Bone restoration body with composite porous structure and preparation method thereof

A porous structure and bone prosthetic technology, applied in the field of biomedical engineering, can solve the problems of poor biological properties, insufficient mechanical properties of degradable biomaterials, mismatching elastic modulus, etc., to improve osseointegration rate and good bone conduction and osteoinductive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the composite porous structure bone prosthesis of the present invention comprises the following steps:

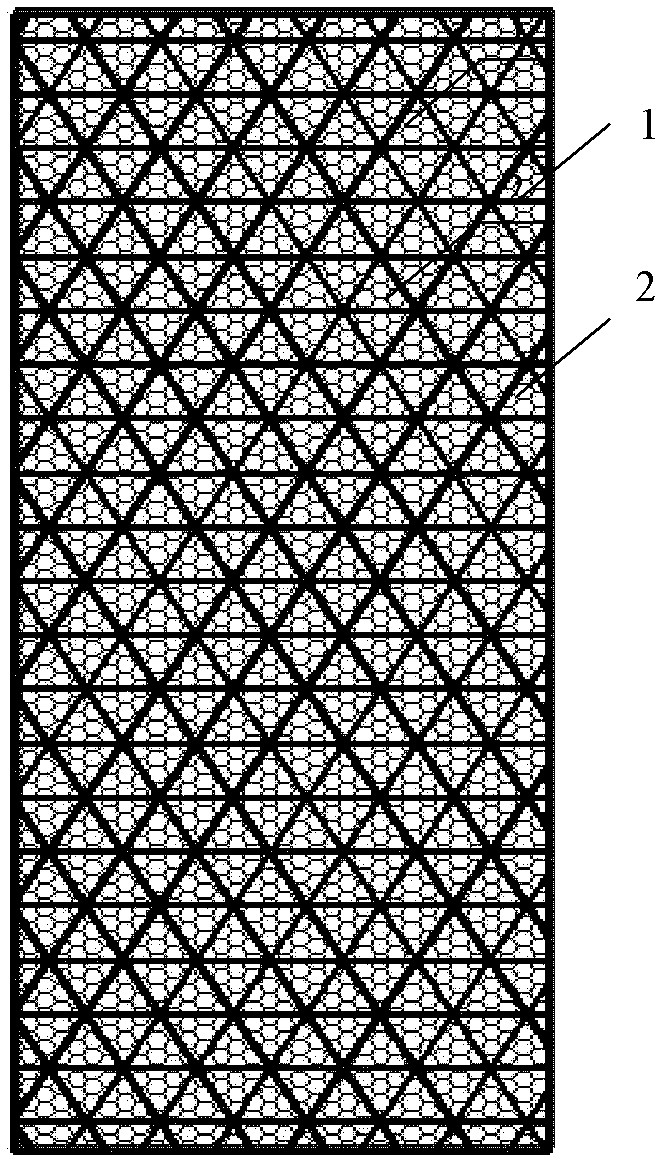

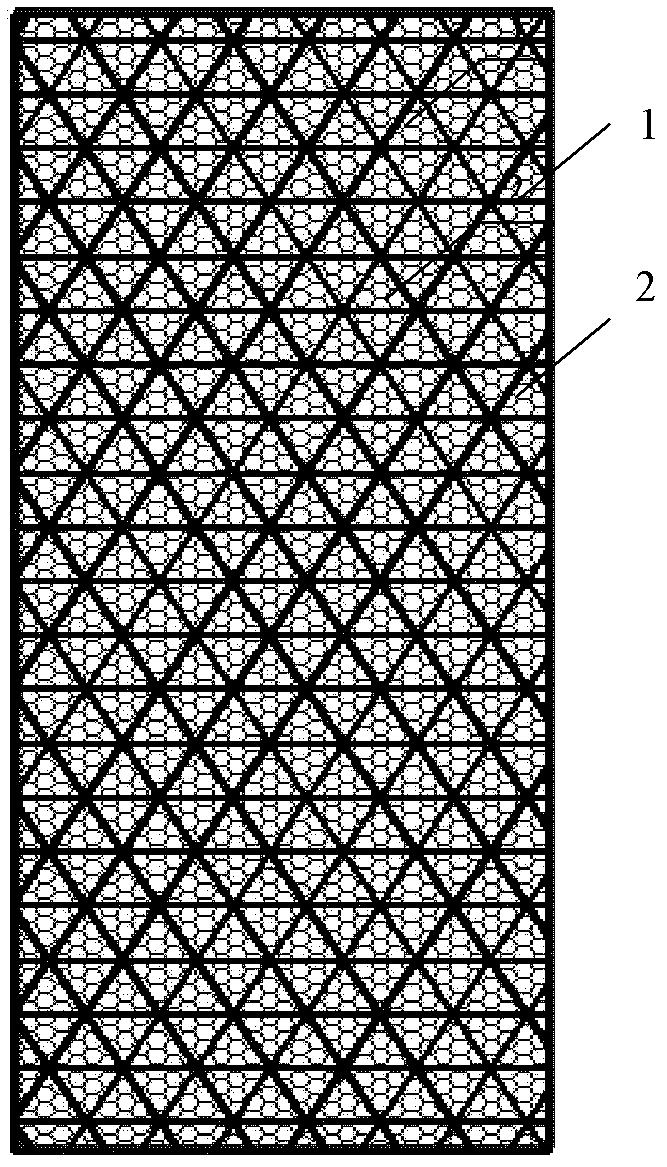

[0026] The first step is to use the direct metal rapid prototyping technology, and the rapid prototyping equipment uses metal materials for direct metal rapid prototyping under the control of the computer to form a porous metal support 1. The porous metal support 1 has a three-dimensional network structure. A plurality of pores, the size of the pores is 300-1500 μm, and the porosity is 60%-85%.

[0027] In the second step, the polymer is mixed with 0.2Mol / L acetic acid solution to prepare a polymer solution with a concentration of 1wt%-5wt%, and vacuumized at room temperature to remove residual bubbles in the solution;

[0028] In the second step, the polymer solution can also be prepared by mixing polymer, bioceramic and 0.2Mol / L acetic acid solution, the bioceramic is hydroxyapatite, tricalcium phosphate or calcium silicate, and the polyme...

Embodiment 1

[0033]First, the computer-aided design (CAD) software Unigraphics is used to design the three-dimensional structure of the porous metal support 1. The designed three-dimensional porous structure is a honeycomb structure, the size of the pores is 300 μm, and the porosity is 60%. Then the designed CAD The data is layered and sliced, and converted into the default data format of the rapid prototyping equipment, and then the rapid prototyping equipment processes the data, and uses titanium as the material under computer control for direct metal rapid prototyping to form a porous titanium metal bracket 1 . A certain amount of chitosan was mixed with 0.2Mol / L acetic acid solution to prepare a polymer solution with a concentration of 1 wt%, and vacuumized at room temperature to remove residual bubbles in the solution. Put the prepared porous titanium metal stent 1 into a container corresponding to its shape, and then pour the polymer solution into the porous titanium metal stent 1, s...

Embodiment 2

[0035] First, use the computer-aided design (CAD) software Unigraphics to design the three-dimensional structure of the porous metal support 1. The designed three-dimensional porous structure is a diamond molecular structure, the size of the pores is 700 μm, and the porosity is 70%. Then the designed CAD data Perform layered slicing processing and convert it into the default data format of the rapid prototyping equipment, and then the rapid prototyping equipment uses the titanium alloy for direct metal rapid prototyping manufacturing under computer control according to the processed data to form a porous titanium alloy bracket 1. A certain amount of chitosan, hydroxyapatite and the acetic acid solution of 0.2Mol / L are mixed, and the mass ratio of chitosan and hydroxyapatite is 4: 1, is prepared into the polymer solution that concentration is 5wt%, and Vacuumize at room temperature to remove residual air bubbles in the solution. Put the prepared porous titanium alloy stent 1 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com