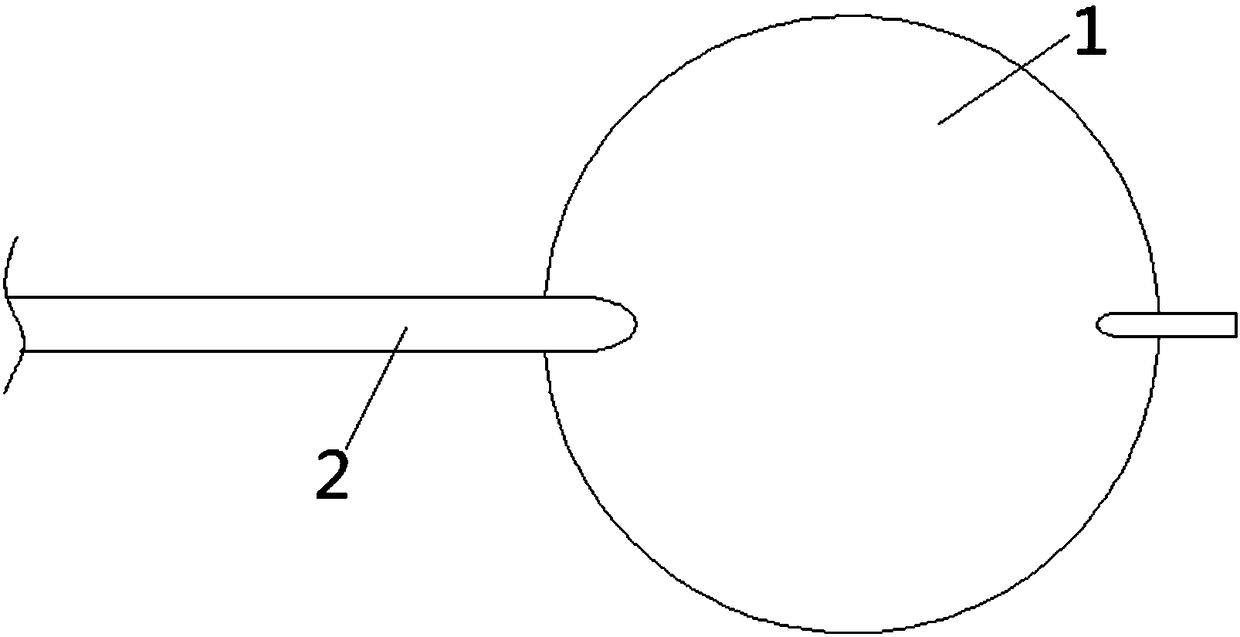

Preparation method of anterior chamber separation saccule

A technology of isolating balls and balloons, applied in ophthalmic surgery, etc., can solve the problems of low corneal endothelial density, corneal endothelial cell damage, corneal damage, etc., to reduce the risk of corneal damage, facilitate surgical operations, and have good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of embodiment of the preparation method of anterior chamber isolation balloon of the present invention comprises the following steps:

[0029] (1) Take polyethylene (PE) for dust removal to remove mixed dust or foreign matter; then place it in a blast drying oven and dry it at 50°C for 24 hours to remove the contained moisture. The moisture content of the dried particles is 0.5% ;

[0030] (2) Put the dried polymer material into the extruder to form a pipe. Extrusion parameters: feed port temperature 79°C, extruder temperature 350°C, screw speed 10RPM, melt pump speed 90RPM, traction speed 10m / min , the water cooling solidification temperature is 10°C;

[0031] (3) The extruded pipe is stretched into a thin-walled pipe in a stretching machine. The stretching parameters: heating to 80°C, 200mm / s stretching speed along the axial direction, stretching distance of 100mm at the left and right ends, heating time 10s;

[0032] (4) The stretched thin-walled pipe is pl...

Embodiment 2

[0035] A kind of embodiment of the preparation method of anterior chamber isolation balloon of the present invention comprises the following steps:

[0036] (1) Take nylon (PA) for dust removal to remove mixed dust or foreign matter; then place it in a blast drying oven and dry it at 55°C for 20 hours to remove the contained moisture. The moisture content of the dried particles is 0.73%;

[0037] (2) Put the dried polymer material into the extruder to form a pipe. Extrusion parameters: feed port temperature 70°C, extruder temperature 300°C, screw speed 20RPM, melt pump speed 80RPM, traction speed 15m / min , the water cooling solidification temperature is 15°C;

[0038] (3) The extruded pipe is stretched into a thin-walled pipe in a stretching machine. The stretching parameters are: heated to 130°C, the stretching speed is 180mm / s along the axial direction, the stretching distance at the left and right ends is 135mm, and the heating time 12s;

[0039] (4) The stretched thin-wa...

Embodiment 3

[0042] A kind of embodiment of the preparation method of anterior chamber isolation balloon of the present invention comprises the following steps:

[0043] (1) Take polyurethane (PU) for dust removal to remove mixed dust or foreign matter; then place it in a blast drying oven and dry it at 60°C for 18 hours to remove the contained moisture, and the moisture content of the dried particles is 1%;

[0044] (2) Put the dried polymer material into the extruder to form a pipe. Extrusion parameters: feed port temperature 60°C, extruder temperature 250°C, screw speed 45RPM, melt pump speed 50RPM, traction speed 40m / min , the water cooling solidification temperature is 25°C;

[0045] (3) The extruded pipe is stretched into a thin-walled pipe in a stretching machine. The stretching parameters are: heated to 180°C, the stretching speed is 150mm / s along the axial direction, the stretching distance at the left and right ends is 160mm, and the heating time 15s;

[0046] (4) The stretched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com