Patents

Literature

93results about How to "Good mechanical compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

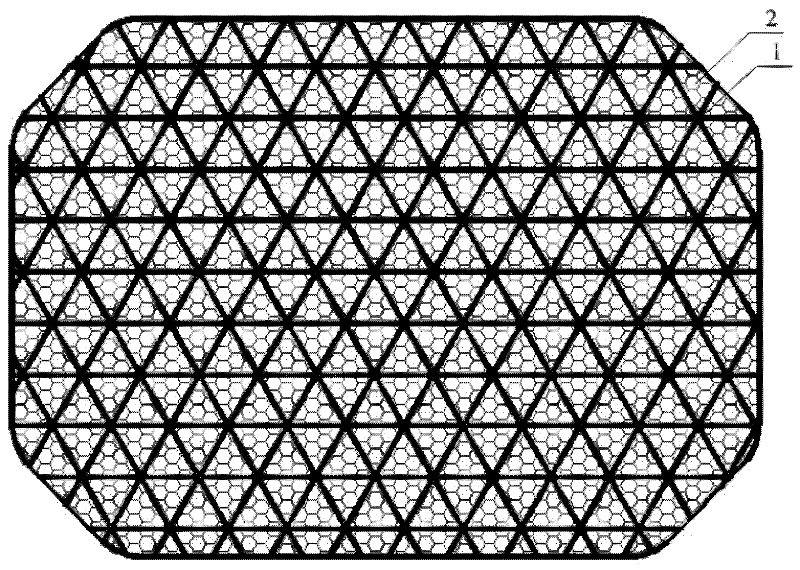

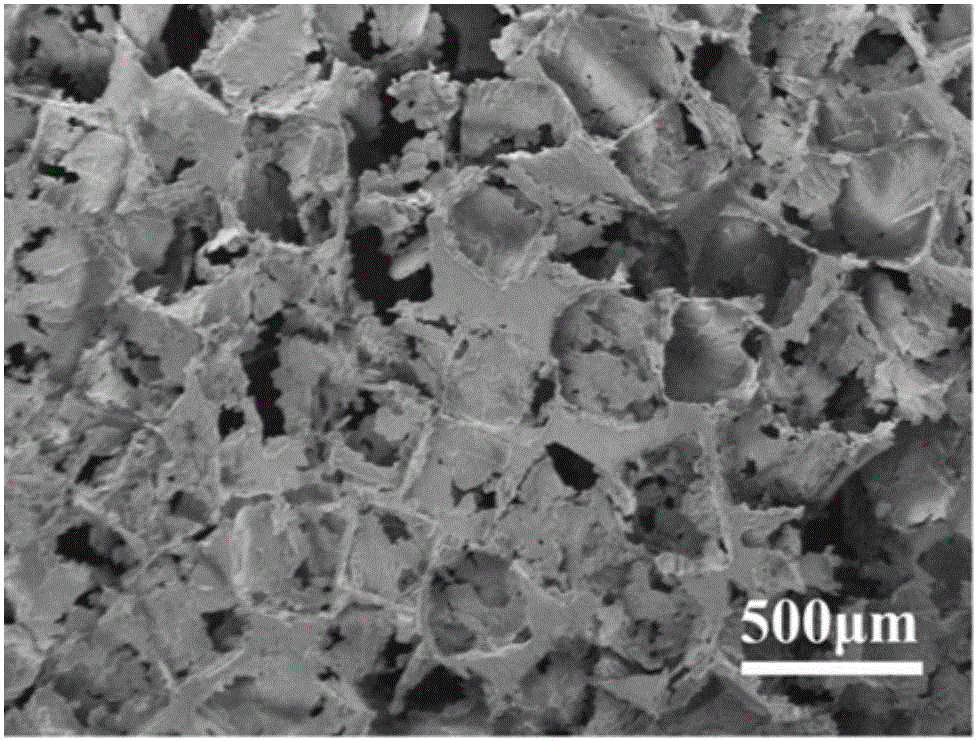

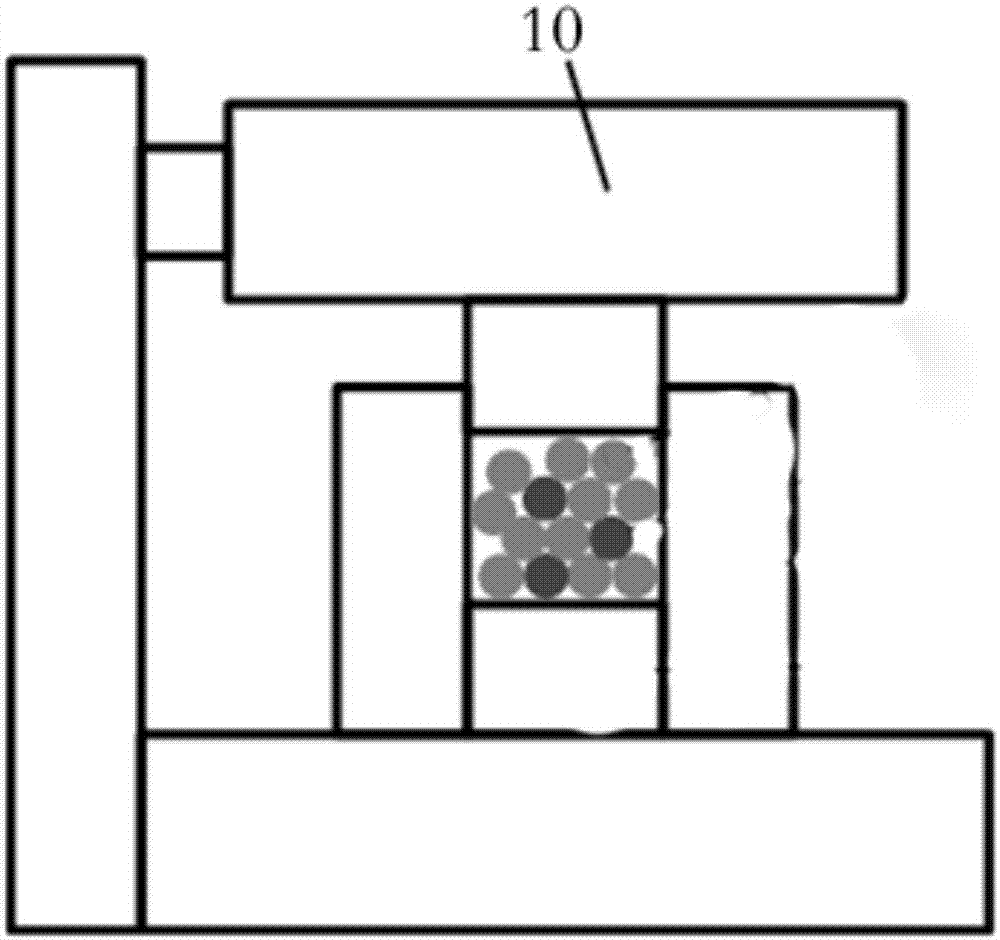

Bone restoration body with composite porous structure and preparation method thereof

InactiveCN102512267AGood mechanical compatibilityGood bone conductionBone implantFreeze-dryingReticular formation

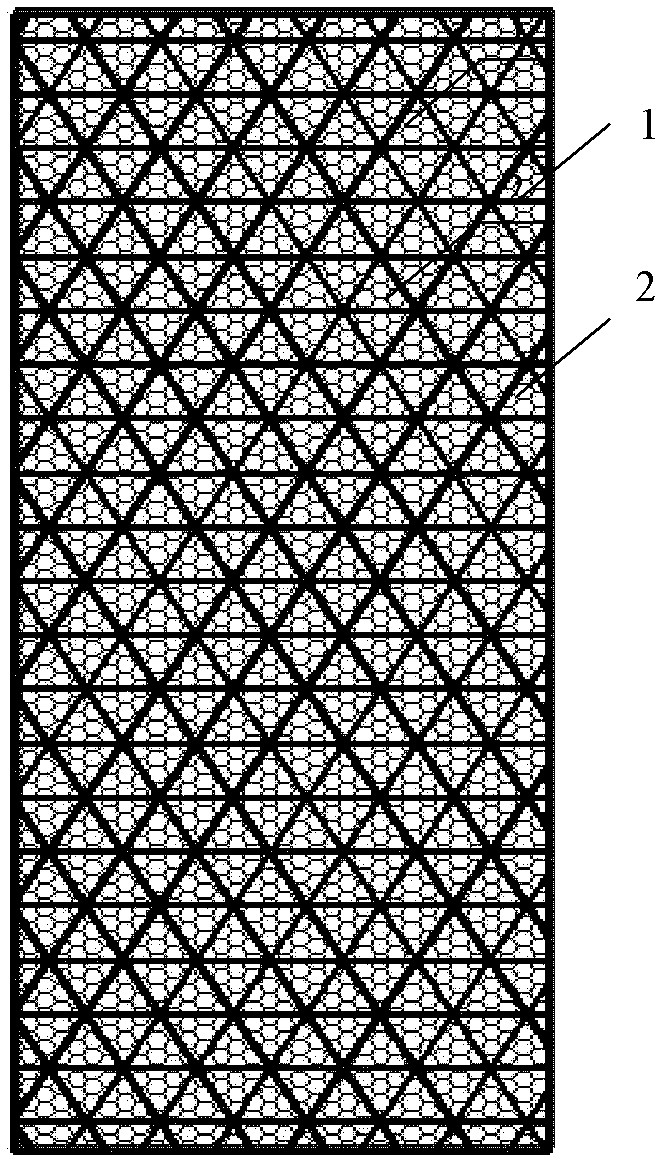

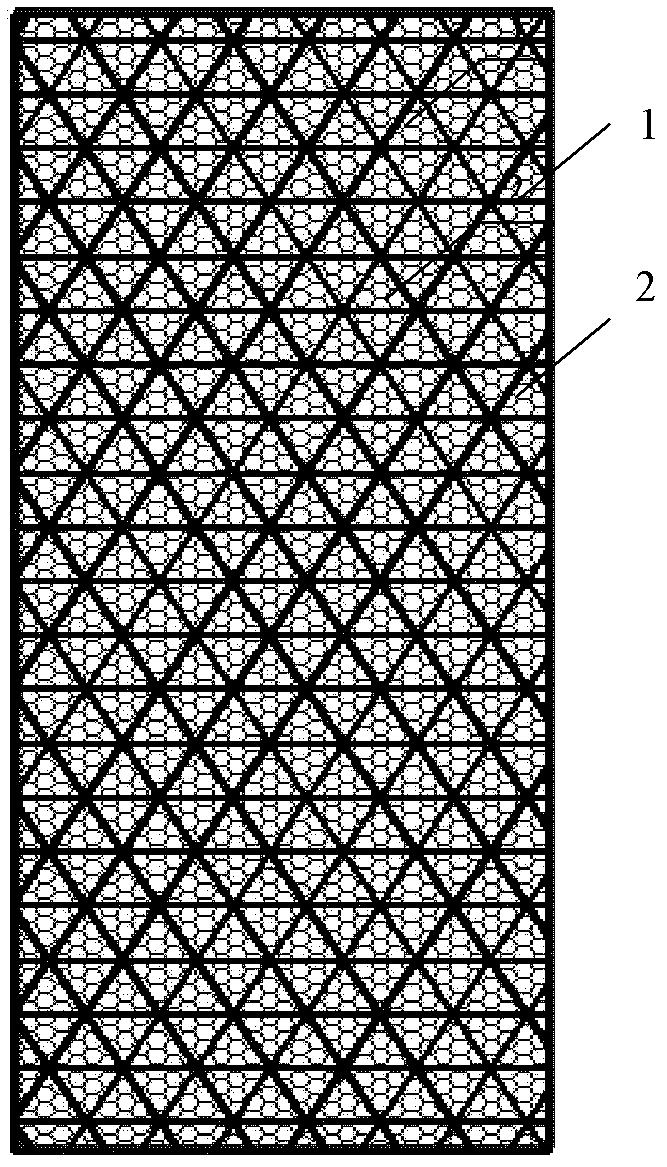

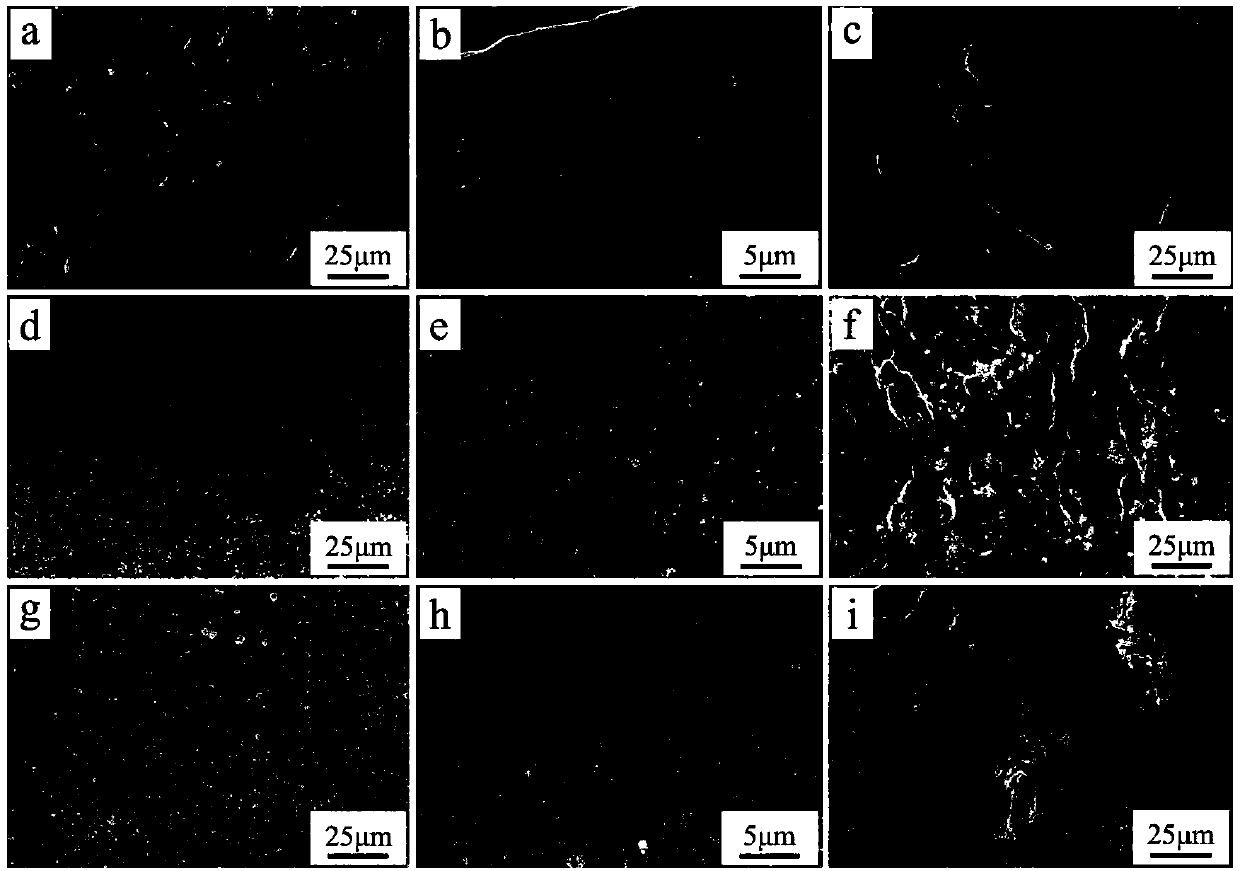

A bone restoration body with a composite porous structure and a preparation method of the bone restoration body. The bone restoration body comprises a porous metal bracket and an infill body with a porous structure, wherein the porous metal bracket is of a three-dimensional net structure, a plurality of pores are arranged in the inner part of the porous metal bracket, and the infill body with the porous structure is fully filled in all the pores. The preparation method combines the direct metal rapid prototyping technology and the freeze drying technology and comprises the steps of preparing the porous metal bracket by a structural design and the direct metal rapid prototyping technology, pouring uniformly-mixed polymer solution or polymer / biological ceramics mixing solution into the porous metal bracket, carrying out freezing treatment, and then forming the infill body with the porous structure through freeze drying so as to obtain the bone restoration body with the composite porous structure, wherein the infill body with the porous structure has micropore characteristics. The bone restoration body has good mechanics compatibility, can obtain good bone conduction performance and bone induction performance, improves bone integration efficiency and can be used for clinical treatment of segmental bone defect of a bearing part.

Owner:SHANGHAI JIAO TONG UNIV

Polyetheretherketone total hip femoral head prosthesis material and preparation method thereof

The invention provides a polyetheretherketone total hip femoral head prosthesis material and preparation method thereof, wherein the material comprises (by weight percentage) 10-60% of carbon fiber and balancing polyetheretherketone. When short carbon fiber is employed, the short carbon fiber and polyetheretherketone resin are weighed and premixed in high speed mixing machine, the premix is compounded, squeezed and granulated with a double bolt extrusion machine. When continuous carbon fiber is employed, orthogonal reinforced carbon fiber tang and polyetheretherketone resin are weighed for laminating, then placed into parallel board die arrangement for compression moulding.

Owner:SHANGHAI JIAO TONG UNIV

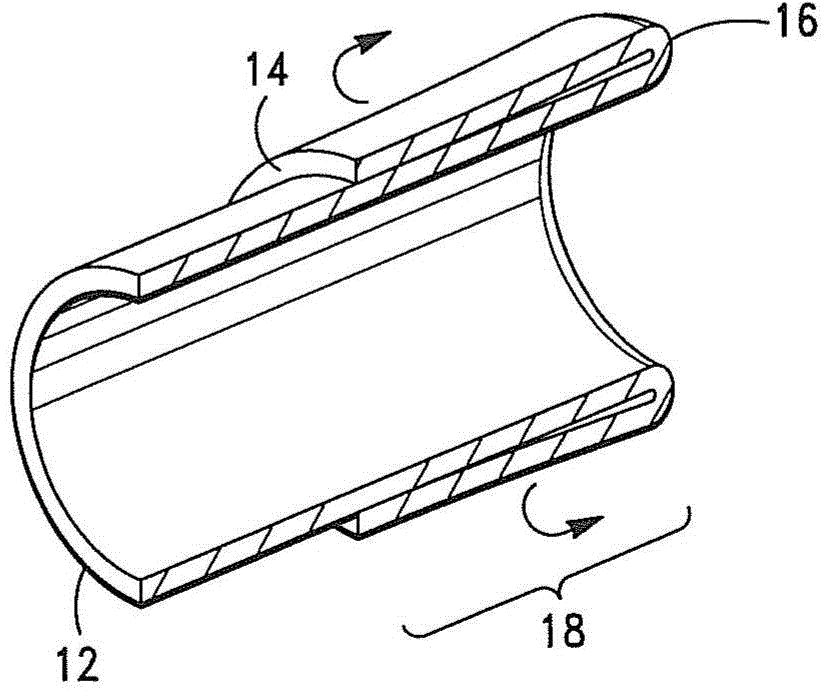

Whole coxa thighbone prosthesis and method for making same

InactiveCN1593356AImprove stress transferImprove bindingJoint implantsFemoral headsFiberRight femoral head

The invention discloses a full coax femoral head prosthetic appliance and its making process, wherein the prosthetic appliance comprises an inner layer and an outer layer, the inner layer being an uninterrupted carbon fiber reinforced polyetheretherketone composite material layer, the outer layer being a short cut carbon fiber reinforced polyetheretherketone composite material layer, and a core rod die arrangement and a prosthesis die arrangement are utilized to realize thermal compression bonding of the two composite material layers. The invention also discloses the process for making the prosthetic appliance.

Owner:SHANGHAI JIAO TONG UNIV

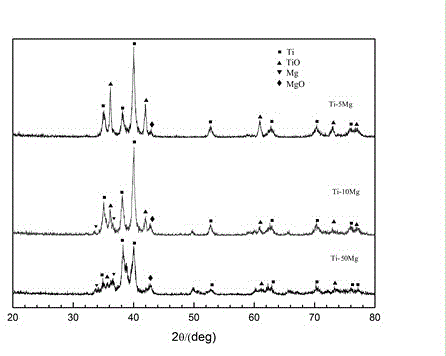

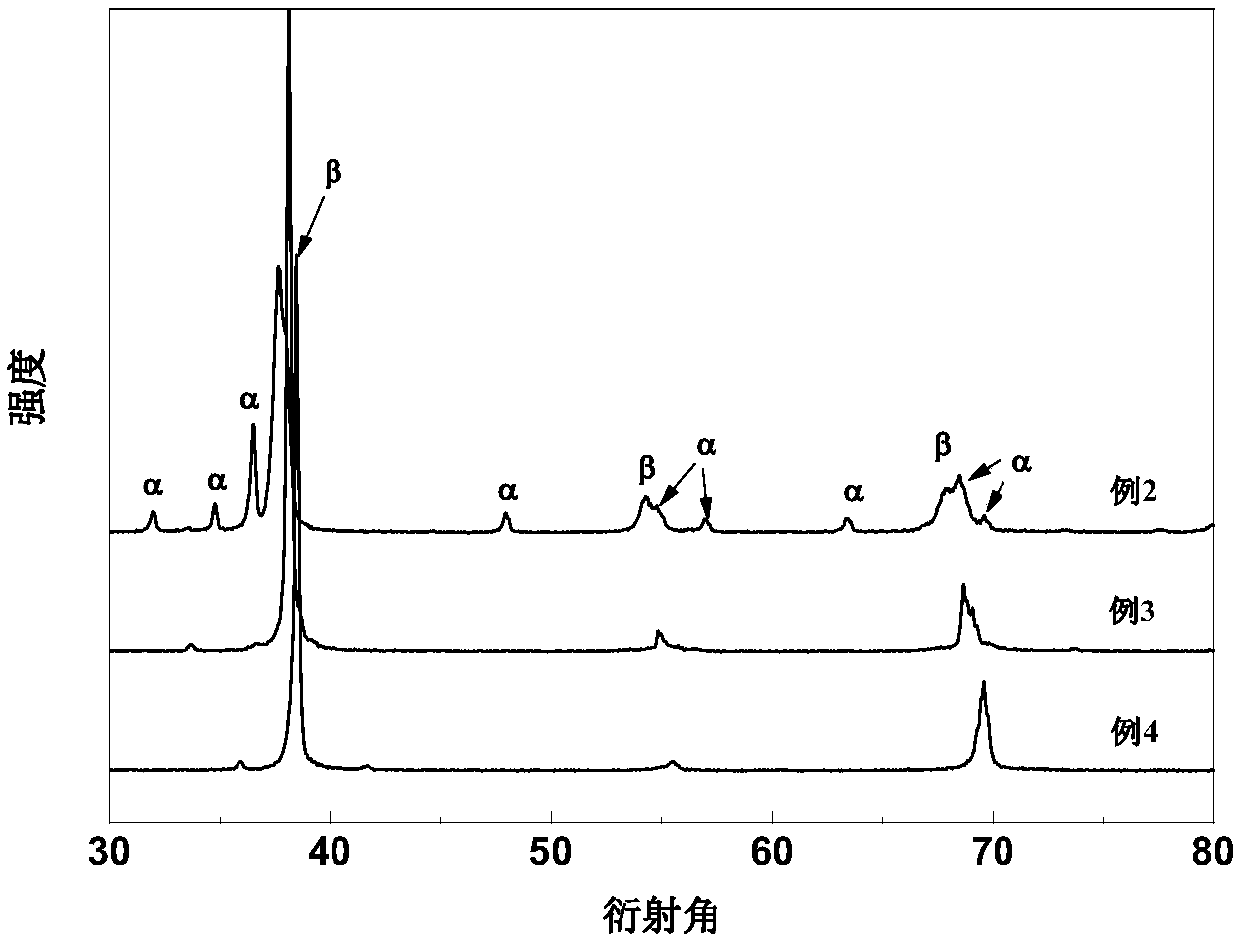

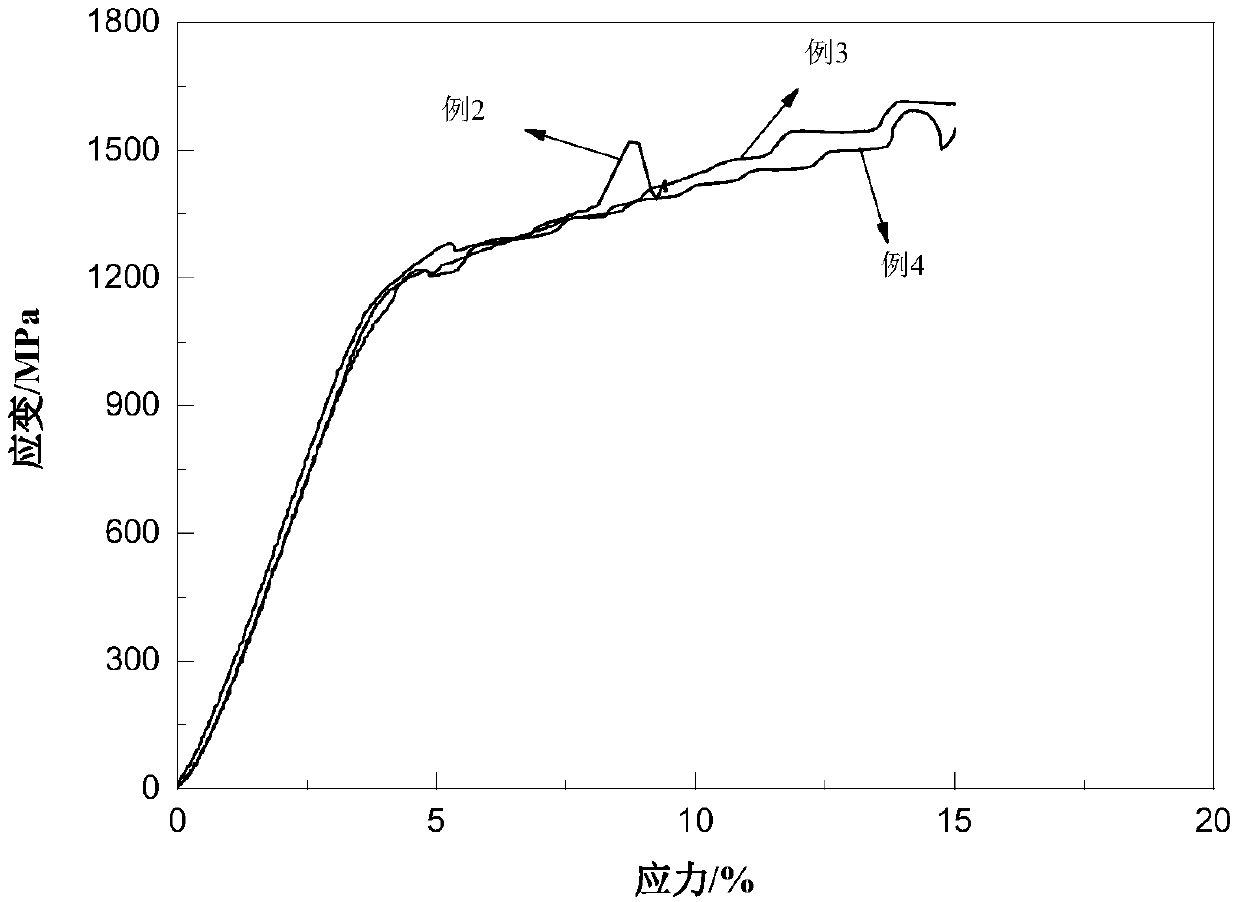

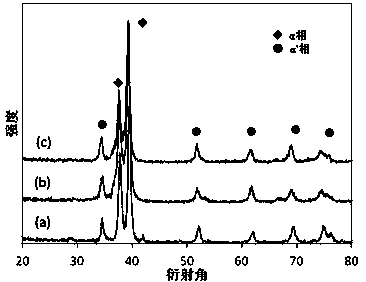

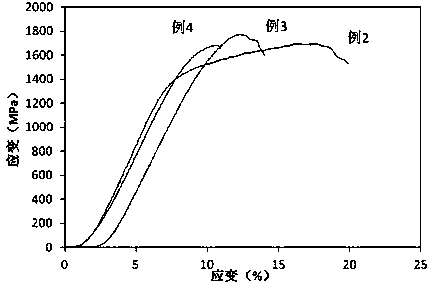

A Ti-Mg alloy material, a preparing method thereof and applications of the alloy material

The invention discloses a Ti-Mg alloy material applied as human tissue bone repair materials and a preparing method thereof. Phase composition of the alloy comprises Ti, Mg, TiO and MgO. The alloy comprises 70-80% of the Ti, 0-10% of the Mg, 8-20% of the TiO and 2-5% of the MgO. The Ti-Mg alloy is prepared by utilization of mechanical alloying and spark plasma sintering. The porosity of the alloy is smaller than 1%, the Vickers hardness of the alloy is HV400-HV500, the compressive strength of the alloy is 1600-1700 MPa, the elasticity modulus of the alloy is 12-13 GPa, the self-corrosion potential of the alloy ranges from -900 mV to -800 mV, the self-corrosion current density is 50-90 [mu]A / cm<2>. The alloy has characteristics of uniform structure, high compactness, good mechanical compatibility, capability of being biodegradable, and good corrosion resistance.

Owner:CENT SOUTH UNIV

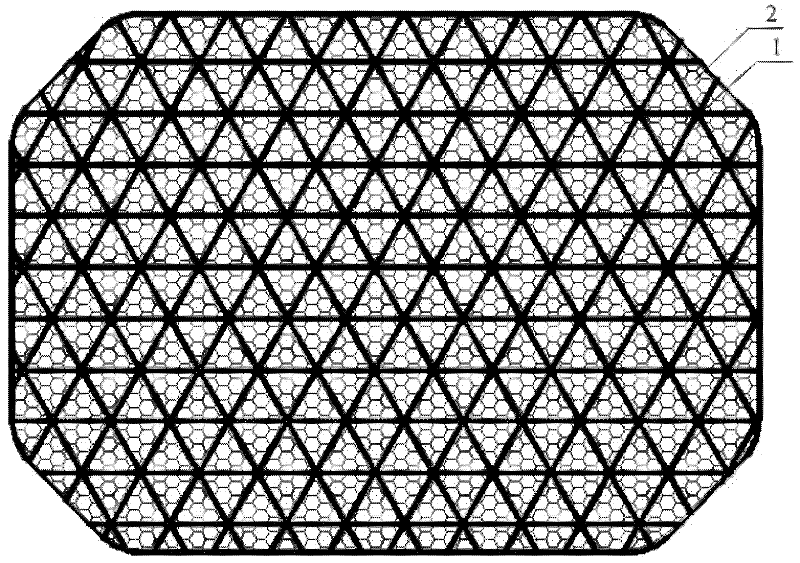

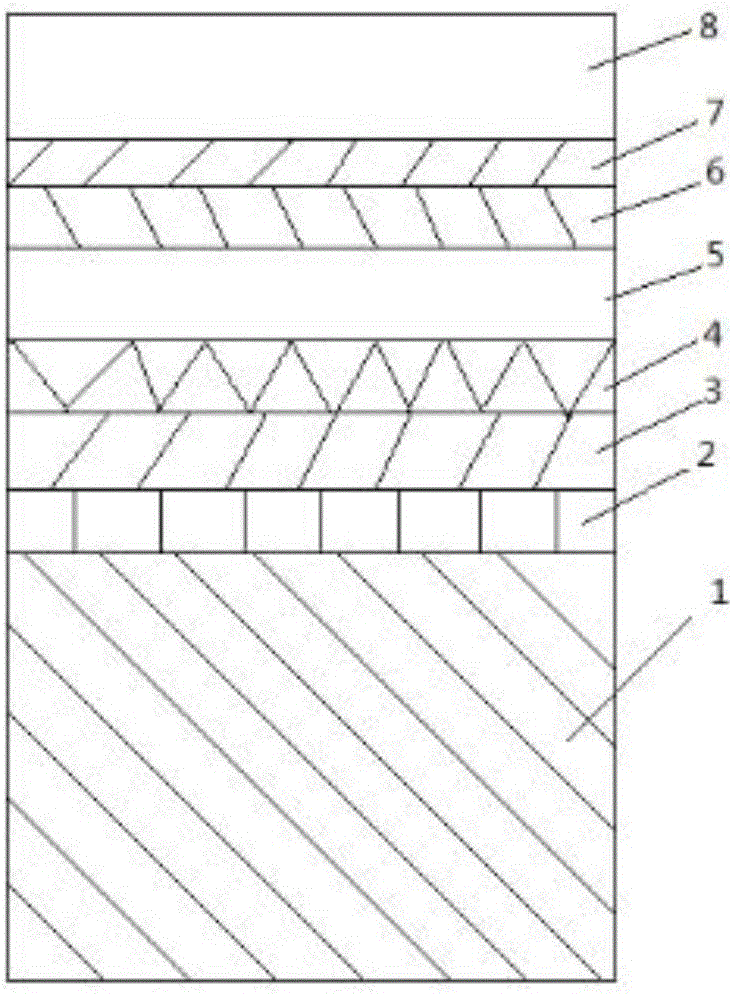

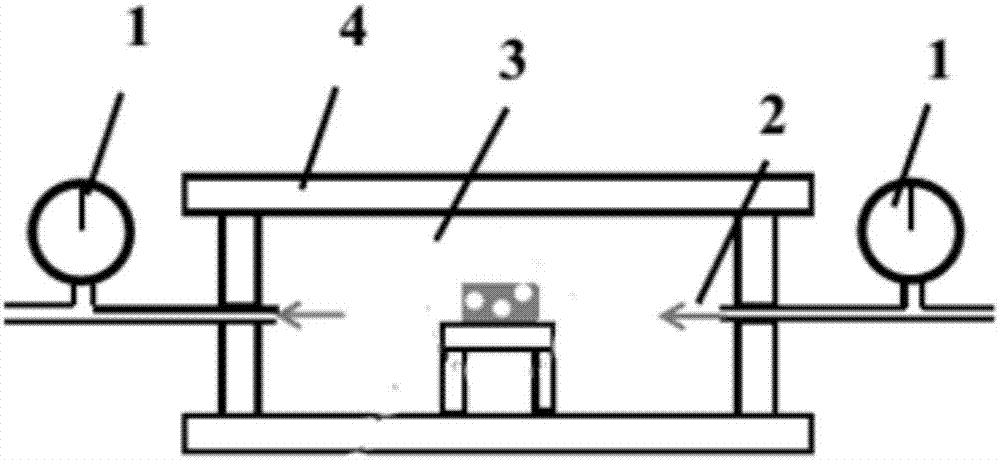

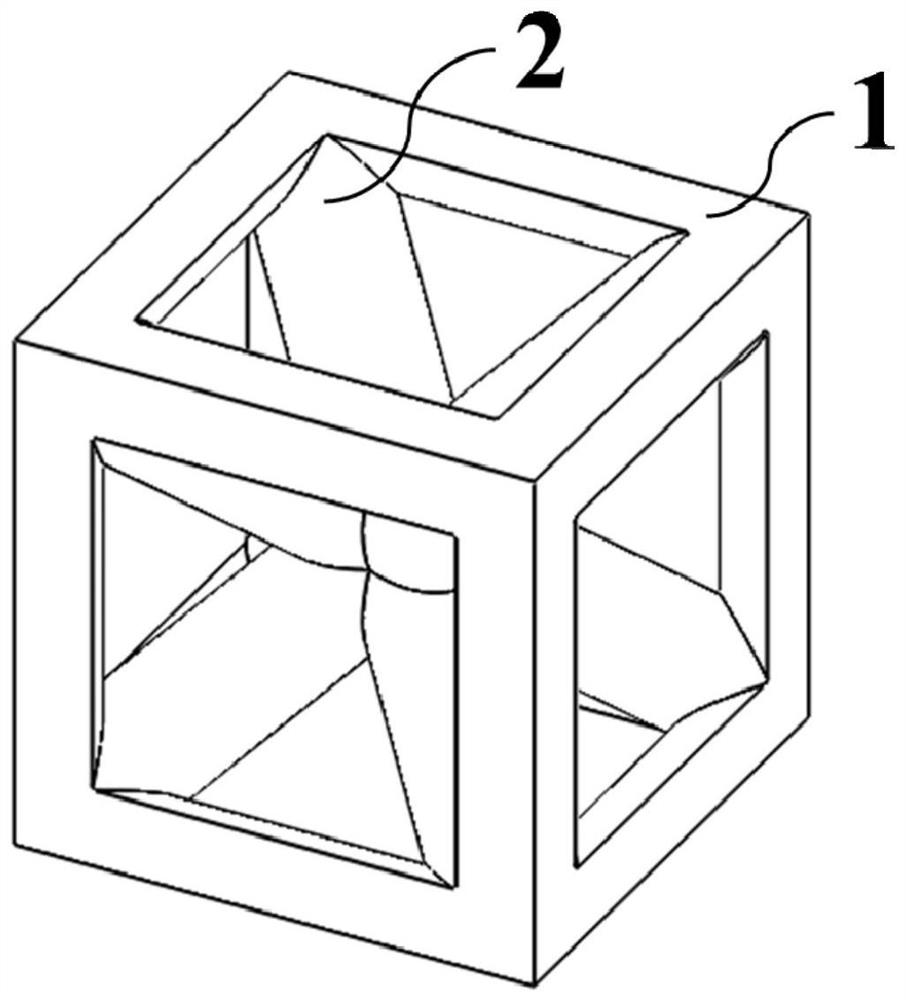

Mixed porous structure interbody fusion cage and preparation method thereof

InactiveCN102440852AGood mechanical compatibilityGood bone conductionSpinal implantsFreeze-dryingReticular formation

Disclosed are a mixed porous structure interbody fusion cage and a preparation method thereof. The interbody fusion cage comprises a porous metal support and porous structure filling bodies, the porous metal support is a three-dimensional net-shaped structure, a plurality of holes are arranged in the porous metal support, and the porous structure filling bodies are fully filled in the holes. The preparation method includes steps that the metal rapid forming technology is directly combined with the freeze drying technology, the porous metal support is manufactured via a structural design and the direct metal rapid forming technology, then uniformly mixed polymer gel or polymer / biological ceramic compound gel is poured in the porous metal support to realize freeze treatment, so that the porous structure filling bodies with the micropore feature are formed after freeze drying, and the mixed porous structure interbody fusion cage is obtained. Mechanical compatibility is good, contact area between the mixed porous structure interbody fusion cage and natural centrum is further increased, instant stability is good, fusion rate is improved, and the mixed porous structure interbody fusion cage and the preparation method thereof can be used for treating clinical degenerative disc diseases.

Owner:SHANGHAI JIAO TONG UNIV

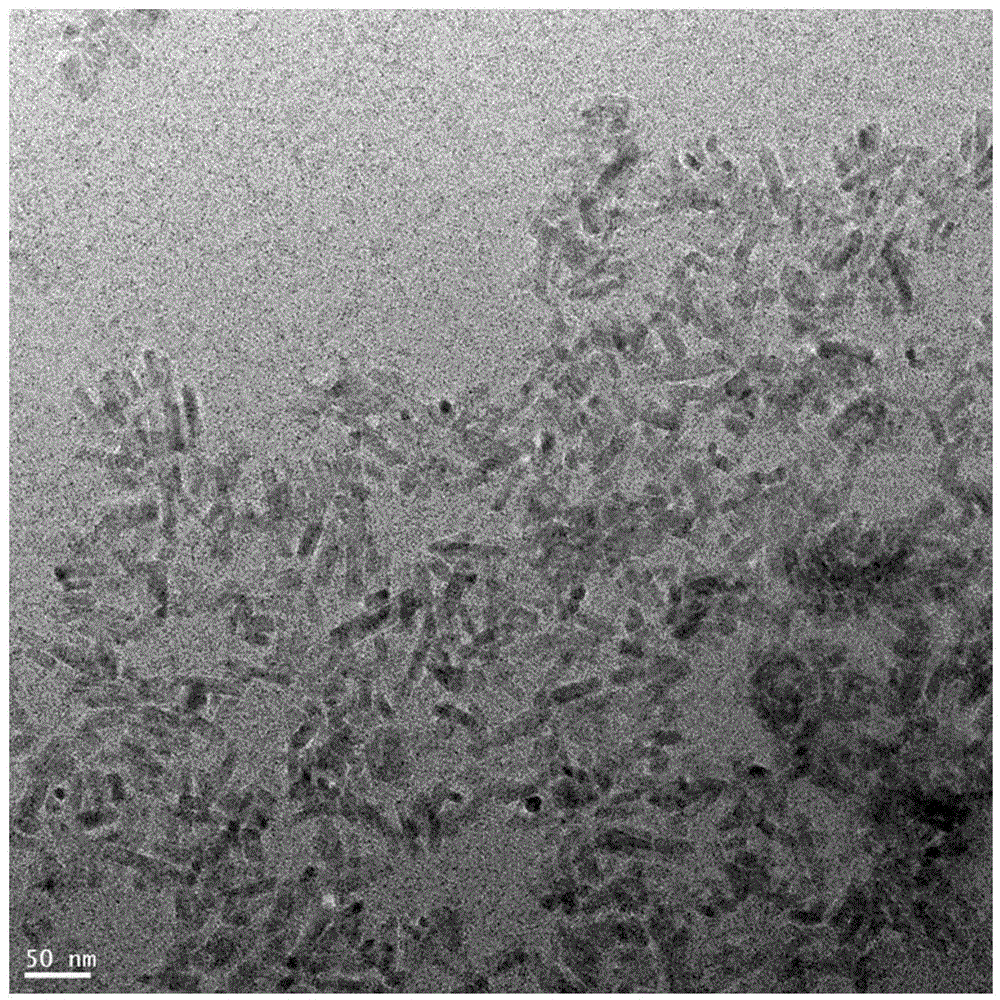

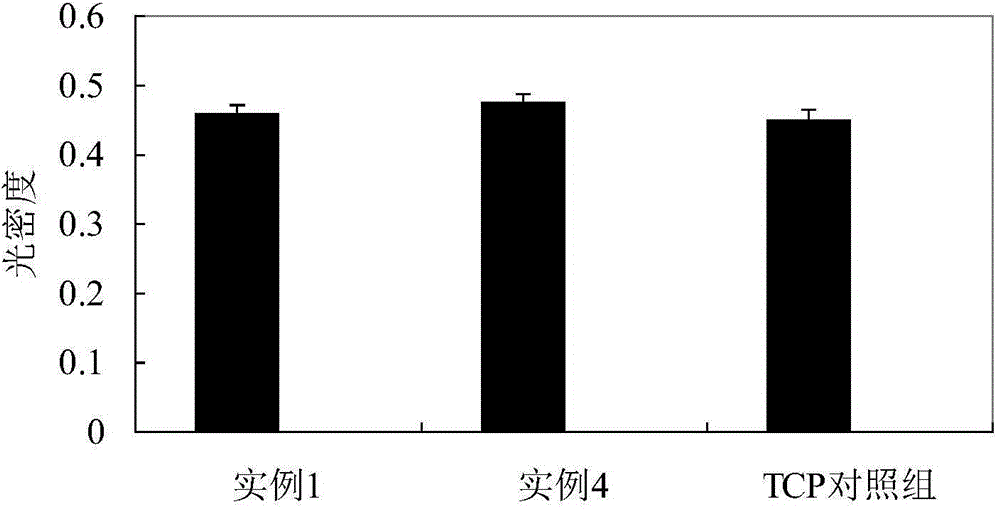

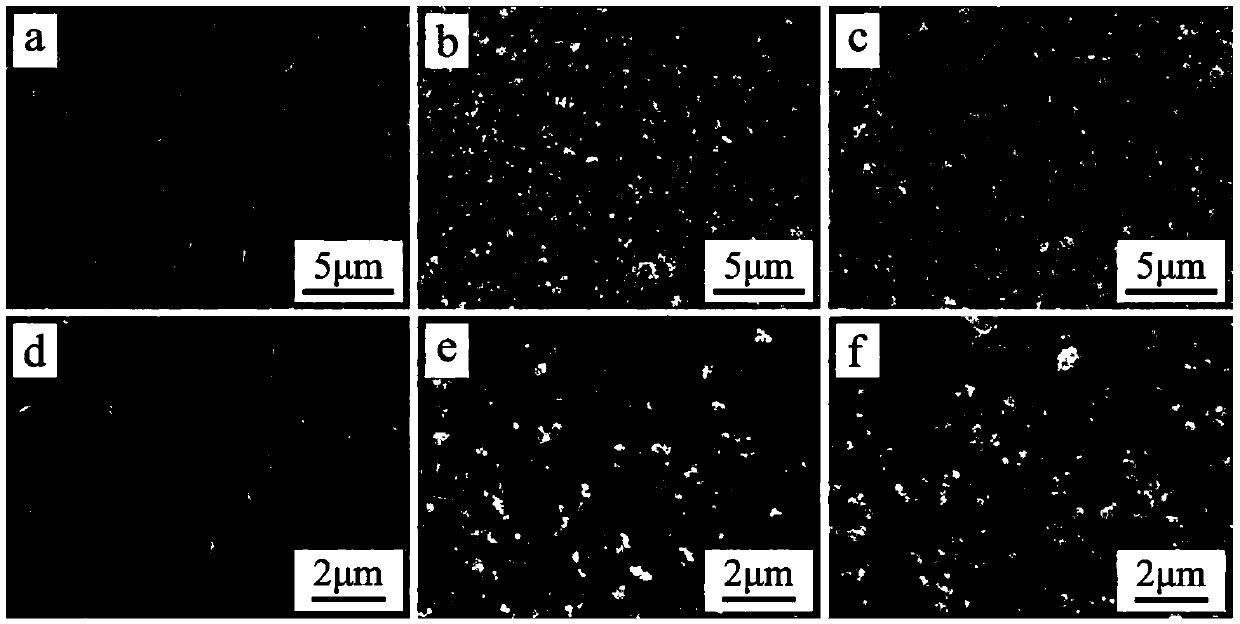

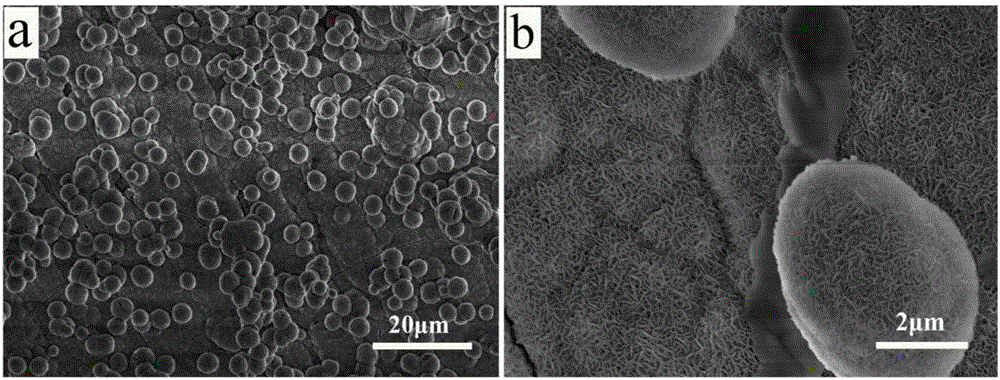

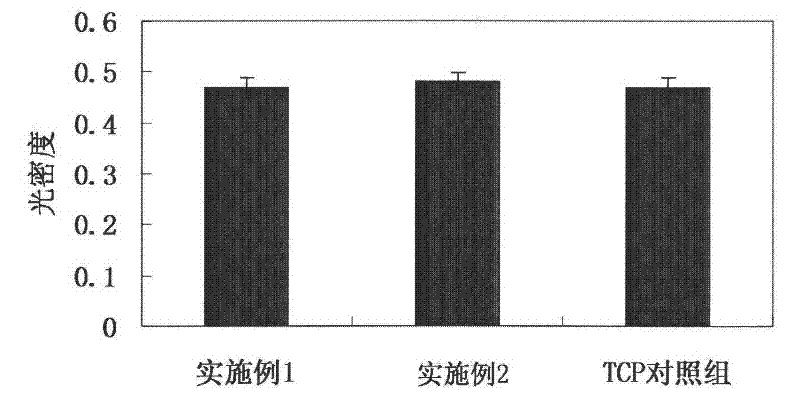

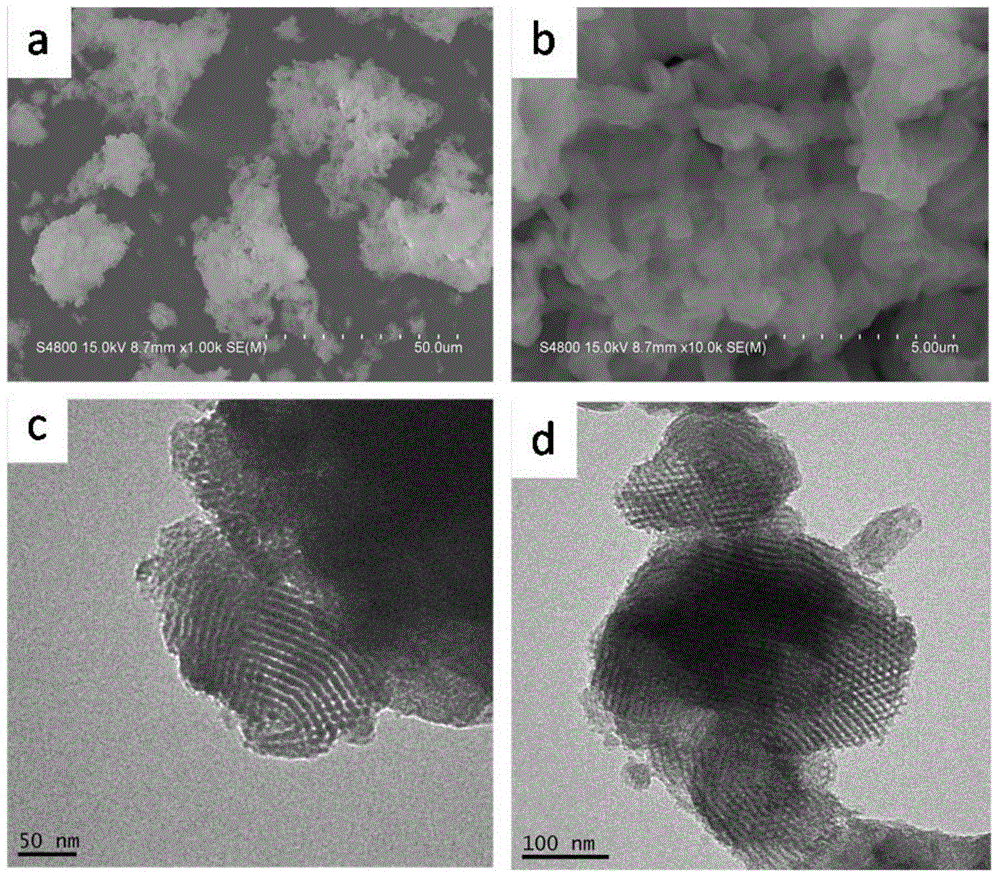

Nano-hydroxyapatite/polyether-ether-ketone composite material and bone repair body as well as preparation method and application thereof

The invention discloses a nano-hydroxyapatite / polyether-ether-ketone composite material and a bone repair body as well as a preparation method and application thereof. The preparation method of the composite material comprises the following steps: uniformly mixing 30-35wt% of 200nm-1mu m hydroxyapatite powder and 65-70wt% of 5-15mu m polyether-ether-ketone powder to obtain mixed powder; and processing the mixed powder and moulding to obtain the composite material. The composite material has good biocompatibility and bioactivity as well as mechanical properties matching the bone tissue, effectively prevents the stress shielding effect, and can stimulate bone growth, accelerate bone healing, shorten the healing time of the injury after material implantation of bone and reduce the probability of second operation. The preparation technology of the composite material can be adjusted to prepare bone repair bodies different in shape, specification and mechanical properties to meet the clinical needs. Inflammatory reaction is avoided after the implantation of the bone repair bodies, the mechanical properties are matched with human bone, negative effects such as bone repair material loosening and bone resorption are prevented, and the clinical needs for bone repair can be met.

Owner:SHENZHEN KEJU NEW MATERIAL

Prestress-reinforced light high-strength controllable-degradation medical composite material and preparation method thereof

InactiveCN103330959AMake full use of the strengthening effectReduce dosageSurgeryAbsorbable polymersProtection layer

The invention relates to a prestress-reinforced light high-strength controllable-degradation medical composite material and a preparation method thereof. The medical composite material is characterized in that a magnesium alloy wire subjected to prestress processing is taken as a reinforced phase to improve strength and stiffness of the composite material, an absorbable high polymer material is taken as a matrix, and meanwhile, the early-stage degradation velocity of the composite material can be further regulated and controlled by regulating the thickness of a shell protection layer formed by the high polymer material of the matrix. According to the composite material, bars or plates are manufactured by utilizing methods of thermal die pressing, extrusion or drawing or the like, and various degradable high-toughness bone repairing and fixing instruments such as bone nails and bone plates can be obtained by carrying out subsequent machining; and compared with the conventional absorbable polymer bone surgery instruments, the composite material has the advantages that the mechanical fixing effect is relatively good, and furthermore, the problems that the degradation speed of the absorbable magnesium alloy bone surgery instruments is difficult to control and the hydrogen release quantity during degradation is large and the like can be overcome.

Owner:SOUTHEAST UNIV

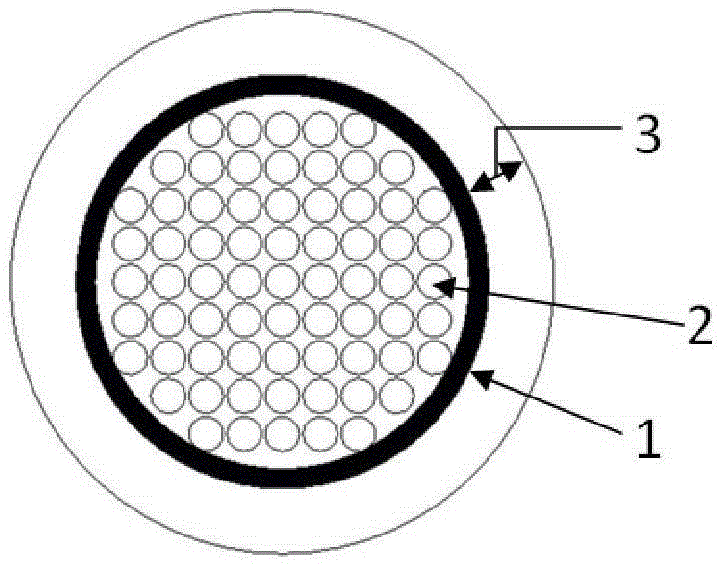

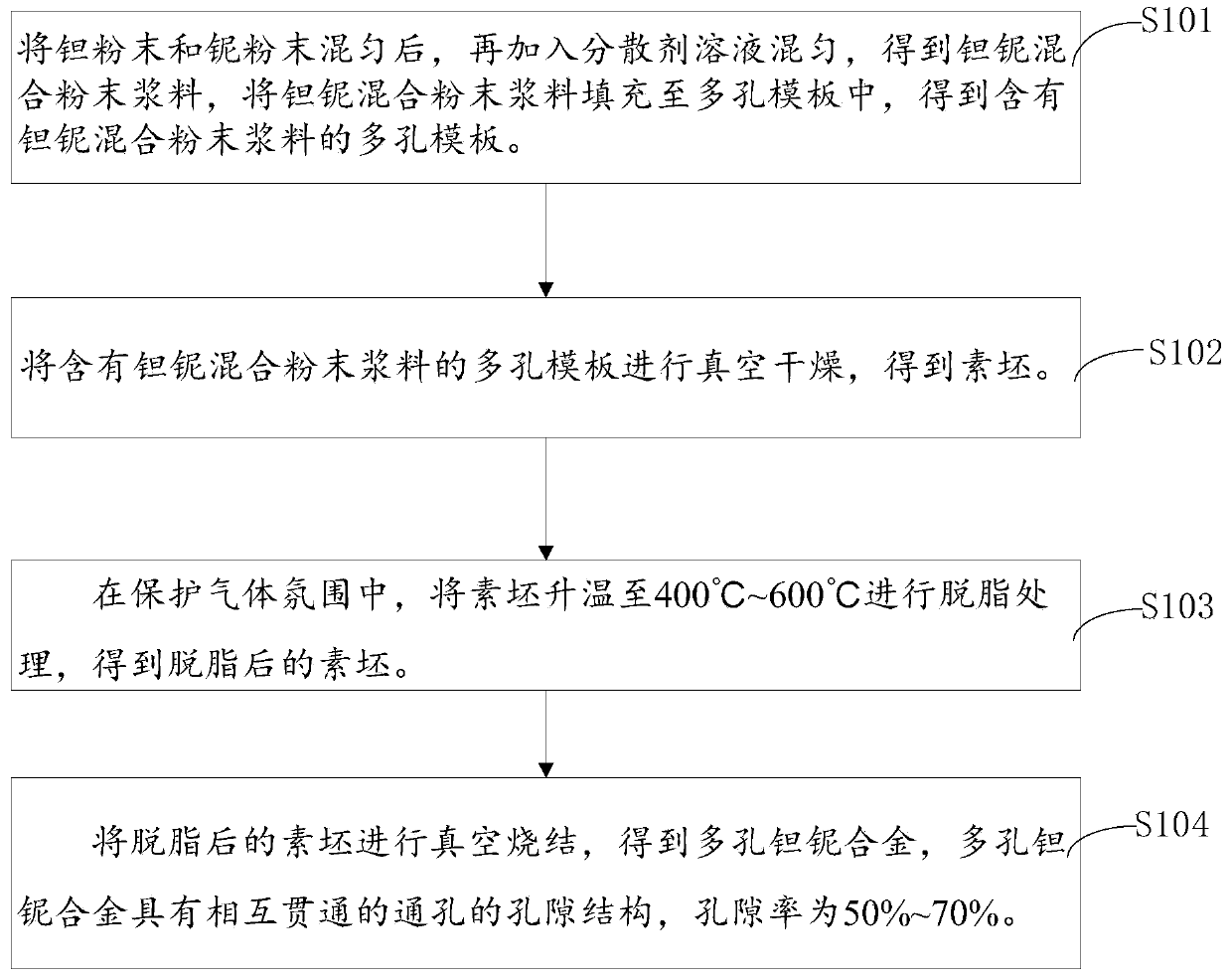

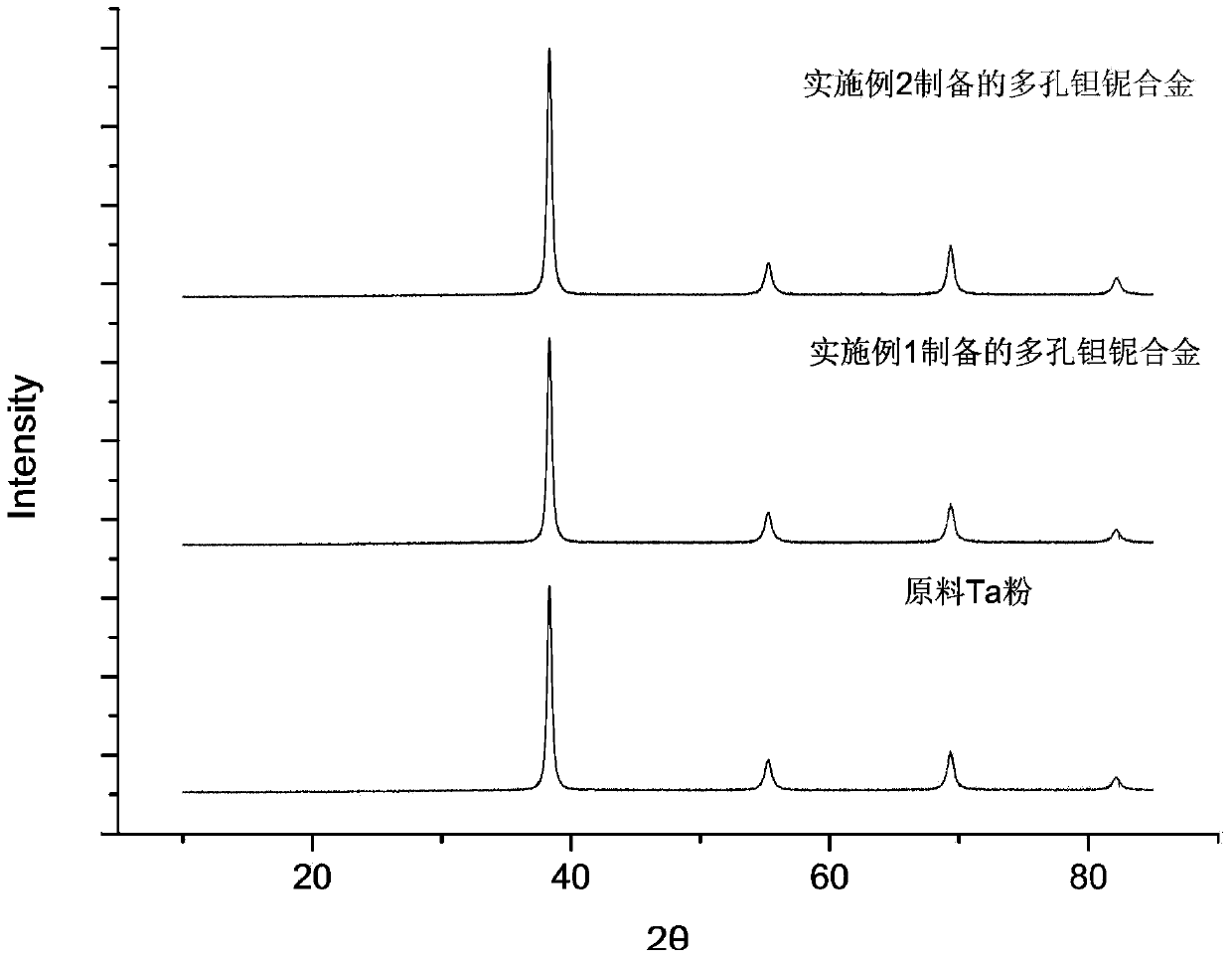

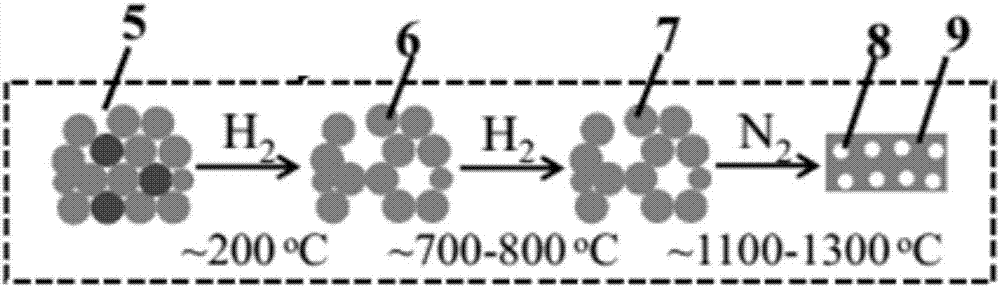

Porous tantalum-niobium alloy and preparation method thereof

The invention provides a porous tantalum-niobium alloy. The porous tantalum-niobium alloy has a pore structure with interconnected through holes. The porosity of the porous tantalum-niobium alloy is 50%-70%. A preparation method of the porous tantalum-niobium alloy comprises the following steps: uniformly mixing tantalum powder and niobium powder, then adding a dispersing agent solution, uniformly mixing so as to obtain tantalum-niobium mixed powder slurry, and filling the tantalum-niobium mixed powder slurry into a porous template, thus obtaining the porous template containing the tantalum-niobium mixed powder slurry; drying the porous template containing the tantalum-niobium mixed powder slurry in vacuum so as to obtain a biscuit; heating the biscuit to 400 DEG C-600 DEG C in a protective gas atmosphere, and carrying out degreasing treatment, thus obtaining the degreased biscuit; and sintering the degreased biscuit in vacuum so as to obtain the porous tantalum-niobium alloy. The porous tantalum-niobium alloy has a three-dimensional connected structure and appropriate porosity, and the elasticity modulus of the material is reduced while the proper strength and porosity are ensured, so that the elasticity modulus is appropriate to that of human bones. The preparation method of the porous tantalum-niobium alloy is simple in process and equipment and low in cost; the porosity of the porous tantalum-niobium alloy is easy to adjust.

Owner:CENT SOUTH UNIV

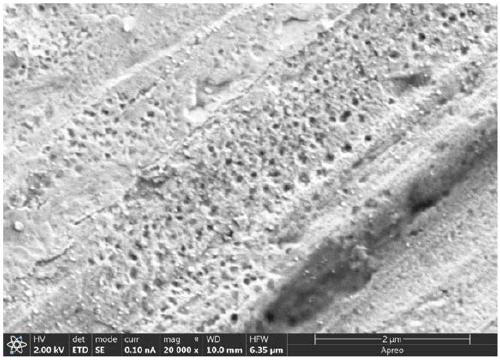

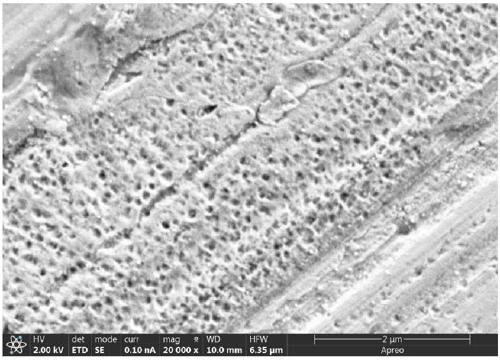

Diamond-like carbon film of gradient structure and preparation method thereof

ActiveCN106521493AImprove performanceImproved deformation coordinationSuperimposed coating processCarbon filmDiamond-like carbon

The invention relates to metal surface treatment, in particular to surface treatment of low-temperature iron-base alloy molds of sliding components, bearings and the like and provides a diamond-like carbon film of a gradient structure and a preparation method of the diamond-like carbon film of the gradient structure. The diamond-like carbon film of the gradient structure is provided with a coating structure comprising a pure metal layer, a first gradient transition layer, a metal nitride layer, a second gradient transition layer, a tungsten carbide, a third gradient transition layer and a surface layer. The surface layer is a diamond-like layer or a silicon-containing type diamond layer. According to the diamond-like carbon film of the gradient structure, gradient control over elasticity modulus and hardness is achieved through ingredient gradient control between all the layers, and therefore the film-substrate cohesion force and the delaminating resistance of the coating are greatly improved.

Owner:广州今泰科技股份有限公司 +1

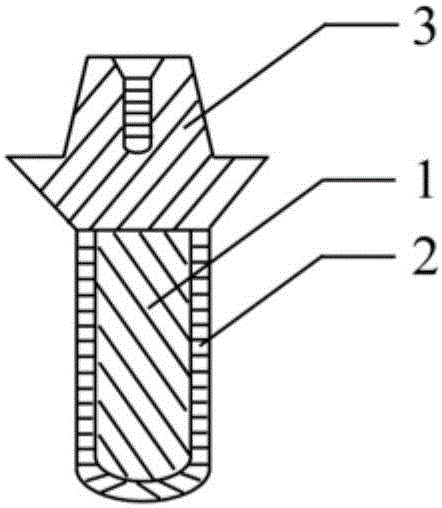

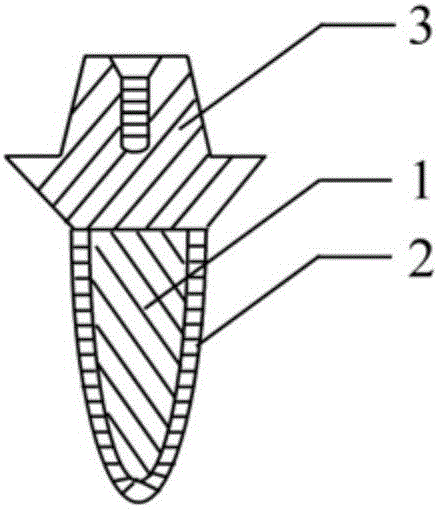

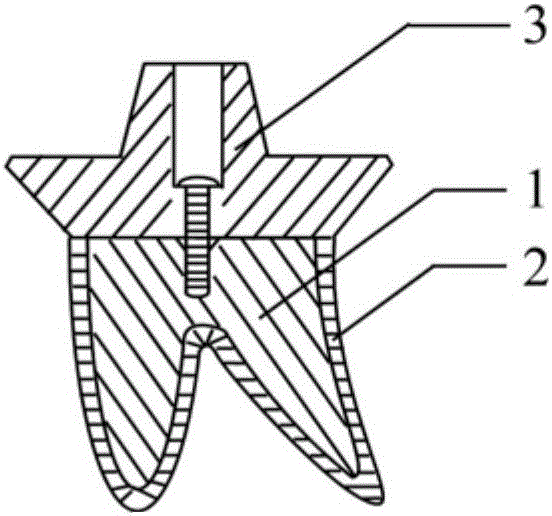

Individualized biomimetic dental implant and manufacture method thereof

InactiveCN106037965ALow elastic modulusImprove biomechanical compatibilityDental implants3d printCell adhesion

The invention relates to an individualized biomimetic dental implant and a manufacture method thereof. The invention is characterized in that the dental implant comprises an implant body for imitating the original tooth root tissue structure of a patient's missing tooth and also comprises a biomimetic artificial alveolar bone structure outer-layer for imitating a patient's alveolar bone tissue structure. The biomimetic artificial alveolar bone structure outer-layer and the external surface of the implant body are combined as a whole. The biomimetic tooth root implant body's outer layer is a 3D printed biomimetic artificial alveolar bone structure outer-layer which is combined with the implant body to form a whole structure, and is similar to the tissue structures of missing tooth's original tooth root and alveolar bone. Thus, the invention provides an ideal implementation scheme of a biomimetic artificial tooth root structure. What is the most important is that the invention provides a structure which is beneficial to bone marrow stem cell and osteogenesis-related cell adhesion, proliferation and mineralization and gives play to final osteogenic function and has good bioactivity. Therefore, a microenvironment for promoting osteogenesis is created, osteocyte generation is induced, and early rapid and firm synosteosis is realized.

Owner:STOMATOLOGICAL HOSPITAL TIANJIN MEDICAL UNIV

Composite, raw material composition, bone repair body, preparation method and application

ActiveCN110935069AGood mechanical propertiesIncreased bone activitySurgeryPharmaceutical delivery mechanismBone growthStress shielding

The invention discloses a composite, a raw material composition, a bone repair body, a preparation method and an application. The raw material composition of the composite comprises the following components of tantalum material powder and polyaryletherketone powder, wherein the volume ratio of the tantalum material powder to the polyaryletherketone powder is(1:4) to (1:1), and the particle diameter of the tantalum material powder is 100nm-5 [mu]m. The composite prepared by the composition has favorable bioactivity and compatibility, is good in mechanical properties, can promote cell adhering,proliferation and polarization, can stimulate bone growth, can accelerate bone healing, and can reduce healing time after a bone implant material is implanted. The bone repair body prepared by the composition cannot cause inflammatory reaction after being implanted, the mechanical properties of the bone repair body including modulus of elasticity, toughness, rupture strength and the like, can cooperate with human bones, and the bone repair body cannot cause negative effect of loosening of the bone repair material caused by stress shielding, bone absorption and the like, and can meet requirements of clinical application for bone repair.

Owner:上海禾麦医学科技有限公司

Bioglass / polyether-ether-ketone composite materials, method for preparing same, application thereof, bone repair body and bone repair body preparation method

InactiveCN103483768ASimple processHas antibacterial propertiesSurgeryProsthesisBiocompatibility TestingBone growth

The invention discloses bioglass / polyether-ether-ketone composite materials, a method for preparing the bioglass / polyether-ether-ketone composite materials, the application of the bioglass / polyether-ether-ketone composite materials, a bone repair body and a bone repair body preparation method. The composite material preparation method comprises the steps that 20-40wt% of 5-20-micron bioglass powder and 60-80wt% 10-20-micron polyether-ether-ketone powder are evenly mixed to obtain mixed powder; the mixed powder is processed and formed, and accordingly the composite materials are prepared. The composite materials have good biological activity and biocompatibility, the composite materials and bone tissues have good mechanical compatibility, and the composite materials can stimulate bone growth, accelerate bone cure, reduce cure time after bone repair materials are implanted, and have bacterium resistance performance. The preparation techniques of the composite materials can be adjusted according to clinic requirements to prepare bone repair bodies of different shapes, difference specifications and different mechanical properties. The bone repair body will not cause inflammatory responses after being implanted, the mechanical property of the bone repair body is matched with human bones, the negative effects that the bone repair materials loosen and bone resorption happens will not be caused, and the bone repair body can meet requirements of clinic for bone repair.

Owner:EAST CHINA UNIV OF SCI & TECH

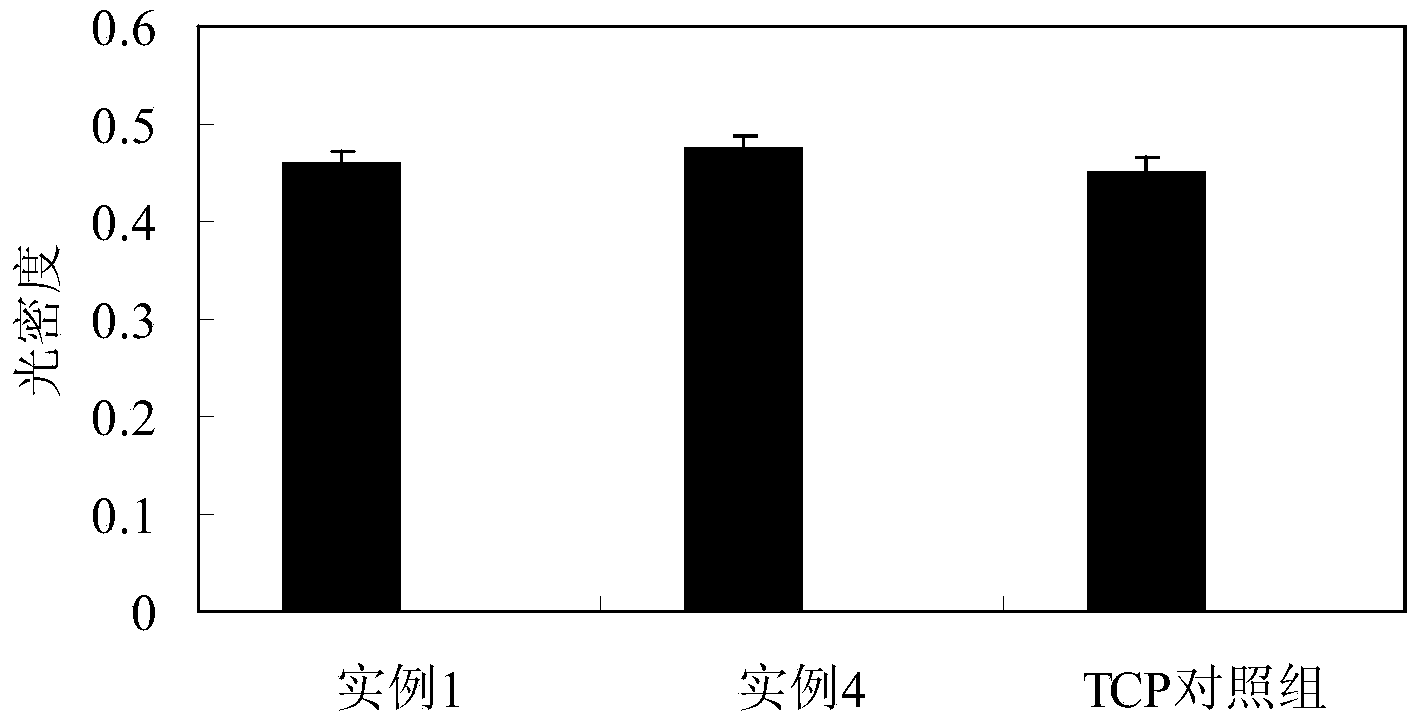

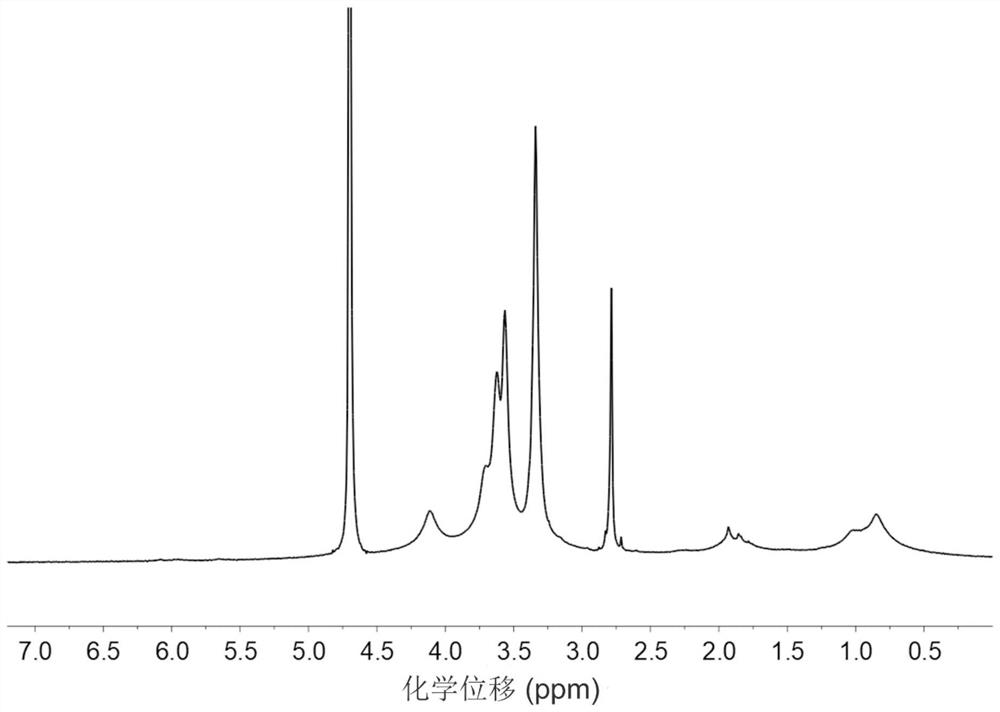

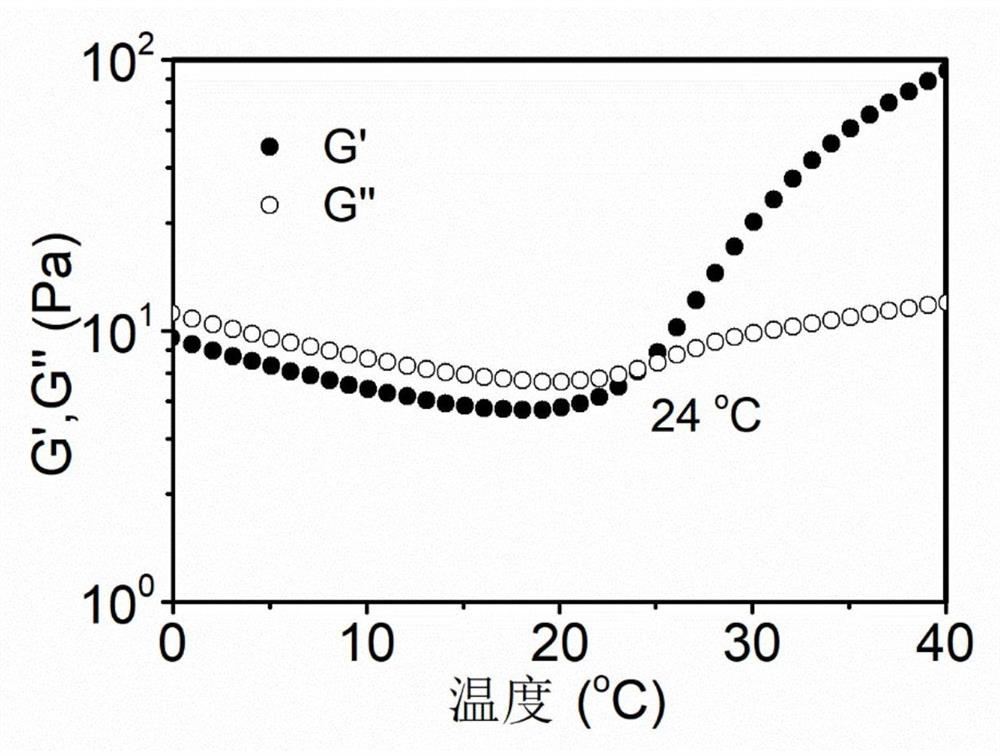

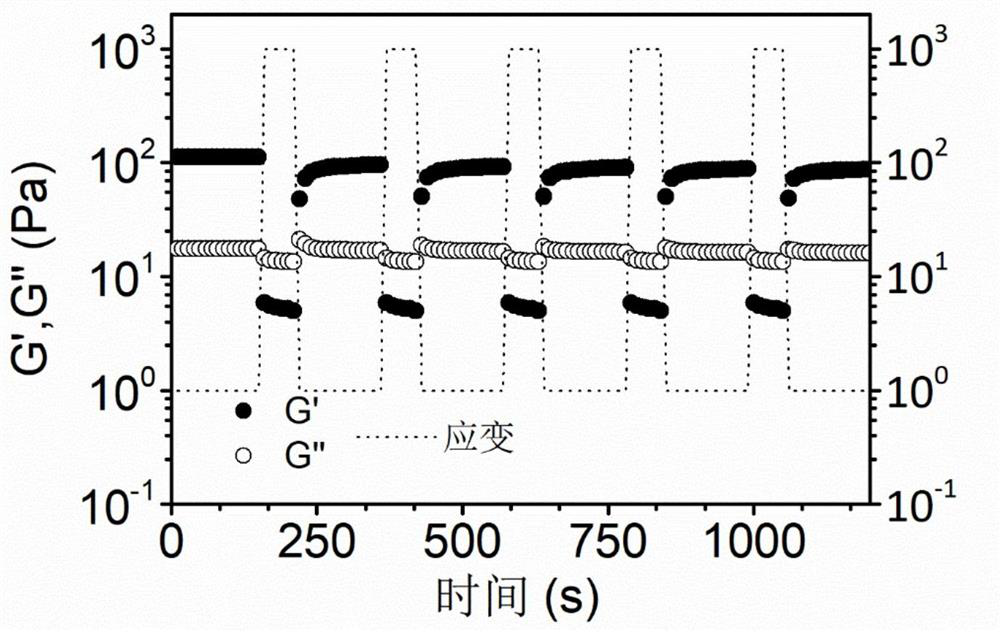

Hyaluronic acid supramolecular hydrogel for three-dimensional culture of chondrocytes, and preparation and application of hyaluronic acid supramolecular hydrogel

ActiveCN111892719AImprove repair effectEvenly dispersedSkeletal/connective tissue cellsCell culture supports/coatingFunctional monomerCartilage repair

The invention belongs to the technical field of regenerative medical materials, and discloses hyaluronic acid supramolecular hydrogel for three-dimensional culture of chondrocytes, and preparation andapplication of the hyaluronic acid supramolecular hydrogel. The method comprises the following steps: with water as a reaction medium, carrying out a copolymerization reaction on methacrylic anhydride modified hyaluronic acid, a double-bond functionalized ureido pyrimidinone functional monomer and 2-(2-methoxyethoxy)ethyl methacrylate under the action of an initiating system, and carrying out subsequent treatment to obtain the hyaluronic acid supramolecular hydrogel. The hydrogel is used in the field of cartilage tissue engineering, and is used for three-dimensional culture of chondrocytes and preparation of cartilage repair materials. The hydrogel disclosed by the invention has sol-gel conversion and self-repairing properties, uniform dispersion of the chondrocytes can be easily realizedby sol at a low temperature, and the sol can undergo phase change to form gel after being conveyed to a cartilage injury part, so in-situ fixation of the chondrocytes is realized; and the formation of a dynamic three-dimensional microenvironment of the hydrogel is beneficial for the maintenance of chondrocyte functions and the secretion of cartilage characteristic matrixes.

Owner:SOUTH CHINA UNIV OF TECH

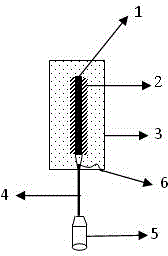

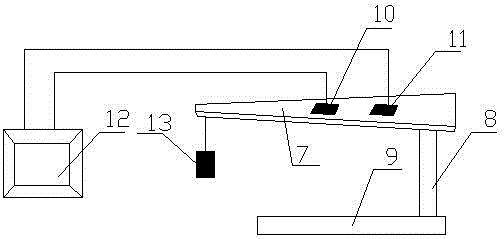

Piezoelectric strain sensor, method for testing strain sensitivity of piezoelectric strain sensor and application of piezoelectric strain sensor

ActiveCN103557989AMonitor healthMonitor strain changesForce measurement using piezo-resistive materialsForce/torque/work measurement apparatus calibration/testingSilica gelLow frequency vibration

The invention discloses a piezoelectric strain sensor, a method for testing the strain sensitivity of the piezoelectric strain sensor and the application of the piezoelectric strain sensor. The sensor comprises a piezoelectric ceramic piece, a silica gel layer and a packaging layer, wherein the silica gel layer makes the sensor stressed evenly and good in sensitivity, and the packaging layer makes the sensor good in insulating property and resistant to interference of the external environment. According to the method, strain sensitivity testing is carried out through a constant-strength beam device, the strain sensitivity (mV / mu epsilon) of the sensor under the condition of different low vibration frequencies of a bridge can be tested, and the strain of a bridge structure can be indirectly reflected according to the strain sensitivity under different vibration frequencies and the voltage output of the sensor; in this way, the piezoelectric strain sensor can replace a strain gage to measure the strain of structures like the bridge under low frequencies, various shortcomings caused by using the strain gage are overcome, and the sensor has broad application prospects in bridge monitoring.

Owner:UNIV OF JINAN

High-purity carbon fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN110105075AProcess preparation cycle shortenedReduce manufacturing costFiberChemical industry

The invention provides a high-purity carbon fiber reinforced silicon carbide composite material and a preparation method thereof and belongs to high-temperature high-purity composite materials and advanced manufacturing technologies thereof. The composite material can be applied to the fields of semiconductor, solar energy, optoelectronics, machinery, metallurgy, chemical industry, materials and the like. The preparation method comprises the steps that carbon fiber felt and a carbon fiber cloth are subjected to purification treatment first, pyrolysis of carbon and SiC interface phase deposition are alternately carried out on the surfaces of the carbon fiber felt and carbon fiber cloth, and then prepared high-purity ceramic slurry is sprayed onto the surface of the carbon fiber felt or carbon fiber cloth containing a composite coating by means of a spraying method; stacking, needling, drying and solidifying are carried out to obtain a composite material blank, and the blank is subjectedto high-temperature carbonization treatment, purification treatment and densification treatment to obtain the high-purity carbon fiber reinforced silicon carbide composite material. The preparation method shortens the preparation cycle and reduces the production cost; the composite material prepared by means of the preparation method has the impurity content lower than 10 ppm, the density higherthan 2.20 g / cm<3> and the bending strength higher than 150 MPa.

Owner:湖南兴晟新材料科技有限公司

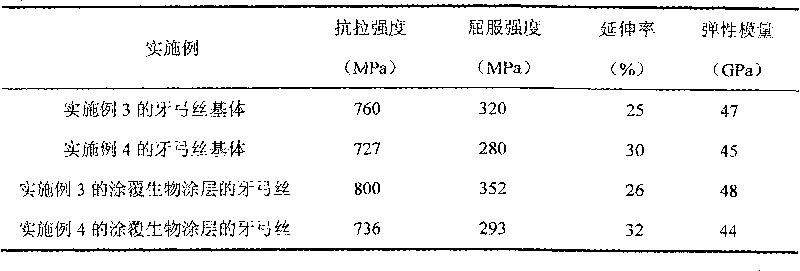

Biological coating and dental arch wire coated with same

InactiveCN101721742AReduce releaseHarm reductionArch wiresSurgeryBiocompatibility TestingMetallic materials

The invention discloses a biological coating and a dental arch wire coated with the same, and belongs to the technical fields of surface modification of biomedical metal materials and medical equipment. The biological coating comprises Ti and Nb serving as main components, and also comprises at least one of tin, aluminum, silicon, zirconium, tantalum, hafnium, palladium, gallium, nickel and oxygen. The invention provides the dental arch wire which uses a TiNbAl titanium alloy serving as a base material and is coated by the coating. Medical equipment products coated by the coating have good biocompatibility and good corrosion resistance and great improvement on superelasticity, shape memory effect, fatigue performance and other composite properties, and can be used in the field of medical treatment serving as functional coatings on surfaces of super-elastic stents, orthodontic dental arch wires, orthopedic implant equipment and the like. The dental arch wire has lower elastic modulus, excellent biocompatibility and mechanical compatibility; and the base material of the dental arch wire has excellent mechanical performance, corrosion resistance, and can be subjected to large deformation cold machining, such as cold rolling, cold wire drawing and the like.

Owner:GRIKIN ADVANCED MATERIALS

CS (calcium silicate)/PEEK (poly(ether-ether-ketone)) composite bone repair material, bone repair body as well as preparation method and application of material

The invention discloses a CS (calcium silicate) / PEEK (poly(ether-ether-ketone)) composite bone repair material, a bone repair body as well as a preparation method and an application of the material. In the CS / PEEK composite bone repair material, CS accounts for 30%-50% and PEEK accounts for 50%-70%; the particle size of CS is 20-30 mu m, and the particle size of PEEK is 30-40 mum. The CS / PEEK composite bone repair material has excellent mechanical properties, has the elasticity modulus similar to that of natural bone, has better osteogenesis bioactivity, has excellent mechanical compatibility, cannot cause bone resorption due to stress shielding, can promote regeneration of peripheral bone tissue and fusion with natural bone tissue after being implanted into a human body and can meet requirements of immediate fixation and long-term stability of postoperative orthopedic instruments.

Owner:汤亭亭 +1

Polyetheretherketone composite material and bone repairing body as well as preparation method and application thereof

InactiveCN102643514ARandom combinationSimple processProsthesisBarium titanateBiocompatibility Testing

The invention discloses a fluorapatite / barium titanate / polyetheretherketone composite material as well as a preparation method and application of the composite material. The preparation method comprises the following step of: carrying out melt blending and extrusion granulating on fluorapatite, barium titanate and polyetheretherketone, wherein the use amount of fluorapatite is 10-30wt%, the use amount of barium titanate is 10-40wt%, and the use amount of polyetheretherketone is 50-60wt%. The invention also discloses a bone repairing body and a preparation method of the bone repairing body. The composite material has excellent biological activity and biocompatibility, and better mechanical compatibility with bone tissue, and can stimulate bone growth, accelerate bone healing and reduce the healing time of the material is implanted to the bone. The preparation method is simple and feasible in process. The bone repairing body has excellent biocompatibility, biological activity, bone mechanical compatibility and microorganism resistance, thereby shortening the bone healing time, and is high in strength, good in fatigue resistance and corrosion resistance and long in service life, thereby meeting the clinical bone repairing requirements.

Owner:EAST CHINA UNIV OF SCI & TECH

Mesoporous calcium magnesium silicate and polyetheretherketone composite, bone prosthesis as well as preparation method and application of composite

InactiveCN104548195AUniform particle size distributionSimple processImpression capsDentistry preparationsImplant materialCorrosion

The invention discloses a mesoporous calcium magnesium silicate and polyetheretherketone composite, bone prosthesis as well as a preparation method and application of the composite. The preparation method of the mesoporous calcium magnesium silicate / polyetheretherketone composite comprises the following steps: uniformly mixing 20-40wt% of mesoporous calcium magnesium silicate and 6-80wt% of polyetheretherketone composite of 10-20microns so as to obtain mixed powder; mixing the mixed powder with absolute ethyl alcohol, ultrasonically dispersing, and evaporating the absolute ethyl alcohol at 58-62 DEG C so as to obtain composite powder; and pressing and molding the composite powder by virtue of a mould pressing method so as to obtain the composite. The mesoporous calcium magnesium silicate is uniform in particle size and is uniform in mesoporous pore size distribution. The composite is good in bioactivity and biocompatibility, relatively good in mechanical compatibility with bone tissue, and capable of stimulating bone growth, accelerating bone healing and shortening healing time of bone after implanting material. The bone prosthesis is good in bone mechanical compatibility and antibacterial property, high in strength, fatigue-resistant, good in corrosion resistance and long in service life.

Owner:EAST CHINA UNIV OF SCI & TECH

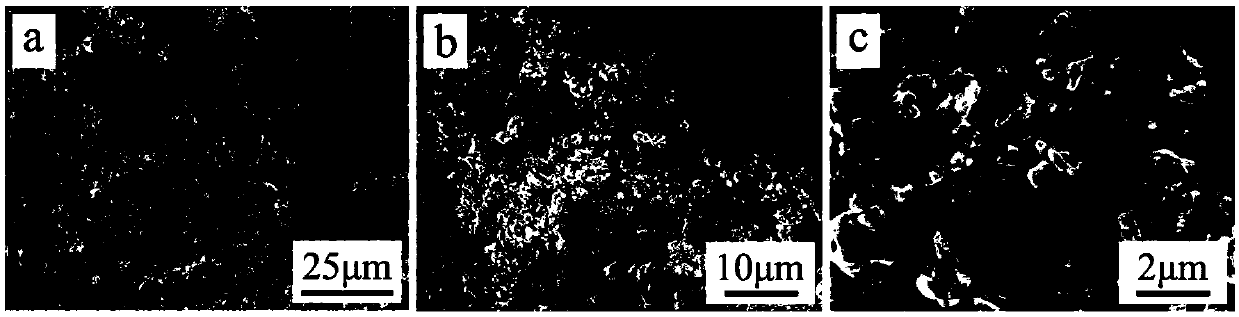

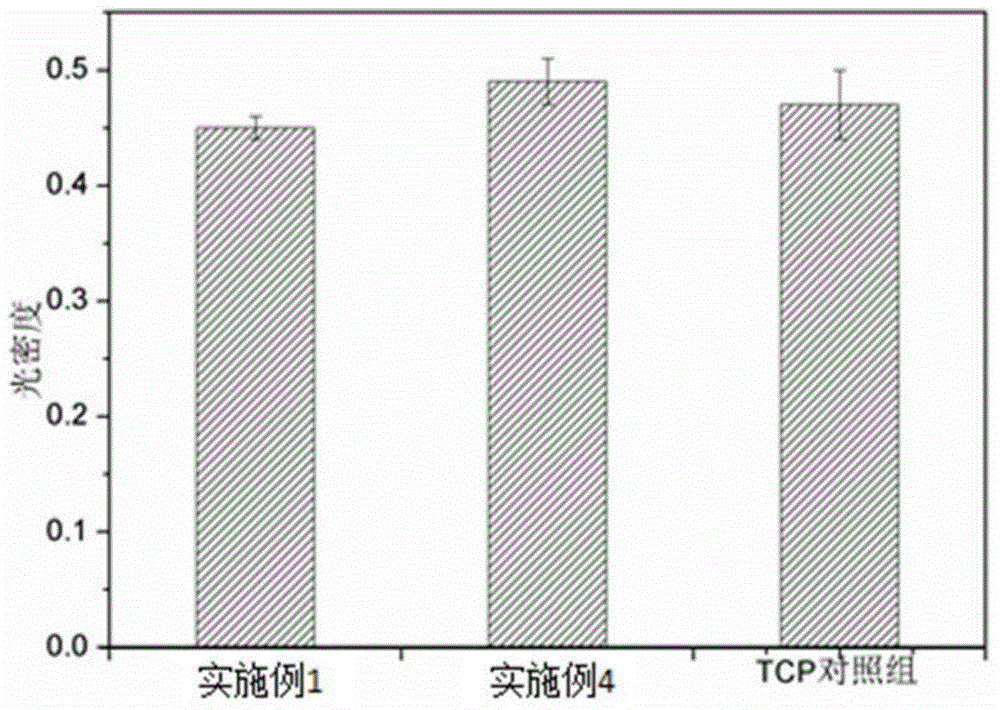

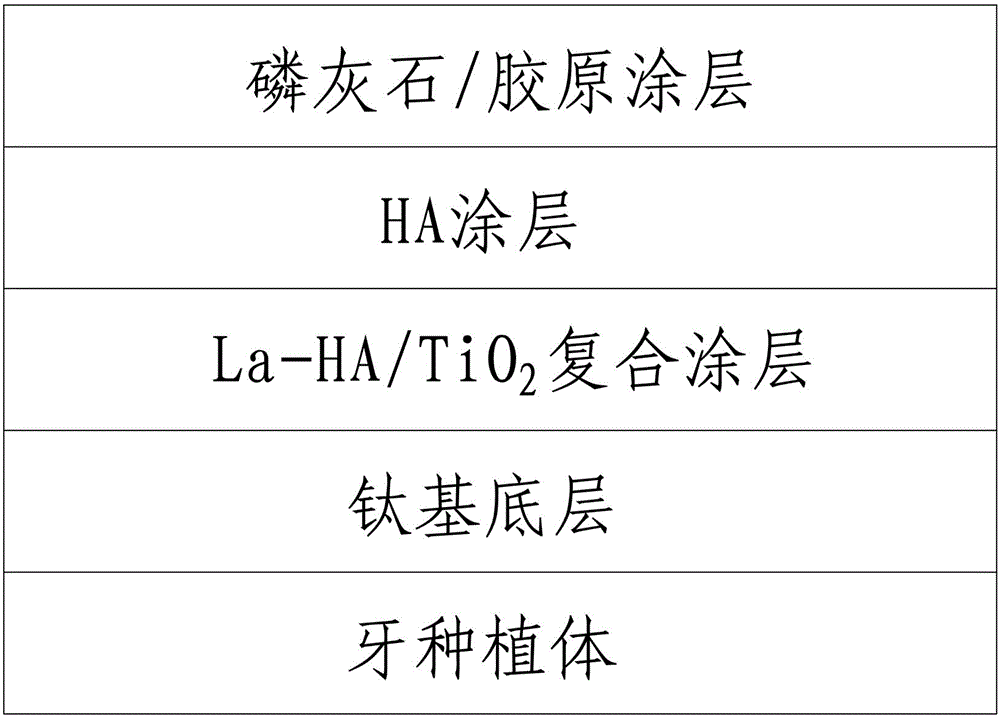

Preparation method of biological gradient coating on surface of dental implant

InactiveCN103598919AImprove the bonding strength of the interfaceInhibit sheddingDental implantsSolid/suspension decomposition chemical coatingSolubilityApatite

The invention discloses a preparation method of a biological gradient coating on the surface of a dental implant. The method is used for performing operation of the following steps on the dental implant: polishing a titanium sheet by SiC metallographic abrasive paper, cleaning, drying, and setting the dried titanium sheet on the surface of the dental implant to form a titanium substrate layer; preparing an La-HA / TiO2 composite coating on the surface of the titanium substrate layer; preparing an HA coating on the surface of the La-HA / TiO2 composite coating; and setting the dental implant in an apatite / collagen solution containing La, thus forming the apatite / collagen coating on the surface of the dental implant. According to the invention, the La-HA / TiO2 composite coating is prepared on the titanium surface, so that the excessively high solubility of the HA coating is effectively lowered, the problem of instability between original HA and a metal interface is solved, and the chemical stability and the bonding force of the coating are improved; with the novel coating design, the biological activity and the solubility are improved in a gradient way from inside to outside, and the chemical stability and the bonding strength are improved in a gradient way from outside to inside.

Owner:温州医科大学附属口腔医院

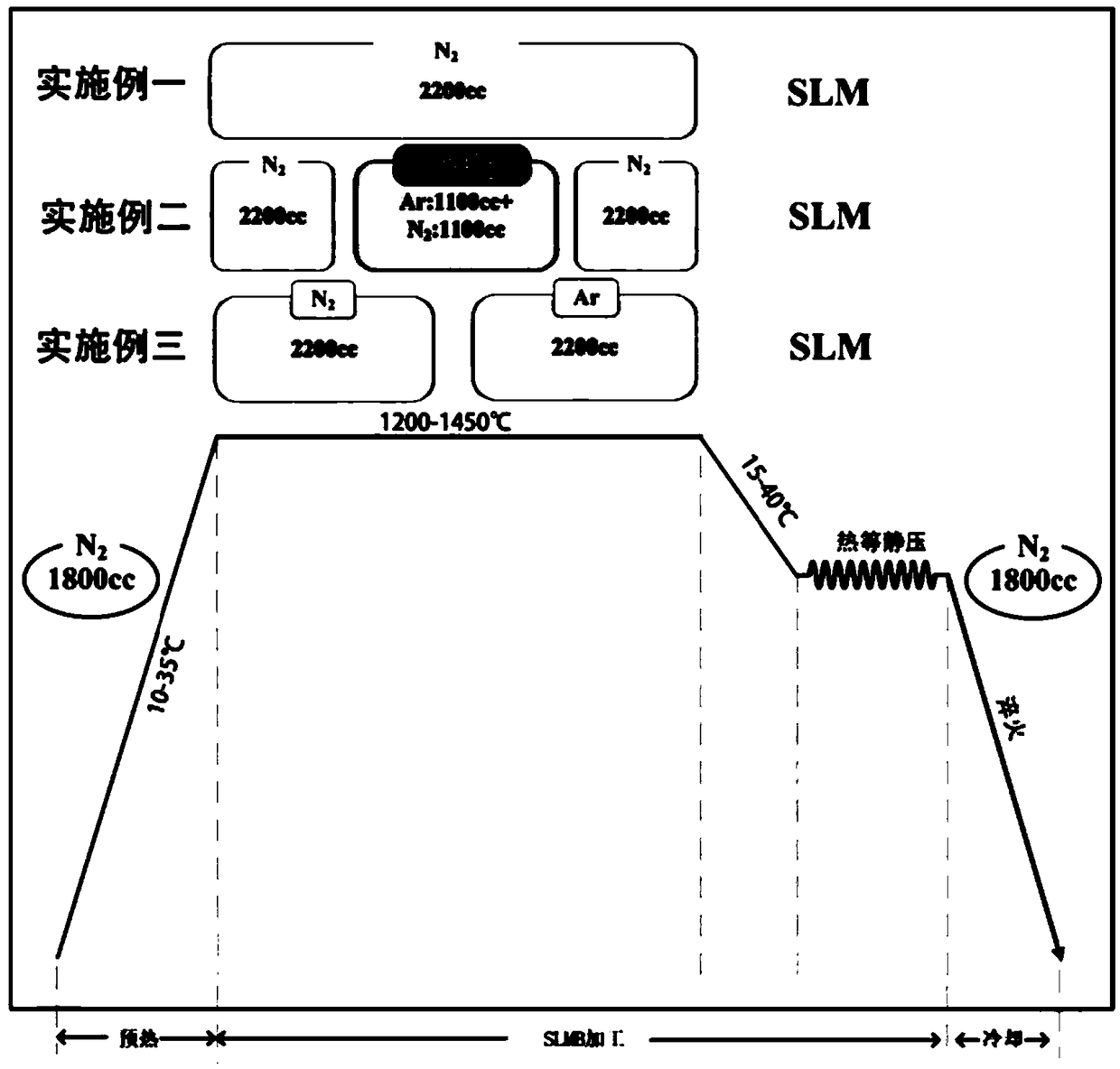

Novel magnesium alloy with high medical performance

ActiveCN109439986AGood biocompatibilityGood mechanical compatibilityAdditive manufacturing apparatusIncreasing energy efficiencyChromiumCorrosion

The invention discloses a novel magnesium alloy with high medical performance. The novel magnesium alloy is prepared through the following method which comprises the steps that various magnesium alloycomponents are subjected to ball grinding, levigation and mixing; German SLM Solutions 500 is adopted for selective laser melting treatment; magnesium alloy products generated after selective laser melting treatment are sequentially subjected to 580-800DEG C incomplete quenching for 1 h to 3 h and 200-280DEG C tempering for 1.5 h to 2.5 h; and finally finished products are obtained through cutting. Alloy powder components are adopted, molybdenum, tantalum, chromium and titanium all have good corrosion resistance, the corrosion resistance of the magnesium alloy can be enhanced, and the tensilestrength of the magnesium alloy can be improved.

Owner:陕西智宇寰宸医疗器械有限公司

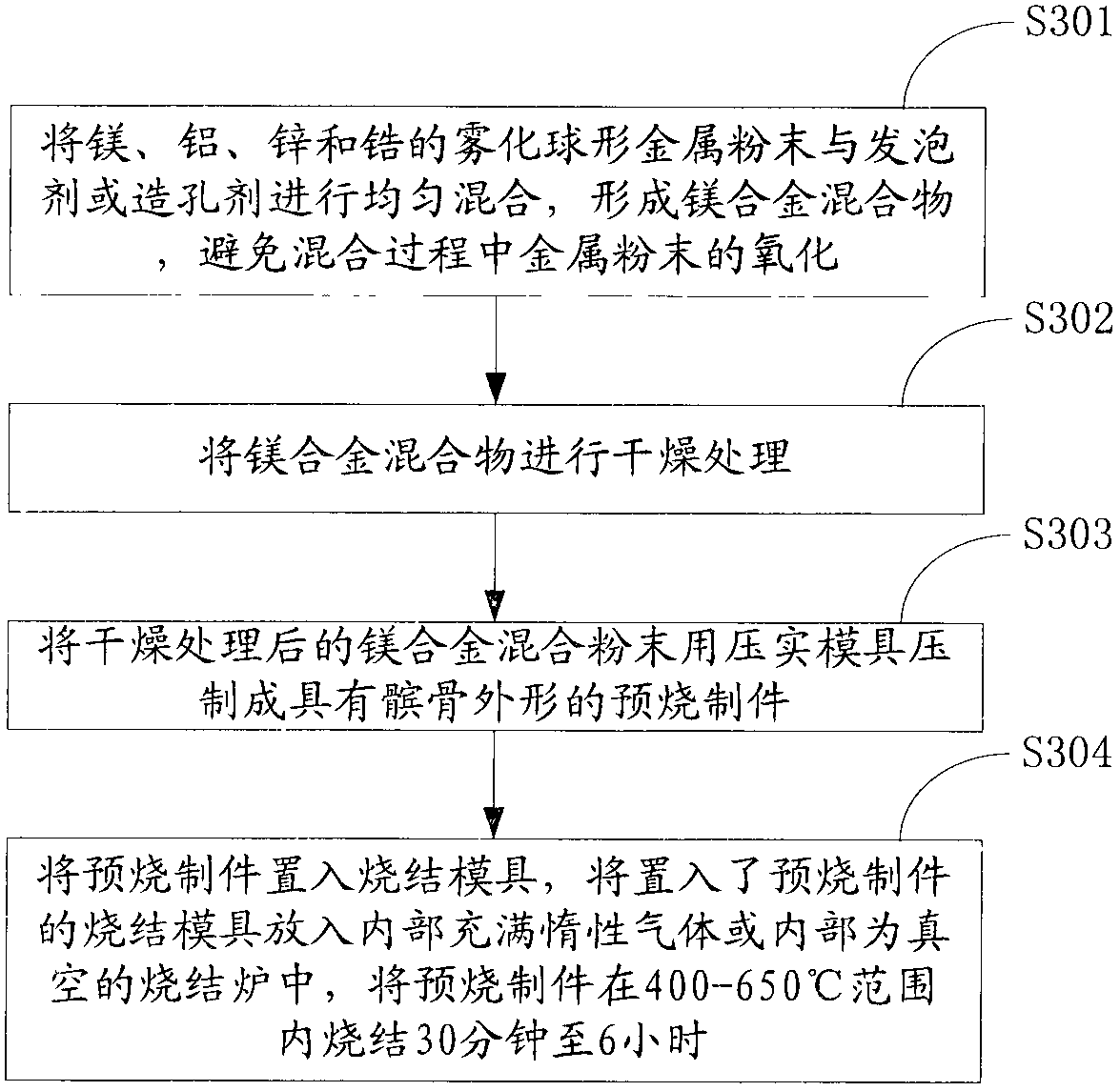

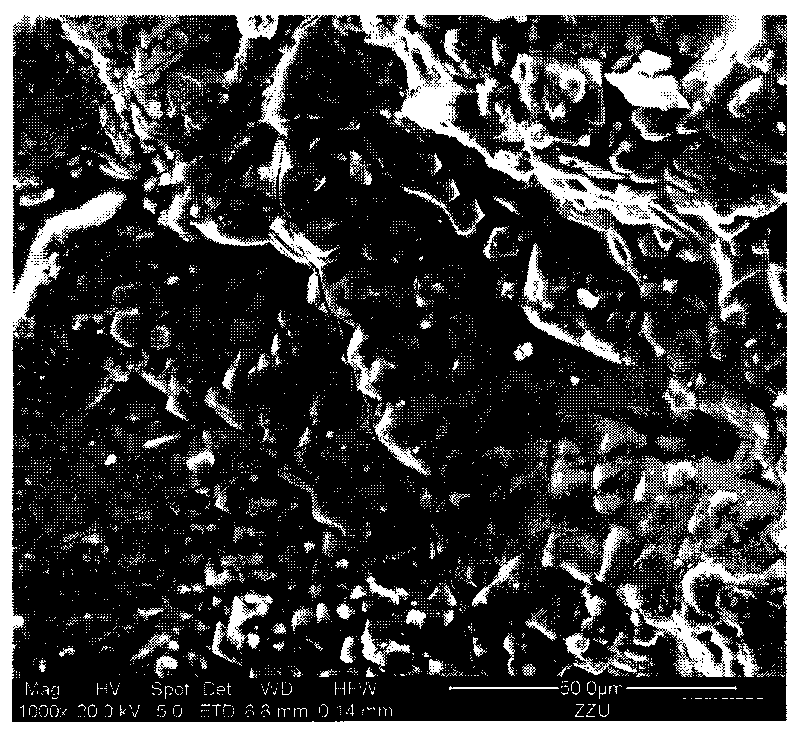

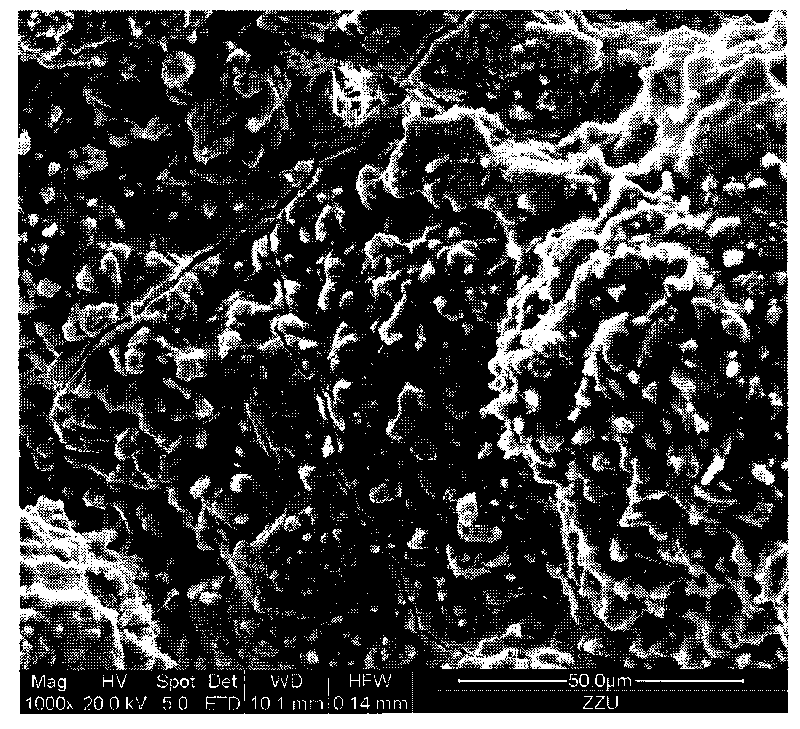

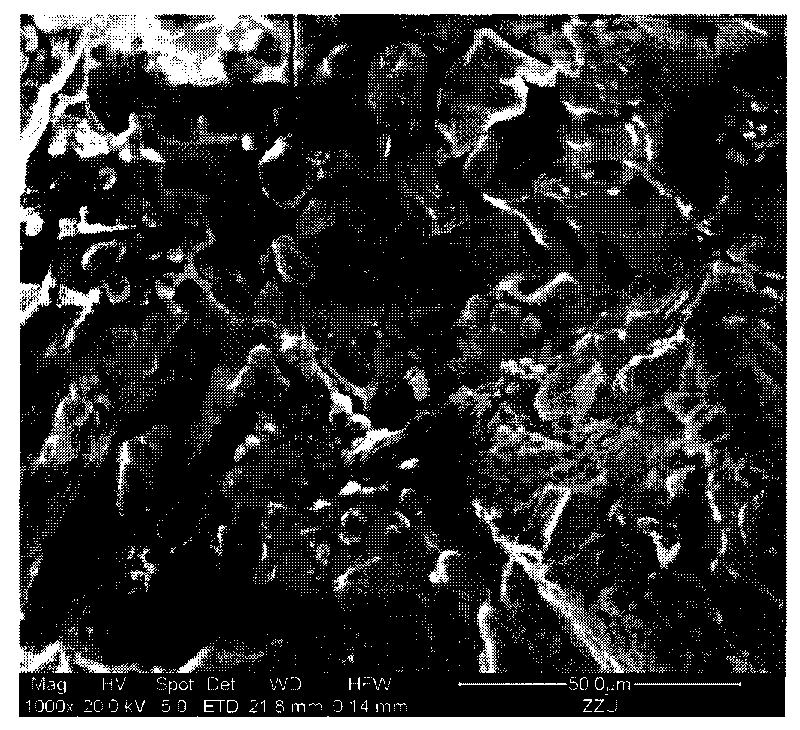

Patella tissue engineering scaffold, and manufacturing material and preparation method thereof

ActiveCN104069542AReduce wearDoes not produce hazardous abrasive debrisBone implantPorosityArticular surfaces

The invention provides a patella tissue engineering scaffold. The patella tissue engineering scaffold is formed by magnesium, aluminum, zinc and zirconium in a mass ratio of 85-95: 0-6: 0-4: 0-4. The scaffold has a shape consistent with the patella of a human body and is formed by arrangement of interlacing trabeculae, a plurality of mutually communicating holes are formed among trabeculae, the diameter of each hole is in a range of 0.1 to 0.8 mm, and porosity of the holes is 30 to 80%. The scaffold has the shape consistent with the human patella, can well match with the articular surface of the human patella or the articular surface of the patella of an artificial knee joint and reduces wearing of the patella tissue engineering scaffold, thereby reducing generation of abrasive dust; since the scaffold is prepared from the above-mentioned components, the scaffold is degradable in a human body, metal ions of magnesium ions and the like beneficial to the human body are produced after degradation, so the scaffold does not produce abrasive dust causing harm to the human body. Moreover, the invention further provides a material used for manufacturing the scaffold and a preparation method for the scaffold.

Owner:SHENZHEN INST OF ADVANCED TECH

Sliding plate antioxidation paint and preparation method thereof

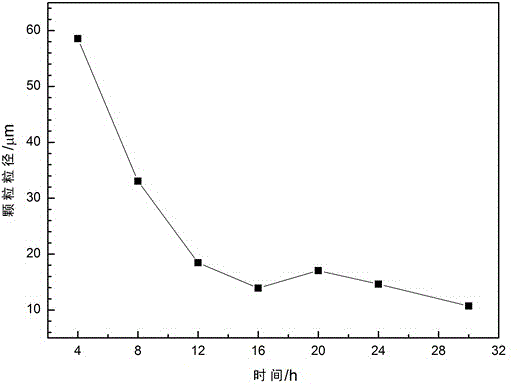

The invention discloses a sliding plate antioxidation paint and a preparation method thereof. The sliding plate antioxidation paint is prepared by the following raw materials in weight percent: 10-70% of antioxidation function additive, 15-80% of binding agent and 5-20% of diluent. The preparation method comprises the following steps: mixing antioxidation function additive and binding agent, and grinding when the ratio of ball to material is (4-1):1, rotating speed is 200-800r / min, and ball-milling time is 5-40h; adding diluent with content in weight percent being 5-20% into the ball-milled paint, and mixing uniformly to obtain a finished product. The inventive paint is gray black and pasty, can be brushed by common technique, and the thickness of coating is adjustable in large range. The preparation method of the antioxidation paint provided in the invention has available raw materials, simple technique and preparation, low cost, and easy scale production; and the obtained paint has outstanding antioxidation and self-lubricating performances at high temperature.

Owner:ZHENGZHOU UNIV +1

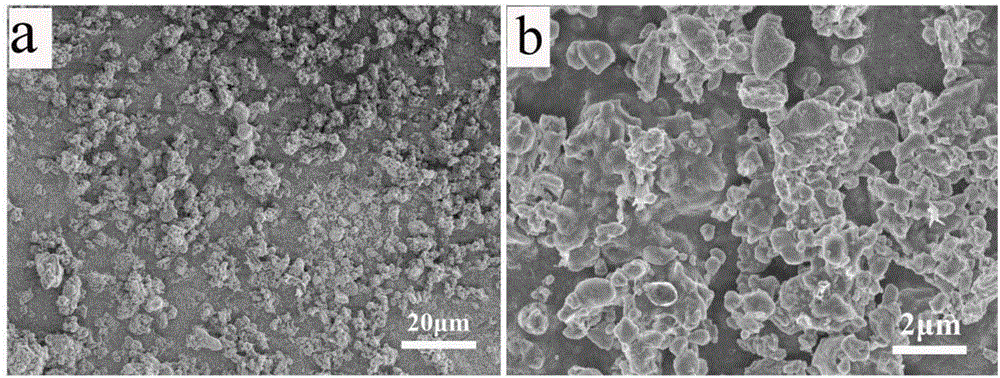

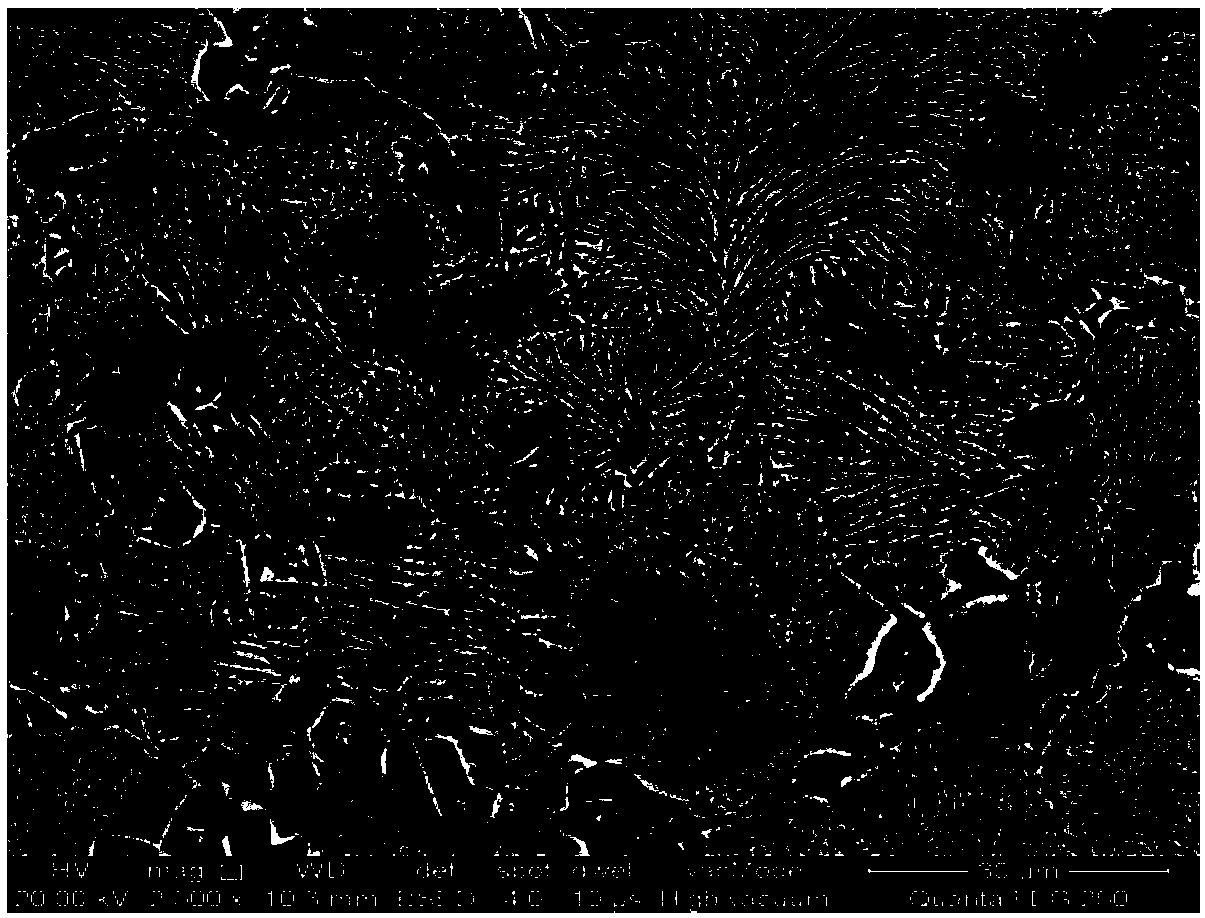

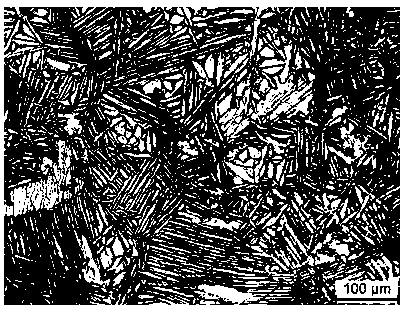

Zirconium-niobium-titanium dental implant material high in strength and low in elastic modulus and preparation method of zirconium-niobium-titanium dental implant material

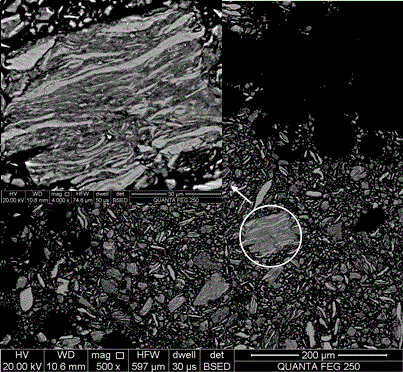

InactiveCN108034846APromote sinteringSolve the problem that it is difficult to prepare zirconium niobium titanium alloy with lower elastic modulusFiberMechanical property

The invention relates to a zirconium-niobium-titanium dental implant material with high compressive strength and low elastic modulus at the same time and a preparation method of the zirconium-niobium-titanium dental implant material. In the sintering cooling process, the zirconium-niobium-titanium dental implant material is provided with lamellar and needle-like precipitation structures, and the structures facilitate that a zirconium-niobium-titanium alloy acquires good mechanical properties and biological compatibility. The preparation method of the zirconium-niobium-titanium dental implant material includes the following steps that zirconium-niobium-titanium powder is mixed uniformly according to a certain proportion, and pressing and forming are performed in a powder metallurgy method;in the protecting atmosphere, temperature rises to 950 DEG C for heat preserving; and finally, vacuum sintering is performed at 1400-1600 DEG C, and the dental implant material high in comprehensive performance is obtained. According to the zirconium-niobium-titanium alloy, the relative density is 90% or above, the comprehensive strength changes in the range of 1100-1289 MPa, the elastic modulus changes in the range of 32-41 GPa, the elastic modulus is low under the condition that the strength is guaranteed, the mechanical compatibility with human body maxillary and mandible is good, and the biological compatibility with oral epithelia and fibrous tissue is good; and the preparation method is simple, and the dental implant material is ideal.

Owner:CENT SOUTH UNIV

Hydroxyl apatite/nylon nanometer artificial bone and preparing method thereof

The invention provides a hydroxyapatite / nylon manometer artificial bone, including hydroxyapatite which accounts for 50-66% of the total weight of the artificial bone; nylon which accounts for 34-50% of the total weight of the artificial bone; the hydroxyapatite disperses in the nylon under the dispersed phase with the average length between 60-80nm; the molecular weight of the nylon is between 9000-13000; in addition, the artificial bone is free of organic solvent. The invention can achieve high filling amount, no use of organic solvent, high product purity and can reach the standard set for the medical material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Medical high-nitrogen nickel-free austenitic stainless steel and preparing method thereof

The invention discloses medical high-nitrogen nickel-free austenitic stainless steel. The material is a single-phase austenite structure and includes, by weight percent, 13%-18% of Cr, 8%-12% of Mn, 2%-4% of Mo, 0.6%-2.5% of N, smaller than or equal to 0.36% of Ni and the balance iron and inevitable impurities, wherein smaller than or equal to 0.43% of the inevitable impurities exist. The invention further discloses a preparing method of the medical high-nitrogen nickel-free austenitic stainless steel. The medical high-nitrogen nickel-free austenitic stainless steel is very suitable for being used as medical implant materials, medical tool materials, jewelries and other stainless steel products, wherein the human body frequently makes contact with the stainless steel products; and in addition, the medical high-nitrogen nickel-free austenitic stainless steel can also be used for chemical engineering and environment friendliness aspects such as high-temperature liquid or gas solid particle filters, sewage treatment and fluid distribution devices and the like.

Owner:SOUTH CHINA UNIV OF TECH

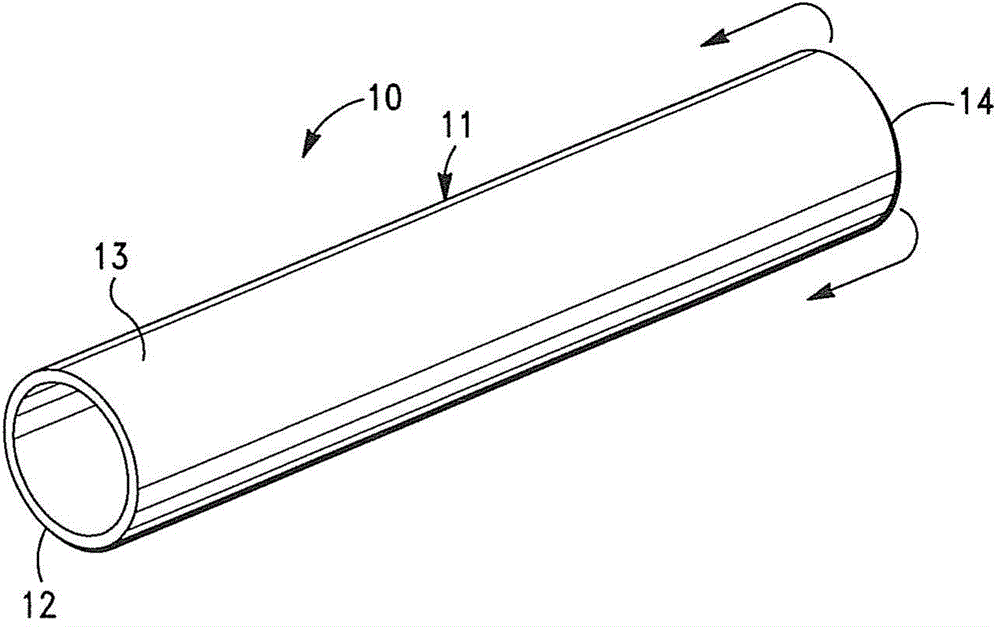

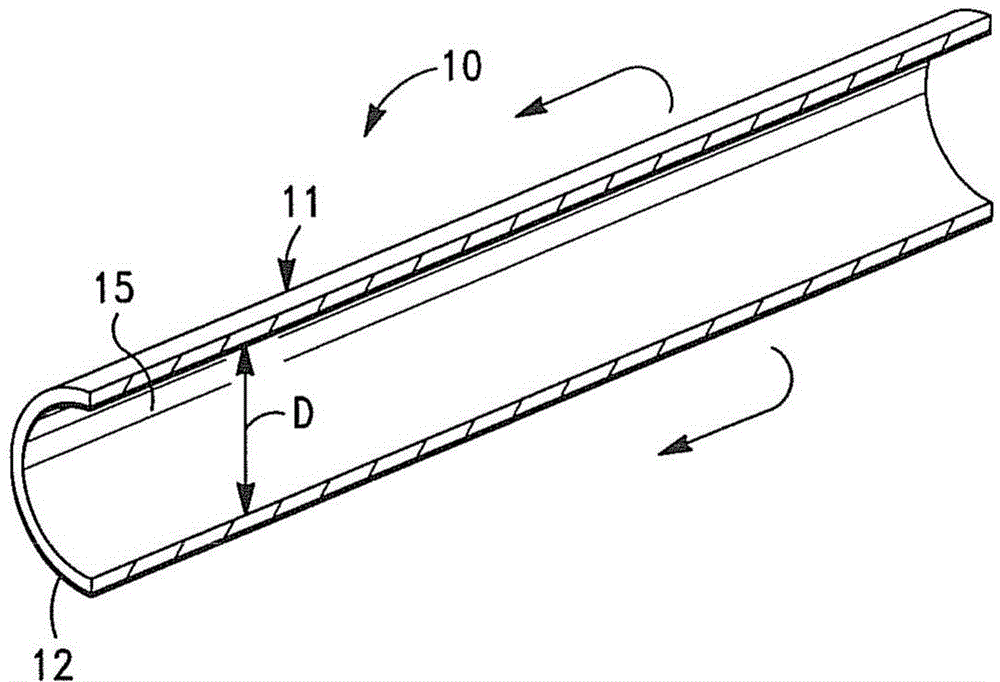

A seamless tubular extracellular matrix prosthetic valve and method for forming same

InactiveCN104869950AReduce or eliminate intimal hyperplasiaGood mechanical compatibilityAntipyreticHeart valvesCell-Extracellular MatrixProsthetic valve

Owner:CORMATRIX CARDIOVASCULAR INC

Low-elastic-modulus titanium-zirconium dental implant material and preparation method thereof

InactiveCN108380890ALower sintering temperatureLow manufacturing costProsthesisBiocompatibility TestingDental implant

The invention relates to a low-elastic-modulus titanium-zirconium dental implant material and a preparation method thereof. The low-elastic-modulus titanium-zirconium dental implant material has needle-shaped and lamellar precipitated structures in the sintering and cooling processes, the structures are beneficial for titanium-zirconium alloy to obtain good mechanical property and biocompatibility. The preparation method comprises the following steps that titanium-zirconium powder is uniformly mixed according to a certain ratio, after pressing and forming are completed, in the protective atmosphere, the temperature is increased to 800 DEG C for heat preservation, finally vacuum sintering is carried out at 1200-1300 DEG C, and the low-elastic-modulus titanium-zirconium dental implant material is obtained. According to the low-elastic-modulus titanium-zirconium alloy, the relative density is 94.1%-94.5%, the compressive strength is changed within the range of 1292.8-1498.5 MPa, the elastic modulus is changed within the range of 21.8-22.8 GPa, the elasticity modulus is relatively low under the condition that the strength is guaranteed, the dental implant material is good in mechanicalcompatibility with an upper jaw bone and a lower jaw bone of a human body, and is good in biocompatibility with epithelium and fiber tissues of an oral cavity; and the preparation method is simple, and the dental implant material is an relatively ideal low-elastic-modulus dental implant material.

Owner:CENT SOUTH UNIV

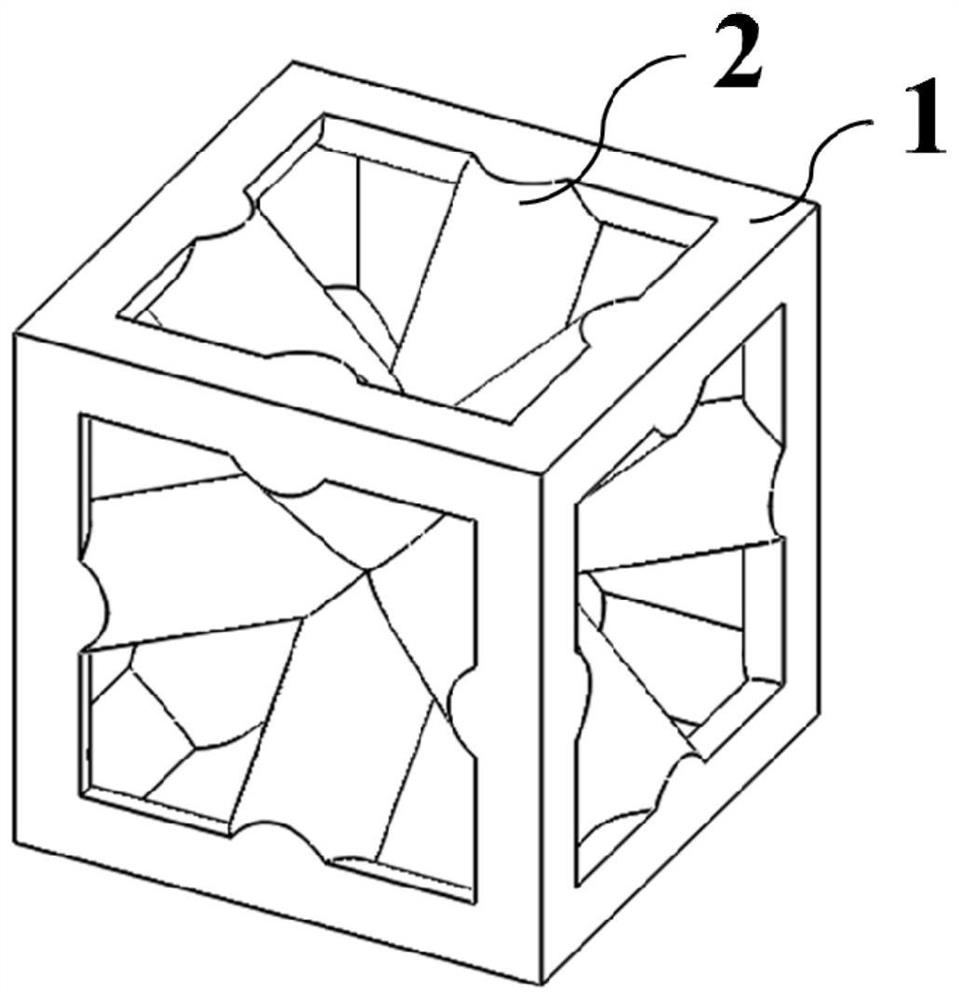

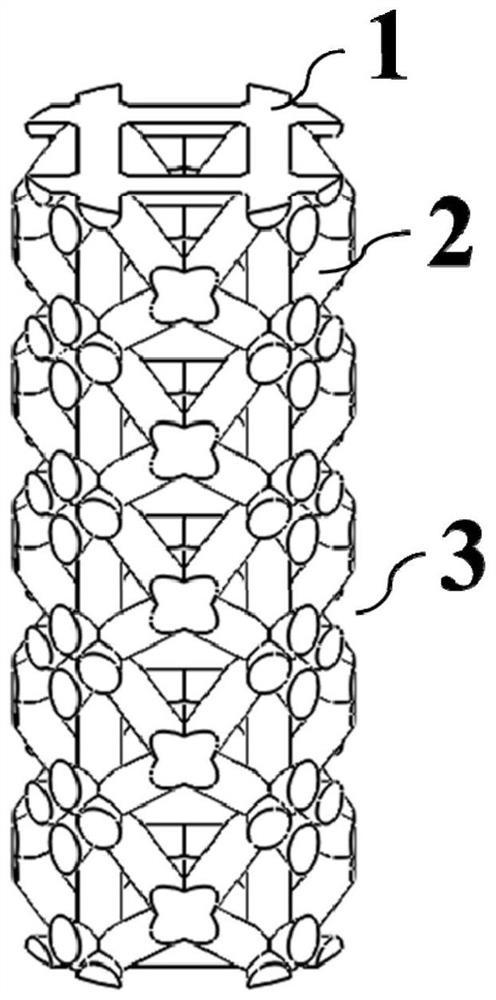

Porous gradient scaffold with mixed structure units, and preparation method

The invention provides a porous gradient scaffold with mixed structure units, and a preparation method. The porous gradient scaffold with mixed structure units comprises a plurality of scaffold structures, each scaffold structure comprises a plurality of structure units, each scaffold structure is formed by arraying the plurality of corresponding structure units along three dimensions of length, width and height, the relative density of each scaffold structure is in gradient change, each structure unit comprises a cubic frame, and a plurality of supporting cylinders arranged inside the cubic frame, and structures of the structure units forming the scaffold structures are different. The porous gradient scaffold with mixed structure units is formed by combining the plurality of scaffold structures, has good mechanical property and biological compatibility, is simple in structure, greatly shortens a design period, and can improve the forming accuracy of the scaffold structures.

Owner:UNIV OF SCI & TECH BEIJING

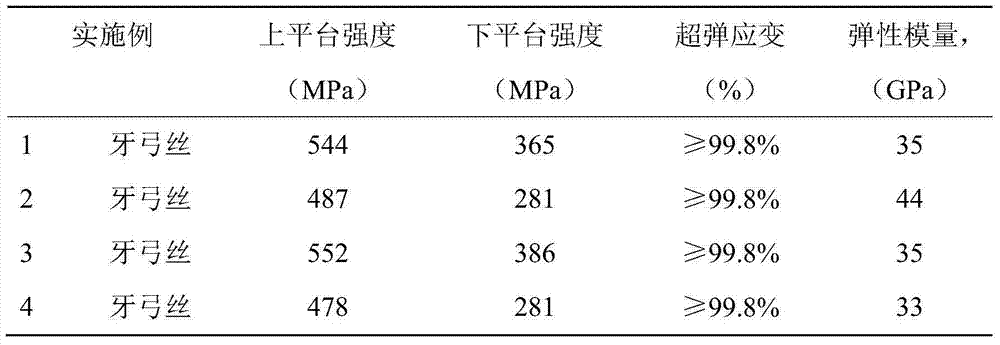

Moderate strength flexible narrow lag NiTiWCu quaternary alloy and preparation method and application thereof

ActiveCN104745878AEasy to processImprove hot workabilityArch wiresStentsChemical compositionUltimate tensile strength

The invention relates to a moderate strength flexible narrow lag NiTiWCu quaternary alloy and a preparation method and application thereof. The alloy comprises the following chemical components by weight: 0.55%-10.5% of W, 0.3%-0.95% of Cu, and balance of Ni and Ti, and the Ni and Ti atom ratio is 1.024-1.072. The compositely modified quaternary alloy has moderate yield strength approximate to the ordinary nickel titanium alloy yield strength, the elastic modulus is lower than that of the ordinary nickel titanium alloy, the quaternary alloy has good mechanical compatibility and good processing performance, and cold and hot processing performances are slightly better than that of the ordinary nickel titanium alloy. The product made of the alloy can be widely used in medical appliances and sporting goods and other fields, and can be used as super elastic brackets, orthodontic tooth arch wires, implantation instruments of orthopedics, and the like, and the arch wire product made of the alloy also has the advantages of flexibility and narrow lag.

Owner:GRINM MEDICAL INSTR BEIJING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com