Bioglass / polyether-ether-ketone composite materials, method for preparing same, application thereof, bone repair body and bone repair body preparation method

A technology of polyether ether ketone and bioglass, which is applied in the field of polyether ether ketone composite materials, can solve the problems of bone repair materials such as loosening and bone resorption, poor mechanical compatibility, and inability to firmly bond, so as to reduce healing time, good bioactivity and biocompatibility, and shortened bone healing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

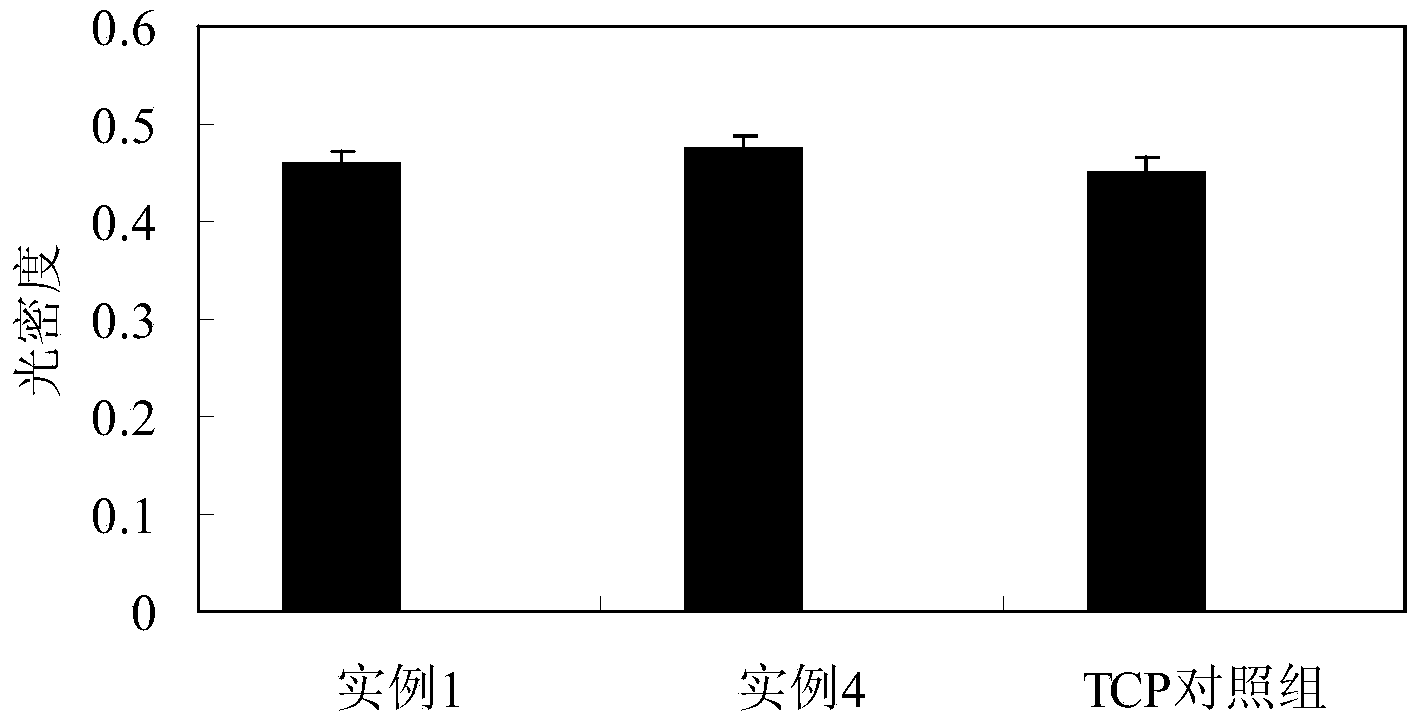

Embodiment 1

[0054] The preparation method of biological glass / polyether ether ketone composite material, it comprises the steps:

[0055] Raw materials: 2kg (20wt%) bio-glass powder (particle size 20μm) and 8kg (80wt%) polyetheretherketone powder (particle size 10μm) were uniformly mixed in a mixer to obtain a mixed powder; Mixed powder injection molding (using a mold of a non-bone prosthetic product), namely; wherein, the injection molding temperature is 360°C; the injection molding pressure is 30MPa. The mechanical properties of the bioglass / polyether ether ketone composite are shown in Table 1.

Embodiment 2

[0057] The preparation method of biological glass / polyether ether ketone composite material, it comprises the steps:

[0058] Raw materials: 3kg (30wt%) bio-glass powder (particle size 20μm) and 7kg (70wt%) polyetheretherketone powder (particle size 10μm) are mixed uniformly in a mixer to obtain a mixed powder; then use injection molding The mixed powder is injection-molded by a machine (using a mold of a non-bone prosthetic product) to obtain it; wherein, the temperature of the injection molding is 380°C; the pressure of the injection molding is 70MPa. The mechanical properties of the bioglass / polyether ether ketone composite are shown in Table 1.

Embodiment 3

[0060] A method for preparing a bone prosthesis, comprising the steps of:

[0061] Raw materials: 4kg (40wt%) bio-glass powder (particle size 20μm) and 5kg (50wt%) polyetheretherketone powder (particle size 10μm) are mixed uniformly in a mixer to obtain a mixed powder; then use injection molding A machine injects the mixed powder into a mold of dog alveolar bone prosthesis to obtain it; wherein, the injection molding temperature is 370° C.; the injection molding pressure is 50 MPa. The mechanical properties of the bone restoration are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com