Medical high-nitrogen nickel-free austenitic stainless steel and preparing method thereof

An austenitic stainless steel and austenitic technology, which is applied in the field of medical stainless steel material preparation, can solve the problems of human health hazards, high nickel price, singleness, etc., and achieve the effects of being beneficial to growth, saving resources and solving allergic reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of medical high-nitrogen nickel-free austenitic stainless steel, comprising the steps of:

[0038] 1) Nitrogen-containing nickel-free duplex stainless steel powder X15CrMn with a particle size of -500 mesh and pore-forming agent NH 4 HCO 3 According to the mass fraction of 70:30, mix it in a V-type powder mixer for 24 hours until the powder is fully mixed and poured into the steel mold. The chemical composition of the nitrogen-containing nickel-free duplex stainless steel powder X15CrMn (wt.%) It is: Mn: 10.84, Cr: 17.5, Mo: 3.400, N: 0.44, Ni: 0.36, C: 0.059, O: 0.134, and the rest is Fe.

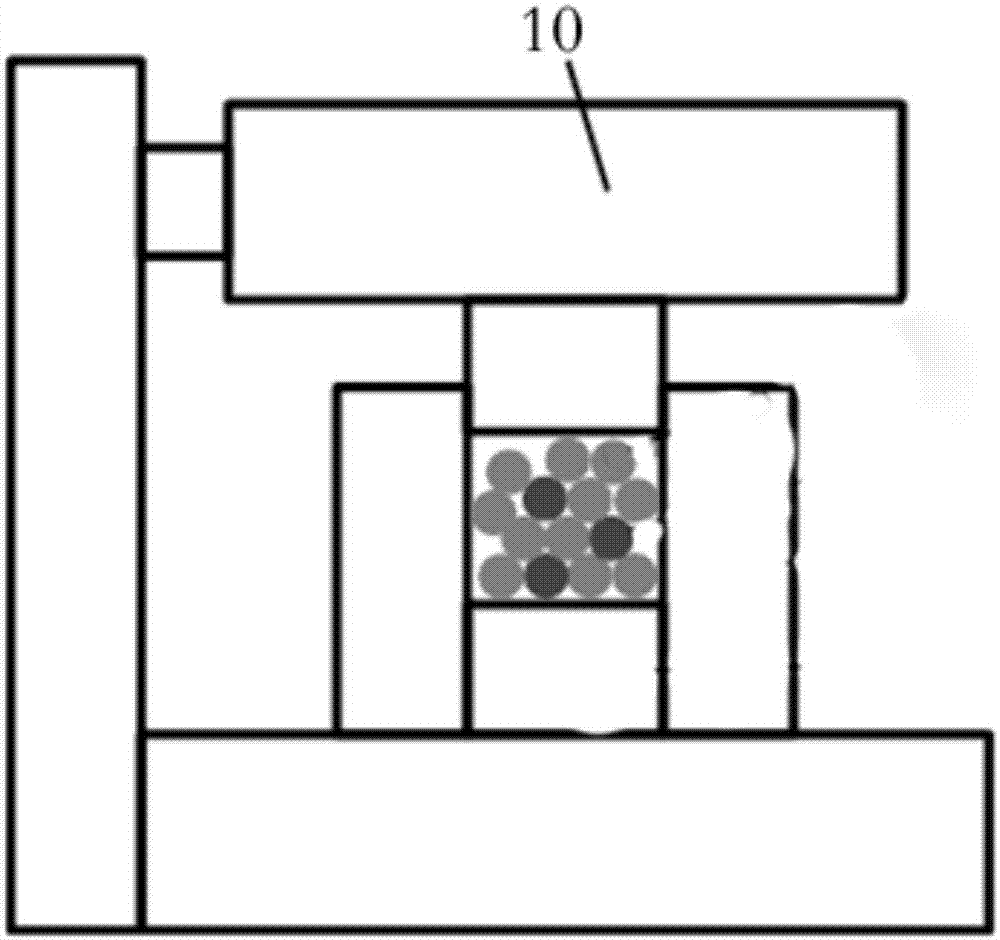

[0039] 2) Then press the mixed powder into a green body with a diameter of about 15 mm and a height of about 5 mm on a CMT5105 electronic universal testing machine 10 with a pressure of 200 MPa (see figure 1 ).

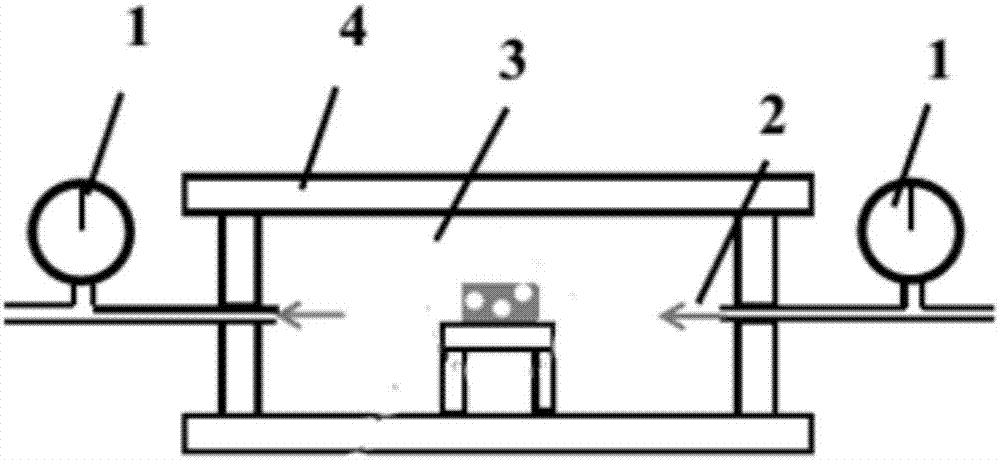

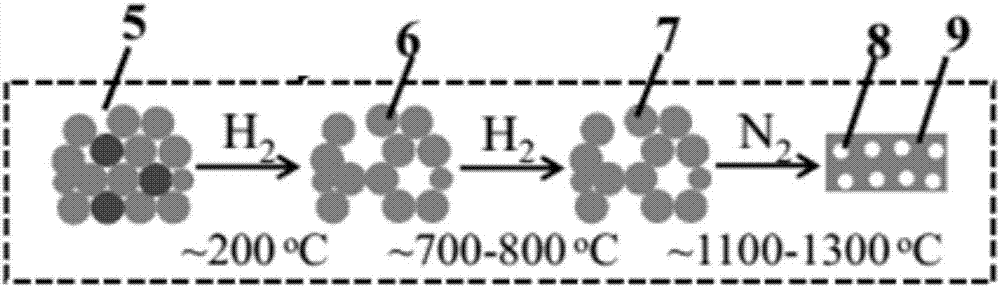

[0040] 3) if figure 2 As shown, the green body is placed in the tube furnace 3 for pre-sintering, the furnace tube is protected by flowing hydroge...

Embodiment 2

[0048] A method for preparing medical high-nitrogen nickel-free austenitic stainless steel, comprising the steps of:

[0049] 1) Nitrogen-containing nickel-free duplex stainless steel powder X15CrMn with a particle size of -500 mesh and pore-forming agent NH 4 HCO 3 According to the mass fraction of 50:50, mix it in a V-type powder mixer for 12 hours until the powder is fully mixed and poured into the steel mold. The chemical composition of the nitrogen-containing nickel-free duplex stainless steel powder X15CrMn (wt.%) It is: Mn: 10.84, Cr: 17.5, Mo: 3.400, N: 0.44, Ni: 0.36, C: 0.059, O: 0.134, and the rest is Fe.

[0050] 2) Then press the mixed powder into a green body with a diameter of about 15 mm and a height of about 5 mm on a CMT5105 electronic universal testing machine with a pressure of 374 MPa.

[0051] 3) Place the green body in a tube furnace for pre-sintering, flow hydrogen protection through the furnace tube, the gas flow rate is 300ml / min, and then o C / min ...

Embodiment 3

[0057] A preparation method of medical high-nitrogen nickel-free austenitic stainless steel, comprising the steps of:

[0058] 1) Nitrogen-containing nickel-free duplex stainless steel powder X15CrMn with a particle size of -600 mesh and pore-forming agent NH 4 HCO 3 According to the mass fraction of 70:30, mix in a V-type powder mixer for 48 hours until the powder is fully mixed and uniform, and the mixed powder is poured into a steel mold. The chemical composition of the nitrogen-containing nickel-free duplex stainless steel powder X15CrMn (wt.%) It is: Mn: 10.84, Cr: 17.5, Mo: 3.400, N: 0.44, Ni: 0.36, C: 0.059, O: 0.134, and the rest is Fe.

[0059] 2) Then press the mixed powder into a green body with a diameter of about 15 mm and a height of about 5 mm on a CMT5105 electronic universal testing machine 10 with a pressure of 500 MPa (see figure 1 ).

[0060] 3) Place the green body in a tube furnace for pre-sintering, the furnace tube is protected by flowing hydrogen ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com