Sliding plate antioxidation paint and preparation method thereof

An anti-oxidation coating and anti-oxidation technology, which is applied in the preparation of the anti-oxidation coating and the field of anti-oxidation coatings, can solve the problems of high price and small application range, and achieve the effect of low cost, good stability and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

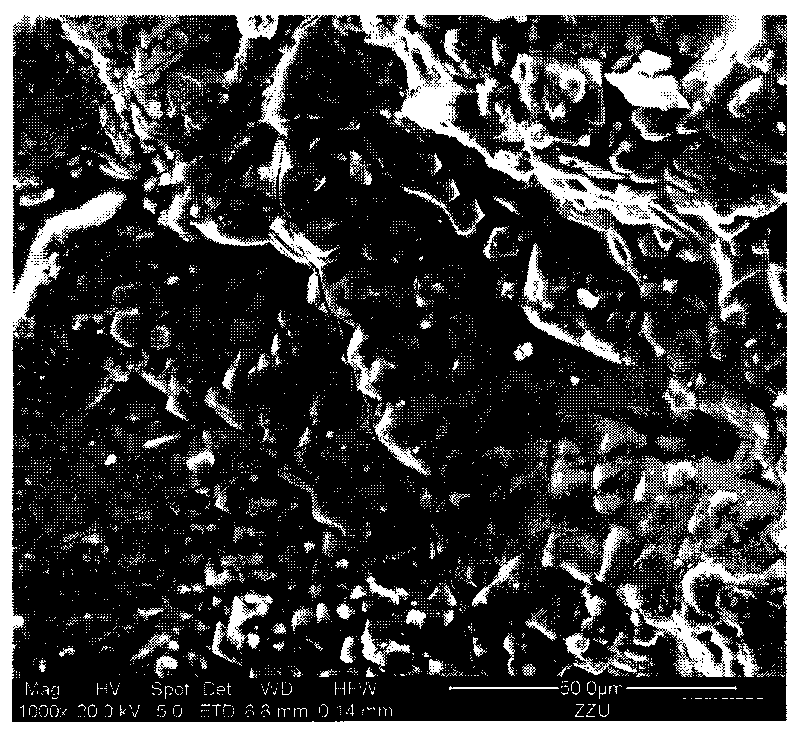

[0024] Antioxidant coating of the present invention and preparation method thereof are as follows: weigh 64.1 parts by weight of sodium water glass and add it into 200 parts by weight of water to prepare a solution. When heating to 60°C while stirring, add 10 parts by weight of clay, 20 parts by weight part of dextrin, continuously stirred for 0.5 hours, and the resulting suspension was the binder. Weigh 50 parts by weight of boron nitride, 150 parts by weight of activated carbon, and 30 parts by weight of silicon carbide, and add the prepared binder into a ball mill tank and use a planetary ball mill for ball milling. The ball-to-material ratio is 4:1, the rotating speed is 400 rpm, and the ball milling time is 10 hours. The obtained coating is a gray-black slurry with uniform mixing and good fluidity. Using the NDJ-8S digital viscometer, the viscosity of the paint is tested at a speed of 12 rpm, the test temperature is 18°C, and the test viscosity value is 14.5MPa·S. Add 1...

Embodiment 2

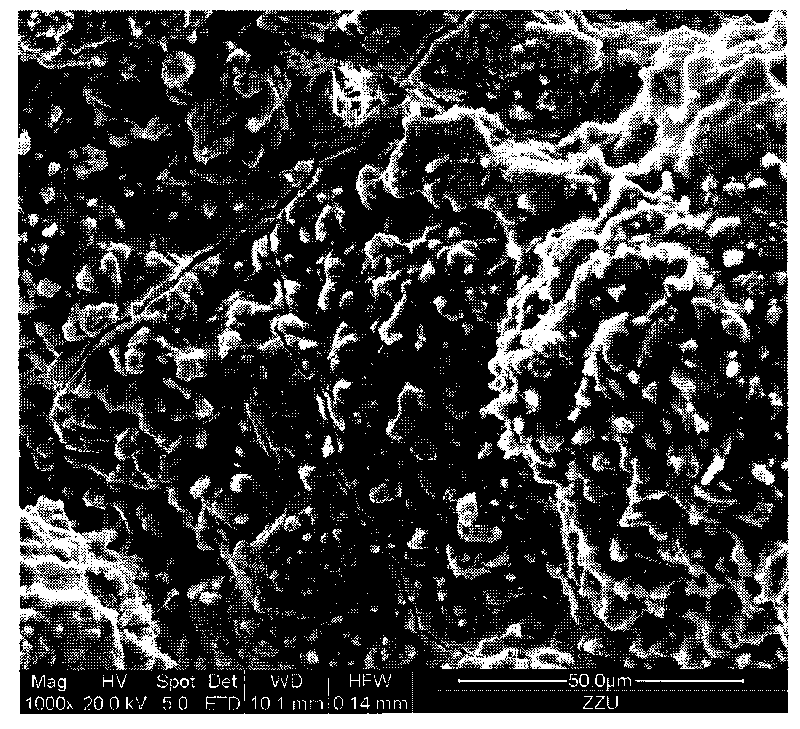

[0026] The anti-oxidation coating of the present invention and its preparation method are as follows: Weigh 64.1 parts by weight of sodium water glass and add it to 250 parts by weight of water to prepare a solution. When heating to 50°C while stirring, add 20 parts by weight of clay and 30 parts by weight of dextrin parts by weight, continuously stirred for 0.5 hour, and the resulting suspension was the binder. Weigh 40 parts by weight of boron carbide, 200 parts by weight of activated carbon, and 30 parts by weight of silicon carbide, and add the prepared binder into a ball mill tank and use a planetary ball mill for ball milling. The ball-to-material ratio is 3:1, the rotating speed is 600 rpm, and the ball milling time is 15 hours. The obtained coating is a gray-black slurry with uniform mixing and good fluidity. Using NDJ 8S digital viscometer, test the viscosity of the paint at a speed of 12 rpm, the test temperature is 18°C, and the test viscosity value is 5.2MPa·S. A...

Embodiment 3

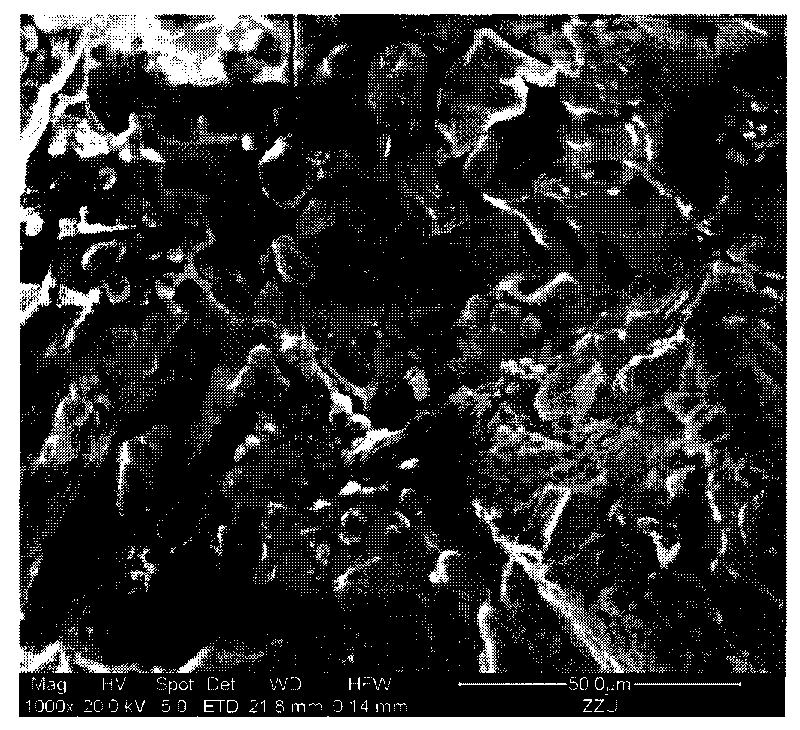

[0028] Antioxidant coating of the present invention and preparation method thereof are as follows: weigh 97.5 parts by weight of sodium water glass and add it into 250 parts by weight of water to prepare a solution. When heating to 60°C while stirring, add 15 parts by weight of clay and 20 parts by weight of dextrin Parts, continue to stir for 0.5 hours, the resulting suspension is the binder. Weigh 45 parts by weight of boron carbide, 200 parts by weight of activated carbon, and 30 parts by weight of silicon carbide, and add the prepared binder into a ball mill tank and use a planetary ball mill for ball milling. The ball-to-material ratio is 2:1, the rotating speed is 800 rpm, and the ball milling time is 30 hours. The obtained coating is a gray-black slurry, which is evenly mixed and has good viscosity and fluidity. Using NDJ 8S digital viscometer, test the viscosity of the coating at a speed of 12 rpm, the test temperature is 20°C, and the test viscosity value is 4.7MPa·S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com