Diamond-like carbon film of gradient structure and preparation method thereof

A technology of diamond film and gradient structure, which is applied in metal material coating process, superimposed layer plating, coating, etc. Destruction and other problems, to achieve the effect of improving the ability to resist delamination and spalling, improving deformation coordination, and good mechanical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, a kind of gradient structure diamond-like carbon film

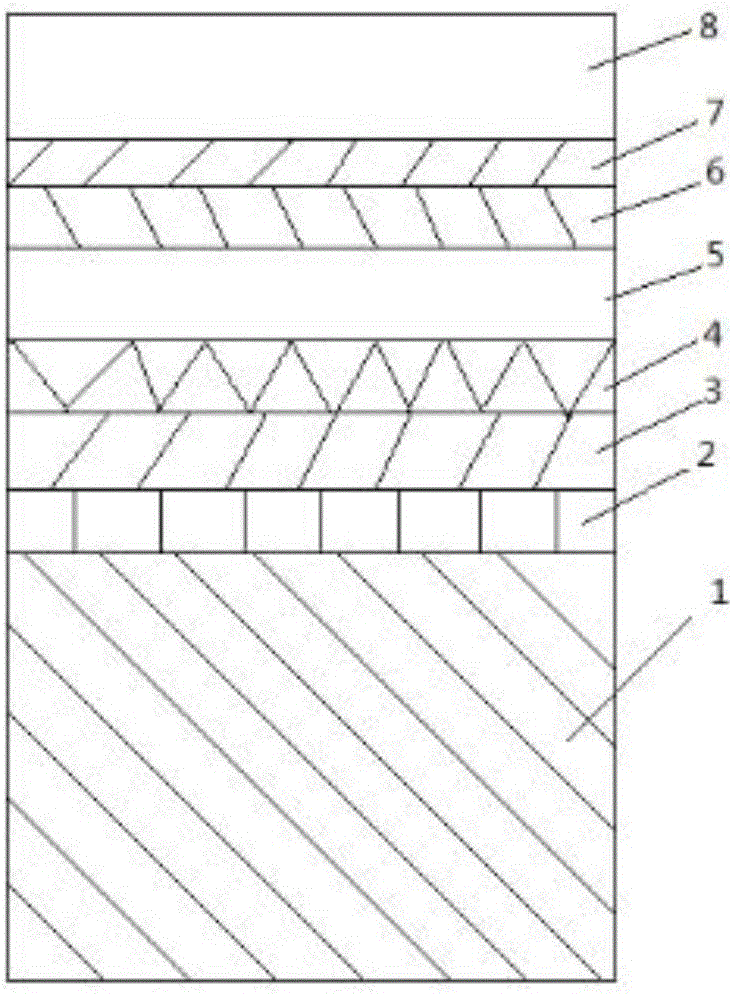

[0057] The diamond-like film described in Example 1 of the present invention includes a workpiece 1, a pure metal layer 2, a first gradient transition layer 3, a metal nitride layer 4, a second gradient transition layer 5, a tungsten carbide layer 6, and a third gradient transition layer from bottom to top. The transition layer 7 and the surface layer 8, the first gradient transition layer 3 is to continuously increase the content of nitrogen in the first gradient transition layer 3 from the side of the pure metal layer 2 to the side of the metal nitride layer 4 The second gradient transition layer 5 is to continuously change the content of nitrogen in the second gradient transition layer 5 from the side of the metal nitride layer 4 to the side of the tungsten carbide layer. The third gradient transition layer 7 is formed continuously from the side of the tungsten carbide layer 6 toward the side of th...

Embodiment 2

[0059] The surface treatment of embodiment 2, GCr15 bearing steel test piece

[0060] After the GCr15 steel specimen with three-dimensional dimensions of length, width and thickness is 100mm×30mm×2mm is polished, the surface treatment is carried out in the following order.

[0061] S1. Ion source bombardment to clean the surface of the workpiece: place the workpiece in a vacuum chamber so that the pressure of the vacuum chamber is 5×10 - 3 Pa, turn on the heating device, heat the workpiece to 100°C; pass in argon gas, set the vacuum chamber pressure to 0.2Pa, the beam current to 60A, apply a DC bias voltage of 400V to the workpiece, and turn off the DC bias voltage after cleaning for 30 minutes;

[0062] S2. Preparation of pure metal layer: adjust the argon flow rate of the magnetron target source to keep the pressure of the vacuum chamber at 0.5Pa; turn on the DC pulse bias mode, set the frequency to 10kHz, the workpiece bias voltage to 30V, and the duty cycle to 30% , turn...

Embodiment 3

[0071] The surface treatment of embodiment 3, M42 tool steel test piece

[0072] After polishing the M42 tool steel test piece with the three-dimensional dimensions of length, width and thickness of 100mm×30mm×2mm, perform surface treatment in the following order.

[0073] S1. The ion source bombards and cleans the surface of the workpiece: place the workpiece in a vacuum chamber so that the pressure of the vacuum chamber is lower than 5×10 - 3 Pa, turn on the heating device, heat the workpiece to 200°C; pass in argon gas, set the vacuum chamber pressure to 0.2Pa, the beam current to 100A, apply a DC bias voltage of 400V to the workpiece, and turn off the DC bias voltage after cleaning for 30 minutes;

[0074] S2. Preparation of pure metal layer: adjust the argon flow rate of the magnetron target source to keep the pressure of the vacuum chamber at 1Pa; turn on the DC pulse bias mode, set the frequency to 100kHz, the workpiece bias voltage to 50V, and the duty cycle to 80%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com