Novel magnesium alloy with high medical performance

A technology of magnesium alloy and high performance, which is applied in the field of selective laser melting preparation technology and heat treatment, can solve the problems of corrosion resistance, poor wear resistance, loss of mechanical integrity, etc., and achieve excellent biocompatibility and mechanical compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The composition of the above alloy powder: 2% molybdenum; 1% tantalum; 0.5% chromium; 5% titanium; the rest is magnesium and inevitably contains C, S, P and other impurities. Pour the above-mentioned powder into the miniature omnidirectional planetary ball mill F-P400E, the speed of the ball mill tank is 600r / min, so that the metal powder is fully mixed and ground.

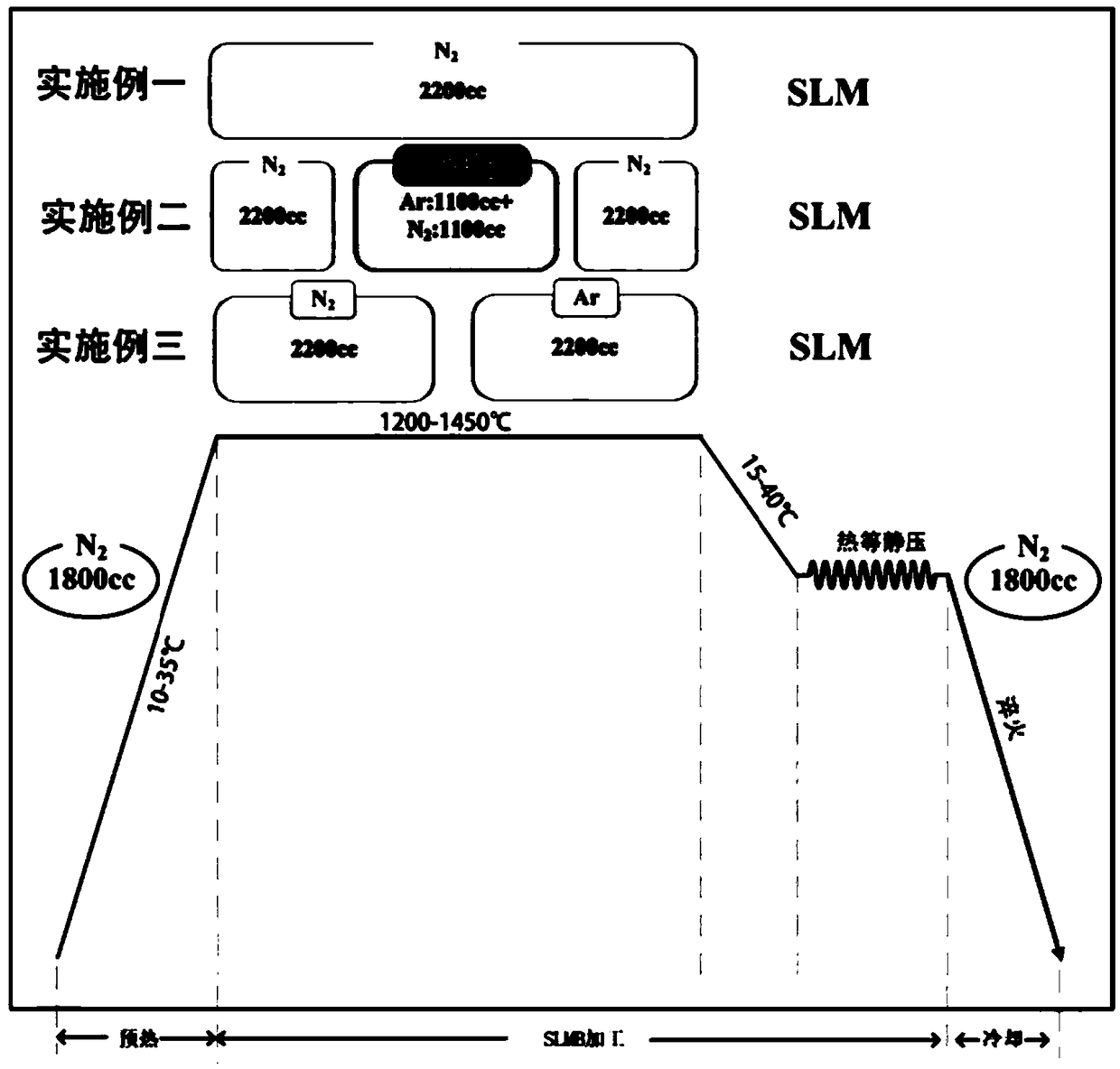

[0035] 2. Such as figure 1 As shown, the selective laser melting method

[0036] SLM Solutions 500 is used to process the ball-milled mixed powder obtained in step (1); SLM parameters include a laser power of 110W, a fiber laser spot size of 0.15mm, a groove pitch of 0.10mm, and a powder layer thickness of 0.03mm; using 200mm The scanning speed of / s prepares a cylindrical sample with a size of 10mm×5mm. The heating rate in the SLM system is 10°C / s, and the protective gas nitrogen is input. The concentration of nitrogen is 1800cc. The temperature is raised to the preset temperature of 1200°C and the temperat...

Embodiment 2

[0040] 1. The composition of the above alloy powder: molybdenum 3%; tantalum 2%; chromium 1.5%; titanium 10%; the rest is magnesium and inevitably containing C, S, P and other impurities. Pour the above powder into the miniature omnidirectional planetary ball mill F-P400E, the rotating speed of the ball mill tank is 700r / min, so that the metal powder is fully mixed and ground.

[0041] 2. Such as figure 1 As shown, the selective laser melting method

[0042] SLM Solutions 500 is used to process the ball-milled mixed powder obtained in step (1); SLM parameters include a laser power of 115W, a spot size of 0.18mm, a groove spacing of 0.11mm, and a powder layer thickness of 00.4mm. A cylindrical sample with a size of 10mm×5mm was prepared with a scanning speed of 220mm / s. The heating rate in the SLM system is 15°C / s, and the protective gas nitrogen is input. The nitrogen concentration is 1800cc, and the temperature is increased to the preset temperature of 1300°C. The temperature is ...

Embodiment 3

[0046] 1. The composition of the above alloy powder: molybdenum 4.5%; tantalum 3%; chromium 2.5%; titanium 10%; the rest is magnesium and inevitably containing C, S, P and other impurities. Pour the above powder into the miniature omnidirectional planetary ball mill F-P400E, the rotating speed of the ball mill tank is 750r / min, so that the metal powder is fully mixed and ground.

[0047] 2. Such as figure 1 As shown, the selective laser melting method

[0048] SLM Solutions 500 is used to process the ball-milled mixed powder obtained in step (1); SLM parameters include a laser power of 125W, a spot size of 0.18mm, a groove pitch of 0.11mm, and a powder layer thickness of 0.06mm; 250mm / s The scanning speed is 10mm×5mm cylindrical sample. The heating rate in the SLM system is 35°C / s, and the protective gas nitrogen is input. The concentration of nitrogen is 1800cc. The temperature is raised to the preset temperature of 1450°C and the temperature is kept for 6 hours. The protective g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com