Patents

Literature

64 results about "Oblate spheroid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

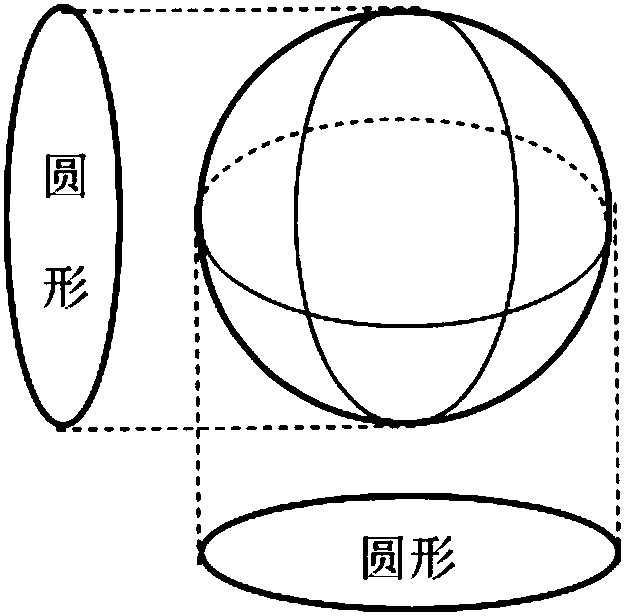

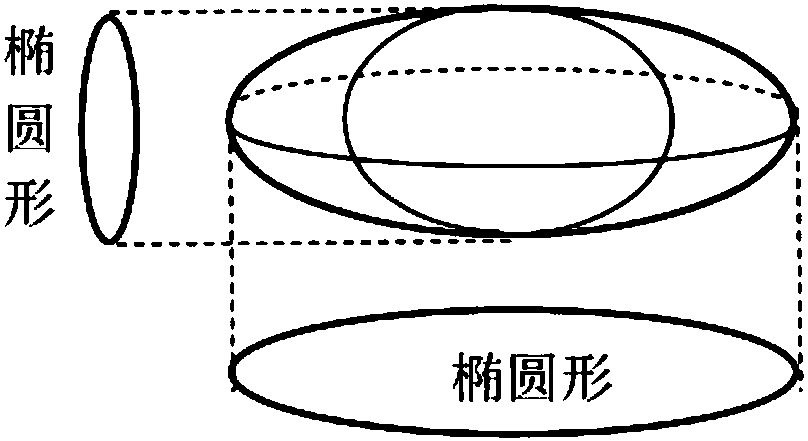

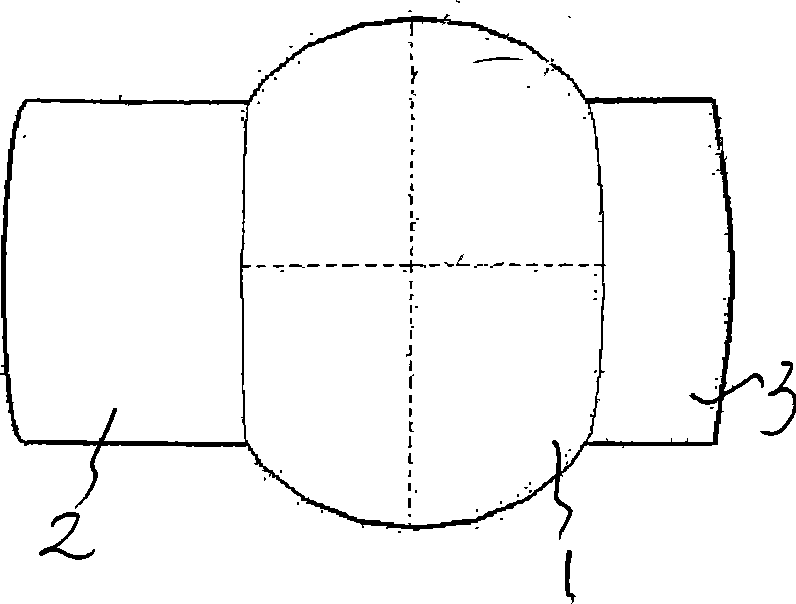

An oblate spheroid is a rotationally symmetric ellipsoid having a polar axis shorter than the diameter of the equatorial circle whose plane bisects it. Oblate spheroids are contracted along a line, whereas prolate spheroids are elongated. It can be formed by rotating an ellipse about its minor axis, forming an equator with the end points of the major axis. As with all ellipsoids, it can also be described by the lengths of three mutually perpendicular principal axes, which are in this case two arbitrary equatorial semi-major axes and one semi-minor axis. An everyday example of an oblate spheroid is the shape of confectionery such as Smarties or M&M's. The shape of the Earth is very close to that of an oblate spheroid. Though local topography deviates from this idealized spheroid, on a global scale these deviations are very small.

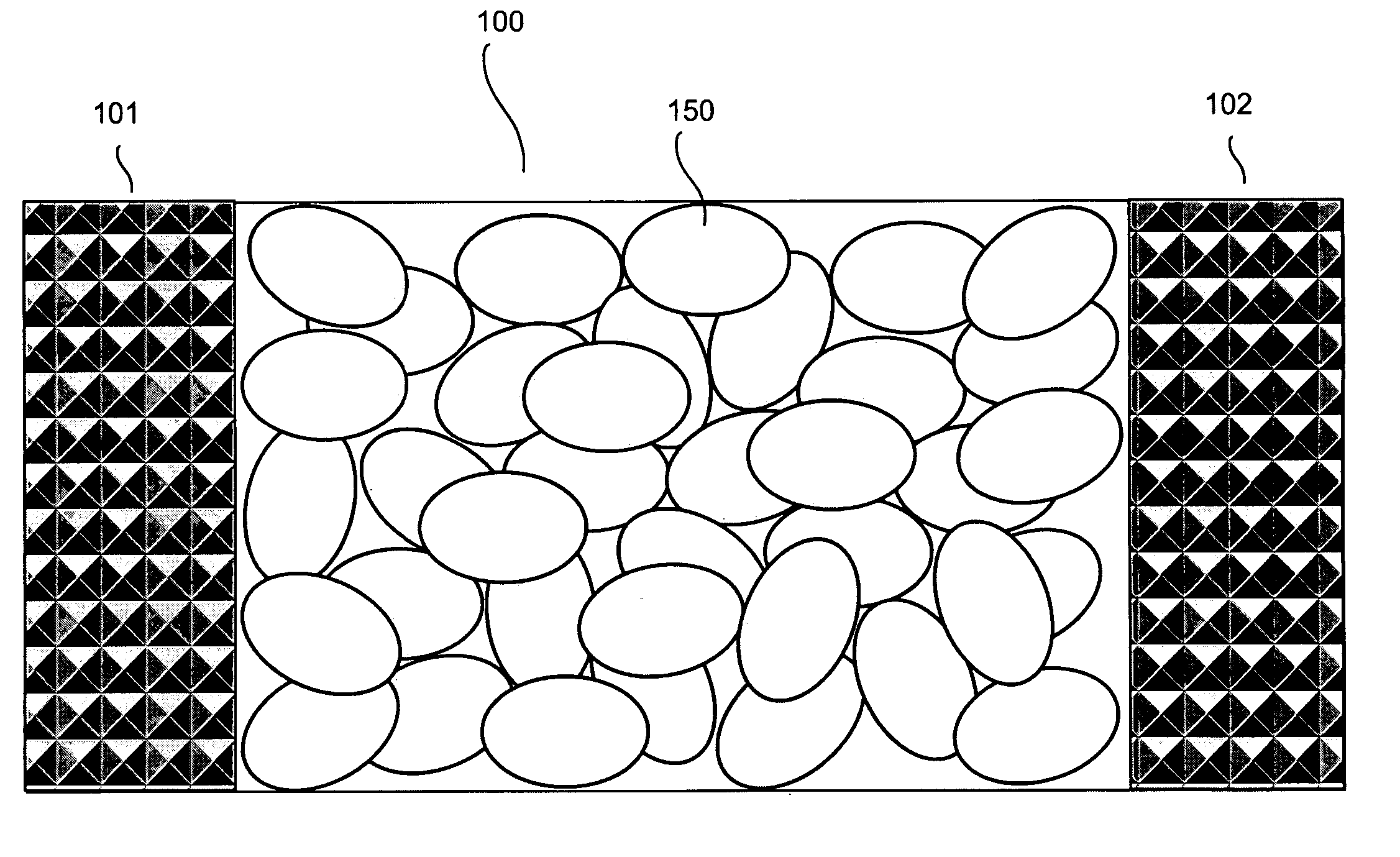

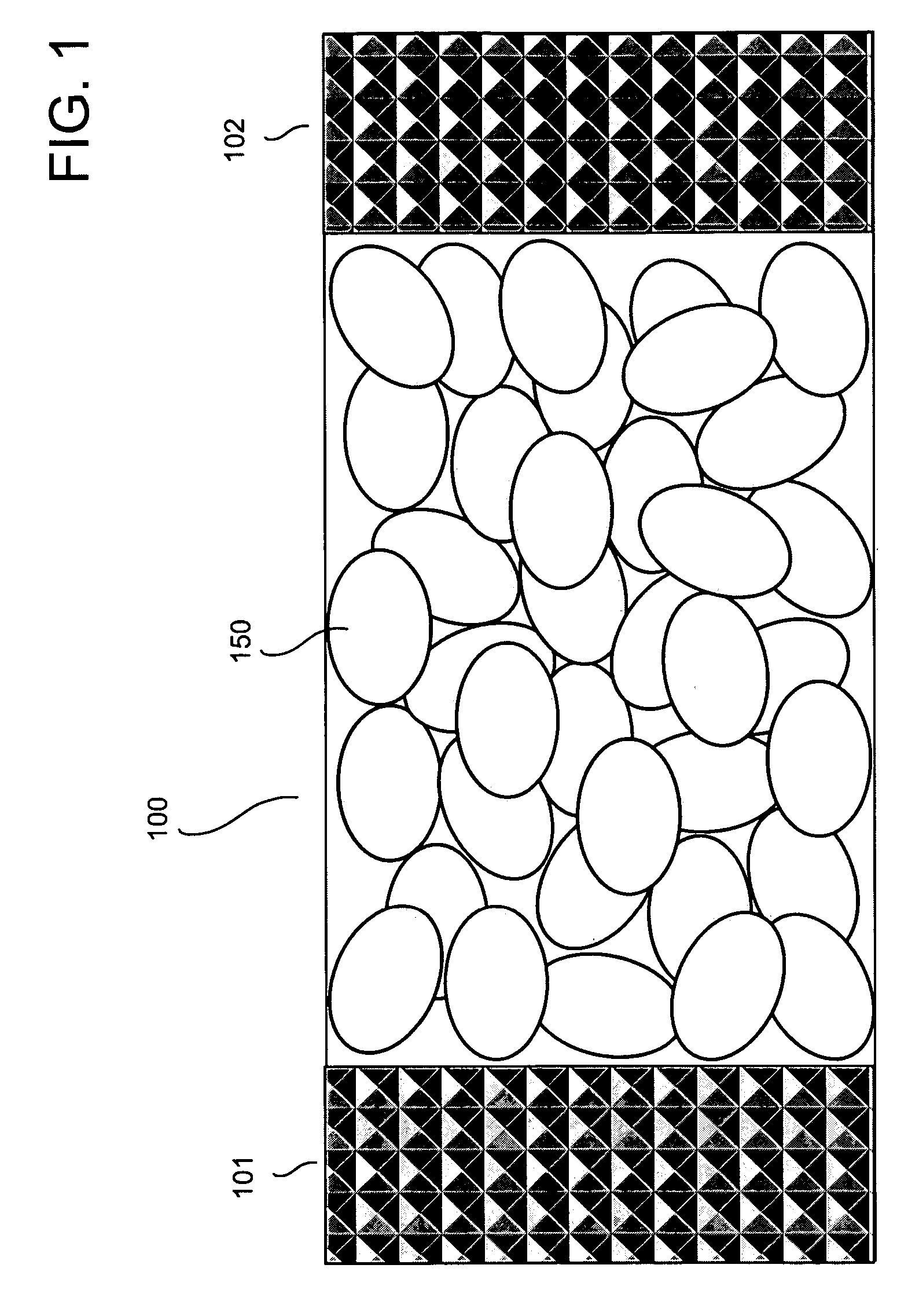

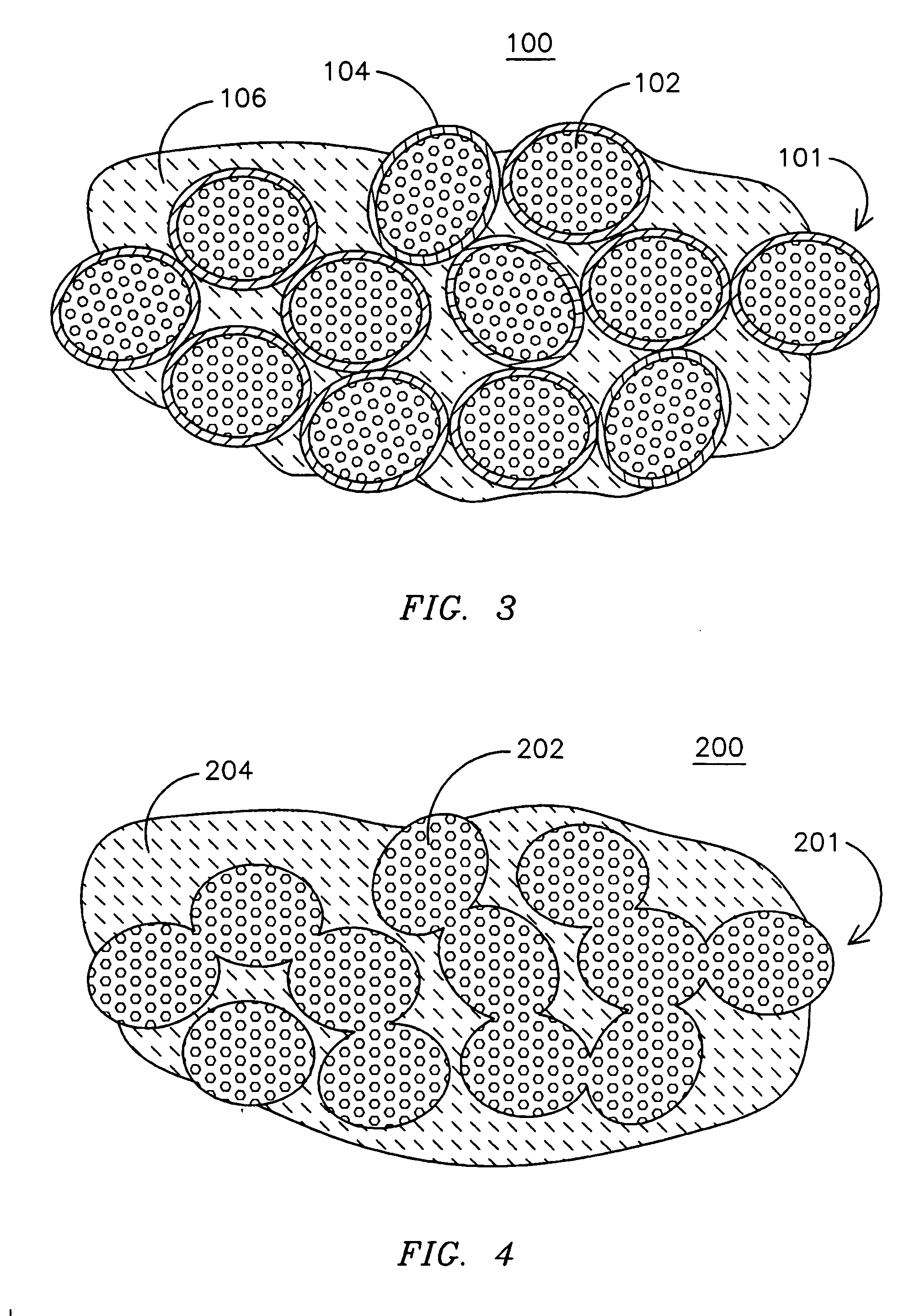

Conformable thermal pack apparatus, manufacture and method

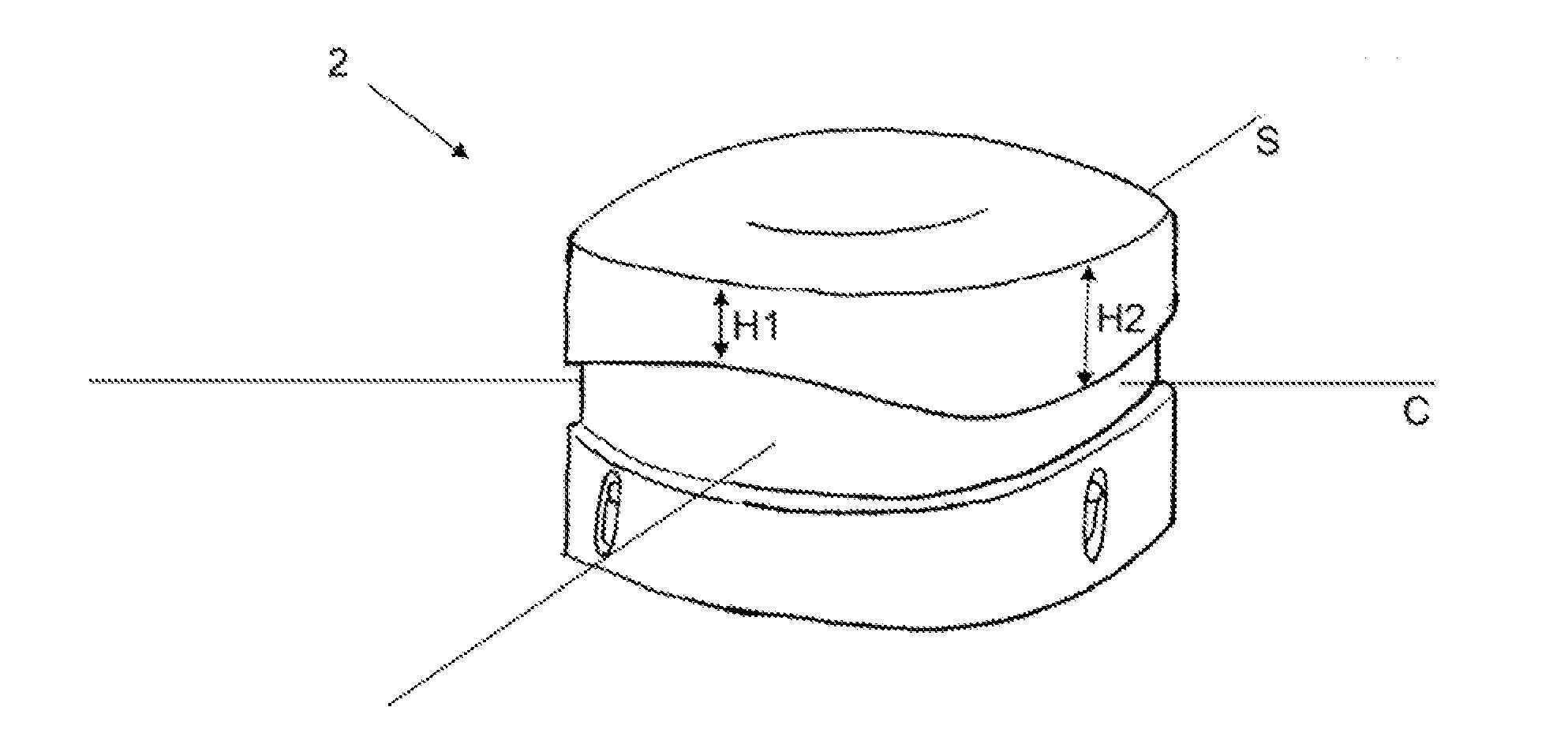

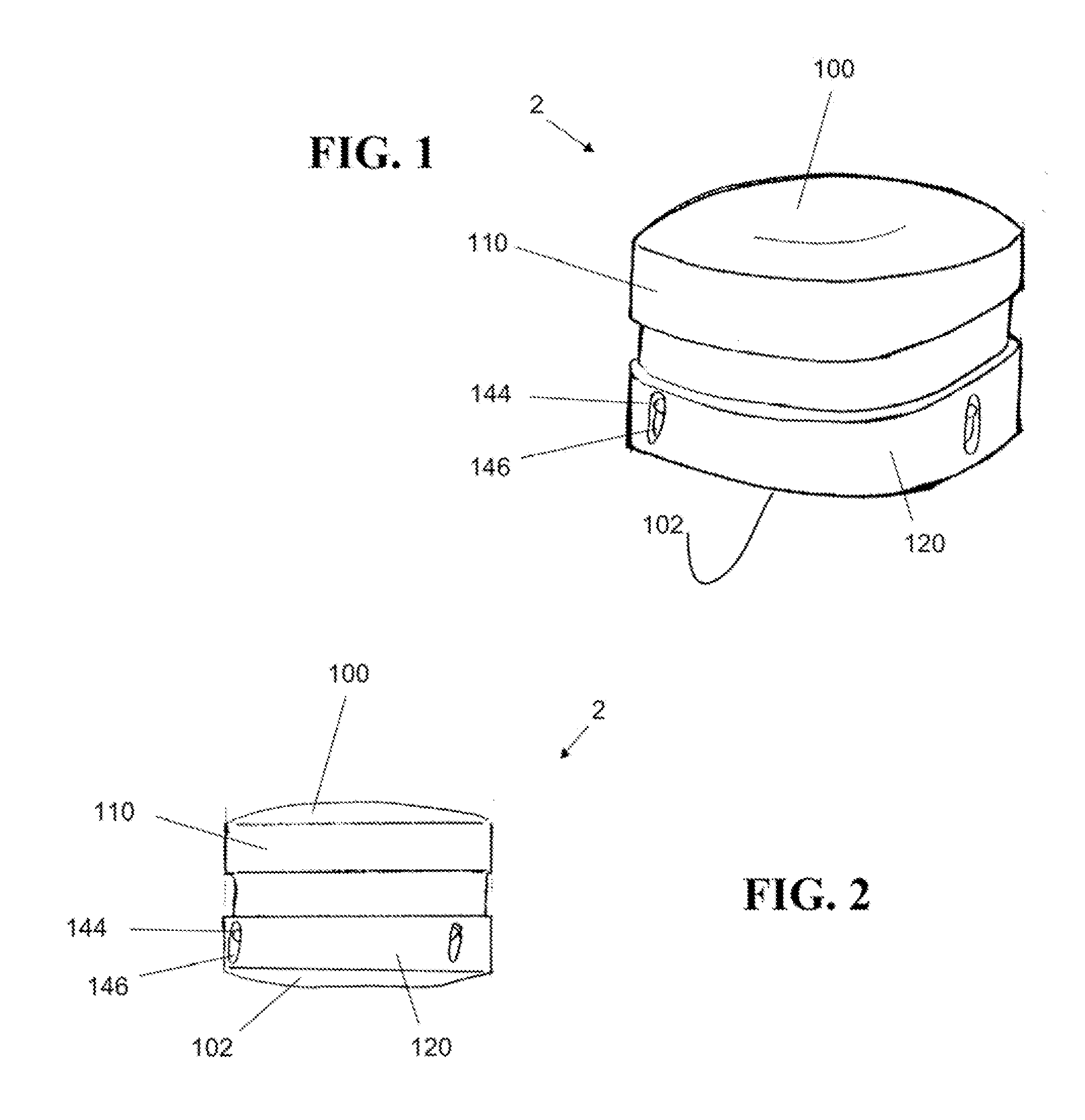

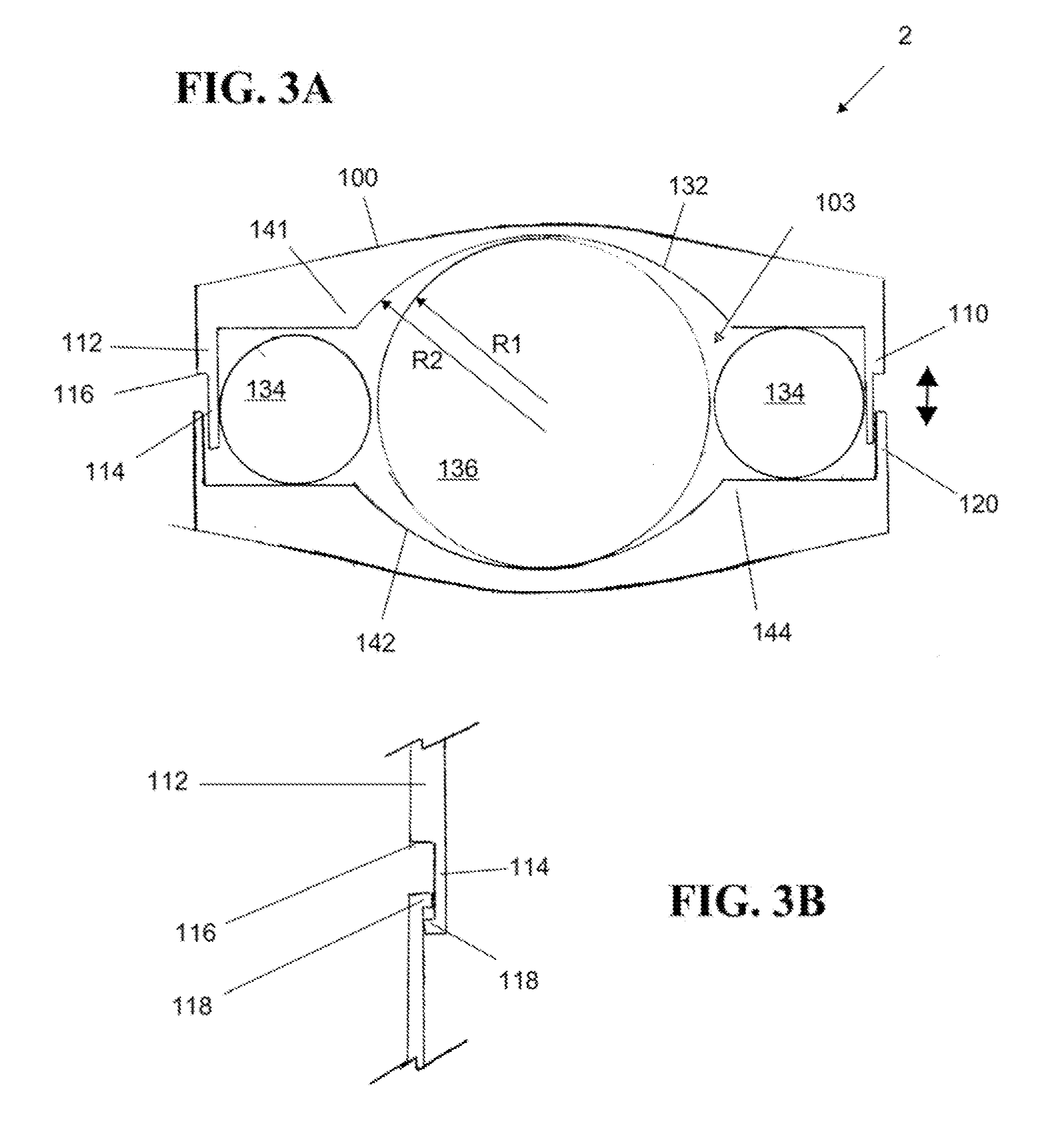

InactiveUS20070021810A1Easy to manufactureTherapeutic coolingTherapeutic heatingOblate spheroidThermal energy

A therapeutic conformable thermal pack having increased thermal energy storage capacity. The apparatus and method enables therapeutic delivery of more stored heat or cold than previously possible to various areas of a treatment area. A new scientific discovery has been made that shows that ellipsoids and oblate spheroids randomly pack more densely than spheres. The thermal pack comprises thermal retaining elements comprising oblate spheroids and / or ellipsoids allowing embodiments to have an improved thermal density and thermal transfer capability.

Owner:PAULIN KATHY WOOD

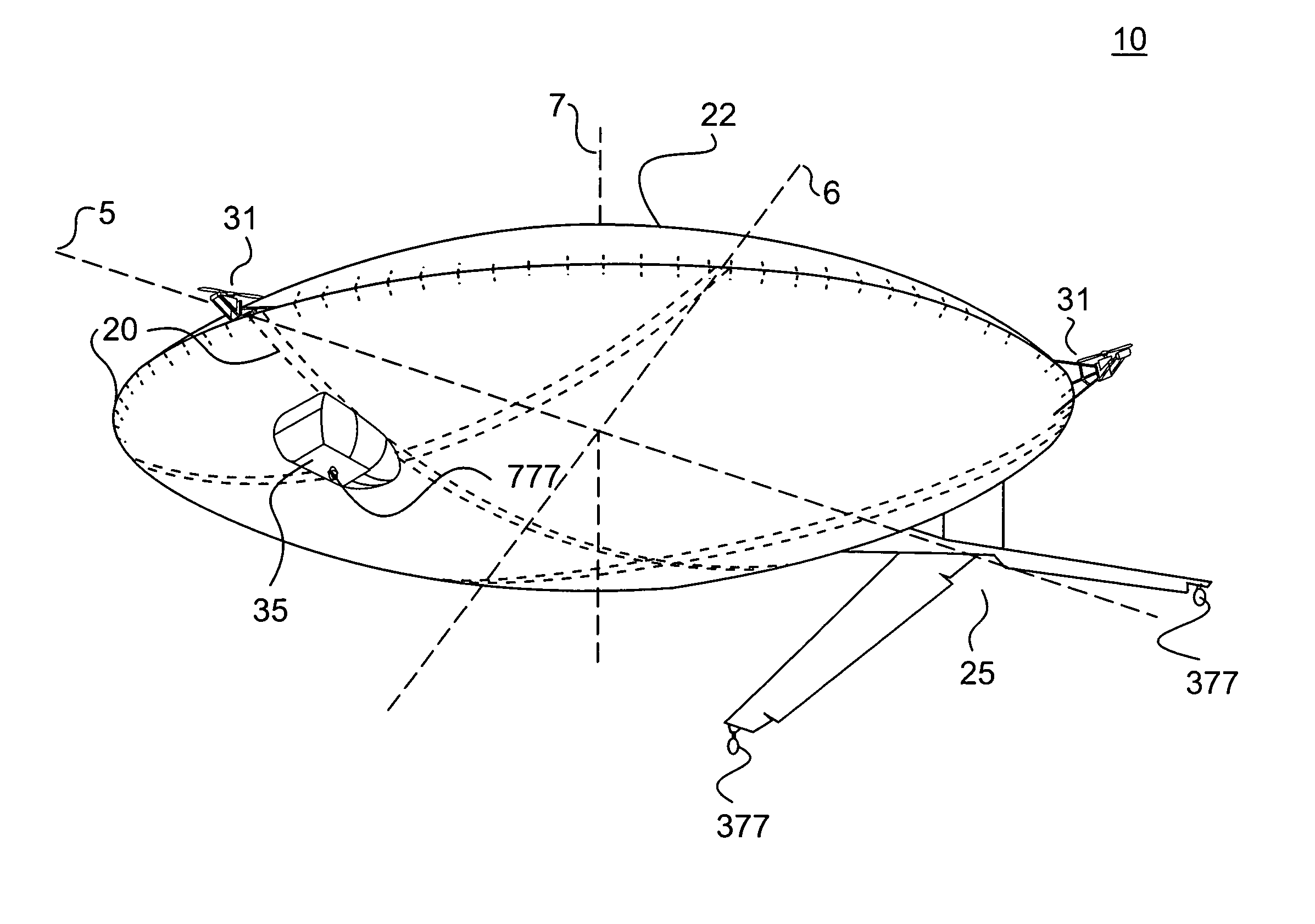

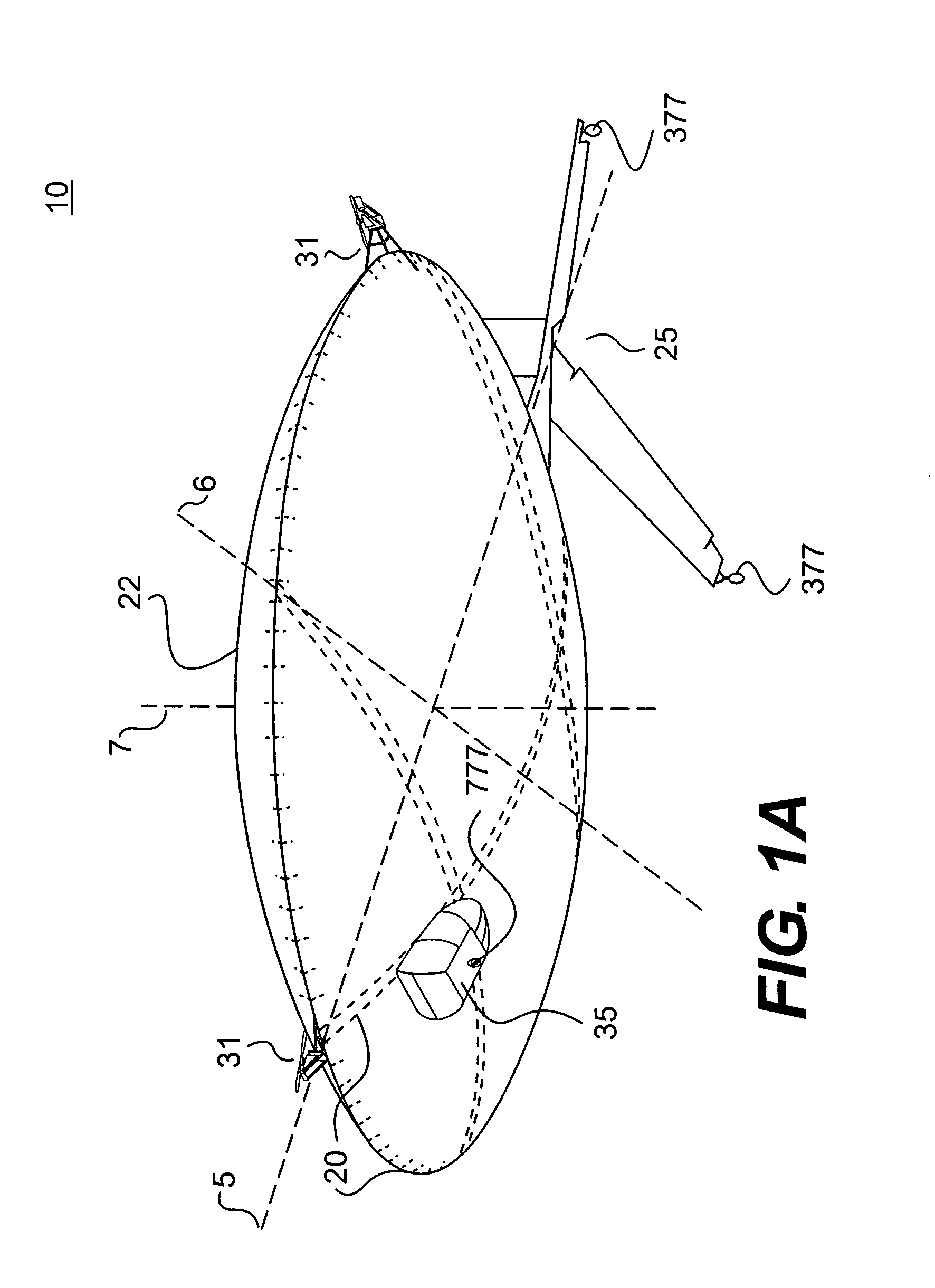

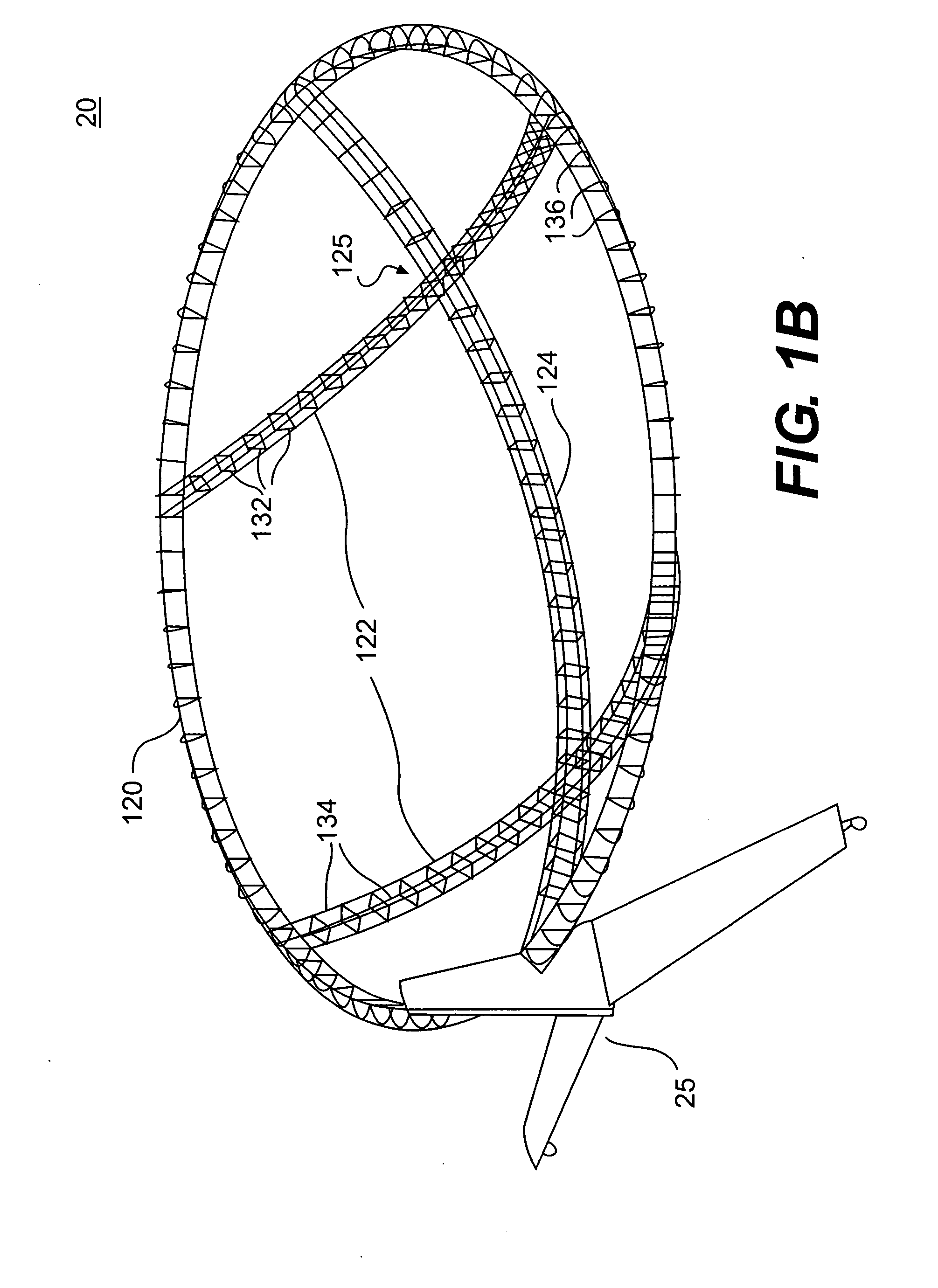

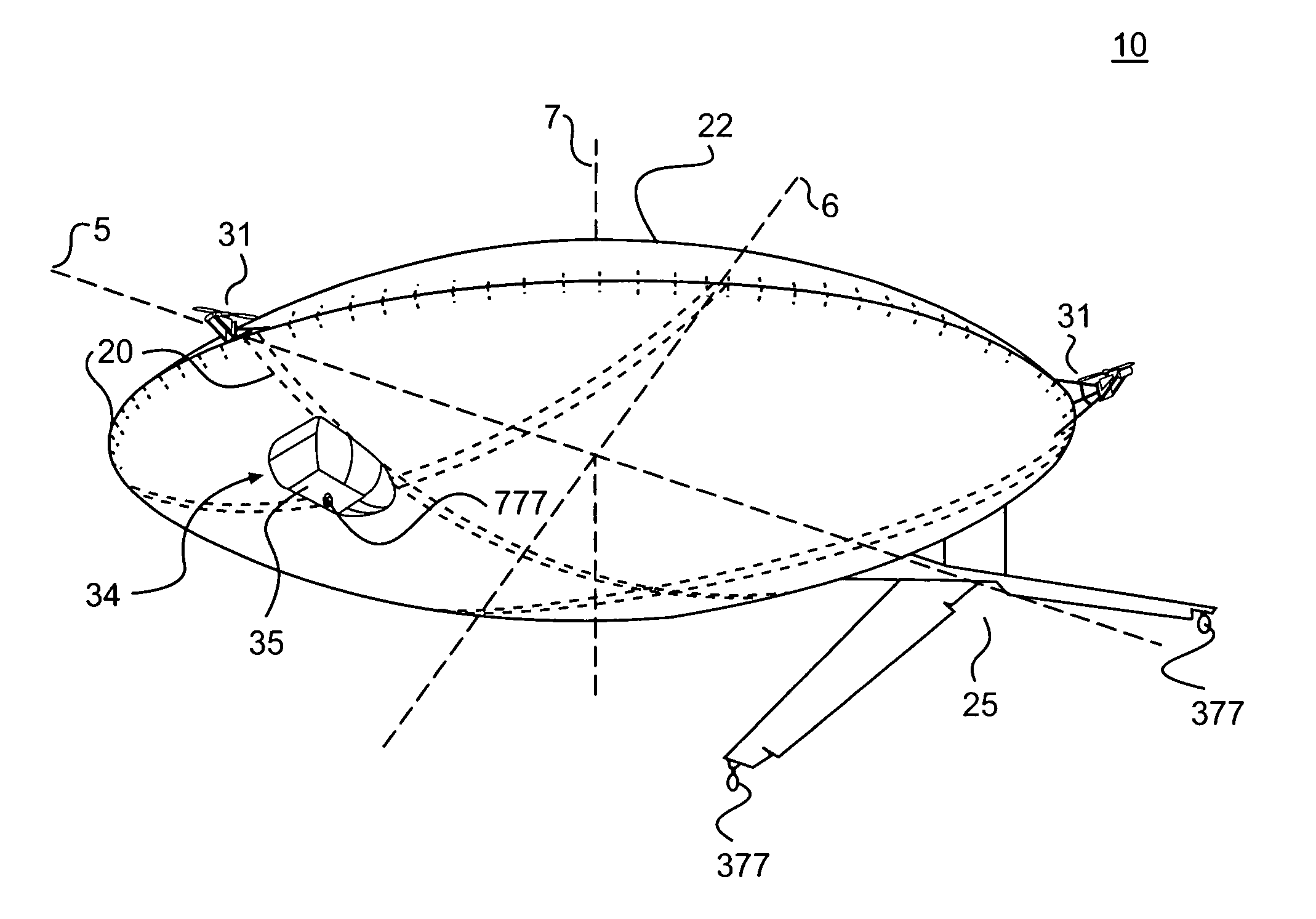

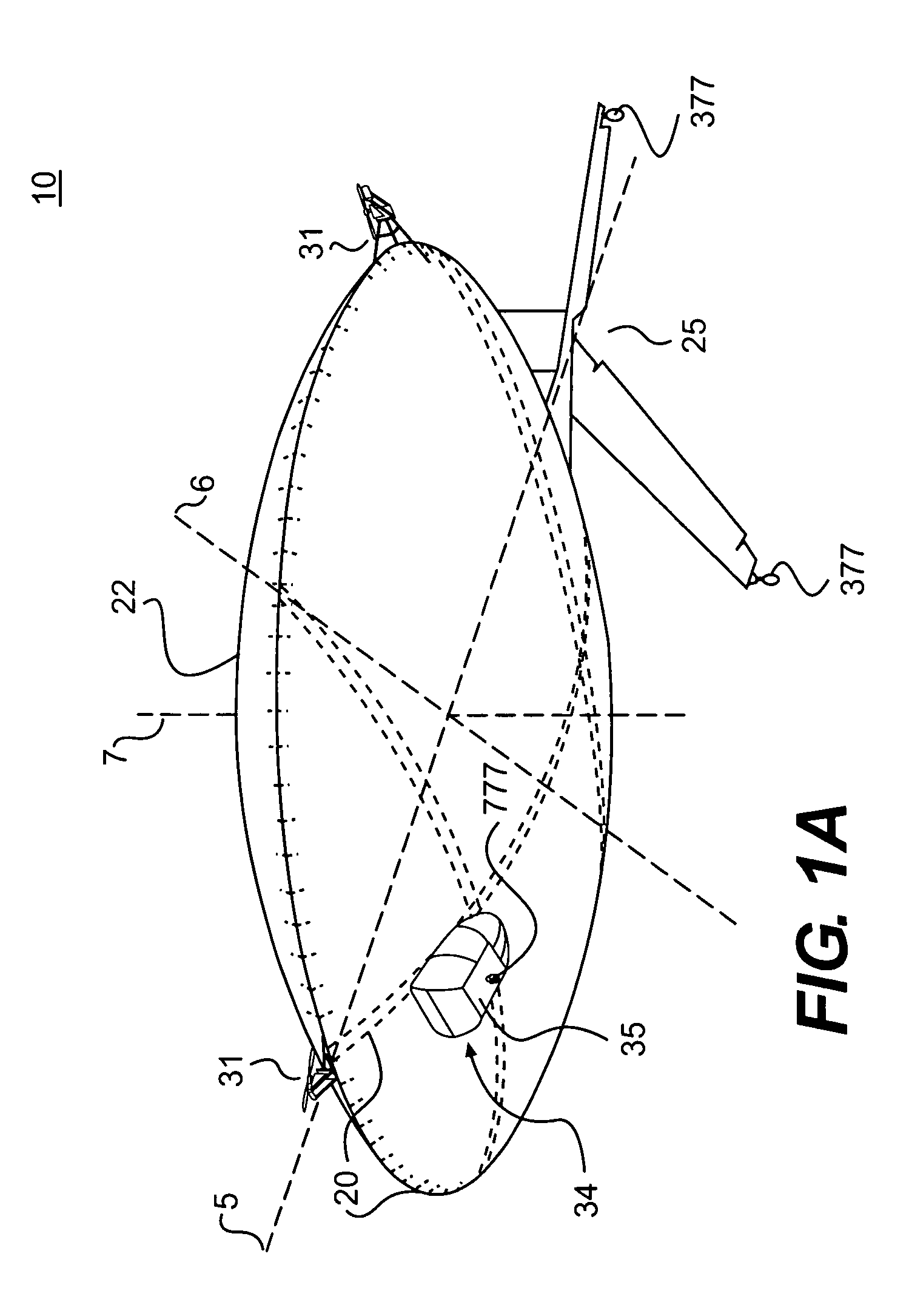

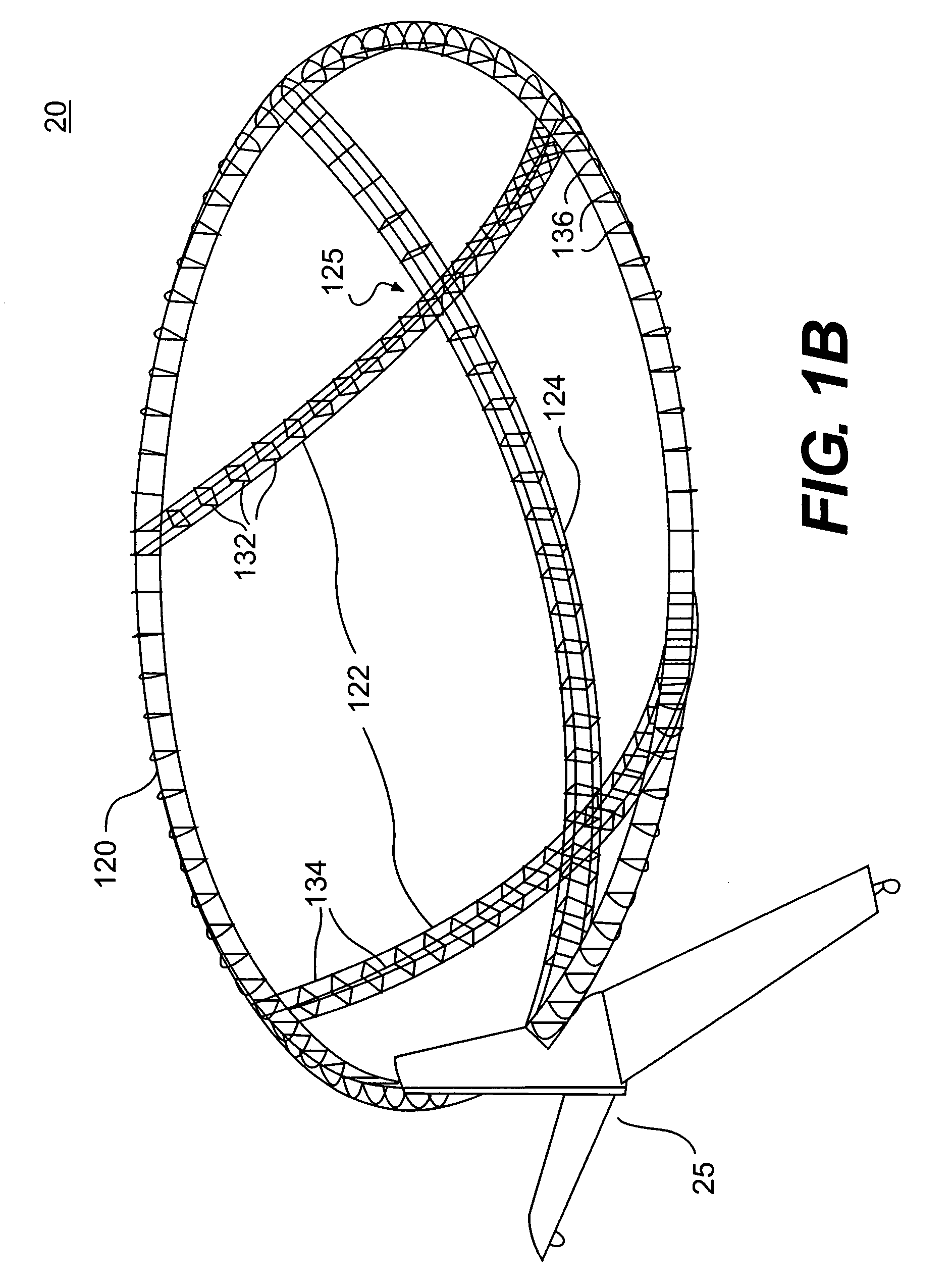

Lenticular airship

InactiveUS20080179454A1Power plant arrangements/mountingAircraft controlOblate spheroidVertical plane

An airship may include a hull substantially shaped as an oblate spheroid, one or more frame members defining a support structure, wherein the support structure forms at least a partial support for the hull, at least one horizontal stabilizing member operably coupled to a lower surface of the airship, and at least one horizontal stabilizing member having a first end and a second end. The at least one horizontal stabilizing member may define an anhedral configuration. The airship may also include a vertical stabilizing member having a first end pivotally coupled to the airship and a second end oriented to remain below an upper surface of the airship. The vertical stabilizing member may be configured to pivot within a vertical plane, and the first end of the vertical stabilizing member and the first end of the at least one horizontal stabilizing member may be operably coupled to one another.

Owner:LTA

Lenticular airship

An airship may include a hull substantially shaped as an oblate spheroid, one or more frame members defining a support structure, wherein the support structure forms at least a partial support for the hull, at least one horizontal stabilizing member operably coupled to a lower surface of the airship, and at least one horizontal stabilizing member having a first end and a second end. The at least one horizontal stabilizing member may define an anhedral configuration. The airship may also include a vertical stabilizing member having a first end pivotally coupled to the airship and a second end oriented to remain below an upper surface of the airship. The vertical stabilizing member may be configured to pivot within a vertical plane, and the first end of the vertical stabilizing member and the first end of the at least one horizontal stabilizing member may be operably coupled to one another.

Owner:LTA

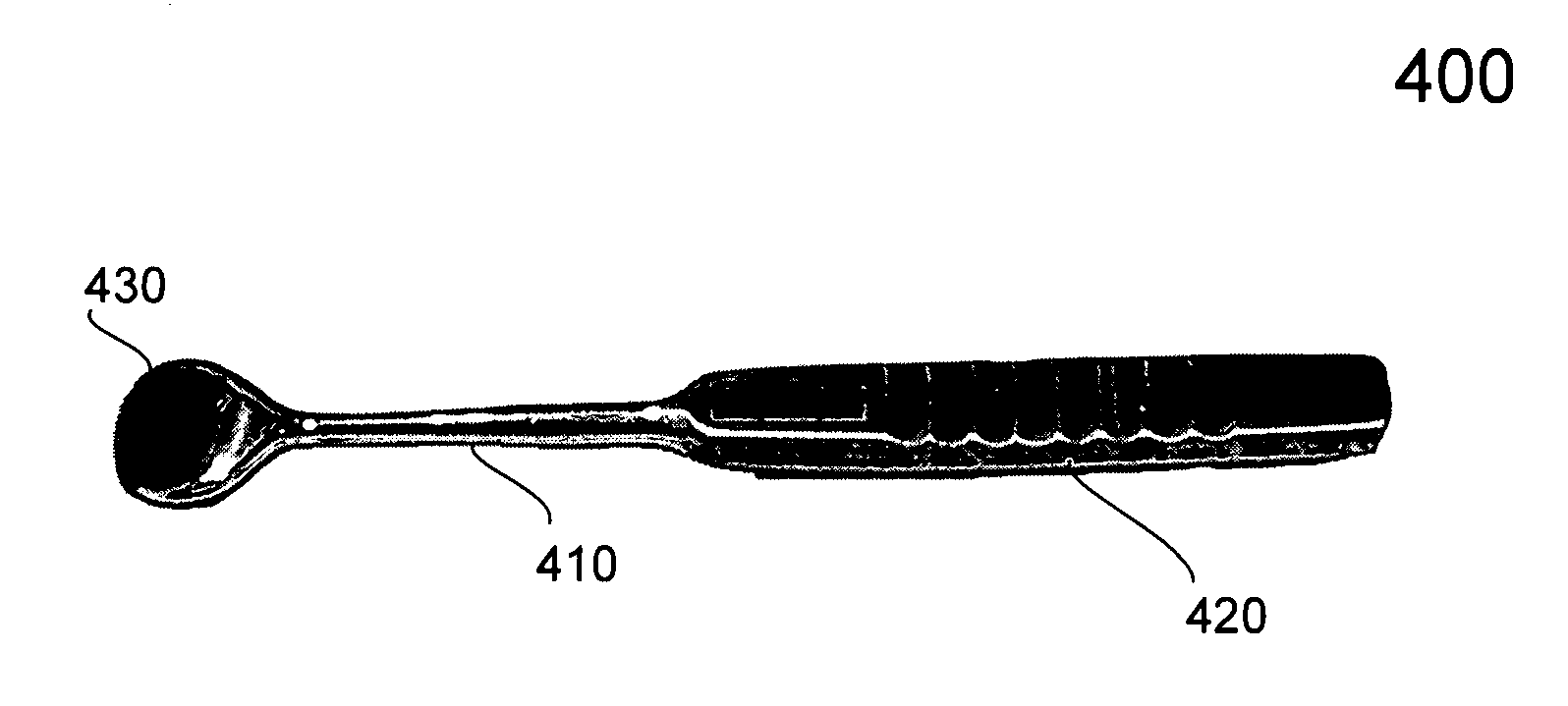

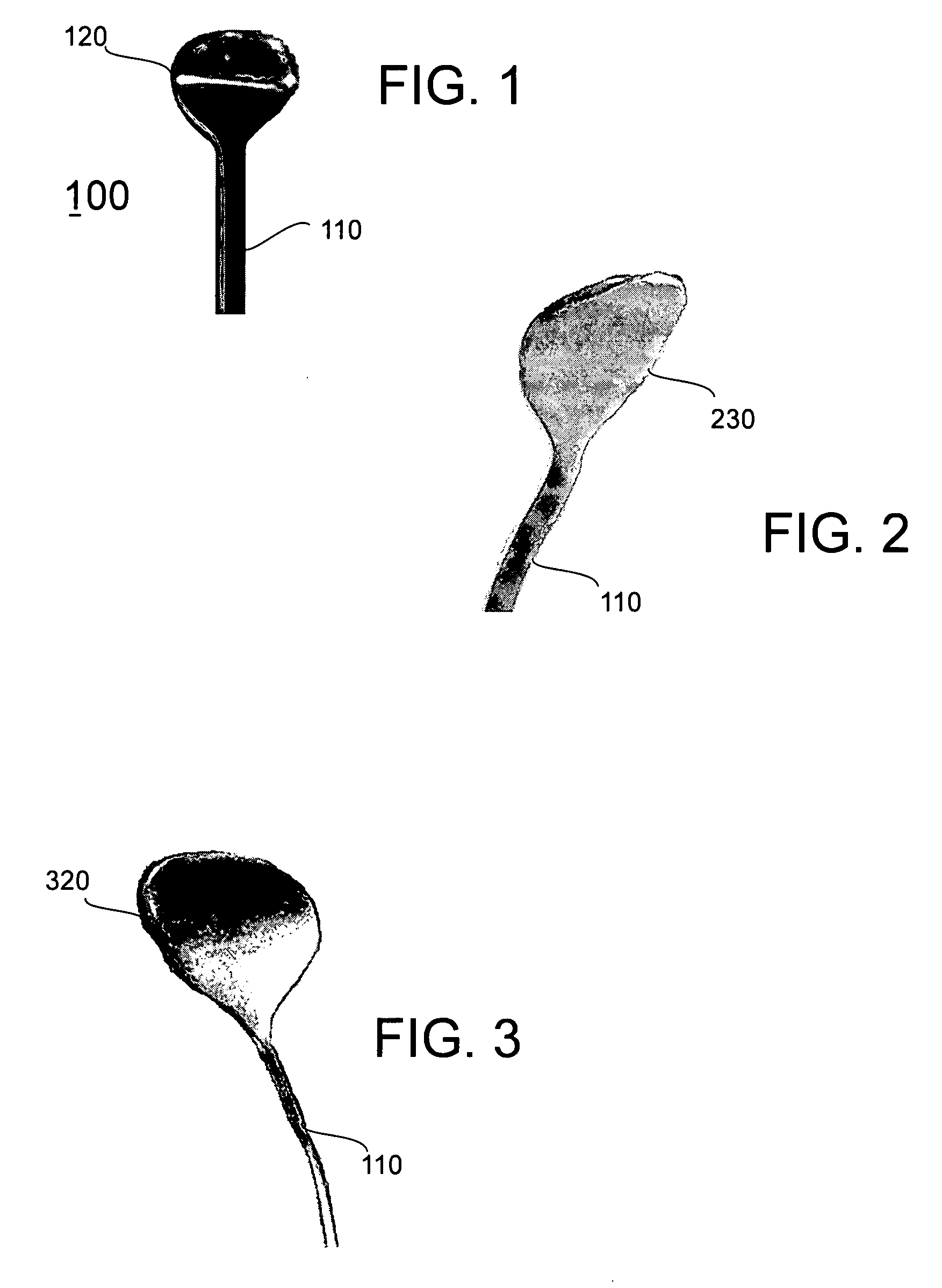

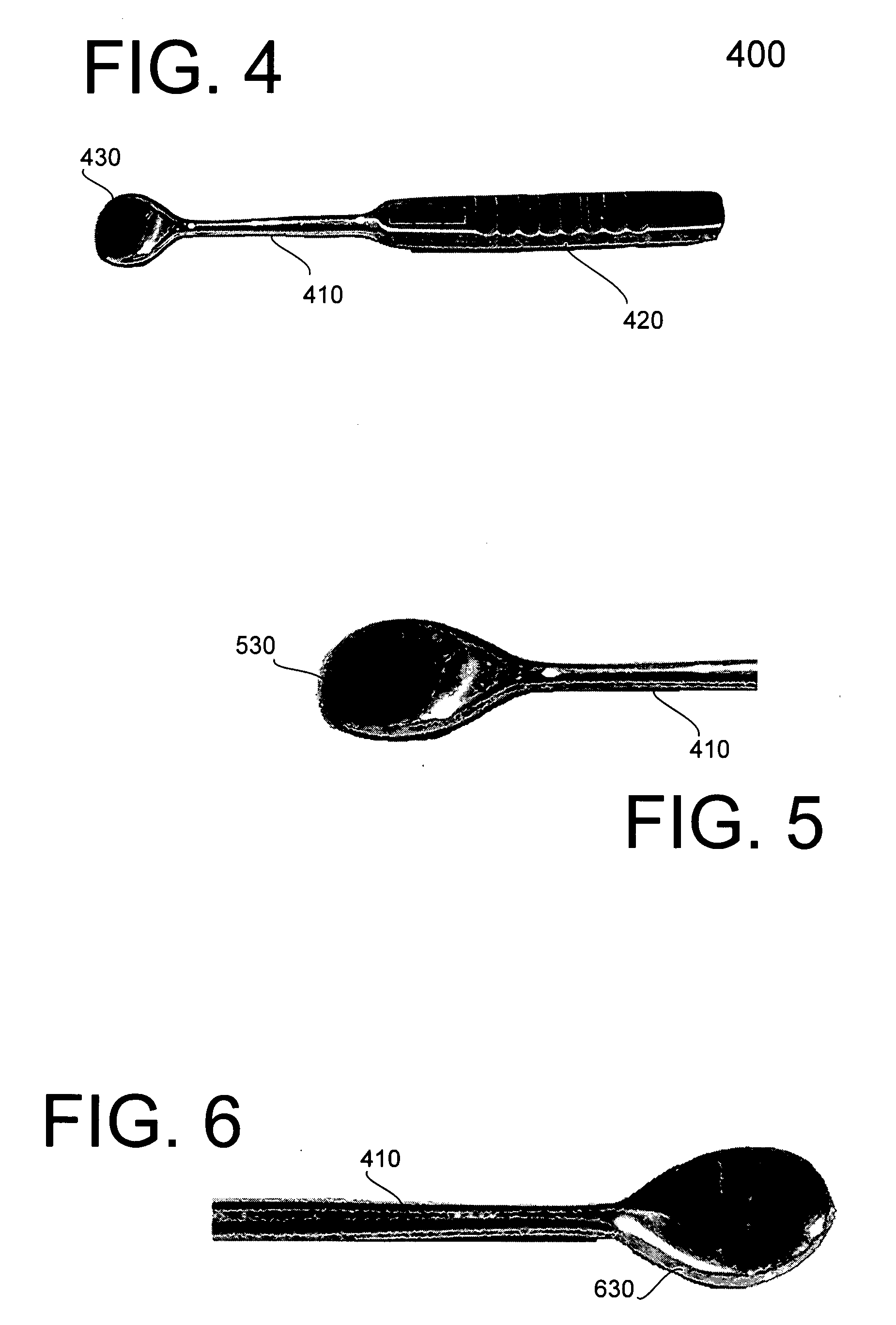

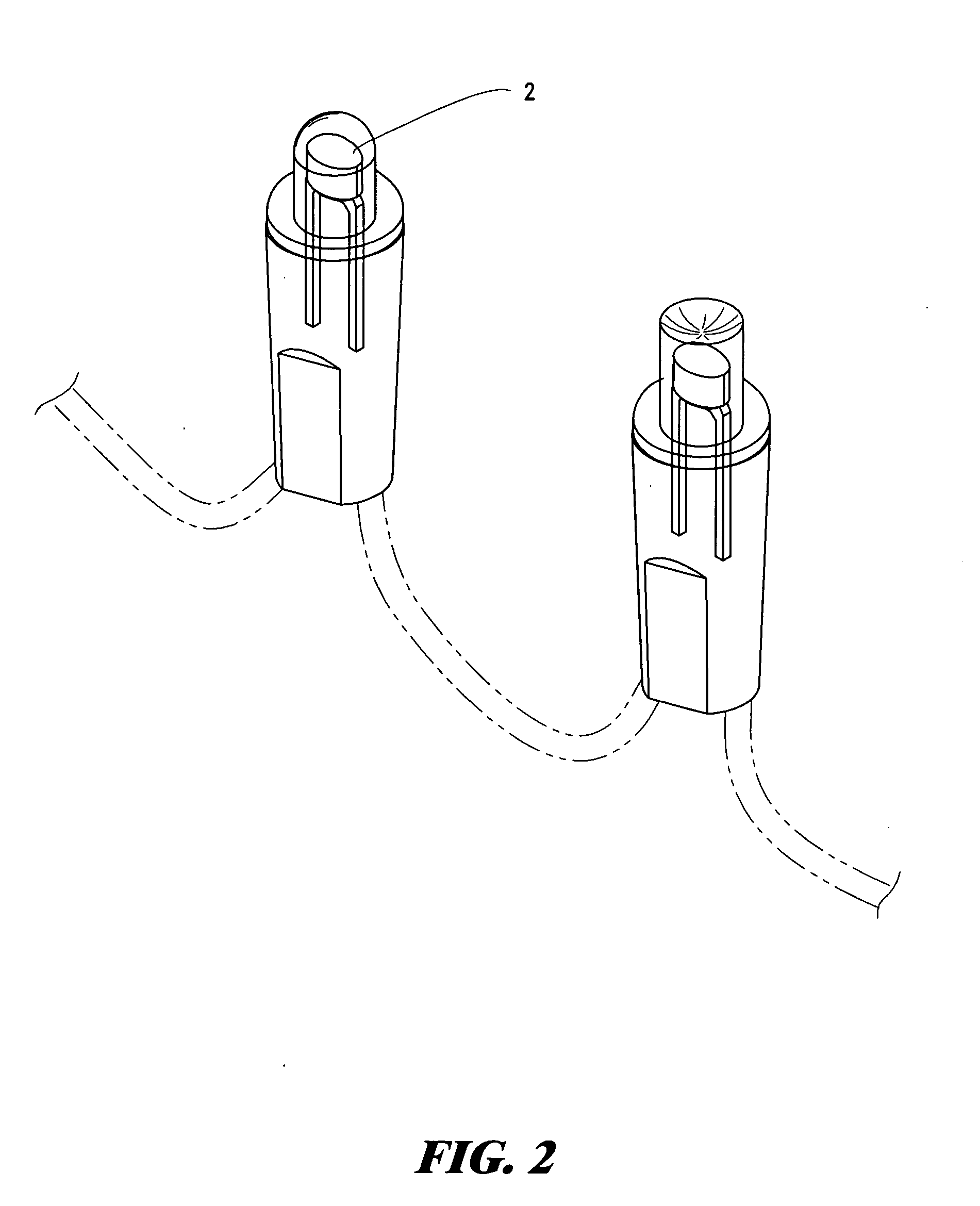

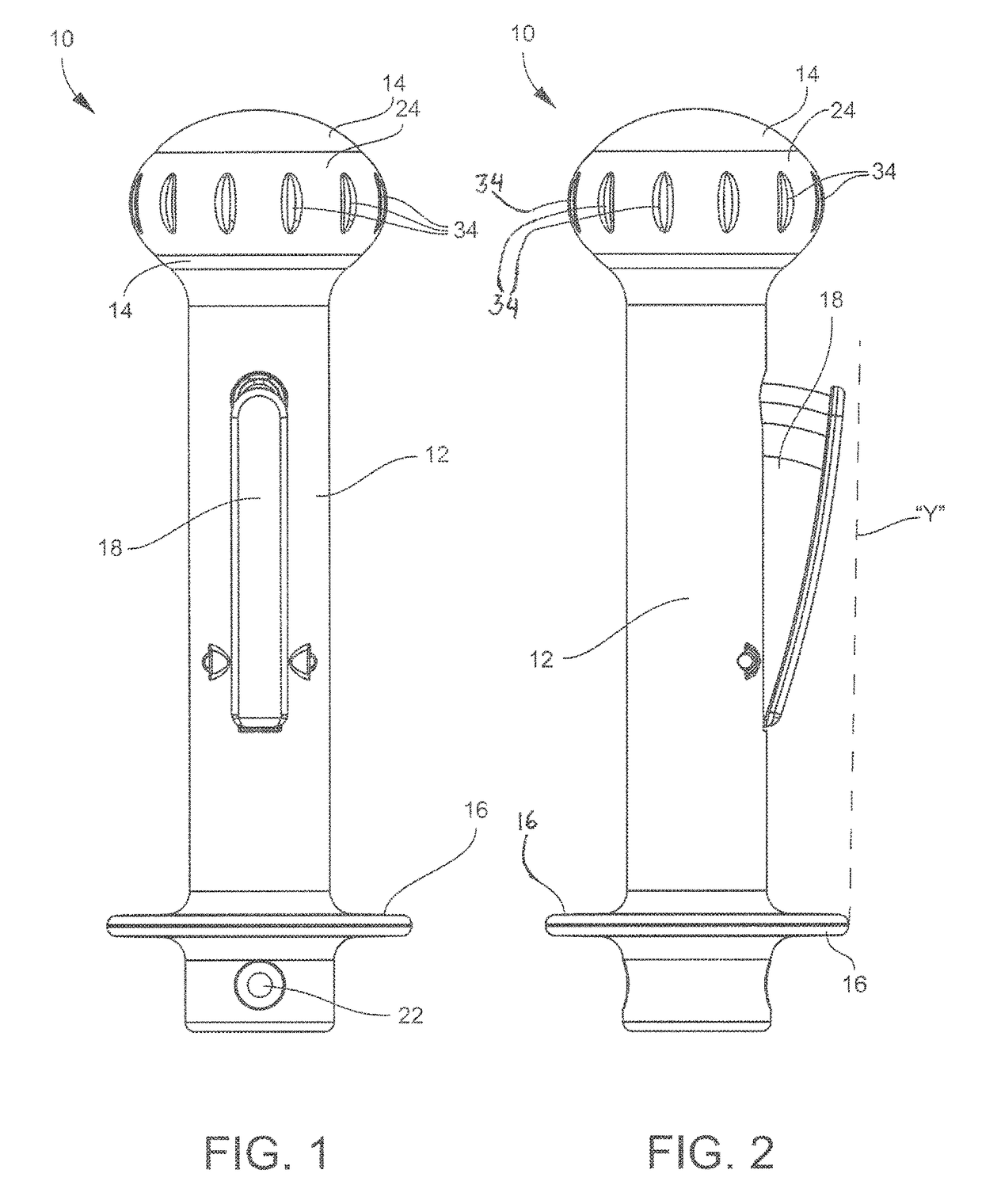

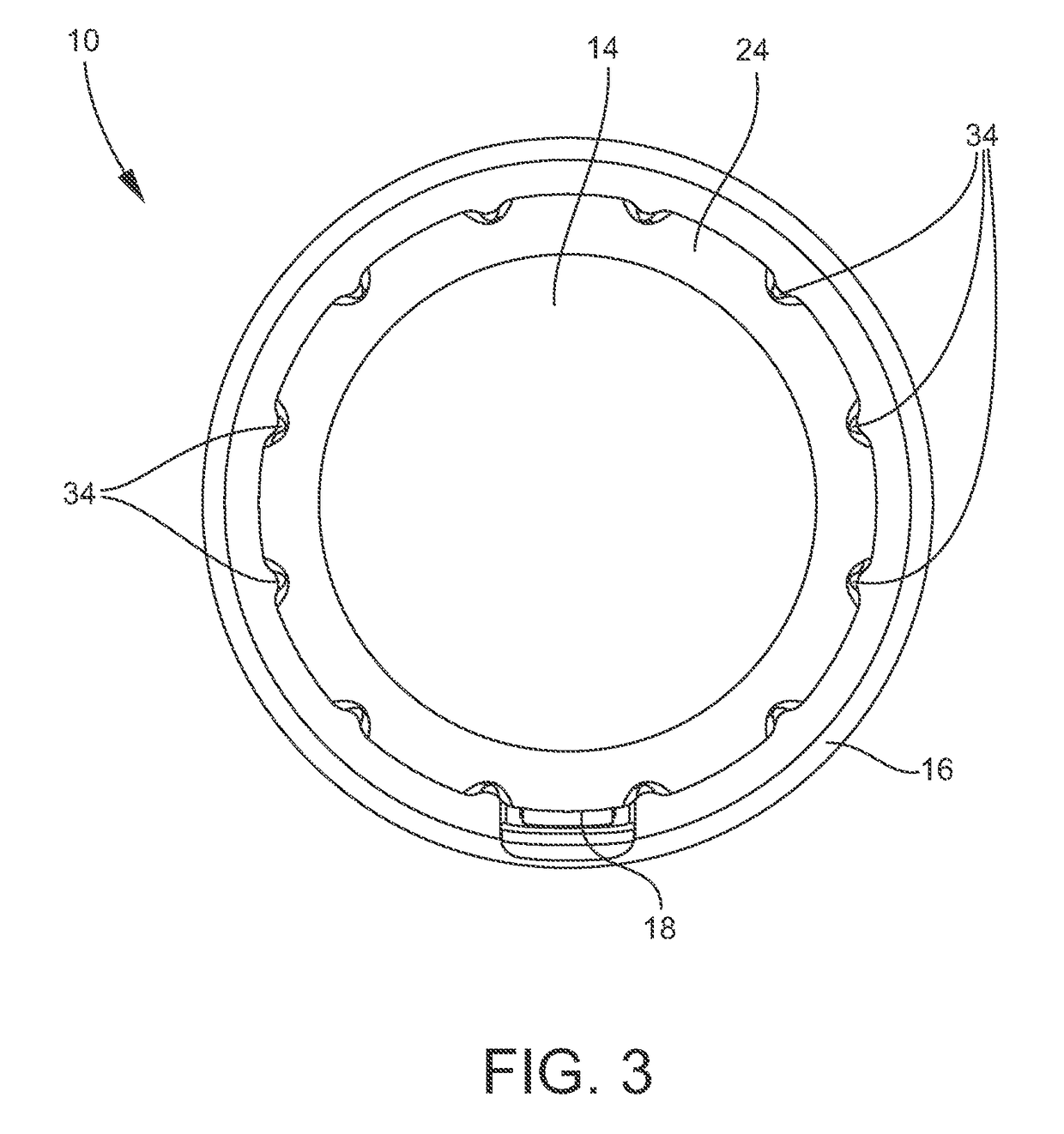

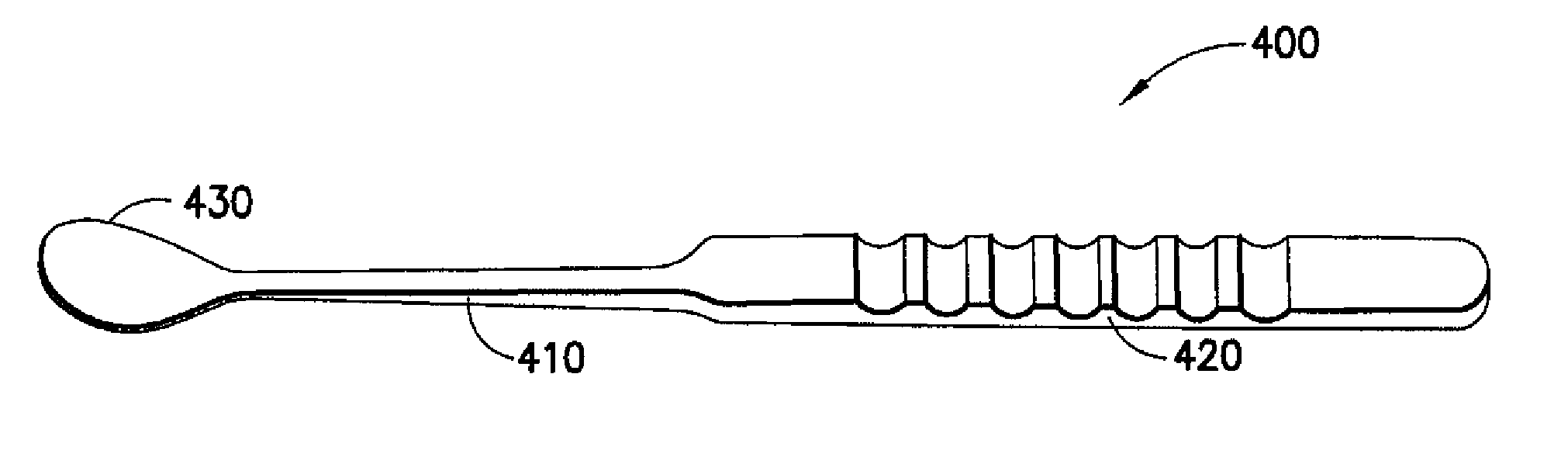

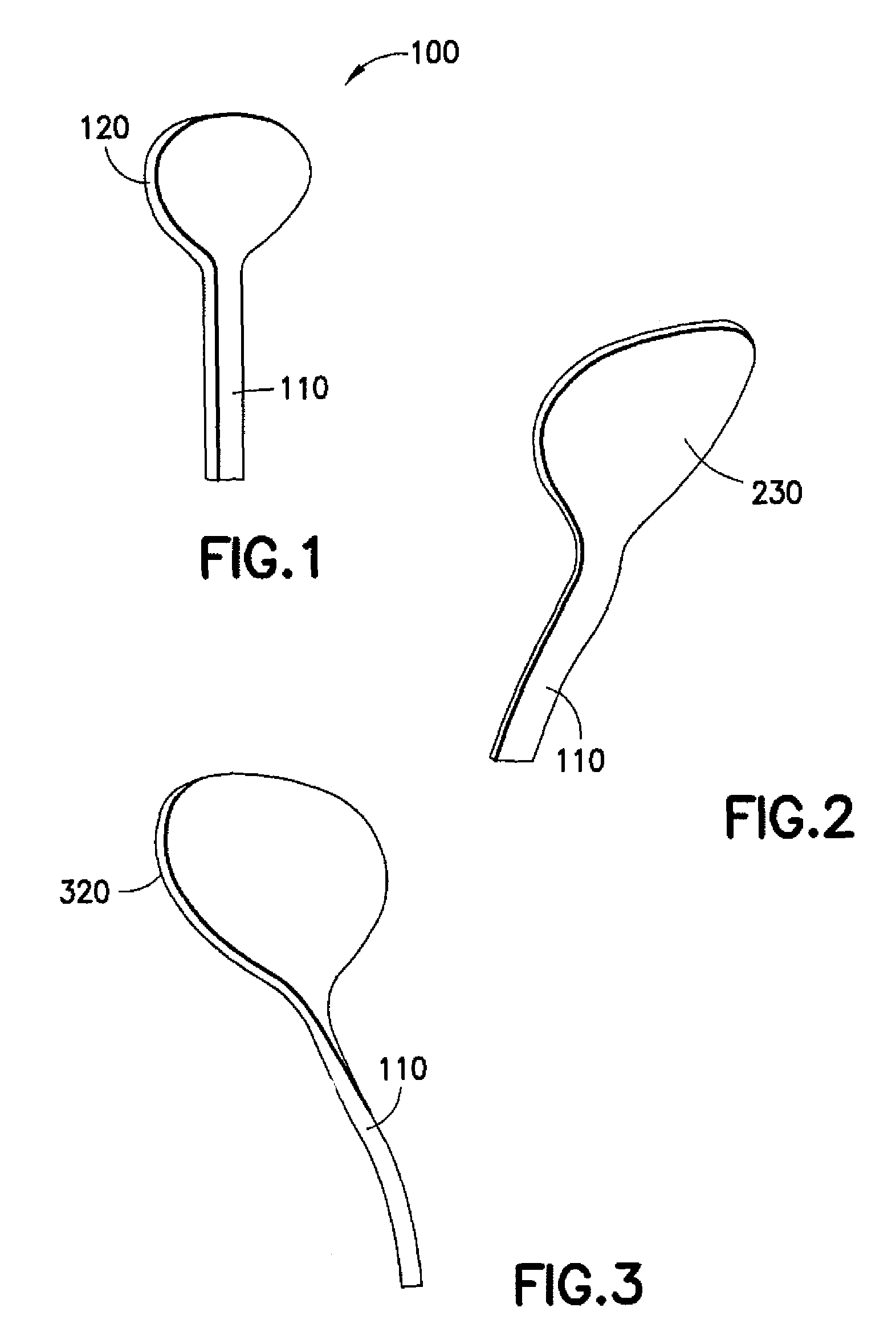

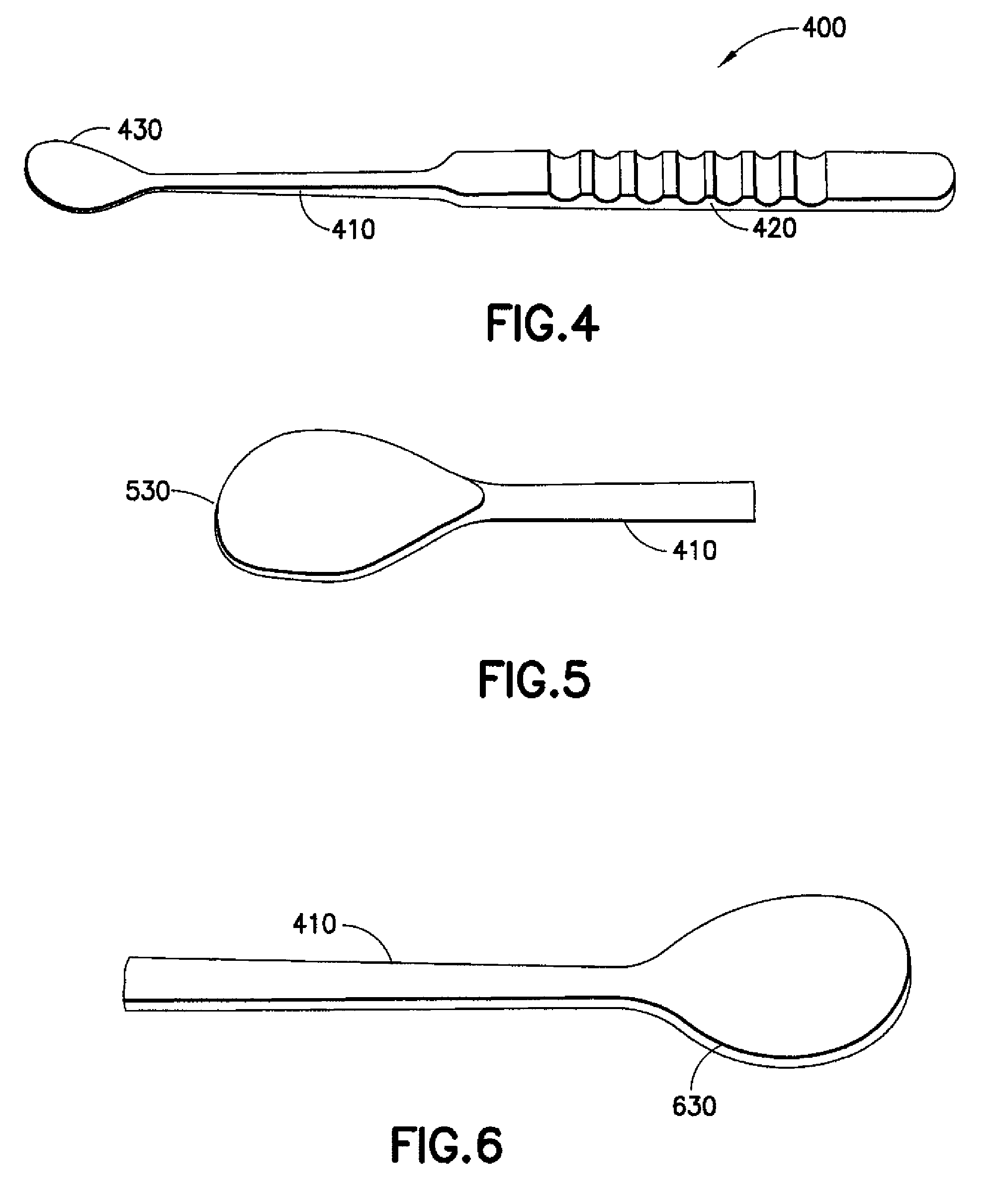

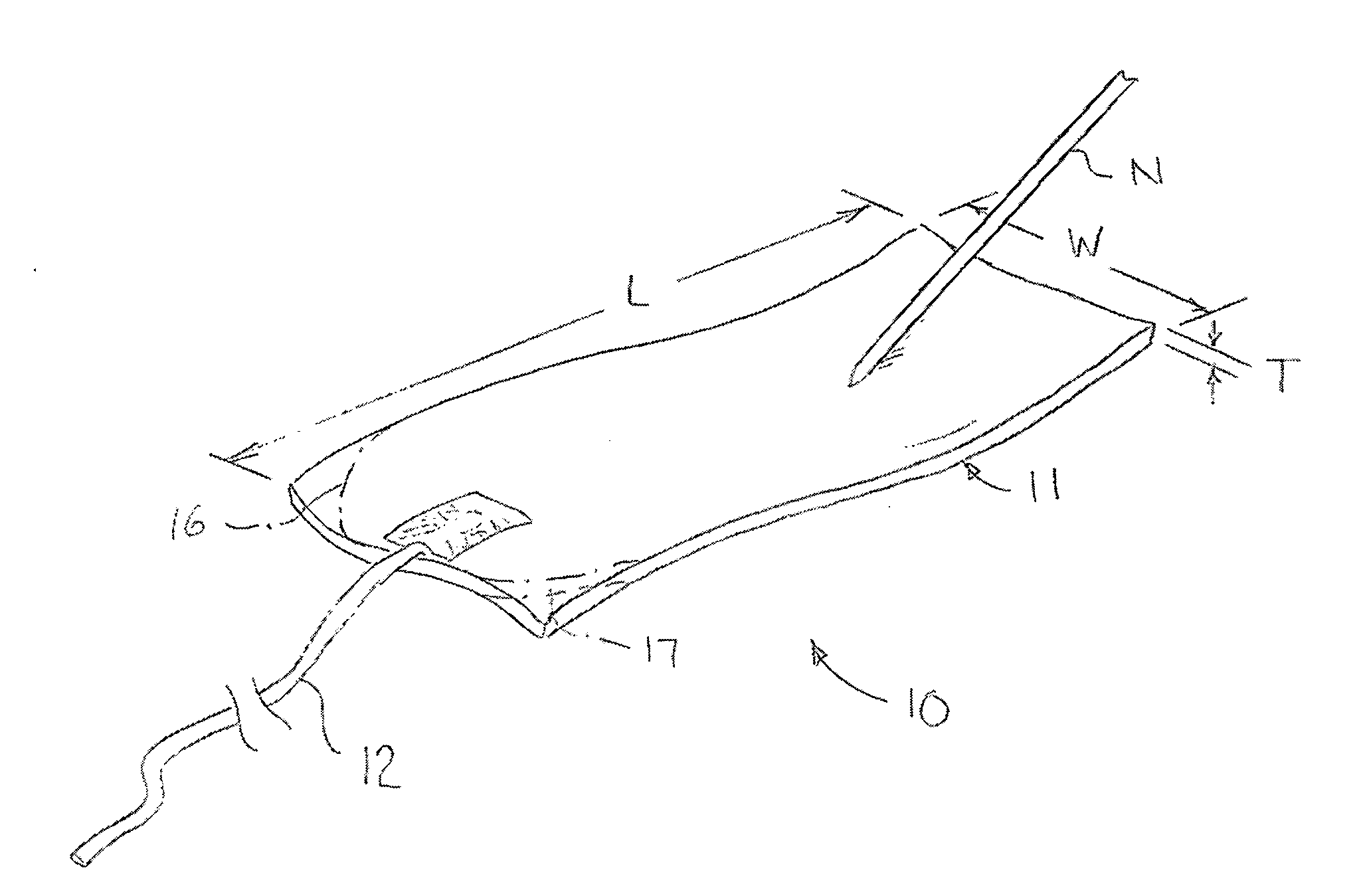

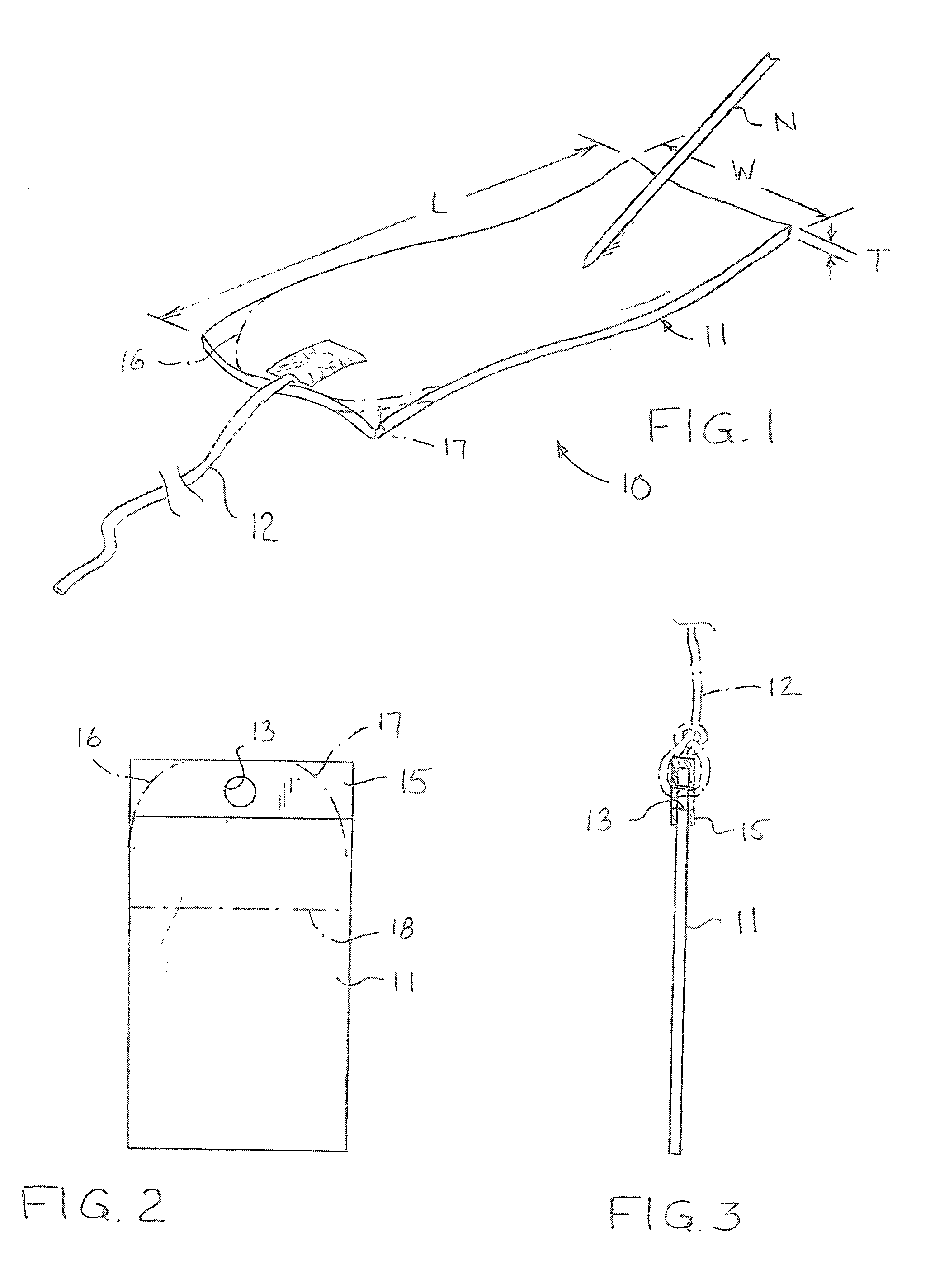

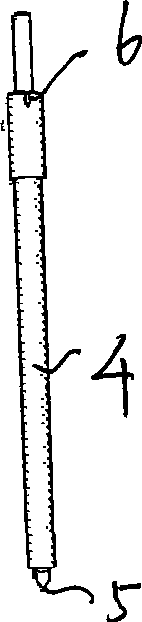

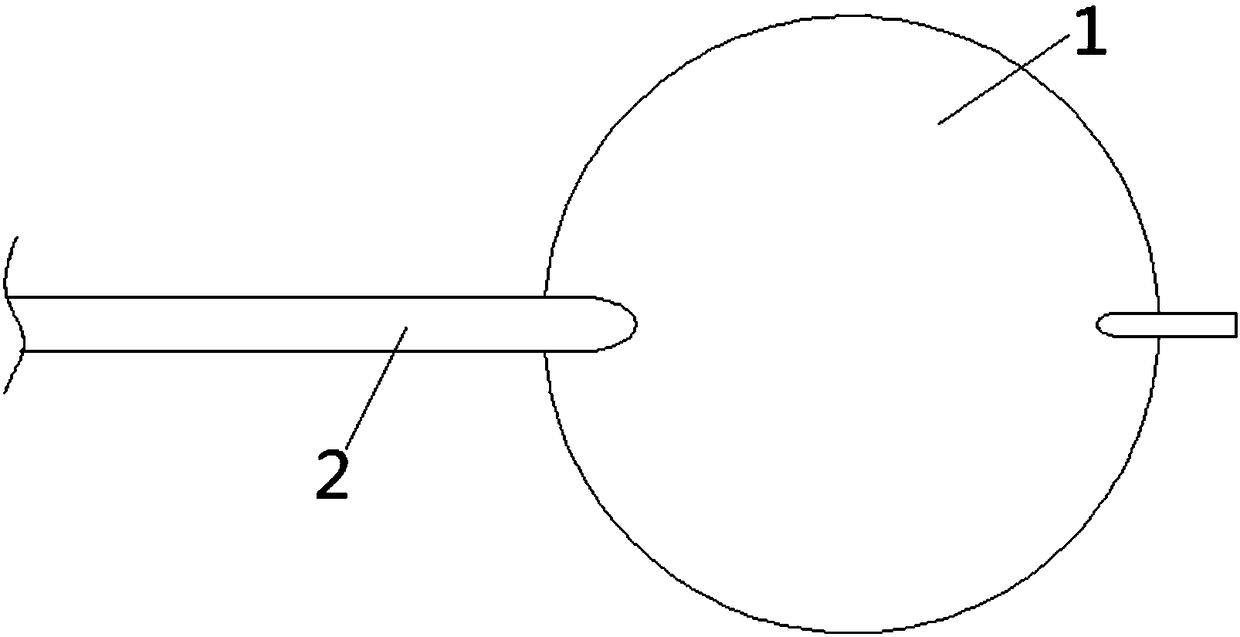

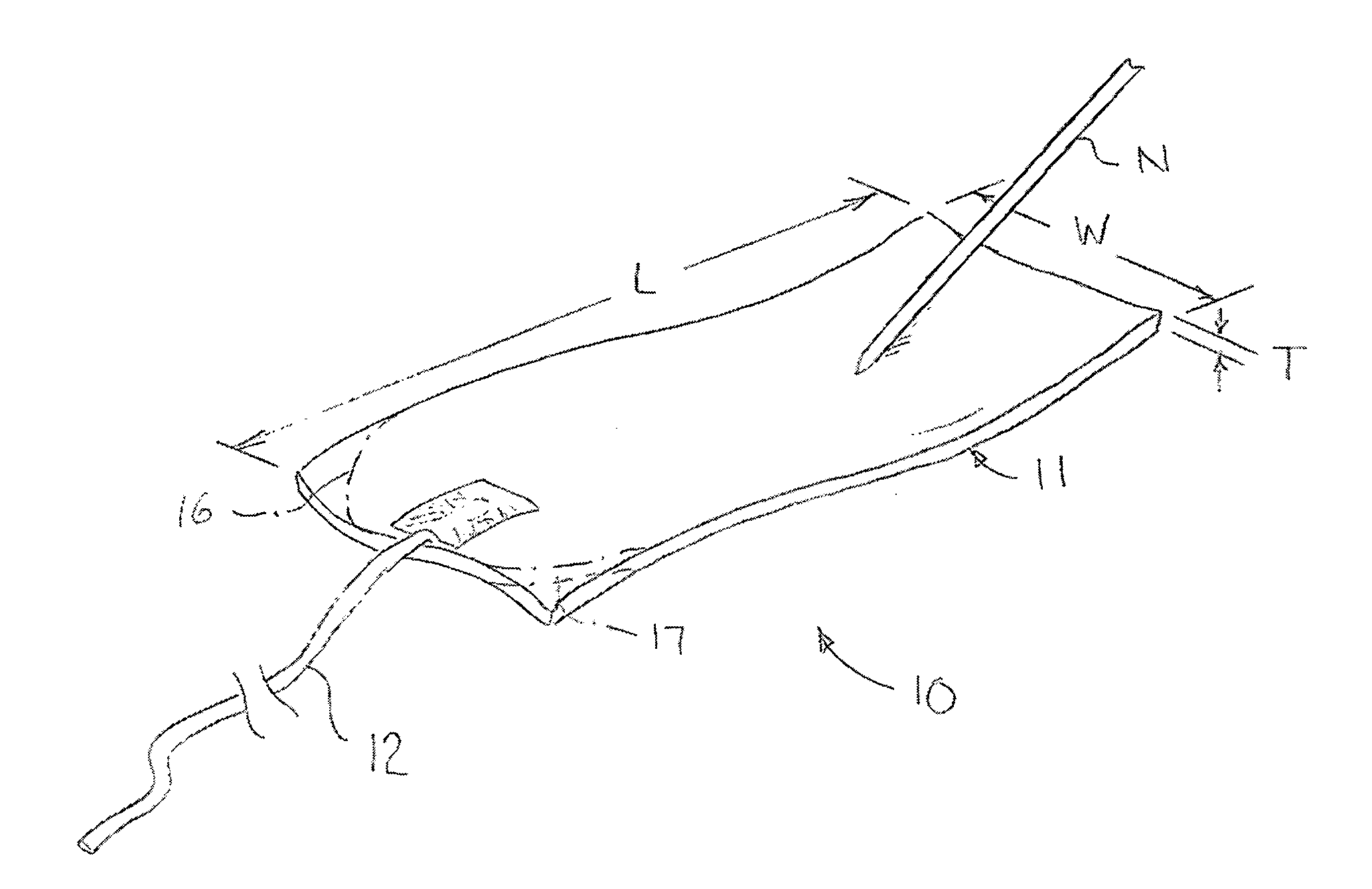

Scleral depressor

ActiveUS20080081952A1Easy to controlAdequate visualizationSurgeryEye diagnosticsOblate spheroidEngineering

A scleral depressor designed to better control the globe of the eye is disclosed. In a preferred embodiment, the scleral depressor has a handle and a blade attached to the handle where the blade is a portion of an oblate spheroid. In one embodiment, the blade has an illuminating device. The handle is attached to the blade at an angle or straight in relation to the plane of the handle. In another embodiment, the blade is attached to a thimble. In another embodiment of the invention, the blade has an access hole for simultaneous use of other instruments during examination or surgery. The resulting apparatus has greatly improved control of the eye, effective visualization of the periphery, ease of use for the examiner, and increased comfort for the patient.

Owner:JOSEPHBERG ROBERT G +1

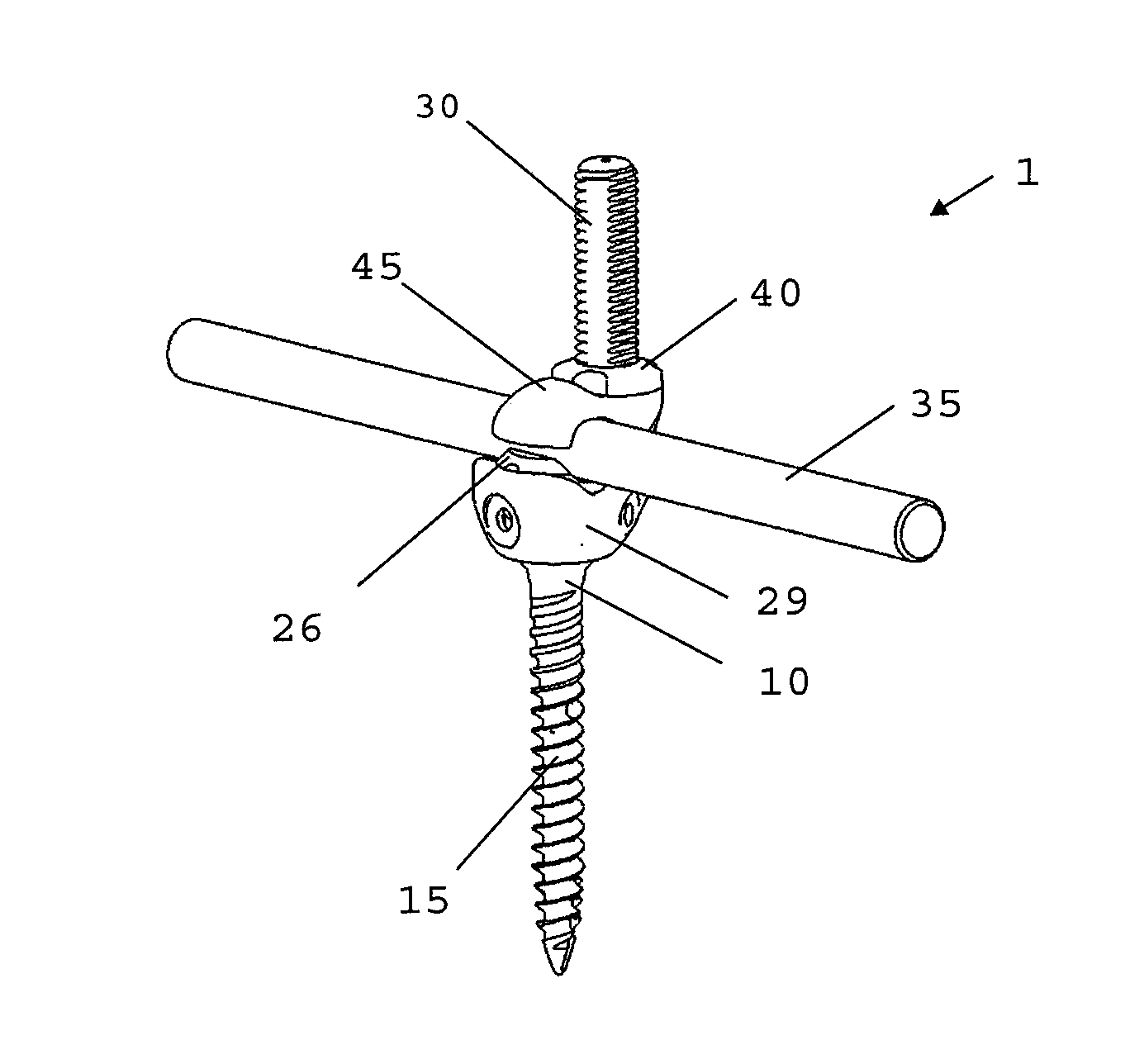

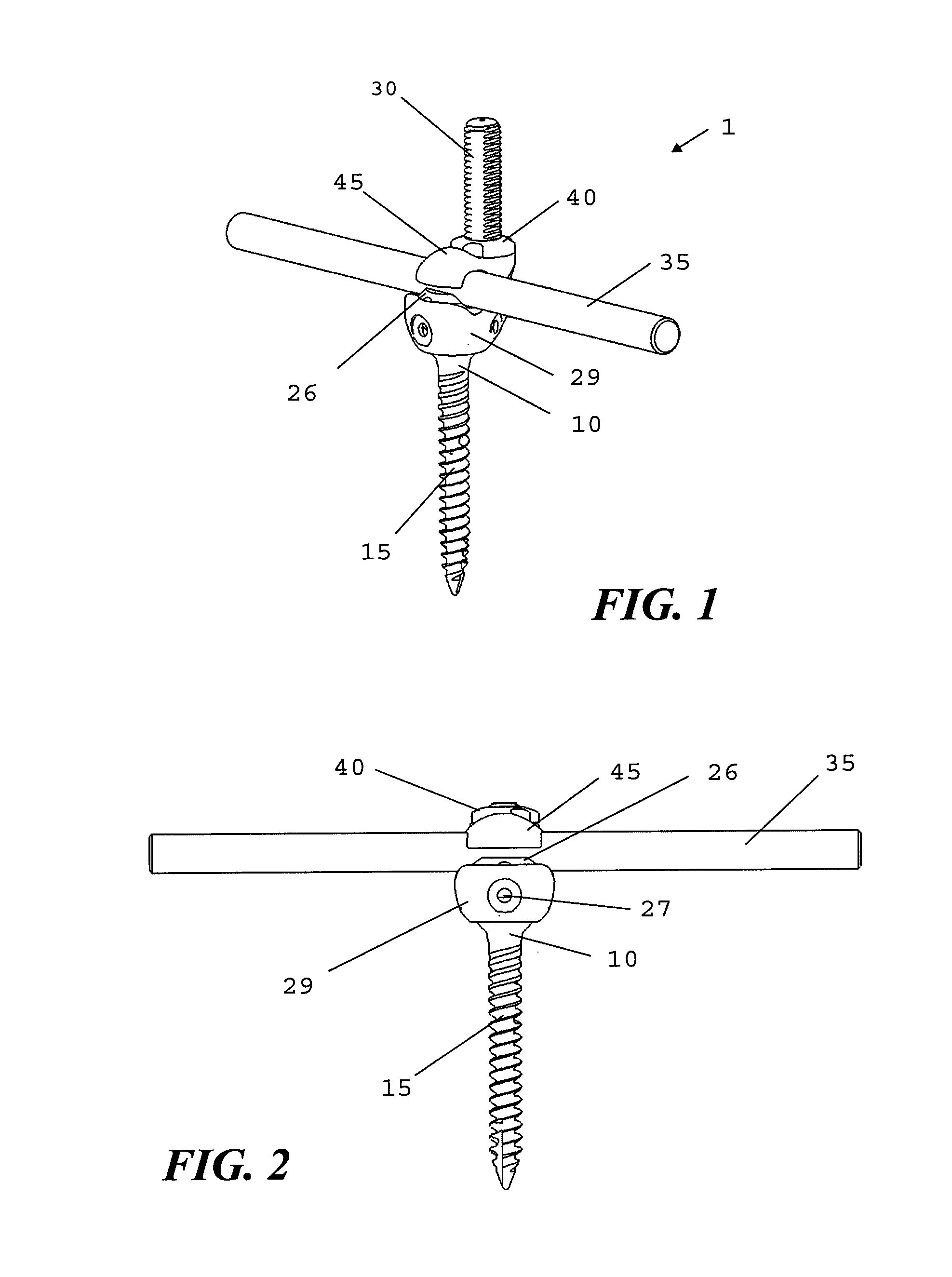

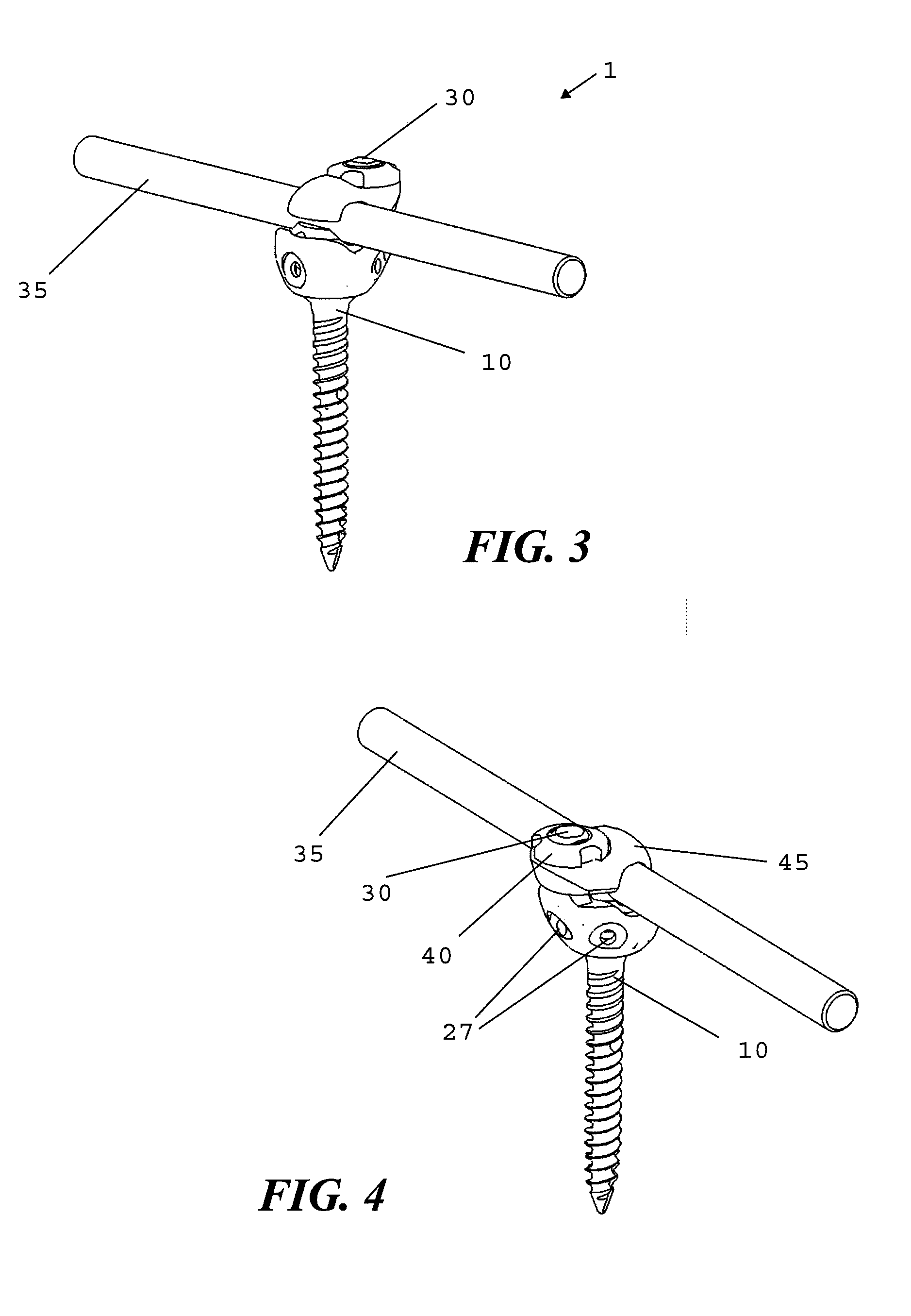

Bone anchoring member with clamp mechanism

A multi-piece disc replacement implant for replacing a disc removed by a discectomy including an upper plate member, a lower plate member, and an intermediate resilient member providing movement between te two plate members replicating the natural movement of the spine. The plate members are rigid and have orthogonal sidewalls forming an enclosure. The resilient member is an elastic solid or a multi-chamber balloon structure of fluid-filled sacks that collectively define a non-uniform shape such as an oblate spheroid, or a helically coiled string of beads. Such an implant is capable of supporting the compressive and cyclic loads required of a natural disc. The upper and lower plate members are cooperatively formed to selectively limit the allowable range of motion in any given direction and a provided with protrusions to be received in one or more channels cooperatively formed in the vertebrae and secured in place by a bone screw.

Owner:ELIASEN KENNETH ARDEN +2

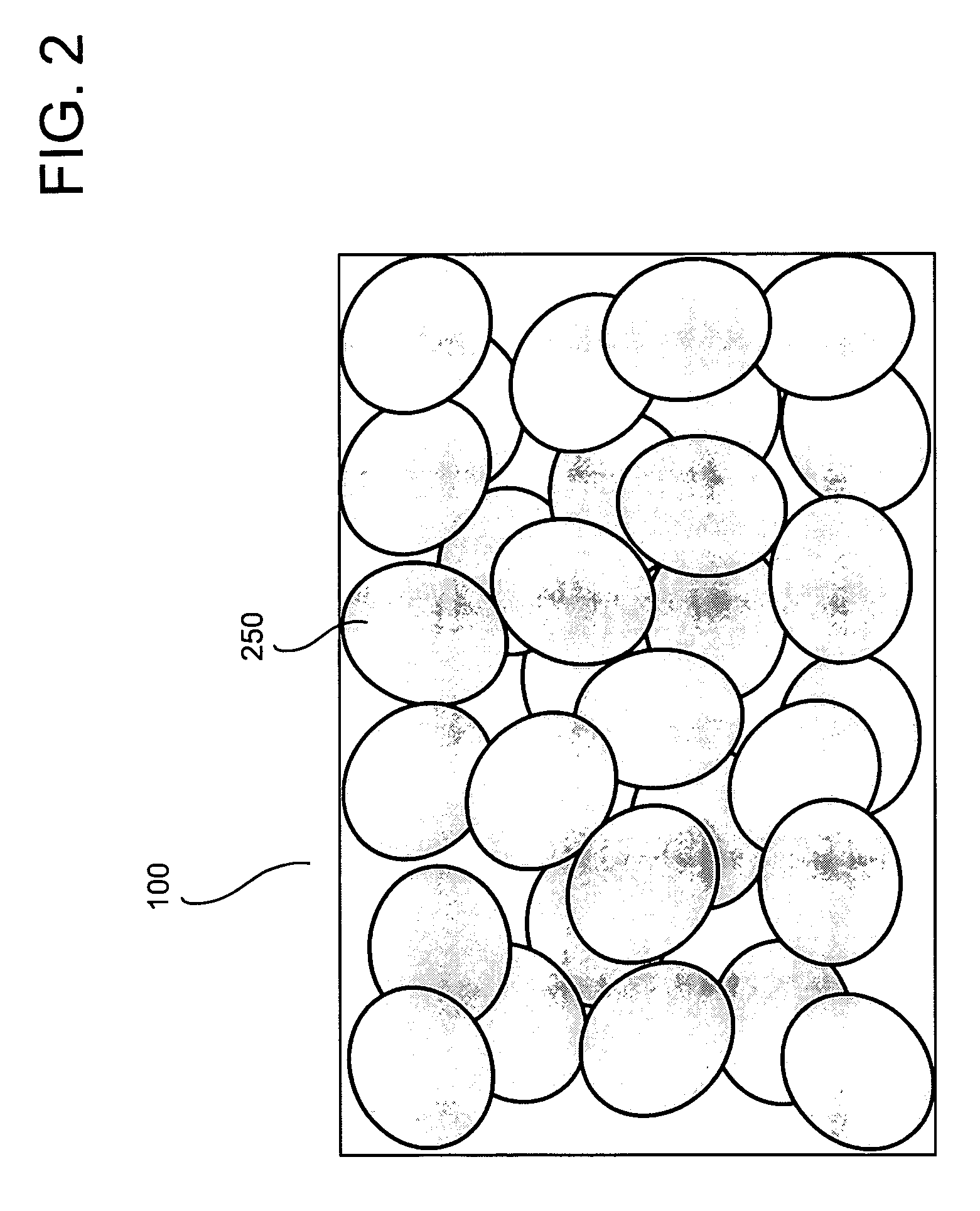

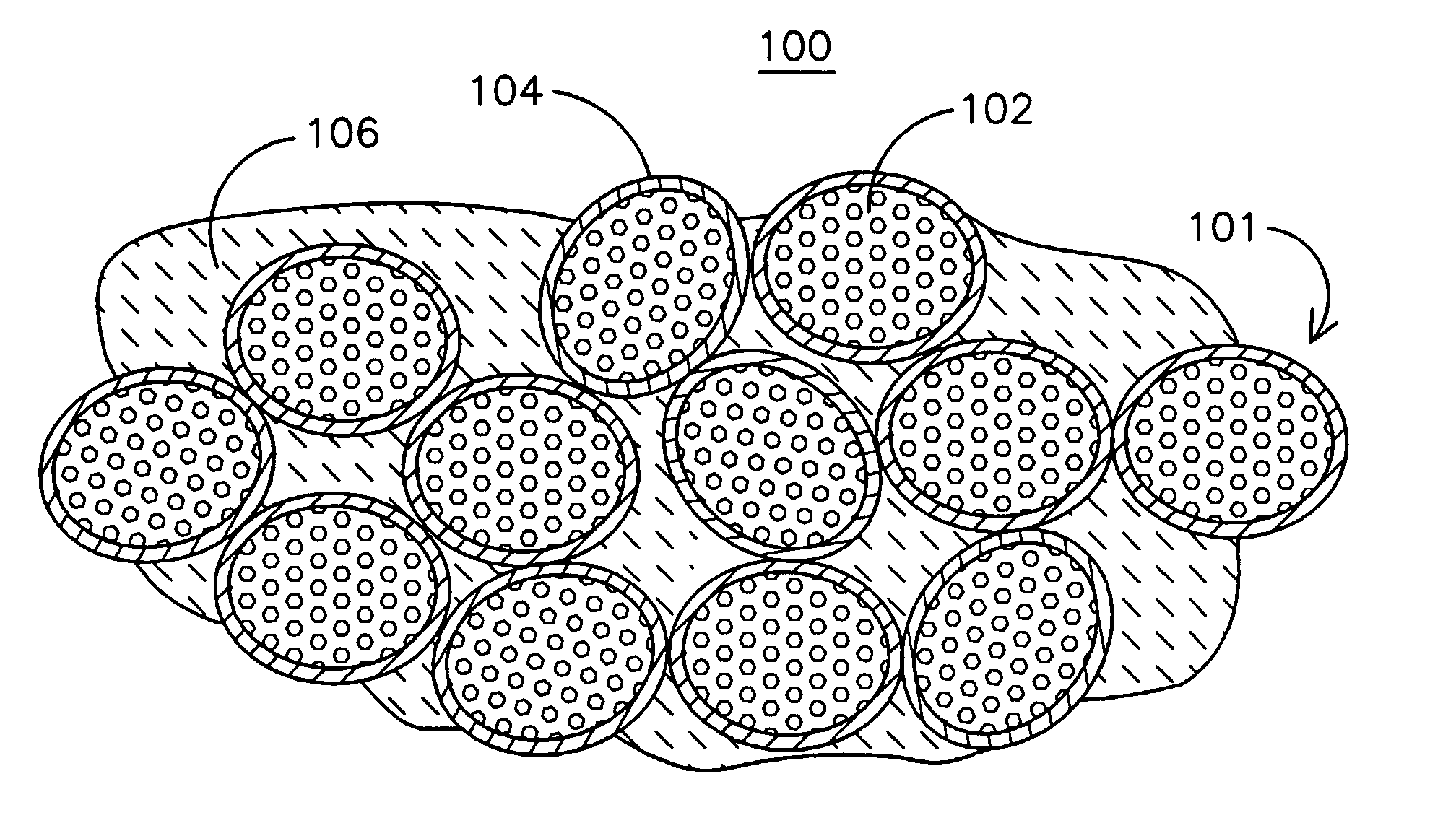

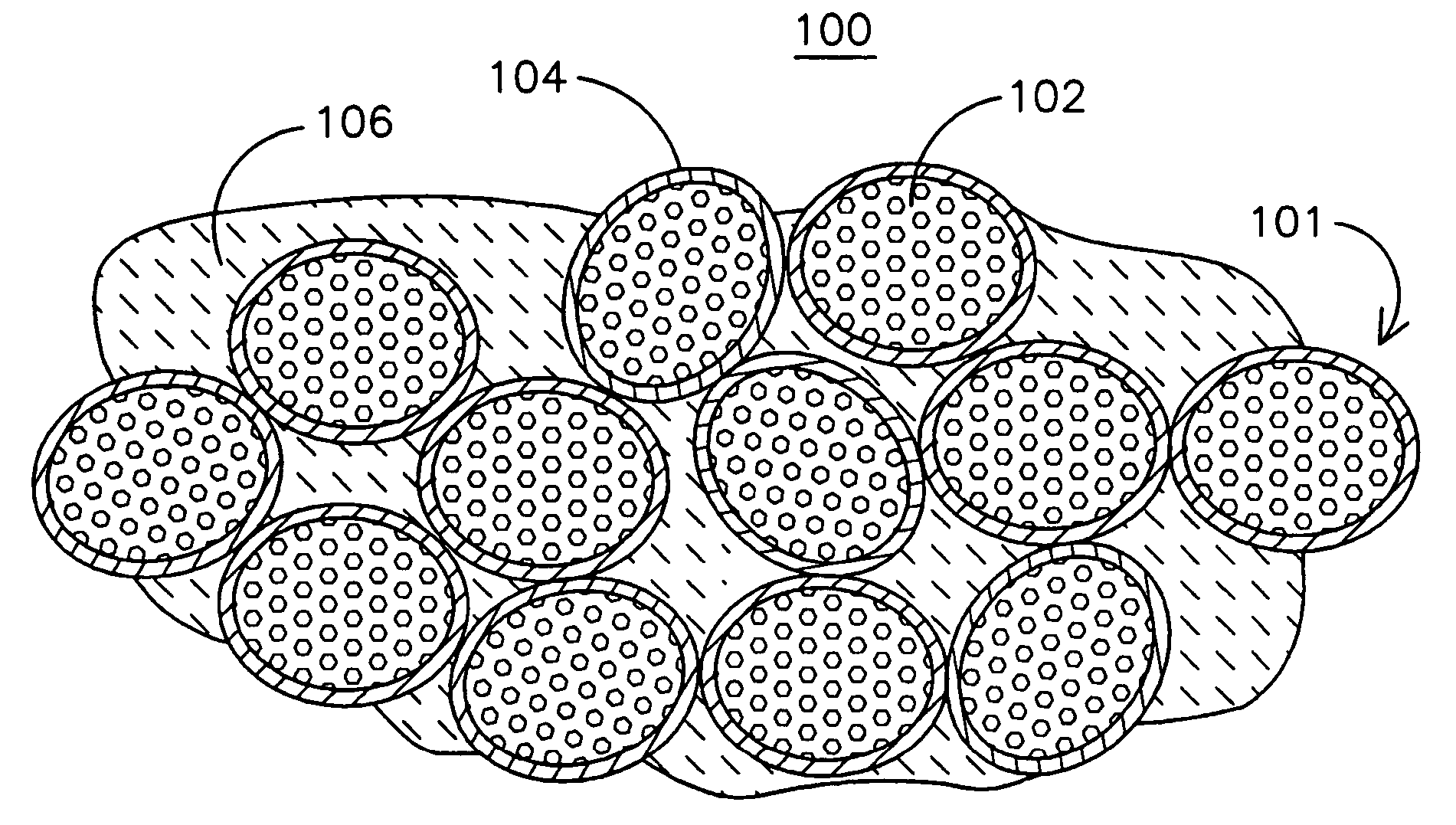

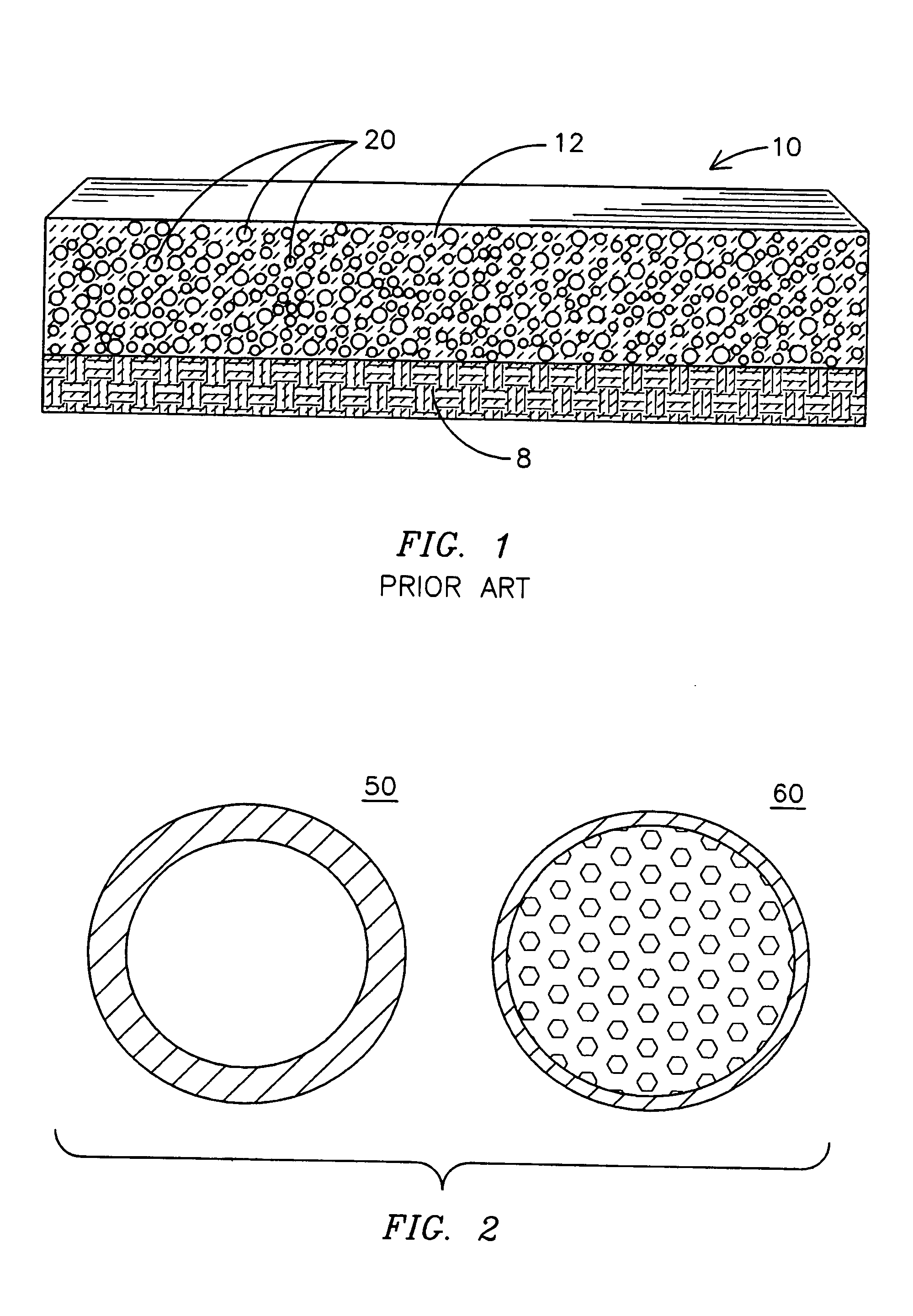

Insulating ceramic based on partially filled shapes

ActiveUS7067181B2Reduced effectivenessMore materialRecord information storagePreformed elementsOblate spheroidWear resistance

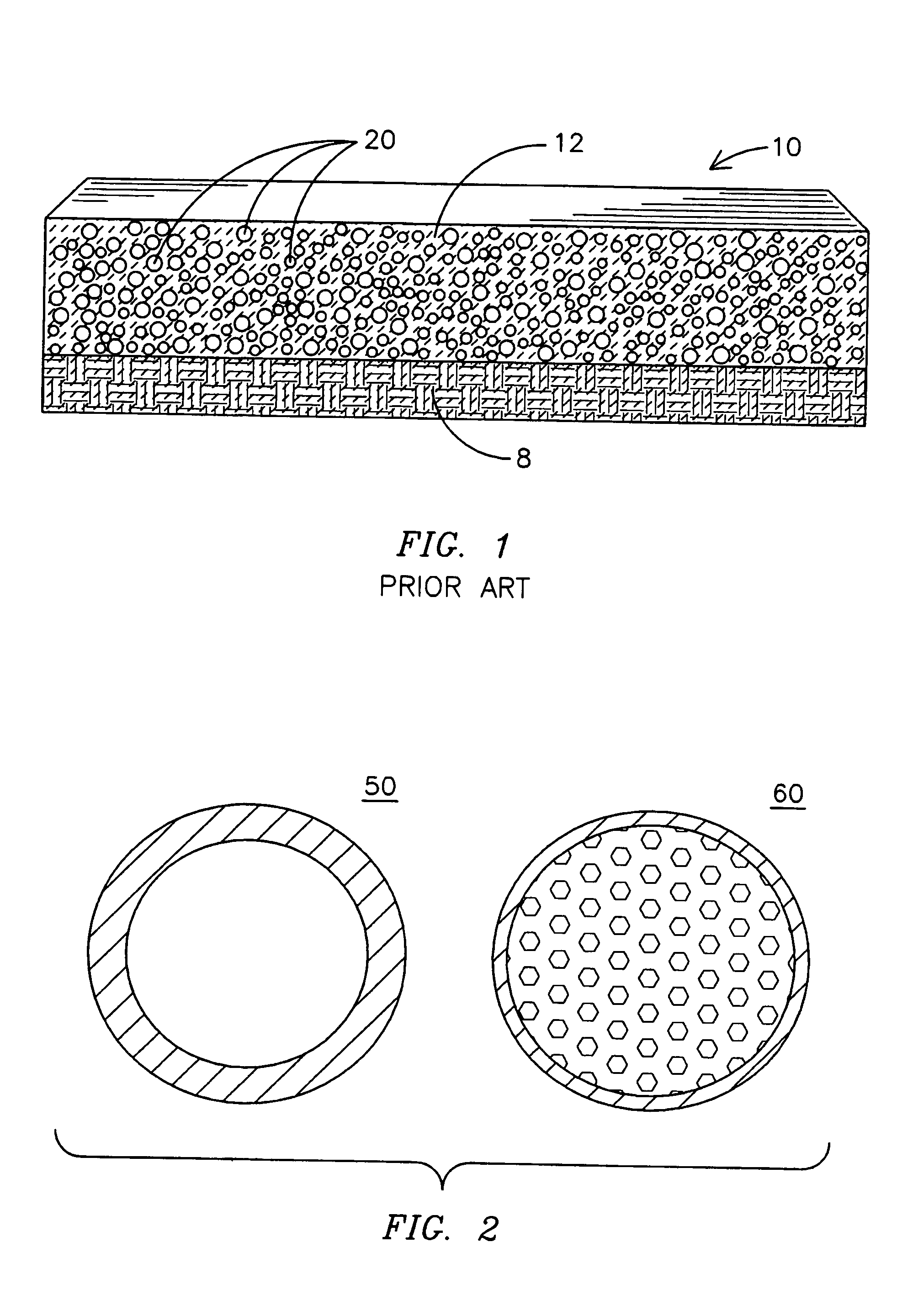

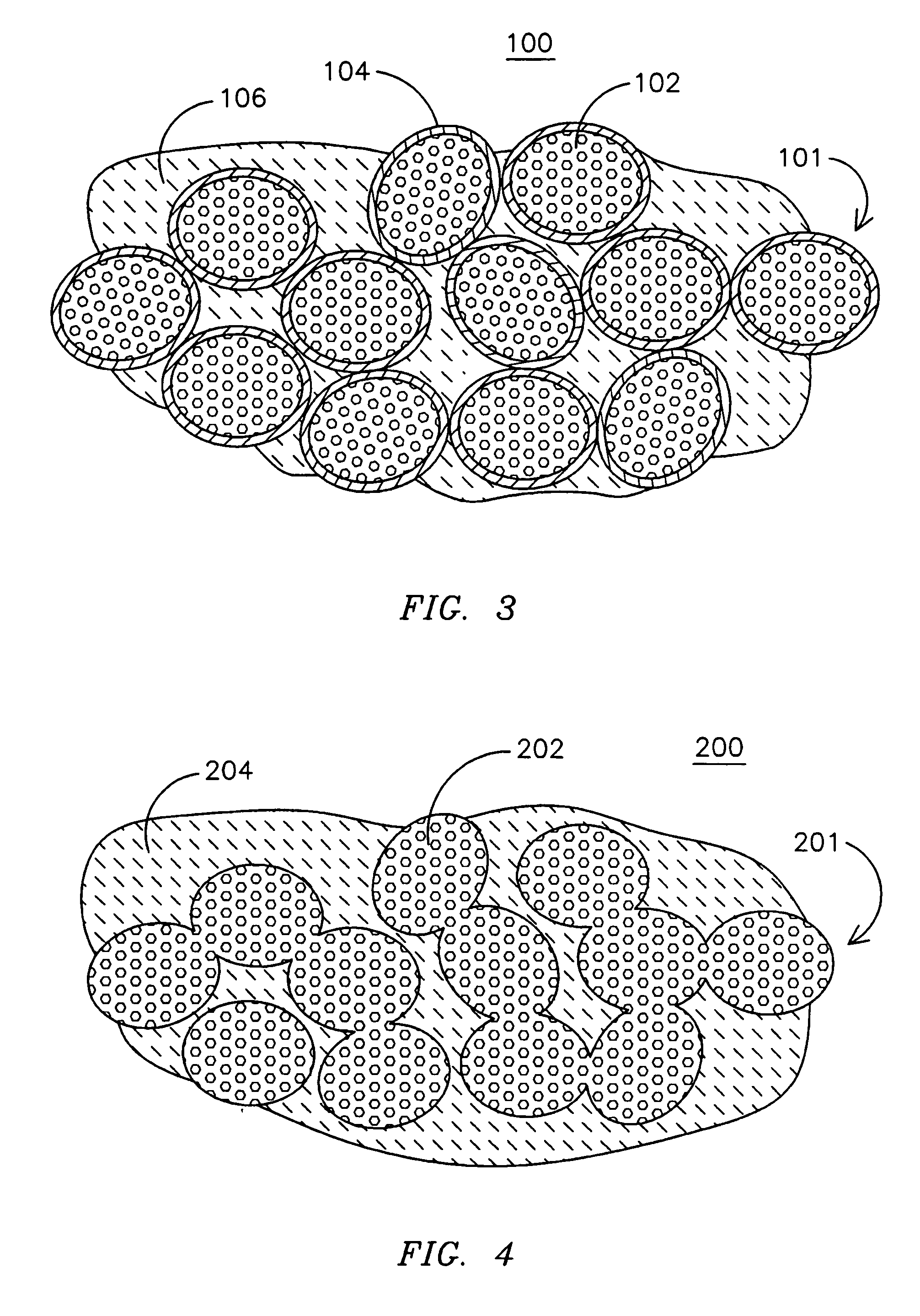

An insulating ceramic made up of a plurality of partially filled shapes (e.g., 101), such as oblate spheroids, spheres, and shapes free of corners, is provided. Each partially filled shape may include an inner skeleton (e.g., 102) and an outer skin (e.g., 104). The inner skeleton may be stabilized at a higher temperature relative to the outer skin. The shapes may be disposed in a binding matrix. The thickness of the outer skin may be very thin in view of the support provided by the inner skeleton, thereby improving the abradability characteristics of the ceramic.

Owner:SIEMENS ENERGY INC

Method for the sysnthesis of metallic NANO products

InactiveUS20110167962A1Accelerates major axis growthEliminate needMaterial nanotechnologyTransportation and packagingOblate spheroidProtic solvent

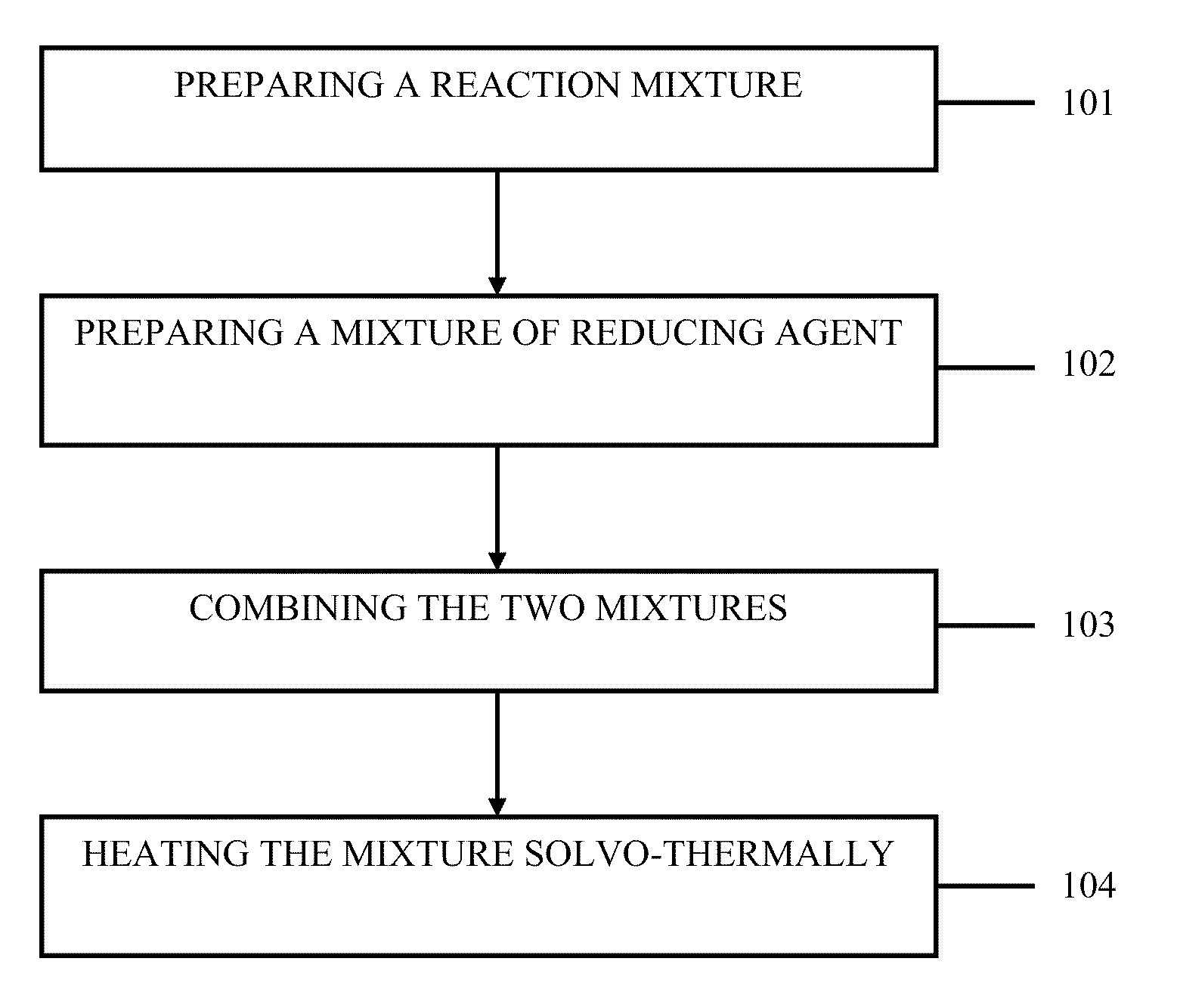

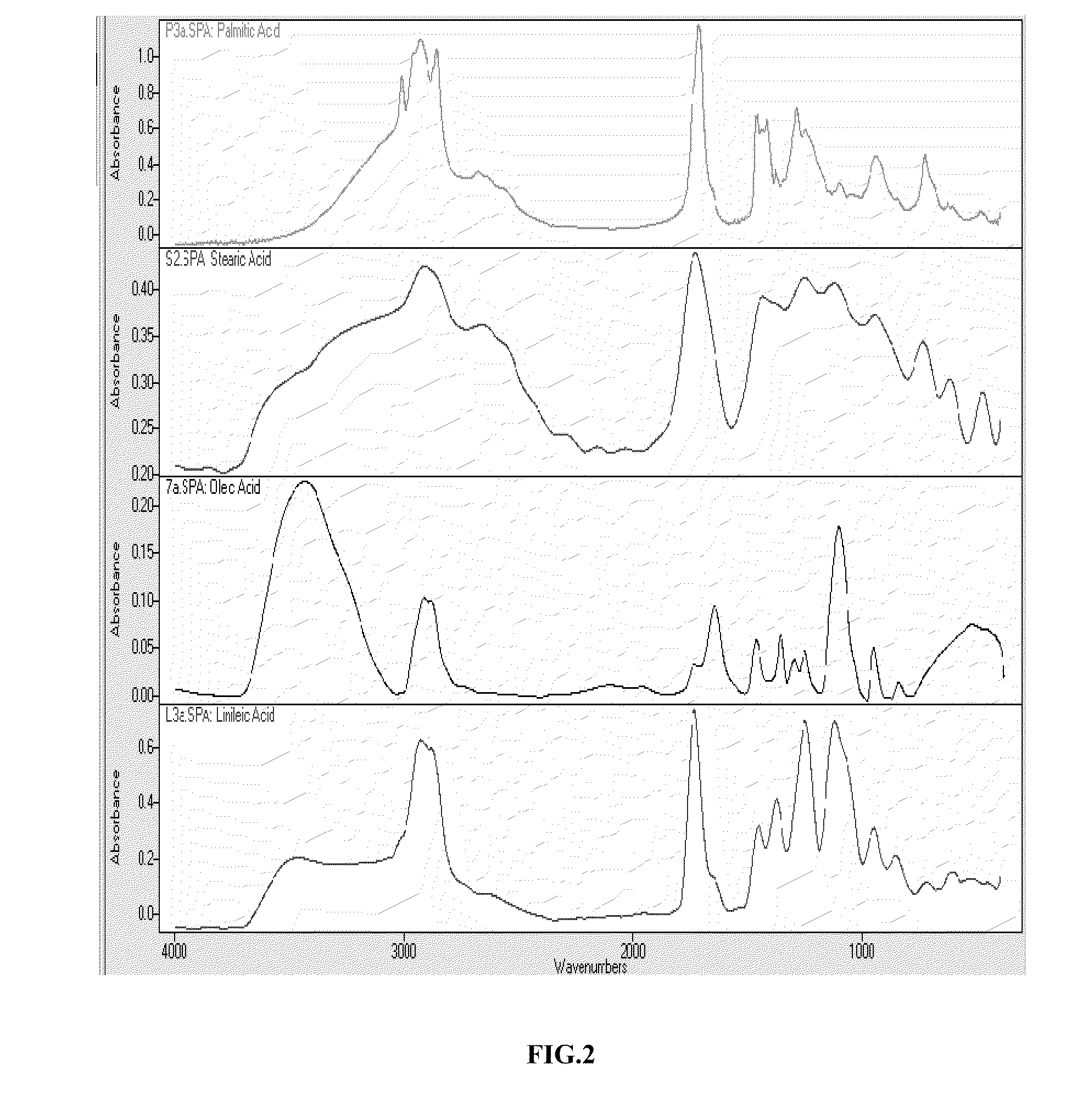

The embodiments herein provide a method of synthesis for metallic nano-products such as metallic nano-antennas, metallic nano-rods, metallic nano-wires, metallic nano-prolate spheroids and metallic nano-oblate spheroids using saturated and unsaturated carboxylic acids. The method involves preparing a reaction mixture by mixing a polar protic solvent, a polar aprotic solvent or a non-polar solvent, a saturated fatty acid or an unsaturated fatty acid and a metallic salt. Then a mixture of reducing agents is prepared by mixing a polar protic solvent, a polar aprotic solvent or a non-polar solvent and a saturated fatty acid or an unsaturated fatty acid. The reaction mixture and the mixture of reducing agents are combined and heated solvo-thermally for a pre-determined period of time at a pre-determined temperature.

Owner:GHANAVI JALALEDIN +2

Nano-antenna apparatus and method

InactiveUS7068225B2Simultaneous aerial operationsAntenna supports/mountingsOblate spheroidBpsk modulation

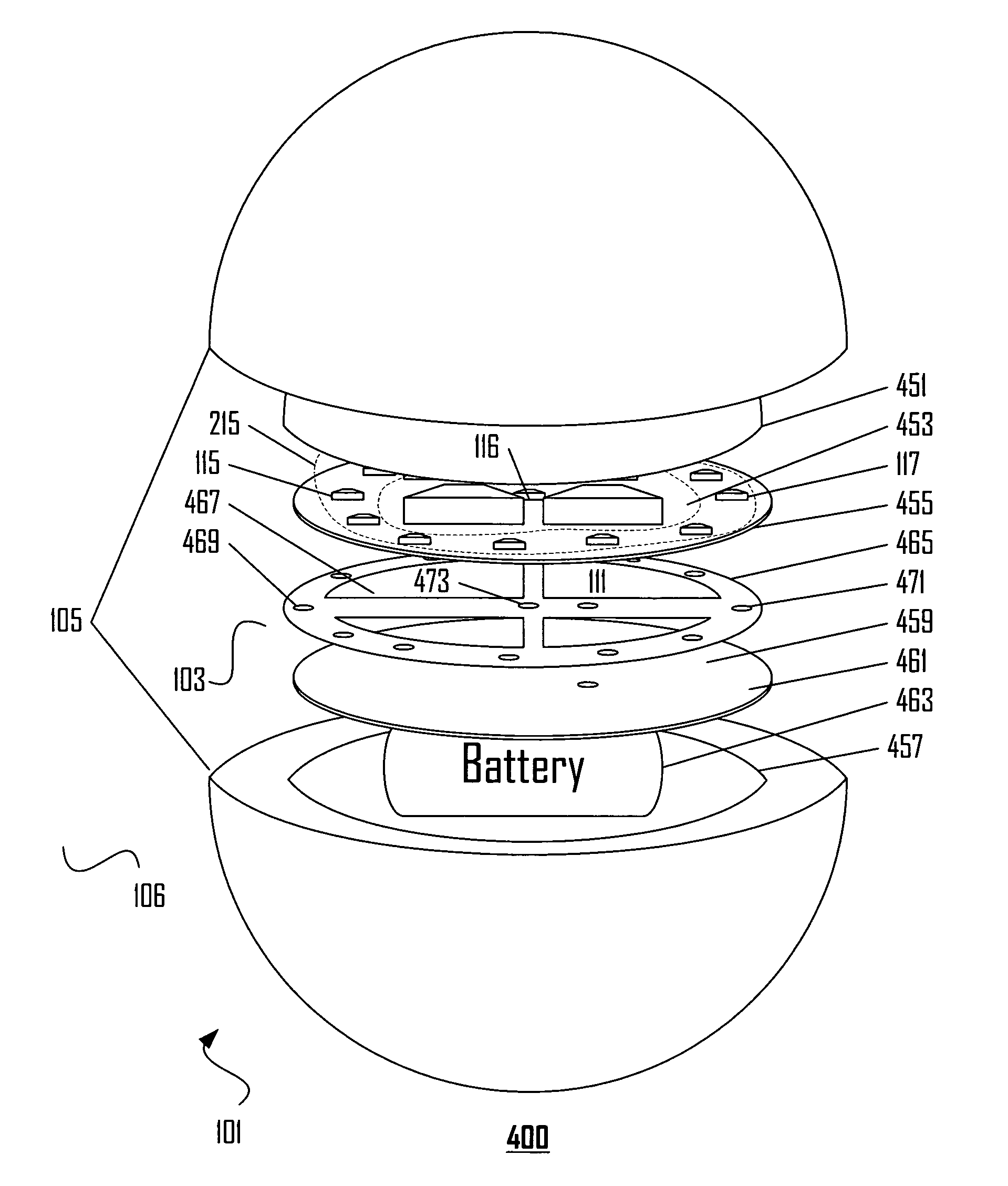

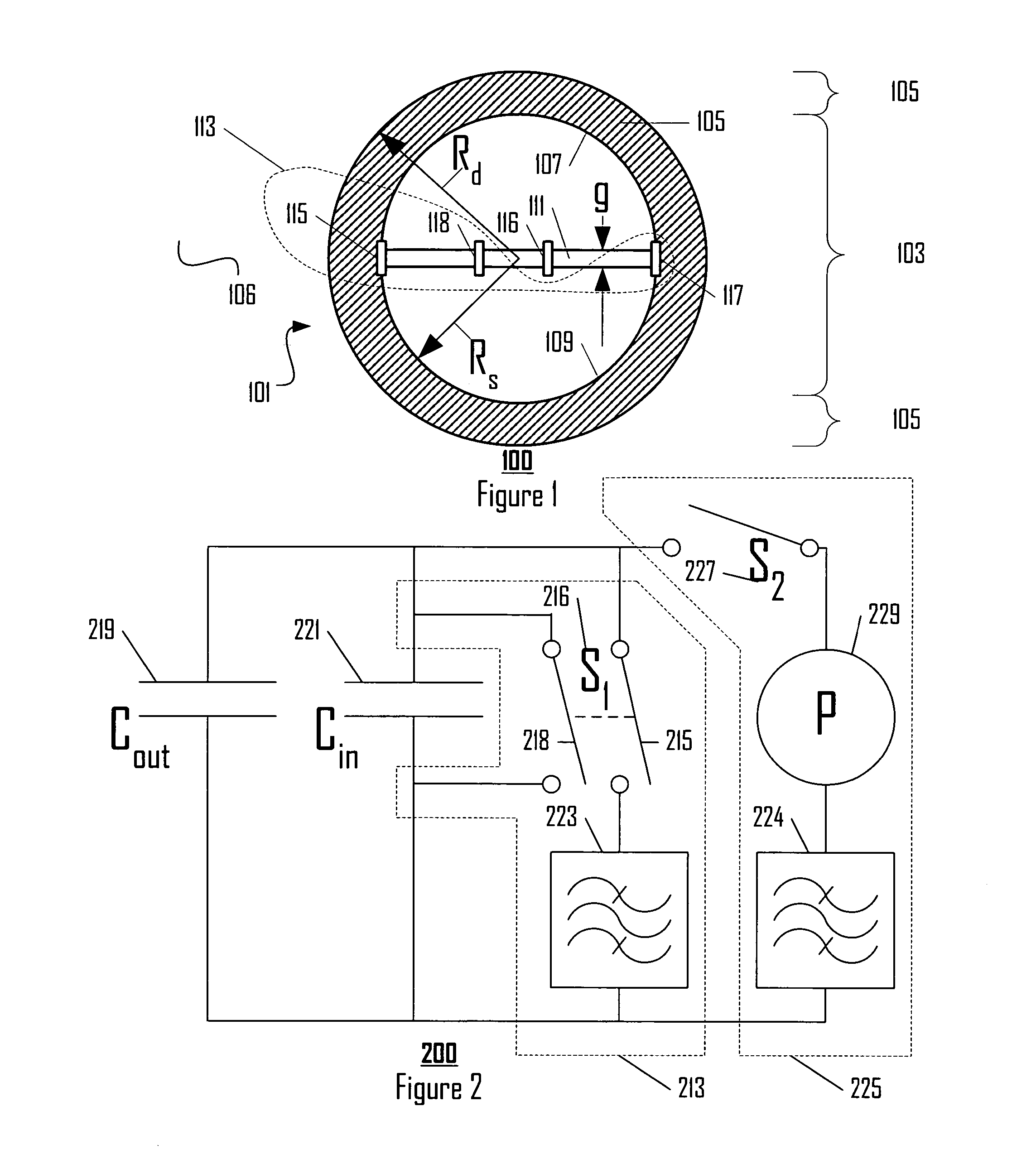

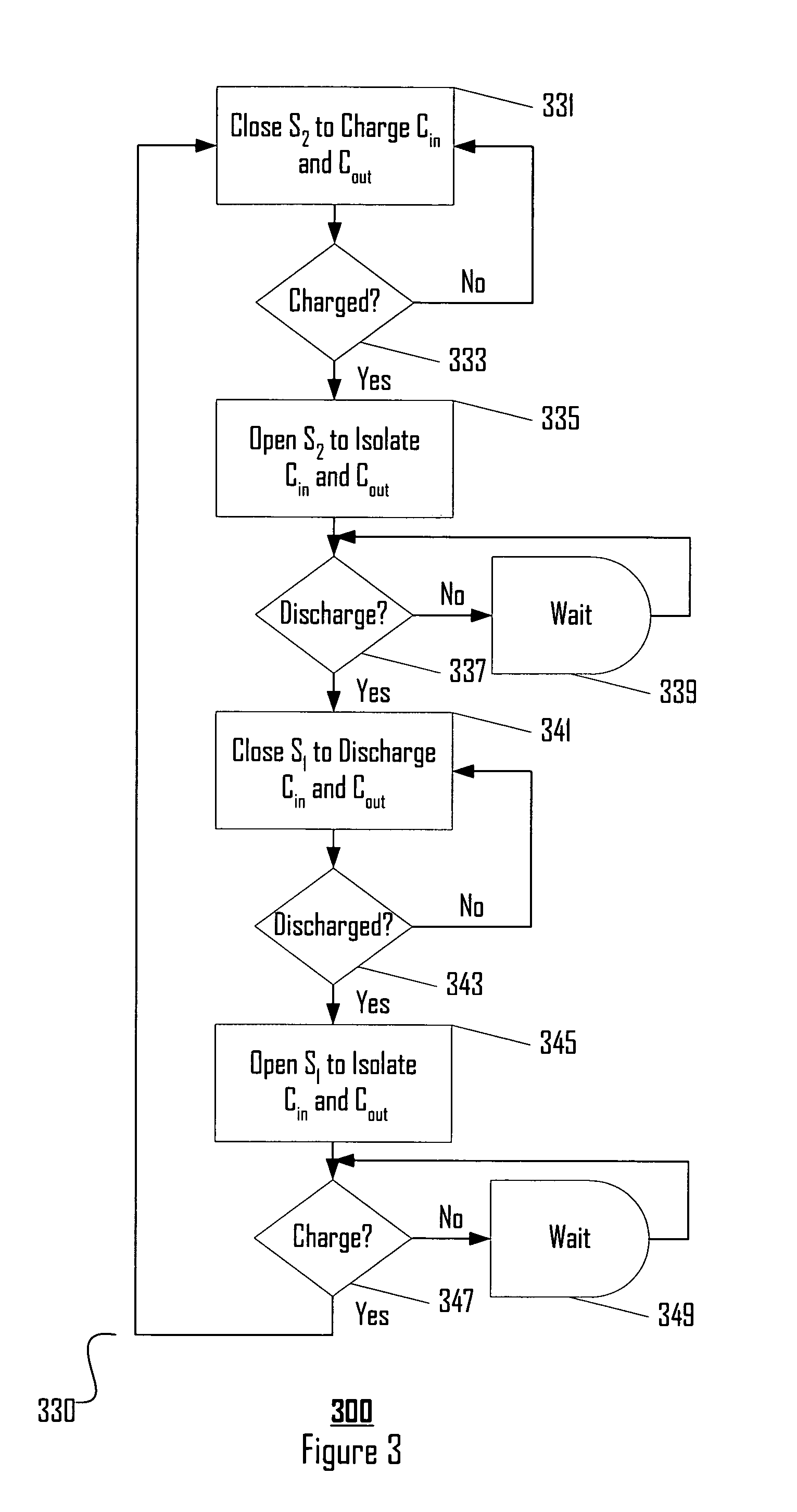

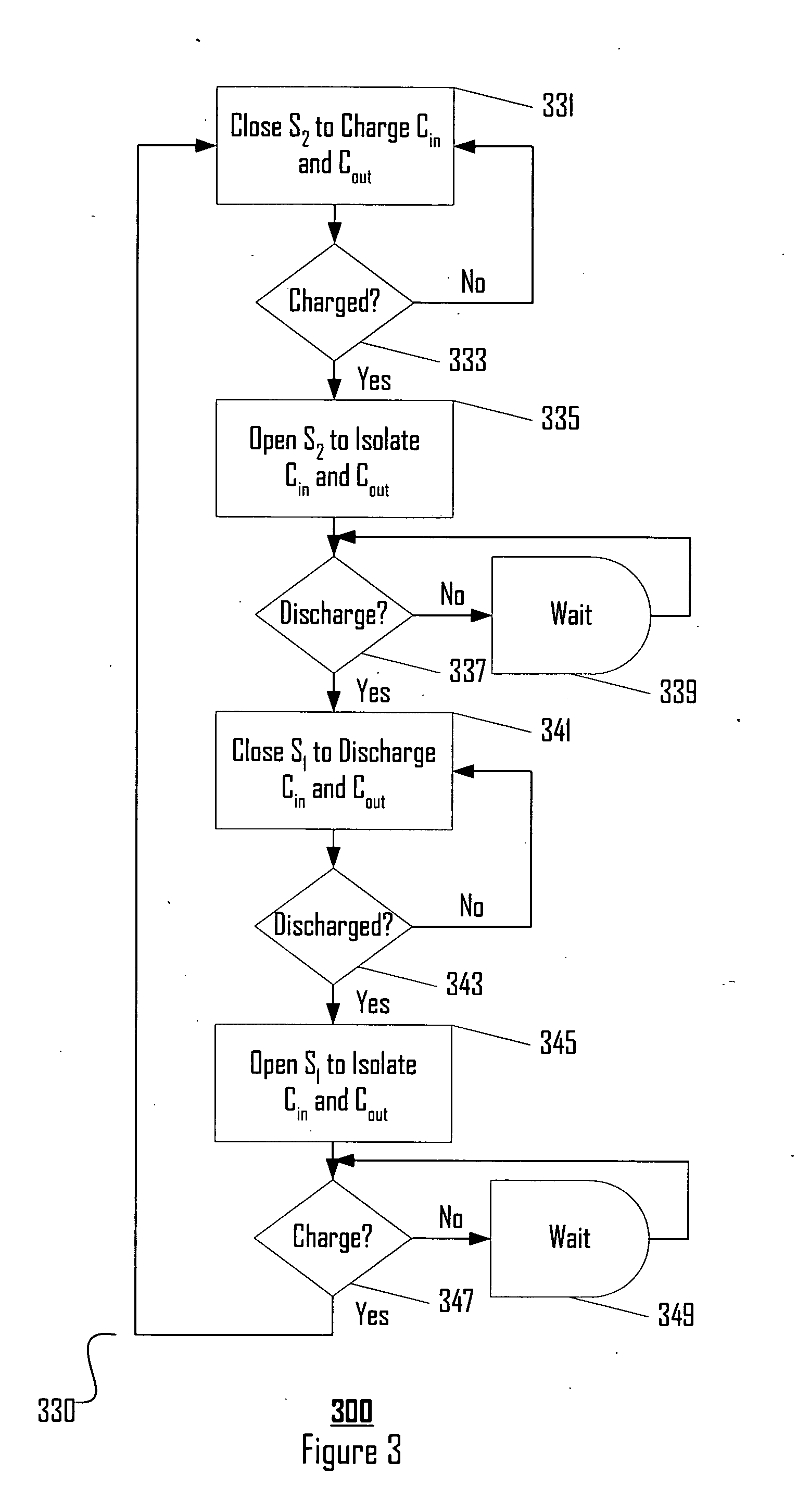

A nano-antenna apparatus (or equivalently a nano-antenna device) comprises a first conducting surface, a second conducting surface, a gap region between a first conducting surface and a second conducting surface and at least one discharge switch at least one discharge switch cooperates with first conducting surface, a second conducting surface to form a substantially continuous closed surface enclosing a volume. This volume may be substantially similar to a spheroid, a prolate spheroid, an oblate spheroid, a Cartesian rectangular solid or other shape. This volume may enclose at least one electric device. A dimension of the volume and a dielectric constant characterizing a dielectric layer may be chosen so as to yield a desired frequency response. Further, this volume may partition outside energy from inside energy, causing the former energy to radiate away.This invention further teaches a method for transmitting UWB impulse. This method comprises the steps of charging a first conducting surface with respect to a second conducting surface, and discharging a first conducting surface with respect to a second conducting surface such that the discharging forms a substantially continuous closed conducting shell from a first conducting surface and a second conducting surface. In alternate embodiments the discharging or charging may be adiabatic. Discharging may be positioned in time in accordance with a pulse position modulation scheme. Charging may be polarized in accordance to a flip or BPSK modulation scheme. Discharging may be effected by diodes, transistors, or MEMS devices.

Owner:NEXT RF

Artificial disc prosthesis for replacing a damaged nucleus

ActiveUS20120116516A1Resists hyper extension of the jointLimit wearSpinal implantsOblate spheroidReplacement implant

A multi-piece disc replacement implant for replacing a disc removed by a discectomy including an upper plate member, a lower plate member, and an intermediate resilient member providing movement between the two plate members replicating the natural movement of the spine. The plate members are rigid and have orthogonal sidewalls forming an enclosure. The resilient member is an elastic solid or a multi-chamber balloon structure of fluid-filled sacks that collectively define a non-uniform shape such as an oblate spheroid, or a helically coiled string of beads. Such an implant is capable of supporting the compressive and cyclic loads required of a natural disc. The upper and lower plate members are cooperatively formed to selectively limit the allowable range of motion in any given direction and a provided with protrusions to be received in one or more channels cooperatively formed in the vertebrae and secured in place by a bone screw.

Owner:AFLATOON KAMRAN

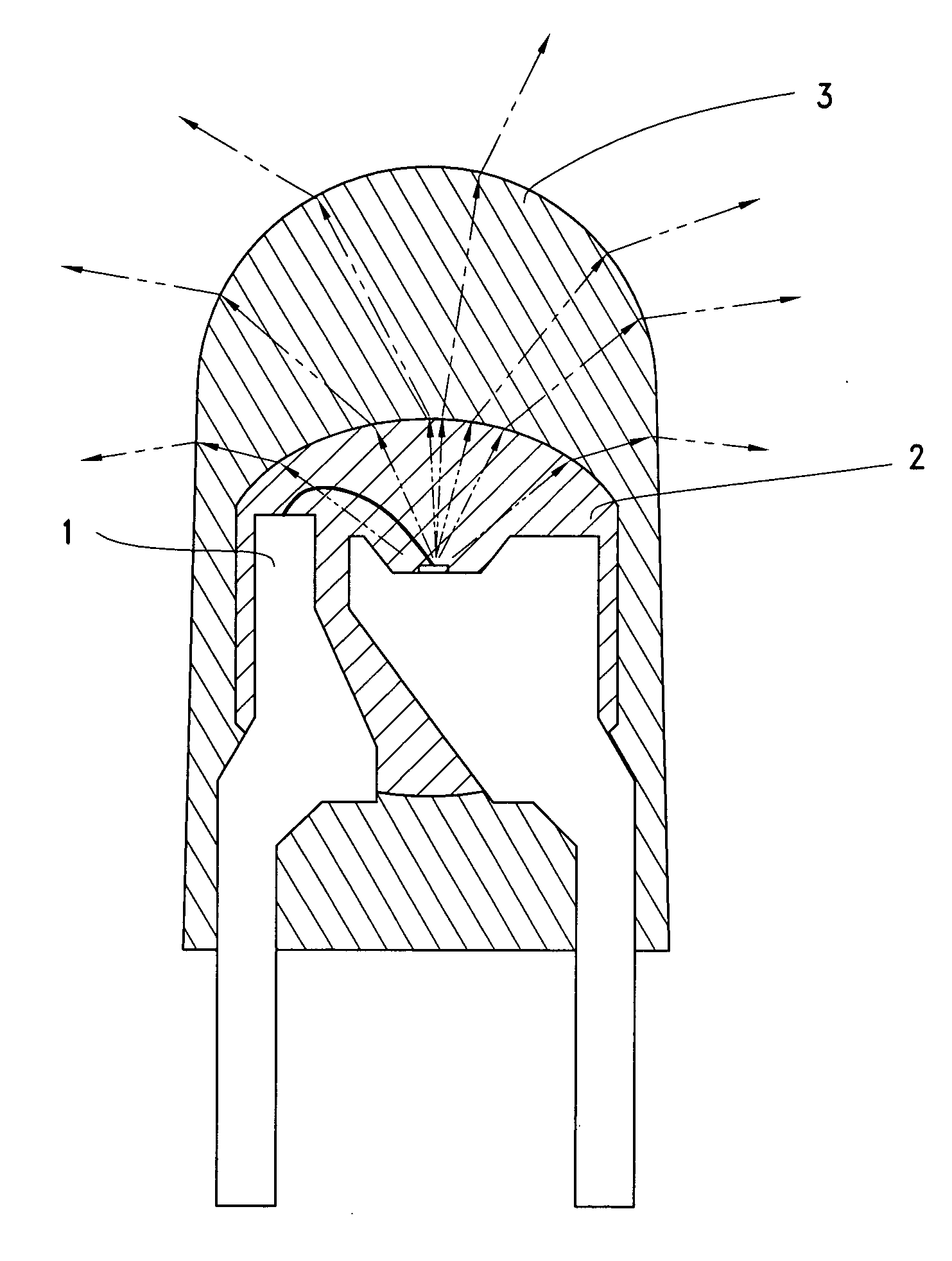

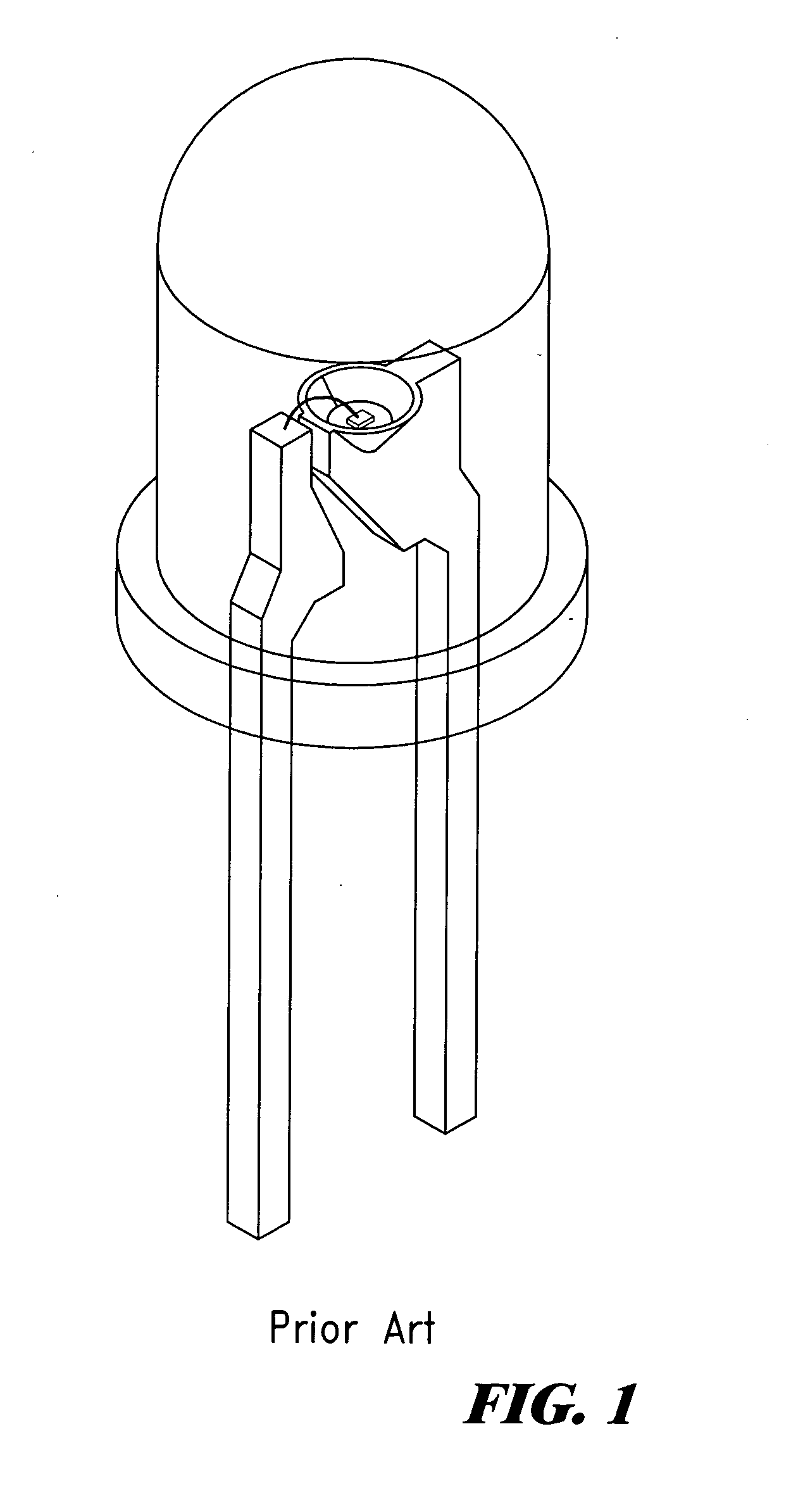

Pre-molded LED light bulb package

InactiveUS20120037934A1Packaging process time can be substantially reducedImprove output performanceSolid-state devicesSemiconductor devicesOblate spheroidEpoxy

The present invention relates to a pre-molded LED light bulb package with its main improvements being: the chip and gold wire outside the chip cup at the top of the traditional conducting bracket is covered with an appropriate quantity of epoxy resin colloid and then baked to form an oblate spheroid, which is inserted into the mold and filled with injection PC or ordinary resin to rapidly condense into LED enclosure package, wherein the special effect of multiple amplified or integrated light source whereby the light source is amplified internally and then gathered externally can be achieved by means of an internal optical amplifying light source effect through the pre-molded oblate spheroid and the convex or concave structure on the upper part of the external injection molded LED enclosure, significantly improving the existing single lighting deflection technology, therefore reducing the time of the packaging process and increasing the output capacity of mass production significantly.

Owner:LEE HAN MING

Method for producing color intrigue blue-and-white ceramic tile

The invention discloses a method for producing a color intrigue blue-and-white ceramic tile. In the method, a plurality of kinds of colored glaze slurry and an active waterproofing agent are used, all kinds of slurry are separated from one another, a kind of colored glaze slurry is sprayed on the surface of an unburned brick, the active waterproofing agent is spray, and another kind of colored glaze slurry is sprayed, wherein a layer of hydrocarbon chain with hydrophobicity is formed between two colored glaze slurry layers by the active waterproofing agent. The method comprises the following steps of: a, glazing on the surface of the unburned brick one time and naturally air-drying to ensure that the fluidity of the colored glaze slurry is lost; b, spraying the active waterproofing agent to form the layer of hydrocarbon chain with hydrophobicity; and c, spraying the second layer of colored glaze slurry, self-gathering the colored glaze slurry to form a micelle and naturally drying to form a color intrigue texture. A color intrigue crack is formed by an active waterproofing agent tension force effect mechanism and a plurality of oblate spheroids formed by self-gathering the colored glaze slurry, and is realized by controlling a glazing process; the texture of the ceramic tile has the characteristics of fixed depth and width and randomness and has strong concave-convex handfeel; and the method is a brand new process method for producing individualized architectural ceramics.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

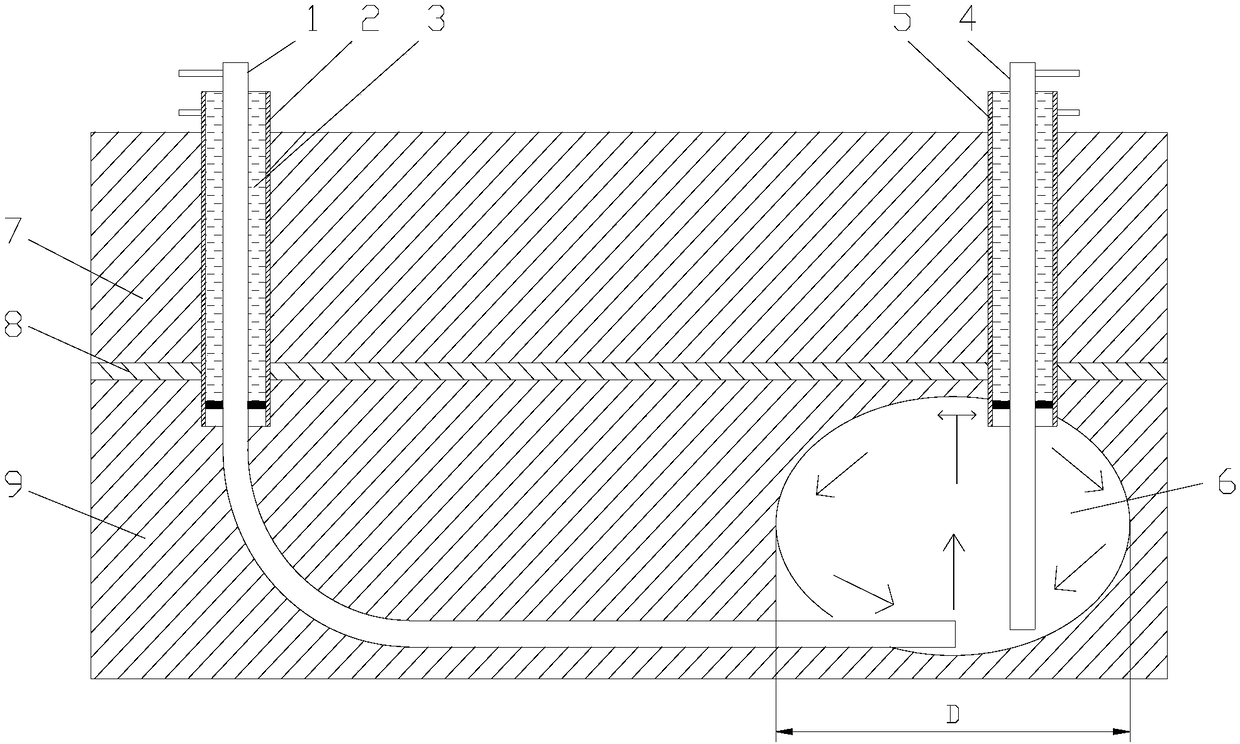

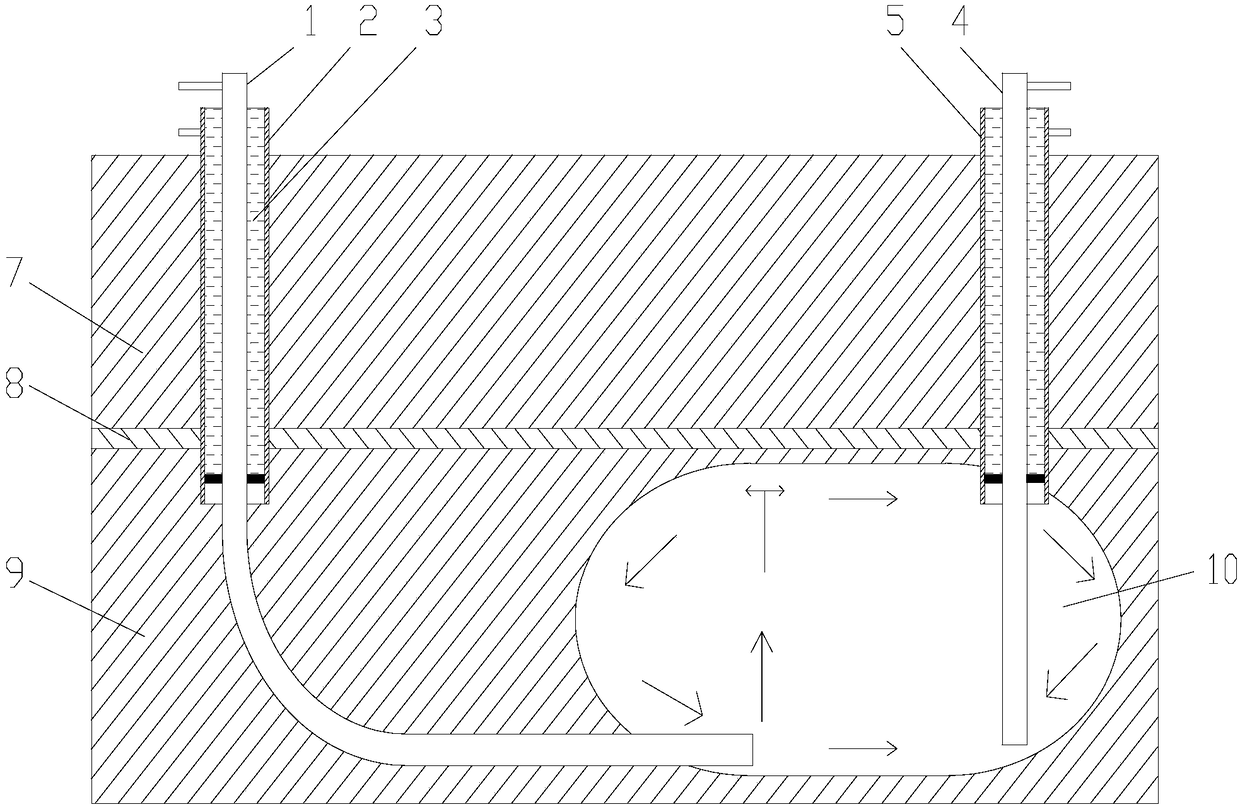

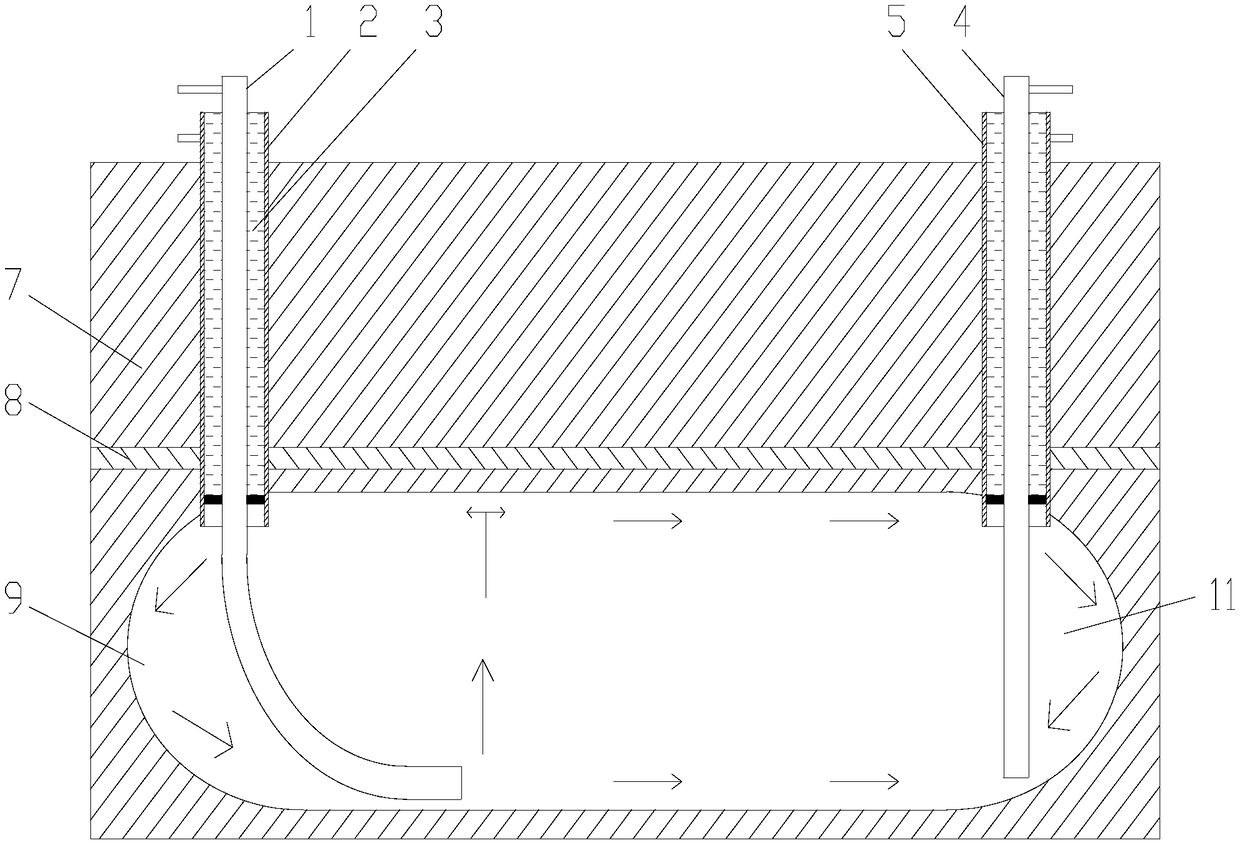

Two-well horizontal connected well group retreating solution mining/cavity-building method

InactiveCN108252739AIncrease storage spaceSafety reserveMining devicesFluid removalOblate spheroidFresh water

The invention discloses a two-well horizontal connected well group retreating solution mining / cavity-building method. The method comprises the following steps of (1) drilling a straight well and an inclined well to a target stratum separately, and then drilling a horizontal wellbore to connect the straight well and the inclined well; lowering a first central pipe into the straight well, and lowering a second central pipe into the inclined well and the horizontal well; and (2) carrying out solution mining / cavity-building in a sectioned mode. During each mining / cavity-building process, fresh water flows out from the second central pipe, a salt coating layer in the affected area above the second central pipe is fully dissolved, and therefore a created cavity has a large volume, no insoluble area exists, the problem that "a middle part is insoluble" in two-well and the horizontal well solution mining / cavity-building is avoided, and the cavity is basically in the shape of a regular oblate spheroid after the completion of the entire mining / cavity-building process. The retreating cavity-building method utilizes the characteristic of the salt rock water solution that "where is injected, where is dissolved", completes the cavity-building horizontally and sectionally, effectively improves the mining rate of the salt rock, expands the volume of the dissolved cavity, specifies the shape ofthe dissolved cavity and increases the space for later use of the cavity and safety performance of the storage, and the cavity can store more various kinds of media (oil, gas, waste, etc.) safely.

Owner:CHONGQING UNIV

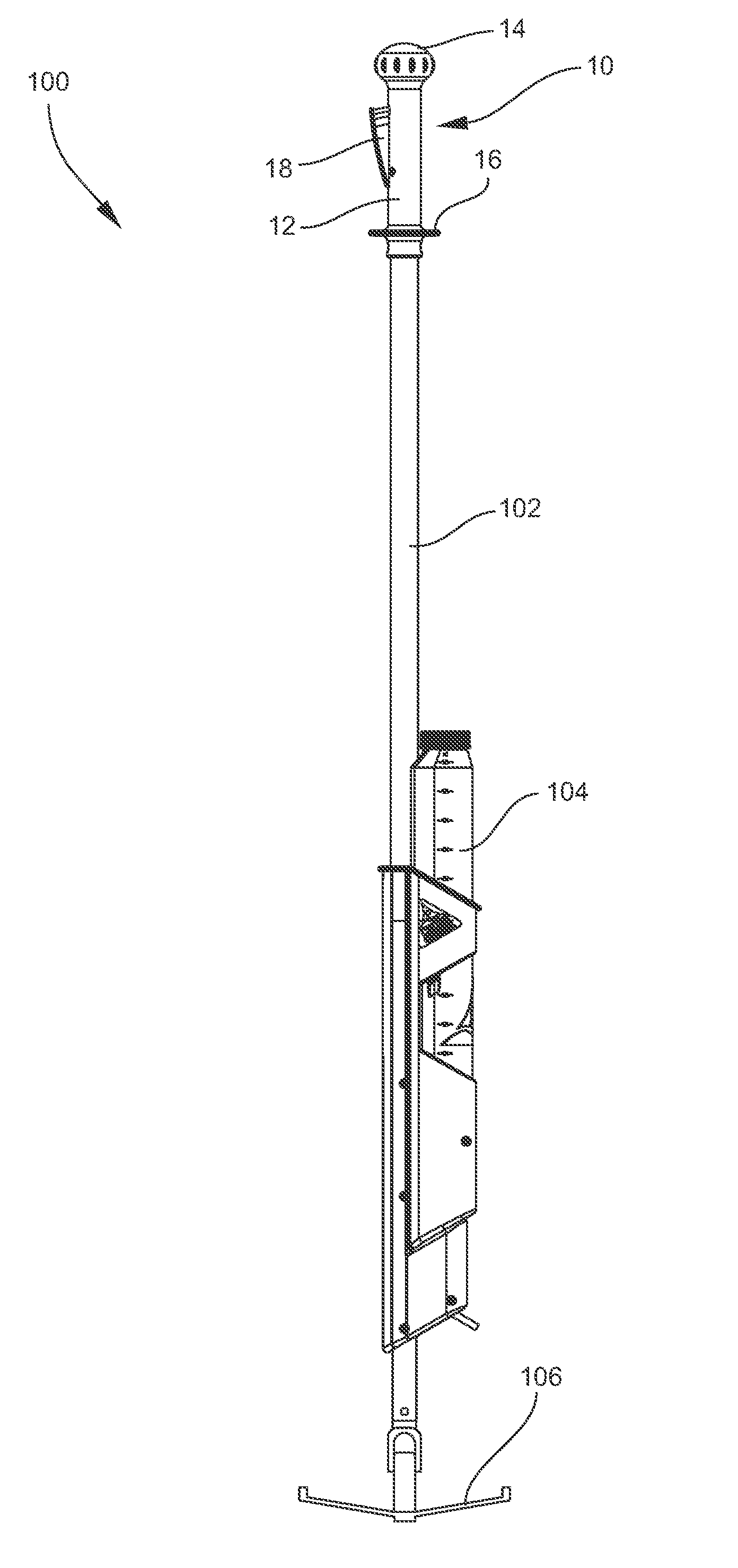

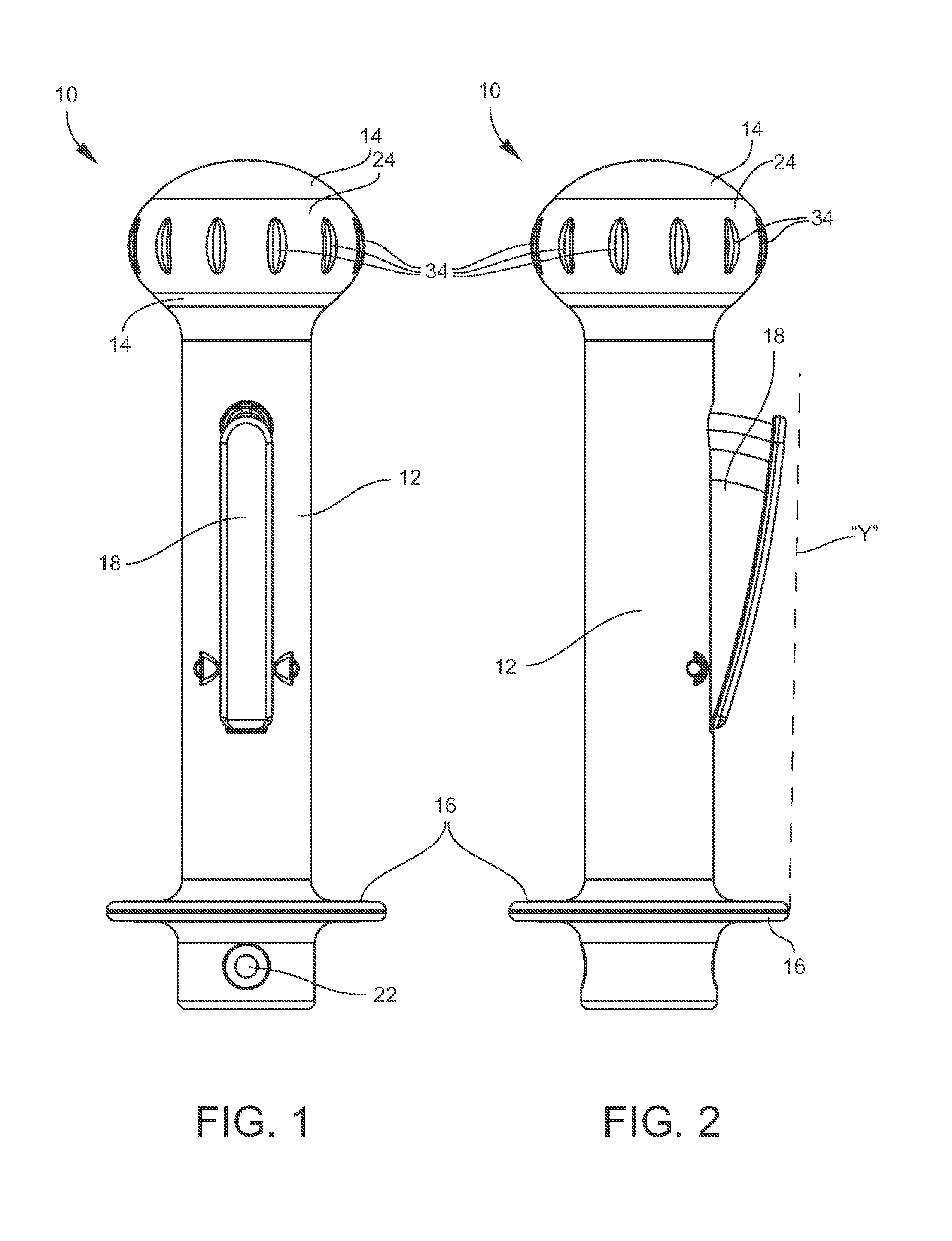

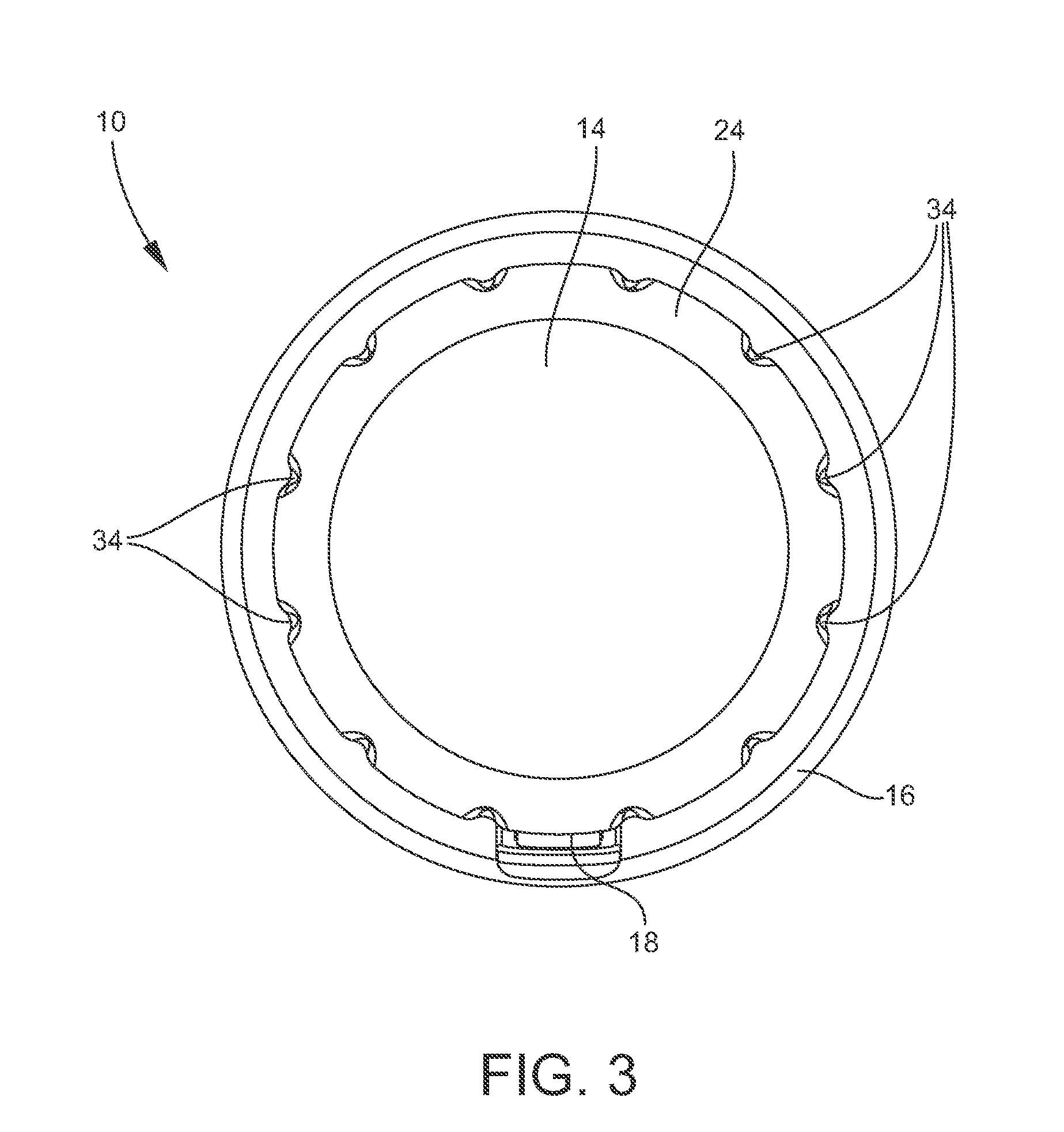

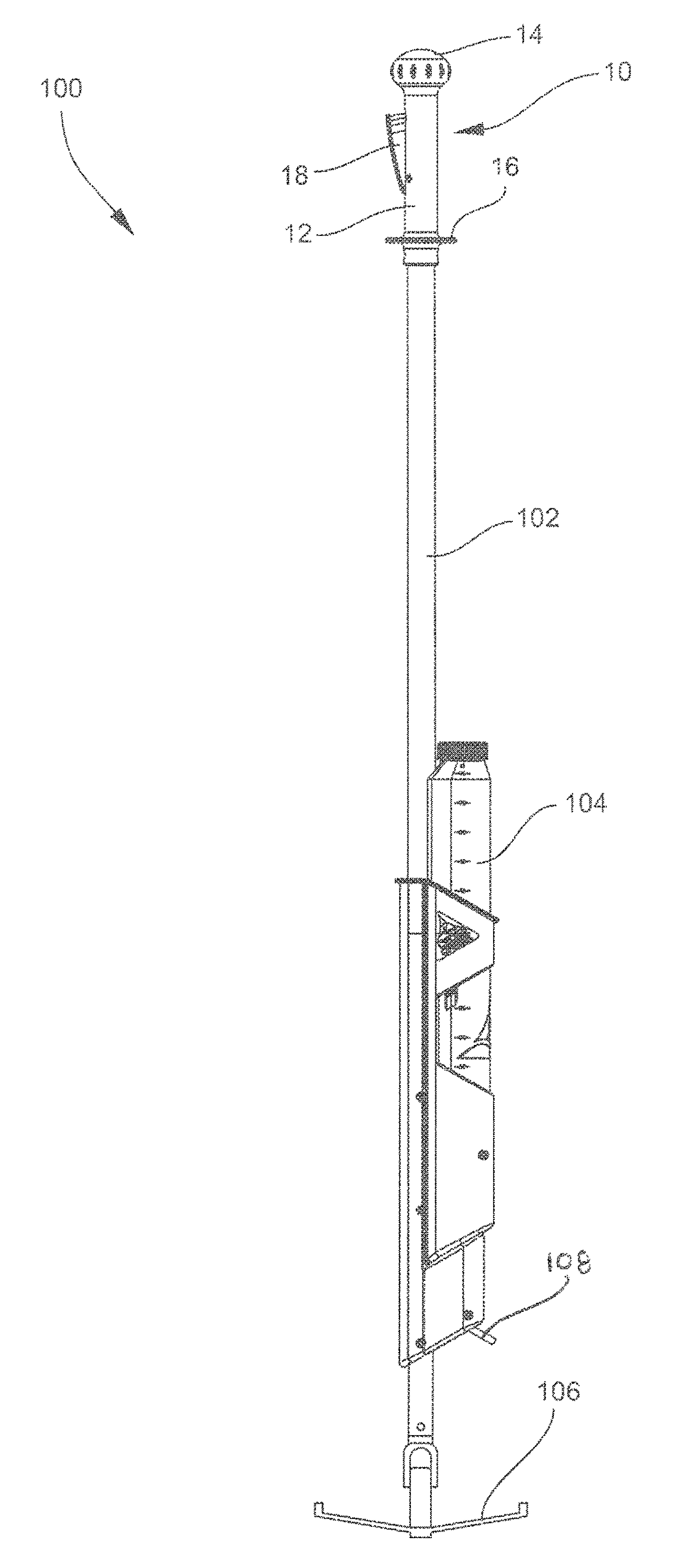

Handle apparatus and cleaning device comprising same

ActiveUS20160198925A1Reduce the possibilityIncreased frictional contactCarpet cleanersBrush bodiesOblate spheroidEngineering

A handle apparatus includes a substantially elongate cylindrical section, a bulbous top section formed at the top of the elongate cylindrical section, and a flange section formed proximate the bottom of the cylindrical section. A trigger can be positioned within a recess formed in the elongate cylindrical section. The flange can extend outwardly from the elongate cylindrical section a greater distance than the trigger to prevent damage to the trigger if the handle falls to the ground. The bulbous section can have an oblate spheroid shape, and a gripping band that provides a comfortable grip to the user and helps prevent the handle from slipping when leaned against a wall. The handle can be utilized on a cleaning implement, such as a liquid dispensing mop.

Owner:NEXSTEP COMMERCIAL PROD LLC

Nano-antenna apparatus and method

InactiveUS20050128146A1Guaranteed normal transmissionSimultaneous aerial operationsAntenna supports/mountingsOblate spheroidEngineering

A nano-antenna apparatus (or equivalently a nano-antenna device) comprises a first conducting surface, a second conducting surface, a gap region between a first conducting surface and a second conducting surface and at least one discharge switch at least one discharge switch cooperates with first conducting surface, a second conducting surface to form a substantially continuous closed surface enclosing a volume. This volume may be substantially similar to a spheroid, a prolate spheroid, an oblate spheroid, a Cartesian rectangular solid or other shape. This volume may enclose at least one electric device. A dimension of the volume and a dielectric constant characterizing a dielectric layer may be chosen so as to yield a desired frequency response. Further, this volume may partition outside energy from inside energy, causing the former energy to radiate away. This invention further teaches a method for transmitting UWB impulse. This method comprises the steps of charging a first conducting surface with respect to a second conducting surface, and discharging a first conducting surface with respect to a second conducting surface such that the discharging forms a substantially continuous closed conducting shell from a first conducting surface and a second conducting surface. In alternate embodiments the discharging or charging may be adiabatic. Discharging may be positioned in time in accordance with a pulse position modulation scheme. Charging may be polarized in accordance to a flip or BPSK modulation scheme. Discharging may be effected by diodes, transistors, or MEMS devices.

Owner:NEXT RF

Anal fistula plug which is insusceptible to dropping

The invention relates to an anal fistula plug which is insusceptible to dropping. The anal fistula plug comprises a circular table body implanting section, wherein the large end face of the implanting section is connected with one end of a plug body section; the other end of the plug body section is connected with a bottom surface of a cylindrical stitching area; the plug body section is formed by connecting more than two oblate spheroids; and the stitching area and the plug body section are made of a small intestinal submucosa or an allogenic biological material. According to the anal fistula plug, a plug body consists of a plurality of oblate spheroids, and the axial self-balancing of uniformly-distributed acting force to which the single oblate spheroid is subjected can be realized, so axial force generated by deformation stretching is generated on the integral plug body section only, and is balanced with 'rectal resting pressure' which acts on the large-end face side of the implanting section to avoid operation failure caused by the dropping of the implanting section. Numerical simulation indicates that the axial component force of the anal fistula plug under weight pressure can be reduced greatly, so that the anal fistula plug is prevented from dropping.

Owner:XI AN JIAOTONG UNIV

Method for rapid preparation of vanadium-nitrogen alloy

The invention discloses a method for rapid preparation of a vanadium-nitrogen alloy. The method comprises the following steps: S1, preparing ingredients: weighing and taking a vanadium pentoxide powder, a graphite powder, a sodium silicate aqueous solution and an iron powder for standby application; S2, pretreating: mixing evenly the above raw materials, pressing into oblate spheroids, and drying; S3, feeding: placing the dried oblate-spheroid material on a graphite material basket, sending into a vacuum furnace by a transfer device, sealing the vacuum furnace, and starting a vacuum pump; S4, carrying out vacuum nitridation sintering: allowing the temperature in the furnace to reach 1400-1500 DEG C in 5 hours, then stopping the vacuum pump, carrying out deep carbonation and nitridation reaction, and continuously filling nitrogen during the reaction; and S5, discharging: after vacuum treatment, continuing to fill the nitrogen, cutting off power, cooling the vacuum furnace, when the temperature is dropped to 190-210 DEG C, stopping supplying nitrogen, opening the furnace, and taking out the graphite material basket. The method has the advantages of simple operation, low production cost, accurate process control, fast preparation, low energy consumption, and stable product production; and the vanadium-nitrogen alloy prepared by the method is high in nitrogen content and low in impurity content.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

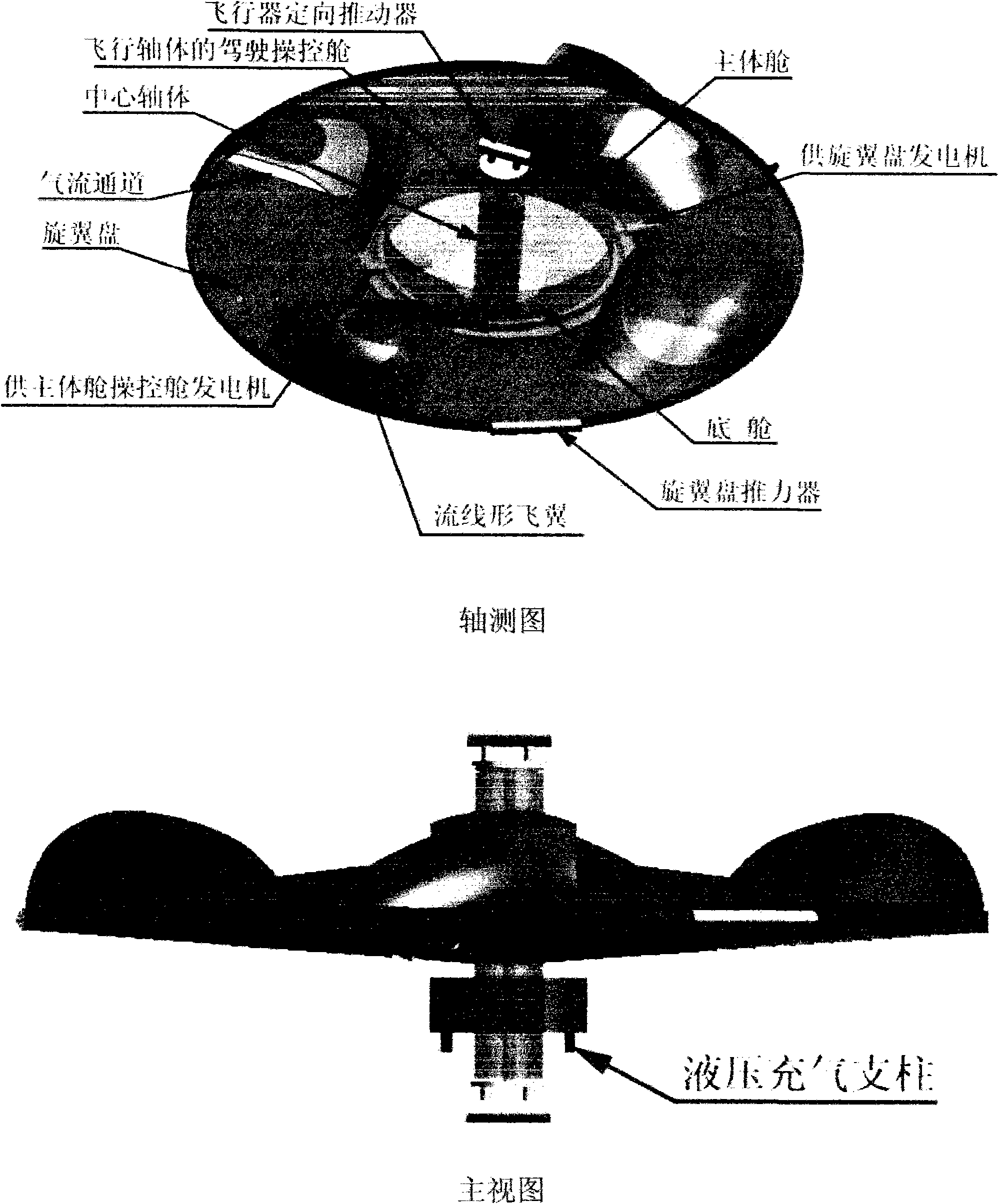

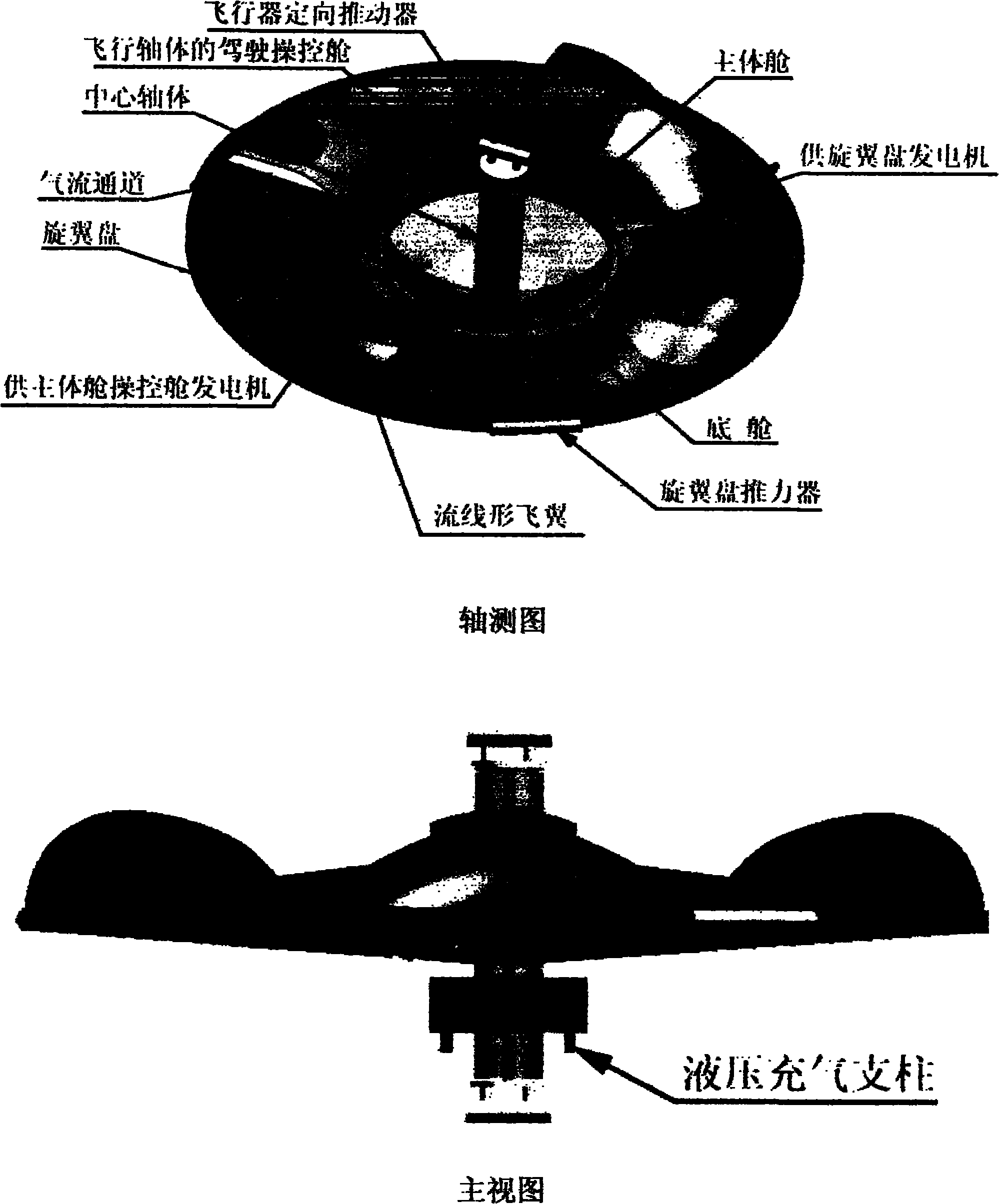

Rotor wing disk-shaped aviation aircraft

The invention discloses a rotor wing disk-shaped aviation aircraft, which is a novel aviation aircraft with a flight principle different from that of the conventional worldwide known aircrafts. The appearance is designed to an oblate spheroid shape and is similar to a top of a gyroscope. The rotor wing disk-shaped aviation aircraft consists of five major parts: a rotor wing disk, a hollow shaft body, namely a driving control cabin, a main cabin body, a rotor wing disk impeller, a directional thruster and a landing hydraulic inflated pillar, has the main characteristic of low energy consumption, and has the advantage of capacity of realizing vertical amphibious launching and landing, origin suspension, zero-gyration supersonic flight, cheap launching and landing sites, steady landing and the like.

Owner:李文奇

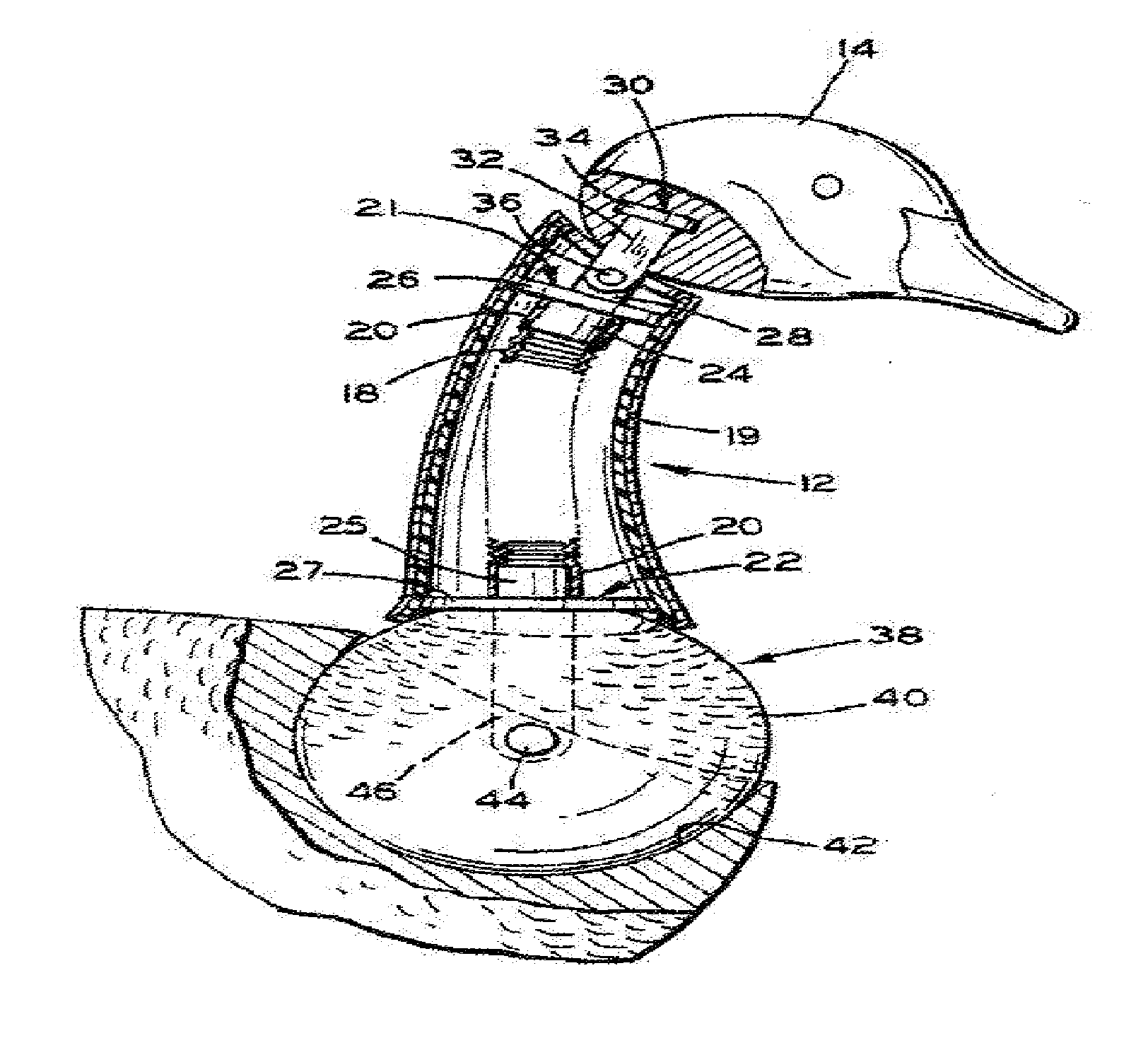

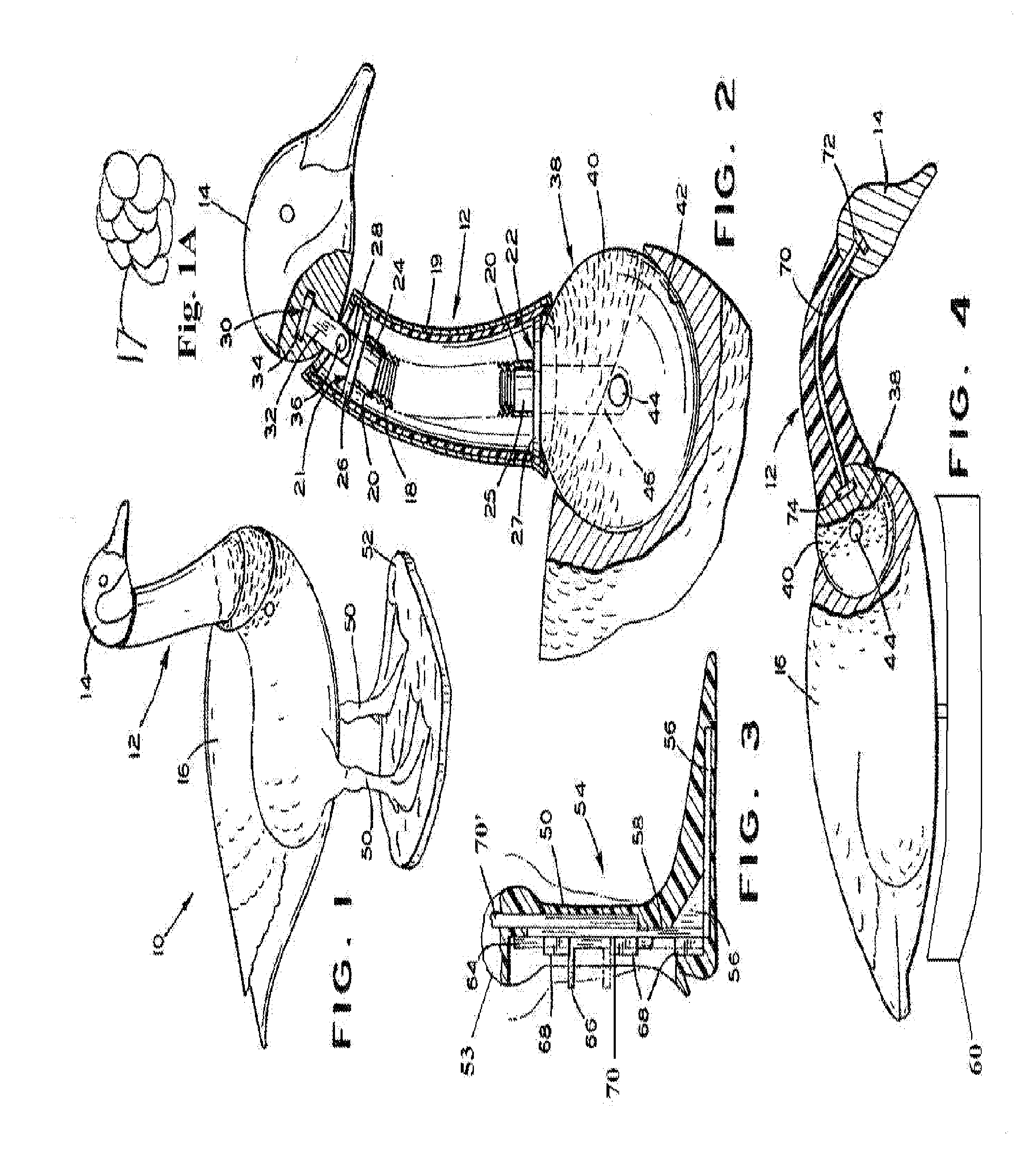

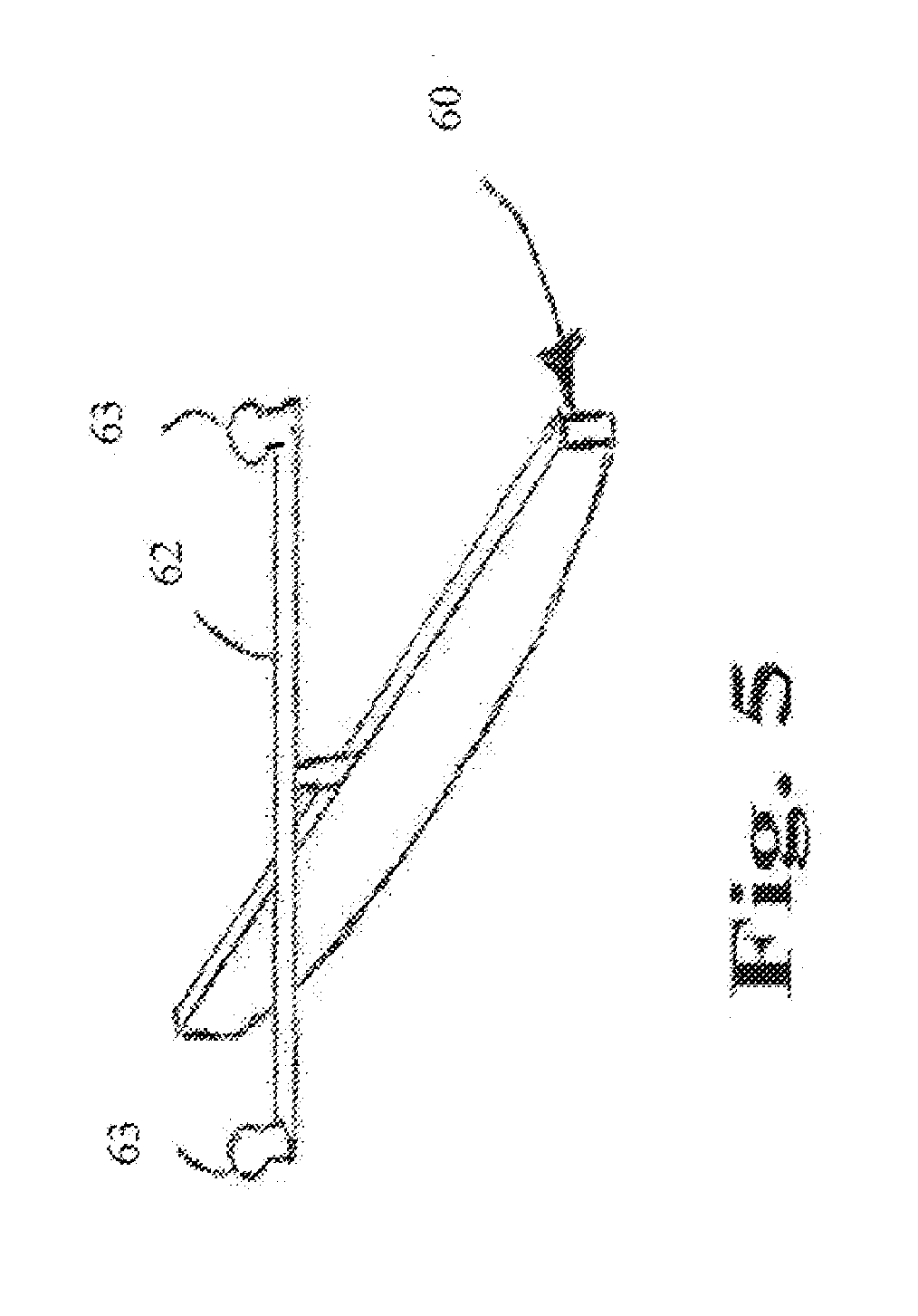

Realistic Waterfowl Decoy Assembly

InactiveUS20140338249A1High similarityFacilitate realistic head movementAnimal huntingOblate spheroidDecoy

A realistic looking waterfowl decoy has repositionable head and body portions to enable members of a group of decoys to be placed in a variety of positions to mimic a resting flock of real birds, for example, geese. At least portions of the bodies, as well as the necks and heads, of the decoys can have faux feathers adhered to their surfaces to more accurately simulate real waterfowl. A preferred embodiment of the decoy assembly has oblate spheroid end portions formed on attachment portions of both the legs and a keel member which allow the decoy assembly to be alternatively adapted for use both on land and in the water.

Owner:HEIGES CHARLES W

Insulating ceramic based on partially filled shapes

ActiveUS20050031846A1Reduced effectivenessMore materialRecord information storagePreformed elementsOblate spheroidWear resistance

An insulating ceramic made up of a plurality of partially filled shapes (e.g., 101), such as oblate spheroids, spheres, and shapes free of corners, is provided. Each partially filled shape may include an inner skeleton (e.g., 102) and an outer skin (e.g., 104). The inner skeleton may be stabilized at a higher temperature relative to the outer skin. The shapes may be disposed in a binding matrix. The thickness of the outer skin may be very thin in view of the support provided by the inner skeleton, thereby improving the abradability characteristics of the ceramic.

Owner:SIEMENS ENERGY INC

Handle apparatus and cleaning device comprising same

ActiveUS9795268B2Reduce the possibilityIncreased frictional contactCarpet cleanersFloor cleanersOblate spheroidEngineering

A handle apparatus includes a substantially elongate cylindrical section, a bulbous top section formed at the top of the elongate cylindrical section, and a flange section formed proximate the bottom of the cylindrical section. A trigger can be positioned within a recess formed in the elongate cylindrical section. The flange can extend outwardly from the elongate cylindrical section a greater distance than the trigger to prevent damage to the trigger if the handle falls to the ground. The bulbous section can have an oblate spheroid shape, and a gripping band that provides a comfortable grip to the user and helps prevent the handle from slipping when leaned against a wall. The handle can be utilized on a cleaning implement, such as a liquid dispensing mop.

Owner:NEXSTEP COMMERCIAL PROD LLC

Method for judging whether gas well carries fluid normally or not

InactiveCN108021769AAccurately judge the effusion statusCalculations are reliableDesign optimisation/simulationSpecial data processing applicationsOblate spheroidWater production

The invention provides a method for judging whether a gas well carries fluid normally or not. According to a liquid droplet model, a critical fluid-carrying flow formula is derived, the critical fluid-carrying flow of the gas well is calculated, compared with the actual yield of a gas producing well, if the critical fluid-carrying flow is larger than the yield, the gas well carries fluid abnormally, fluid is accumulated in the gas well, and if the critical fluid-carrying flow is smaller than the yield, the gas well carries fluid normally; if the liquid droplet model is in an oblate-spheroid shape, the projection, in the vertical direction, of the model is in a regular circular shape, and the projection, in the horizontal direction, of the model is in an oval shape. The critical fluid-carrying flow value obtained by the method can more accurately judge the fluid accumulation condition of the water-production gas well in the Sulige gas field, and compared with other kinds of calculationresults, the critical fluid-carrying flow value obtained by the method is more reliable.

Owner:PETROCHINA CO LTD

Scleral depressor

ActiveUS8235893B2Easy to controlAdequate visualizationSurgeryEye diagnosticsOblate spheroidEngineering

A scleral depressor designed to better control the globe of the eye is disclosed. In a preferred embodiment, the scleral depressor has a handle and a blade attached to the handle where the blade is a portion of an oblate spheroid. In one embodiment, the blade has an illuminating device. The handle is attached to the blade at an angle or straight in relation to the plane of the handle. In another embodiment, the blade is attached to a thimble. In another embodiment of the invention, the blade has an access hole for simultaneous use of other instruments during examination or surgery. The resulting apparatus has greatly improved control of the eye, effective visualization of the periphery, ease of use for the examiner, and increased comfort for the patient.

Owner:JOSEPHBERG ROBERT G +1

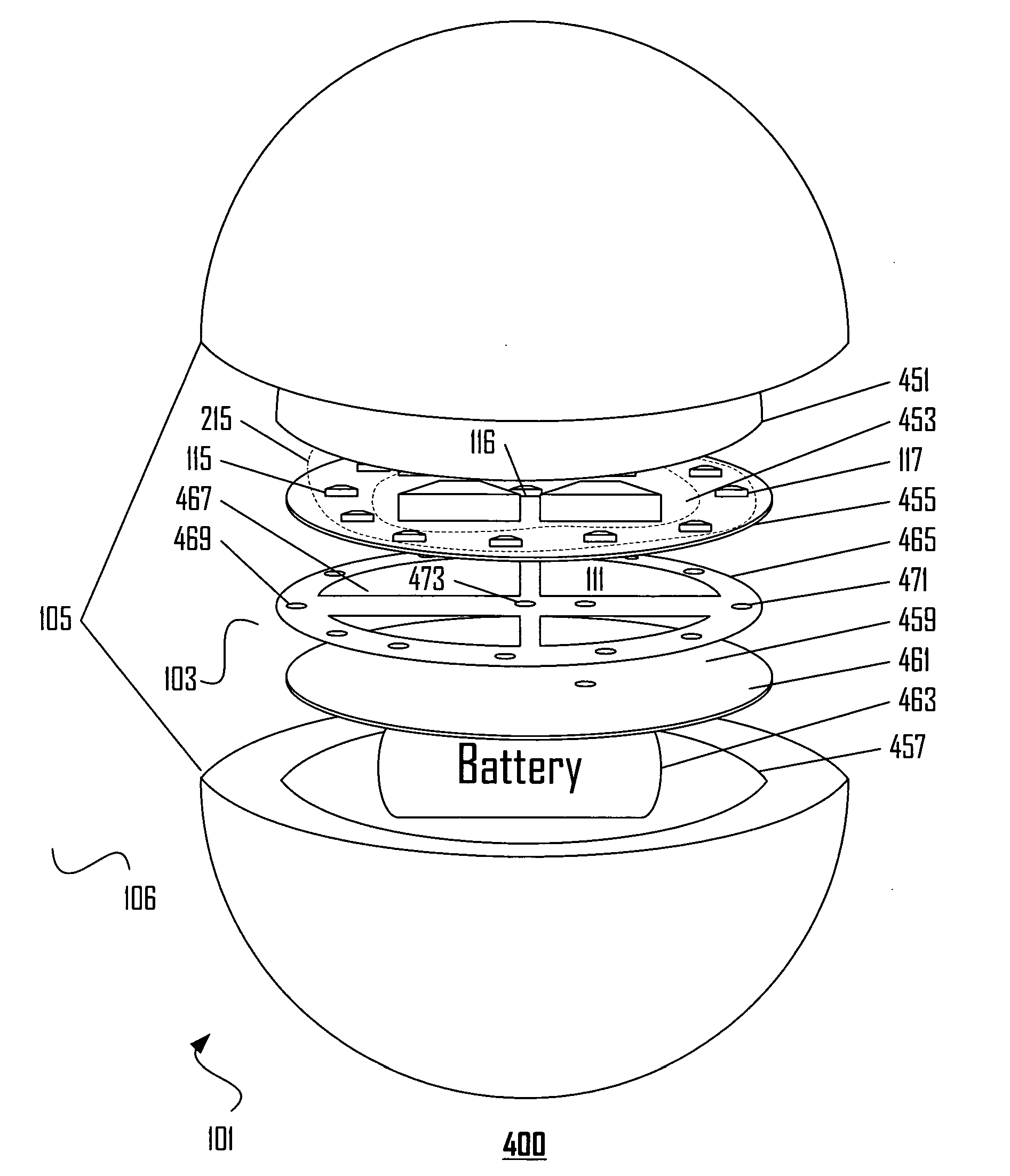

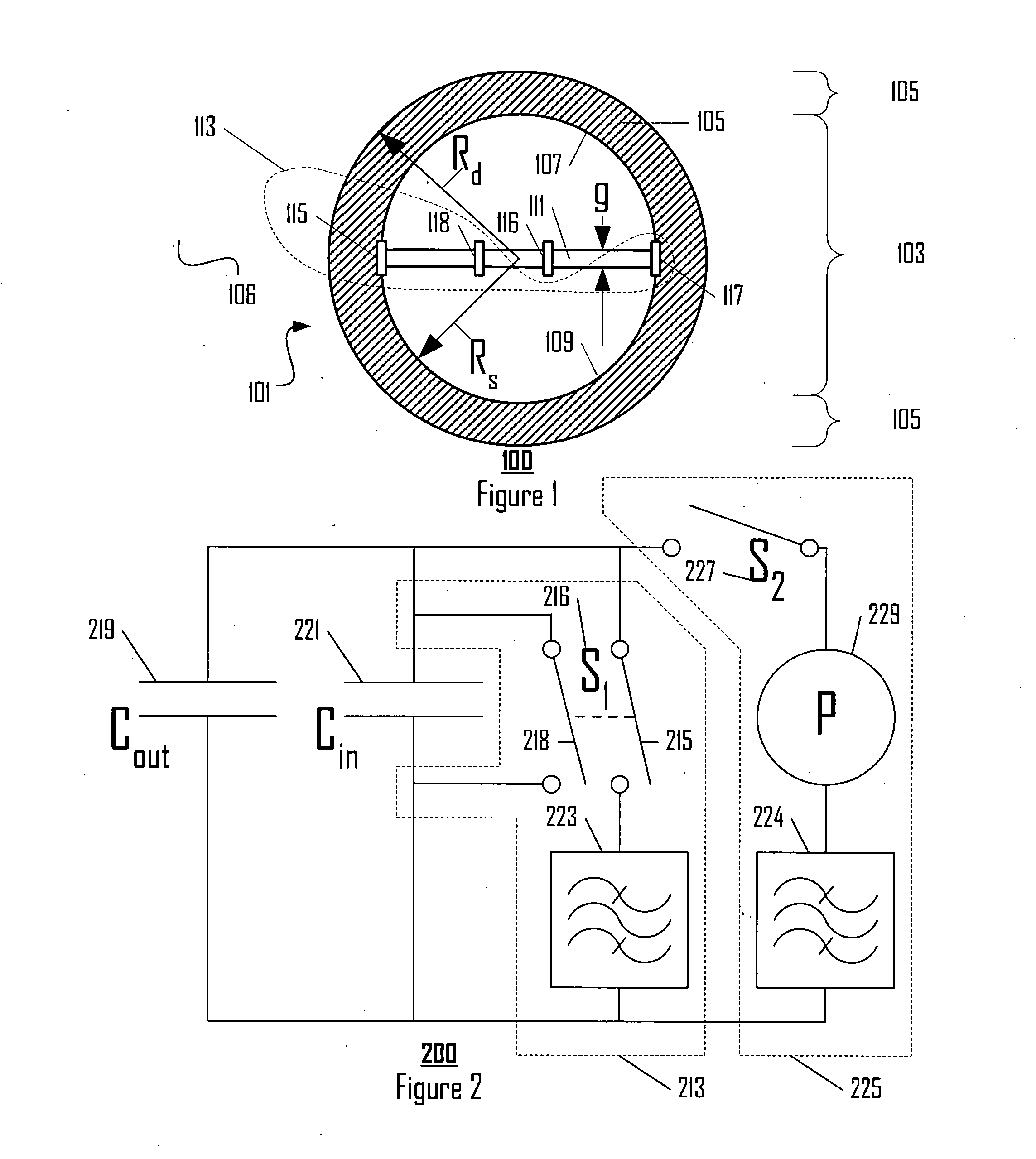

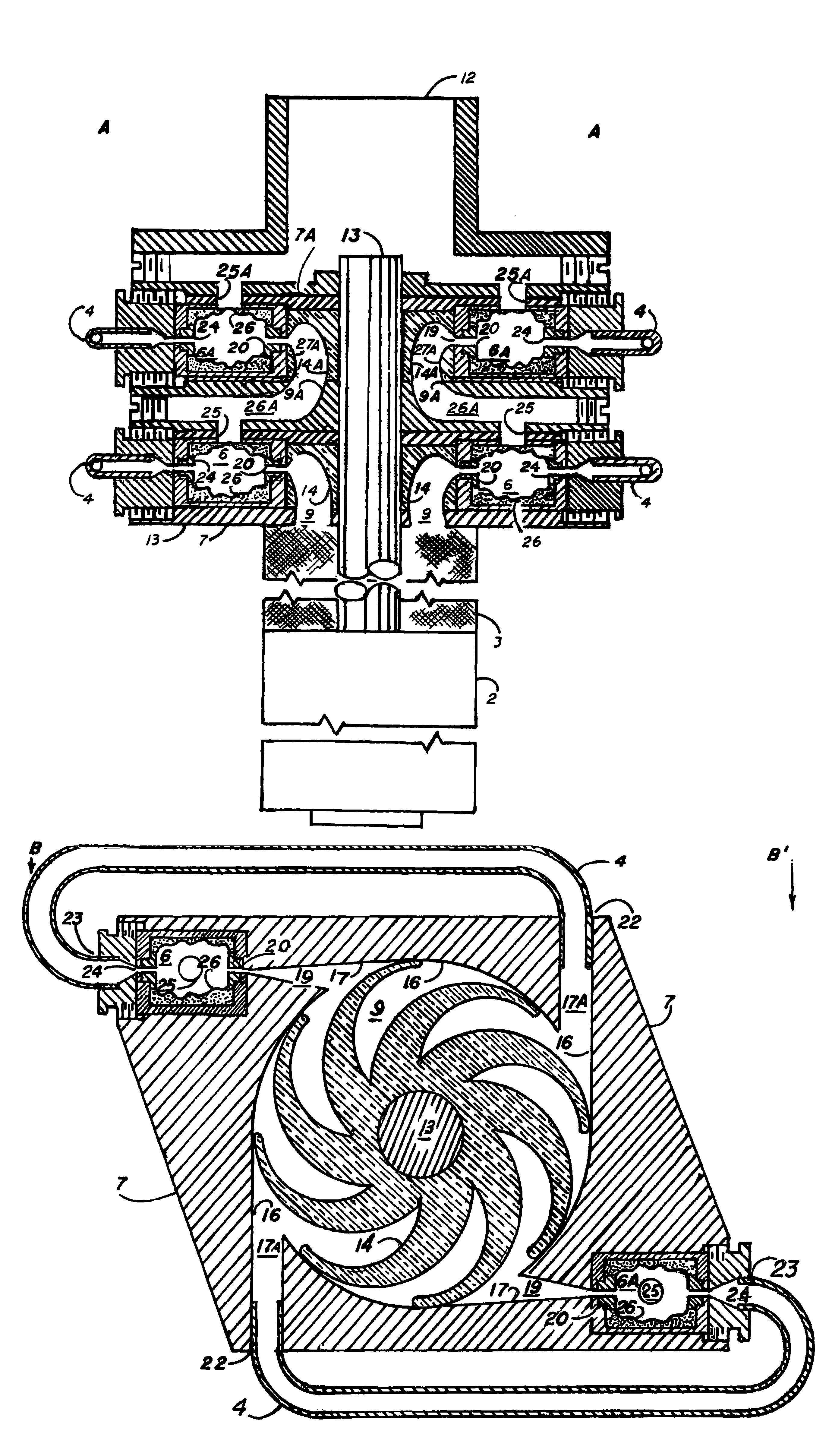

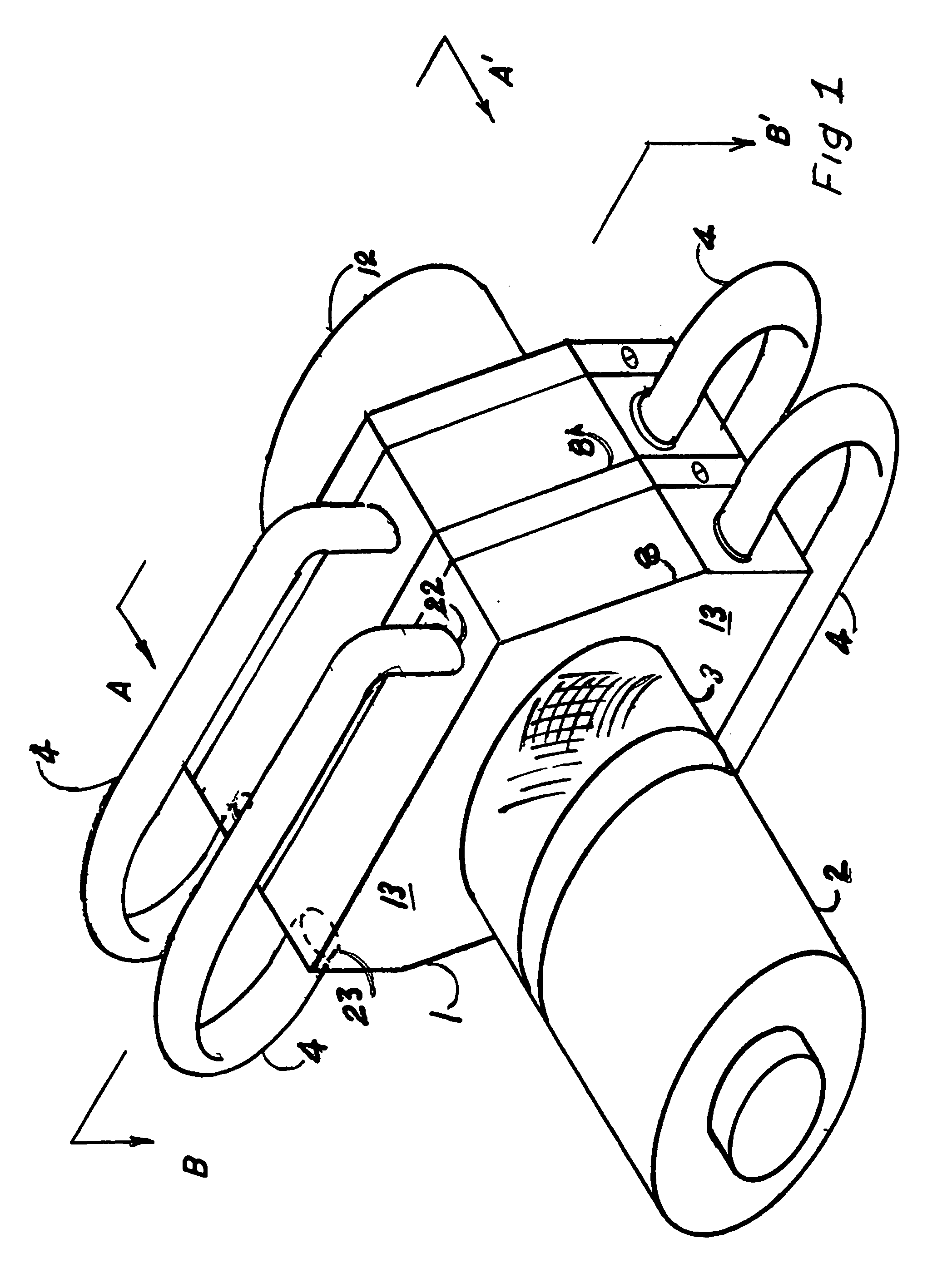

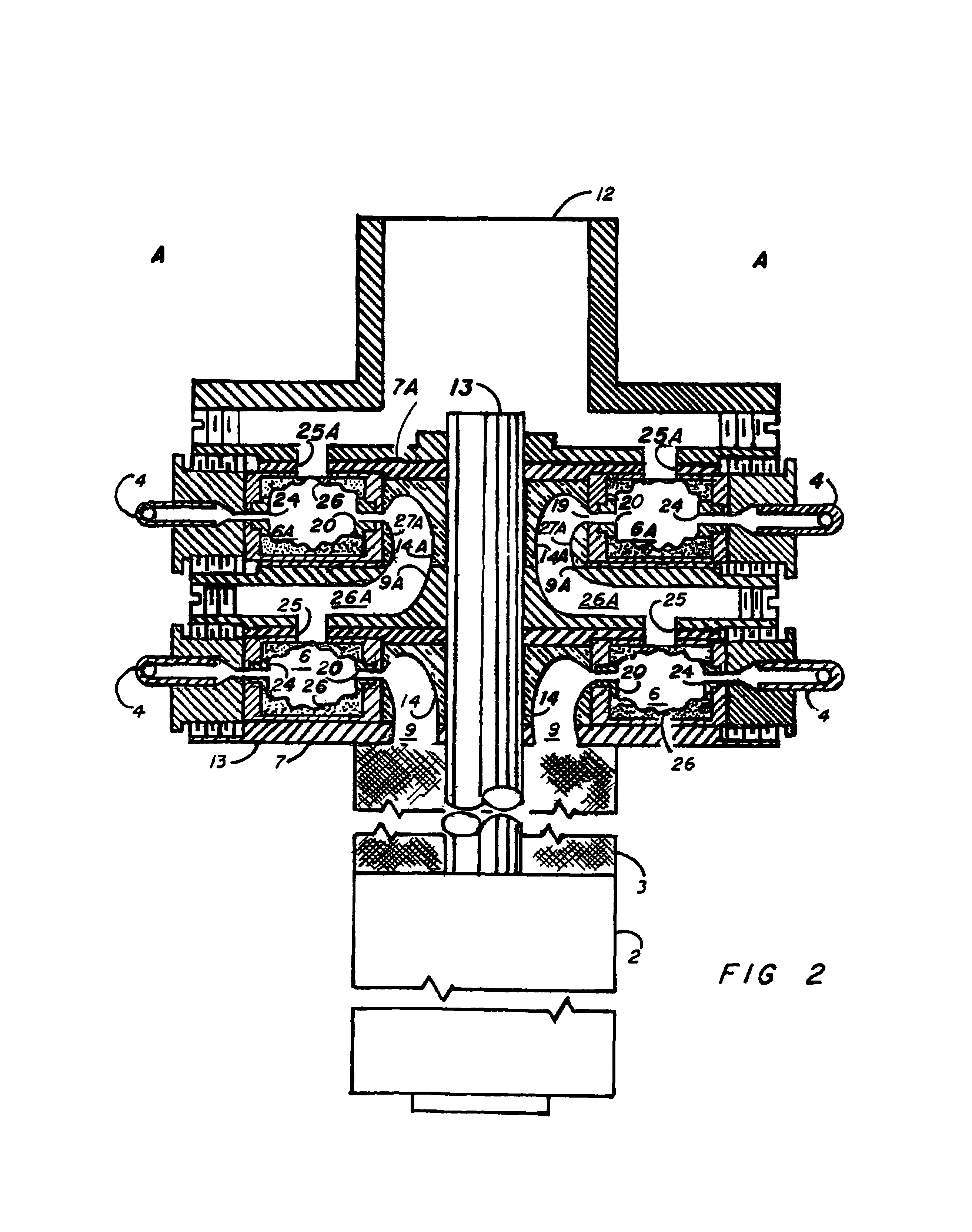

Apparatus and method for processing fluids

InactiveUS7214031B2Increase pressureIncrease kinetic energyFlow mixersPump componentsOblate spheroidDrive shaft

An apparatus and a method for a versatile, multi-stage, centrifugal fluids-processing device adaptable to efficiently mixing, blending, emulsifying, deagglomerating or homogenizing fluids. The device comprises a centrifugal-pump-type mechanism comprising an electric motor, an intake screen, an elongate metal body, a central drive shaft extending from the motor to the discharge end of the device. Attached internally to the drive shaft is one impellor per stage, which by rotation of the motor, imparts kinetic energy to the fluid being processed. The fluid discharged from the impellors passes through separate conduits and opposing nozzles into opposite ends of a chamber having the internal shape of an oblate-spheroid with internally-ribbed ceramic walls. As the fluid streams being slightly divergent upon contact with each other they are mutually deflected at high-velocity and high turbulence to impact against the ribbed inner walls of the fluid processing chamber in directions away from the outlet from fluid processing. The orientation of the incoming fluid streams aids in providing optimum use of the fluid's kinetic energy in turbulence and high-sheer contact prior to the fluids exiting the fluid processing chamber.

Owner:PARRENT KENNETH GAYLORD

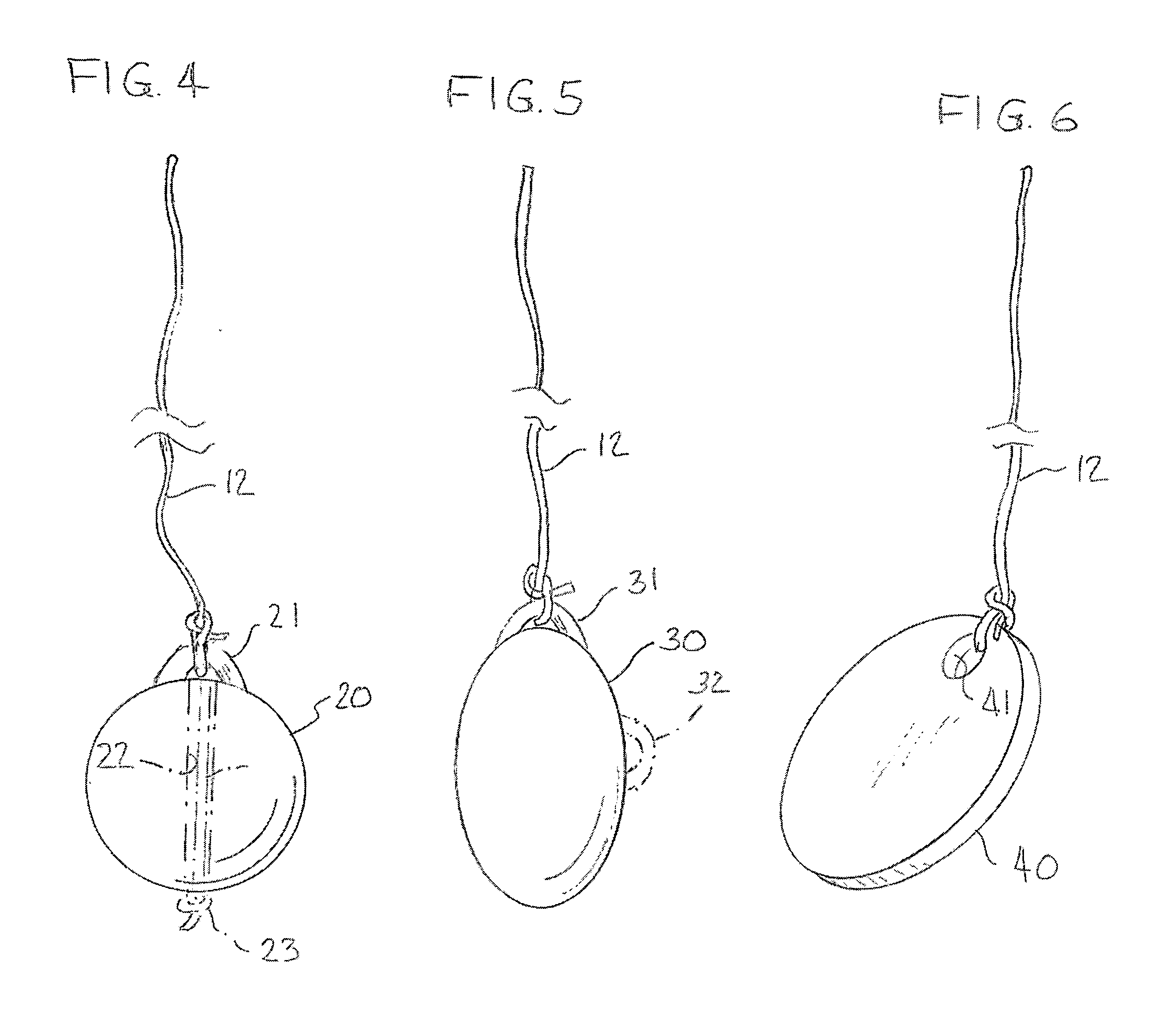

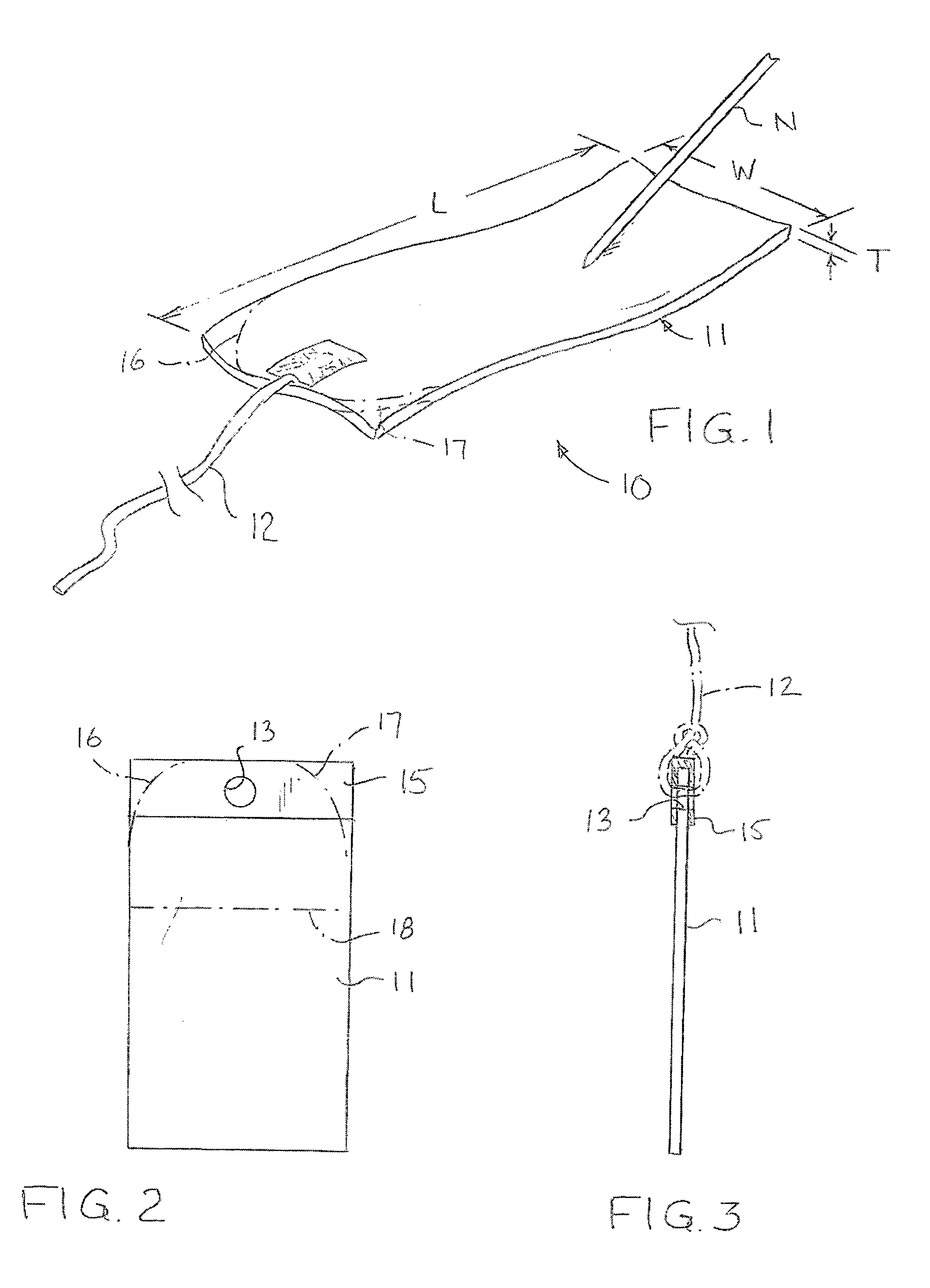

Surgical magnetic retrieval tool

A surgical magnetic retrieval tool for retrieving objects attractable by a magnet lost in a surgical cavity during a surgical procedure. The tool is a permanent magnet having a size and shape adapted to be placed in and moved through a surgical cavity to attract and hold the objects for retrieval of them from the cavity, and a flexible tether is attached to the magnet for supporting the magnet, pulling it through the cavity, and retrieving the magnet and objects attracted thereto from the cavity. In one form of the invention the magnet is a flexible magnetic sheet; in another form it is a sphere; in another form it is an oblate spheroid; and in another form it is a disc. The tool is disposable following use.

Owner:JACKSON III AVERY M

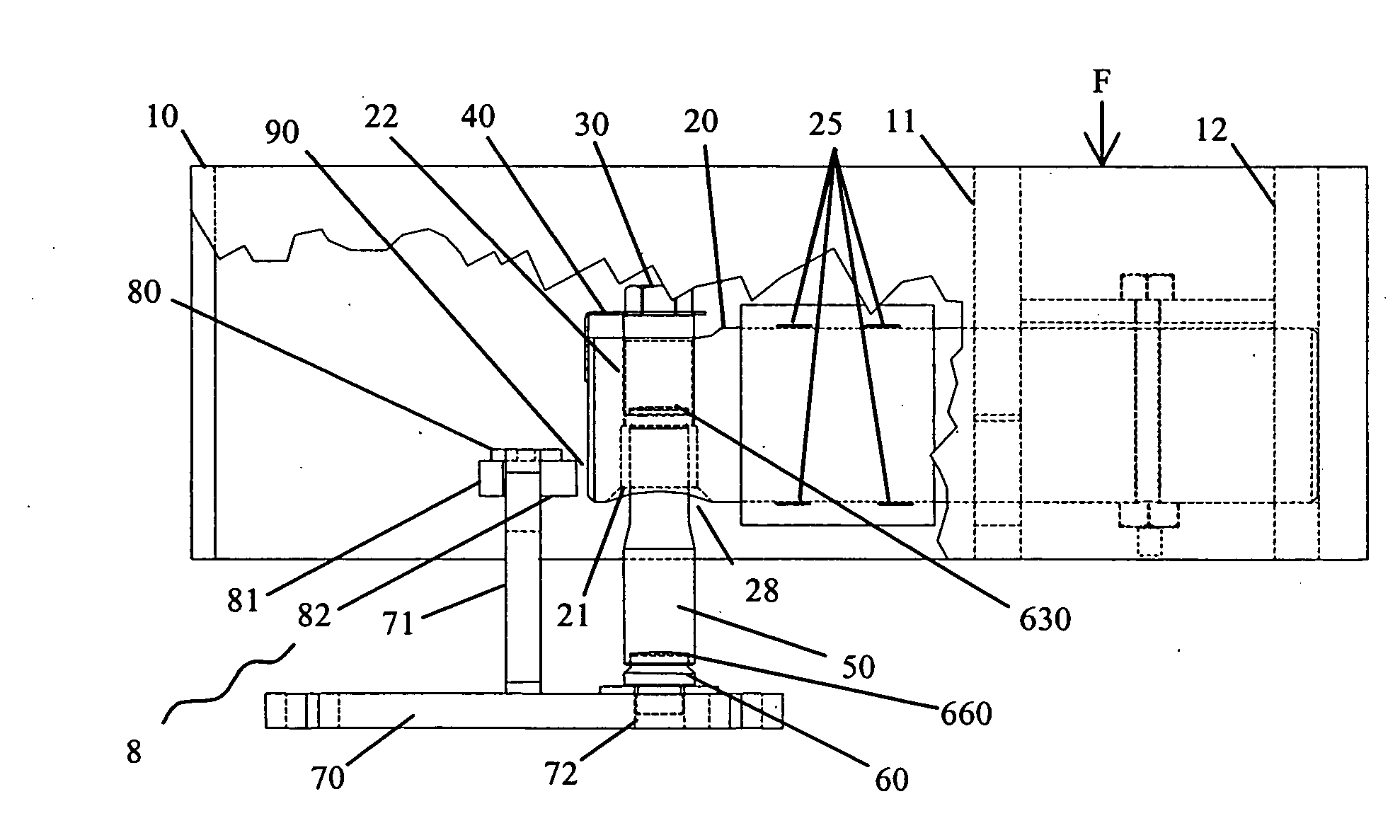

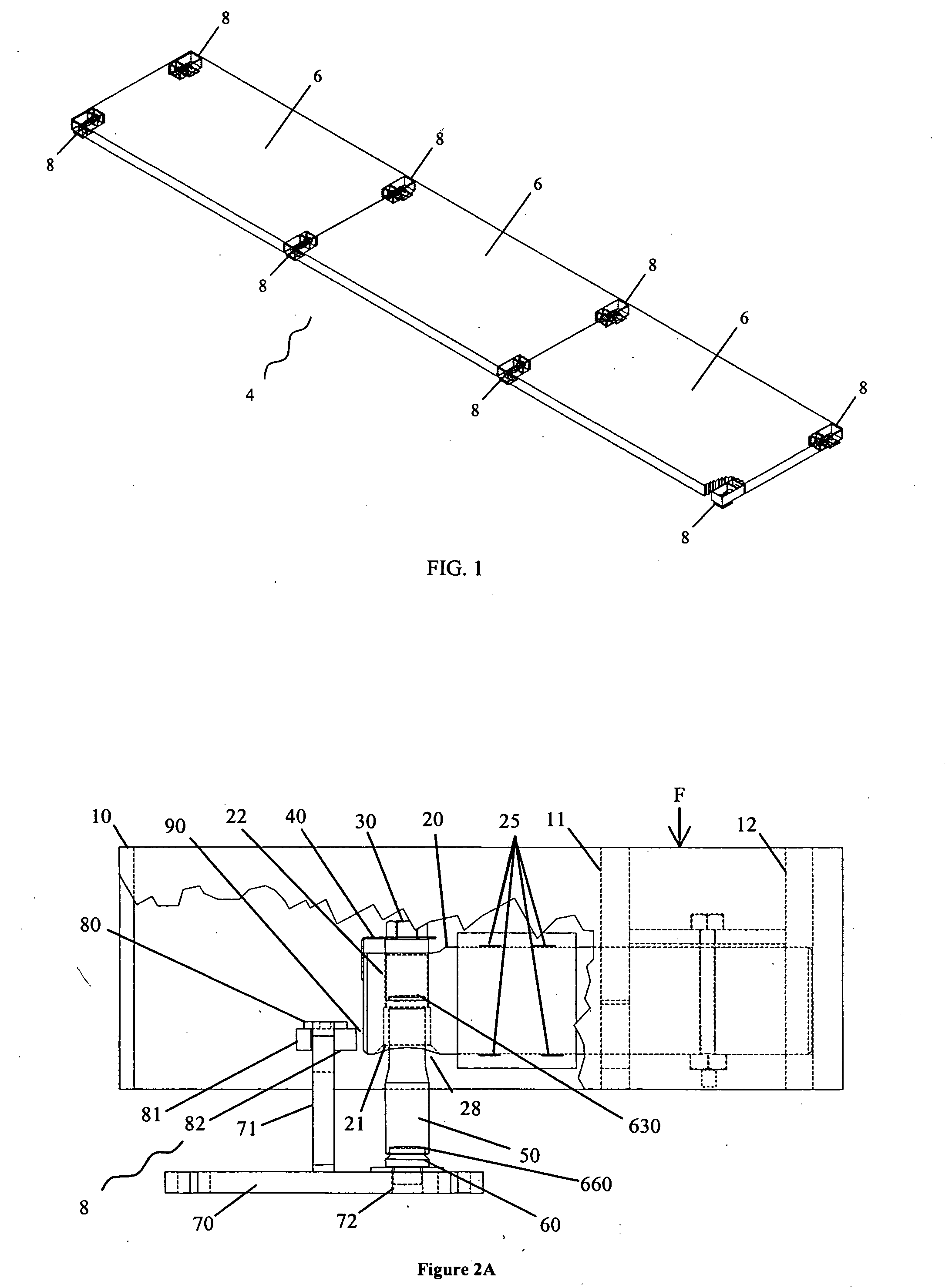

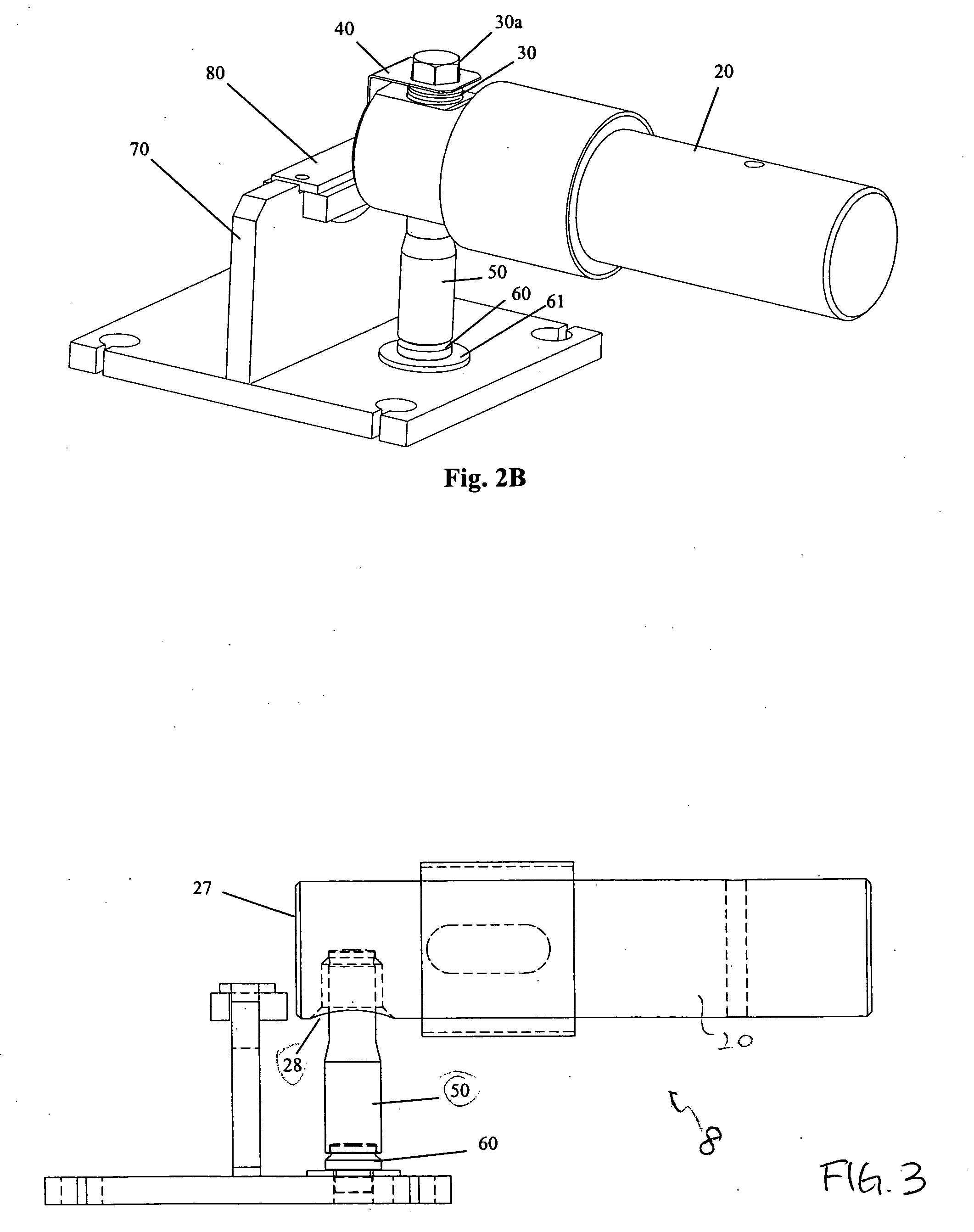

Support structure for a load-bearing device

ActiveUS20050132819A1Reduce horizontal forceReduce the effective heightApparatus for force/torque/work measurementForce measurement by elastic gauge deformationOblate spheroidEffective height

A mechanism for reducing horizontal force in load measurement is presented. The mechanism includes a structure having surfaces of nonuniform radii of curvature (e.g., oblate spheroid surfaces) at both ends. The ends of the structure contact a force-sensor coupling element and a base-coupling element, forming two interfaces. Each interface includes a contact area between a convex surface and a concave surface. When a horizontal force is applied, the contact area at each interface shifts, allowing the structure to tip from the vertically aligned position that it is in when no horizontal force is applied. Compared to conventional mechanisms, the structure of the invention has a lower effective height because interfaces between oblate spheroid surfaces allow a larger angle of deflection than flat interfaces. The oblate spheroid interfaces also allow deflection to occur with less wear and tear at the interfaces compared to the flat-interfaced structures.

Owner:AVERY WEIGH-TRONIX

Synarthrosis device for waist articular process and implantation device thereof

InactiveCN101433479AImprove fusion rateEliminate loosenessSurgeryJoint implantsOblate spheroidSide effect

The invention discloses a waist joint zygapophysis cage and an implanting device thereof. The waist joint zygapophysis cage comprises an oblate spheroid, and both ends of the oblate spheroid are provided with an upper cylinder and a lower cylinder respectively which have coincided center shafts and the same diameter; the oblate spheroid is 6 mm in diameter and 4 mm in height; the diameters of the upper cylinder and the lower cylinder are 2 mm, the upper cylinder is 2 mm in height, and the lower cylinder is 1mm in height; and the oblate spheroid, the upper cylinder and the lower cylinder are made of cortical bone materials of adult thighbone. The implanting device comprises a positioning device, a working channel, a straight drill, a spherical drill and an implanting machine. The waist joint zygapophysis cage has the advantages of improving the medium and long term fusion rates of the lumbar facet joint and the remission rate of postoperative symptoms, eliminating the loosening and breaking of bolts and reducing side effects of bolts such as neurologic damage and the like caused by epidural rupture and vertebral canal puncture. The implanting device has the advantages of simple structure, easy operation and good use effect.

Owner:崔志明 +2

Preparation method of anterior chamber separation saccule

ActiveCN108606868AEasy accessReduces the risk of damaging the corneaEye surgeryOblate spheroidSaccule

The invention discloses a preparation method of an anterior chamber separation saccule. The preparation method includes the steps: taking a half-compliance and / or non-compliance high-molecular material to remove dust, and placing the material into an air dry oven to perform drying; (2) placing the dried material into an extruding machine to form a pipe; (3) stretching the extruded pipe in a stretcher to form a thin-wall pipe; (4) placing the stretched thin-wall pipe into a saccule mold to perform blow molding, blowing-up a parison to cling on the inner wall of the mold, performing cooling anddemolding to obtain the saccule, and arranging a catheter on the saccule; (5) folding the saccule prepared in the step (4) by taking the catheter as a axis through a saccule folding machine to obtainthe anterior chamber separation saccule. The saccule prepared by the method is high in strength, good in durability and of an oblate spheroid structure, the diameter of the saccule is 8-9mm, the plumped height of the saccule is about 1mm, sufficient space can be reserved for an operation when phacoemulsification cataract extraction is performed, and corneal endothelial cells can be effectively protected.

Owner:广州锐澄医疗技术有限公司

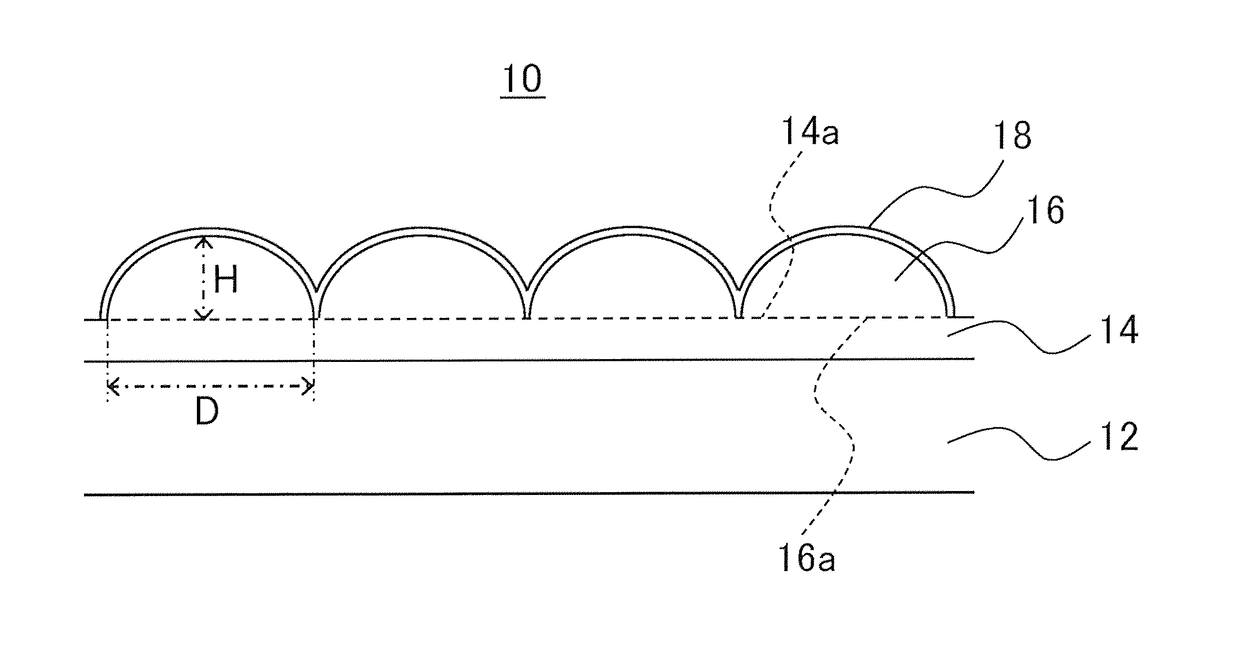

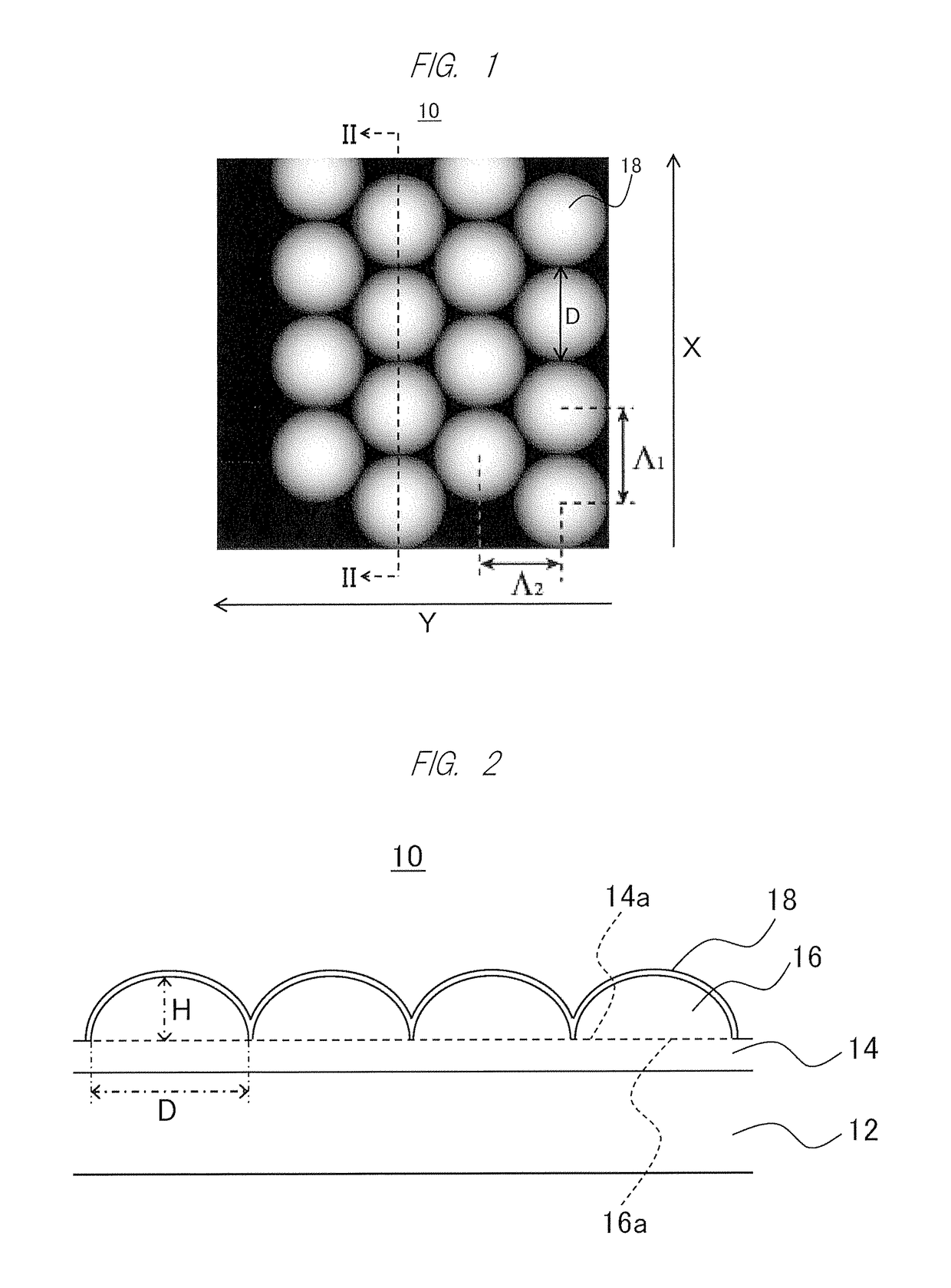

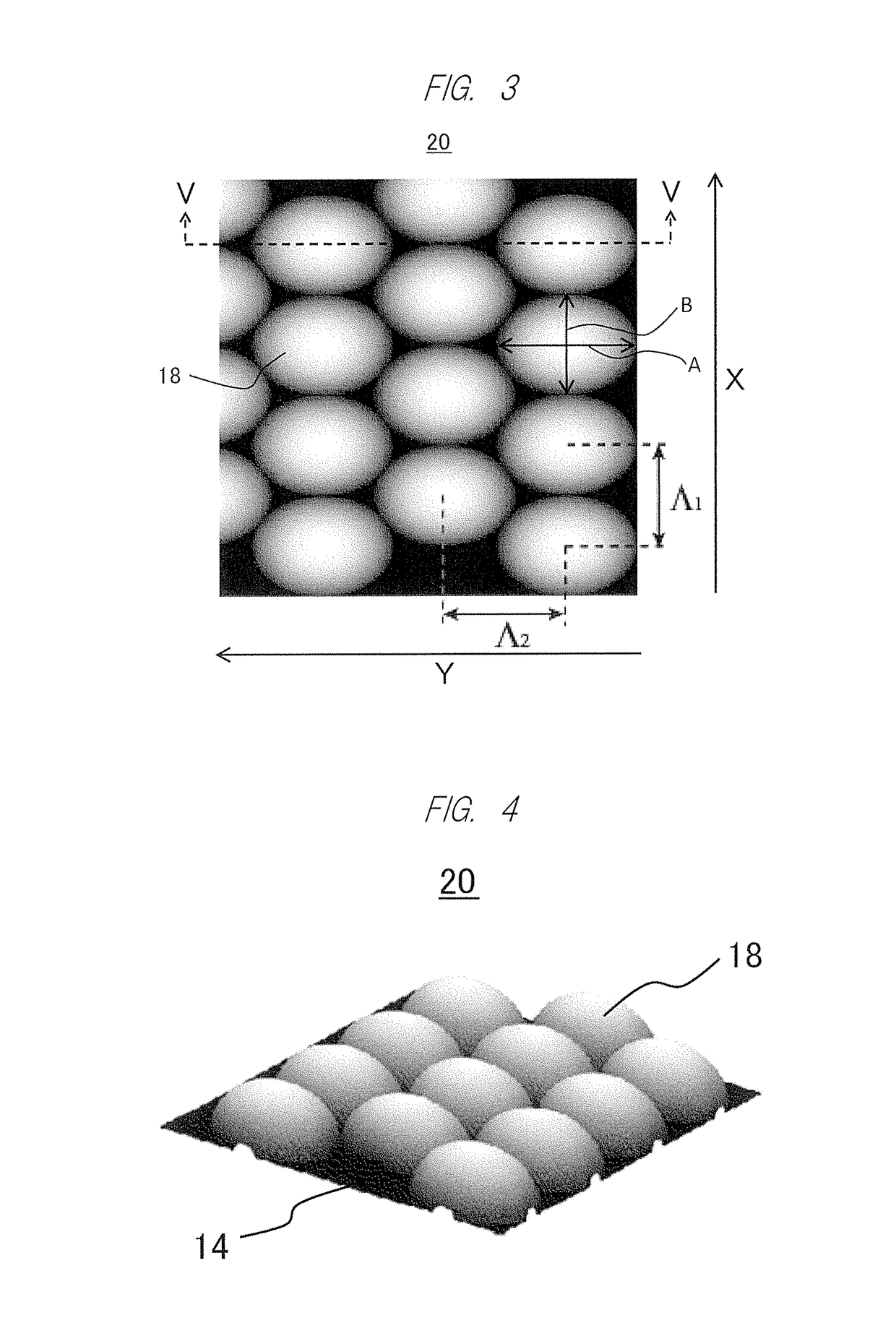

Localized surface plasmon resonance sensing chip and localized surface plasmon resonance sensing system

InactiveUS20170219488A1Improve accuracyScattering properties measurementsOptical elementsOblate spheroidPhotodetector

There are provided a localized surface plasmon resonance sensing chip in which a linewidth of an absorption spectrum originating from localized plasmon resonance is narrow and with which a peak wavelength shift of an optical spectrum accompanying a change in refractive index of a surface can be accurately measured, and a localized surface plasmon resonance sensing system using this sensing chip. A sensing chip 10 includes a base 14 having a flat-plate shape, a plurality of protruding portions 16, and a metal layer 18 covering each front surface of the plurality of protruding portions 16. The protruding portions 16 each have a shape like a semi-oblate spheroid which is one of three-dimensional parts obtained by dividing an oblate spheroid in half along an equatorial plane and are arranged such that a divided surface 16a of the semi-oblate spheroid faces a front surface 14a of the base 14. A sensing system includes the sensing chip 10, a light source irradiating a detection region of the sensing chip 10 with light, and a photodetector detecting the optical spectrum of light emitted from the light source and then reflected in or transmitted through the detection region of the sensing chip 10.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Surgical magnetic retrieval tool

A surgical magnetic retrieval tool for retrieving objects attractable by a magnet lost in a surgical cavity during a surgical procedure. The tool is a permanent magnet having a size and shape adapted to be placed in and moved through a surgical cavity to attract and hold the objects for retrieval of them from the cavity, and a flexible tether is attached to the magnet for supporting the magnet, pulling it through the cavity, and retrieving the magnet and objects attracted thereto from the cavity. In one form of the invention the magnet is a flexible magnetic sheet; in another form it is a sphere; in another form it is an oblate spheroid; and in another form it is a disc. The tool is disposable following use.

Owner:JACKSON III AVERY M

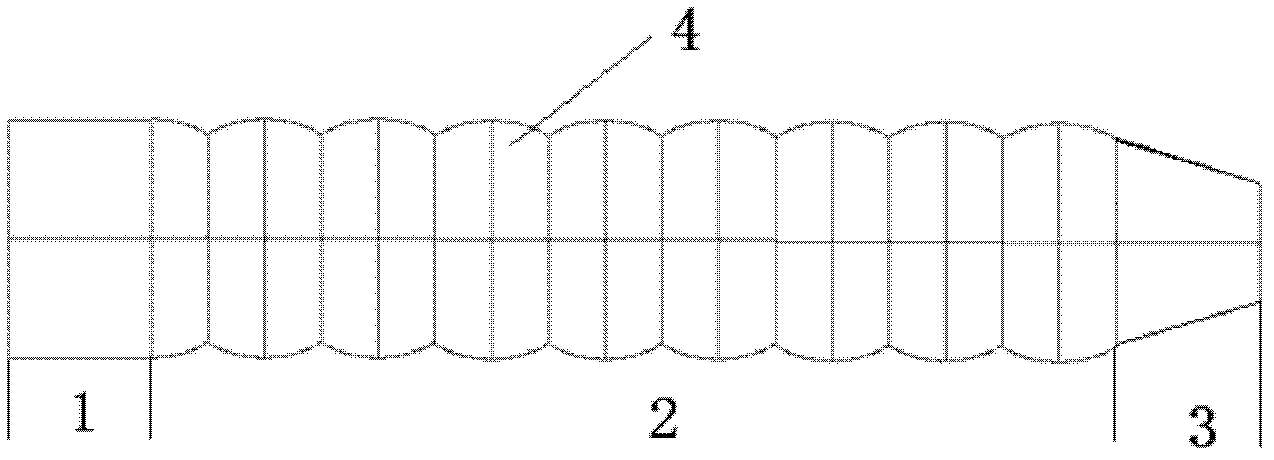

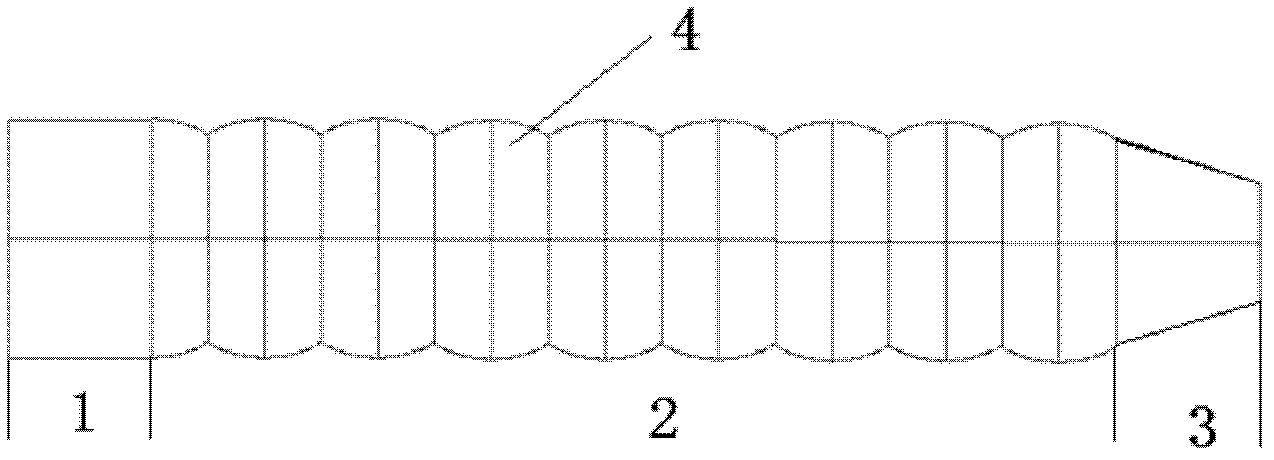

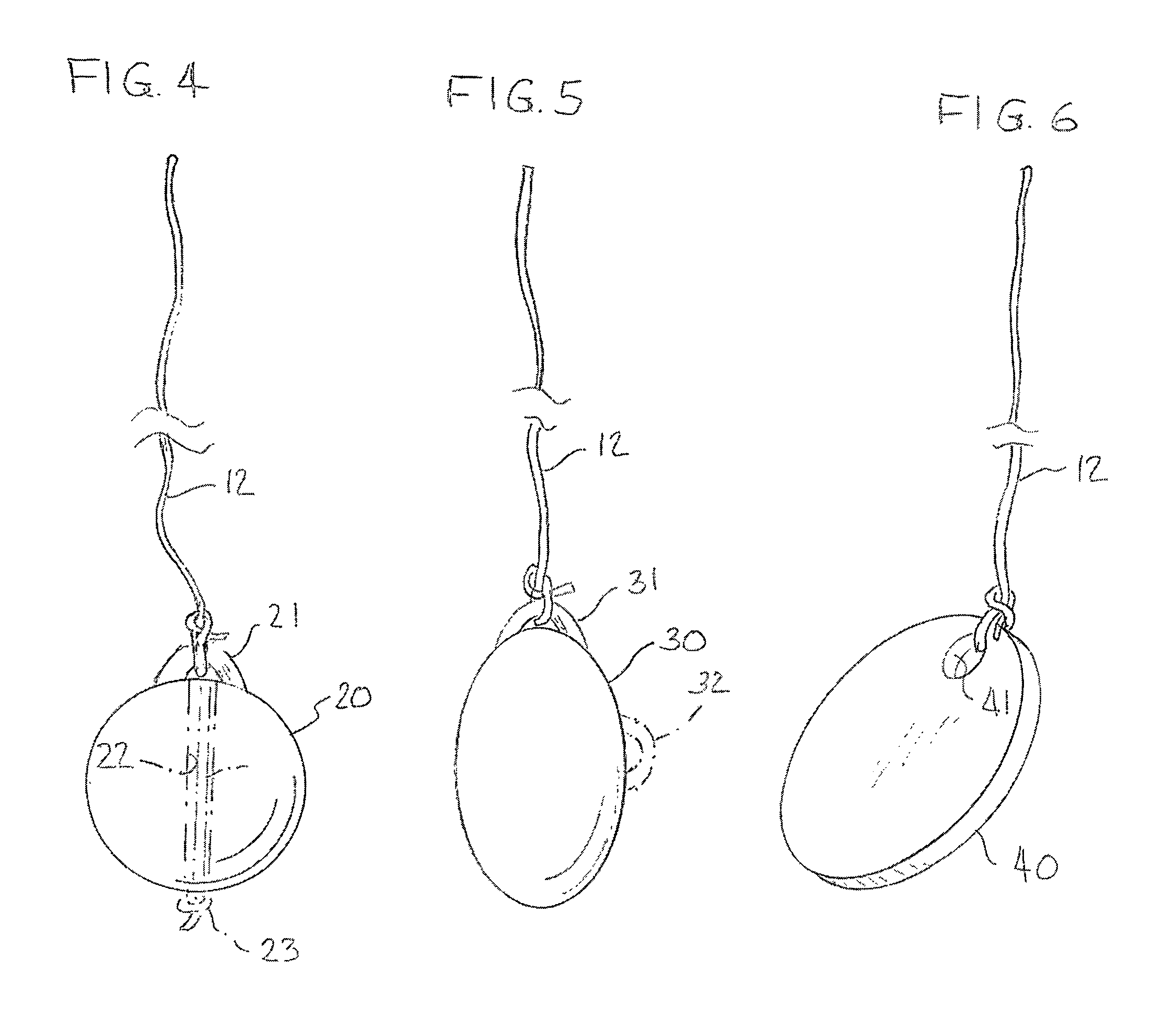

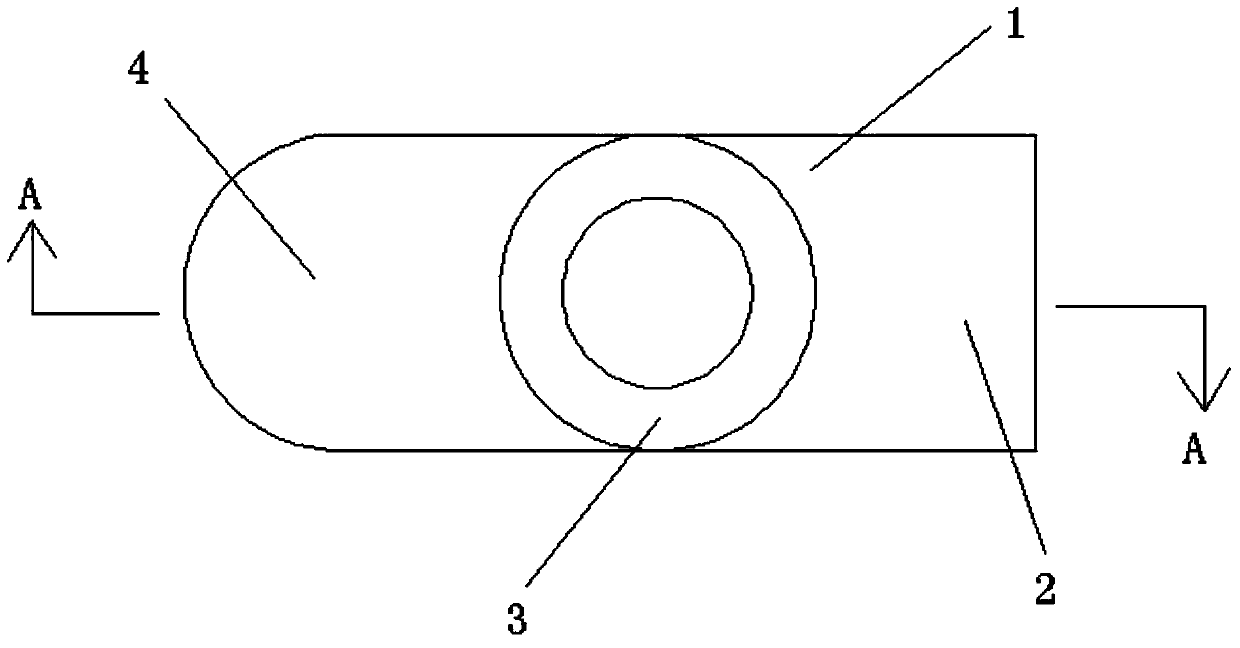

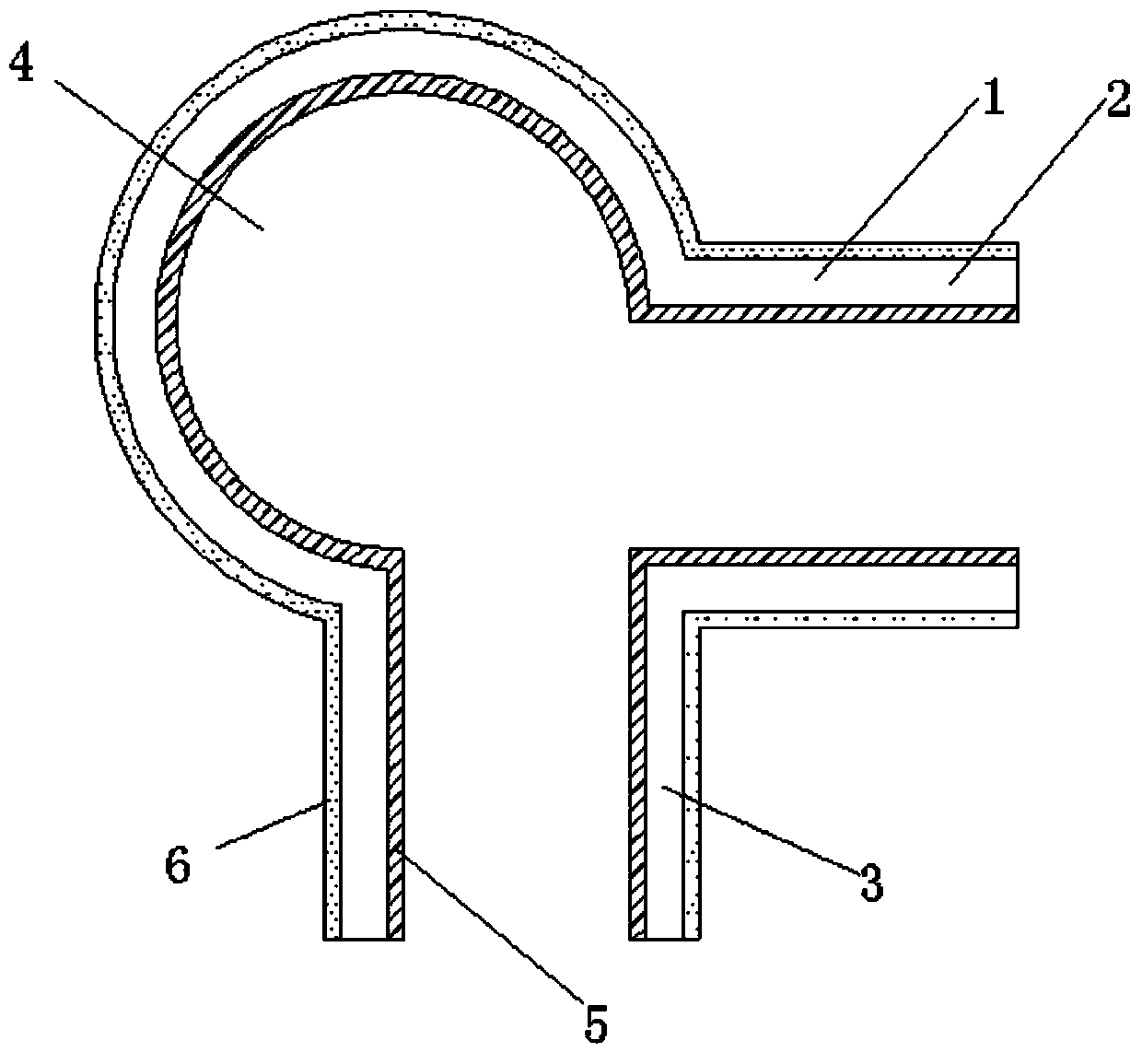

Bent pipe capable of preventing high-speed fluid impacting

InactiveCN103742749AExtended service lifeLow costCorrosion preventionPipe protection against corrosion/incrustationOblate spheroidCivil engineering

The invention discloses a bent pipe capable of preventing high-speed fluid impacting. The bent pipe comprises a bent pipe body (1) and is characterized in that the bent pipe body (1) comprises a horizontal pipe (2) and a vertical pipe (3) which are the same in diameter, and the horizontal pipe (2) and a vertical pipe (3) are integrally connected through a hollow oblate spheroid (4). The bent pipe capable of preventing high-speed fluid impacting is simple in structure and reasonable in design, the high-speed fluid impacting preventing effect of the bent pipe is effectively achieved through the arrangement of the hollow oblate spheroid, so that service life is prolonged, production cost is lowered, production efficiency is improved, and the bent pipe is suitable for wide popularization and application.

Owner:JIANGSU DIWEI HIGH VOLTAGE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com