Bent pipe capable of preventing high-speed fluid impacting

A high-speed fluid and pipe bending technology, which is applied in the direction of elbows, siphons, pipe components, etc., can solve the problems that ordinary elbows cannot be transported with high-speed fluid, do not have the effect of anti-shock, and are easy to wash and damage corners, etc., to achieve structural Simple, reasonable design, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

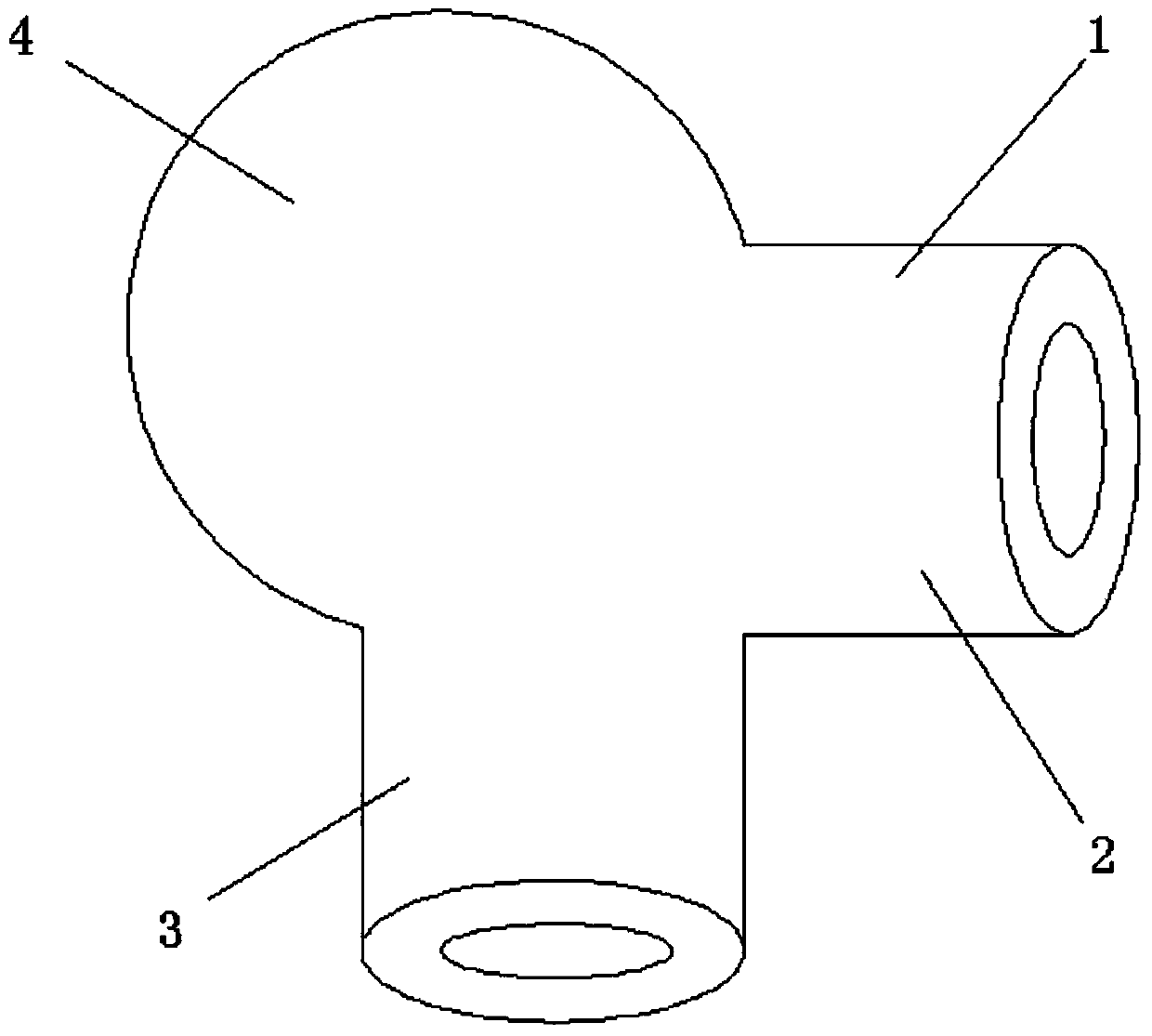

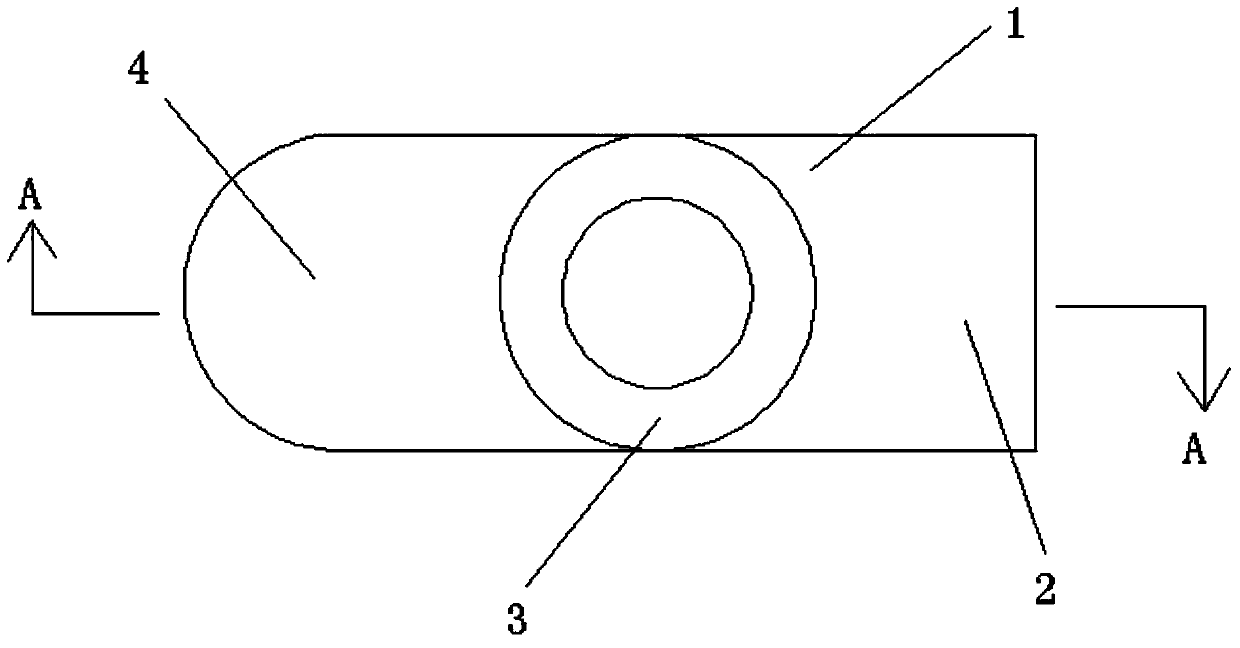

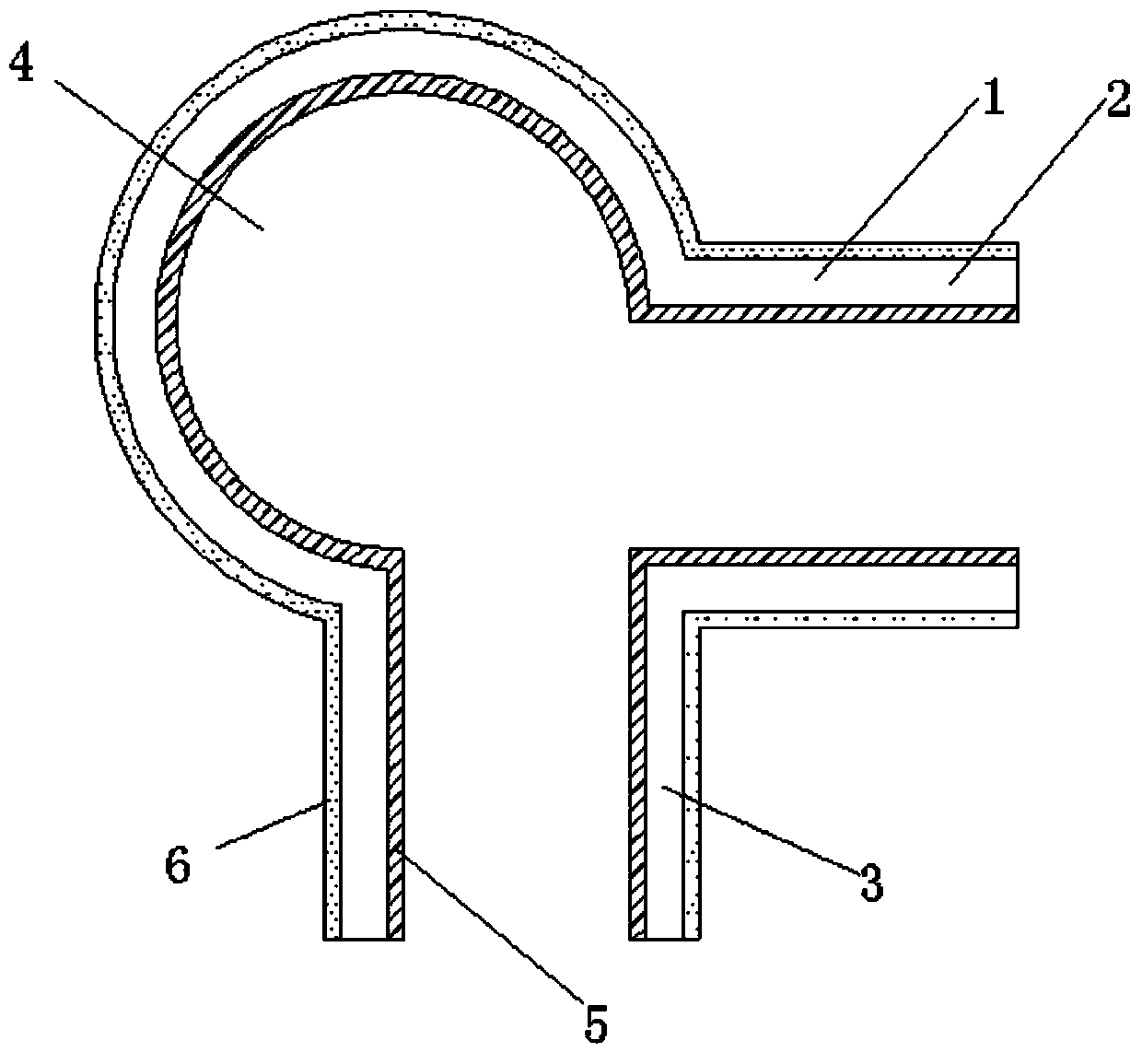

[0017] like Figure 1-4 As shown, an elbow for preventing high-velocity fluid impact includes: an elbow body 1, which is characterized in that: the elbow body 1 includes a horizontal tube 2 and a vertical tube 3 with the same diameter, and the horizontal tube 2 and the vertical tube The pipes 3 are integrally connected by hollow oblate spheroids 4 .

[0018] The angle of the hollow oblate spheroid 4 is 270°, the thickness is the same as the diameter of the transverse tube 2 , and the radius is the diameter of the transverse tube 2 .

[0019] The inner wall of the elbow body 1 is provided with an anti-corrosion coating 5 , and the outer wall of the elbow body 1 is provided with an anti-oxidation and anti-corrosion coating 6 .

[0020] The material of the anti-corrosion coating 5 is enamel paint.

[0021] The anti-oxidation and anti-corrosion coating 6 is an inorganic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com