.5% of an enzyme stabilizer, 0.1-0.5% of a preservative, 1-5% of glucose and the balance of deionized water. When fruits and vegetables are washed with the fruit / vegetable bio-enzyme detergent disclosed by the invention, components of the fruit and vegetable bio-enzyme detergent take a synergic effect into play, particularly the synergic effect of the enzyme preparation and the surfactant, organophosphorus pesticides, protein type botanical insecticides and novel pesticides such as esters and amides retained on the fruits and vegetables can be decomposed or degraded by composite enzymes, and decomposed or degraded products can be rapidly eliminated by the surfactant; meanwhile, the fruit and vegetable bio-enzyme detergent disclosed by the invention is capable of effectively removing various bacteria of the fruits / vegetables, and after being washed, the fruits and vegetables can be free of surfactant resides on surfaces and are healthy and safe.

Owner:深圳市芭格美生物科技有限公司

In-situ preparation method of copper nanowires in microchannel

ActiveCN105598464AUniform horizontal sizePure ingredientsTransportation and packagingMetal-working apparatusControl flowMicro nano

The invention provides a method for preparing copper nanowires in a microchannel in situ by virtue of insoluble liquid-liquid two-phase interface reaction. The method comprises the following steps: preparing an oil phase solution and an aqueous phase solution which are mutually insoluble, wherein one phase contains copper salt and the other phase contains a reducing agent; treating a microchannel wall surface so that a reaction resultant can easily grow on and adhere to the microchannel wall surface; controlling flow parameters of the two phases so as to enable the two phases to form a low-speed parallel flow in the microchannel; controlling the position of a two-phase liquid-liquid interface in the microchannel; and keeping the stability of the position and the form of the interface, performing chemical reaction at the interface to generate copper, and depositing on the channel wall surface at the interface position to form the copper nanowires. The obtained copper nanowires are uniform in transverse size, and are as long as the channel in which the parallel flow is formed; and the positions of the generated copper nanowires in the microchannel are determined by the position of the two-phase interface and can be flexibly adjusted. By the preparation method, a graphical micro-nano structure can be directly prepared in the microchannel; and the preparation method is low in temperature, simple, good in compatibility, low in cost and high in practicality.

Owner:HARBIN INST OF TECH AT WEIHAI

Preparation method for superfine copper nano particles

The invention provides a method for preparing superfine copper nano particles by utilizing immiscible liquid-liquid two-phase interface reaction. The method comprises the following steps of firstly, dissolving a copper salt into a non-polar solvent to prepare a copper-containing source solution or dissolving a copper salt into a non-polar solvent and then emulsifying witha polar solvent to prepare a copper-containing source solution, and dissolving a reducing agent into the polar solvent to prepare a reducing solution; forming an immiscible two-phase system by the reducing solution and the copper-containing source solution, thereby obtaining a stable liquid-liquid interface; and at certain temperature, reacting at the liquid-liquid interface to generate the superfine copper nano particles. The method can be used for preparing the superfine copper nano particles with particle diameters smaller than 10 nanometers, and the superfine copper nano particles have fewer impurities, pure components, good crystallization quality, and uniform sizes and morphology, can be stably dispersed into the immiscible two-phase system obtained by reaction without surface modifying and coating, and can standfor a long time in normal-temperature air without being oxidized. The method is simple, is low in energy consumption, is low in cost, is easy to control, and is high in practicability, and can be used for continuously preparing and gathering the superfine copper nano particles. Preferably, water and oleic acid are adopted as a solvent, so that the preparation method is enabled to be non-toxic and environmentally-friendly.

Owner:HARBIN INST OF TECH AT WEIHAI

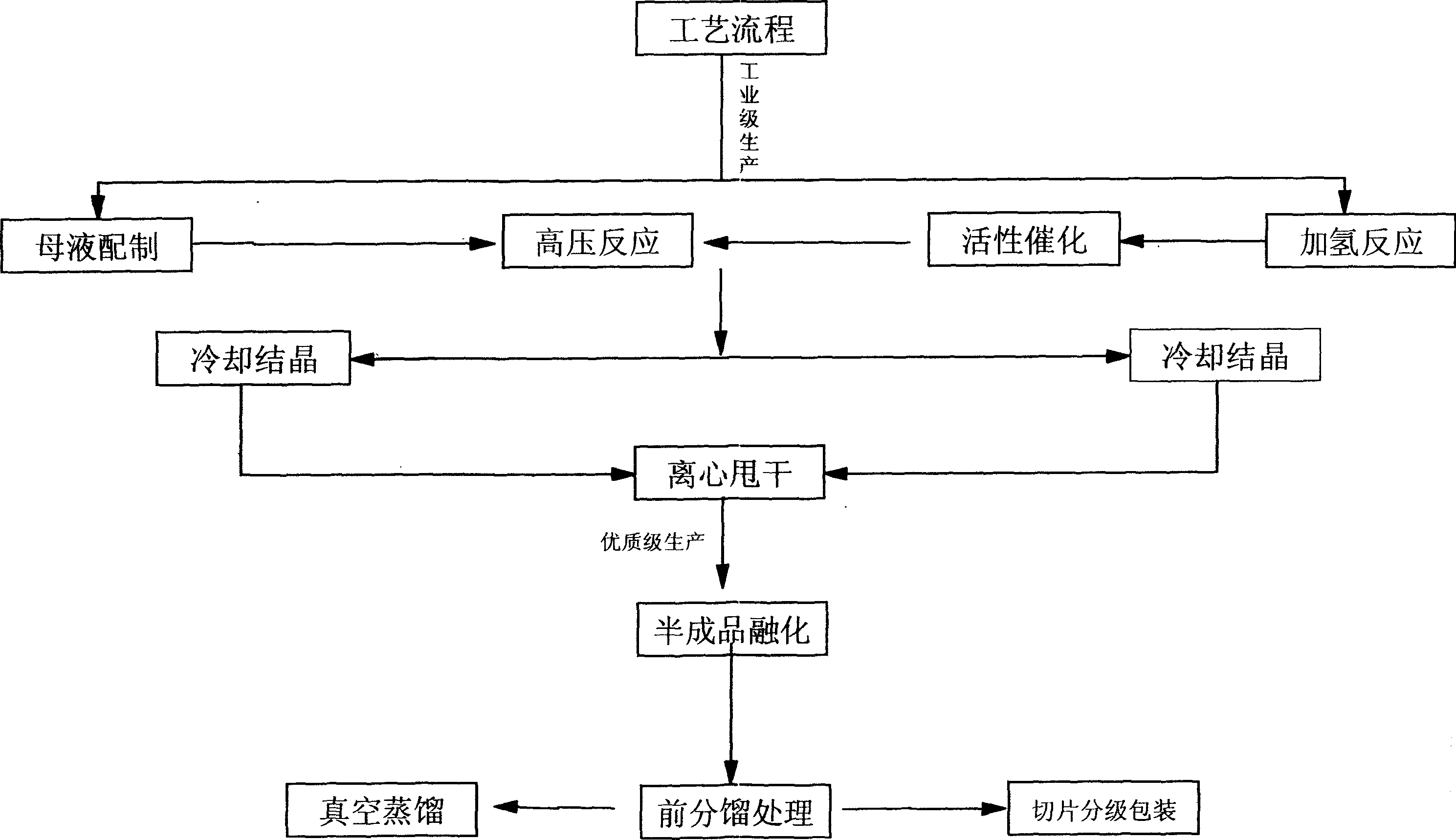

Succinic anhydride and its preparation method

The present invention prepares succinic anhydride with material including pure benzene, cis-butenedioic anhydride, catalyst and hydrogen. The preparing process features the flake product with fast dissolving, and less caking and crystallizing. The present invention has the advantages of less material consumption, simple preparing process, low cost, high product purity and bright color, and the product may be used in producing pesticide, plant growth regulator and medicines and as brightener for paper and paint production.

Owner:葛勇

Vacuum cavity isolating mechanism

InactiveCN101812670AUniform thicknessPure ingredientsVacuum evaporation coatingSolid-state devicesCavity wallLinear drive

The invention discloses a vacuum cavity isolating mechanism, which is suitable for isolating a processing board from an evaporation source in a vacuum cavity providing a vacuum coating. The isolating mechanism comprises a blocking cover and a control mechanism, wherein the control mechanism comprises a pushing shaft, a pushing plate and a linear driving device; one end of the pushing shaft is hermetically inserted into the cavity wall of the vacuum cavity and is fixedly connected with the blocking cover; the blocking cover is accommodated in the vacuum cavity and is positioned between the evaporation source and the processing board in the vacuum cavity; the other end of the pushing shaft is fixedly connected with the pushing plate; the pushing plate is positioned outside the vacuum cavity; the linear driving device is arranged on the cavity wall of the vacuum cavity and is positioned outside the vacuum cavity; and an output shaft of the linear driving shaft is fixedly connected with and vertical to the pushing plate. The vacuum cavity isolating mechanism can enhance the uniformity and purity of an organic light-emitting diode substrate coating to the maximum extent, greatly enhances the quality of the substrate coating and prolongs the service life of a substrate.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

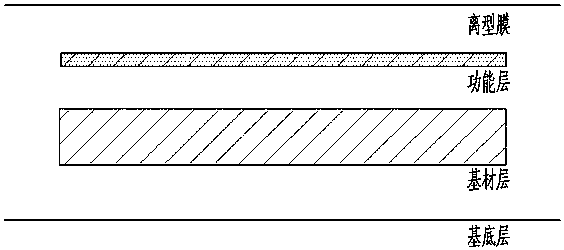

Preparation method of electron beam radiation crosslinking composite polymer hydrogel dressing

InactiveCN107789658ASimple processAvoid formulation residuesAbsorbent padsRadiationIonComposite polymer

The invention relates to a preparation method of an electron beam radiation crosslinking composite polymer hydrogel dressing, in particular to an electron beam radiation chemical technology. The dressing consists of a substrate layer, a base material layer, a functional layer and a release film which are closely laminated in sequence, wherein the substrate layer is a hydrogel formed by mixing polyvinyl alcohol, polyvinyl pyrrolidone, gelatin and deionized water to form a settable dope which is crosslinked by electron beam radiation; the functional layer is formed by adding low-molecular chondroitin sulfate and low-molecular hyaluronic acid into the hydrogel of the substrate layer; electron beam irradiation, a pure physical means, is adopted to synchronously realize polymer crosslinking andproduct sterilization, thereby avoiding problems of preparation residues and chemical waste liquid emission of a chemical crosslinking method and a problem of pollution of ethylene oxide sterilization; and the high-cost low-molecular chondroitin sulfate and the low-molecular hyaluronic acid are only used for a thin functional layer on the surface, thereby reducing the material cost.

Owner:SHANDONG LANFU HIGH ENERGY PHYSICS TECH CO LTD

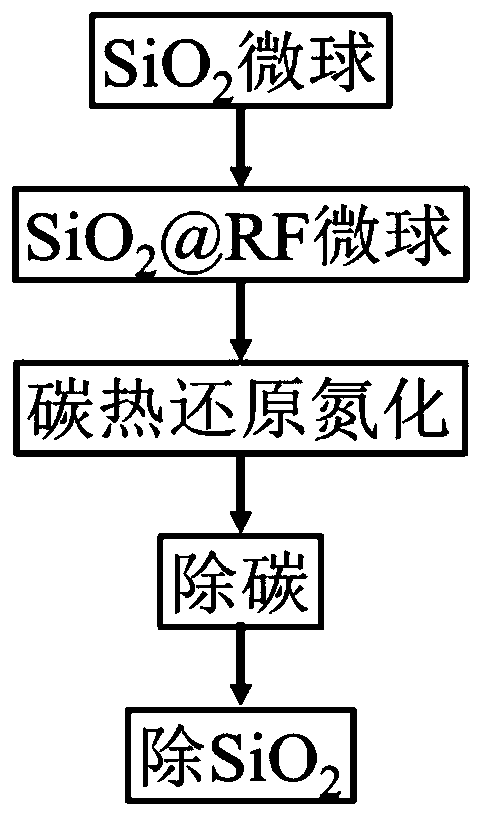

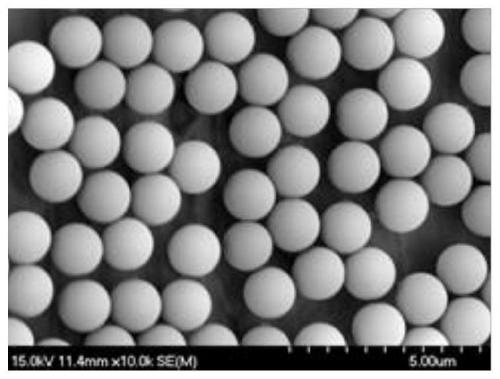

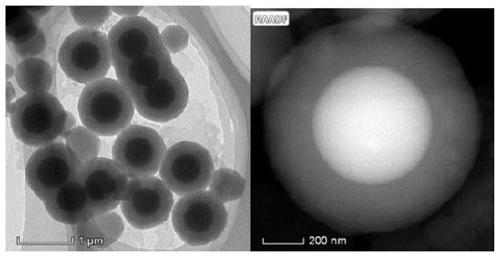

Submicron silicon nitride hollow microspheres and preparation method

The invention relates to submicron silicon nitride hollow microspheres and a preparation method. The preparation method is technically characterized by comprising steps as follows: (1), silicon dioxide microspheres synthesized with a stober method are taken as a silicon source, phenol-formaldehyde resin synthesized from resorcinol and formaldehyde is taken as a carbon source, and a synthesized SiO2@RF(Resorcinol-formaldehyde resin) core-shell structure is taken as a precursor; (2) a certain quantity of the precursor prepared in step (1) is subjected to a carbothermal reduction-nitridation reaction at a certain temperature; (3), powder prepared in step (2) is oxidized to remove carbon and subjected to acid pickling to remove silicon dioxide, and the silicon nitride hollow microspheres are obtained. With the adoption of the technical scheme, the submicron silicon nitride hollow microspheres with controllable and uniform particle size, uniform microstructure and morphology and relativelypure composition can be prepared. The preparation technology is stable, high in repeatability and low in cost and facilitates mass production of the silicon nitride hollow microspheres.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Zinc stearate sol low in free acid content and preparation method thereof

InactiveCN107253910AReduce contentPure ingredientsCosmetic preparationsNon-fibrous pulp additionChemistryFree acid

The invention discloses zinc stearate sol low in free acid content and a preparation method thereof. The zinc stearate sol is prepared by reaction under model temperature of krfft*2 DEG C. The zinc stearate sol comprises, by weight percentage, 86.7% of stearic acid emulsion and 13.3% of zinc oxide dispersion liquid, wherein the zinc oxide dispersion liquid comprises, by weight percentage, 4% of zinc oxide, 1% of dispersing agent, 0.1% of multifunctional catalyst, 0.1% of defoaming agent, 0.1% of environment-friendly sterilizing agent and 8% of deionized water. The preparation method has the advantages that the reaction is complete, the generation of three wastes is avoided, reaction byproducts are avoided, the prepared zinc stearate sol is low in free fatty acid content, pure in component and small in particle size, and the low viscosity of high-solid-content products is guaranteed; independent catalyst pollution is avoided, and low fatty acid residues are achieved; the conversion rate and fineness of zinc stearate are increased; the method is high in yield, minimum in energy consumption and simplified in process control, and the prepared zinc stearate sol is low in particle size distribution.

Owner:江苏三瑞生物技术有限公司

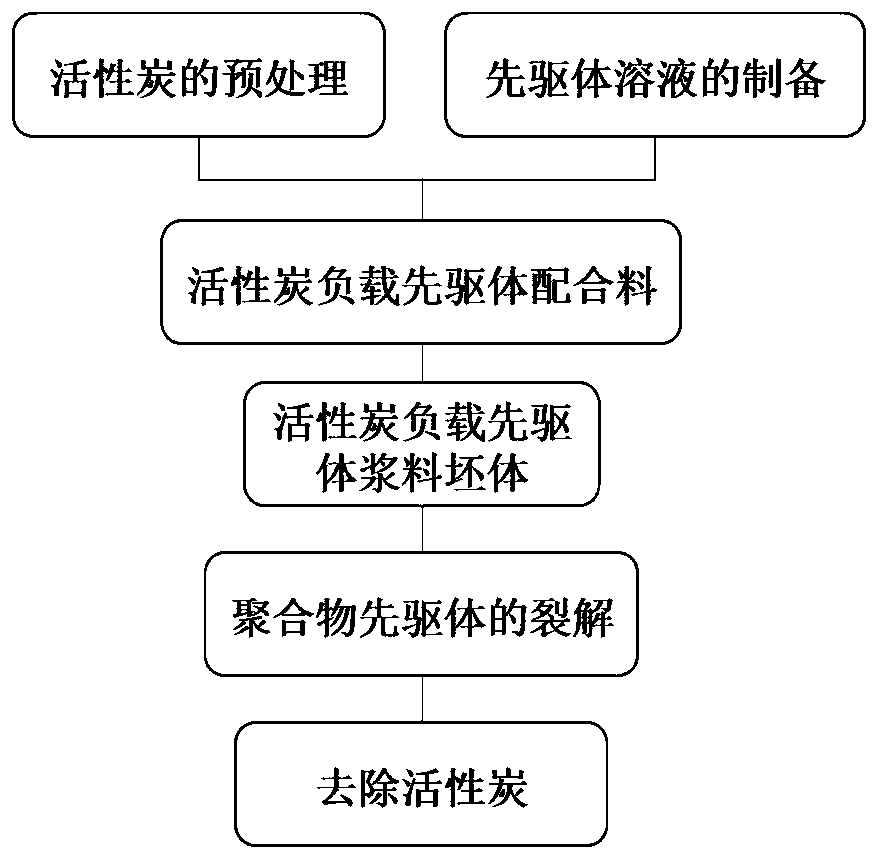

Preparation method of isotropic ceramic nanowire preform

ActiveCN110606747AGuaranteed outputImprove mechanical propertiesCarbon compoundsActivated carbonElectricity

The invention relates to a preparation method of an isotropic ceramic nanowire preform, which comprises the following steps: loading a polymer precursor on activated carbon powder to form a mixture, pressing the mixture into a green body template; cracking the polymer precursor on the template at a certain temperature to grow a large number of nanowires which are crossed and lapped with one another; then performing oxidation to remove the activated carbon to prepare the isotropic ceramic nanowire preform material with the interconnected three-dimensional network structure. The nanowires in theisotropic ceramic nanowire preform prepared by the method are pure in component, uniform in structure, controllable in size and adjustable in volume fraction. The method has the advantages of simpleprocess steps, short period, relatively low cost, good stability and good repeatability. Meanwhile, the ceramic nanowire preform has the functions of heat insulation, light weight, electricity, opticsand the like, requirement for multifunctional integration is expected to be met, and the application field of ceramic matrix composite materials is expanded.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

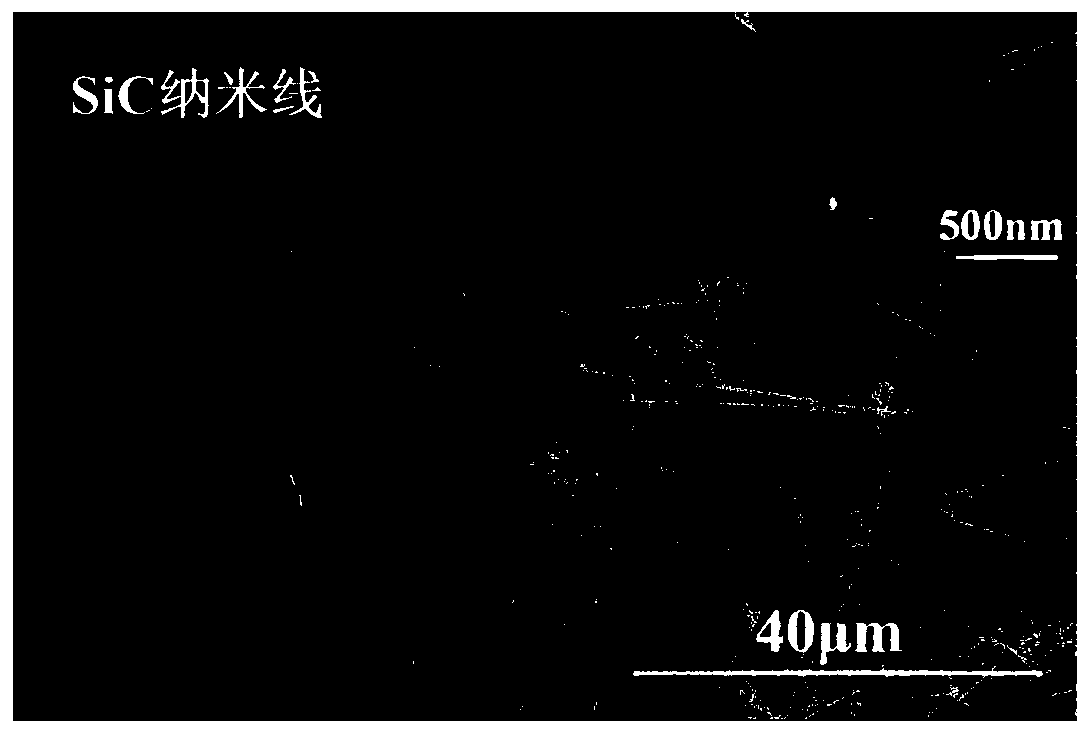

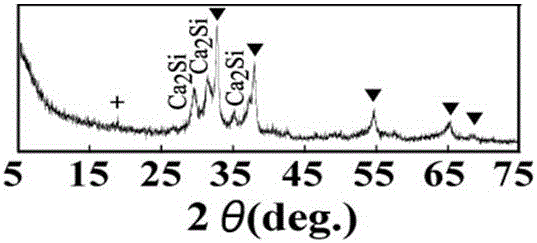

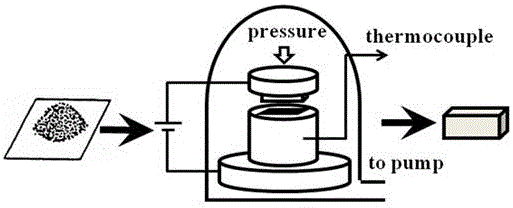

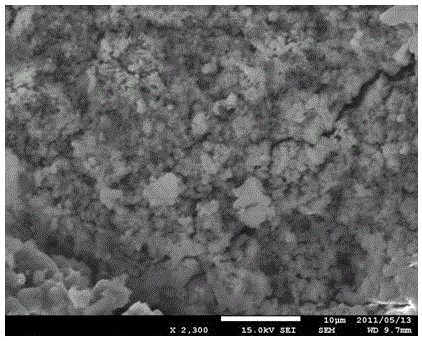

Cubic-phase Ca2Si thermoelectric material and preparation method thereof

InactiveCN106116587ANot prone to decompositionLow reaction temperatureThermoelectric materialsSteel ball

The invention discloses a cubic-phase Ca2Si thermoelectric material and a preparation method thereof. The method comprises the following steps that 1, Ca powder and Si power are mixed to be uniform in an Ar protective atmosphere, and a mixture is obtained; 2, the mixture, a grinding ball, a stainless steel ball grinding tank and electronic scales are put into a glove box inflated with an atmosphere of Ar, after accurate weighing is conducted in the glove box, the mixture is put into the ball grinding tank, the ball grinding tank is well sealed, oxygen is prevented from entering the ball grinding tank, and then the ball grinding tank is taken out of the glove box; 3, the well-prepared ball grinding tank in the second step is put into a ball grinder, ball grinding is conducted at a certain rotating speed, and the powder reacts completely; 4, the well reacted powder in the third step is taken out and put into a stainless steel mold with a required specification, vacuum-sintering tabletting is conducted by means of a vacuum plasma sintering mode, and the cubic-phase Ca2Si flake or blocky thermoelectric material is obtained. The cubic-phase Ca2Si thermoelectric material and the preparation method thereof have the advantages that the technology is simple, operation is easy, the cost is low, and the obtained cubic-phase Ca2Si flake or blocky material is high in product purity and close in integration and has a good industrialization prospect.

Owner:FUZHOU UNIV

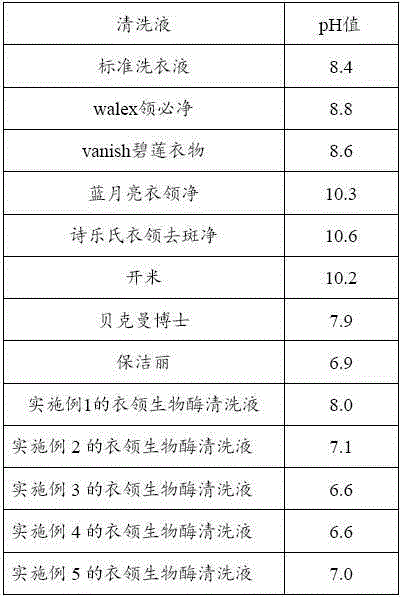

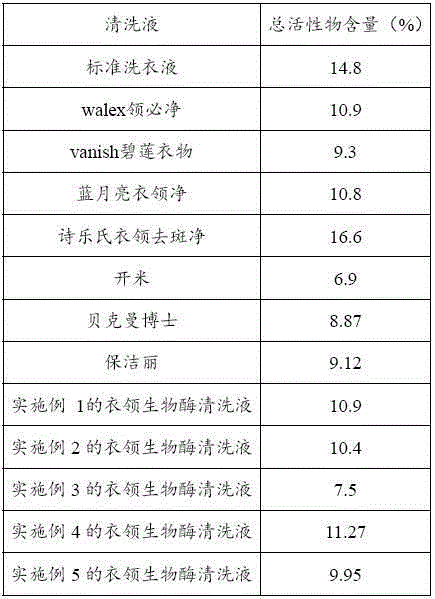

Bio-enzyme cleaning solution for collar, and preparation method and application of cleaning solution

InactiveCN106833925AQuick removalStrong decontaminationInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAcetic acidPreservative

The invention discloses a bio-enzyme cleaning solution for a collar. The bio-enzyme cleaning solution for the collar comprises the following components by weight percent: 7.5-12% of nonionic surfactant, 3-6% of anionic surfactant, 0.1-0.5% of disodium edetate, 1-3% of enzyme preparation, 0.1-1.5% of borax, 4.5-7.5% of dipropylene glycol butyl ether, 0.1-0.5% of fluorescent whitening agent, 0.1-0.5% of essence, 0.1-0.5% of preservative and the balance of deionized water. A pH value of the bio-enzyme cleaning solution for the collar is neutral and meta-acidic, so that skin and clothing are not damaged; when the bio-enzyme cleaning solution for the collar is used for cleaning the clothing, the components exert a synergistic effect, particularly the enzyme preparation and the surfactants exert a synergistic effect, so that stains in the clothing, particularly sweat stains on the collar and local stubborn dirt in the clothing can be rapidly removed; the detergency under an equivalent condition is high.

Owner:深圳市芭格美生物科技有限公司

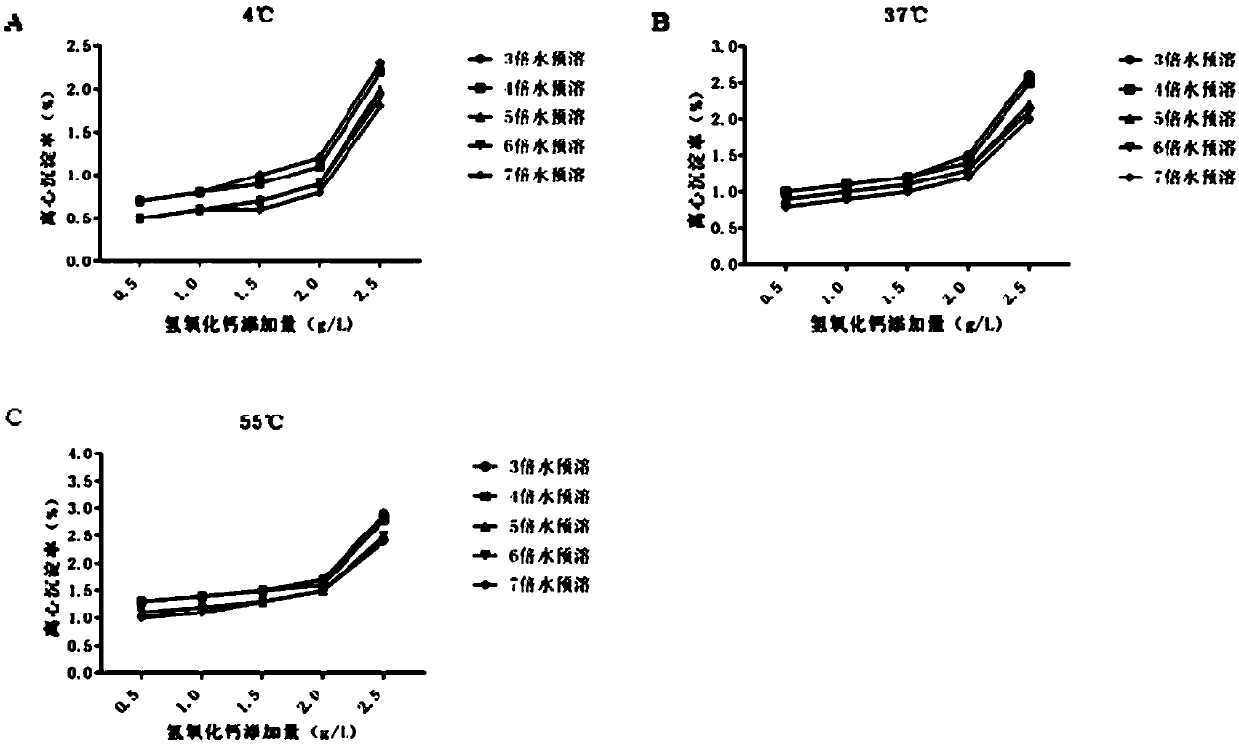

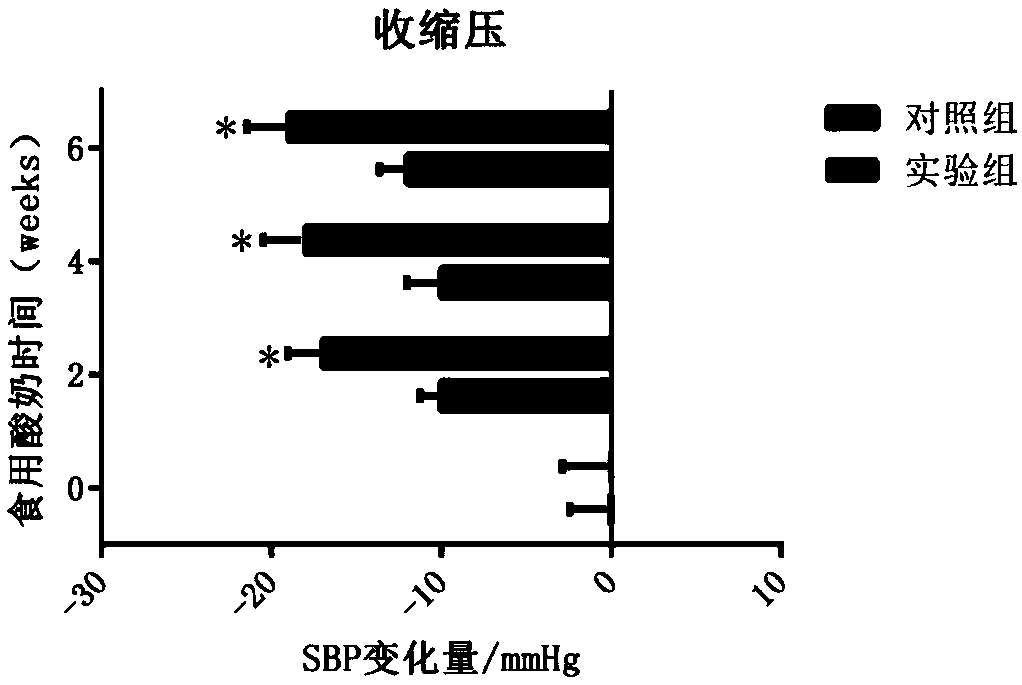

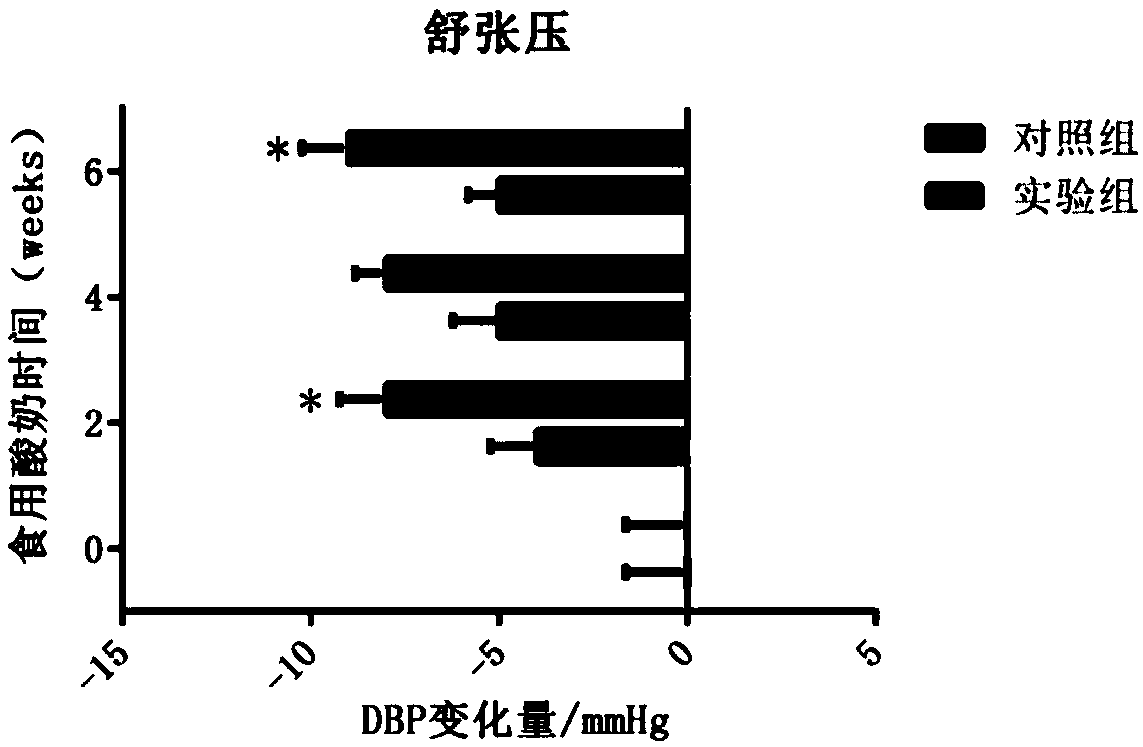

High-calcium low-sugar yogurt with blood pressure-lowering function and preparation method thereof

The invention provides a high-calcium low-sugar yogurt with a blood pressure-lowering function and a preparation method thereof. The raw materials of the high-calcium yoghurt comprise, in percent by weight, 0.04%-0.16% of calcium hydroxide, 1%-4.5% of sugar, 0.01-1% of a starter, and the balance milk. Based on a large number of experimental studies, calcium hydroxide is cleverly used as an additive for preparing the high-calcium yogurt, various factors that restrict the addition of calcium hydroxide are solved, and the high-calcium low-sugar yogurt added with calcium hydroxide is creatively invented. The yogurt is endowed with the high-calcium nutritional value, the texture of the yogurt can be maintained, and stability of the yogurt is ensured. In addition, the long-term consumption of the yogurt has a certain curative effect on hypertension, and thereby the yogurt can be used for adjuvant therapy of hypertension as a food therapy manner. The provided novel high-calcium low-sugar yogurt is a yogurt with fine taste, rich nutrition and unique flavor, and is suitable for drinking of ordinary consumers, calcium-deficient people, and people sensitive to sugar content.

Owner:SHANGHAI YAODAN BIOTECHNOLOGY CO LTD

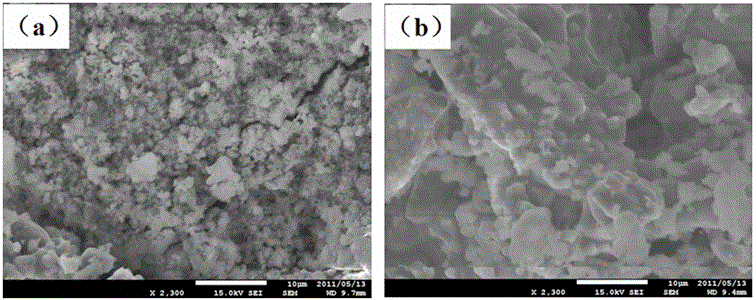

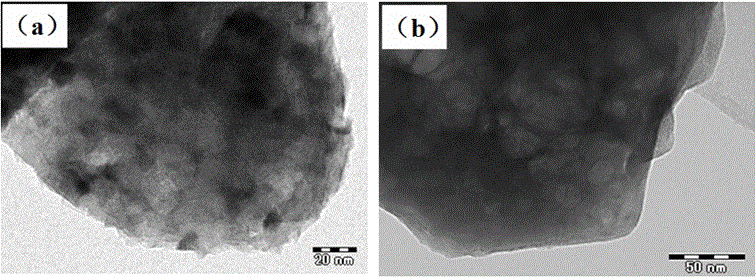

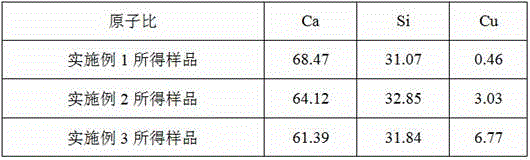

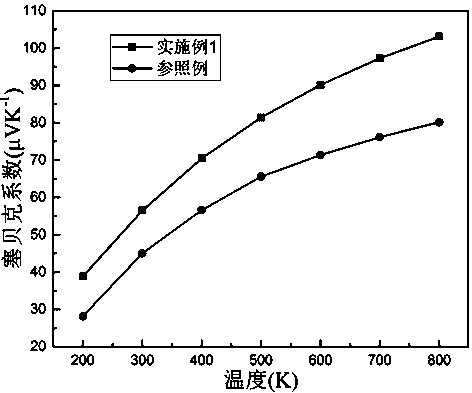

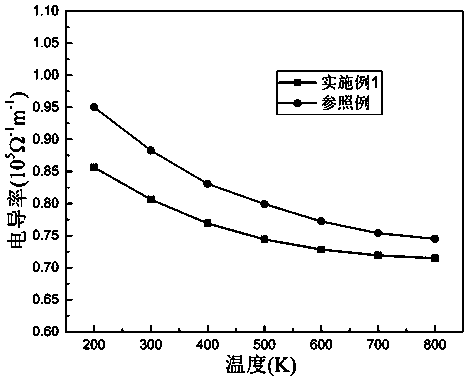

Cu-doped cubic phase Ca2Si thermoelectric material

InactiveCN106098922AControl oxidationReduce volatilityThermoelectric device manufacture/treatmentMetal silicidesAlkaline earth metalMetallurgy

The invention discloses a Cu-doped cubic phase Ca2Si thermoelectric material. A preparation method of the Cu-doped cubic phase Ca2Si thermoelectric material comprises the steps of: uniformly mixing Ca powder, Si powder and Cu powder under a protective atmosphere of Ar gas; then placing the obtained mixture powder and a grinding steel ball in a vacuum stainless steel ball mill jar under the protective atmosphere of Ar gas for sealing; and after a ball-milling reaction, carrying out vacuum sintering and tabletting on the sealed powder in a manner of plasma sintering to obtain a flaky Cu-doped cubic phase Ca2Si thermoelectric material. Because the Cu element has the characters similar with those of an alkaline-earth metal, after the Cu element is added and is used as donor doping, a Ca position is easily substituted, a conduction electron is provided to be used as a current carrier, thus the electric conductivity and the thermoelectric property of the material are improved. The Cu-doped cubic phase Ca2Si thermoelectric material has the advantages of simple process, easy operation, low cost and the like; and the obtained Cu-doped cubic phase Ca2Si thermoelectric material is high in purity, close in bonding and good in industrial prospect.

Owner:FUZHOU UNIV

Rapid solidification method for preparation of Te-doped cubic Ca2Ge

The invention discloses a rapid solidification method for preparation of Te-doped cubic Ca2Ge. The method comprises the following steps: respectively weighing Ca powder, Ge powder and Te powder in proportion, and uniformly mixing the powder in an argon protective atmosphere; then, placing the powder into an electromagnetic induction suspension smelting furnace for smelting; placing an obtained molten liquid in a vacuum quick quenching furnace, feeding high-purity argon gas for alloy remelting, and then preparing needle-shaped rapid solidification powder from a melt body; next, grinding and sieving the obtained rapid solidification powder, and performing heating and hot pressing step by step under the vacuum condition to prepare a massive blank; finally, performing hot pressing on the obtained blank to be placed in a vacuum tube furnace, and performing heating for reaction to obtain the Te-doped cubic Ca2Ge. The obtained Te-doped cubic Ca2Ge has fine grains, uniform alloy composition and structure and compact structure, and has good industrialization prospect.

Owner:FUZHOU UNIV

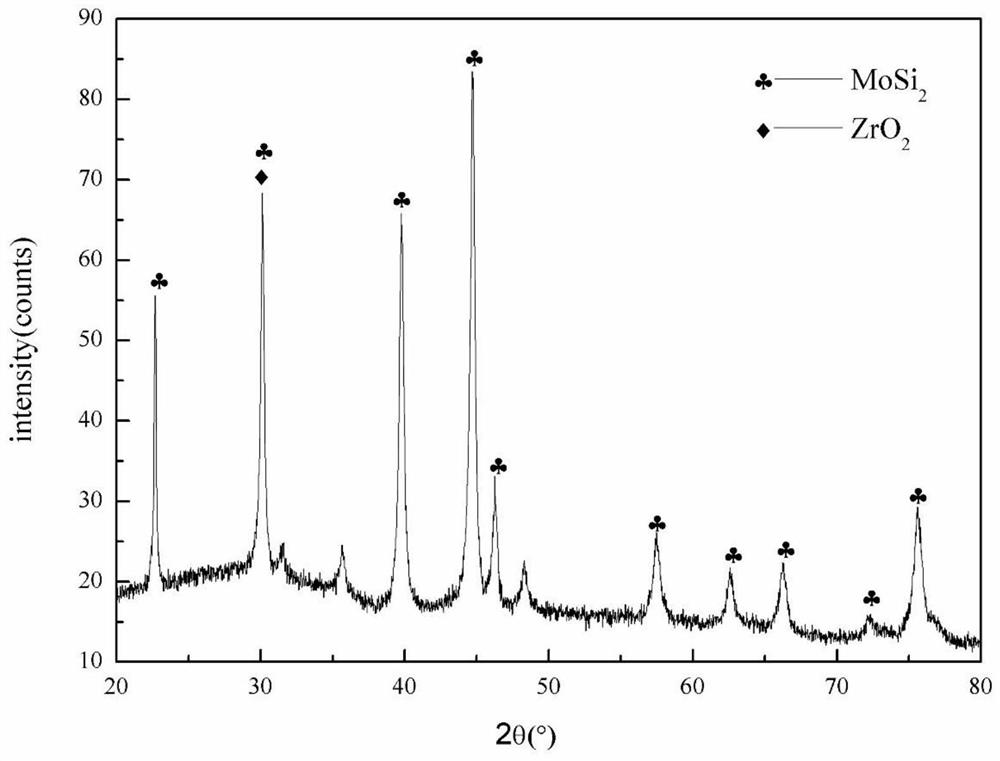

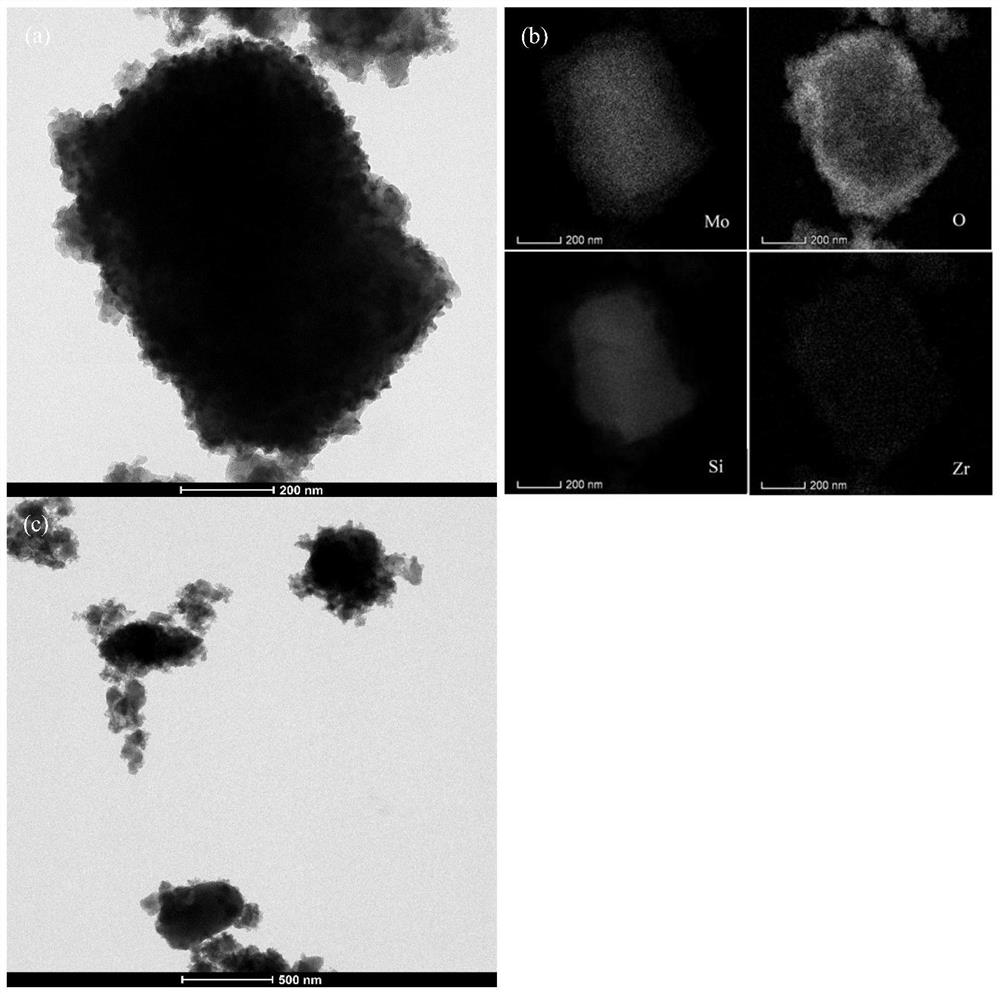

Preparation method of MoSi2@ZrO2 core-shell structure

The invention discloses a preparation method of a MoSi2@ZrO2 core-shell structure. The method comprises the following steps: (1), adding MoSi2 powder and SDS into a beaker, carrying out mechanical ultrasonic stirring, and using water or alcohol as a dispersion medium; (2), after dispersing for a certain time, adding a zirconium source into a suspension, and dropwise adding an alkaline solution NH3.H2O or NaOH until the pH value is between 7 and 14; continuously performing stirring for a certain time until the materials are uniformly mixed; (3), placing the prepared suspension liquid in a reaction kettle, the curing time being 12-48 h, and the curing temperature being 160-220 DEG C; performing heating by using a drying oven, and keeping the temperature after the suspension liquid reaches acertain temperature at a certain heating rate; (4), after hydrothermal reaction synthesis, performing filtering, washing, drying and sieving to obtain powder; (5), calcining the prepared powder in calcining equipment for 1-6 hours, the heat preservation temperature being 300-400 DEG C; and (6), obtaining a MoSi2@ZrO2 core-shell structure through the steps, and the volume fraction of the synthesized ZrO2 powder being 10-30 vol%. A hydrothermal method is adopted, no pollution is caused, the requirement for equipment is lowered, and the method is environmentally friendly.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation process of elastic protein

InactiveCN108517341APure ingredientsHigh activityConnective tissue peptidesPeptide preparation methodsPhosphoric acidActive carbon

The invention discloses a preparation process of an elastic protein, which includes the steps of: 1) washing and mincing ligament, and mixing the ligament with a phosphoric acid buffer solution to obtain a ligament solution, and adding elastinase to the ligament solution; 2) adding NaCl to the ligament solution and performing ultrasonic treatment and vibration culture; 3) filtering the solution through a plurality layers of gauze and abandoning filter residue, discoloring the filtrate through active carbon, and treating the filtrate through a semi-permeable membrane; 4) collecting the elasticprotein passing through the semi-permeable membrane and dissolving the elastic protein in pure water, performing centrifugal separation and collecting a supernatant; 5) treating the supernatant through a semi-permeable membrane in an ultra-filtering apparatus. The elastic protein is pure, is high in activity and is very suitable for various fields, such as foods, medicines, cosmetics and the like.

Owner:西安德氏禾本生物科技有限公司

Preparation method of arc extinction material for high voltage fuse

ActiveCN108538690ALow thermal conductivityEasily brokenFuse device manufacturePolyamidePhosphoric acid

The invention discloses a preparation method of an arc extinction material for a high voltage fuse, and belongs to the technical field of preparation of arc extinction materials. Prepared quartz sandis amorphous silica prepared from diatomite through infiltration of phosphoric acid and urea and chemical purification, the synthesized arc extinction material has low impurity content and pure composition, microcrystalline cellulose is produced in the quartz sand under the action of infiltration and can integrate functions of filling, thickening and emulsifying, nylon can produce flame-retardantgas polyamide in high-voltage arc, through composition of the components in specific quantities, the components can affect mutually, act jointly and produce a synergistic effect, so that the arc extinction material based on the flame-retardant gas polyamide produces obviously increased gas after being subjected to arc, gas pressure is increased obviously, and the material is decomposed more easilyin presence of high-temperature arc to produce gas and further has high flame retardance and broad application prospect.

Owner:广西振钢再生资源有限公司

Precise alloy casting for mechanical arm and casting method of precise alloy casting

The invention provides a precise alloy casting for a mechanical arm and a casting method of the precise alloy casting, and relates to the technical field of precise alloy materials. The precise alloy casting comprises chemical elements including, by mass percent, 1.1%-1.6% of C, 1.8%-3.5% of Mn, 1.52%-2.83% of Al, 0.11%-0.2% of Cr, 0.08%-0.16% of Ni, 0.12%-0.19% of Co, 0.23%-0.37% of W, 0.22%-0.43% of Cu, 0.12%-0.43% of Nb, 0.12%-0.20% of Fe, smaller than or equal to 0.04% of Re, smaller than or equal to 0.04% of S, smaller than or equal to 0.04% of P and the balance Ti. According to the precise alloy casting, rare metal elements are adopted, many external cores are formed when the casting is cast, grains are refined or the crystal habit is changed, and the precise alloy casting is formed; and accordingly, the mechanical performance of the casting is improved, the surface smoothness of the casting is high, internal defects of the casting are few, components are pure, and performance is stable.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

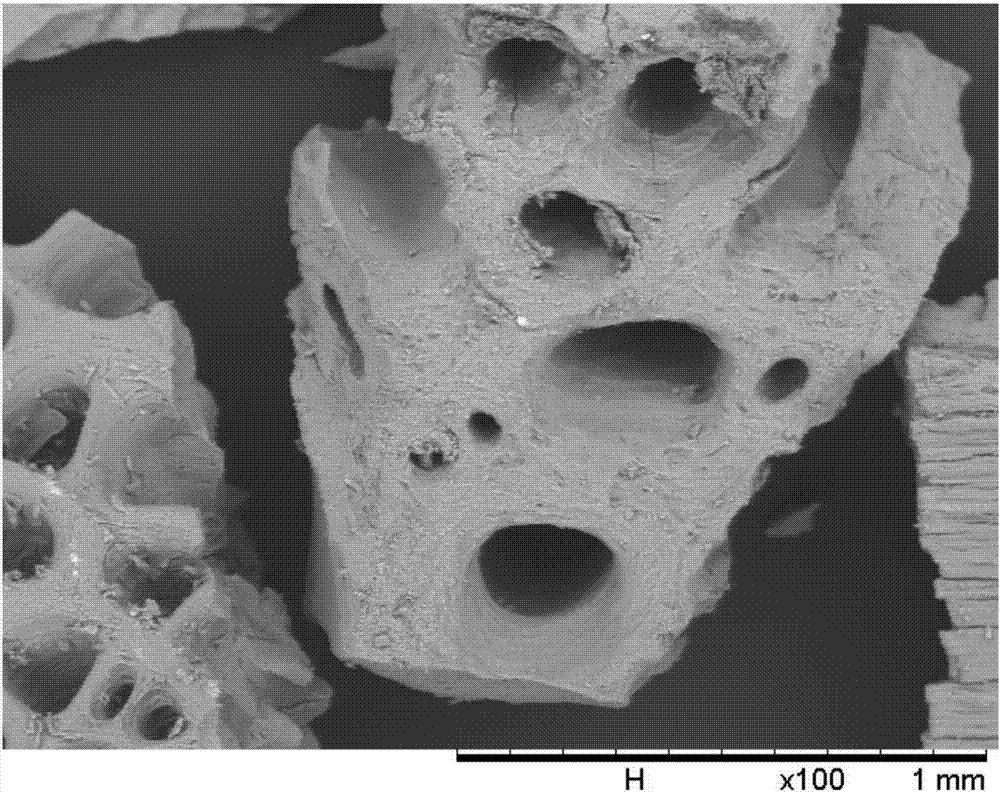

Biphasic calcium phosphate porous bioceramic bone scaffold material and preparation method thereof and application

The invention relates to the field of bioceramic materials, in particular to a biphasic calcium phosphate porous bioceramic bone scaffold material which is prepared from salmon spine as a raw material, is composed of main ingredients hydroxyapatite and beta-tricalcium phosphate , has high porosity, reserves a natural three-dimensional pore structure, has a particle size of 500-1000 [mu]m, and is prepared through steps of washing and drying, high temperature calcination, grinding, sieving and sterilization. The biphasic calcium phosphate porous bioceramic bone scaffold material is rich in sources of raw materials and low in preparation cost, high purity biphasic calcium phosphate ceramic can be prepared without artificial addition of compounds, and the content of hydroxyapatite and beta-tricalcium phosphate can be changed by controlling the calcination temperature in the preparation process, and the biphasic calcium phosphate porous bioceramic bone scaffold material contains a small amount of carbonated hydroxyapatite and various trace elements such as magnesium, potassium and strontium, with the content close to the content in the human body. The calcium phosphate ceramic prepared through the method can serve as a good bone scaffold material to be applied to clinical bone defect repair.

Owner:SHANGHAI CHANGHAI HOSPITAL

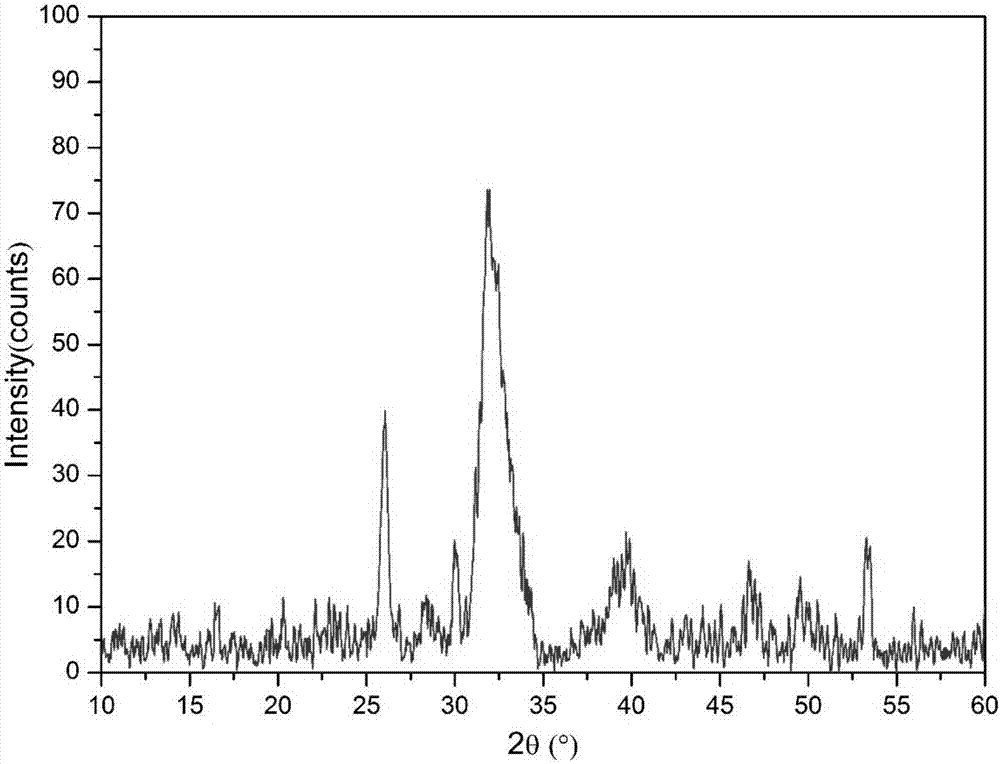

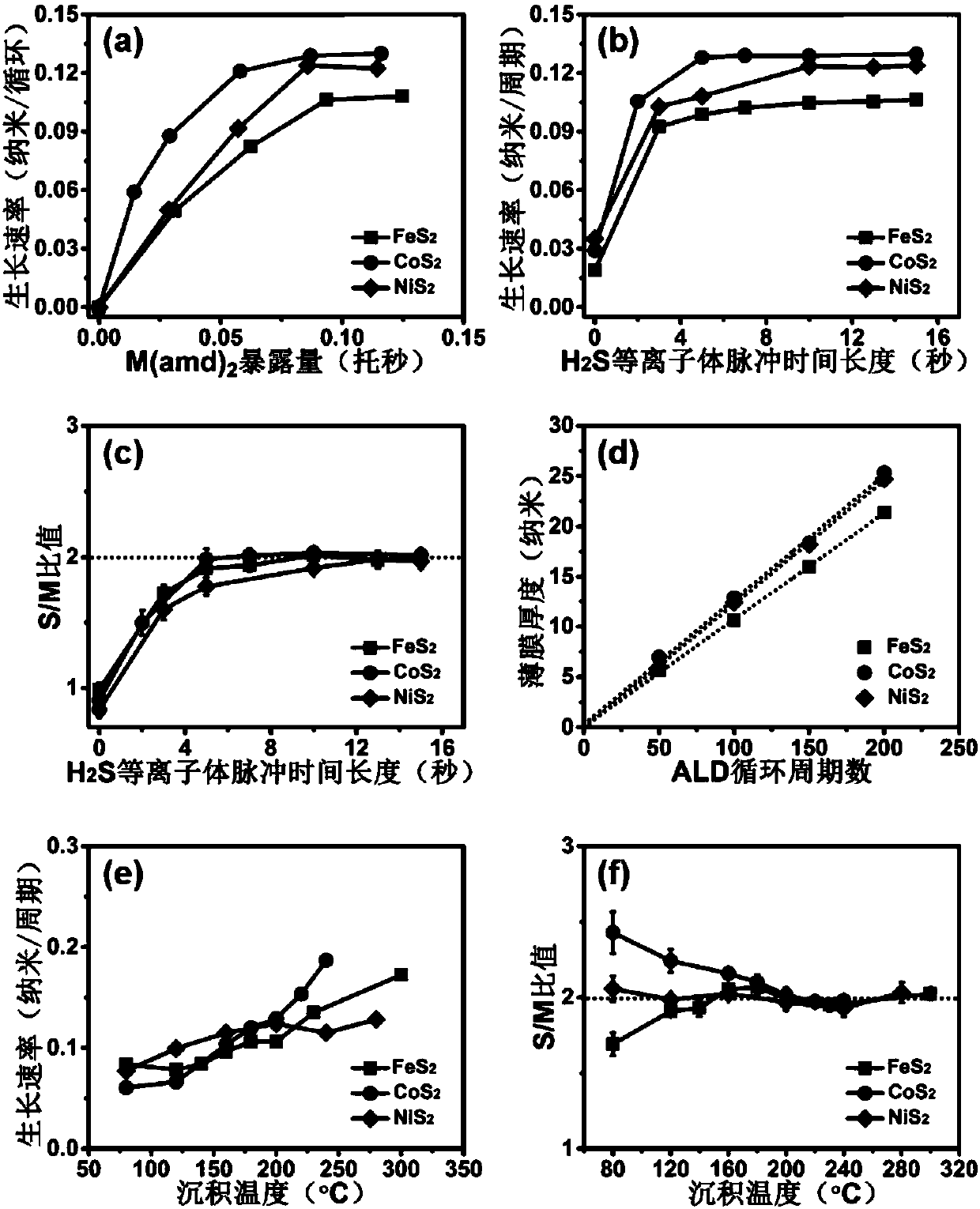

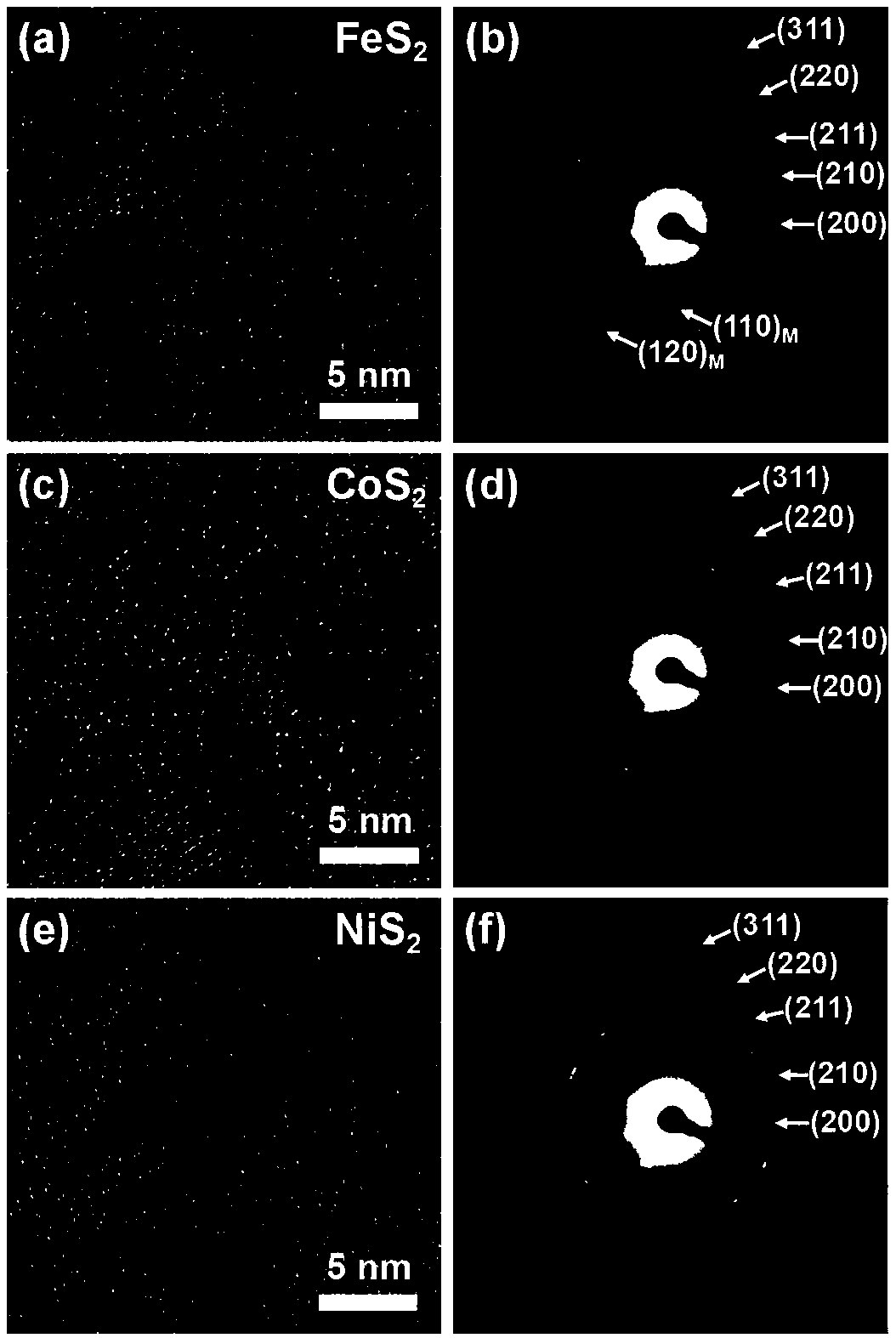

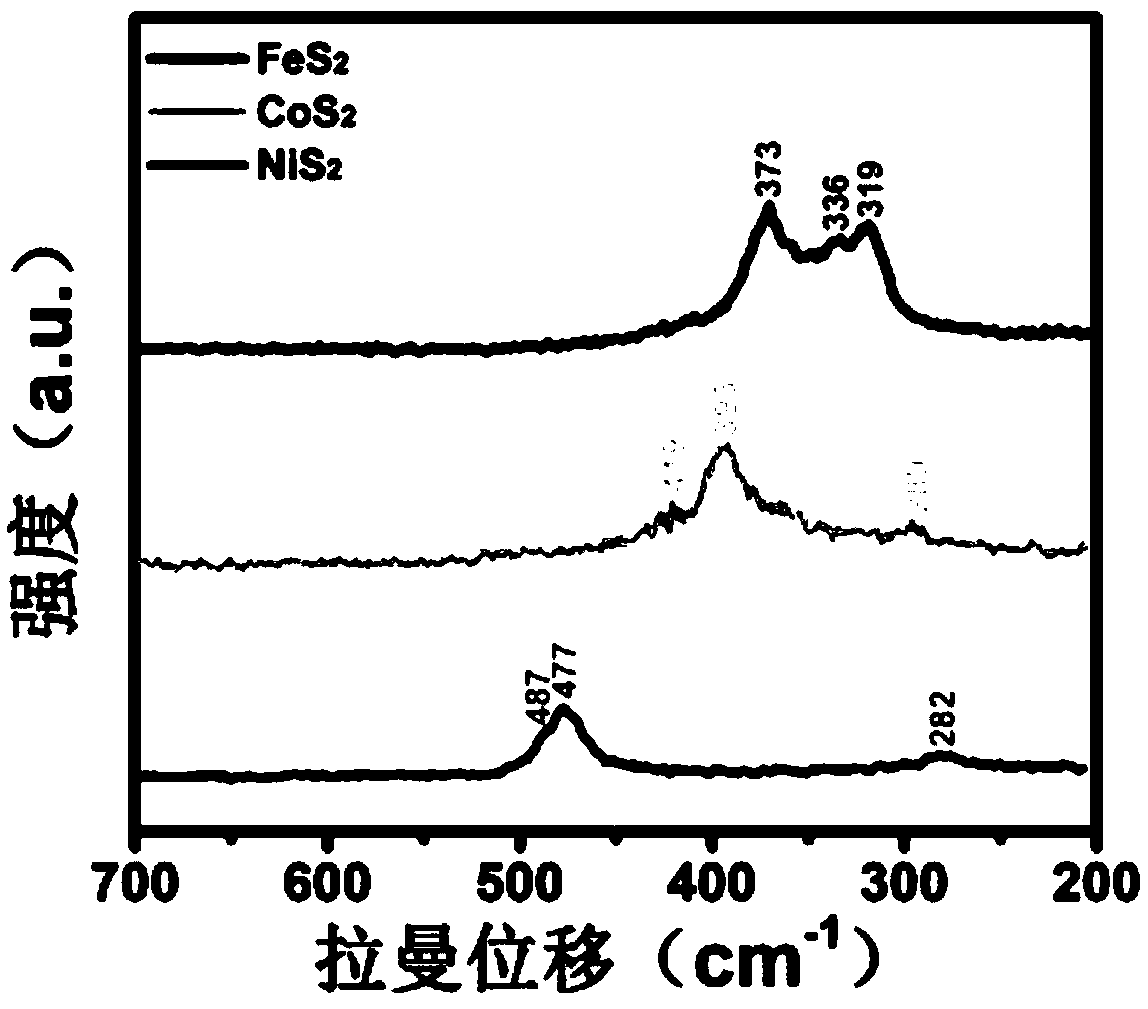

Method for growing transition metal disulfide film

ActiveCN108441841AWide applicabilityPure ingredientsChemical vapor deposition coatingChemistryWidth ratio

The invention discloses a method for growing a transition metal disulfide film. The method is characterized in that a metal amidine compound is taken as a metal precursor, and a H2S plasma is taken asa sulfur source, so that pyrite FeS2, CoS2 and NiS2 films are synthesized through an ALD process. A deposition process for FeS2, CoS2 and NiS2 follows layer-by-layer ALD growth behaviors within a relatively wide deposition range, and can obtain a transition metal disulfide film which is very pure in component, is smooth in surface and is of a pyrite structure. Furthermore, FeS2, CoS2 and NiS2 films deposited through the ALD process can be deposited into grooves with depth-width ratios being 10 to 1 in a conformal mode, and therefore, the ALD process has a wide range of performing conformal film deposition on the 3D framework with a complex height-depth-width ratio, and has prospect applicability.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com