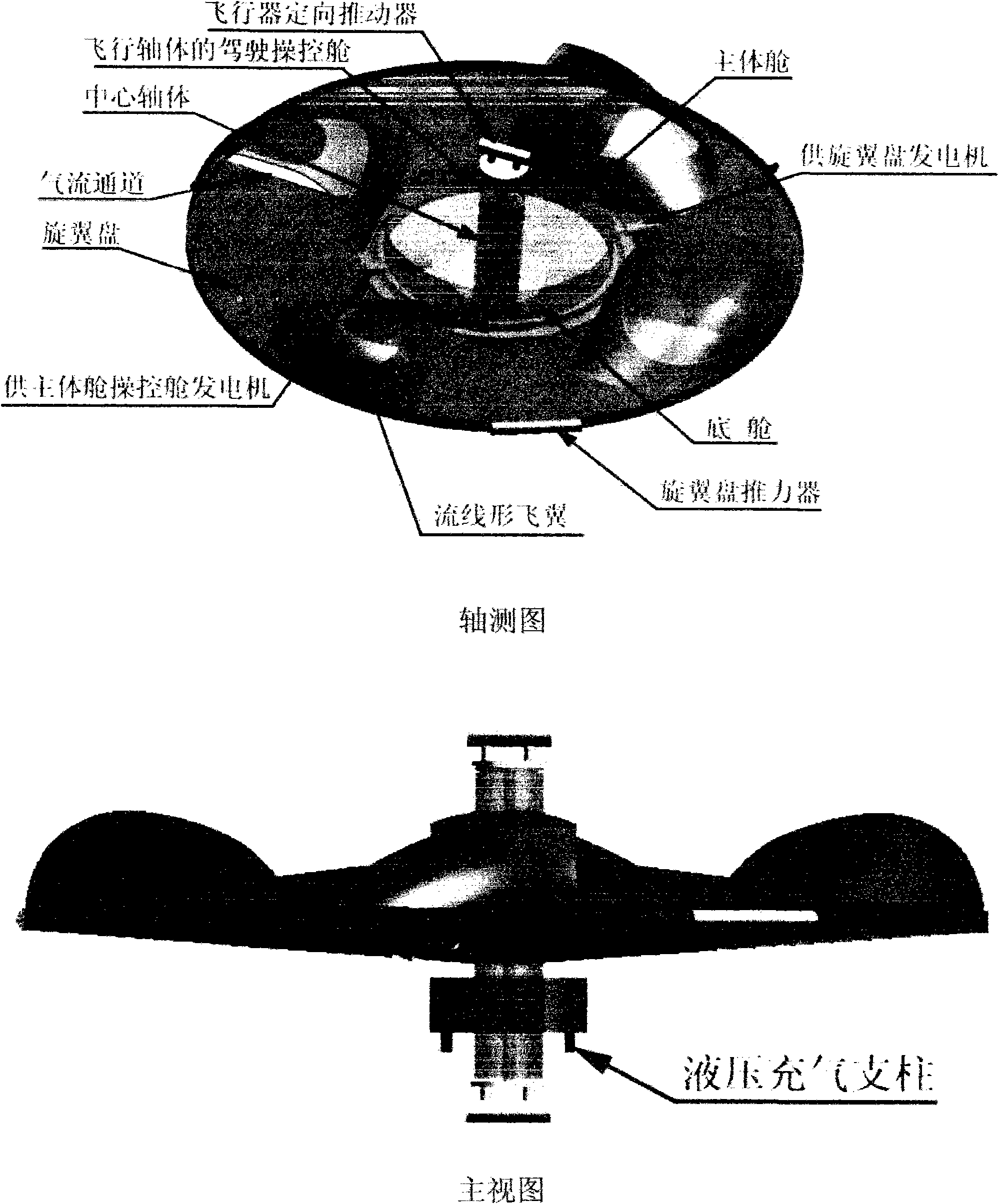

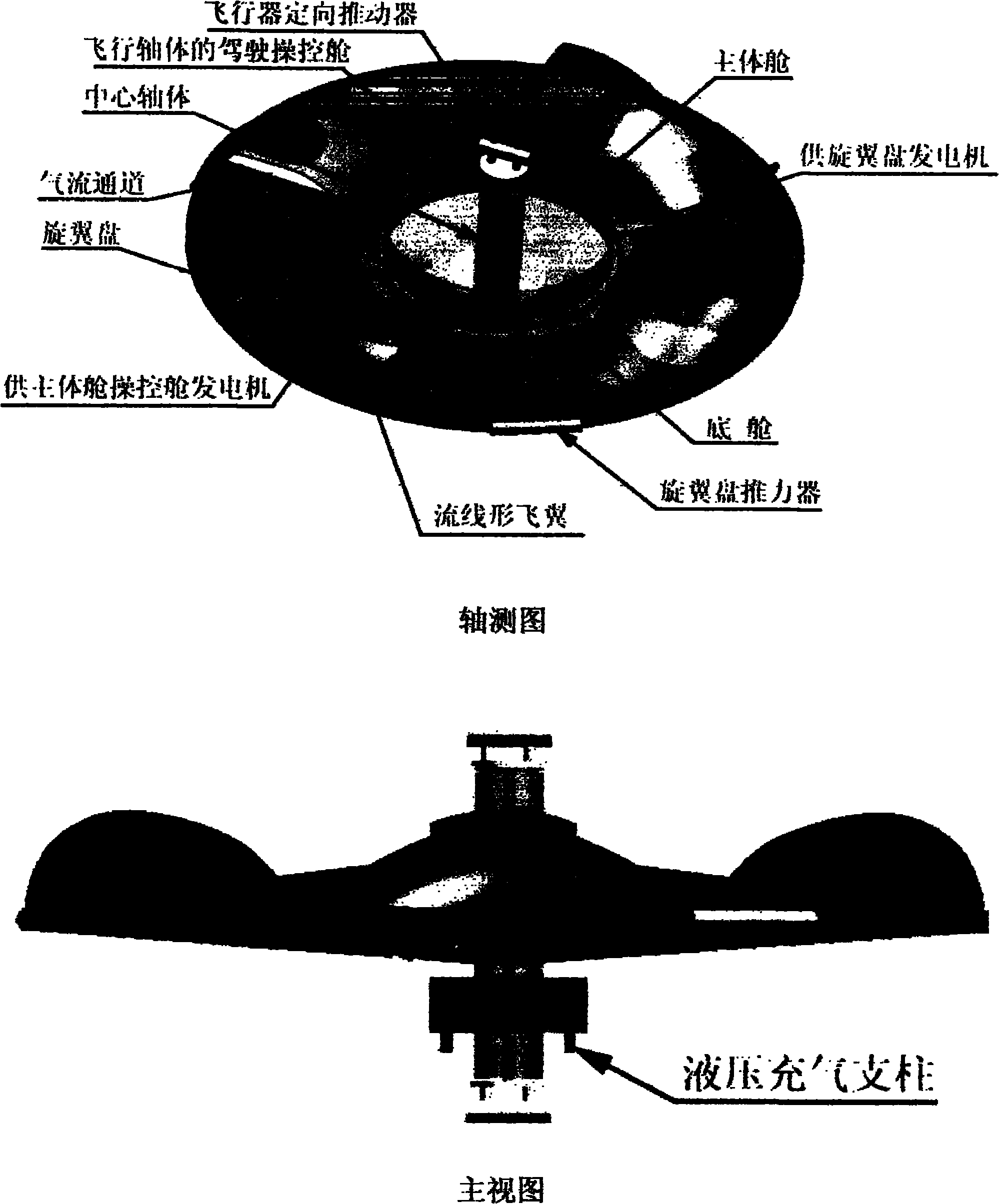

Rotor wing disk-shaped aviation aircraft

A technology for rotor discs and aircraft, which is applied in aircraft, motor vehicles, transportation and packaging, etc., can solve problems such as high energy consumption, heavy take-off and landing conditions, and limited air movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] The design structure of the aircraft is relatively simple, and the current existing technology can implement and make it fly. Its specific implementation is as follows: A hollow cylinder is fixed up and down by two bearings with the same diameter, and is divided into upper, middle and lower parts (shown in the figure). The upper, lower and central parts of the rotor disc are respectively connected with the upper and lower bearings on the central shaft as a whole (as shown in the figure). The expansion space in the middle section of the hollow shaft is the main cabin (pictured). The upper part of the hollow shaft body is designed as a driving control cabin. Powerful rotor disc; streamlined flying wing and airflow channel under the streamlined flying wing are designed (pictured), and three thrusters are designed and installed on the edge of the rotor disc to push the flexible rotor disc to rotate at high speed (pictured). When the rotor disk rotates at a high speed, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com