Low-elastic-modulus titanium-zirconium dental implant material and preparation method thereof

A dental implant, titanium and zirconium technology, applied in the field of medical oral materials, can solve the problems of unguaranteed strength, low elastic modulus, high elastic modulus, etc., to avoid stress shielding effect, reduce elastic modulus, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

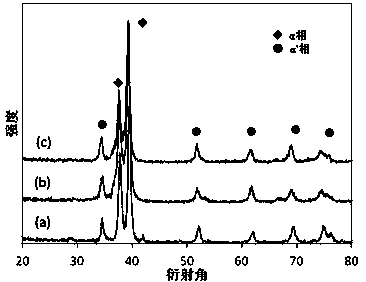

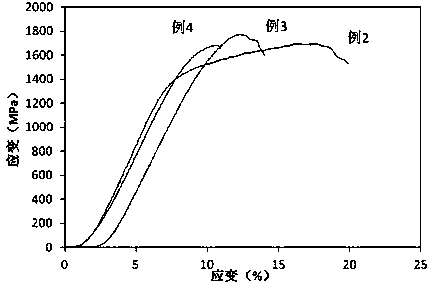

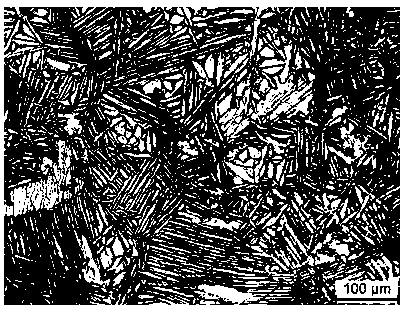

[0029] The mass ratio of zirconium to titanium in the low elastic modulus titanium-zirconium dental implant material is (3:17) to (7:13).

[0030] Wherein, the particle size of titanium powder in the low elastic modulus titanium-zirconium dental implant material is 1-22 μm, and the particle size of zirconium powder is 2-35 μm. The compressive strength of the low elastic modulus titanium zirconium dental implant material is 1292.8 to 1498.5 MPa, the elastic modulus is 21.8 to 22.8 GPa, and the relative density is 94.1% to 94.5%.

Embodiment 2

[0032] The method of low elastic modulus titanium-zirconium dental implant material described in Example 1 includes the following steps:

[0033] 1. According to the ratio of zirconium powder and titanium powder mass ratio of 3:17, weigh 15.0g zirconium powder and 85.0g titanium powder with a balance. The powder requires oxygen content less than 0.3% and carbon content less than 0.02%. The titanium-zirconium composite powder is obtained after powder ball milling.

[0034] 2. The titanium-zirconium composite powder obtained after ball milling is pressed and molded under a press. Each sample weighs 4.8 g and is formed under a pressure of 150 MPa, without edge or corner drop, and the surface of the compact is smooth.

[0035] 3. Place the pressed compact sample in a tungsten crucible, put it in a vacuum furnace for sintering, and pump the vacuum of the vacuum furnace to 10 -3 Pa. Then the temperature in the vacuum furnace was increased from room temperature to 800°C at a rate of 5°C / mi...

Embodiment 3

[0039] The method of low elastic modulus titanium-zirconium dental implant material described in Example 1 includes the following steps:

[0040] 1. According to the ratio of titanium powder and zirconium powder atomic ratio 1:3, weigh 25.0g zirconium powder and 75.0g titanium powder with a balance. The powder requires oxygen content less than 0.3% and carbon content less than 0.02%. The titanium-zirconium composite powder is obtained after powder ball milling.

[0041] 2. The titanium-zirconium composite powder obtained after ball milling is pressed and molded under a press. Each sample weighs 5.2 g and is formed under a pressure of 150 MPa without falling edges and corners, and the surface of the compact is smooth.

[0042] 3. Place the pressed compact sample in a tungsten crucible, put it in a vacuum furnace for sintering, and pump the vacuum of the vacuum furnace to 10 -3 Pa. Then the temperature in the vacuum furnace was increased from room temperature to 800°C at a rate of 5°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com