Patents

Literature

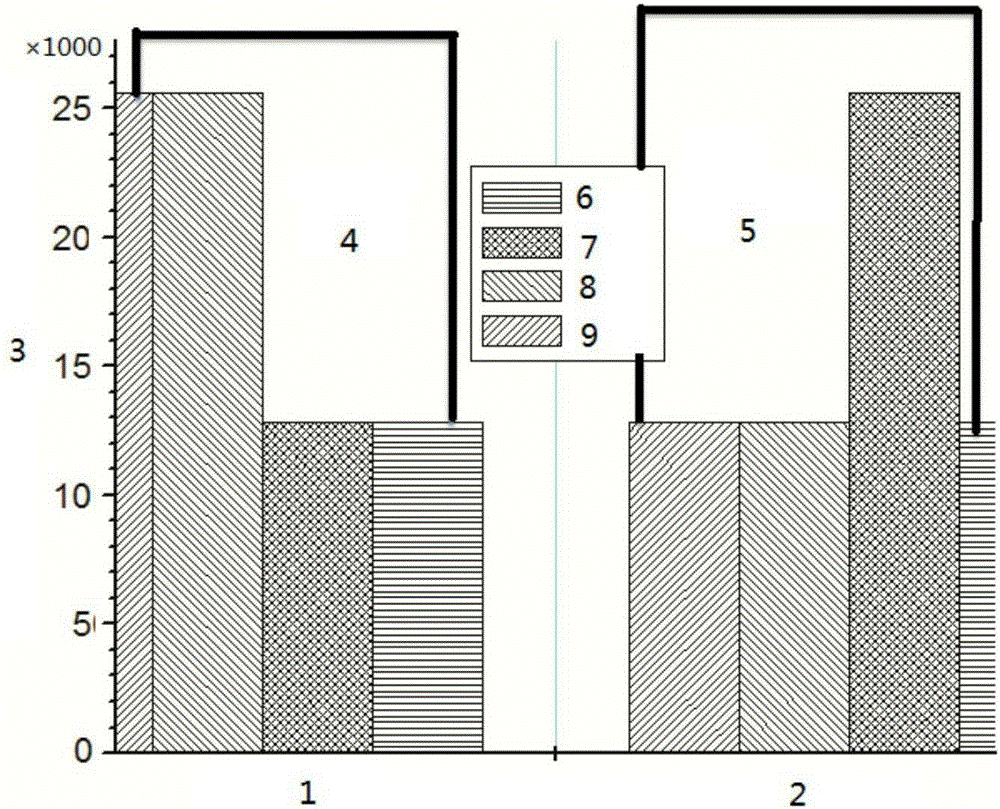

138results about How to "Improve fusion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

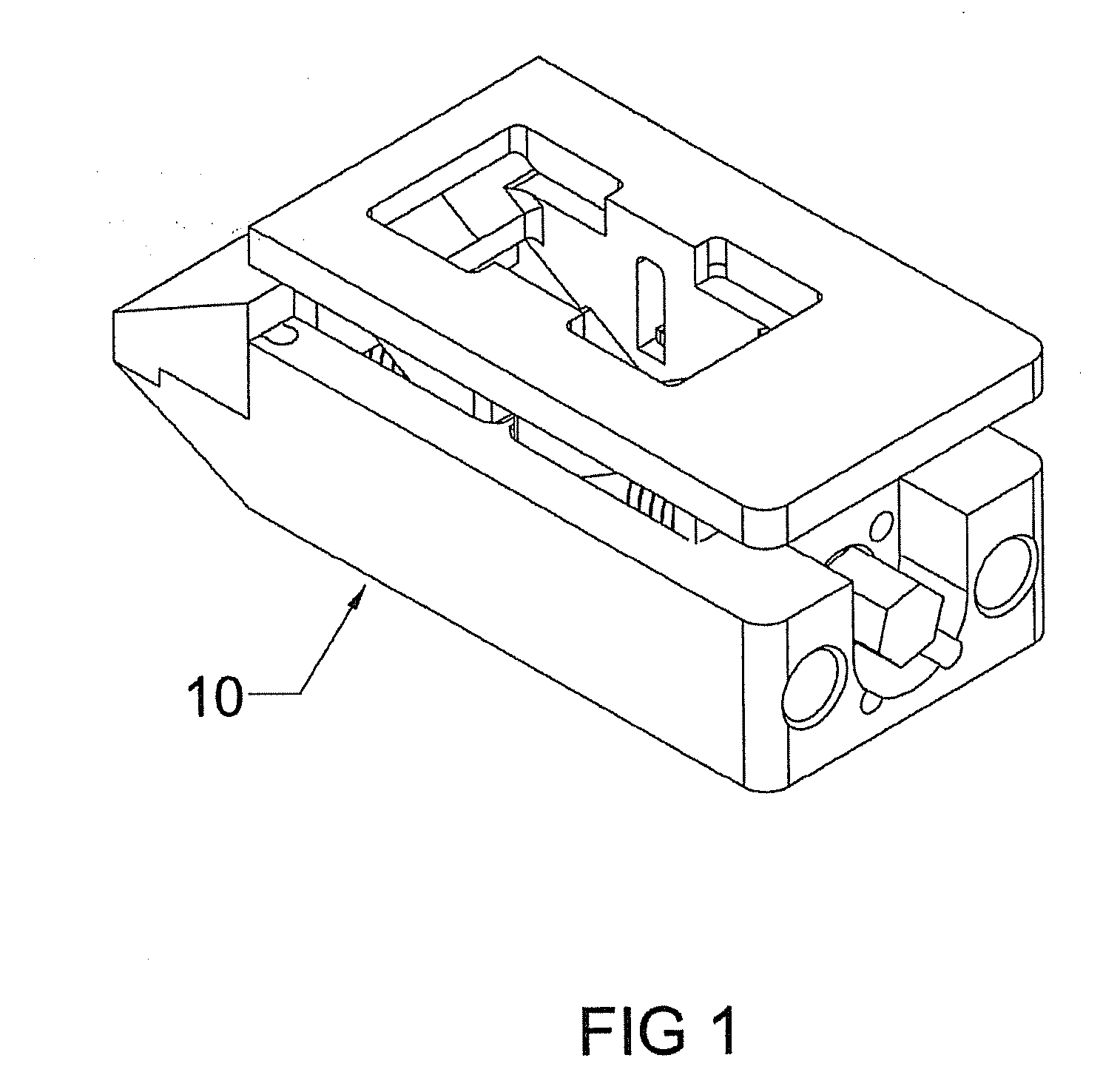

Expandable Self-Anchoring Interbody Cage for Orthopedic Applications

ActiveUS20130158669A1Maintain and create lordosisEasy to useBone implantSpinal implantsSpinal cageInterbody cage

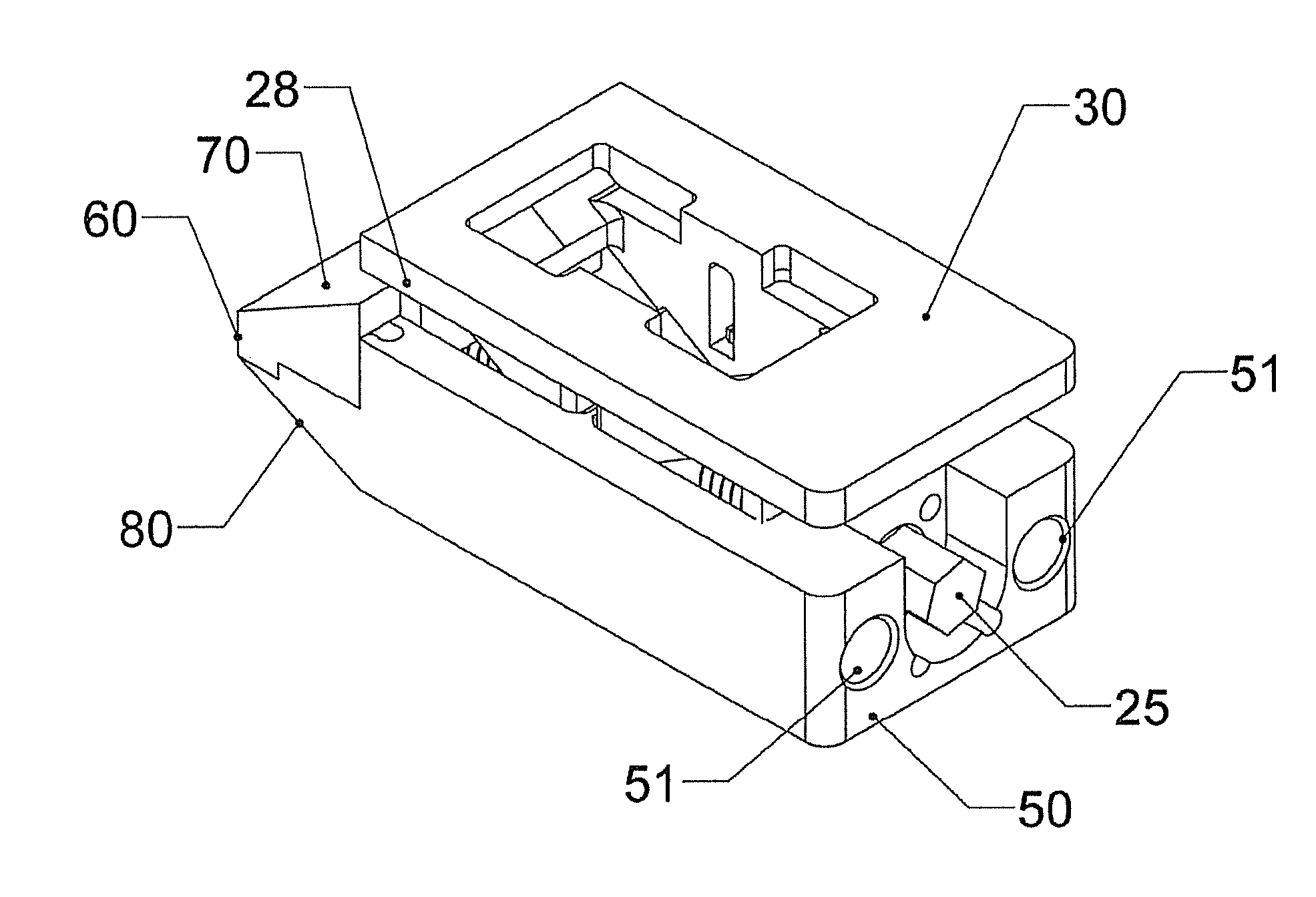

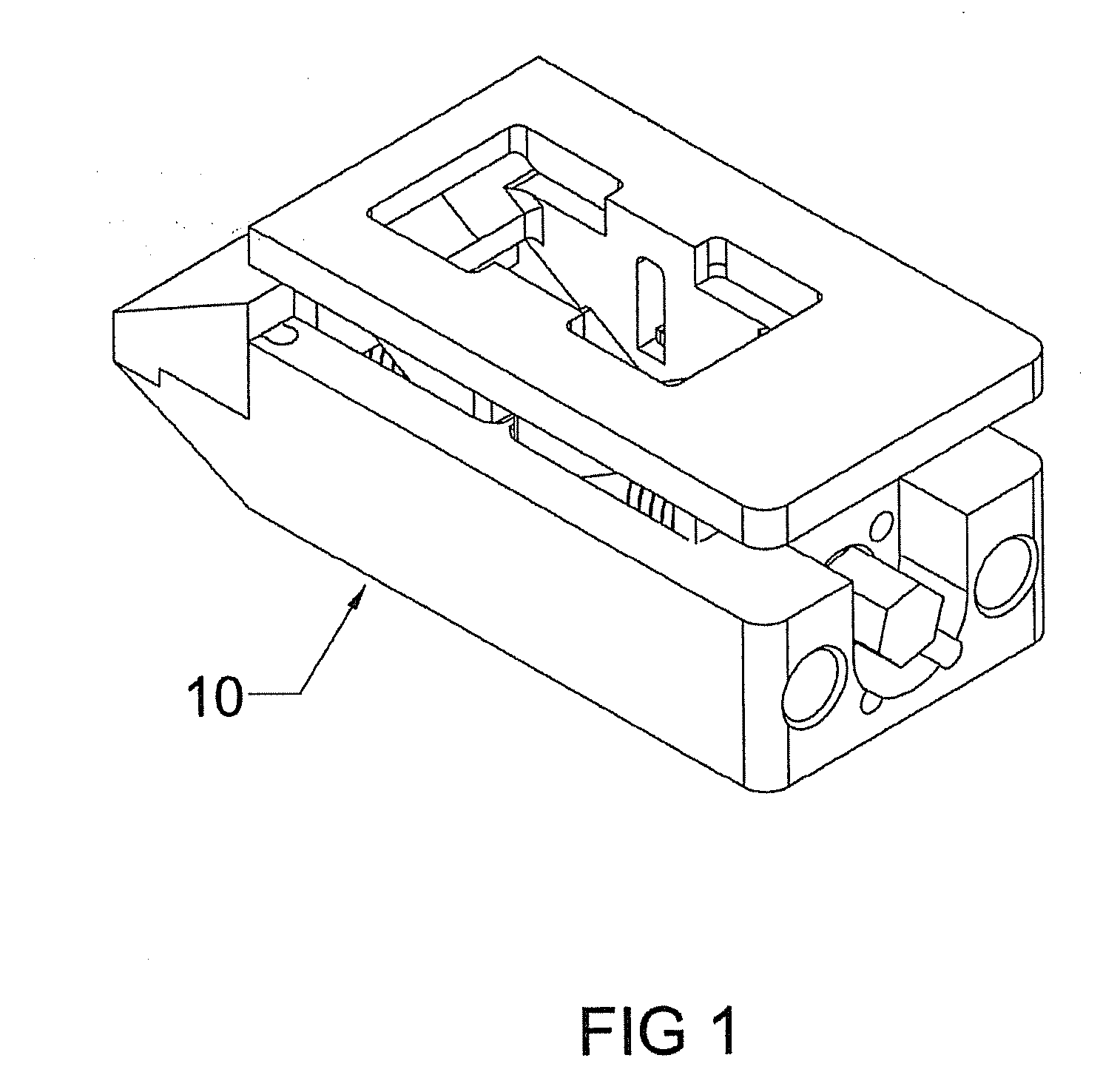

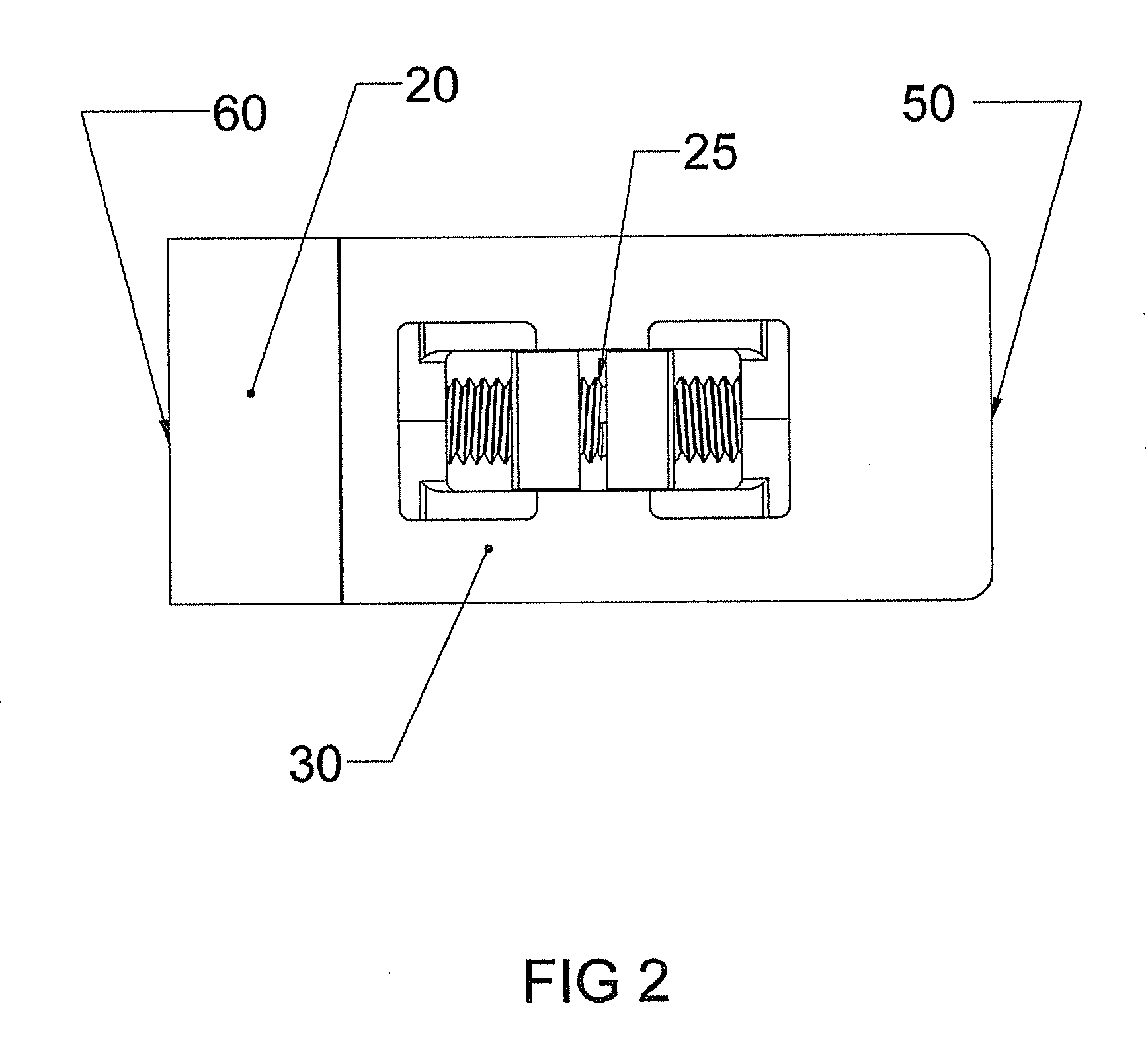

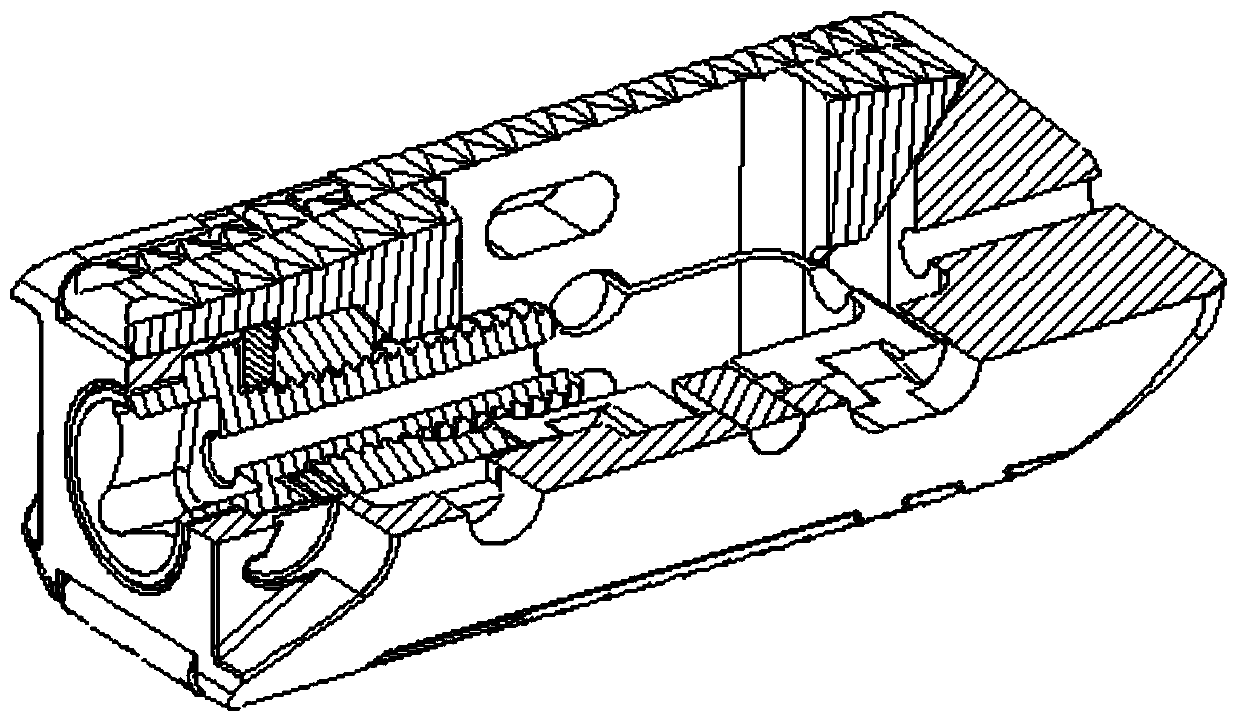

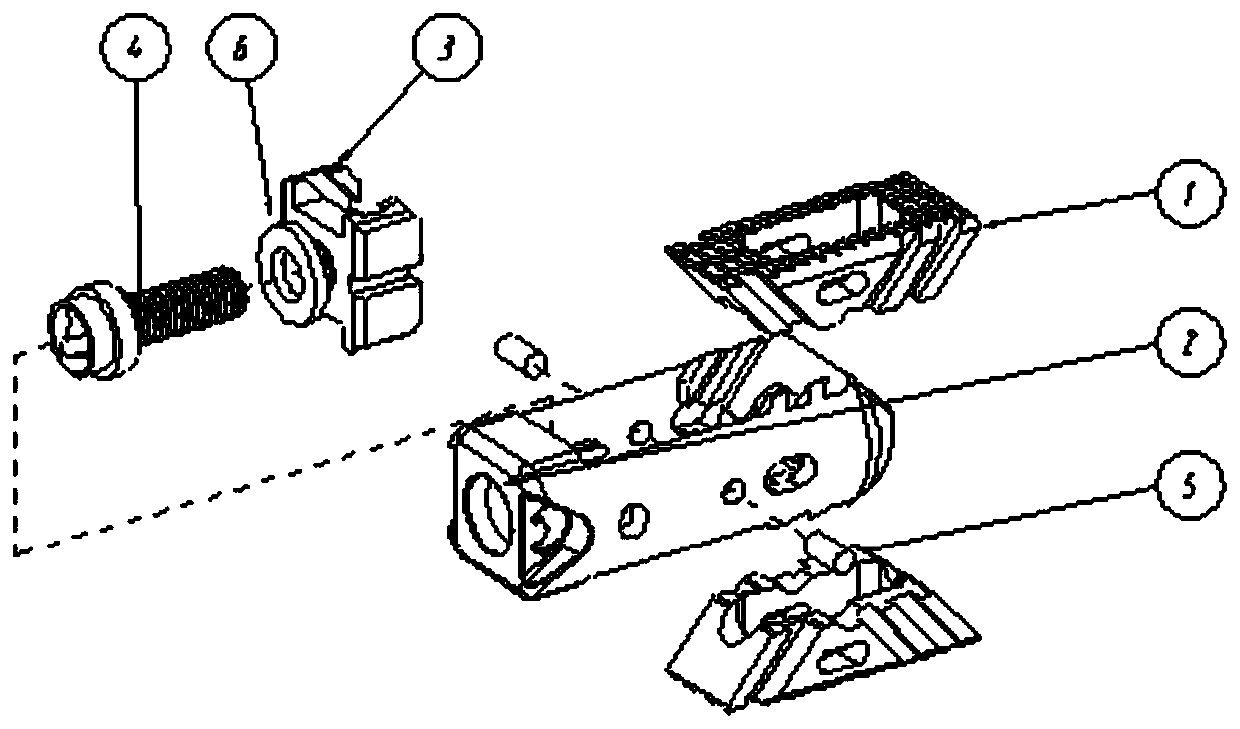

The present invention is directed to an expandable spinal fusion intervertebral implant that provides for maintaining and creating lordosis in the human spine that can be filled with biologics while in situ to encourage spinal fusion. A threaded rod that traverses an insertion / injection handle can be rotated to operate a screw within the interbody cage that displaces opposing vertical tapped sliding wedges, causing them to converge towards each other. Such contact causes the operation of a horizontal wedge that acts as a lift to expand the interbody cage to one of various dimensions in a preferred range. At its desired expansion, the spinal fusion implant of the present invention is sized to fit within the disc space between two vertebral bodies and fill all voids left while the vertical and horizontal wedges operate within, due to the biologics being contained within the interbody cage.

Owner:BLUE TIP BIOLOGICS

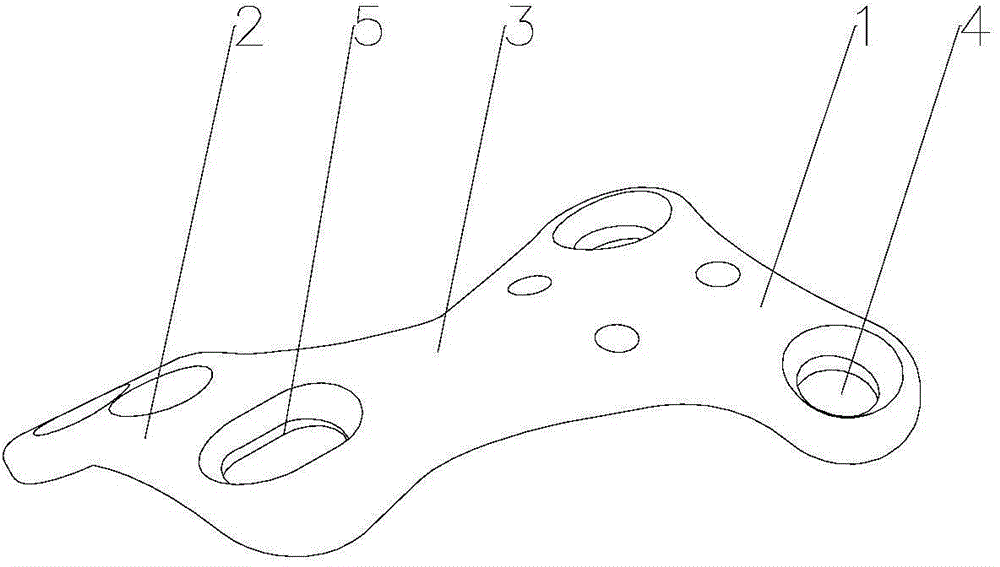

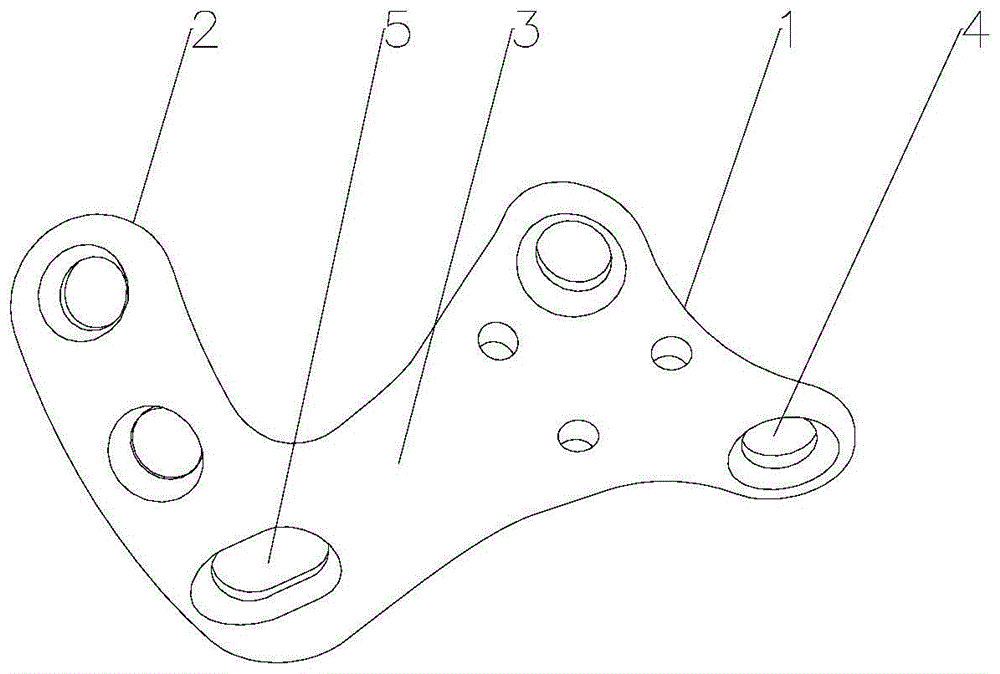

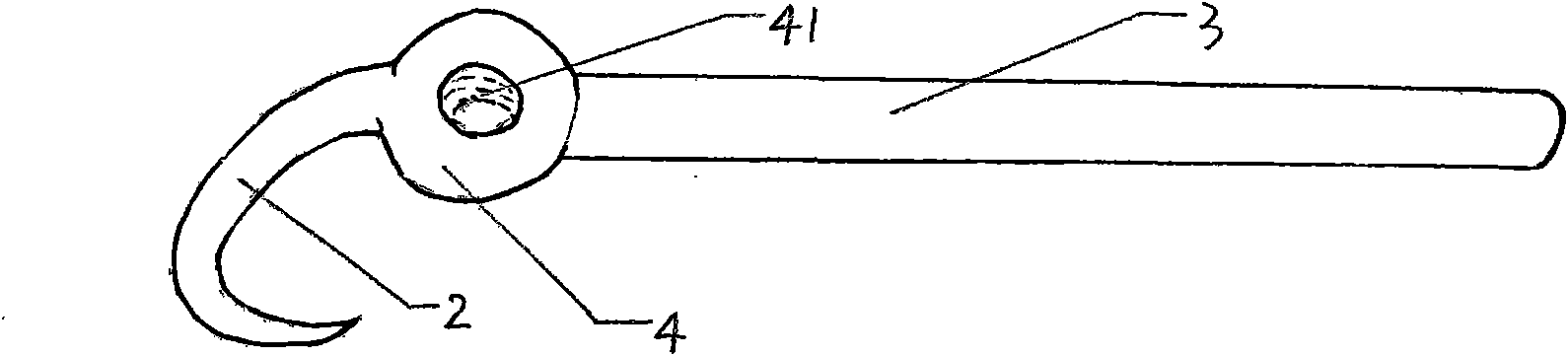

Talonavicular fusion plate

InactiveCN104523327AFacilitates anatomical reductionImprove gripBone platesAnkle boneStress concentration

The invention relates to the technical field of medical instruments, in particular to a talonavicular fusion plate which comprises a fusion plate near end, a fusion plate far end and a fusion plate body connecting the fusion plate near end and the fusion plate far end. The fusion plate near end, the fusion plate far end and the fusion plate body are formed integrally. The fusion plate near end is provided with a fixing hole used for being fixedly connected with a talus bone, and the fusion plate far end is provided with a fixing hole used for being fixedly connected with a tarsal navicular bone. According to the talonavicular fusion plate, an anatomic design is adopted, the fusion plate does not need to be bent in advance in an operation, the problem that the fusion plate is prone to loose and fail to be fixed when being fixed by adopting hollow nails, straddle nails and the like is solved, and the problems that in a common fusion plate operation, the fusion plate needs to be bent, as a result, stress concentration is prone to occurring, the fusion plate is broken, the fixing holes are deformed, and the fusion plate is not firmly fixed are solved.

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

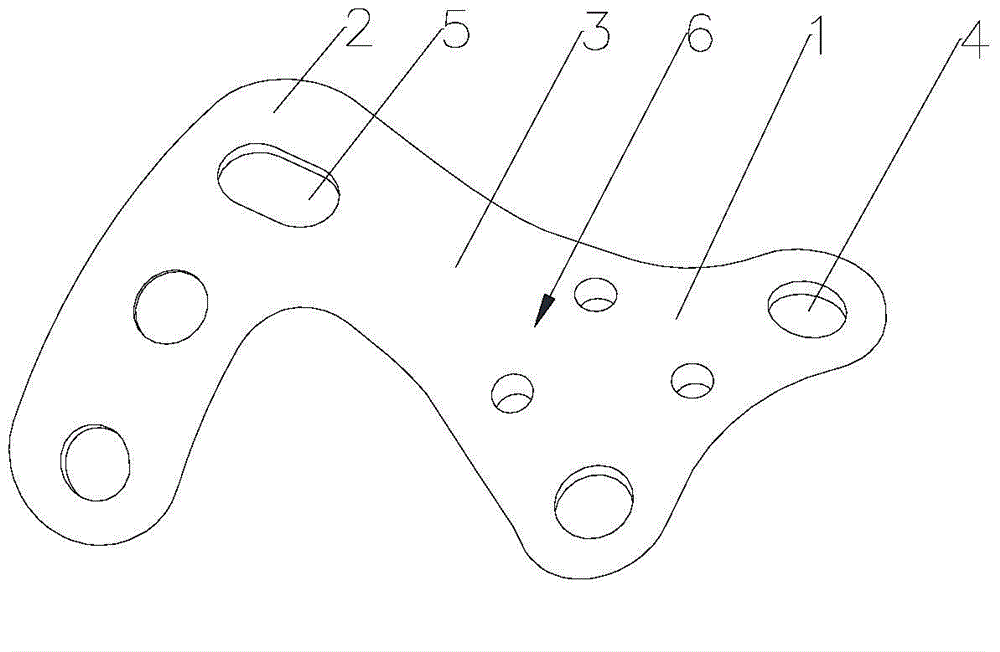

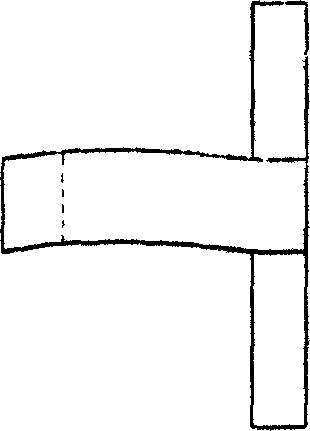

Lisfrance joint injury fusion plate

The invention relates to the field of medical devices, in particular a Lisfrance joint injury fusion plate. The fusion plate comprises a first tarsometatarsal joint plate, a second tarsometatarsal joint plate and a first transition plate for connecting the first tarsometatarsal joint plate and second tarsometatarsal joint plate; and the fusion plate provided with a plurality of fixing holes for fixing the fusion plate on a first metatarsal bone, an inner cuneiform bone, a second metatarsal bone and an intermediate cuneiform bone. The Lisfrance joint injury fusion plate has dissection-type design; in an operation, the fusion plate is not required to be pre-bent, the operation time is saved, and the bending influence on the plate strength; the close-end fixing holes of the first tarsometatarsal joint plate and the second tarsometatarsal joint plate have strong holding force for the inner cuneiform bone and the intermediate cuneiform bone; the curvature of human anatomy of Asian people is fully taken in to consideration of the design of the plates and bolts; and the fusion of multiple joint surfaces is conductive to arch anatomy reconstruction, excellent stability for joint fusion is provided, and the fixing effect of the fusion plate is further improved.

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

Expandable self-anchoring interbody cage for orthopedic applications

The present invention is directed to an expandable spinal fusion intervertebral implant and a method for surgically implanting said implant that provides for maintaining and creating lordosis in the human spine that can be filled with biologics while in situ to encourage spinal fusion. A threaded rod that traverses an insertion / injection handle can be rotated to operate a screw within the interbody cage that displaces opposing vertical tapped sliding wedges, causing them to converge towards each other. Such contact causes the operation of a horizontal wedge that acts as a lift to expand the interbody cage to one of various dimensions in a preferred range. In its expanded height, the overall length of the interbody cage is maintained. At its desired expansion, the spinal fusion implant of the present invention is sized to fit within the disc space between two vertebral bodies and fill all voids left while the vertical and horizontal wedges operate within, due to the biologics being contained within the interbody cage.

Owner:BLUE TIP BIOLOGICS

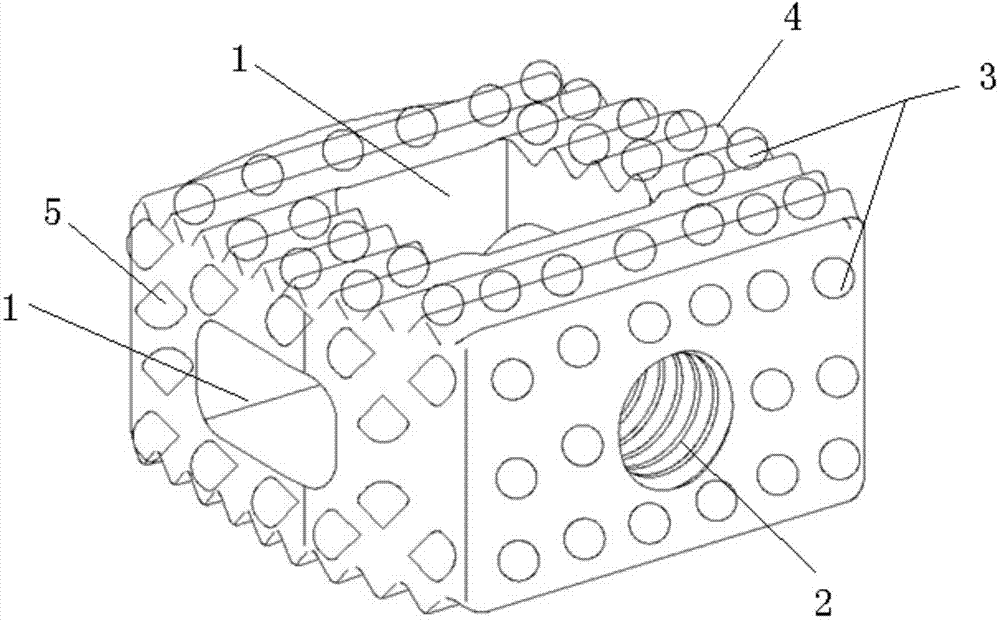

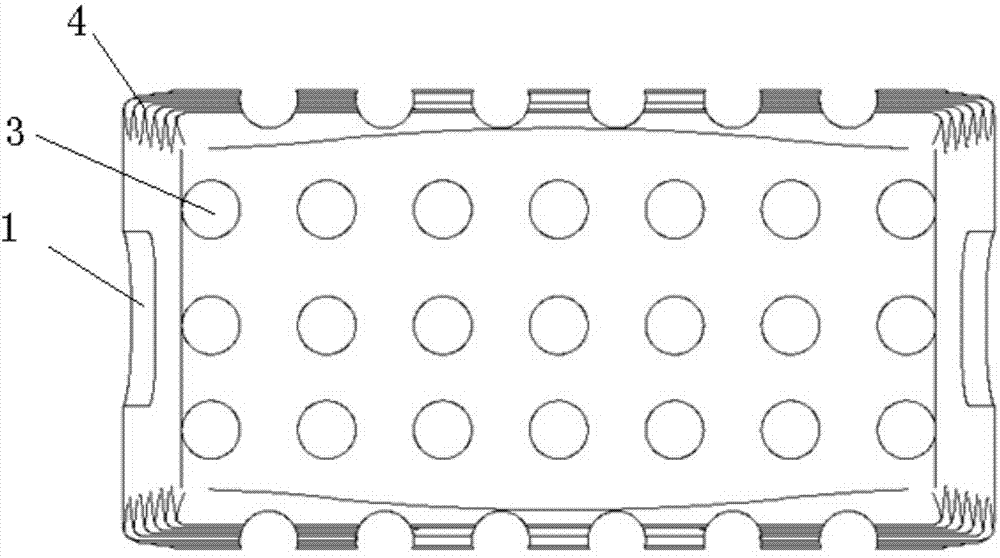

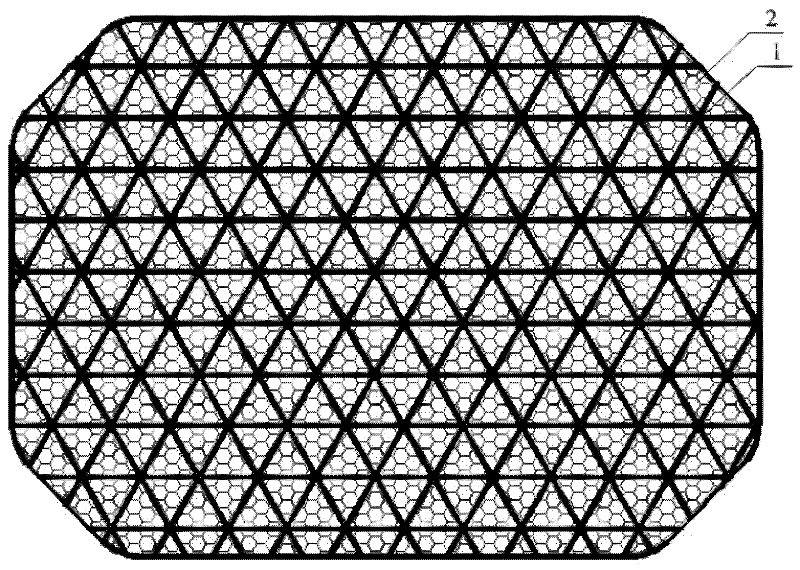

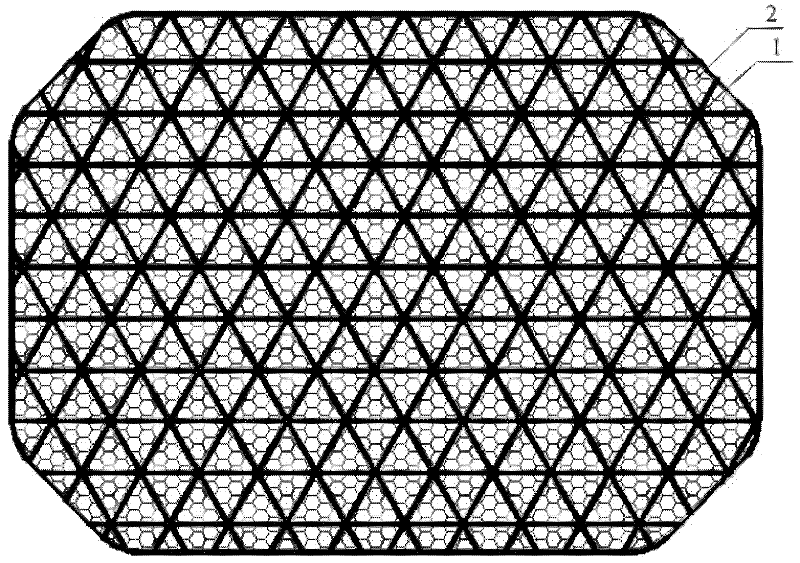

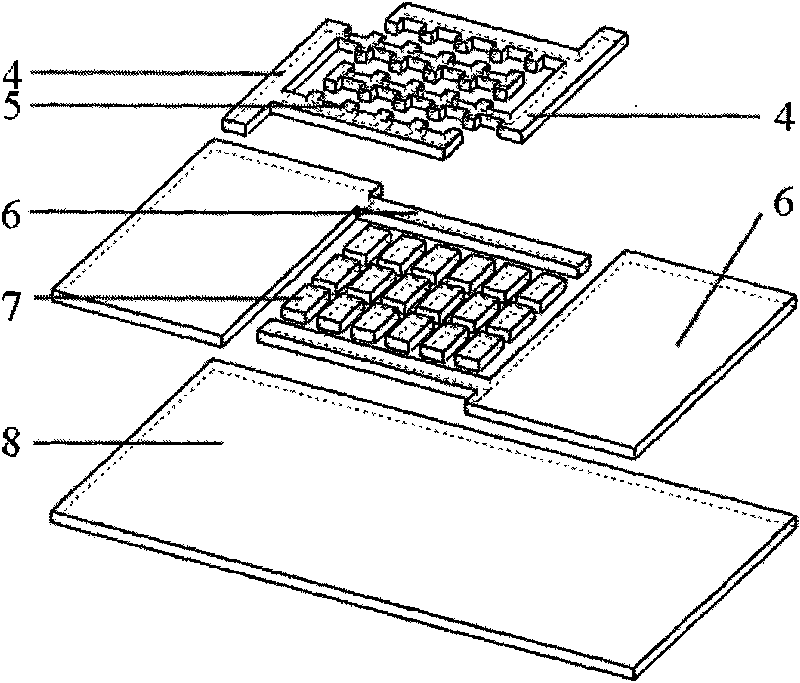

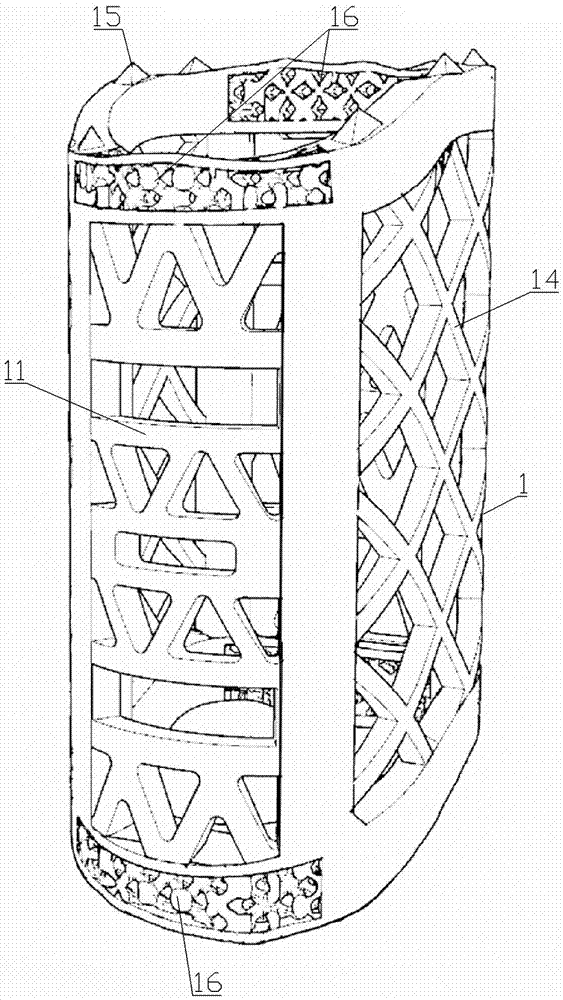

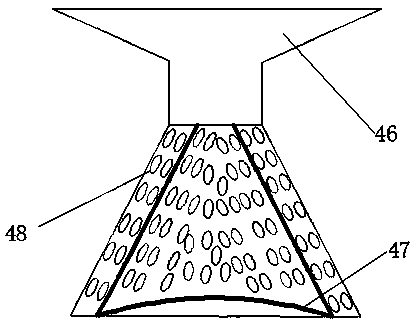

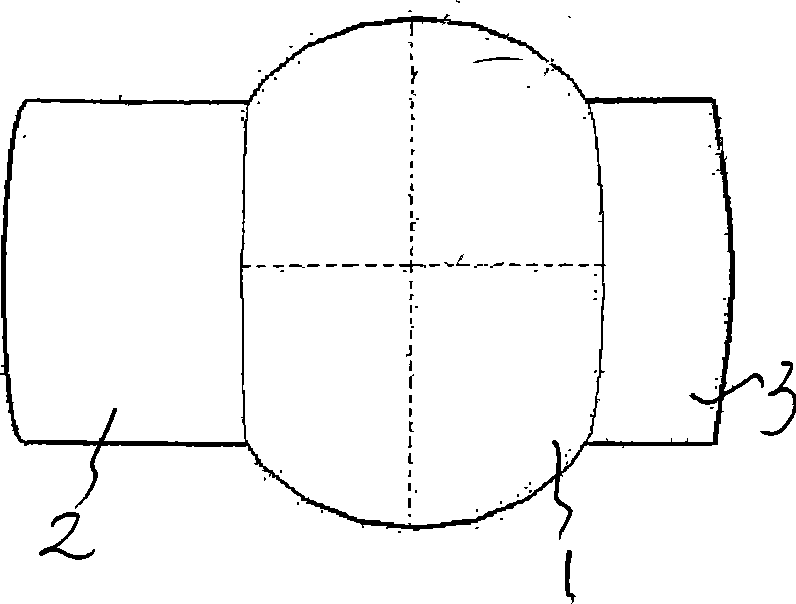

Bionic bone trabecula cervical vertebral fusion cage and manufacturing method thereof

InactiveCN104706446AImprove fusion rateGood medical recovery effectSpinal implantsHuman bodyCancellous bone

The invention discloses a bionic bone trabecula cervical vertebral fusion cage. The bionic bone trabecula cervical vertebral fusion cage is characterized in that a body of the cervical vertebral fusion cage is in the shape of a hexagonal prism, the interior of the body is in the shape of a three-dimensional net, and square through holes (1) are formed in the middles of the upper end face, the lower end face, the front end face and the rear end face of the body respectively. A manufacturing method of the bionic bone trabecula cervical vertebral fusion cage comprises the following steps that 1, original parameters of the bone trabecula are calculated; 2, a target model is established; 3, specific hole unit bodies are stacked within the boundary range of the target model disorderly, the sizes of the hole unit bodies, the distance between hole units, the sizes of ribs in the hole unit bodies, the sizes of connecting ribs between the hole unit bodies and the precision and appearance precision of an integrated bone trabecula structure are set, and finally the original target model is deleted, and the bone trabecula structure obtained after filling is reserved. According to the bionic bone trabecula cervical vertebral fusion cage and the manufacturing method of the bionic bone trabecula cervical vertebral fusion cage, a cancellous bone structure of a human body is simulated in the microstructure aspect through a 3D printing product, and the technical problems that according to a traditional centrum fusion cage, only the mechanical supporting function is achieved, and a formed bone can not be induced to grow are solved.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

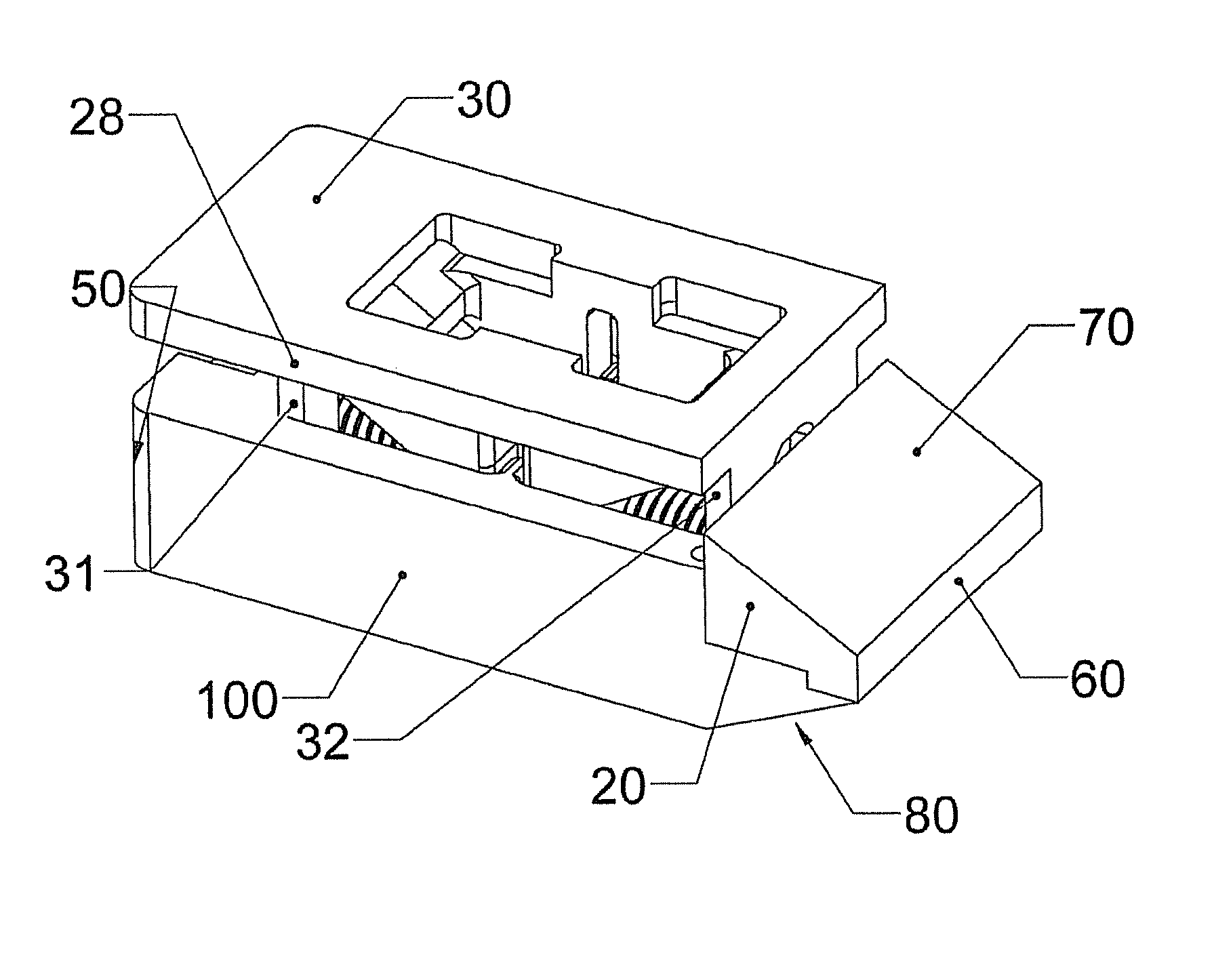

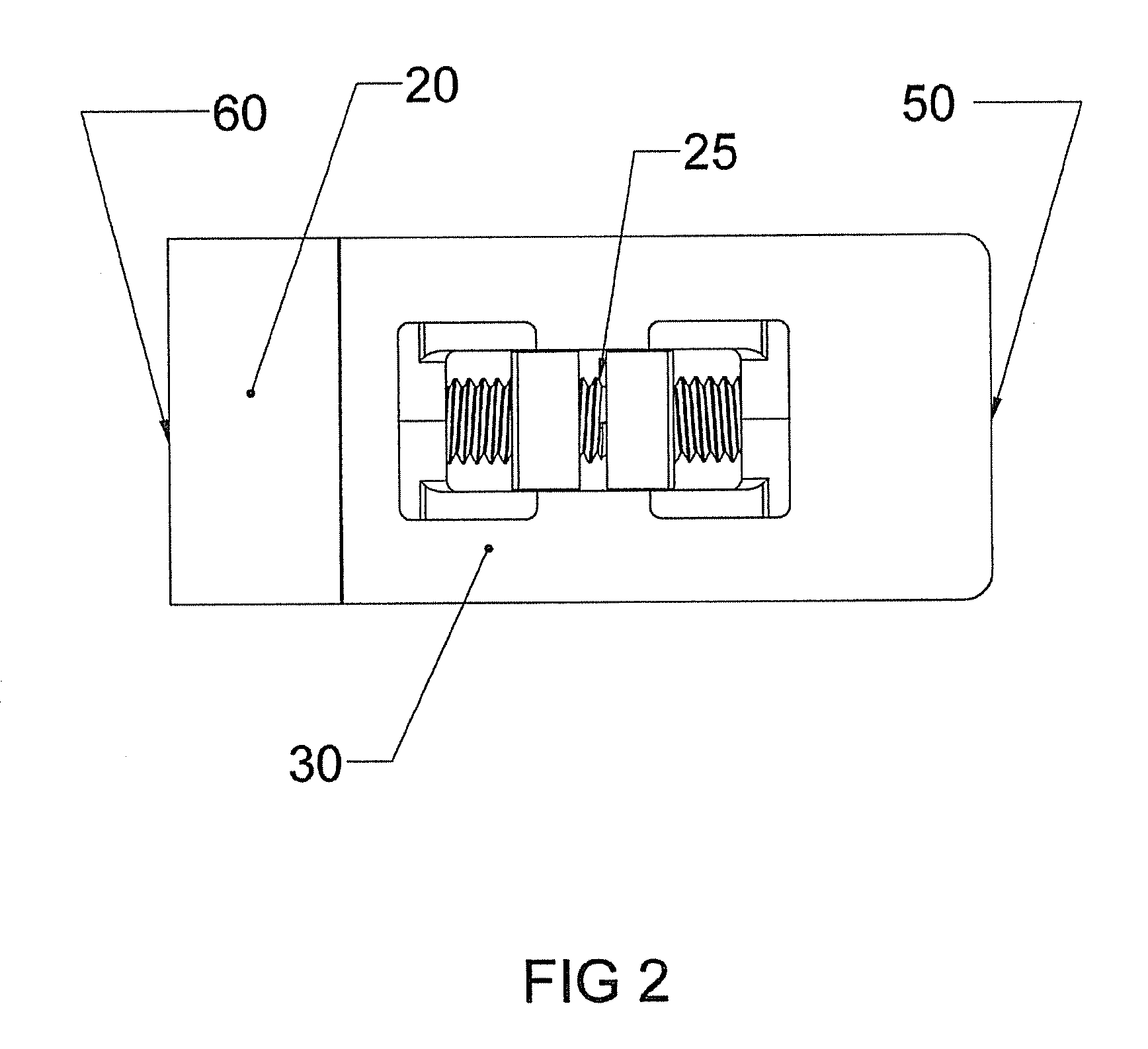

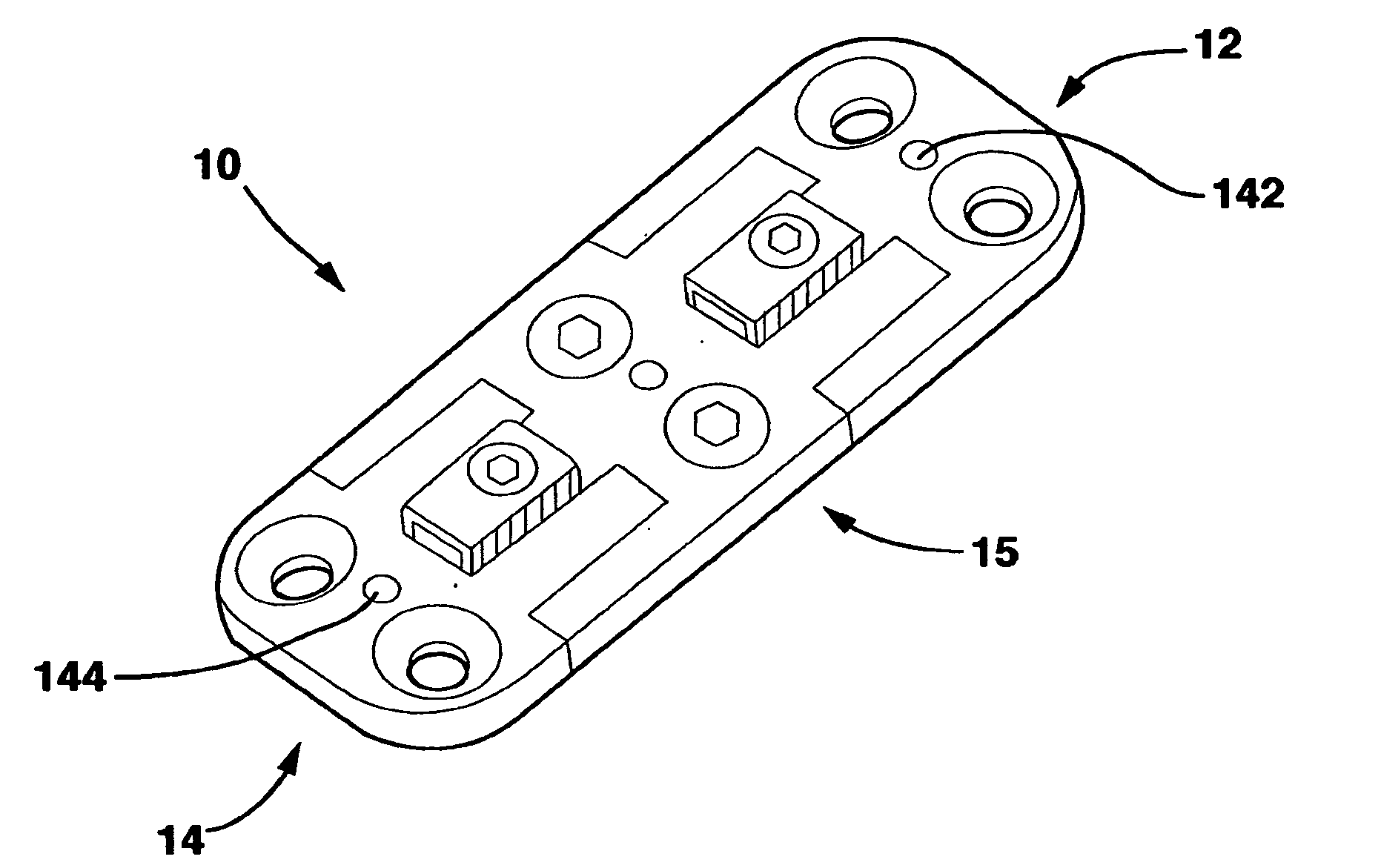

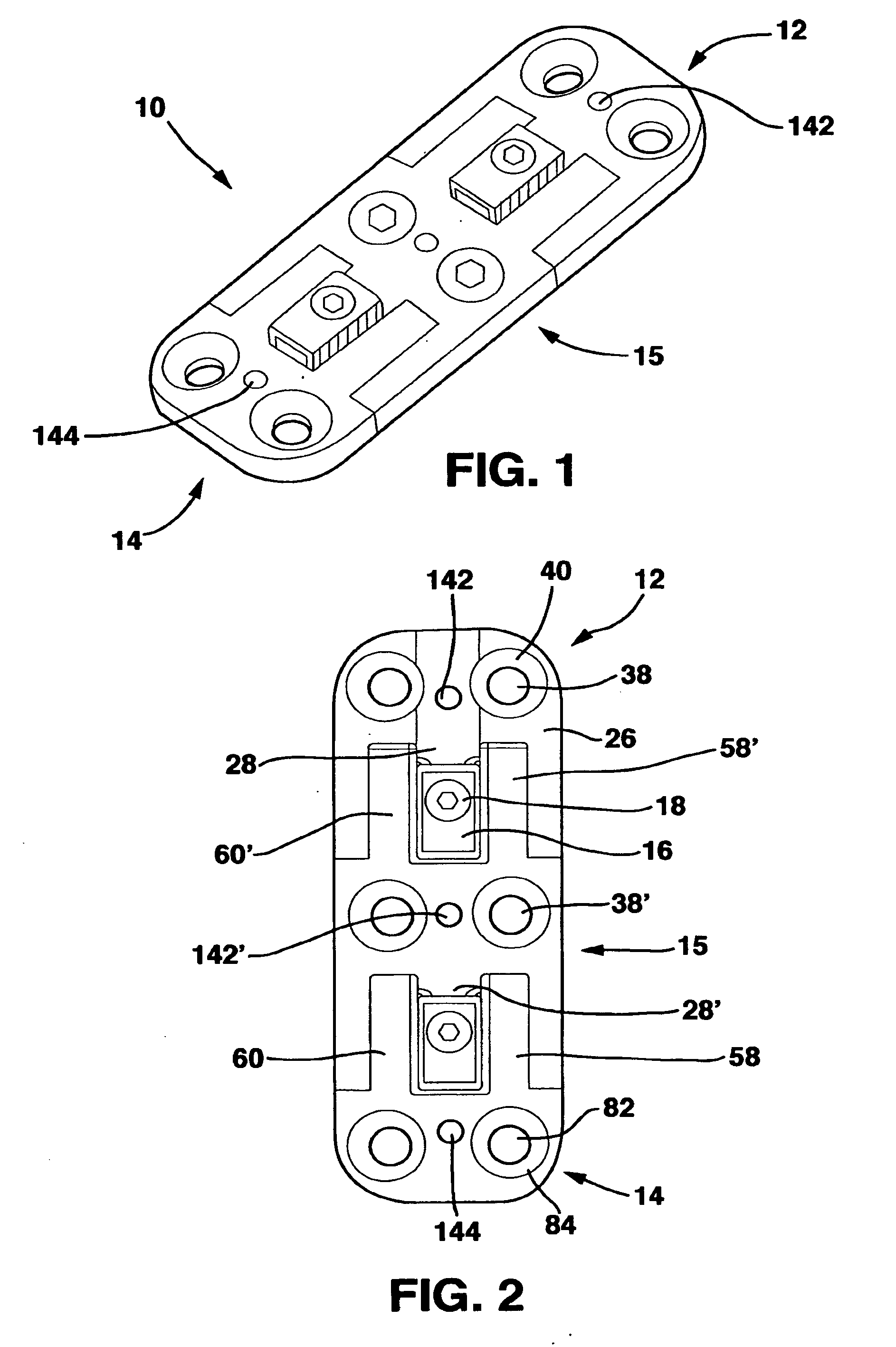

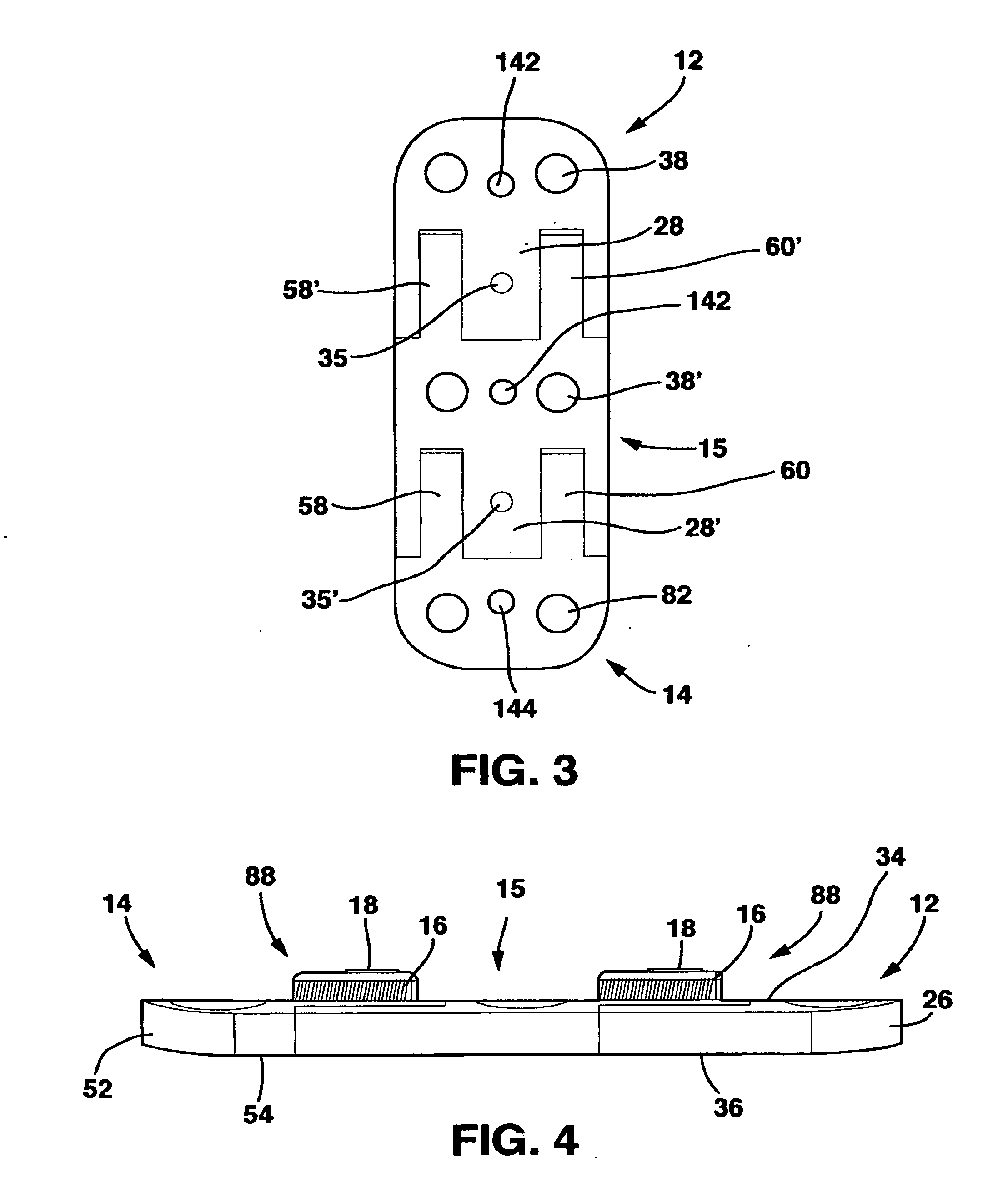

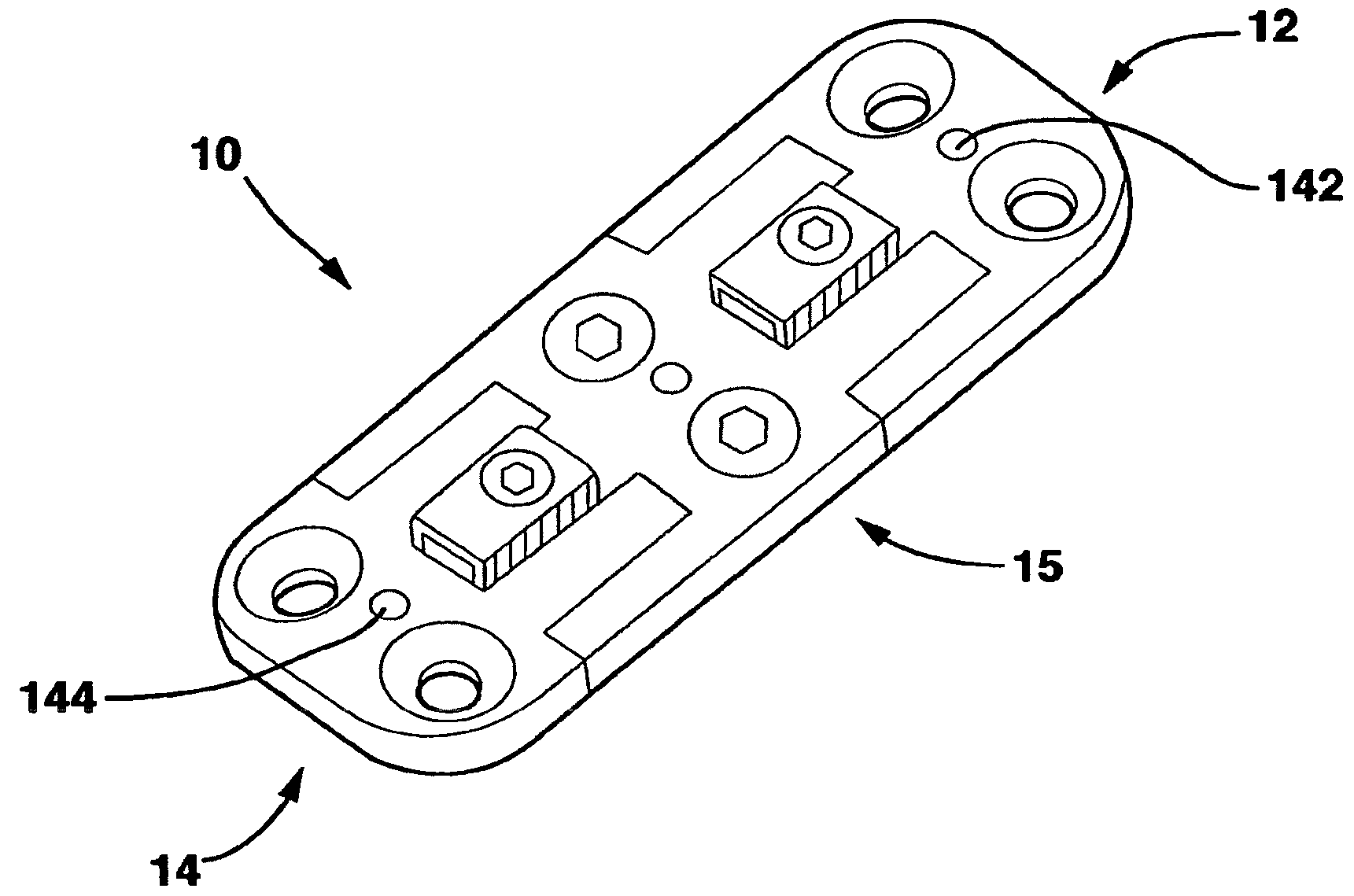

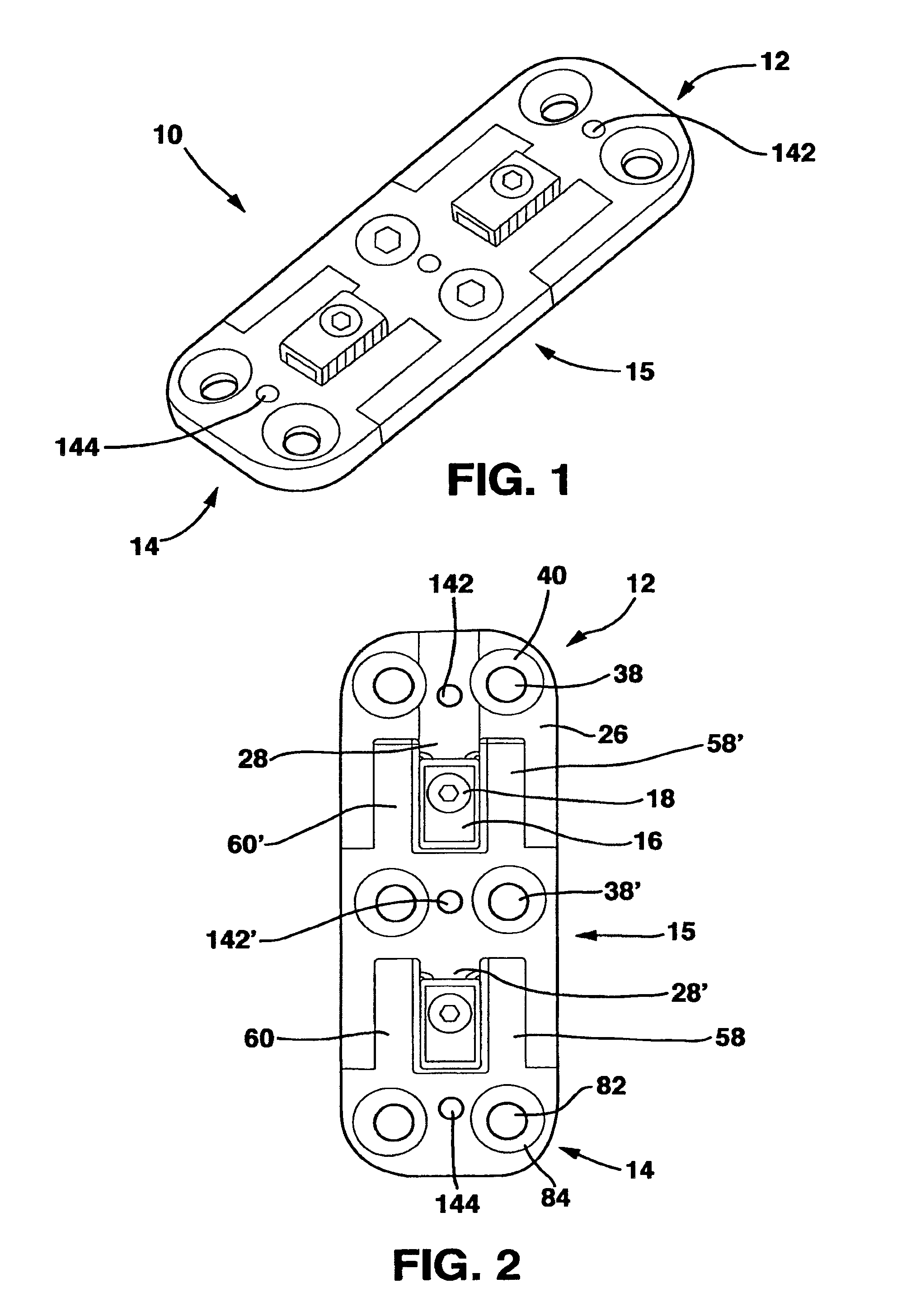

Static Compression Device

InactiveUS20100082029A1Force is limitedAvoid compressionInternal osteosythesisDiagnosticsStatic compressionIntervertebral disc

A Static Compression Device (SC device) for active, measurable compression of a fusion graft by the surgeon at the time of surgery is disclosed. The SC device is attachable to adjacent vertebral bodies or other pieces of bone and has a device that applies compressive force to the adjacent vertebral bodies or pieces of bone to assist fusion according to Wolffs law. The SC device has a locking mechanism that maintains the compression applied at surgery, but prevents further compression (settling) from occurring after surgery. The SC device allows the surgeon the ability to compress a segment, measure the applied compression, and lock the segment in the compressed position. In one embodiment of the invention, the pressure is applied to the SC device through a compression device that applies a desired and measurable amount of force. In this embodiment, the combination of the SC device with a pressure applying and measuring device allows the surgeon more control over the force applied to a cervical, thoracic or lumbar implant than has previously been available. In the preferred embodiment, the SC device compresses two or more adjacent vertebrae across an adjacent bone graft to facilitate fusion of these vertebrae to treat pain produced by pressure from the disks between such vertebrae bulging and resulting in contact with and pressure on the spinal cord and adjacent nerve roots. In other embodiments, the SC device may be used to apply measurable compression across any type of bony interface (e.g. fractures) to facilitate union.

Owner:IB MEDICAL

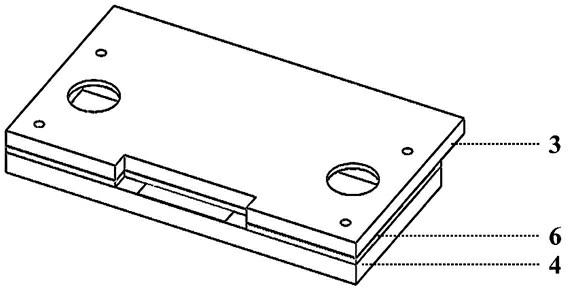

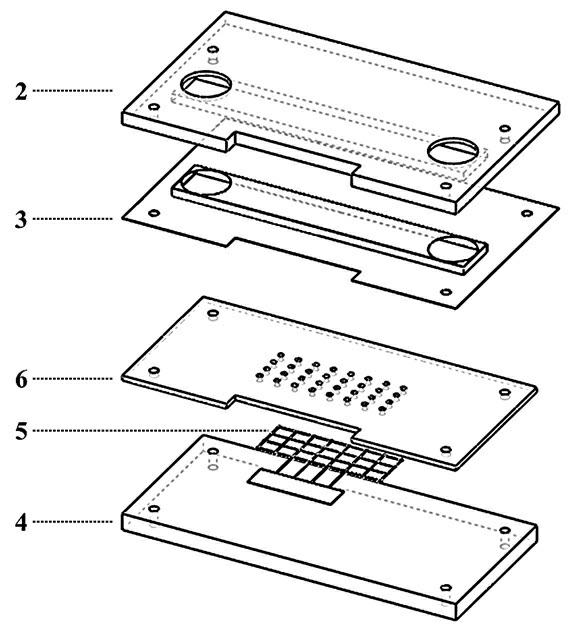

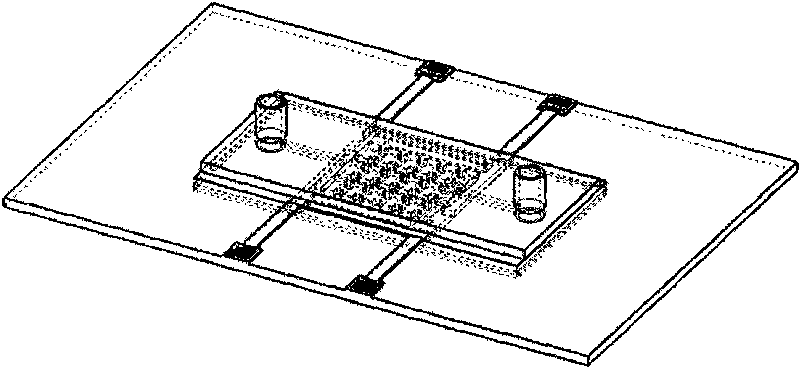

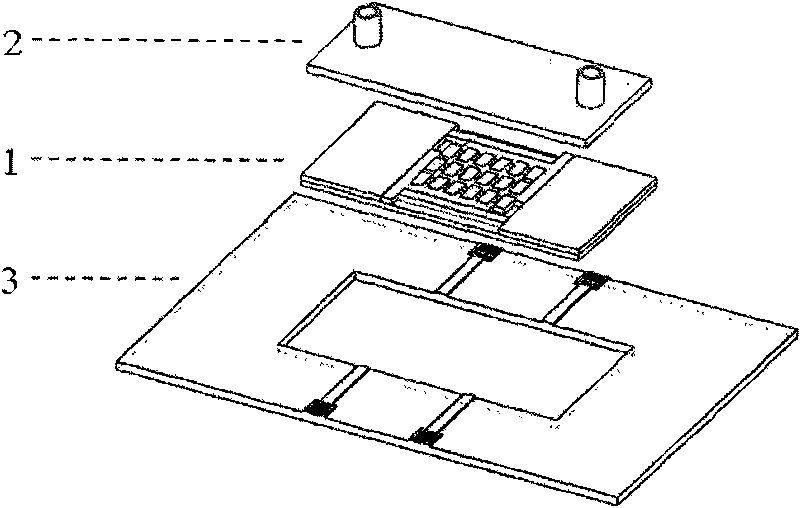

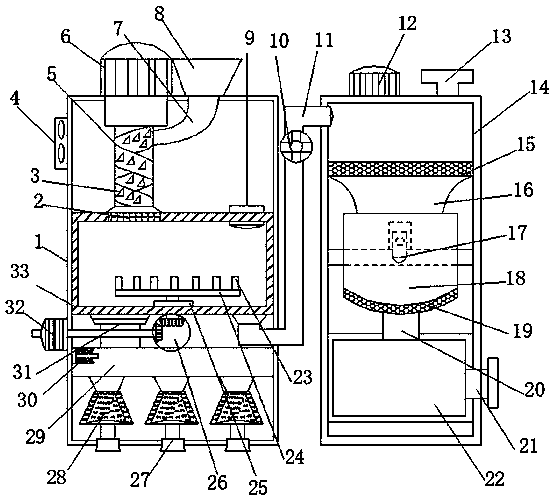

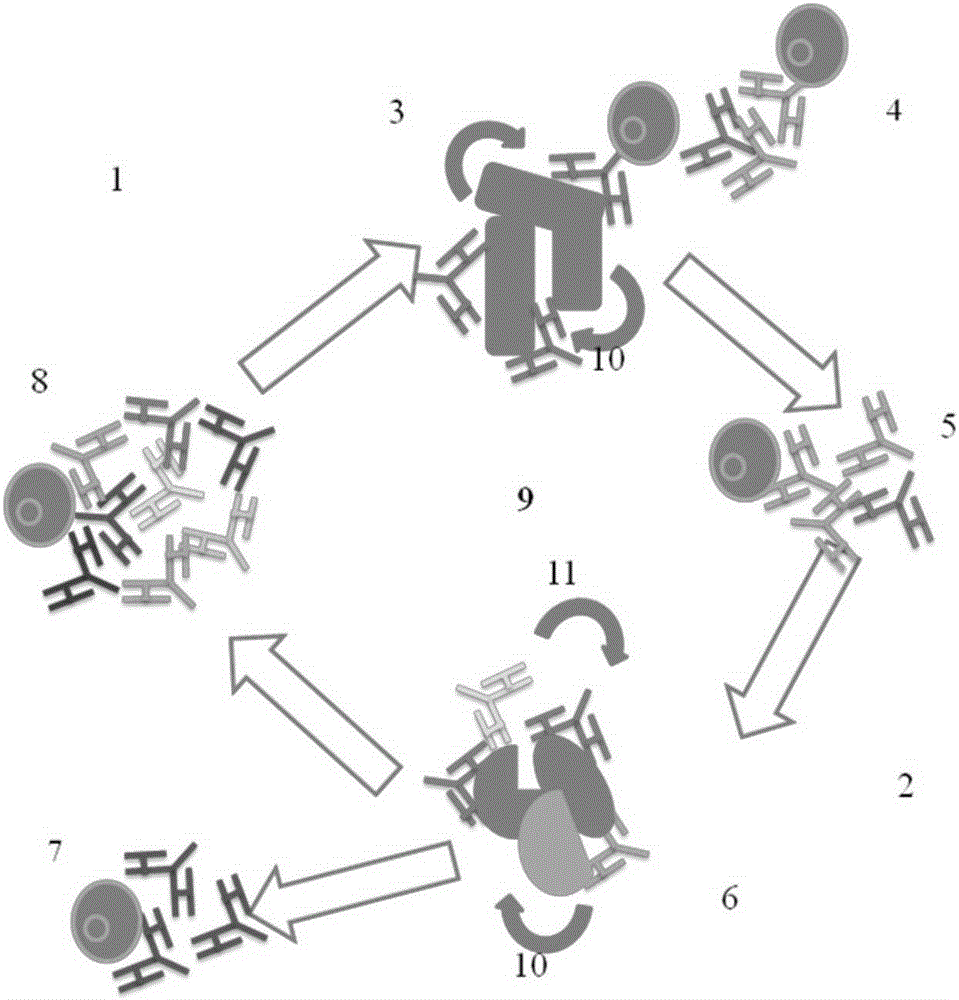

High-throughput cell electrofusion microfluidic chip device based on microwell microelectrode array

InactiveCN102296028AEfficient pairingImprove fusion rateStress based microorganism growth stimulationMicrofluidic chipElectrode array

The invention discloses a high-flux cell electrical fusion microfluidic chip device based on a microporous microelectrode array, which consists of a microelectrode microporous array chip and a microfluidic cover plate with top electrodes. In the invention, a micro electro mechanical system (MEMS) processing technique is adopted, and a microporous microelectrode array is constructed on a quartz substrate by using both a microelectrode array and a polymer microporous array; the microporous microelectrode array can better control cell pairing, so that a pair of cells fuses in each micro pore; the array structure can improve the flux of cell fusion; and the materials used for making the device disclosed by the invention have high biocompatibility and corrosion resistance and can ensure the reliability of chip and improve the safety of cell fusion. The device can be widely used in fields of genetics, animal and plant distant hybridization breeding, development biology, medicine screening, preparation of monoclonal antibody, mammalian cloning and the like.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

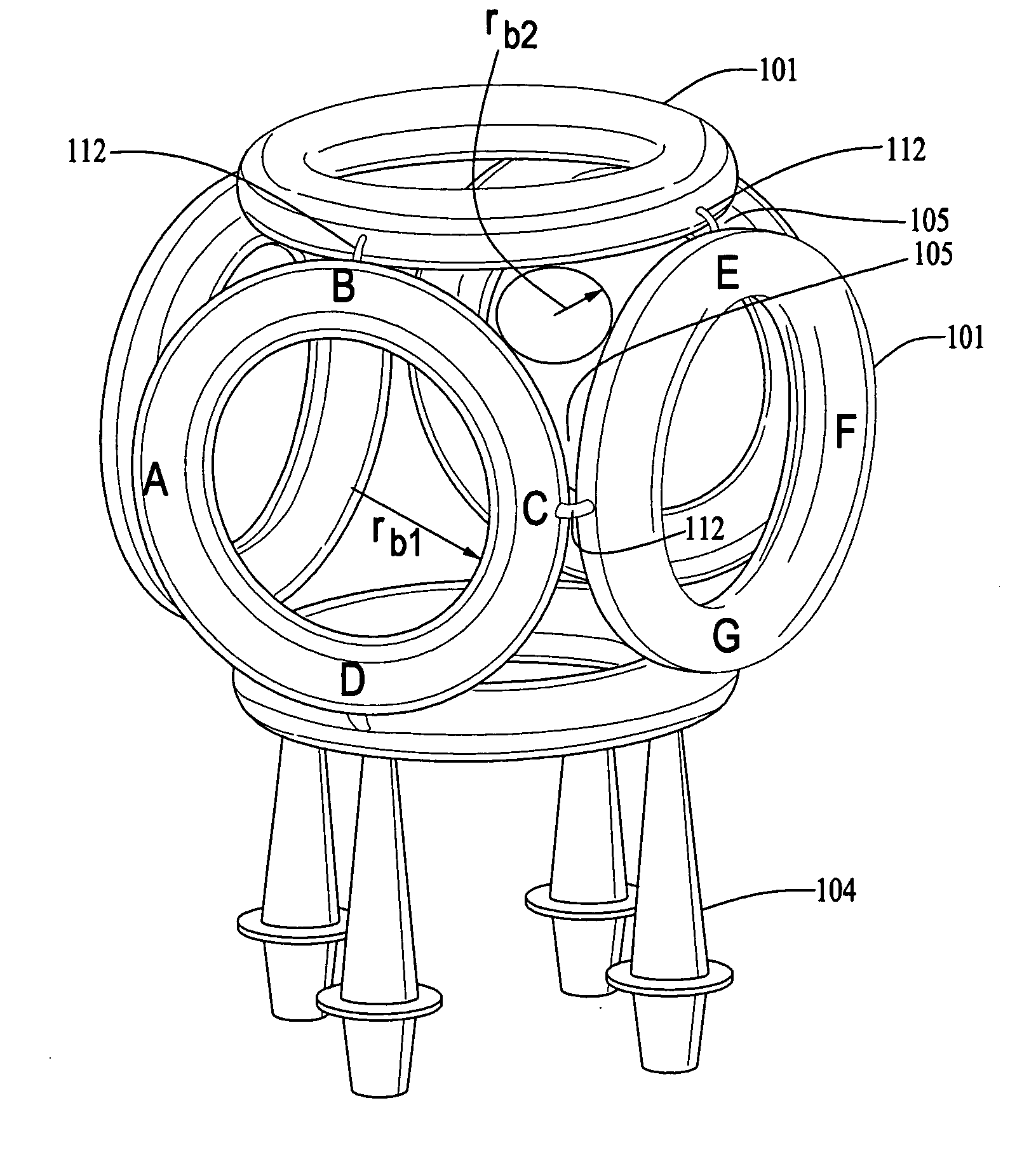

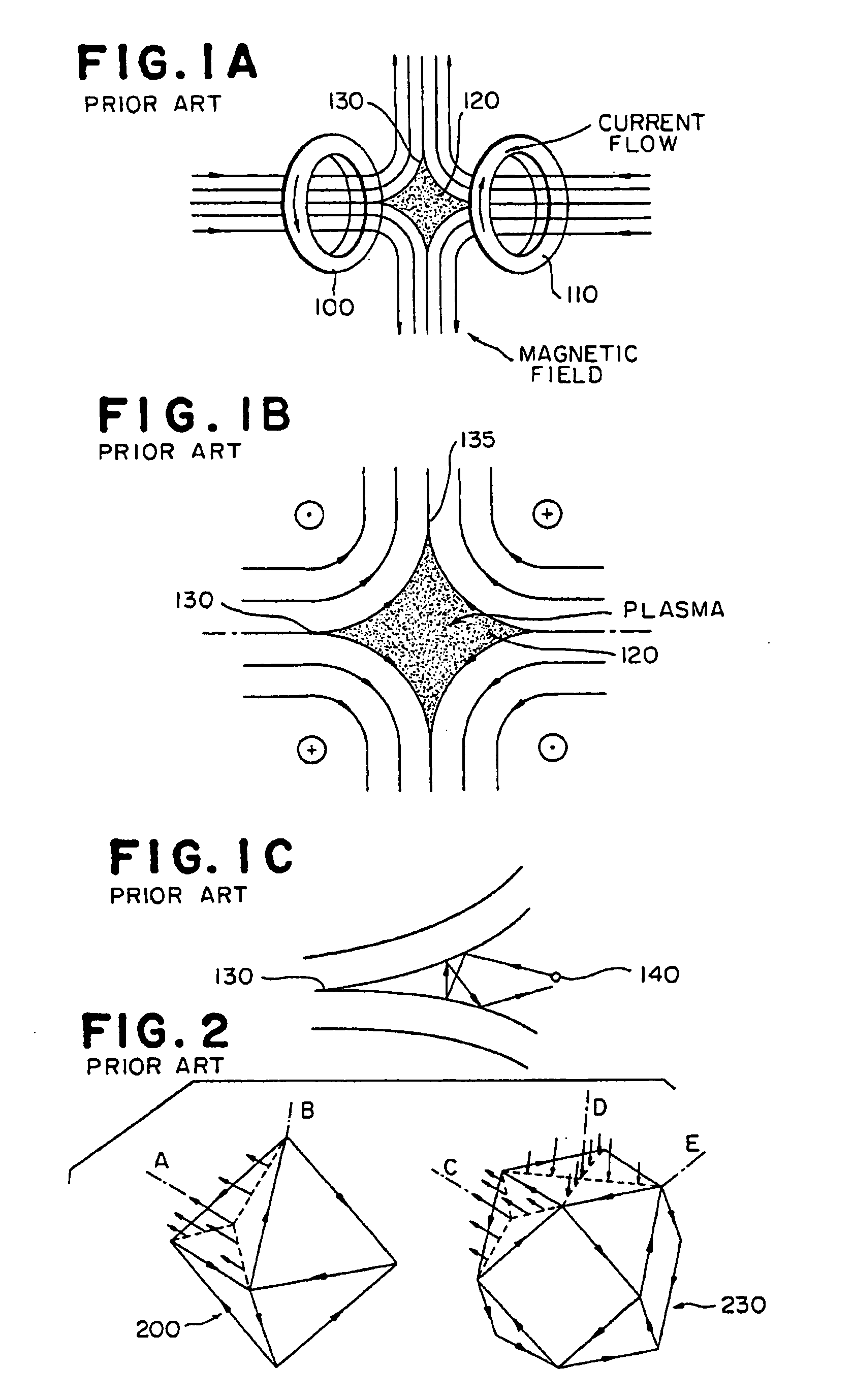

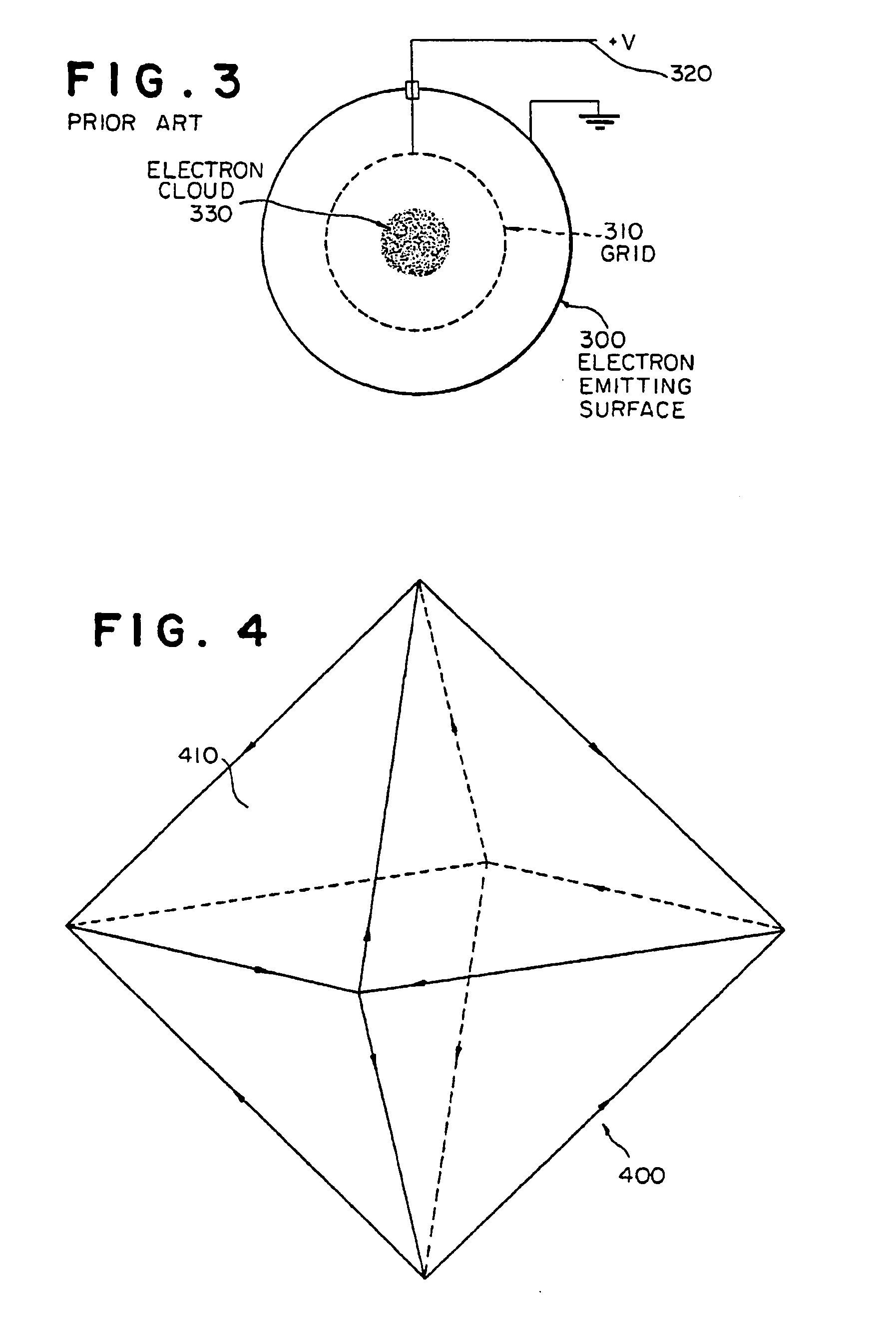

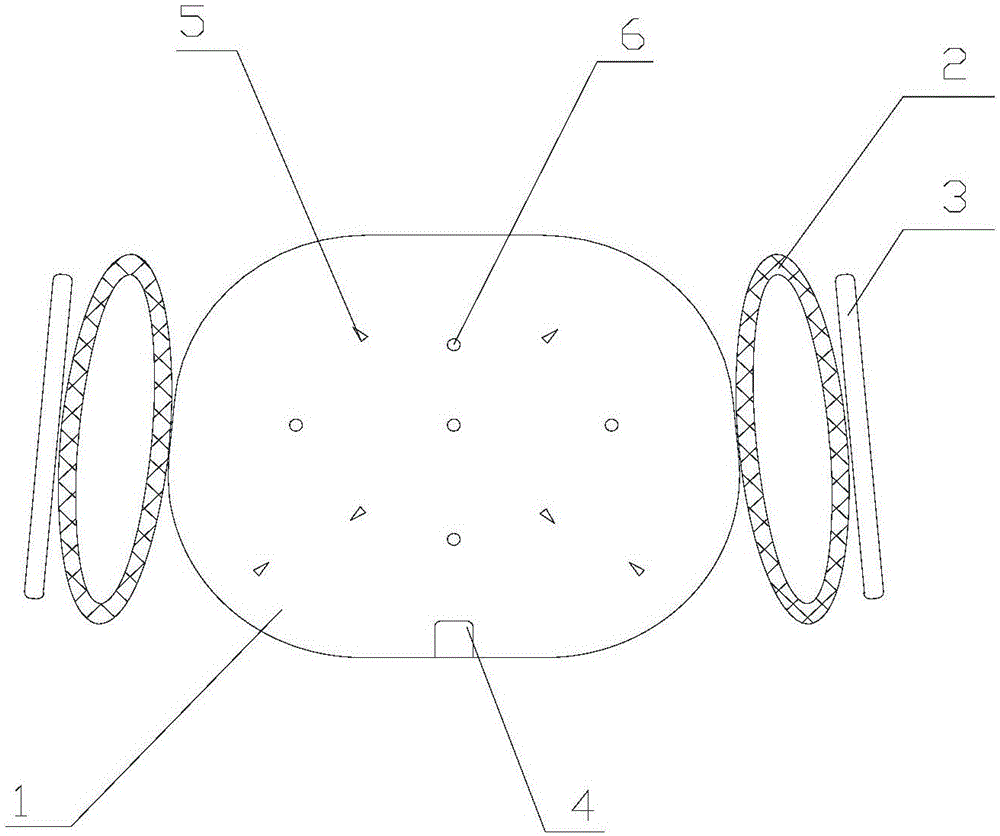

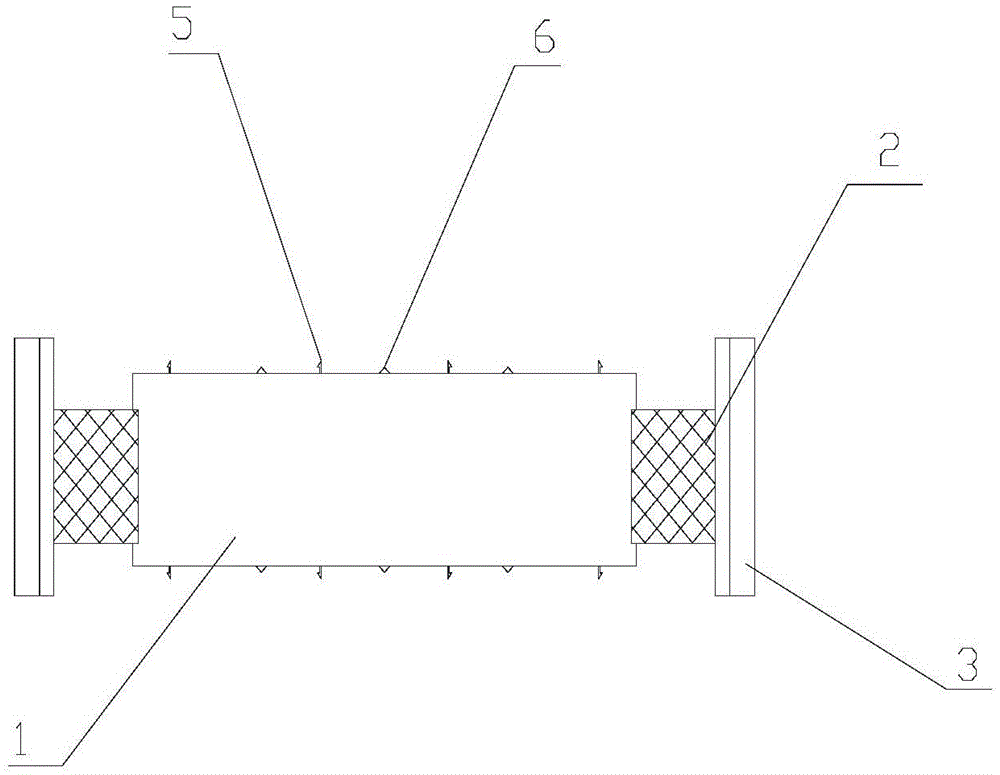

Method and apparatus for controlling charged particles

InactiveUS20110170647A1Increase dynamic pressureGood magnetic surface “ reflection ”Nuclear energy generationPlasma techniqueNegative potentialCharged particle

An apparatus and method for controlling charged particles. The charged particles comprise electrons and positive ions. A magnetic field having only point cusps is used to confine energetic injected electrons and so to generate a negative potential well. Positive ions injected into or created within the negative potential well are trapped therein. The magnetic field is generated by current-carrying elements arranged at positions spaced from but closely adjacent and parallel to edges of a polyhedron which has an even number of faces surrounding each vertex or corner. The current-carrying elements must be spaced apart at their corners (the vertices of the polyhedron) so as not to touch, and the containing structures for the current-carrying coils of the magnetic-field-providing system are conformal to the fields so produced.

Owner:EMC2

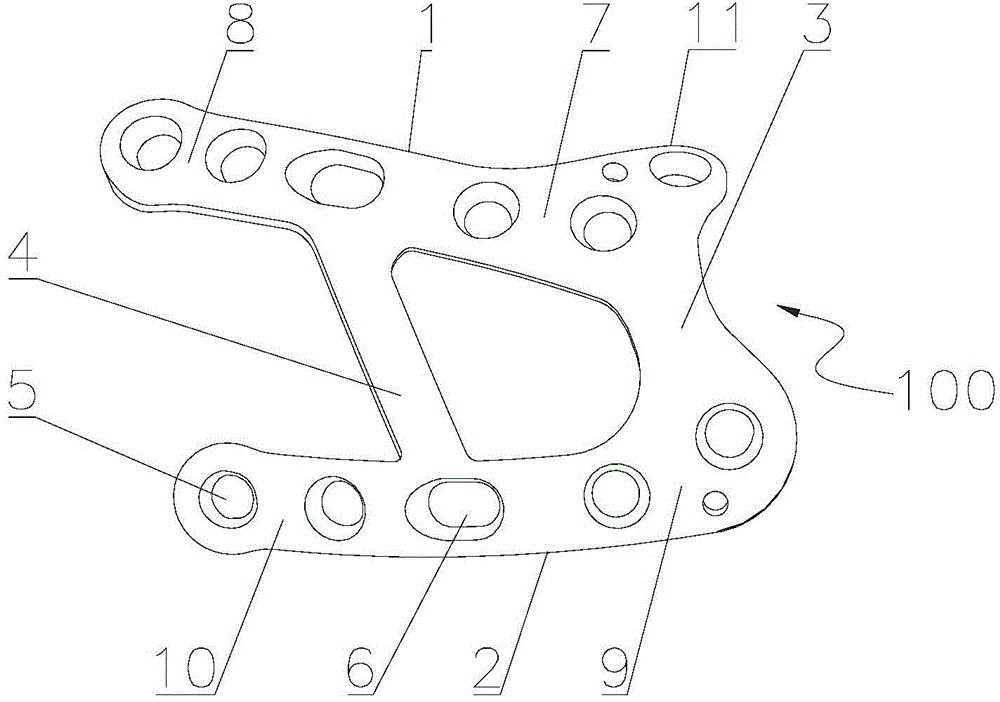

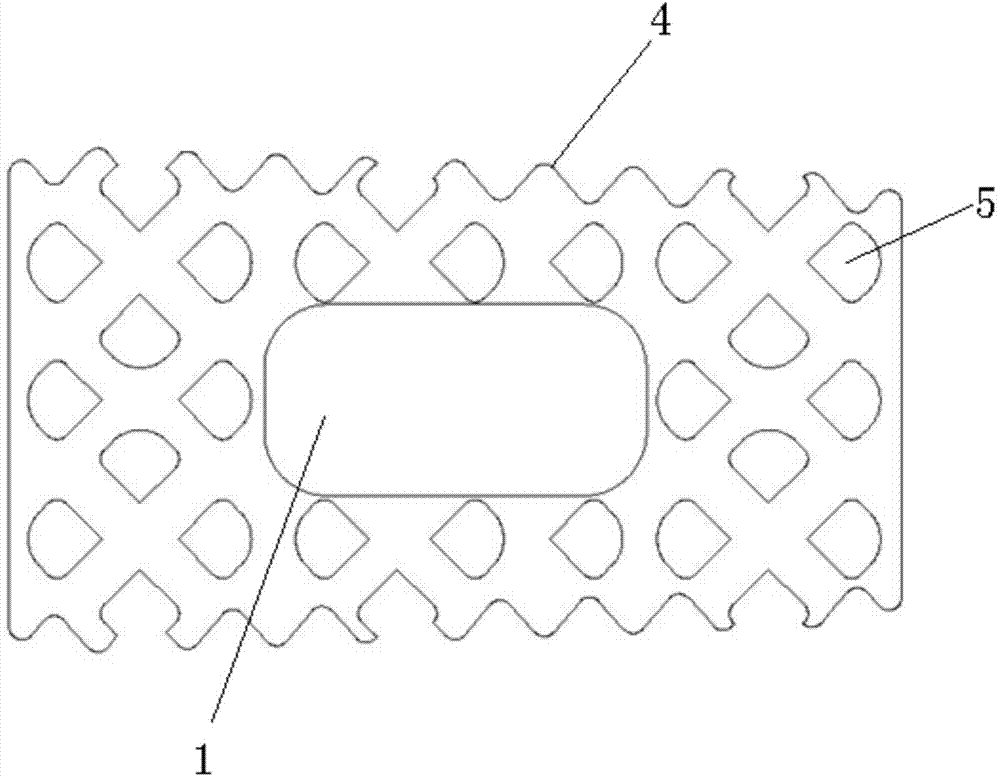

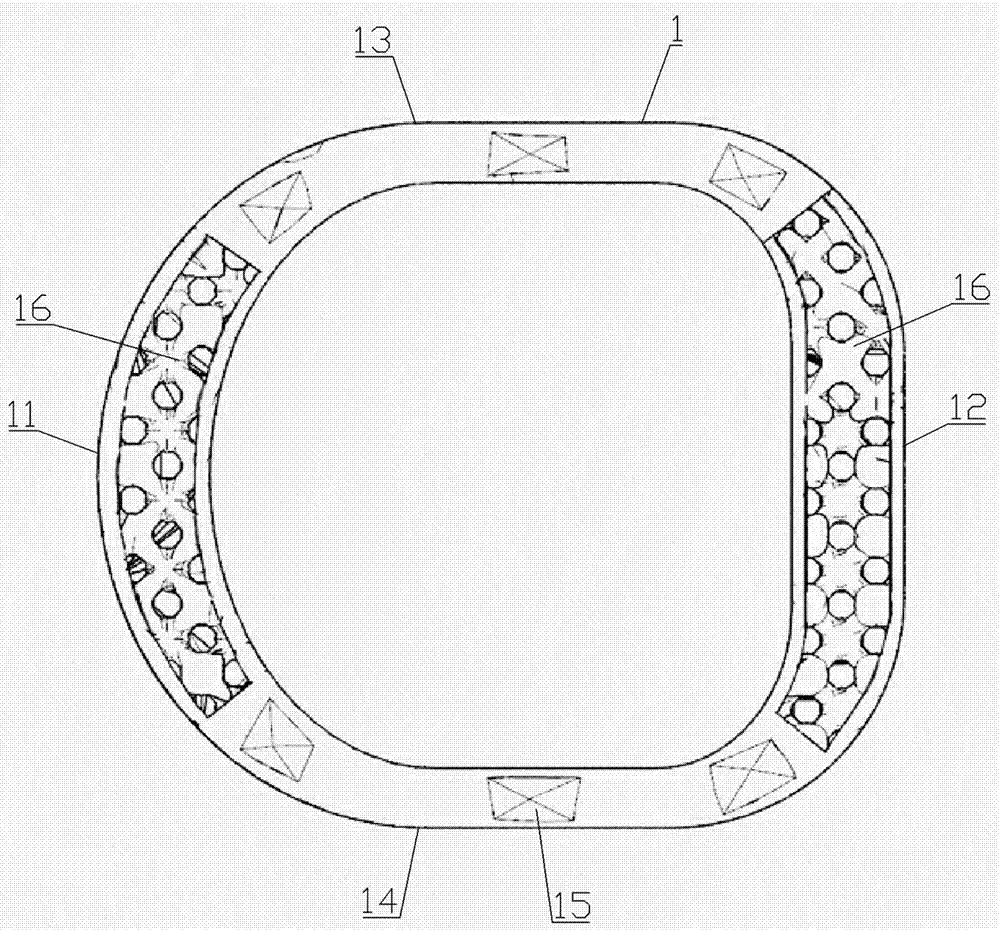

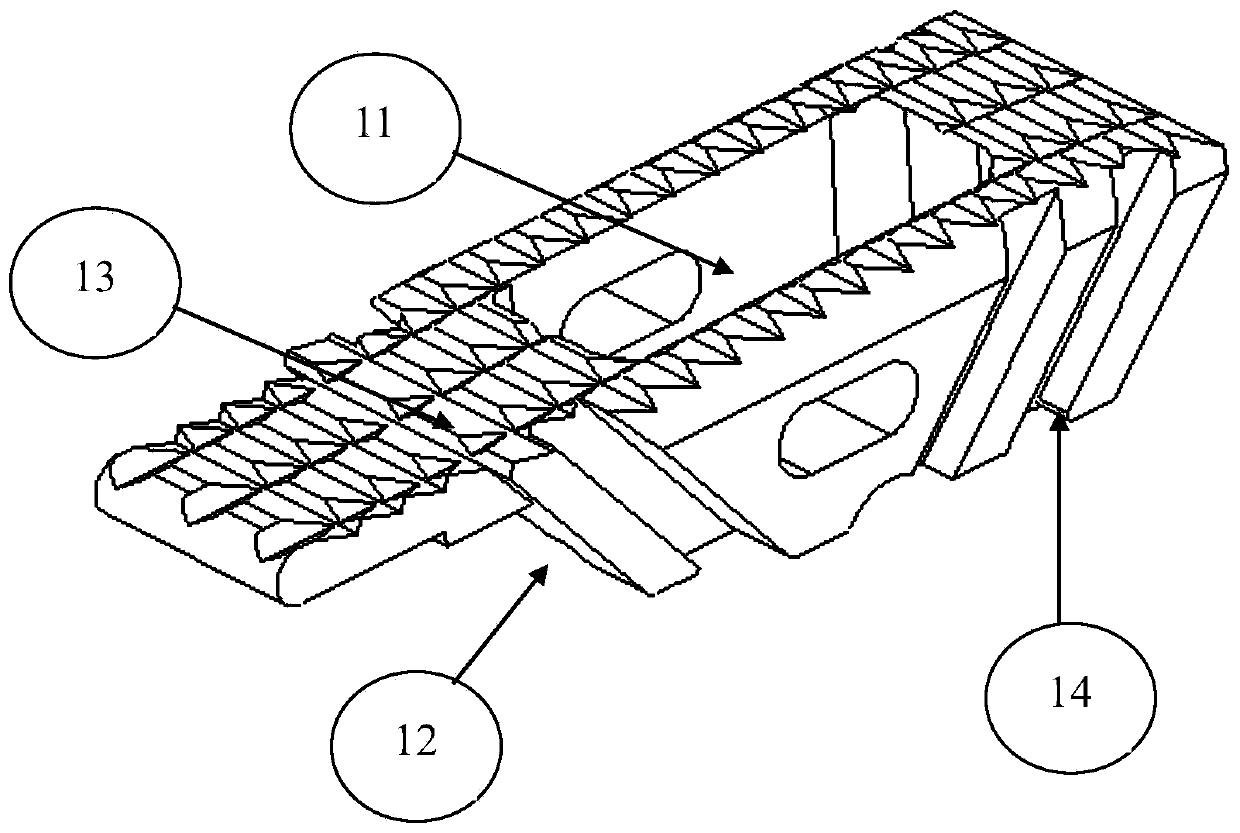

Mixed porous structure interbody fusion cage and preparation method thereof

InactiveCN102440852AGood mechanical compatibilityGood bone conductionSpinal implantsFreeze-dryingReticular formation

Disclosed are a mixed porous structure interbody fusion cage and a preparation method thereof. The interbody fusion cage comprises a porous metal support and porous structure filling bodies, the porous metal support is a three-dimensional net-shaped structure, a plurality of holes are arranged in the porous metal support, and the porous structure filling bodies are fully filled in the holes. The preparation method includes steps that the metal rapid forming technology is directly combined with the freeze drying technology, the porous metal support is manufactured via a structural design and the direct metal rapid forming technology, then uniformly mixed polymer gel or polymer / biological ceramic compound gel is poured in the porous metal support to realize freeze treatment, so that the porous structure filling bodies with the micropore feature are formed after freeze drying, and the mixed porous structure interbody fusion cage is obtained. Mechanical compatibility is good, contact area between the mixed porous structure interbody fusion cage and natural centrum is further increased, instant stability is good, fusion rate is improved, and the mixed porous structure interbody fusion cage and the preparation method thereof can be used for treating clinical degenerative disc diseases.

Owner:SHANGHAI JIAO TONG UNIV

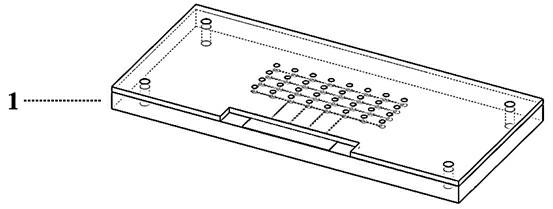

Cell electrofusion chip device based on micro-chamber array structure

InactiveCN101693874AHigh queuing rateImprove fusion rateHybrid cell preparationStress based microorganism growth stimulationElectricityElectrical connection

The invention provides a cell electrofusion microelectrode array chip device based on a micro-chamber structure, which consists of a micro-chamber array chip, a periphery printed circuit board and a flow passage control module. The micro-chamber array chip consists of a quartz substrate layer, a metal microelectrode array, polymer side walls and a polymer water surrounding fender, wherein two opposite metal microelectrodes and two opposite polymer sidewalls form one micro-chamber which is arranged in an array shape; the micro-chamber array chip is bonded on the periphery printed circuit board to form electrical connection; the flow passage control module covers the micro-chamber array chip. In the invention, a certain electrical field is formed in the micro-chamber by outside electrical signals so as to control high-efficient queue and electrofusion of cells inside the micro-chamber, thus realizing that only one pair of cells inside the micro-chamber are subjected to fusion, and improving throughout and safety of cell fusion.

Owner:CHONGQING UNIV

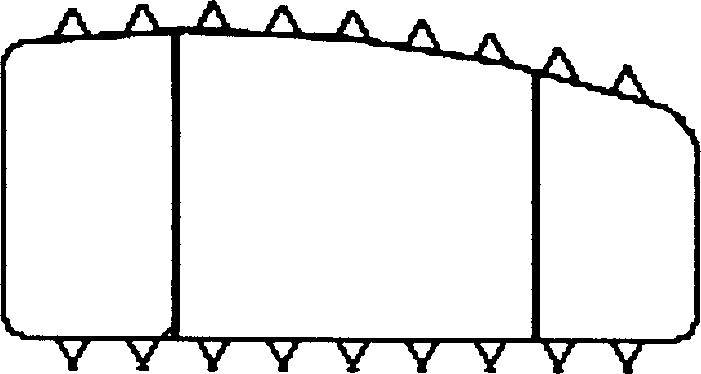

Interverterbral fusion implement

InactiveCN1436518ANo foreign body reactionPromote bone fusionInternal osteosythesisProsthesisHuman bodyBiocompatibility Testing

The interverterbral fusion implement for cervical vertebra anterior operation is one hollow column with polygonal or circular cross section, holes on side wall and sharp teeth on the upper and the lower surfaces. It is made of polymer material capable of being absorbed by human body, poly(DL-lactic acid), poly(L-lactic acid), polyglycolic acid or their copolymer. It has determined early-stage locking effect, late-stage bone fusion effect, good biocompatibility and proper mechanical structure, and may be self-degraded after being fused with vertebra. It results in no rejection and may be also used in thoracic vertebra and lumbar vertebra operation.

Owner:成都迪康中科生物医学材料有限公司

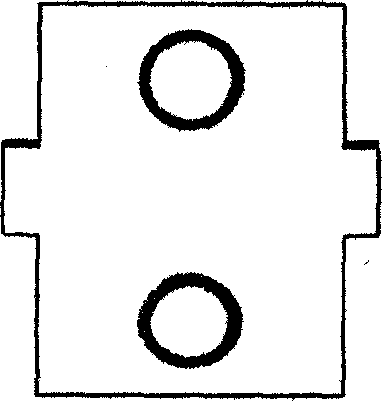

Cervical vertebra uncovertebral joint fusion cage

The invention discloses a cervical vertebra uncovertebral joint fusion cage which comprises uncovertebral joint fusion components and a vertebrae inter elastic supporting body. The cross section of the vertebrae inter elastic supporting body is trapezoidal, and the front end of the vertebrae inter elastic supporting body is a small end. The two uncovertebral joint fusion components are connected to two waist outer side surfaces of the vertebrae inter elastic supporting body respectively and are of a cylindrical mesh structure, and baffles are connected to the side faces, away from the vertebrae inter elastic supporting body, of the uncovertebral joint fusion components. The cervical vertebra uncovertebral joint fusion cage can reduce cost, the fusion time is short, the wearing time of a neck collar is shortened, the comfort level of a patient is improved, an end plate does not need to be ground, the surgical time is shortened, and the sinking risk of prostheses after an operation is reduced.

Owner:山东康盛医疗器械股份有限公司

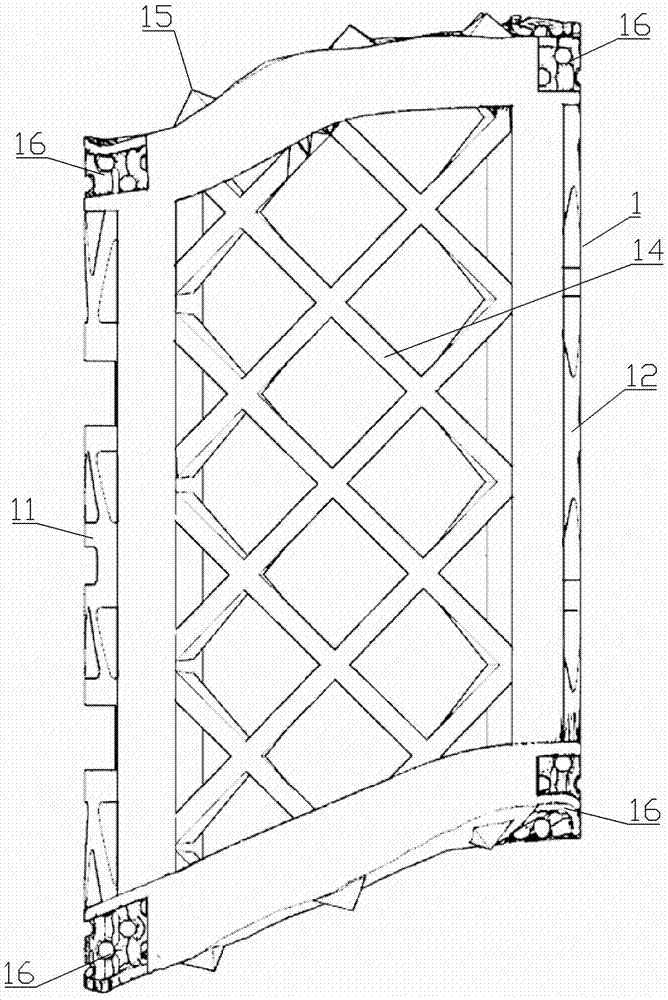

Customized 3D printing spinal column reconstruction apparatus and preparation method thereof

PendingCN107137166ARe-replicationImprove the quality of lifeJoint implantsSpinal implantsThree dimensional modelVertebra

The invention discloses a customized 3D printing spinal column reconstruction apparatus which comprises a spinal column supporter. The spinal column has a sleeve shape and comprises a front wall, a rear wall, a left wall and a right wall, wherein each wall comprises a quadrilateral framework and a grid arranged inside the framework. The method for preparing the customized 3D printing spinal column reconstruction apparatus comprises the steps of S01 obtaining medical image data; S02 obtaining a spinal column iconography parameter; S03 establishing a three-dimensional model of a spinal column supporter in the type to be selected; S04 selecting the type of a spinal column supporter for operation; and S05 manufacturing a customized 3D printing spinal column reconstruction apparatus. The apparatus is used for various spinal column or intervertebral disk resection and fusion operation among the spinal columns. As a spinal column supporter, the apparatus is adapted to both the upper and the lower bone surface of the spinal column completely to build a good stability; the physiological curvature of the spinal column, the intervertebral height and the spinal column dissect structure can be reconstructed; the characteristics of vertebra biomechanics can be copied; and the patient's life quality can be improved.

Owner:王文军 +1

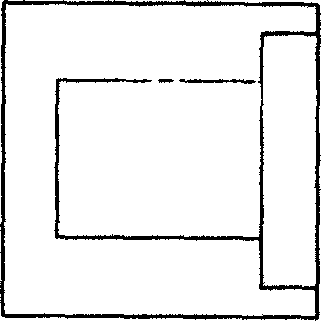

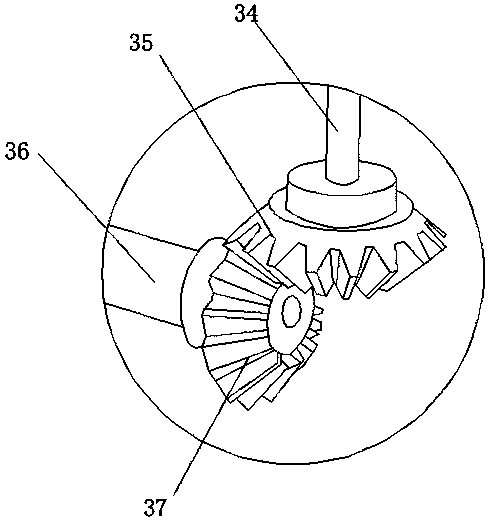

Distractable fusion cage with adjustable middle bone grafting height

ActiveCN109758272ABuild and maintain stabilityReduces the risk of damaging surrounding tissueSpinal implantsIntervertebral spaceEngineering

The invention relates to a fusion instrument under a mirror, in particular to a distractable fusion cage with the adjustable middle bone grafting height. The distractable fusion cage comprises a supporting platform, a support and an adjusting assembly, adopts an internal hollow and external hollow design, has a large bone grafting space and facilitates bone grafting, so that the stability of the lumbar vertebra can be better established and maintained after the fusion cage is implanted, the parallel distracting function of the fusion cage main body can be achieved, the lifting height is increased, the distractable fusion cage adapts to the heights of intervertebral spaces of different segments, the application range is wide, and the overall cost is low.

Owner:ZHUHAI WEIERKANG BIOTECH

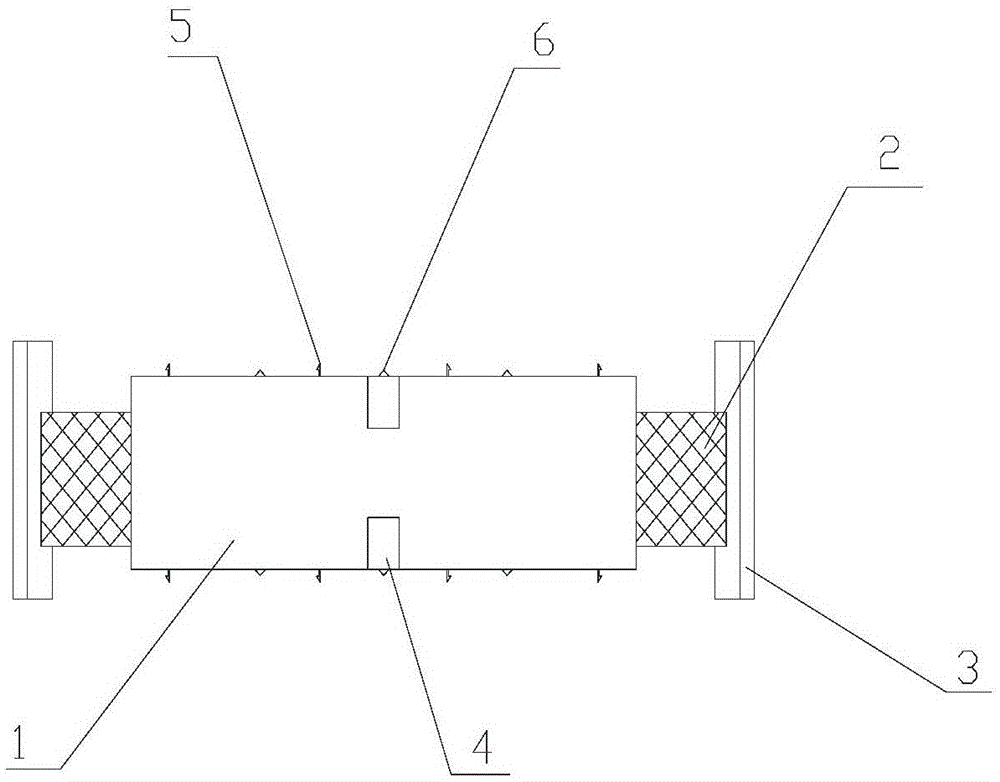

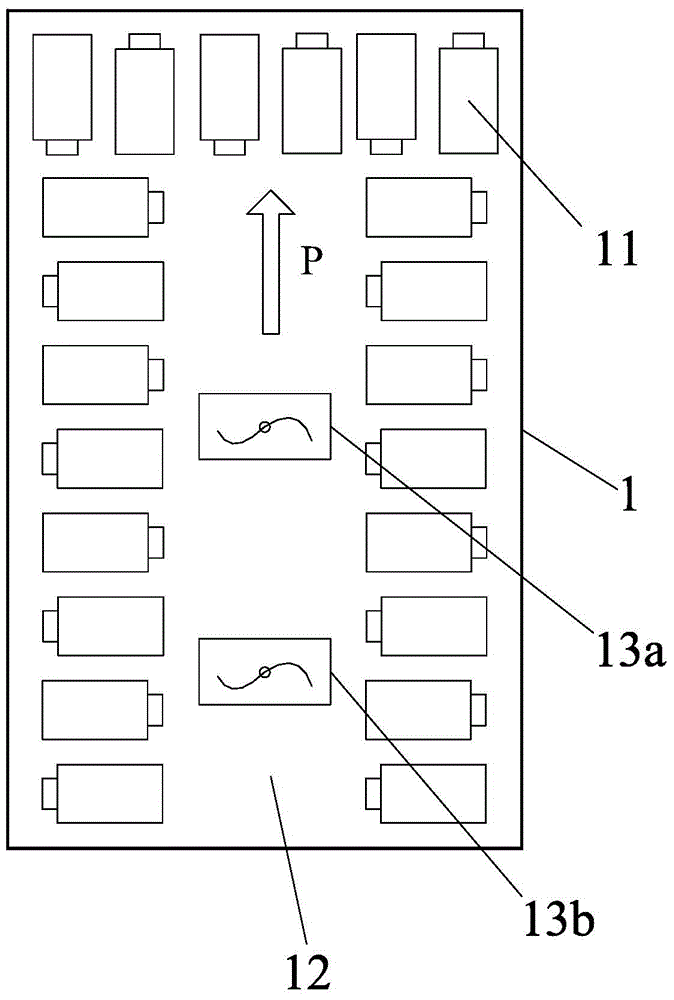

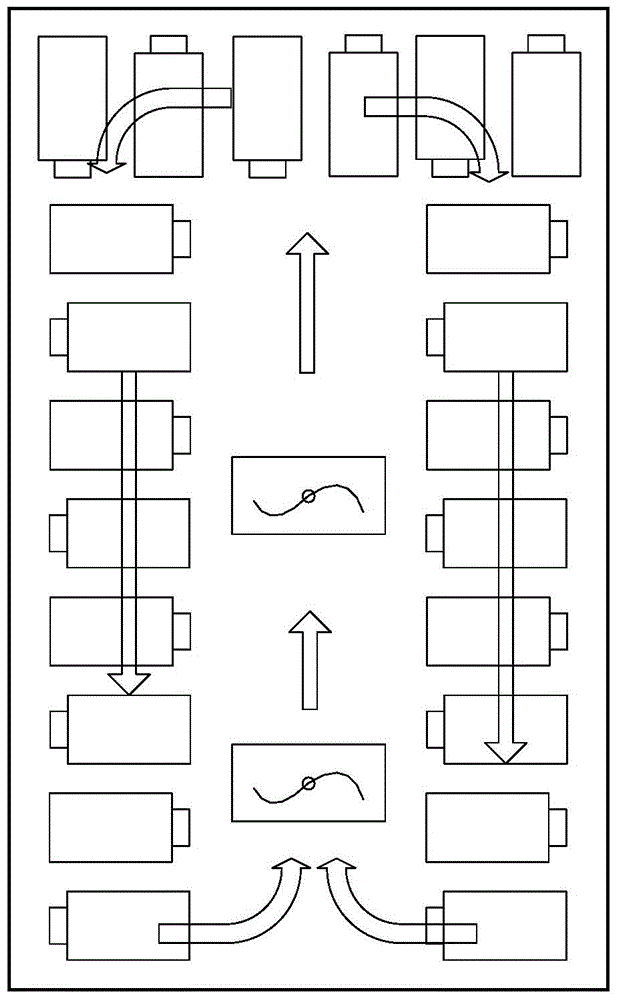

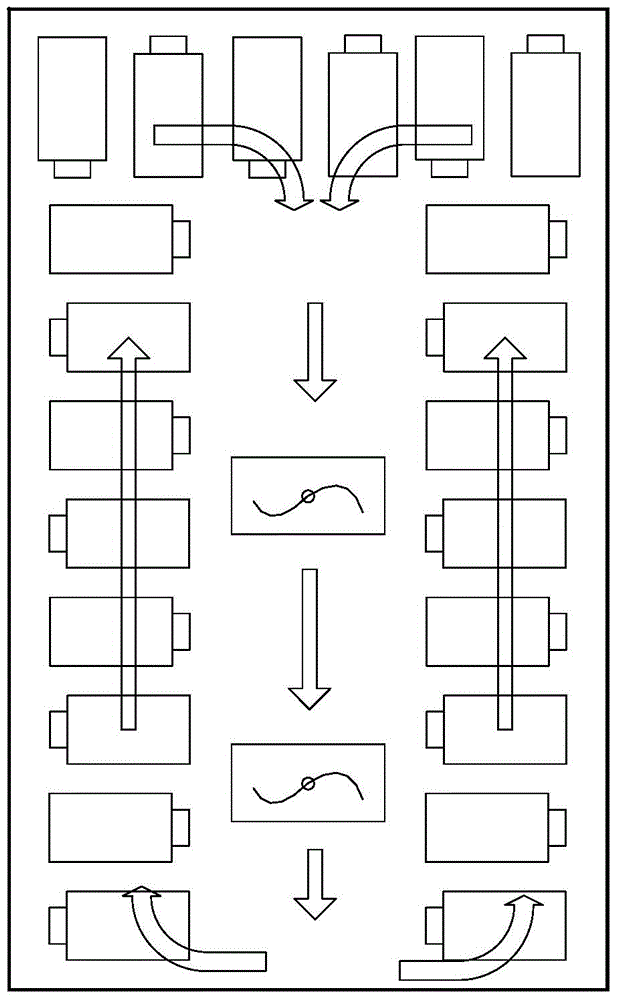

Thermal management system for centralized power battery pack

ActiveCN104577255AEffective control of thermal balanceImprove fusion rateSecondary cellsVehicular energy storagePower batteryElectrical battery

The invention discloses a thermal management system for a centralized power battery pack. The thermal management system comprises first and second fans, a controller and temperature sensors, wherein the temperature sensors are mounted in the battery pack, the first and second fans are mounted on a central channel located in the battery pack, and air outlets of the first and second fans are oppositely arranged in the length direction of the central channel; the controller acquires current temperature values of corresponding positions from temperature signals output by all the temperature sensors and calculates the maximum temperature difference between the current temperature values of different positions; the controller drives the first and second fans to work alternately when the maximum temperature difference is larger than a preset temperature difference threshold until the controller detects that the maximum temperature difference is smaller than or equal to the temperature difference threshold. According to the system, air circulation paths in opposite directions are formed in different periods in such a manner that the two fans work alternately, so that the fusion rate and the thermal conduction efficiency of air in the battery pack can be increased, and the thermal balance of the battery pack can be effectively improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

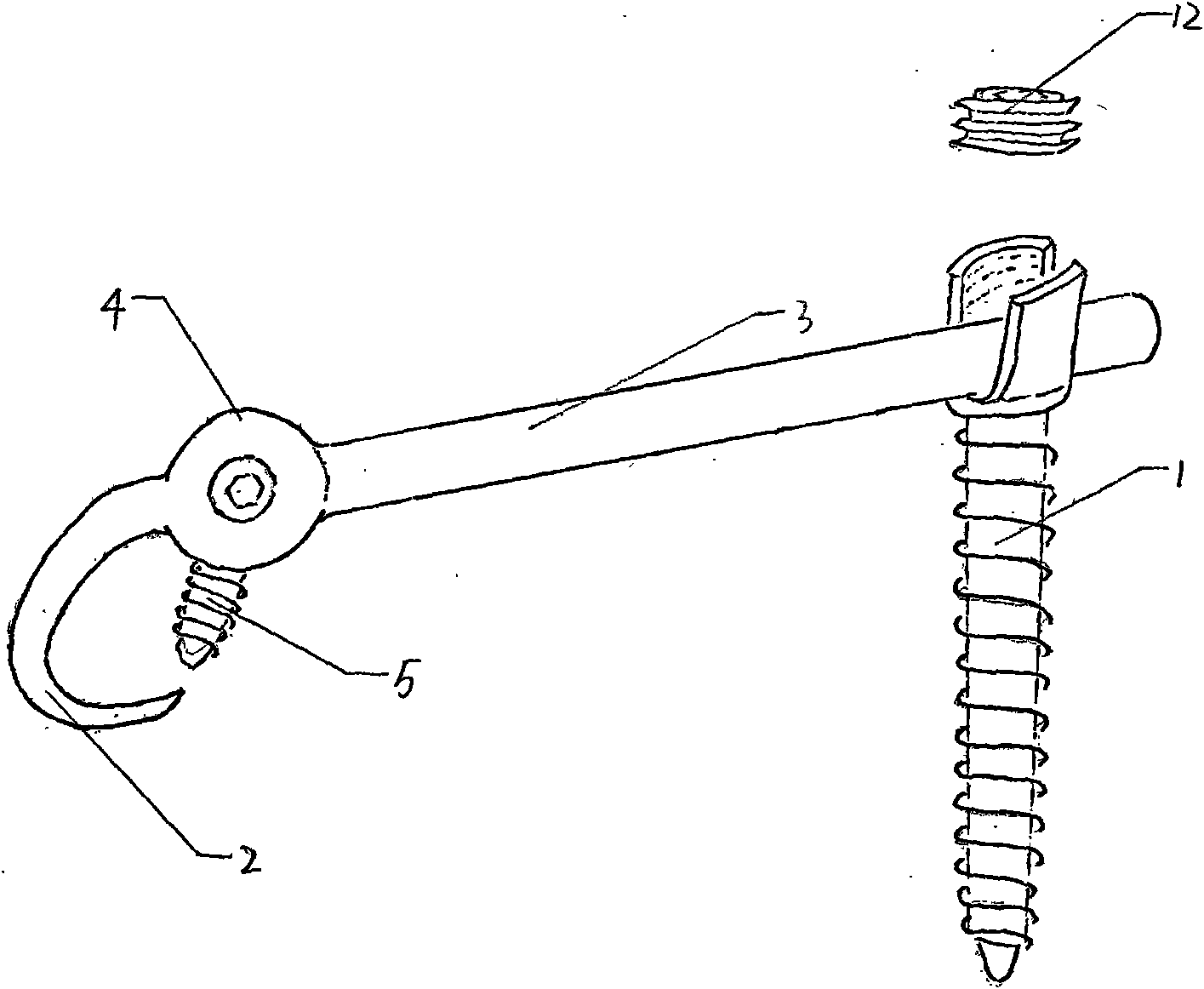

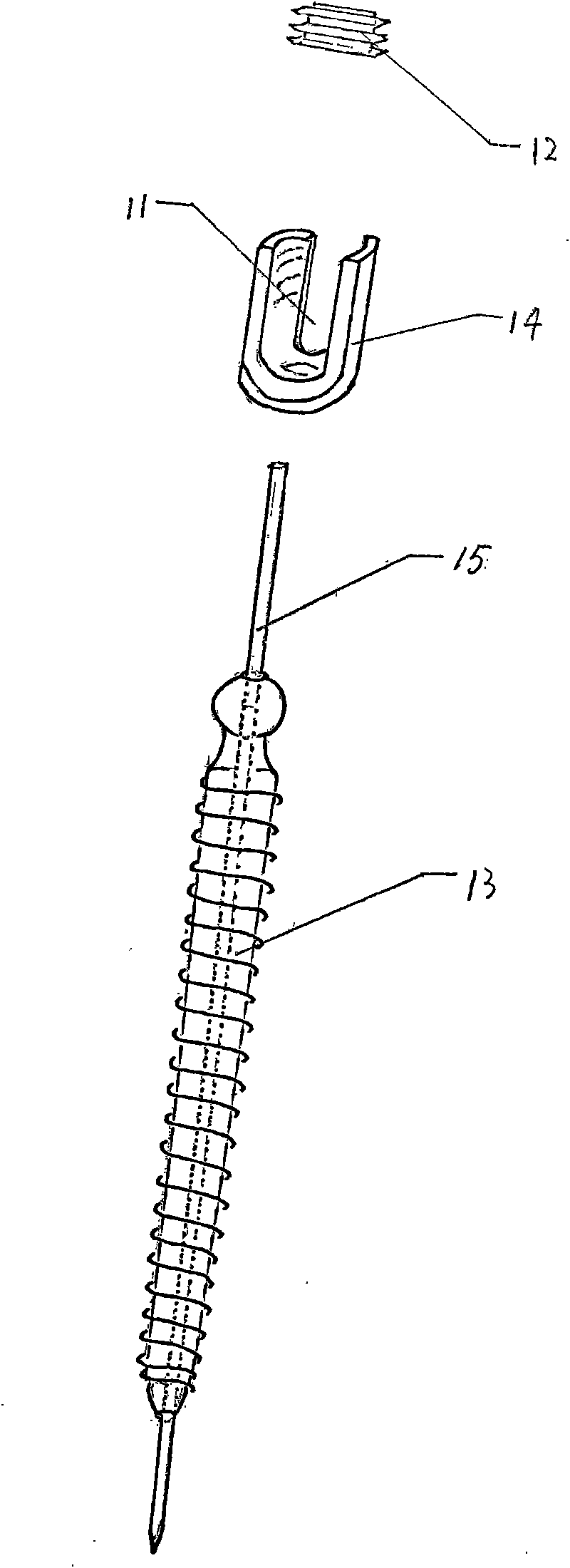

Lumbar spondylolysis restoration internal fixation system

InactiveCN101579253AEliminate frettingEliminate instabilityInternal osteosythesisEngineeringInternal fixation

The invention relates to a lumbar spondylolysis restoration internal fixation system, comprising a pedicle screw implanted into pedicle and a vertebral plate hook hooking the lower edge of a vertebral plate; the pedicle screw is connected with the vertebral plate hook by a cylindrical connecting rod; the head part of the pedicle screw is provided with a U-type groove; the connecting rod can be arranged in the U-type groove in a sliding manner; the top part of the U-type groove is provided with internal threads; the U-type groove is connected with a plug screw which is used for fixing the connecting rod; the vertebral plate hook is fixedly connected to the connecting rod by a locking plate; the vertebral plate hook is positioned at the end, which is far from the pedicle screw, of the connecting rod; the locking plate is an expanded part at the tail end of the connecting rod; the vertebral plate hook, the locking plate and the connecting rod are integrated to form a repository; and the locking plate is fixed on the vertebral plate by locking screws and is provided with locking holes matched with the locking screws. The invention has the advantages of elimination of tender moving of the vertebral plate after operation, high positioning precision of screws, simple and convenient operation, reservation of lumbar motion segment and high fusion rate of fracture end after operation.

Owner:陈哲

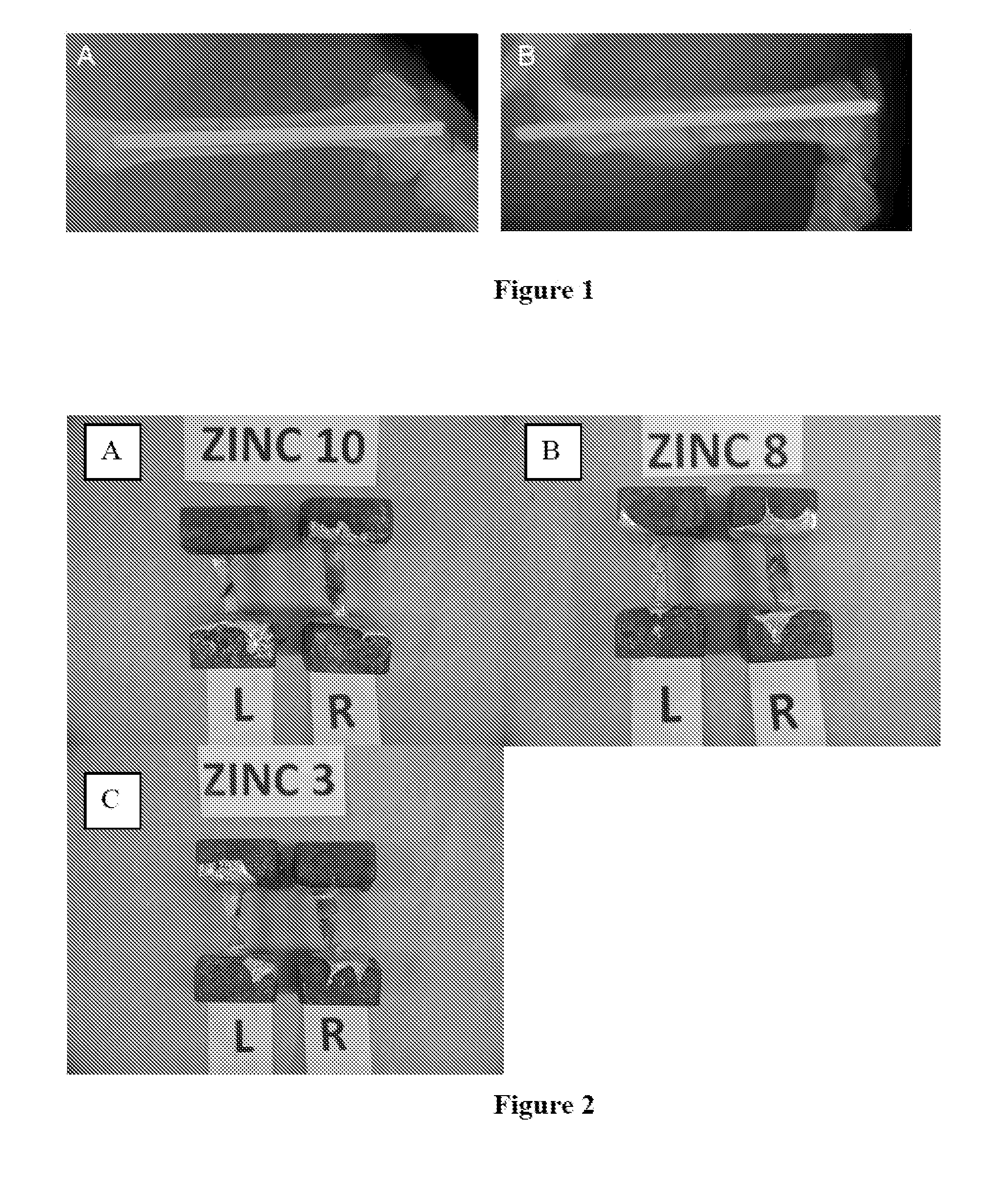

Laser cladding and manual arc welding combined repairing method for abraded TRT hub

InactiveCN107813051AImprove fusion rateHigh creep limitLaser beam welding apparatusShielded metal arc weldingSilicon alloy

Disclosed is a laser cladding and manual arc welding combined repairing method for an abraded TRT hub. The method includes the six steps of preparation before laser cladding, research of crack problems during cladding, determining of cladding materials, laser cladding, manual welding of the TRT rotor hub, heat treatment, detection and machining. Iron-based self-fluxing alloy powder nickel-boron-silicon alloy serves as the cladding materials. The abraded TRT hub is repaired through the process combining manual arc welding and laser cladding, the repaired TRT hub is free of cracks and high in rate of fusing with raw materials, the abrasion resistance, corrosion resistance and comprehensive mechanical performance of the repaired TRT hub all reach or are higher than those of base metal, and the service life is greatly prolonged. The abrasion resistance of the repaired TRT hub is 1.3-1.5 times that of the raw materials, the corrosion resistance of the repaired TRT hub is 1.5-1.8 times thatof the raw materials, and the service life of the repaired TRT hub is 1.2-1.4 times that of the raw materials. The deformation amount can be controlled within 0.5 mm, meanwhile, heat damage to the base metal is quite small, and the overall mechanical performance is not lower than that of new products.

Owner:河北瑞兆激光再制造技术股份有限公司

Pre-expanded particles or crystalline aromatic polyester-based resin, and in-mold expanded product and expanded laminated using the same

InactiveCN1333799AImprove welding effectHigh crystallization peak temperatureSynthetic resin layered productsPolyesterPolymer chemistry

Pre-expanded particles of crystalline aromatic polyester-based resin which is excellent in expansion fusion bonding during expansion molding, and an in-mold expanded product being improved particularly in fusion bonding ratio and mechanical strength and an expanded laminate using the pre-expanded particles. The pre-expanded particles have a bulk density of 0.01 to 1.0 g / cm<3> and a peak temperature of crystallization of 130 to 180 DEG C, and can be suitably used in in-mold expansion molding. The in-mold expanded product is formed by the in-mold expansion molding of the above pre-expanded particles, and the expanded laminate is prepared by laminating a film or sheet of an aromatic polyester-based resin directly on the above in-mold expanded product and forming them in one piece.

Owner:SEKISUI PLASTICS CO LTD

Inter vertebral fusing device

InactiveCN1640368AHigh mechanical strengthGood biocompatibilityInternal osteosythesisSpinal implantsMetallic materialsCervical vertebral body

The present invention discloses a cervical synostosis device for front enter operation of cervical vertebrae. Said device is formed from upper and lower two arms, screws and a hollow column body and is prepared by using absorbable material of poly-DL-lactic acid, poly-L-lactic acid and polyglycollic acid or copolymer of them, biological ceramics or composite of hydroxyapatite and the above-mentioned polymer. The side wal of said column body can have or have not open pore, its upper surface is made into the risen form, and its upper and lower surface can have or have not pointed tooth, and its cross-section is polygonal or circular. Said invention also provides its advantages and application range.

Owner:宋跃明 +2

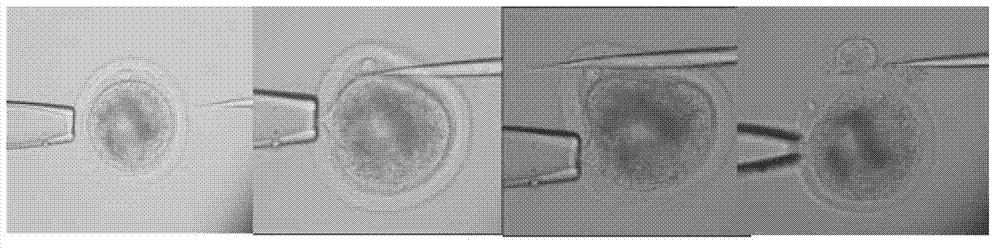

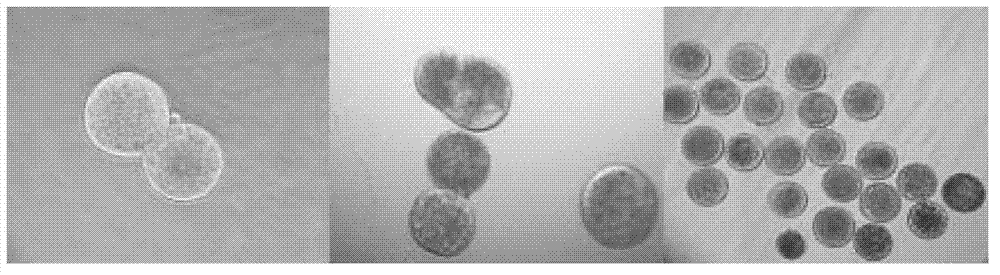

Method for producing somatic cell cloned bovine blastocyst

InactiveCN102766655AImprove fusion rateIncrease cleavage rateGenetic engineeringFermentationBovine oocyteCells oocytes

he invention discloses a method for producing somatic cell cloned bovine blastocysts. According to the method, to bovine ear limbal fibroblasts are used as nuclear transfer donorcells, and mature bovine oocytes cultivated in vitro are used as nuclear transfer receptor cells; the oocytes are denucleated by extrusion and removed with the zona pellucida; the oocytes and the donor cells are adhered in an arrangement way of oocytes-donor cells-oocytes and treated with electro-fusion to obtain reconstructed embryos; and the reconstructed embryos are activated and cultured in vitro to obtain the cloned blastocysts. The method can improve the production efficiency of the cloned bovine blastocysts.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

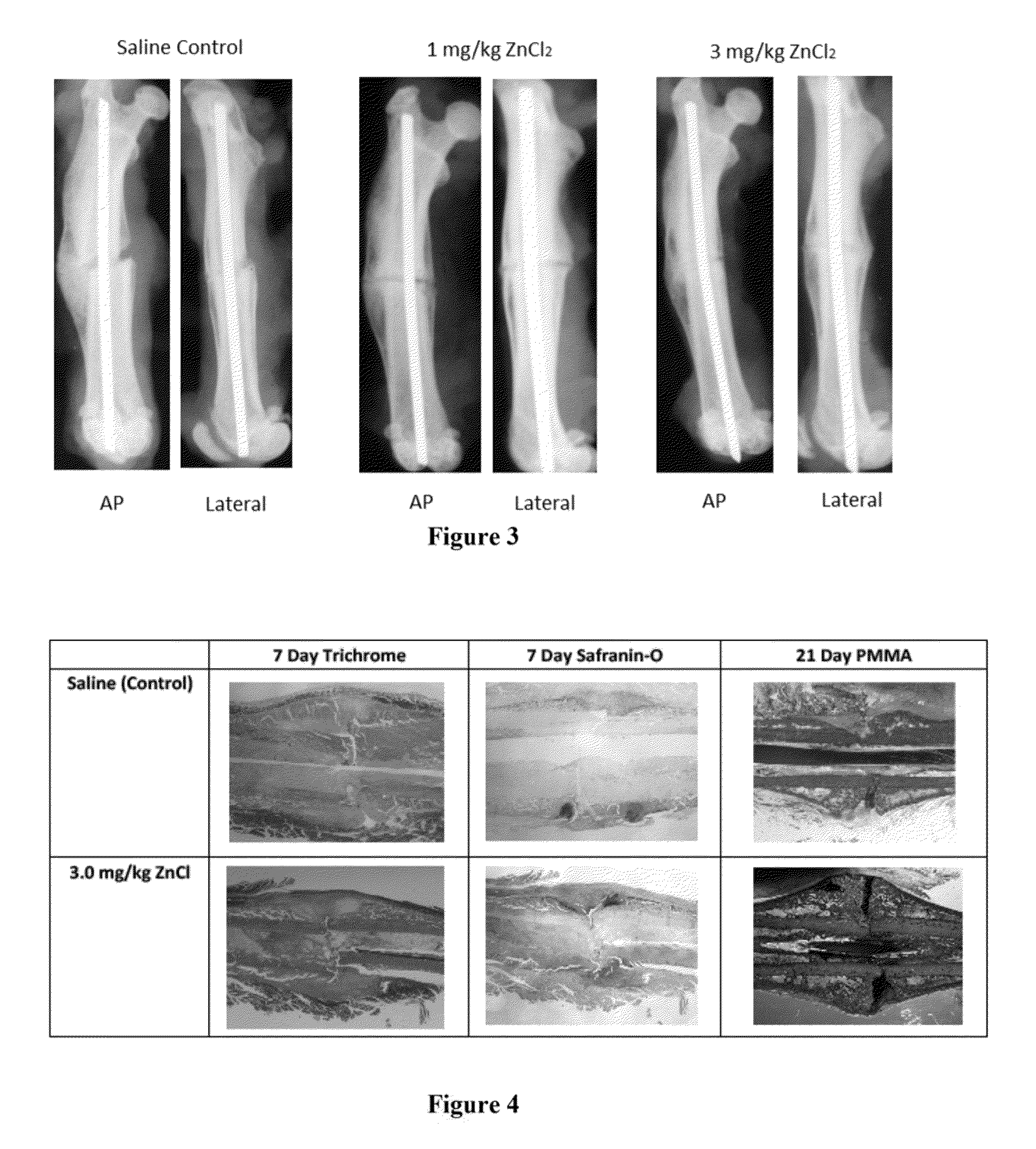

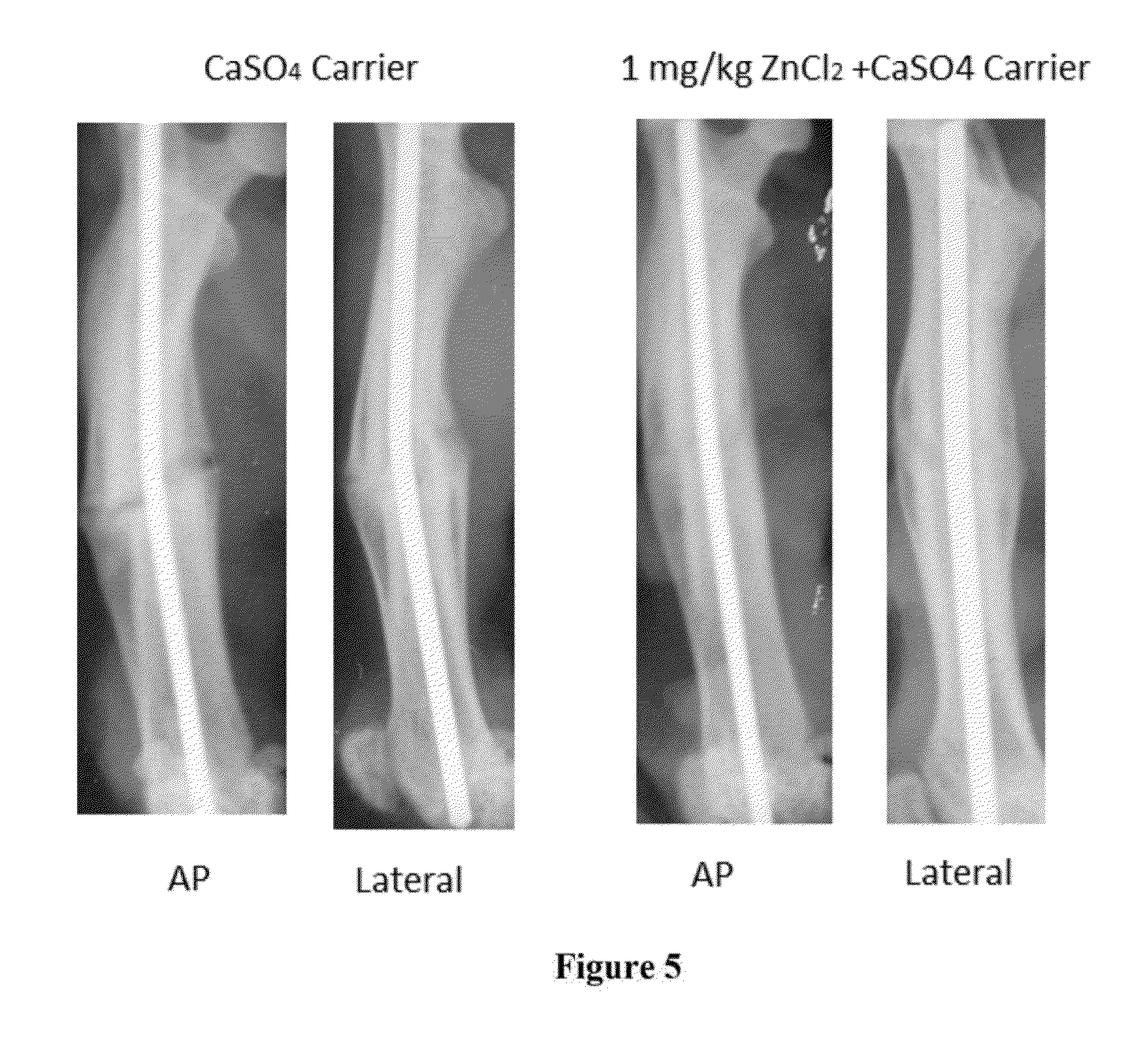

Insulin-mimetics as therapeutic adjuncts for bone regeneration

ActiveUS20150010499A1Improve fusion rateIncrease ratingsBiocideHeavy metal active ingredientsInsulin mimeticBones regeneration

Methods of promoting bone healing or regeneration by locally administering insulin mimetic agents to patients in need thereof and new uses of insulin-mimetic compounds for accelerating bone-healing processes are disclosed. Bone injury treatment and void filler devices, products and kit suitable for local administration of insulin-mimetic agents or compositions thereof to patients in need of such treatment are also disclosed.

Owner:RUTGERS THE STATE UNIV

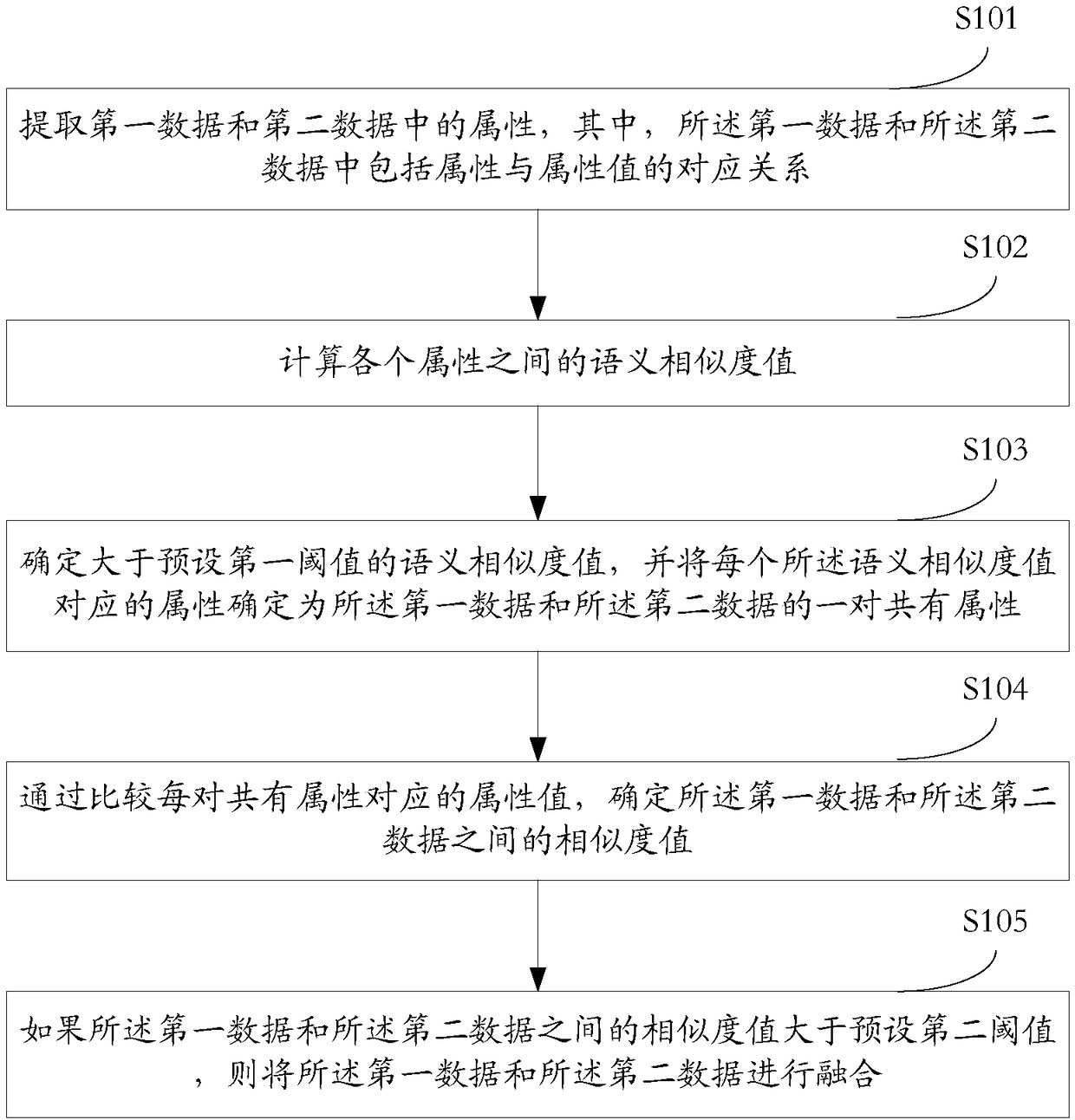

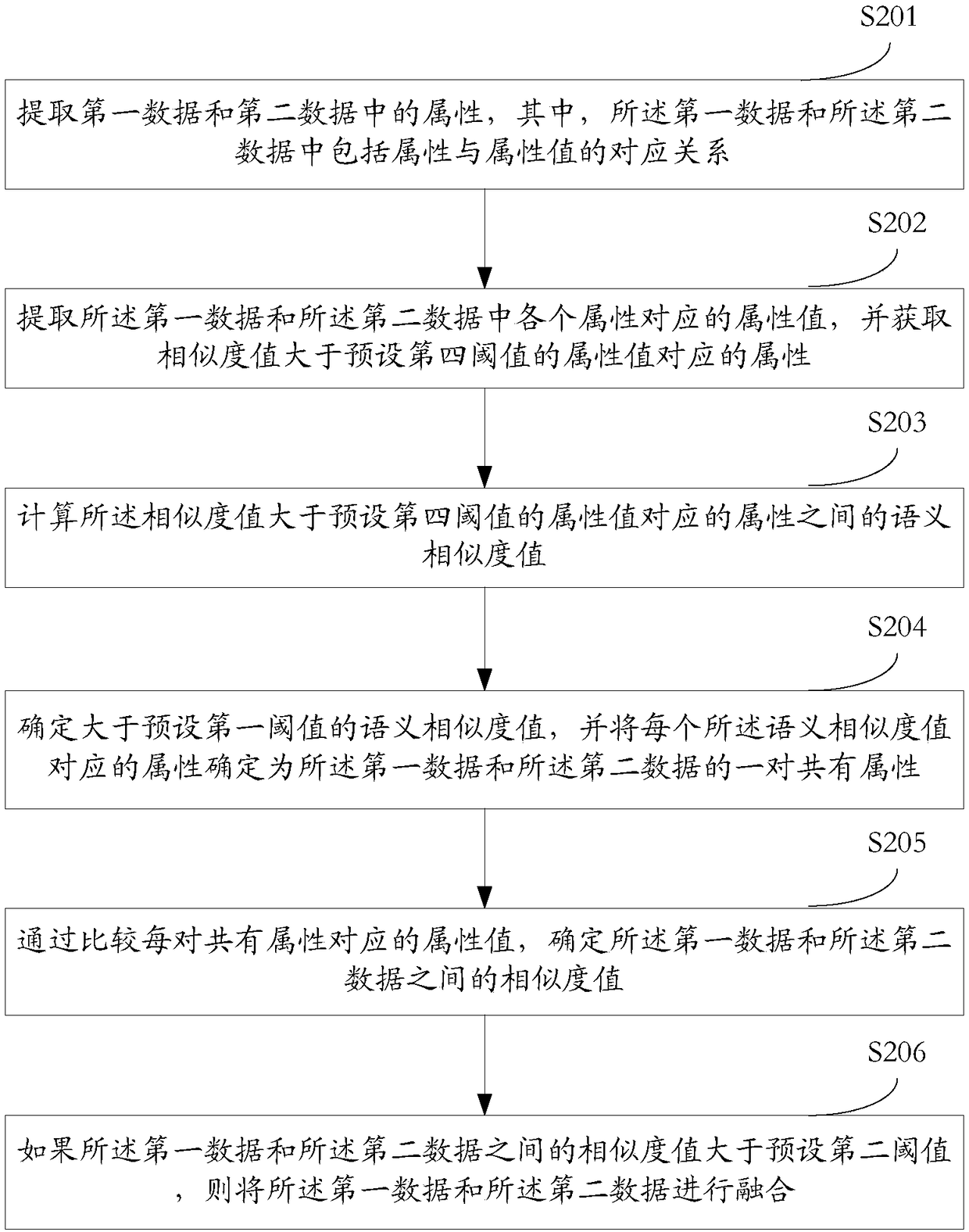

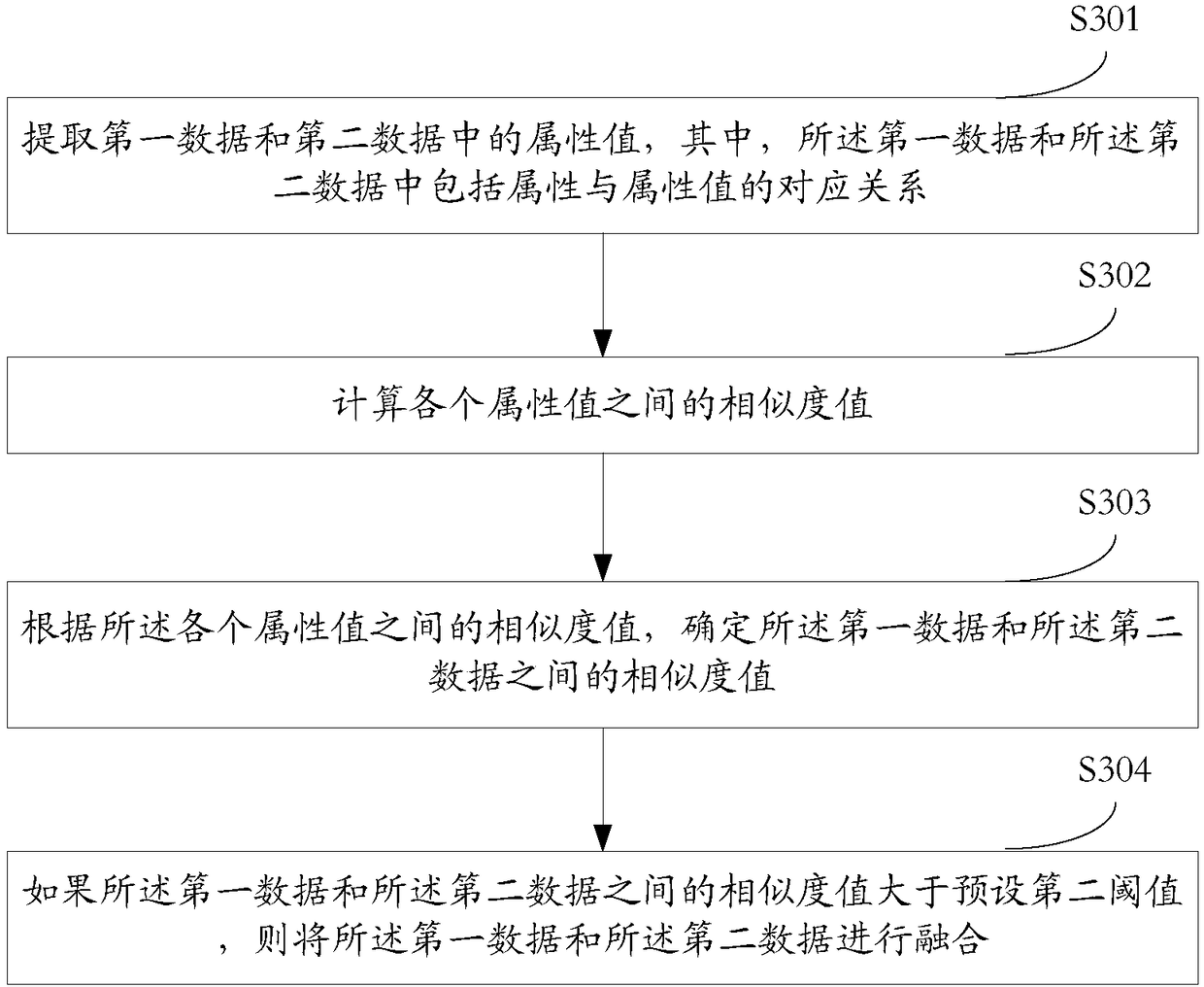

Data fusion method and device

ActiveCN108572947AGuaranteed Fusion AccuracyImprove fusion rateSemantic analysisSpecial data processing applicationsData miningSemantic similarity

The invention discloses a data fusion method and device. The method comprises the steps of extracting attributes in first data and second data, wherein the first data and the second data comprise a corresponding relationship of the attributes and attribute values; calculating semantic similarity values among all the attributes, determining the semantic similarity values larger than a first presetthreshold value, and determining attributes corresponding to all the semantic similarity values as pairs of common attributes of the first data and the second data; determining the similarity value between the first data and the second data by comparing the attribute values corresponding to each pair of common attributes, and fusing the first data and the second data if the similarity value between the first data and the second data is larger than a second preset threshold value. According to the data fusion method and device, on the premise of guaranteeing the accuracy of data fusion, the rate of data fusion is increased.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Method of compressing adjacent pieces of bone

InactiveUS7901440B2Force is limitedEasy to integrateInternal osteosythesisDiagnosticsStatic compressionWolff's law

A Static Compression Device (SC device) for active, measurable compression of a fusion graft by the surgeon at the time of surgery is disclosed. The SC device is attachable to adjacent vertebral bodies or other pieces of bone and has a device that applies compressive force to the adjacent vertebral bodies or pieces of bone to assist fusion according to Wolff's law. The SC device has a locking mechanism that maintains the compression applied at surgery, but prevents further compression (settling) from occurring after surgery. The SC device allows the surgeon the ability to compress a segment, measure the applied compression, and lock the segment in the compressed position. In one embodiment of the invention, the pressure is applied to the SC device through a compression device that applies a desired and measurable amount of force. In this embodiment, the combination of the SC device with a pressure applying and measuring device allows the surgeon more control over the force applied to a cervical, thoracic or lumbar implant than has previously been available. In the preferred embodiment, the SC device compresses two or more adjacent vertebrae across an adjacent bone graft to facilitate fusion of these vertebrae to treat pain produced by pressure from the disks between such vertebrae bulging and resulting in contact with and pressure on the spinal cord and adjacent nerve roots. In other embodiments, the SC device may be used to apply measurable compression across any type of bony interface (e.g. fractures) to facilitate union.

Owner:IB MEDICAL

Insulin-mimetics as therapeutic adjuncts for bone regeneration

InactiveUS20140322292A1Promoting bone healingEnhancing spinal fusionOrganic active ingredientsPeptide/protein ingredientsInsulin mimeticTreatment Adjuncts

Methods of promoting bone healing or regeneration by locally administering insulin mimetic agents to patients in need thereof and new uses of insulin-mimetic compounds for accelerating bone-healing processes are disclosed. Bone injury treatment and void filler devices, products and kit suitable for local administration of insulin-mimetic agents or compositions thereof to patients in need of such treatment are also disclosed.

Owner:RUTGERS THE STATE UNIV

Health product process device and method for extracting yang-strengthening and kidney-tonifying components from donkey penis and testis

InactiveCN109123650APromote absorptionNo wasteBioreactor/fermenter combinationsBiological substance pretreatmentsPenisEconomic benefits

The invention discloses a health product process device and method for extracting yang-strengthening and kidney-tonifying components from donkey penis and testis and belongs to the technical field ofhealth products from donkeys. According to the device disclosed by the invention, a first tank body and a second tank body are arranged and combined with a drying furnace, a pulverizing device and a mixing box to reasonably separate donkey penis and testis powder from soup and the health components are extracted through respective processing; and therefore, the problem that the absorption efficiency of the donkey penis and testis is low in the prior art is effectively solved, the utilization rate and the economic benefit of donkey products are increased, moreover, waste of raw materials is notcaused, either the soup or the residue can be used as a supplement and the soup and the residue are separately processed to make the best use of things and turn waste into treasure.

Owner:哈哈驴(天津)国际贸易有限公司

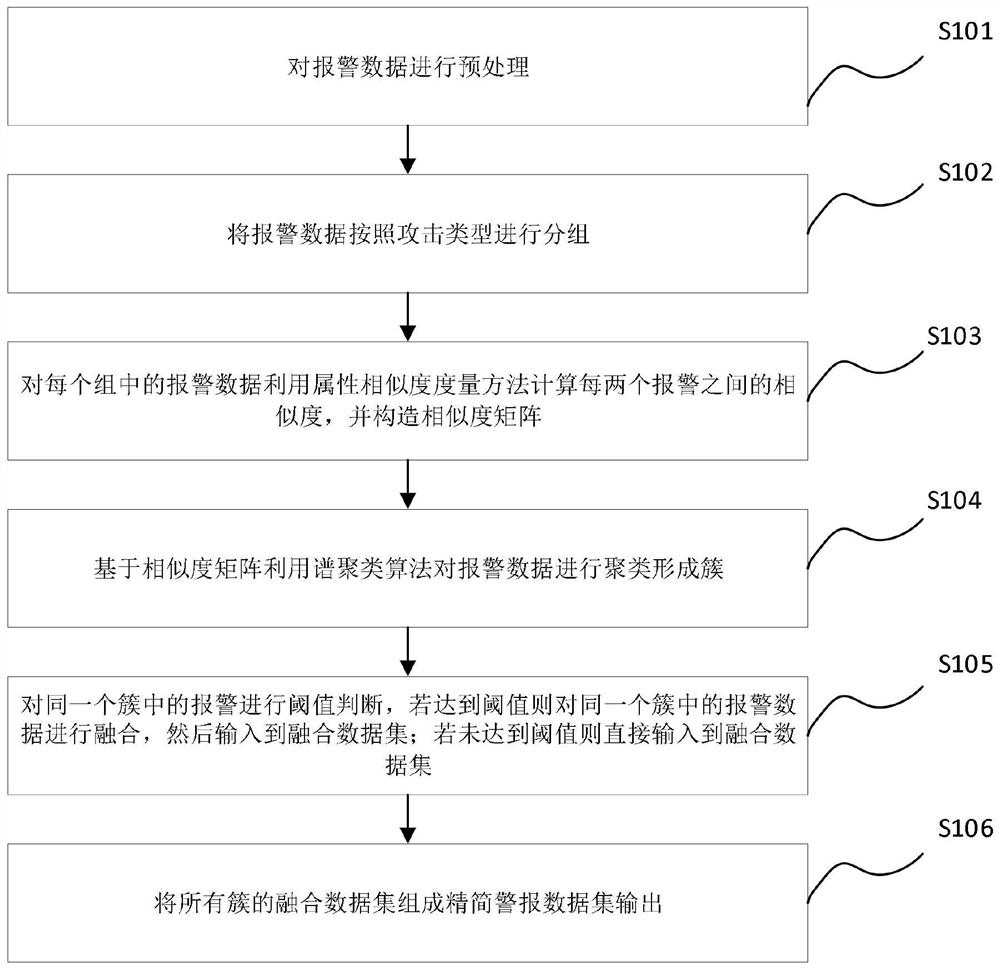

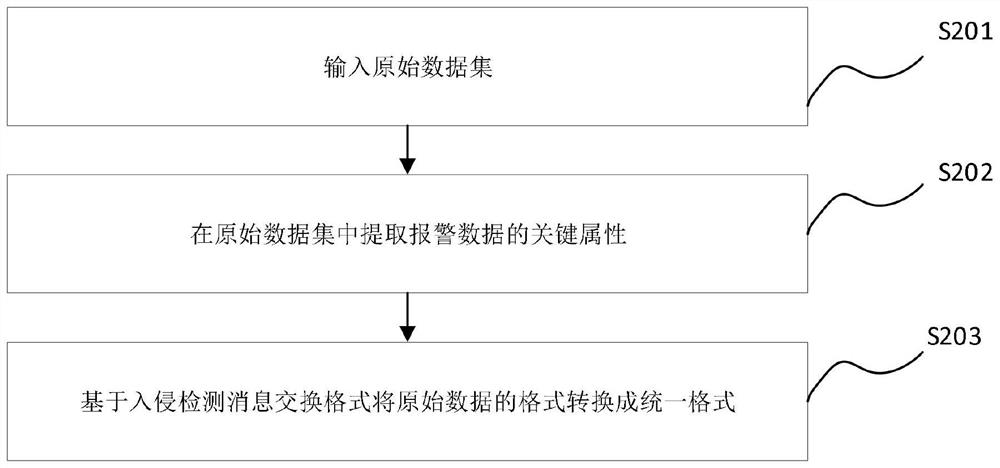

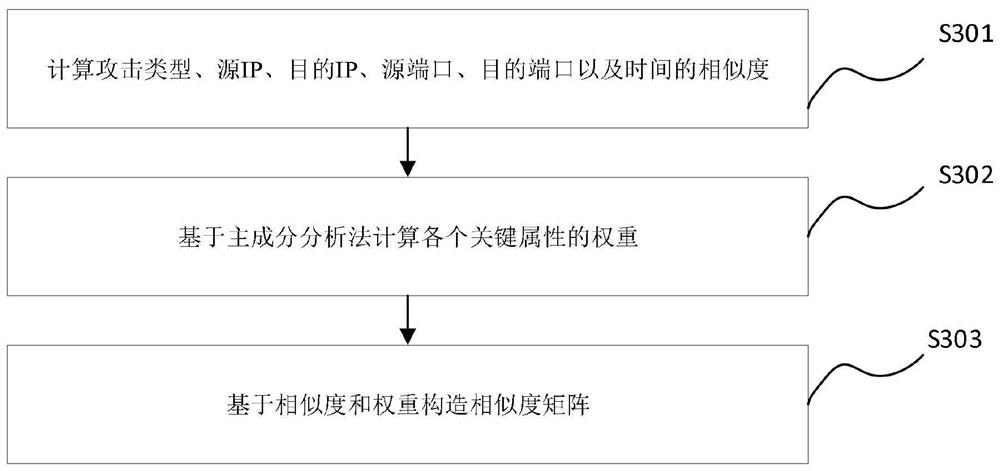

Alarm data fusion method based on improved spectral clustering

ActiveCN113420802AReduce false alarm rateReduce deletionCharacter and pattern recognitionTransmissionPattern recognitionSpectral clustering algorithm

The invention relates to the field of data processing, and discloses an alarm data fusion method based on improved spectral clustering. The method comprises the following steps: preprocessing alarm data; grouping the alarm data according to attack types; calculating the similarity between every two alarms for the alarm data in each group by using an attribute similarity measurement method, and constructing a similarity matrix; clustering the alarm data by using a spectral clustering algorithm based on the similarity matrix to form clusters; performing threshold judgment on the alarms in the same cluster: if the threshold is reached, fusing the alarm data in the same cluster, and then inputting the fused data into a fused data set; if the threshold value is not reached, directly inputting the data into a fusion data set; and combining the fusion data sets of all clusters into a simplified alarm data set and outputting the simplified alarm data set. According to the method, better clustering fusion can be realized under the condition that the relation between alarms is not damaged, the information loss is reduced, and the false alarm rate of the alarm data can be reduced while the fusion rate is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

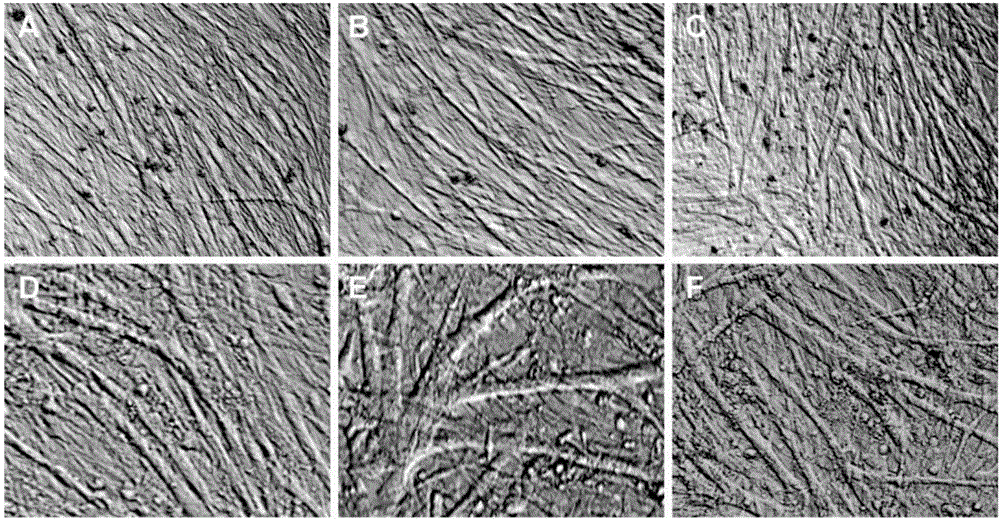

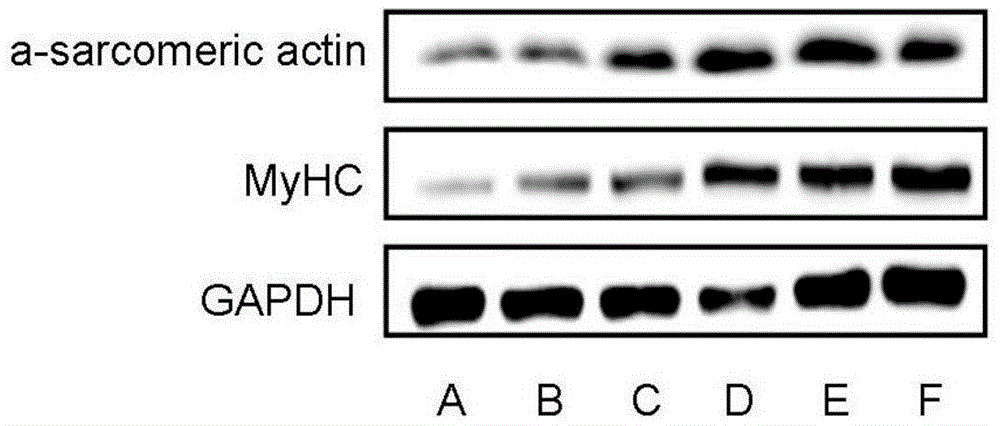

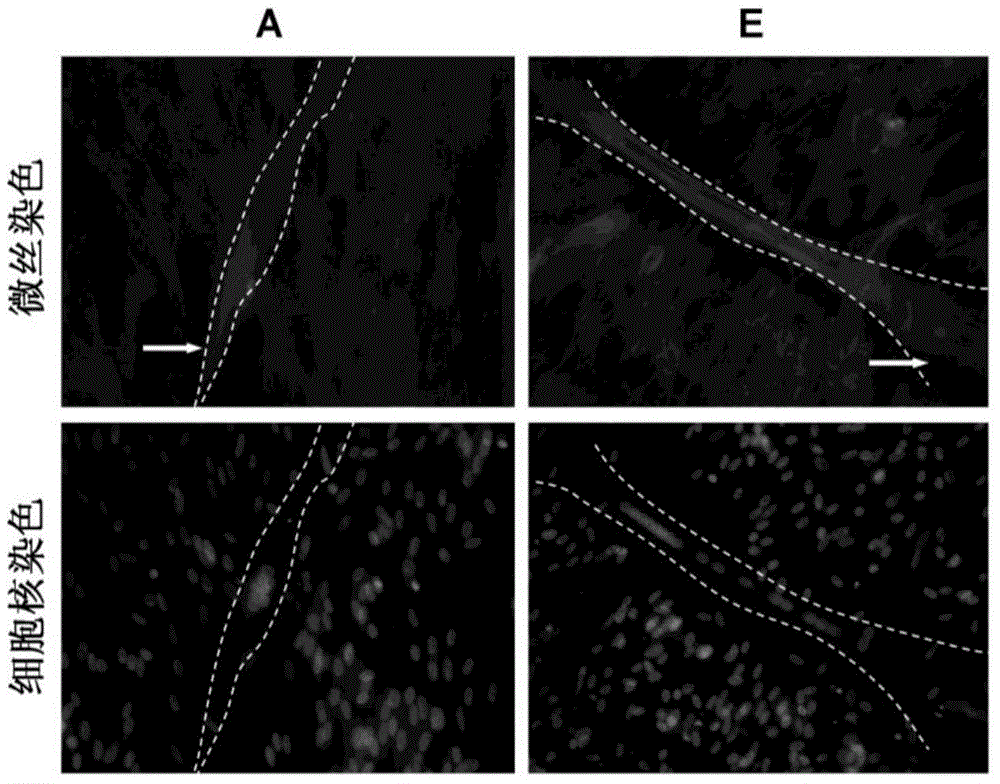

Preparation for enhancing differentiation capacity of chicken skeletal muscle myoblast and application thereof

ActiveCN104152406AInhibit apoptosisPromote migrationSkeletal/connective tissue cellsBiotechnologyCalcium pyruvate

The invention discloses a preparation for enhancing differentiation capacity of chicken skeletal muscle myoblast and application thereof, and belongs to the technical field of biological engineering. The preparation provided by the invention is composed of a muscle derived fibroblast extractive, pyruvate and calcium salt. The muscle derived fibroblast extractive is obtained from the steps of: conducting ultrasonic cracking on chicken muscle derived fibroblast, isolating to obtain a protein solution less than 10KDa, and conducting vacuum drying. Calcium salt and pyruvate can be calcium pyruvate. The preparation provided by the invention has the characteristics of simple and easily available composition and simple and effective usage, and can significantly improve the fusion rate of chicken skeletal muscle myoblast and promote the increase of skeletal muscle fiber diameter and expression of functional contractile protein. The preparation provided by the invention can be used for culturing myoblast; and the fusion rate of the myoblast is increased by 32.01%, the average number of nuclei in myotubes is increased by 91.63%, and average diameter of myotubes is increased by 45.59%.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

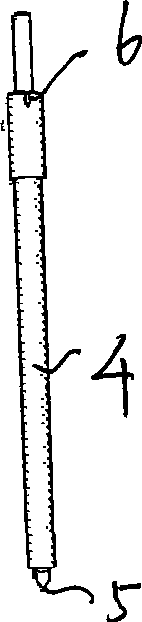

Synarthrosis device for waist articular process and implantation device thereof

InactiveCN101433479AImprove fusion rateEliminate loosenessSurgeryJoint implantsOblate spheroidSide effect

The invention discloses a waist joint zygapophysis cage and an implanting device thereof. The waist joint zygapophysis cage comprises an oblate spheroid, and both ends of the oblate spheroid are provided with an upper cylinder and a lower cylinder respectively which have coincided center shafts and the same diameter; the oblate spheroid is 6 mm in diameter and 4 mm in height; the diameters of the upper cylinder and the lower cylinder are 2 mm, the upper cylinder is 2 mm in height, and the lower cylinder is 1mm in height; and the oblate spheroid, the upper cylinder and the lower cylinder are made of cortical bone materials of adult thighbone. The implanting device comprises a positioning device, a working channel, a straight drill, a spherical drill and an implanting machine. The waist joint zygapophysis cage has the advantages of improving the medium and long term fusion rates of the lumbar facet joint and the remission rate of postoperative symptoms, eliminating the loosening and breaking of bolts and reducing side effects of bolts such as neurologic damage and the like caused by epidural rupture and vertebral canal puncture. The implanting device has the advantages of simple structure, easy operation and good use effect.

Owner:崔志明 +2

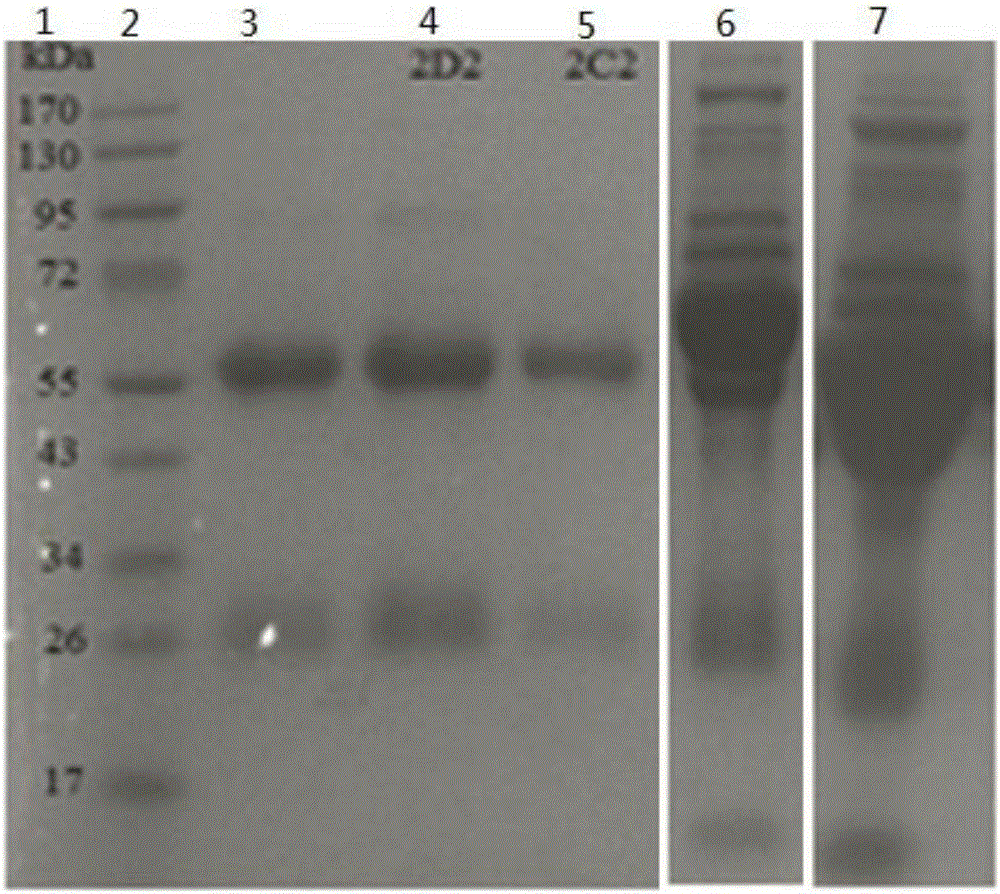

Preparation method and application of bacillus cereus monoclonal antibody

InactiveCN105237634AHigh potencyStrong specificityImmunoglobulins against bacteriaMaterial analysisCapture antibodyBacillus cereus

The invention provides a preparation method and application of a bacillus cereus monoclonal antibody. The preparation method comprises the following steps of: 1, preparing bacterial antigen through fixation of bacillus cereus by incubation treatment of paraform; 2, injecting the bacterial antigen so as to avoid emulsification; 3, performing short spacing impulse injection so as to quickly promote immunization; 4, planting solid tumors so as to rejuvenate tumor cells; 5, performing chemical induction and fusion; 6, performing semifluid selection so as to obtain monoclonal hybridoma; 7, performing cooperation of negative screening and positive screening so as to obtain a specific antibody; and 8, using a polyclonal antibody as a capture antibody and using a monoclonal antibody as a detection antibody to establish dual-antibody sandwich ELISA.

Owner:FUDEAN OF BEIJING TECH +1

Repair method for worn central disc of main exhauster in sintering plant

InactiveCN104070269AImprove fusion rateReduce distortionArc welding apparatusSinter PlantWear resistance

The invention relates to a repair method for a worn central disc of a main exhauster in a sintering plant. The repair method comprises steps of preparation before repair, the repair process and detection after repair, and particularly comprises the following steps: cleaning a workpiece; detecting the size of each part of the main exhauster, and determining the damaged part and the abrasion; determining basic parameters of the main exhauster; conducting radial and end surface runout detection on the main exhauster; determining a repair scheme for the main exhauster; determining the repair technique according to a detection result; selecting welding materials, and replacing plates at the seriously worn part and the washing leakage part; partially welding strip-shaped wear layers on a wear-resisting plate, and conducting thermal tailor-melding on the wear-resisting plate; conducting partial thermal treatment on welding parts; polishing the welding parts to be smooth; conducting detection after repair. The repair method is good in wearing resistance, high in rigidity, few in cracks of a repair layer, high in fusion rate of a cladding layer and base metals of the central disc, and low in deformation of the main exhauster.

Owner:河北瑞兆激光再制造技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com