Moderate strength flexible narrow lag NiTiWCu quaternary alloy and preparation method and application thereof

A quaternary alloy, narrow hysteresis technology, applied in the field of nickel alloys, can solve the problem of wide stress hysteresis, and achieve the effect of narrow stress hysteresis, low elastic modulus and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

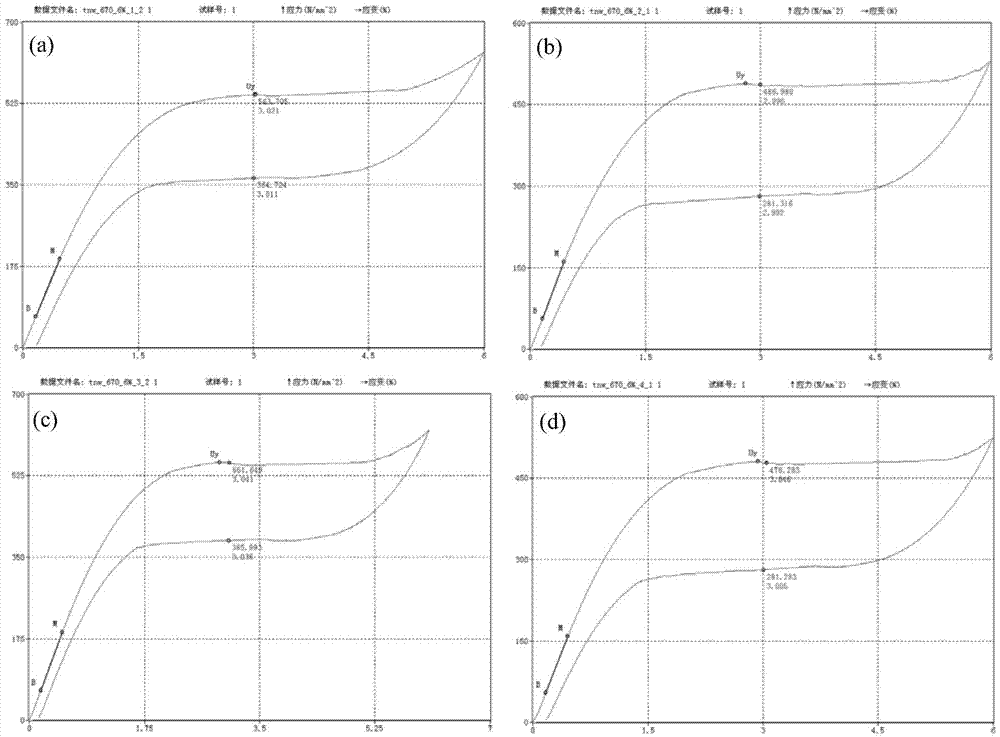

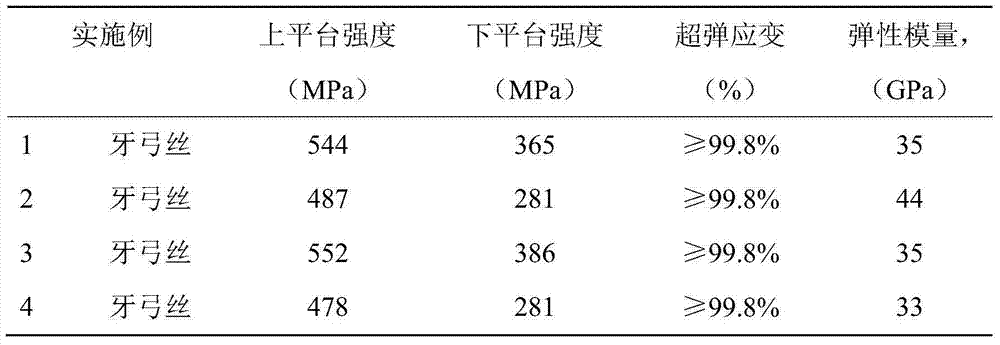

Embodiment 1

[0024] Using sponge titanium, electrolytic nickel, tungsten-titanium alloy, pure copper plate, tungsten-nickel alloy as raw materials, the total weight is 27 kg, and the design masses of each component are: tungsten (W): 2.835 kg, Cu: 0.175 kg, nickel ( Ni): 13.407 kg, titanium (Ti): 10.583 kg. A 2.3 kg electrode is pressed and melted into a cylindrical ingot through a vacuum induction furnace. The vacuum used for melting is not greater than 7Pa. The chemical composition of the ingot was tested after smelting. The actual measured tungsten weight percentage was 10.5%, copper weight percentage was 0.7%, nickel weight percentage was 49.80%, oxygen weight percentage was 0.033%, carbon weight percentage was 0.026%, and silicon weight percentage was 0.03%. , the weight percentage of iron is 0.032%, and the weight percentage of other elements is less than 0.025%. The weight percentage of titanium is the balance. After ingot homogenization and heat preservation at 1000°C for 60 minu...

Embodiment 2

[0026] Using sponge titanium, electrolytic nickel, pure copper plate, tungsten-titanium alloy, tungsten-nickel alloy as raw materials, the total weight is 27 kg, and the design masses of each component are: tungsten (W): 0.432 kg, Cu: 0.095 kg, nickel ( Ni): 14.973 kg, Titanium (Ti): 11.500 kg. A 2.3 kg electrode is pressed and melted into a cylindrical ingot through a vacuum induction furnace. The vacuum used for melting is not greater than 7Pa. The chemical composition of the ingot was tested after smelting. The actual measured tungsten weight percentage was 1.7%, copper weight percentage was 0.4%, nickel weight percentage was 55.5%, oxygen weight percentage was 0.043%, carbon weight percentage was 0.027%, and silicon weight percentage was 0.028%. , the weight percentage of iron is 0.03%, and the weight percentage of other elements is less than 0.025%. The weight percentage of titanium is the balance. After the ingot is homogenized and held at 850°C for 240 minutes, it is ...

Embodiment 3

[0028]Using sponge titanium, pure nickel plate, tungsten-titanium alloy, pure copper plate, tungsten-nickel alloy as raw materials, the total weight is 27 kg, and the design masses of each component are: tungsten (W): 0.189 kg, Cu: 0.257 kg, nickel (Ni): 14.782 kg, titanium (Ti): 11.772 kg. A 2.3 kg electrode is pressed and melted into a cylindrical ingot through a vacuum induction furnace. The vacuum used for melting is not greater than 7Pa. The chemical composition of the ingot was tested after smelting. The actual measured tungsten weight percentage was 0.66%, copper weight percentage was 0.95%, nickel weight percentage was 54.8%, oxygen weight percentage was 0.04%, carbon weight percentage was 0.027%, and silicon weight percentage was 0.028%. , the weight percentage of iron is 0.03%, and the weight percentage of other elements is less than 0.025%. The weight percentage of titanium is the balance. After the ingot is homogenized and kept at 950°C for 120 minutes, it is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com