Mixed porous structure interbody fusion cage and preparation method thereof

A technology of intervertebral fusion and porous structure, which is applied in the field of biomedical engineering, can solve the problems of poor mechanical properties, collapse and fusion rate of non-metallic intervertebral fusion, and achieve good bone conduction and osteoinduction, Good immediate stability, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the mixed porous structure intervertebral fusion device of the present invention comprises the following steps:

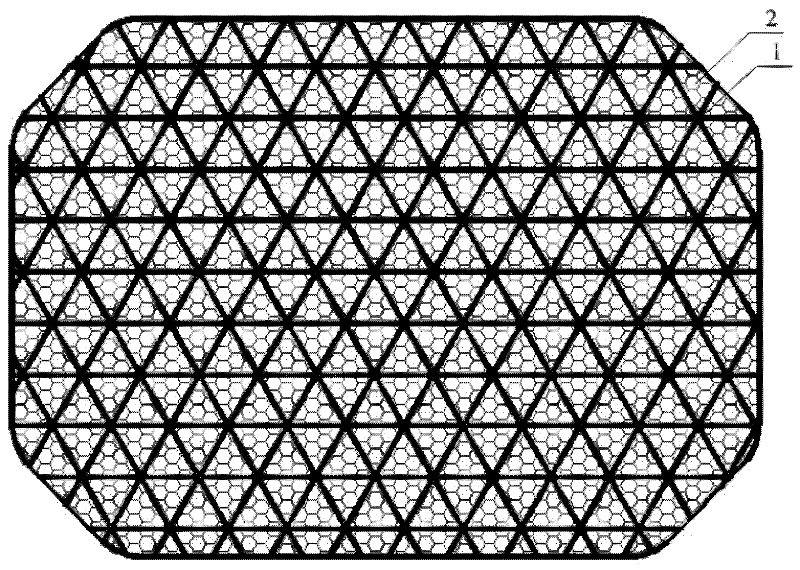

[0026] The first step is to use the direct metal rapid prototyping technology, and the rapid prototyping equipment uses metal materials for direct metal rapid prototyping under the control of the computer to form a porous metal support 1. The porous metal support 1 has a three-dimensional network structure. A plurality of pores, the size of the pores is 300-1500 μm, and the porosity is 60%-80%.

[0027] In the second step, the microporous polymer is mixed with deionized water to prepare a polymer solution with a concentration of 1%-5%. The microporous polymer is sodium alginate, and then 0.3mol / L of Calcium chloride solution is added to it, the volume ratio of polymer solution and calcium chloride solution is 5:1, so that calcium ion replacement reaction occurs to form a gel solution, and continue to stir for 30-60 minutes to make t...

Embodiment 1

[0033] First, the computer-aided design (CAD) software Unigraphics is used to design the three-dimensional structure of the porous metal support 1. The designed three-dimensional porous structure is a honeycomb structure, the size of the pores is 300 μm, and the porosity is 60%. Then the designed CAD The data is layered and sliced, and converted into the default data format of the rapid prototyping equipment, and then the rapid prototyping equipment processes the data, and uses titanium as the material under computer control for direct metal rapid prototyping to form a porous titanium metal bracket 1 . Mix a certain amount of sodium alginate and deionized water to prepare a polymer solution with a concentration of 1%, and then add 0.3mol / L calcium chloride solution to it under stirring conditions, and the polymer solution and calcium chloride The volume ratio of the solution is 5:1, so that a calcium ion replacement reaction occurs to form a gel solution, and the stirring is c...

Embodiment 2

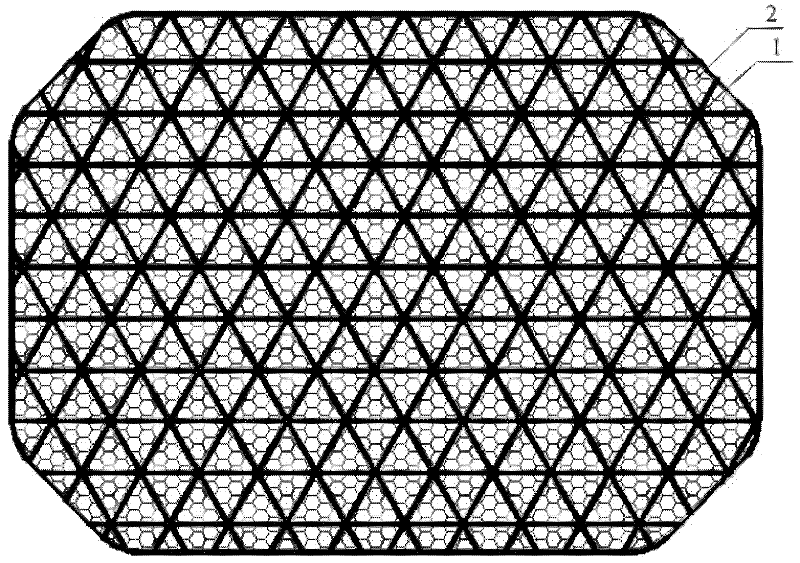

[0035] First, use the computer-aided design (CAD) software Unigraphics to design the three-dimensional structure of the porous metal support 1. The designed three-dimensional porous structure is a diamond molecular structure, the size of the pores is 700 μm, and the porosity is 70%. Then the designed CAD data Perform layered slicing processing and convert it into the default data format of the rapid prototyping equipment, and then the rapid prototyping equipment uses the titanium alloy for direct metal rapid prototyping manufacturing under computer control according to the processed data to form a porous titanium alloy bracket 1. Mix a certain amount of sodium alginate, hydroxyapatite and deionized water, the mass ratio of sodium alginate and hydroxyapatite is 4:1, prepare a polymer solution with a concentration of 5%, and then , 0.3mol / L calcium chloride solution is added therein, the volume ratio of polymer solution and calcium chloride solution is 5: 1, make it take place ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com