Rapid solidification method for preparation of Te-doped cubic Ca2Ge

A technology of cubic phase and solidification method, applied in the field of Ca-Ge alloy materials, can solve the problem that Ge material preparation research has not been reported, and achieve the effect of meeting the needs of large-scale production, high density and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

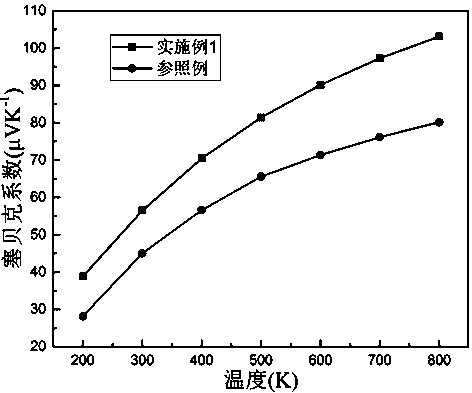

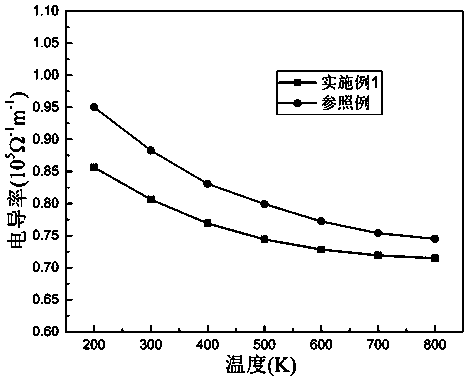

Embodiment 1

[0028] (1) Weigh Ca powder, Ge powder and Te powder respectively at a molar ratio of 82:21:0.5, and mix them evenly under an argon protective atmosphere;

[0029] (2) Vacuum the electromagnetic induction levitation melting furnace, and then fill it with argon, then place the mixture obtained in step (1) in the water-cooled crucible of the electromagnetic induction levitation melting furnace, and raise the temperature to 950 °C to make the Ca in the crucible , Ge and Te are in a molten state, and the surface impurities are removed after smelting for 15 minutes; this operation is repeated 3 times to obtain a molten liquid;

[0030] (3) Put the molten liquid obtained in step (2) in a vacuum quenching furnace, and then fill it with high-purity argon for alloy remelting; then the melt is thrown out by the molybdenum wheel at a linear speed of 25 m / s, Obtain needle-shaped quick-setting powder;

[0031] (4) After the quick-setting powder obtained in step (3) was manually ground and ...

Embodiment 2

[0040] (1) Weigh Ca powder, Ge powder and Te powder respectively at a molar ratio of 82:21:1.5, and mix them evenly under an argon protective atmosphere;

[0041] (2) Vacuumize the electromagnetic induction levitation melting furnace, and then fill it with argon, then place the mixture obtained in step (1) in the water-cooled crucible of the electromagnetic induction levitation melting furnace, and raise the temperature to 1000 °C to make the Ca in the crucible , Ge and Te are in a molten state, and the surface impurities are removed after smelting for 25 minutes; this operation is repeated 4 times to obtain a molten liquid;

[0042] (3) Put the molten liquid obtained in step (2) in a vacuum quenching furnace, and then fill it with high-purity argon for alloy remelting; then the melt is thrown out by the molybdenum wheel at a linear speed of 30 m / s, Obtain needle-shaped quick-setting powder;

[0043](4) After the quick-setting powder obtained in step (3) was manually ground a...

Embodiment 3

[0048] (1) Weigh Ca powder, Ge powder and Te powder respectively at a molar ratio of 82:21:3, and mix them evenly under an argon protective atmosphere;

[0049] (2) Vacuum the electromagnetic induction levitation melting furnace, and then fill it with argon, then place the mixture obtained in step (1) in the water-cooled crucible of the electromagnetic induction levitation melting furnace, and raise the temperature to 1100 °C to make the Ca in the crucible , Ge and Te are in a molten state, and the surface impurities are removed after smelting for 35 minutes; this operation is repeated 5 times to obtain a molten liquid;

[0050] (3) Put the molten liquid obtained in step (2) in a vacuum quenching furnace, and then fill it with high-purity argon for alloy remelting; then the melt is thrown out by the molybdenum wheel at a linear speed of 50 m / s, Obtain needle-shaped quick-setting powder;

[0051] (4) After the quick-setting powder obtained in step (3) was manually ground and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com