Method for producing color intrigue blue-and-white ceramic tile

A production method and technology of illusion, applied in the field of manufacture of illusion blue and white textured glazed tiles, can solve problems such as weak layering, lack of natural texture, and unrealistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

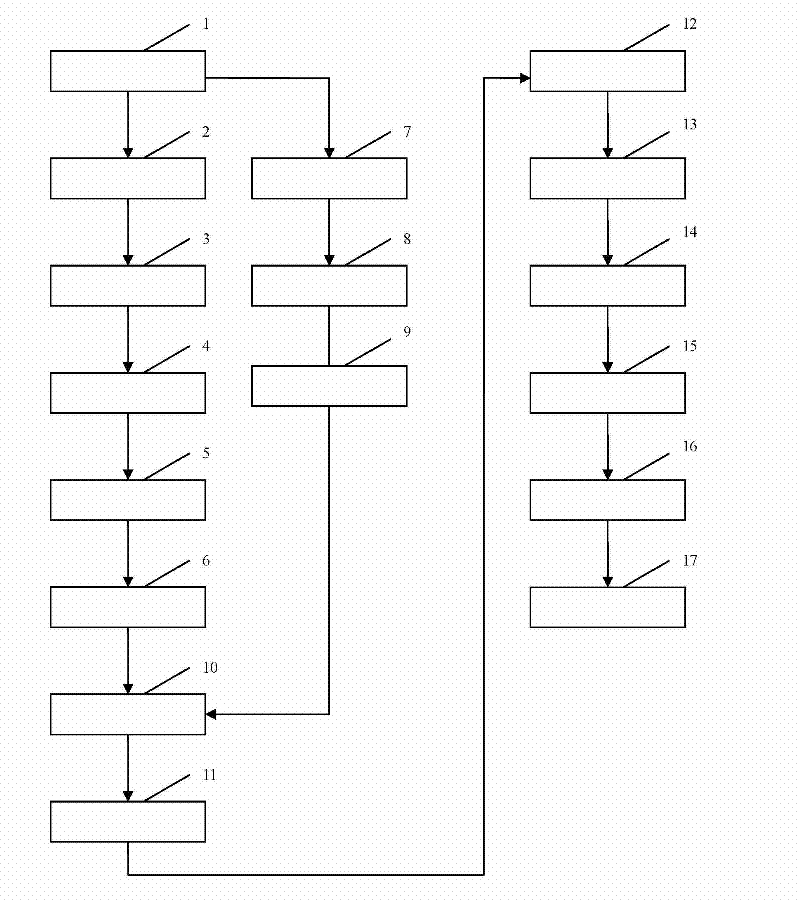

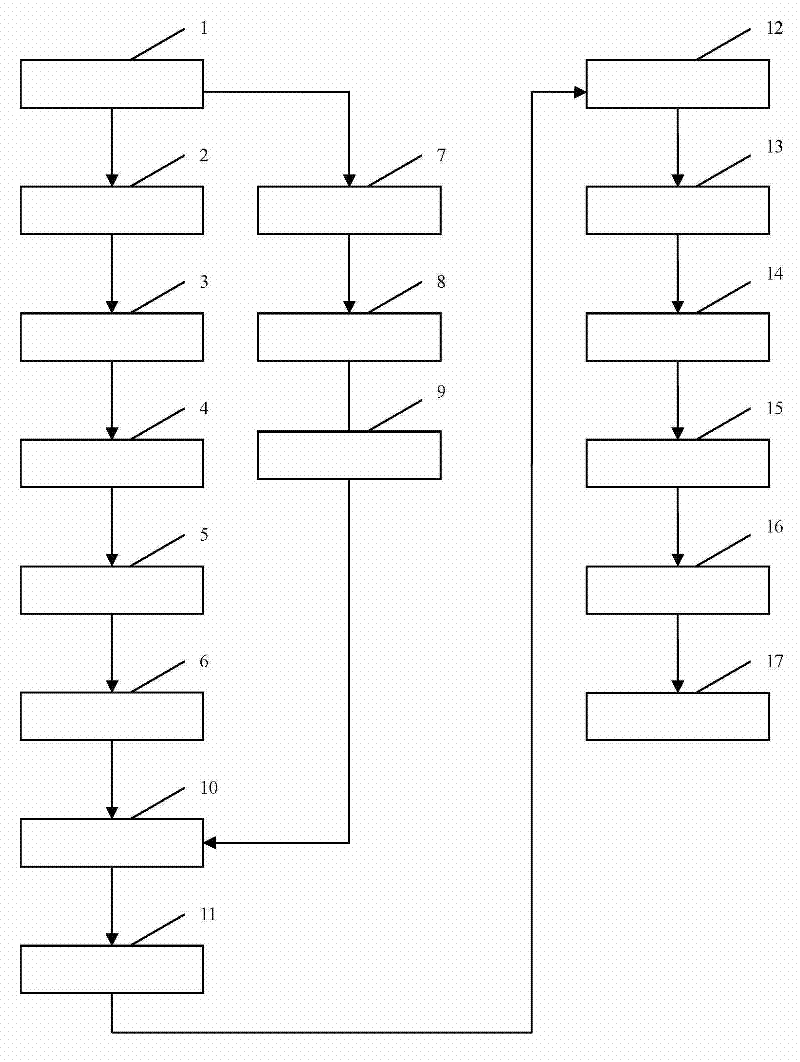

Method used

Image

Examples

Embodiment Construction

[0013] The production method of a magic color blue and white ceramic tile of the present invention, it uses active agent surface tension action mechanism, uses multi-color glaze paste and a kind of active additive, all pastes are separated respectively, sprayed on the upper surface of brick adobe respectively according to a certain order, The active agent forms a layer of hydrophobic hydrocarbon chains between the two glaze layers. The second layer of glaze slurry solution is subjected to tension, and internally self-assembles to form many oblate spherical molecular micelles. The micelles are gradually set during the natural drying process. The micelles form a deep crack effect similar to the cracking of the earth after a long period of sunshine and dryness. After being calcined at a high temperature, the edges and corners of the cracks become round and beautiful under the action of a small amount of liquid phase, forming a natural concave textured illusion blue and white tile. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com