Cell electrofusion chip device based on micro-chamber array structure

A technology of array structure and array chip, which is applied to the device of biological cell electrofusion and provides the field of cell electrofusion chip, which can solve the problems of precise control of difficult cells, large chip spacing, and increased system cost, and achieve a high fusion rate of two pairs , lower requirements and higher queuing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

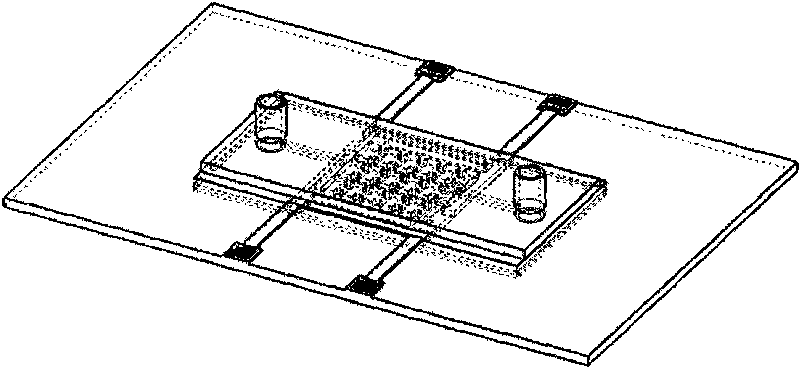

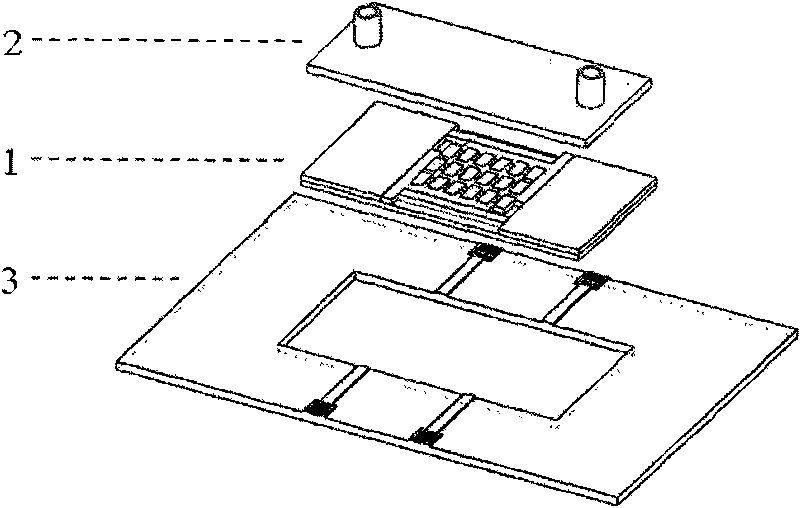

[0046] see figure 1 , figure 2 , the cell electrofusion microelectrode array chip device based on the micro-chamber structure is composed of a micro-chamber array chip 1 , a flow path control module 2 and a peripheral printed circuit board 3 .

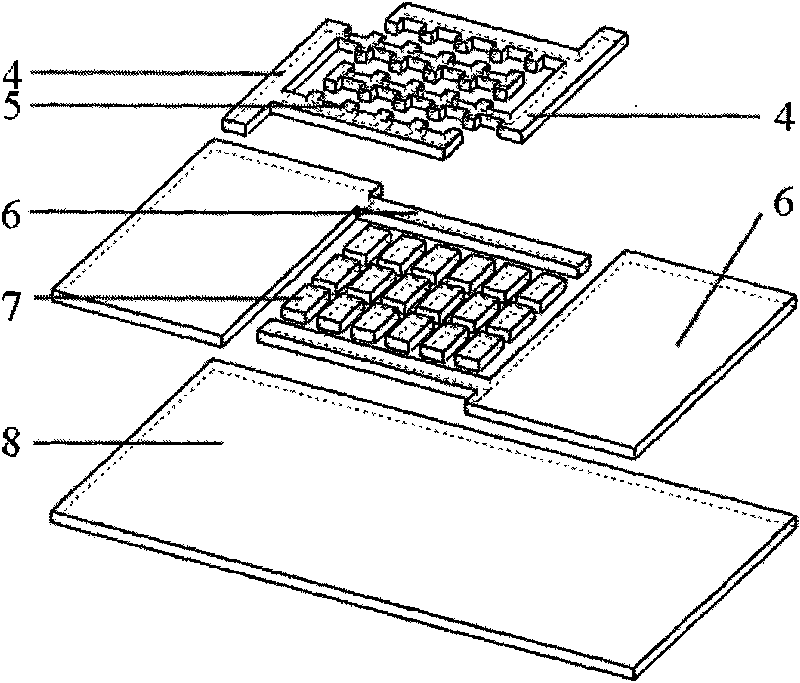

[0047] see figure 2 , image 3 and Figure 4 The micro-chamber array chip 1 has a quartz base layer 8 on which a metal micro-electrode array 4 , polymer side walls 7 and polymer water barriers 6 are formed using micromachining techniques. The metal microelectrode array 4 integrates a large number of metal microelectrodes 5 , and two opposite metal microelectrodes 5 and two opposite polymer sidewalls 7 constitute a tiny chamber 9 , and the microchambers 9 are also arranged in an array. Materials such as metal microelectrode array 4 can be selected from gold and platinum, and polymer materials can be selected from materials such as polyimide and parylene; the depth of the micro-chamber 9 is 15 μm, the width is 5-30 μm, and the leng...

Embodiment 2

[0051] Embodiment 2: the processing technology of part structure in the above-mentioned device

[0052] 1. The micro-chamber array chip is realized by MEMS processing technology, and the processing steps are as follows (the metal array electrode layer material described here is gold Au, and the polymer layer material is polyimide):

[0053] A. Use quartz as the substrate for processing chips;

[0054] B. sputtering a layer of Ti / W on the quartz substrate, wherein the thickness of the Ti / W layer is 50nm;

[0055] C. Electroplate a layer of gold on the surface of the Ti / W layer by electroplating, with a thickness of 15 μm;

[0056] D. Etch the shape of the microelectrode array on the Ti / W / Au layer by means of photolithography;

[0057] E. Spin-coat polyimide glue on the surface of the above structure to form a polyimide layer with a thickness equivalent to the thickness of the Ti / W / Au layer (15 μm);

[0058] F. Photolithography of polyimide to form the sidewall structure of t...

Embodiment 3

[0065] Example 3: Application of Cell Electrofusion

[0066] From the sample inlet 14 described in embodiment 1, use micropump to inject cell suspension; Under the action of gravity, it will sink into the lower micro chamber 9 corresponding to the sample reservoir 12; the special structure of the micro chamber 9 can only accommodate 2 cells in a single layer, and the excess cells will accumulate on it; at this time, combined with the flow control device 2. Use a micropump to inject the cell electrofusion buffer; since the microchamber 9 is a micropit structure, under the obstruction of the polymer side wall 7, the two cells in the microchamber 9 will not be washed out by the microflow; and The superfluous cells accumulated on it will flow out along the microchannel 13, the sample outlet 15 and the conduit 10 due to the lack of blocking of the micro 7; cells; and then apply a sine wave electrical stimulation signal to the metal microelectrode array 4 through the peripheral pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com