Patents

Literature

78results about How to "Improve the binding force of membrane base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

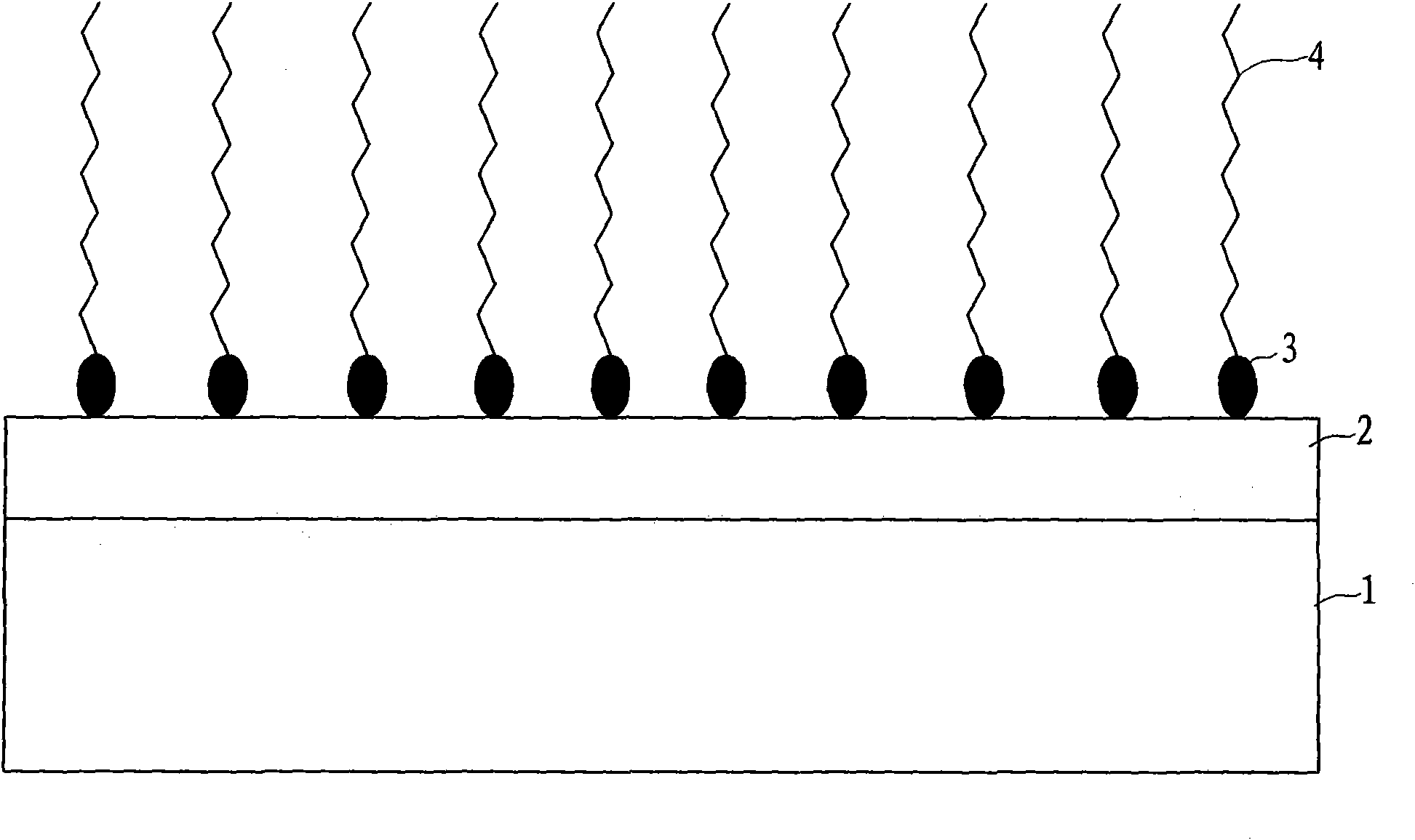

Preparation method of photovoltaic glass surface antireflection film

The invention discloses a preparation method of a photovoltaic glass surface antireflection film, which is characterized by comprising the following steps of firstly, preparing inorganic-organic hybrid silicasol; secondly, coating; thirdly, hydrophobic treatment; and fourthly, solidification treatment. Compared with the prior art, the invention has the advantages that the film-substrate cohesion between an antireflection film and substrate photovoltaic glass is stronger, and therefore, the wiping resistance of the coated photovoltaic glass surface antireflection film is enhanced; a layer of hydrophobic group with low surface energy is formed on the surface of the antireflection film, and therefore, the corrosion of moisture to a film microstructure is reduced, and the long service life of the coated photovoltaic glass is ensured; and the invention has low whole process cost and simple technical route and is suitable for industrial and large-scale application.

Owner:CHANGZHOU ALMADEN

Fuel cell metal bipolar plate with conductive and anti-corrosion plating and preparation method thereof

ActiveCN102931421AImprove the binding force of membrane baseReduced corrosion resistanceFinal product manufactureVacuum evaporation coatingChromium carbideBinding force

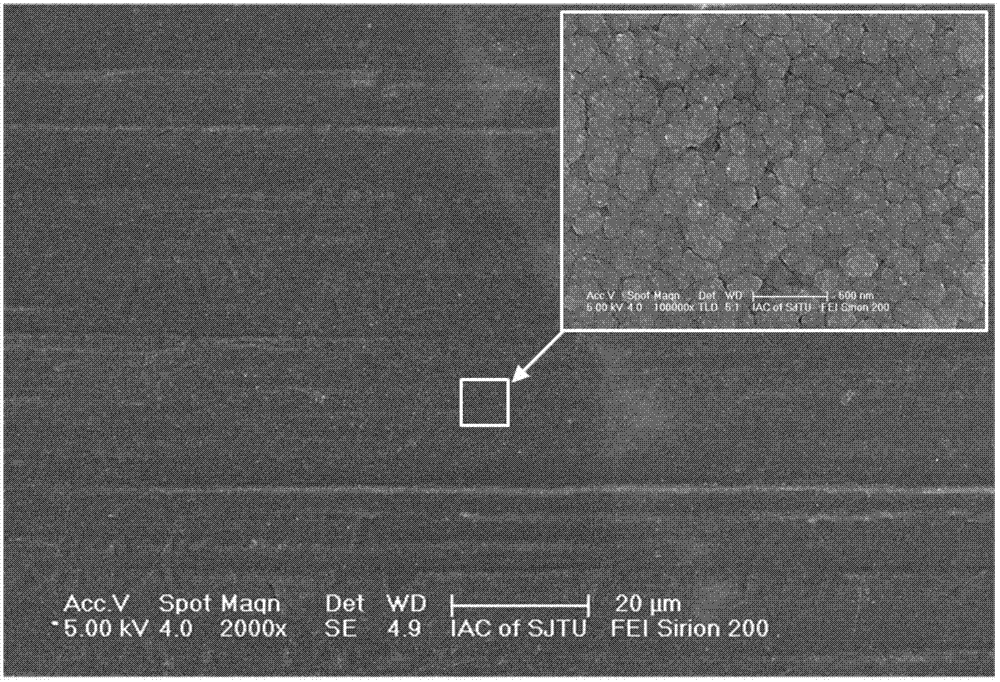

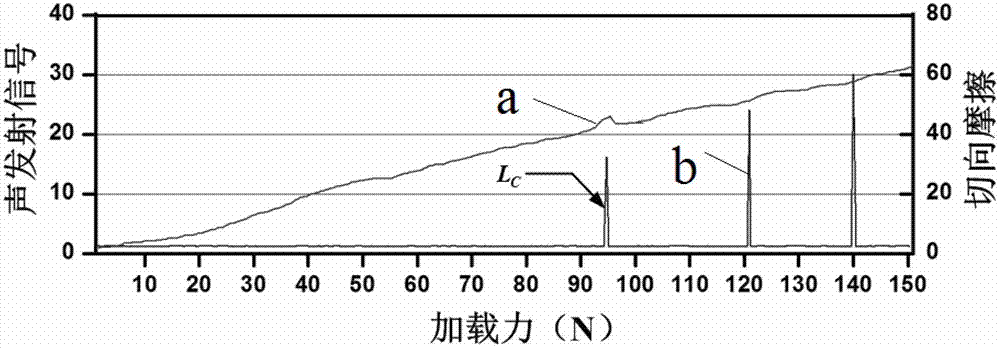

The invention relates to a fuel cell metal bipolar plate with the conductive and anti-corrosion plating and a preparation method thereof. Chromium-nitrogen-carbon ternary composite step plating is formed on the surface of the metal bipolar plate by using a closed field unbalanced magnetron sputtering technology, and a pure chromium base layer, a chromium nitride transition layer, a chromium-carbon-nitrogen coexistence layer and an amorphous carbon layer are arranged upwards successively on the surface of the metal bipolar plate. Compared with the prior art, the fuel cell metal bipolar plate with the conductive and anti-corrosion plating and the preparation method thereof combine toughness of the chromium nitride, the corrosion resistance of the chromium carbide and the conductivity of amorphous carbon film fully, and the chromium nitride, the chromium carbide and the amorphous carbon film are composited through a step transition method. The modified metal bipolar plate film base binding force is improved apparently, the corrosion resistance and the conductivity are enhanced apparently, and high-performance and long-time use requirements of the fuel cell metal bipolar plate can be met.

Owner:苏州治臻新能源装备有限公司

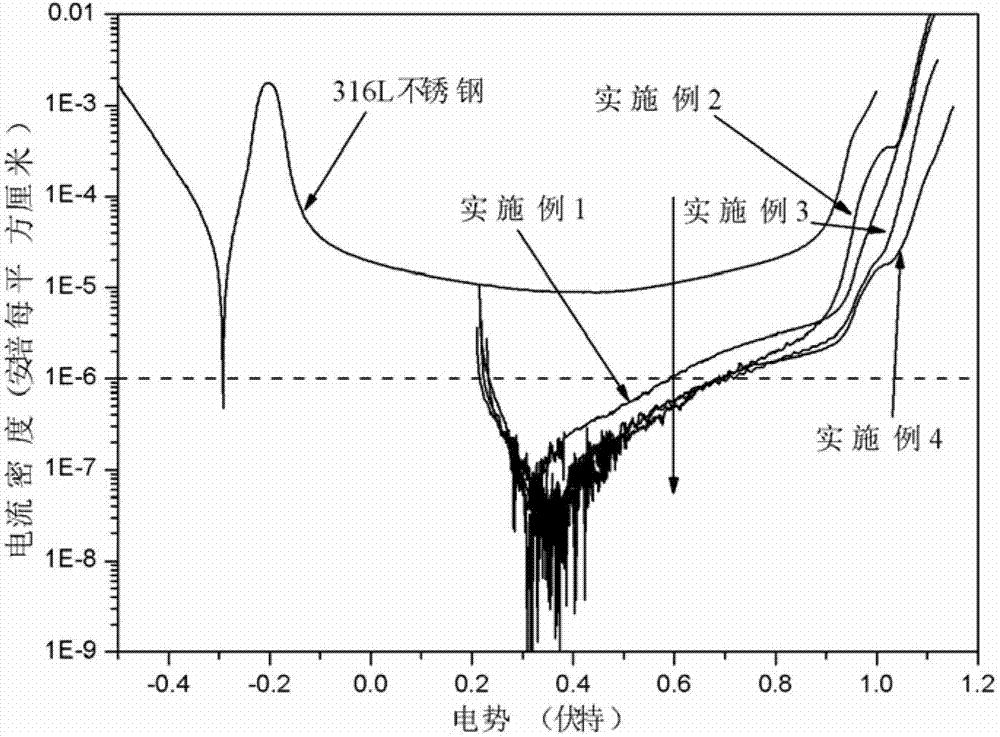

Doped multilayer gradient coating for metal bipolar plates of fuel cell

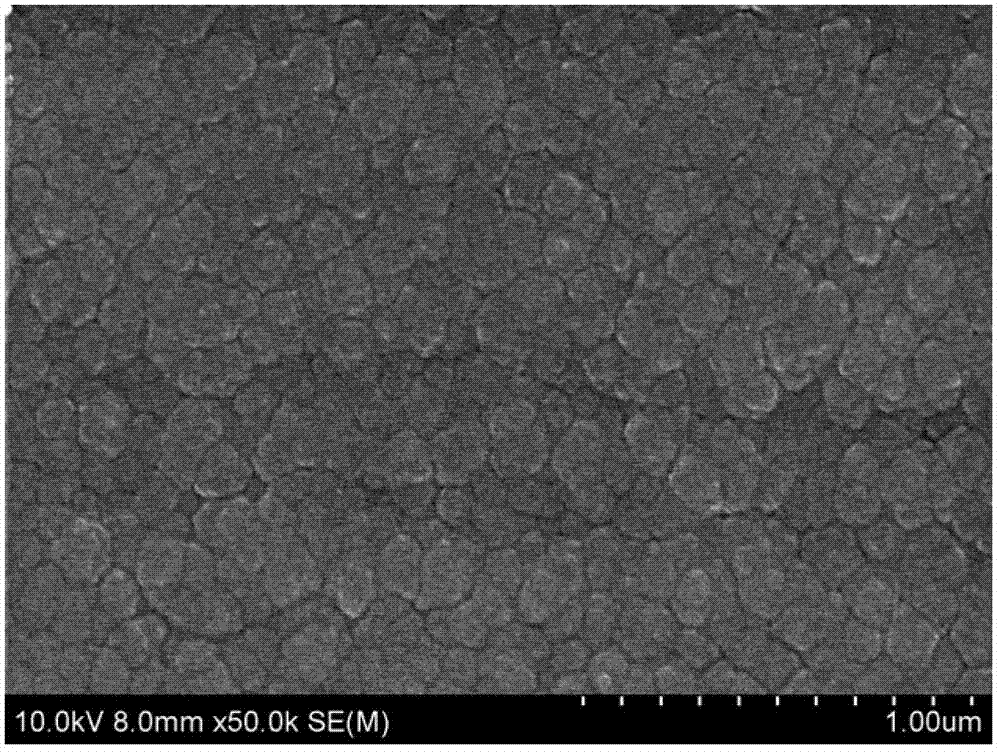

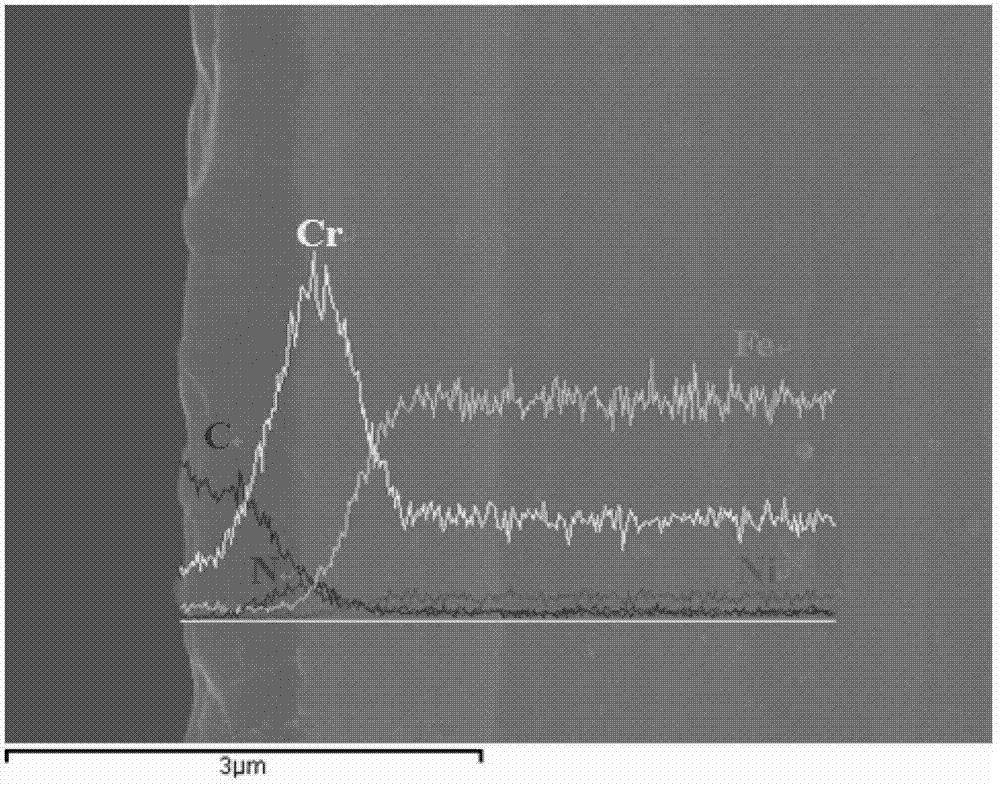

ActiveCN103199279AImprove the binding force of membrane baseExcellent electrical conductivity and corrosion resistanceCell electrodesVacuum evaporation coatingCarbon coatingChemistry

The invention discloses a proton exchange membrane fuel cell metal bipolar plate doped with a multilayer gradient membrane on the surface, and a preparation method of the proton exchange membrane fuel cell metal bipolar plate. The Ti, Al and / or Mo doped C / CrN multilayer gradient membrane is prepared on the surface of the metal bipolar plate by a closed-field unbalanced magnetron sputtering technology. The doped C / CrN multilayer gradient coating comprises a graphite-like carbon coating, a CrN coating and a Cr transition layer as well as Ti, Al, Mo, W, Nb, Ni, Zr, Fe, Si and other elements doped in the graphite-like membrane and / or the CrN coating for structure and component control. Compared with the prior art, the proton exchange membrane metal bipolar plate provided by the invention has the characteristics of excellent conductivity and corrosion resistance, low open porosity and cost and the like, the stacking performance of a fuel cell is greatly improved, and the service life of the fuel cell is greatly prolonged; and the metal bipolar plate can meet the use requirements of the fuel cell, and has broad application prospect.

Owner:SHANGHAI JIAO TONG UNIV

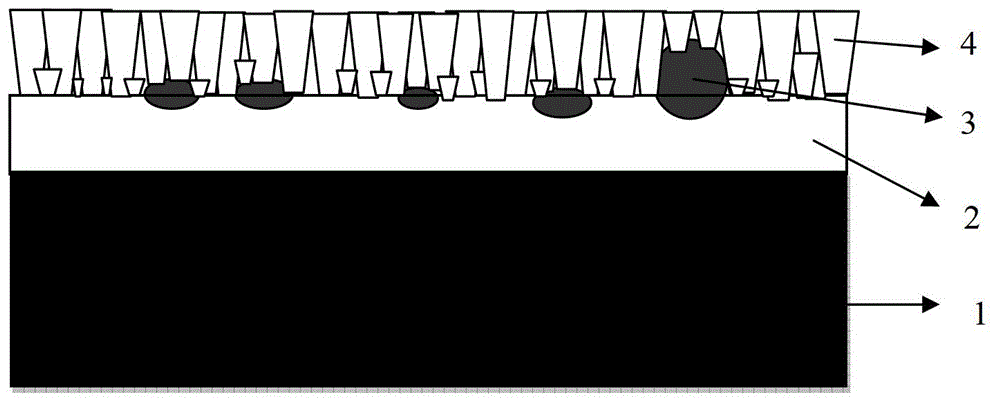

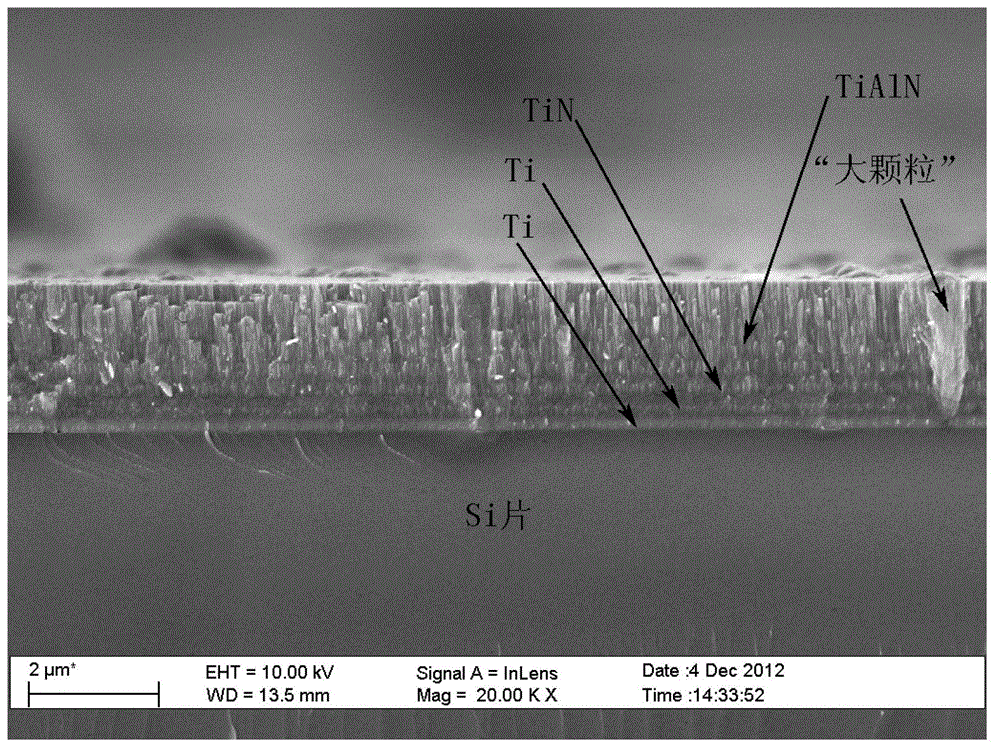

Ti/TiN/TiAlN composite coating on surface of cutting tool material and preparation method of Ti/TiN/TiAlN composite coating

InactiveCN103334082AImprove the binding force of membrane baseImprove bindingVacuum evaporation coatingSputtering coatingFilm baseBinding force

The invention discloses a Ti / TiN / TiAlN composite coating on the surface of a cutting tool material and a preparation method of the Ti / TiN / TiAlN composite coating. The method comprises the following steps of: (1) cleaning the surface of the cutting tool material; (2) sequentially coating a Ti layer and a TiN layer through ion coating equipment; and (3) coating a TiAlN layer through magnetron sputtering equipment to obtain the Ti / TiN / TiAlN composite coating. The Ti / TiN / TiAlN composite coating has a relatively smooth surface, and is large in film base binding force and high in abrasion resistance; the service life of a tool can be prolonged; a coating film is high in processing quality; the Ti / TiN / TiAlN composite coating is simple in preparation process, easy to operate and suitable for batch production; automatic electric and mechanical control is adopted in a film coating process.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for super-hydrophobic metal surface

InactiveCN103981547AEliminate differencesImprove general performanceLiquid/solution decomposition chemical coatingChemical platingAlloy

The invention discloses a preparation method for a super-hydrophobic metal surface. The method comprises the following steps: constructing a micrometer structure on the surface of a frequently used engineering material (such as copper, iron, stainless steel, nickel, aluminum, an aluminum alloy and a high-molecular section covering the above-mentioned metal through chemical plating) by using an electrocoppering process; then constructing a nanometer structure by using a chemical silvering process; and carrying out modification with low-surface energy substances like octadecanethiol so as to obtain excellent and stable super-hydrophobicity. The method has a wide application scope and can be used on pure metal, alloys and metalized high-molecular sections; an obtained surface has stable and reliable surface performance, strong film-substrate bonding force and good corrosion resistance, especially good acid resistance, can be extensively applied in fields like self-cleaning, water prevention and dehumidification, corrosion prevention, fluid drag reduction, frost prevention and condensation and heat exchange, and has an industrialization value.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Diamond-like carbon film of gradient structure and preparation method thereof

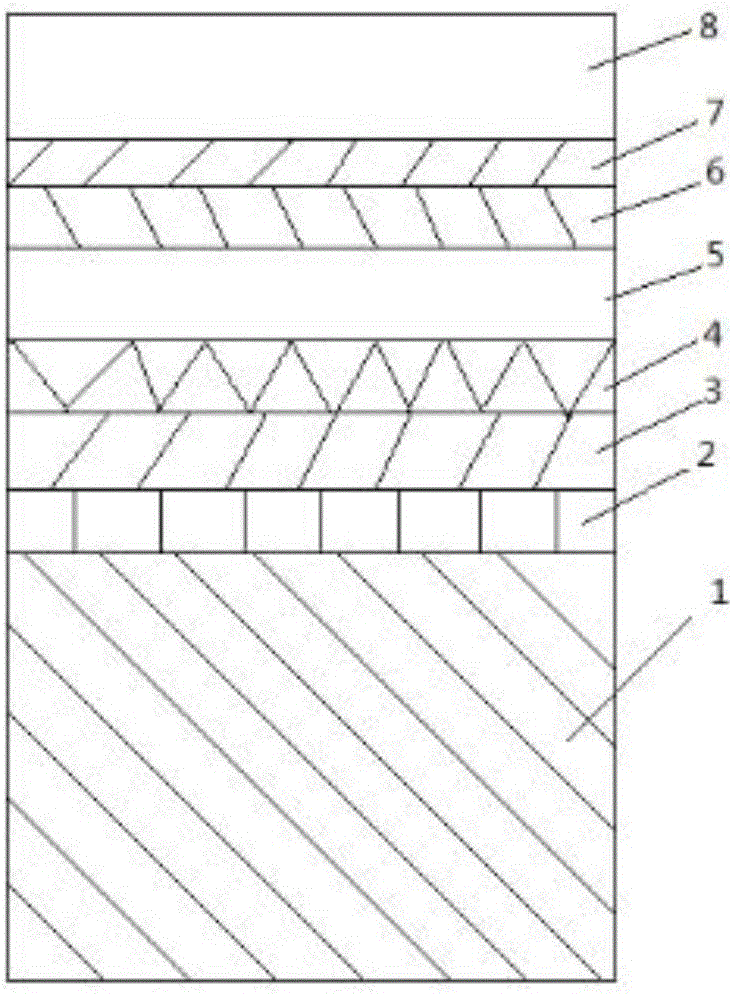

ActiveCN106521493AImprove performanceImproved deformation coordinationSuperimposed coating processCarbon filmDiamond-like carbon

The invention relates to metal surface treatment, in particular to surface treatment of low-temperature iron-base alloy molds of sliding components, bearings and the like and provides a diamond-like carbon film of a gradient structure and a preparation method of the diamond-like carbon film of the gradient structure. The diamond-like carbon film of the gradient structure is provided with a coating structure comprising a pure metal layer, a first gradient transition layer, a metal nitride layer, a second gradient transition layer, a tungsten carbide, a third gradient transition layer and a surface layer. The surface layer is a diamond-like layer or a silicon-containing type diamond layer. According to the diamond-like carbon film of the gradient structure, gradient control over elasticity modulus and hardness is achieved through ingredient gradient control between all the layers, and therefore the film-substrate cohesion force and the delaminating resistance of the coating are greatly improved.

Owner:广州今泰科技股份有限公司 +1

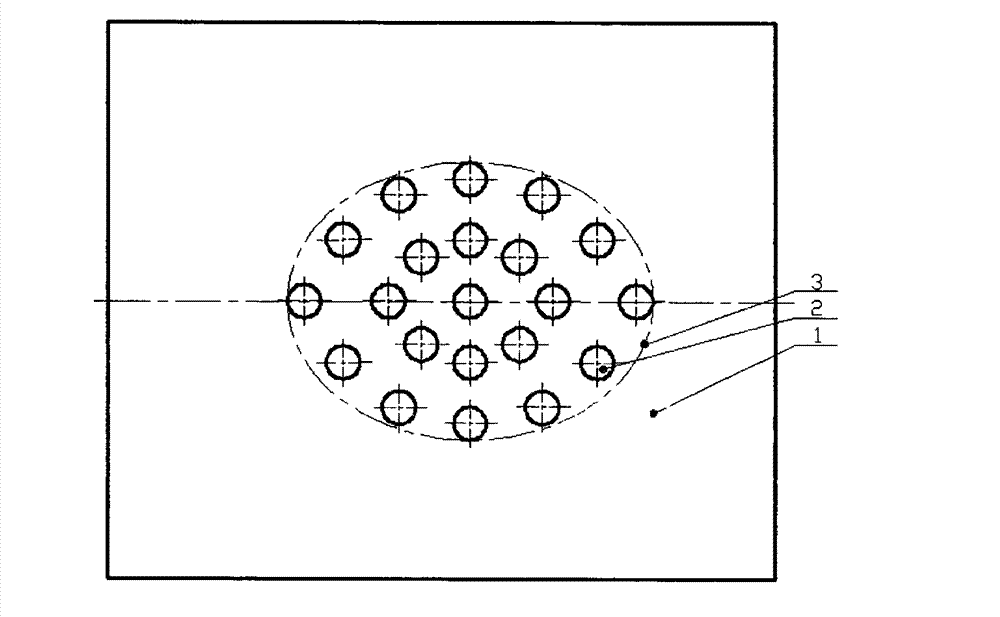

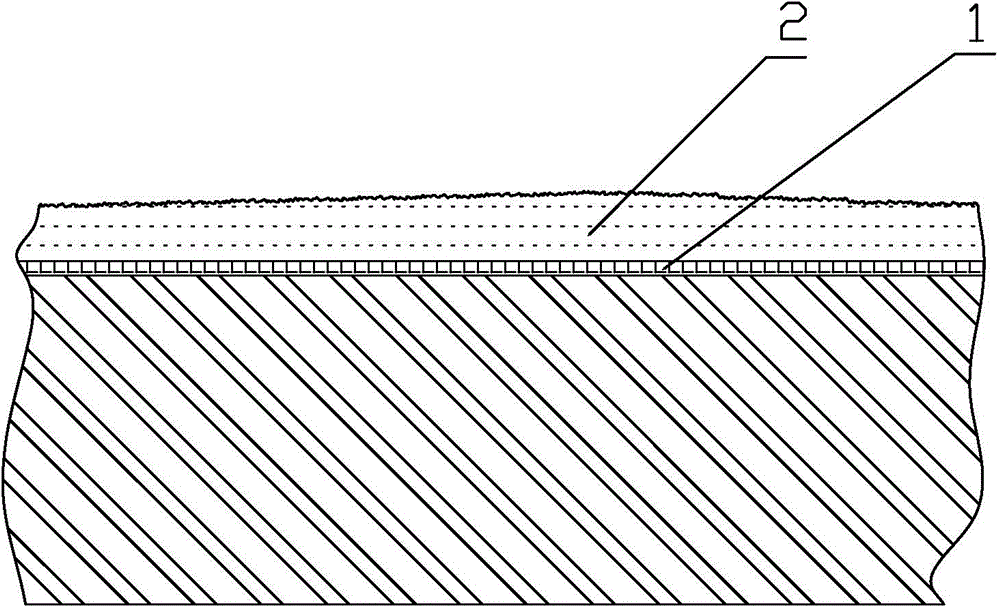

Preparation method of multi-metal doping hydrogen-free diamond carbon film

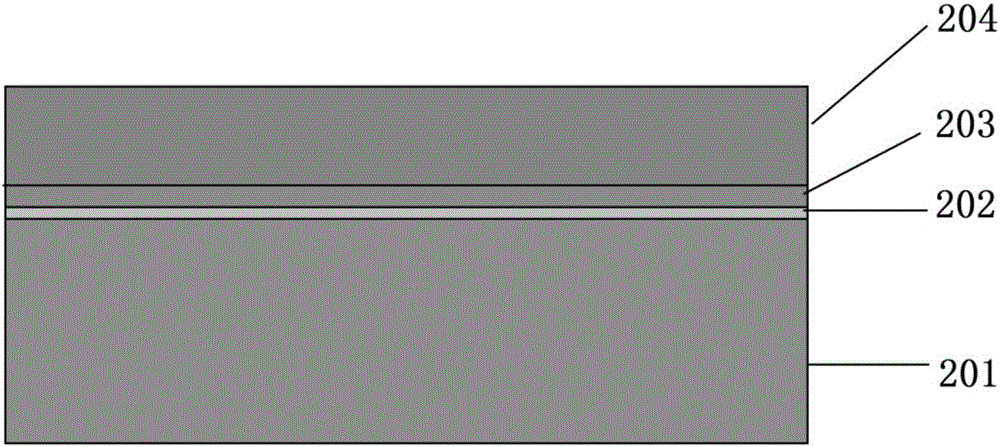

InactiveCN102965619AHigh film hardnessImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingSputteringHydrogen

The invention discloses a preparation technology of a multi-metal doping hydrogen-free diamond carbon film. The preparation technology is characterized in that by using an ion beam auxiliary deposition technology, a multi-metal mosaic target (formed by mosaicking a mosaic block 2 in a sputtering region 3 on a base target material 1) and a graphite target are used for double-target sputtering, and the multi-metal doping hydrogen-free diamond film is deposited and prepared on the surface of a workpiece. The preparation technology comprises the following specific steps: preparing the mosaic target, cleaning and activating ions on the surface of the workpiece, and depositing and preparing the multi-metal doping hydrogen-free diamond film. Compared with the prior art, the film prepared by the method has the advantages of higher hardness, film-based bonding force, elasticity modulus, abrasion resistance and hot stability property; and doping components can be adjusted so that the film can meet the requirement of transmission parts of precise instruments for accuracy and increases the reliability of the transmission parts. The film is suitable for surface treatment of silicon and various metal workpieces.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Wear-resistant hydrophobic nano composite film and preparation method thereof

InactiveCN104694877AImprove mechanical propertiesImprove hydrophobicityVacuum evaporation coatingSputtering coatingComposite filmWear resistant

The invention relates to a wear-resistant hydrophobic nano composite film and a preparation method thereof, belonging to the technical field of metal surface treatment and modification. The composite film is based on high-speed steel, or titanium alloy, or hard alloy, or pure metal, and a pure metal film and a microstructure nano composite film are sequentially prepared on the base surface. The preparation method comprises the following steps: depositing a nano composite hard film with excellent mechanical properties on the base material surface by arc ion plating, and generating a micro / nano dual structure on the film surface by an ultra-fast laser processing technique to obtain the surface film with favorable mechanical properties and certain hydrophobicity. The film maintains excellent mechanical properties of the nano composite hard film: high surface hardness, high toughness, high wearability and high scratch resistance; and the microstructure on the film surface is constructed, so that the film has certain hydrophobicity. The preparation method has the advantages of simpler equipment, low cost, low energy consumption and no pollution, and can implement efficient green manufacturing.

Owner:常州翊迈新材料科技有限公司

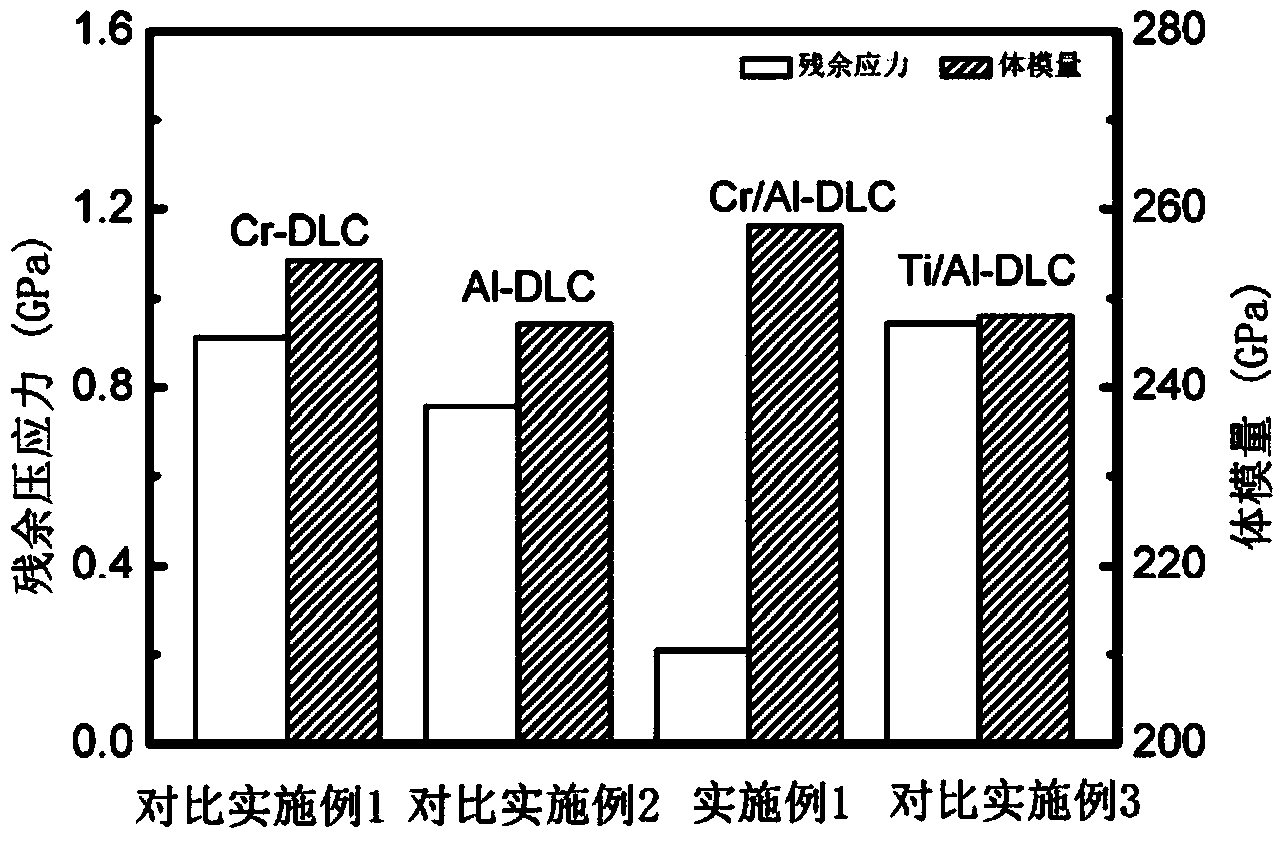

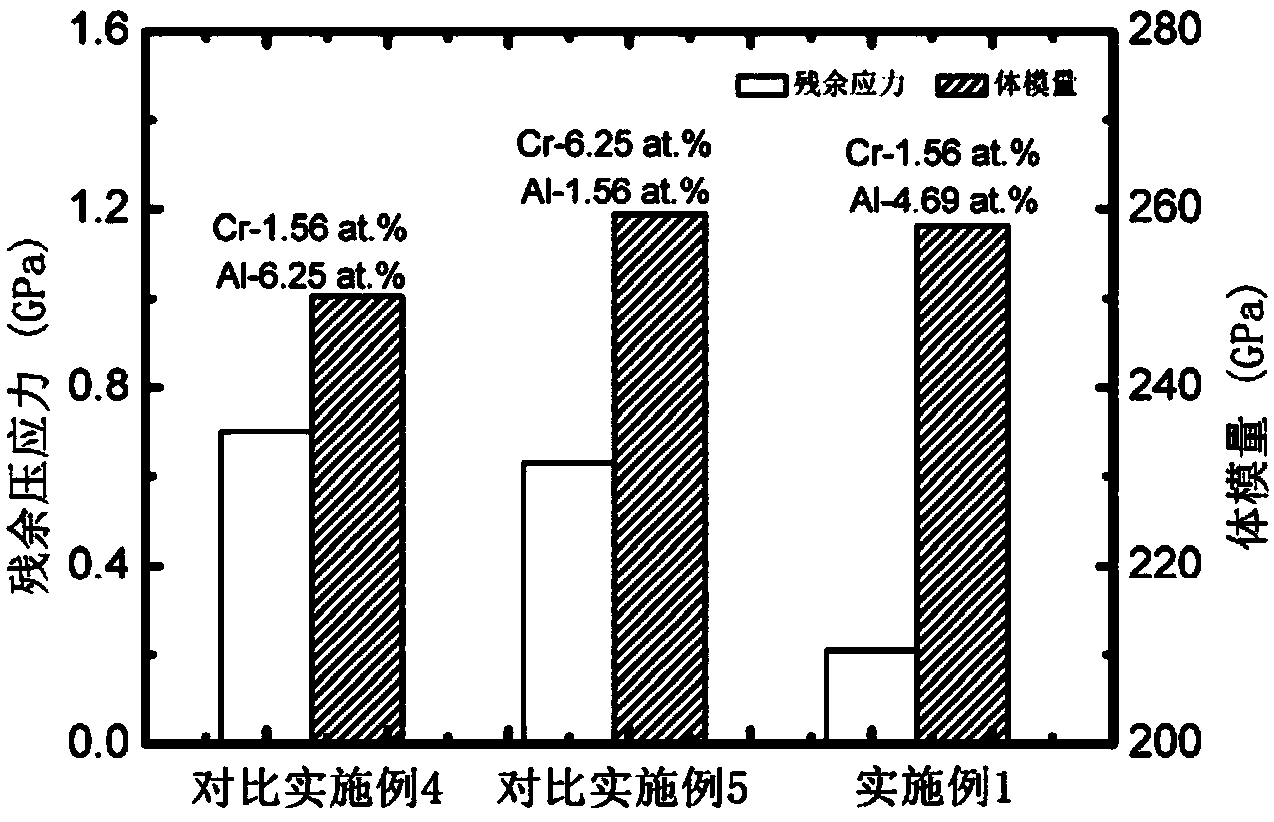

High-hardness and low-stress multi-element composite diamond-like coating and preparation method thereof

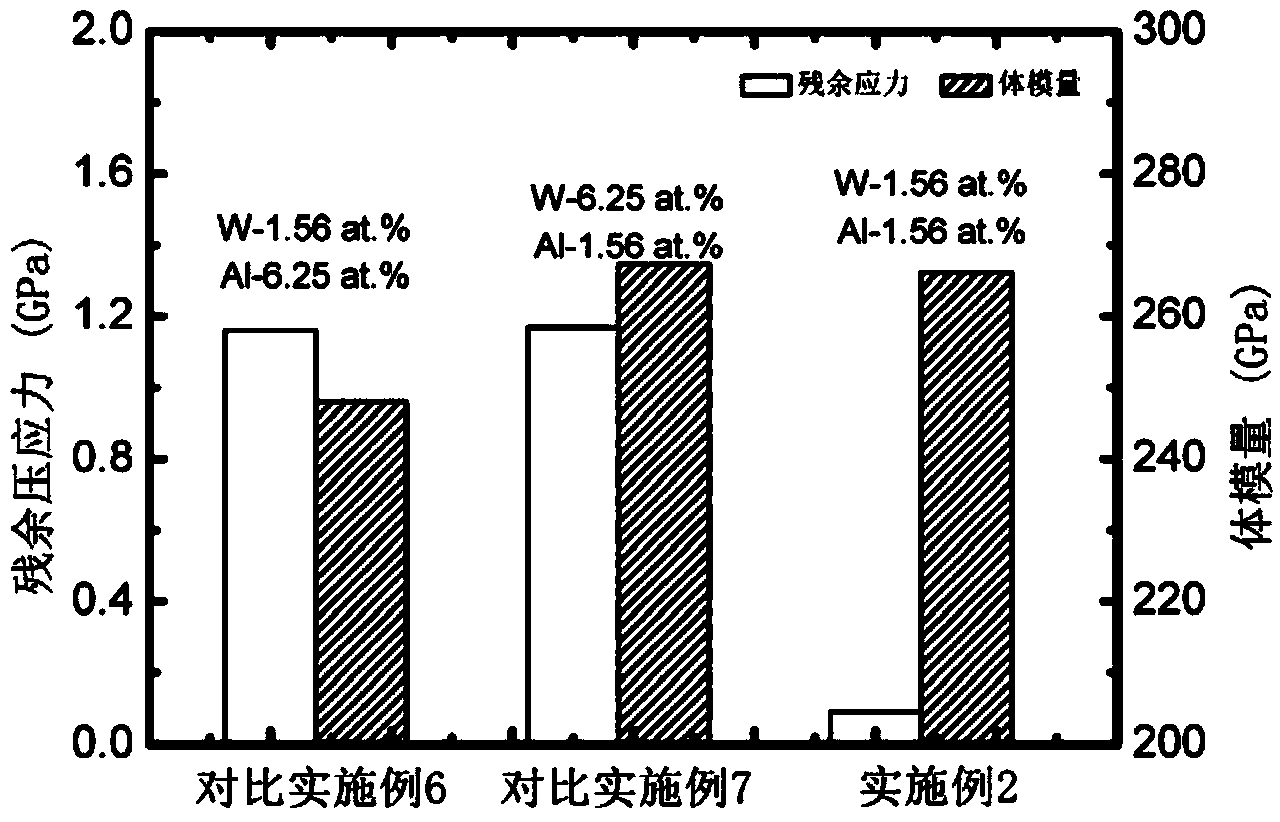

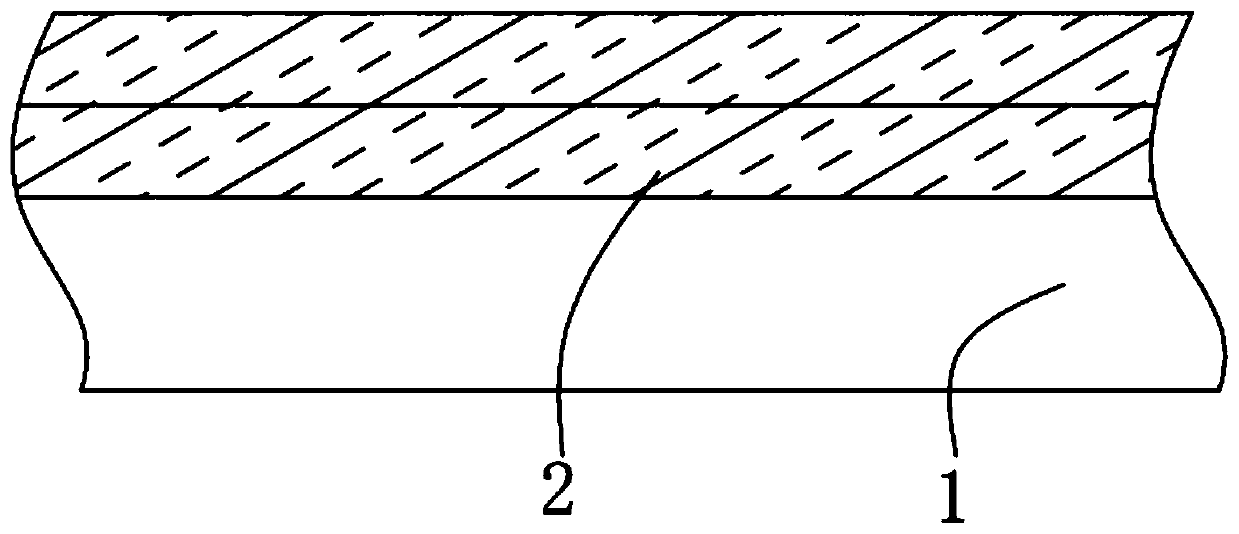

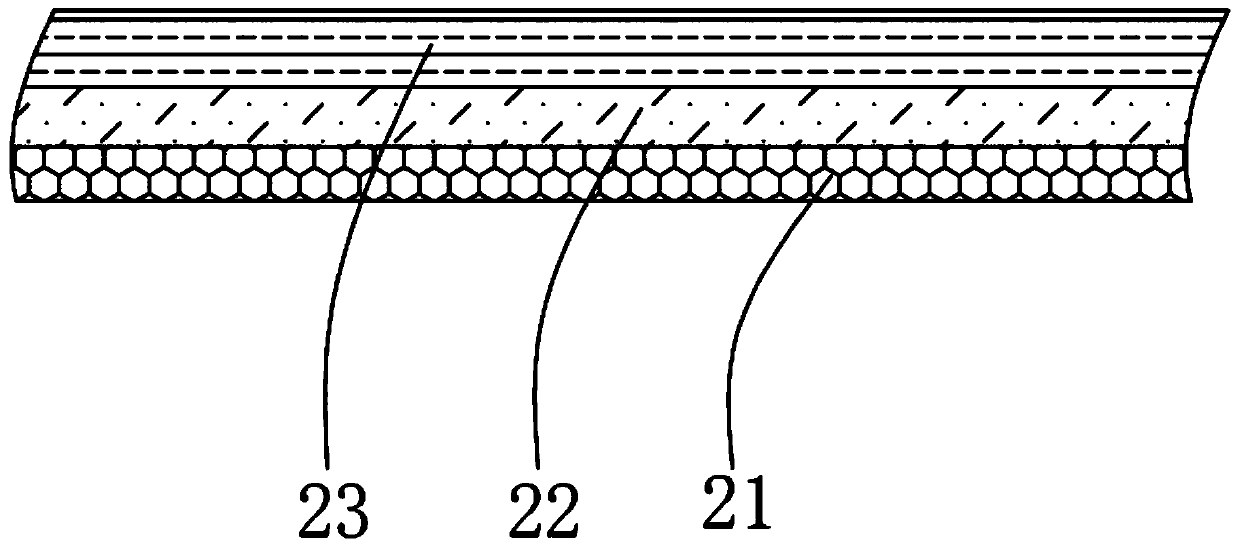

ActiveCN104294230AReduce coefficient of frictionReduce wear rateVacuum evaporation coatingSputtering coatingCorrosionHardness

The invention discloses a high-hardness and low-stress multi-element composite diamond-like coating. The coating is prepared from diamond-like carbon, a first doping element Al or Cu and a second doping element Cr or W, wherein the atomic percentage contents of the first doping element and the second doping element in the multi-element composite diamond-like coating are respectively 1.56%-4.69%. An experiment proves that the codoped diamond-like coating has high hardness and low stress, simultaneously also has low friction coefficient and attrition rate, good tenacity and corrosion resistance, and high film-based adhesion, therefore, the high-hardness and low-stress multi-element composite diamond-like coating is a multifunctional coating with good overall performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for impulsive bias arc ion plating multi-player super-hard nano films of titanium/titanium nitrate

InactiveCN1680618AImprove the binding force of membrane baseHigh hardnessVacuum evaporation coatingSputtering coatingTitanium nitrideTitanium oxide

A surface modification technology of nanometer multi-layer hard membrane of Ti / titanium oxide by way of pulsed biasing. Apply to pulsed biasing to improve deposit quality of membrane in the arc process. Interchange Ar and N2 interchange and control the time interval. Then cover is fit on the preface of metal.

Owner:DALIAN UNIV OF TECH

Accident fault tolerance nuclear fuel cladding coating for zirconium alloy surface

InactiveCN111139434AImprove accident fault tolerance and protection abilityImprove coating adhesionOptical rangefindersNuclear energy generationProtection layerThermal water

The invention discloses an accident fault tolerance nuclear fuel cladding coating for a zirconium alloy surface, and belongs to the technical field of accident fault tolerance nuclear fuel cladding coating. A first protection layer is mounted on the outer surface of zirconium alloy, a second protection layer is mounted on the outer surface of the first protection layer, and a third protection layer is mounted on the outer surface of the second protection layer. According to the accident fault tolerance nuclear fuel cladding coating for the zirconium alloy surface, through advantages of a laminated construction and compositing multiple coatings, a Cr coating can effectively improve the attaching force between the coating and a zirconium alloy substrate, meanwhile, the accident fault tolerance protection capacity is achieved, a CrTiAlN coating has the good high-temperature oxidation resistance property, and can be normally used in the normal state, and the high-temperature working condition, a CrN coating has the good corrosion resistance, and meets the long-term service under the hot water corrosion working condition, and the laminated composite protection coating can comprehensively improve the stability and the safety of accident fault tolerance nuclear fuel cladding.

Owner:XI AN JIAOTONG UNIV

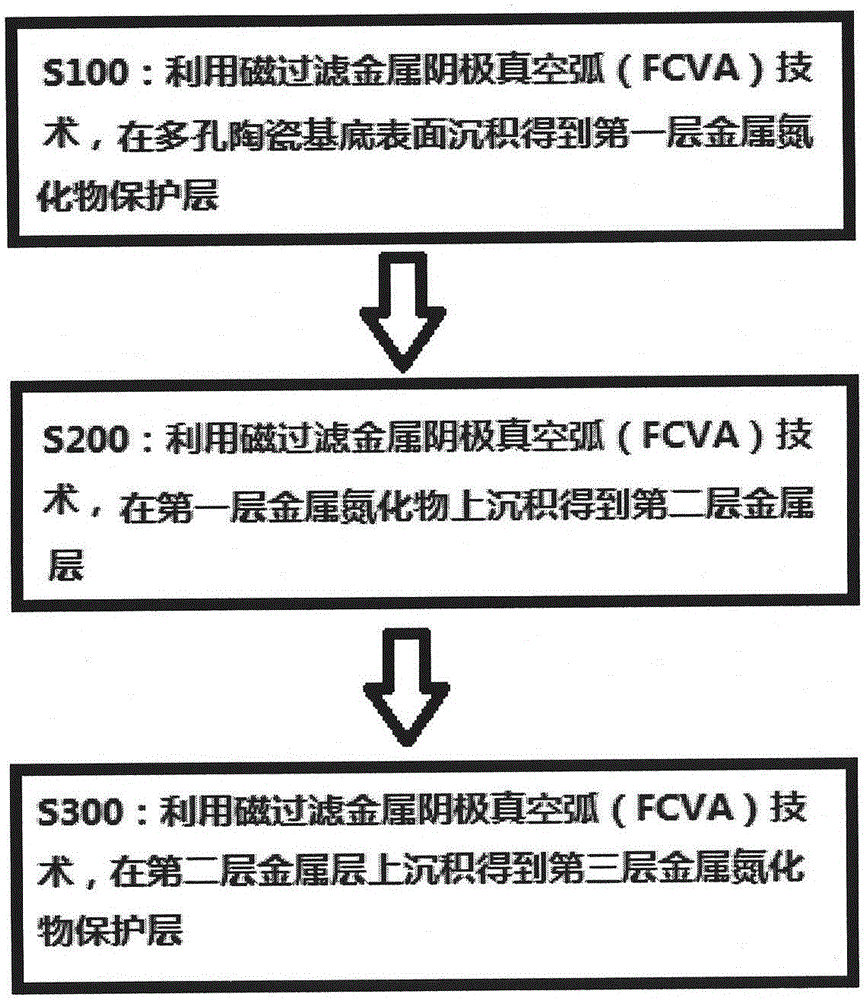

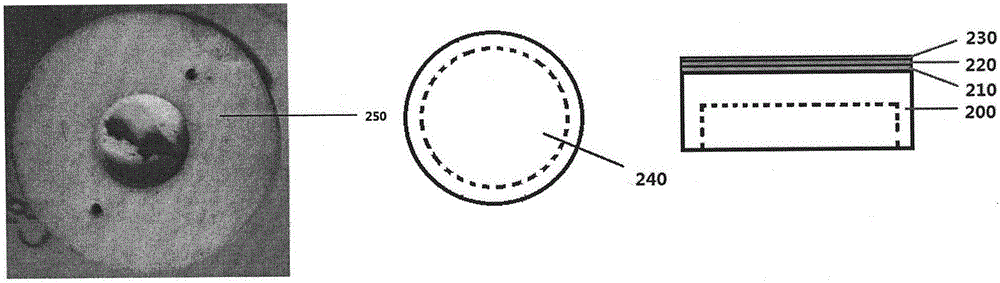

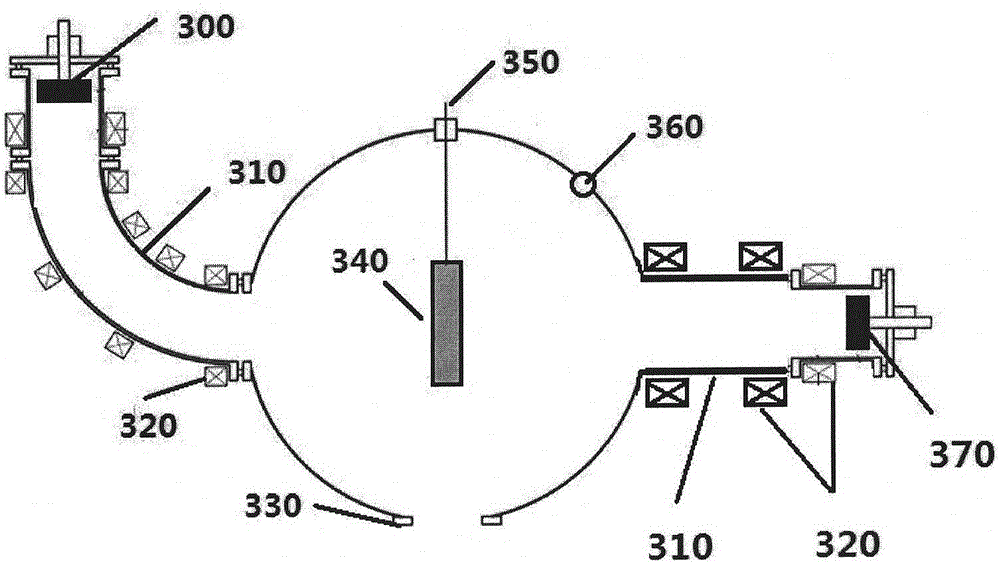

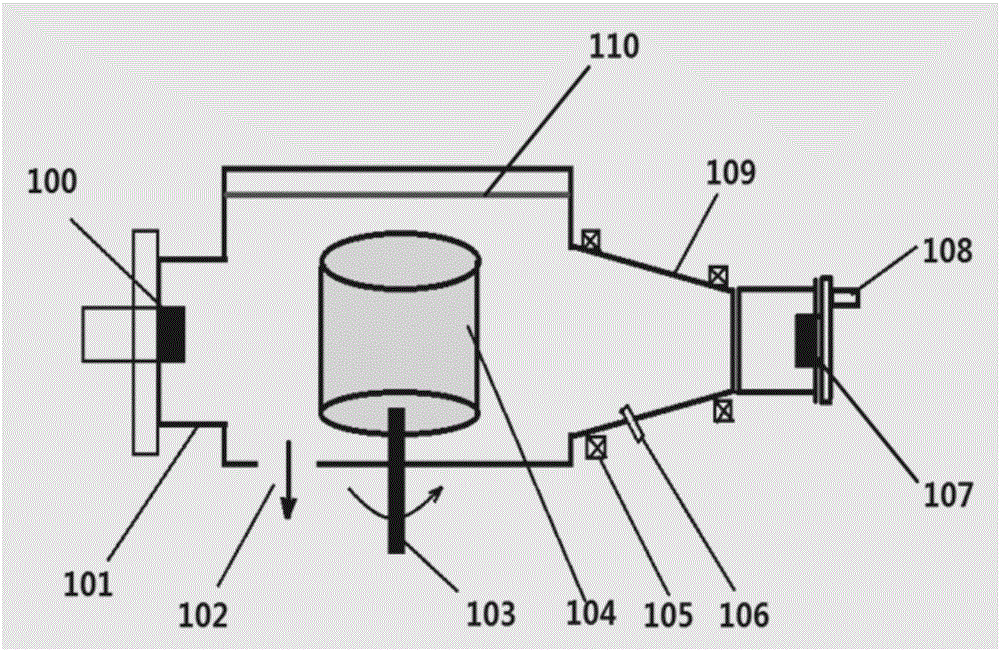

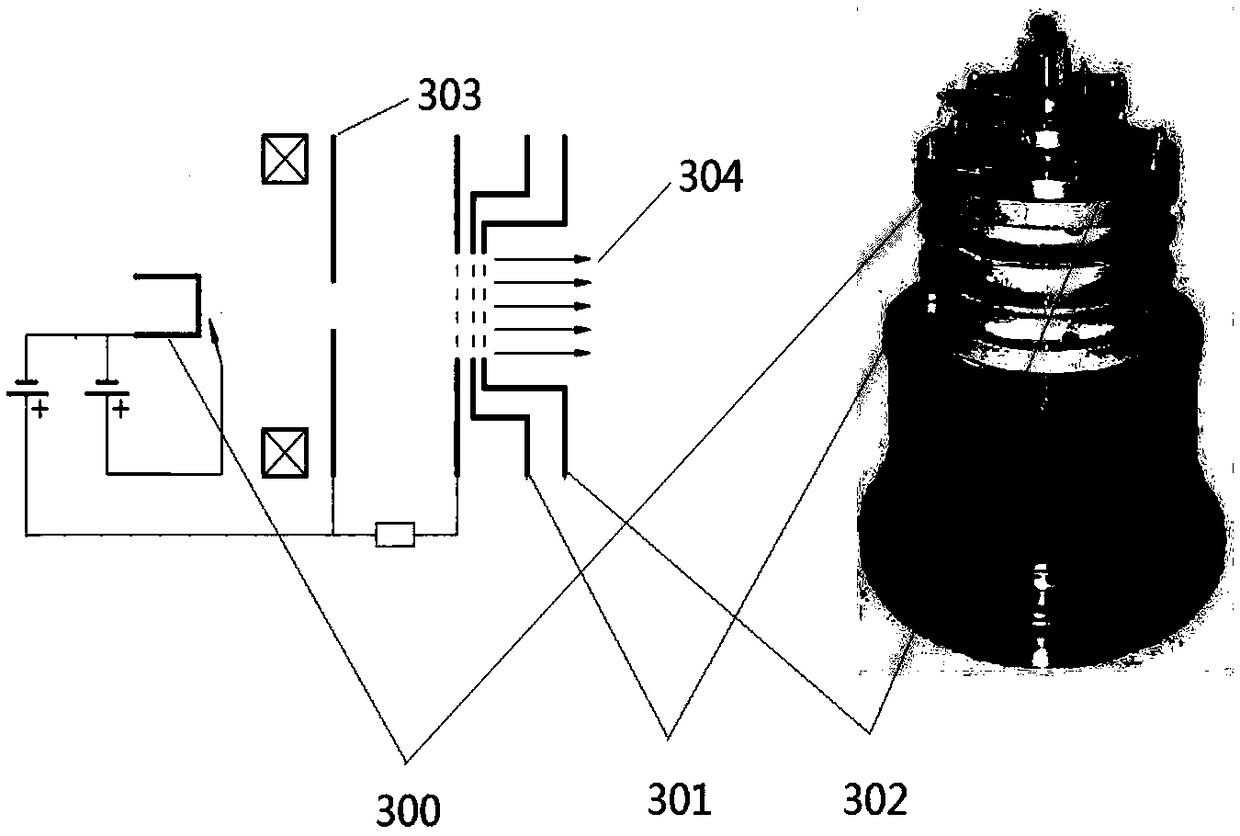

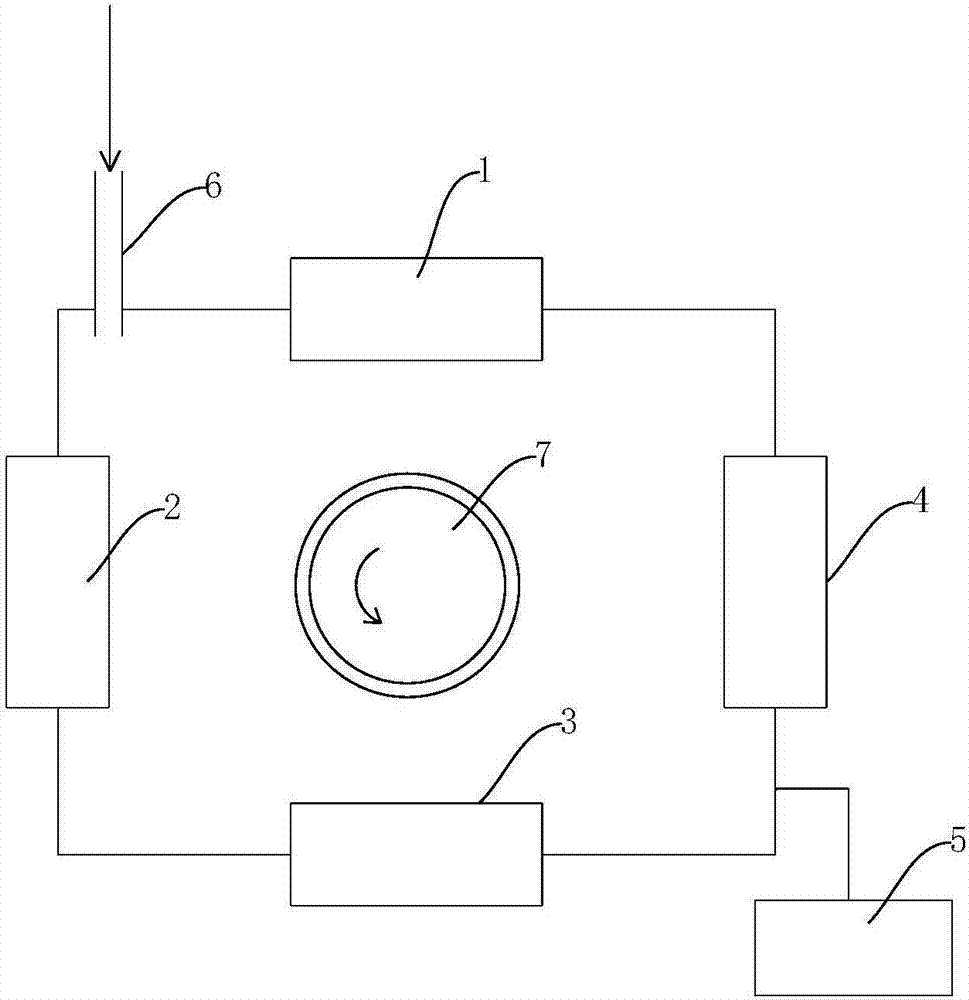

Manufacturing method and equipment for conductive layer in novel electronic cigarette atomizer device based on ion beam technology

ActiveCN105755434AExtended service lifeHigh atomic ionization rateVacuum evaporation coatingSputtering coatingSecondary layerTotal thickness

The invention discloses a manufacturing method and equipment for a conductive layer in a novel electronic cigarette atomizer device based on the ion beam technology. The preparation method for preparing the conductive layer in the electronic cigarette atomizing device comprises the following steps of: taking porous aluminum nitride ceramic as a basal body, adopting a magnetic filter metal cathode vacuum arc (FCVA) technology, depositing a first metal nitride conductive layer on the surface of the basal body, and depositing on the first layer by adopting the FCVA process to obtain a second metal layer; and depositing on the second metal layer by adopting the FCVA depositing method to obtain a third conductive metal nitride layer, wherein the total thickness of the three layers of composite films is 1-10 microns, and the resistance is 1-10 ohms. According to the manufacturing method and the equipment, the novel electronic cigarette atomizer device with a long service life can be manufactured.

Owner:BEIJING NORMAL UNIVERSITY

Apparatus for rapidly depositing DLC film on surface of piston ring, and method thereof

ActiveCN106011771AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingPiston ringHardness

The invention discloses an apparatus for rapidly depositing a DLC film on the surface of a piston ring, and a method thereof. The apparatus comprises: an ion injection system used for vertically uniformly injecting ion flow; a vacuum chamber, wherein one end of the vacuum chamber is in sealing connection with the ion injection system, the other end of the vacuum chamber is in sealing connection with one end of a broad-beam magnetic filtering deposition system, and the other end of the broad-beam magnetic filtering deposition system is provided with an FCVA deposition cathode; a tool system used for realizing autorotation of a piston ring tool cylinder; and an intelligent control device used for controlling the ion injection and film deposition process, displaying a measurement result and preliminarily processing data. The apparatus and the method can realize large-batch uniform plating of the surface of the piston ring with the DLC film with high hardness and low friction coefficient.

Owner:BEIJING NORMAL UNIVERSITY

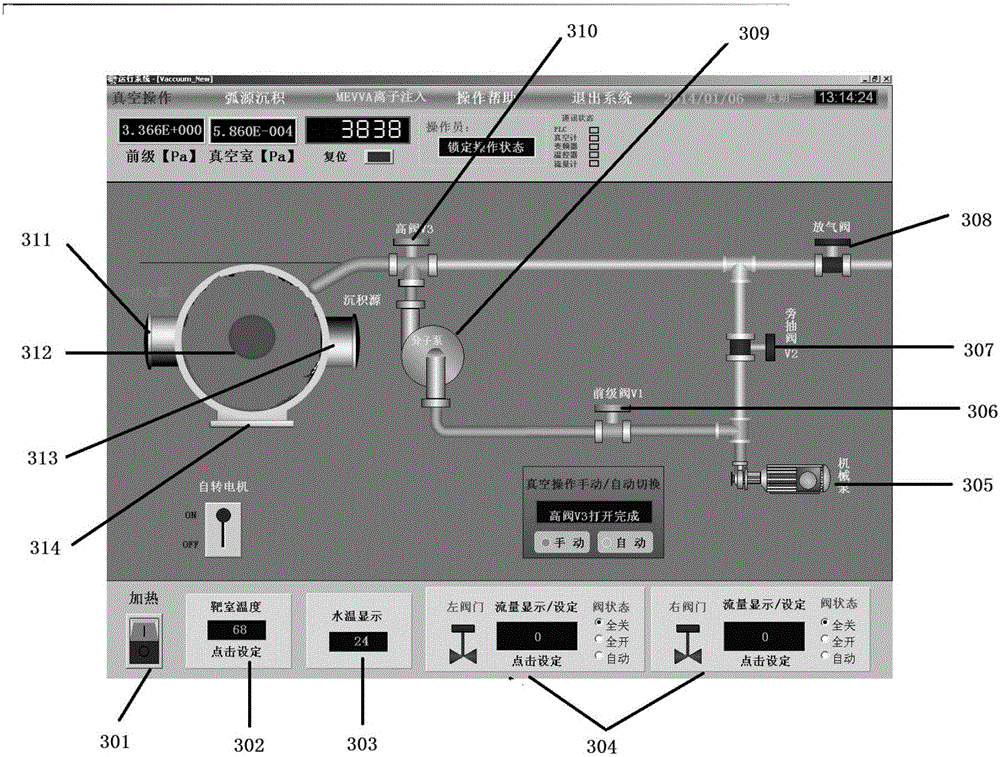

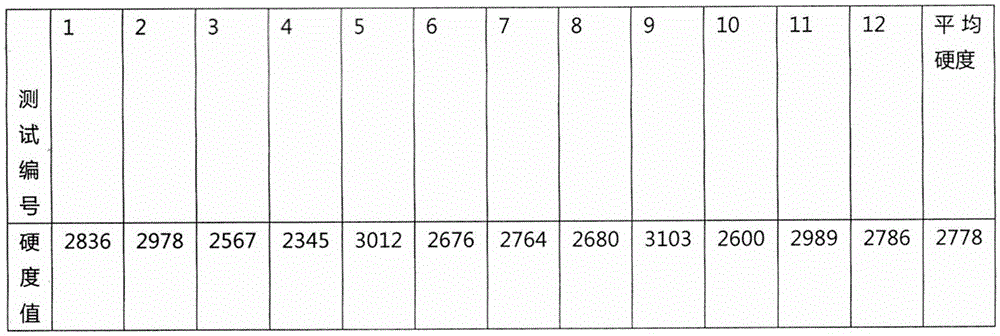

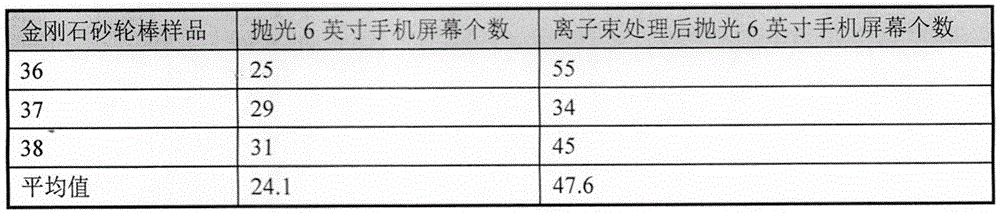

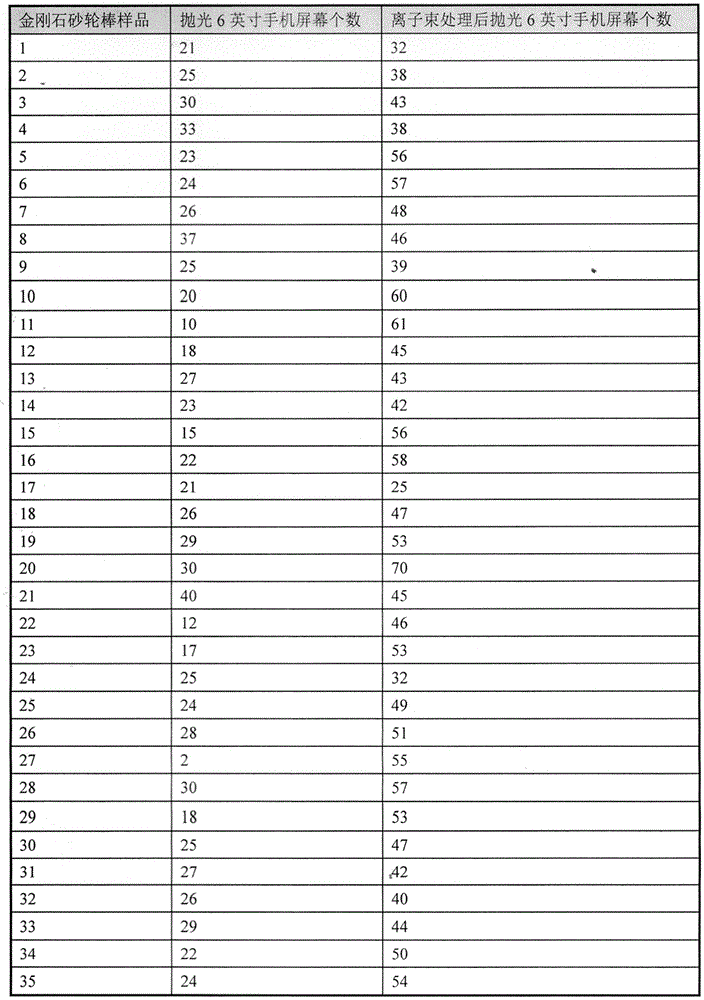

Method and device for prolonging service life of diamond grinding wheel rod of polished optical glass based on ion beam technology

InactiveCN105773462AImprove bindingHigh peel strengthVacuum evaporation coatingAbrasion apparatusComposite filmHigh energy

The invention discloses a method for prolonging the service life of a diamond grinding wheel rod of polished optical glass based on the ion beam technology. According to the method, an ultra-thick and ultra-hard (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film which is high in friction coefficient and good in toughness is deposited on the surface of silicon carbide through an ion implantation technique and a magnetic filtration deposition technique. A method for preparing the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film comprises the steps that a metal cathode filtered cathodic vacuum arc (FCVA) system is adopted, and a workpiece is cleaned on the surface of the grinding wheel rod through high-energy large-beam metal ion beams; then a metal vacuum vapor ion source (MEVVA) method is adopted, and a metal "pinning layer" capable of improving the film-base combination force is injected into the surface of the workpiece; sine or cosine modulated deposition is conducted on the gas inlet amount on the metal"pinning layer" through a magnetic filtration filtered cathodic vacuum arc (FCVA) method, and the ultra-hard thick (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film which is good in toughness is obtained; and the modulation period is repeated till the total thickness of the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film reaches 10-30 microns. By the adoption of the method, the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film deposited on the workpiece is good in toughness and quite high in microhardness, and the service life of the grinding wheel rod can be prolonged by 2-5 times.

Owner:BEIJING NORMAL UNIVERSITY

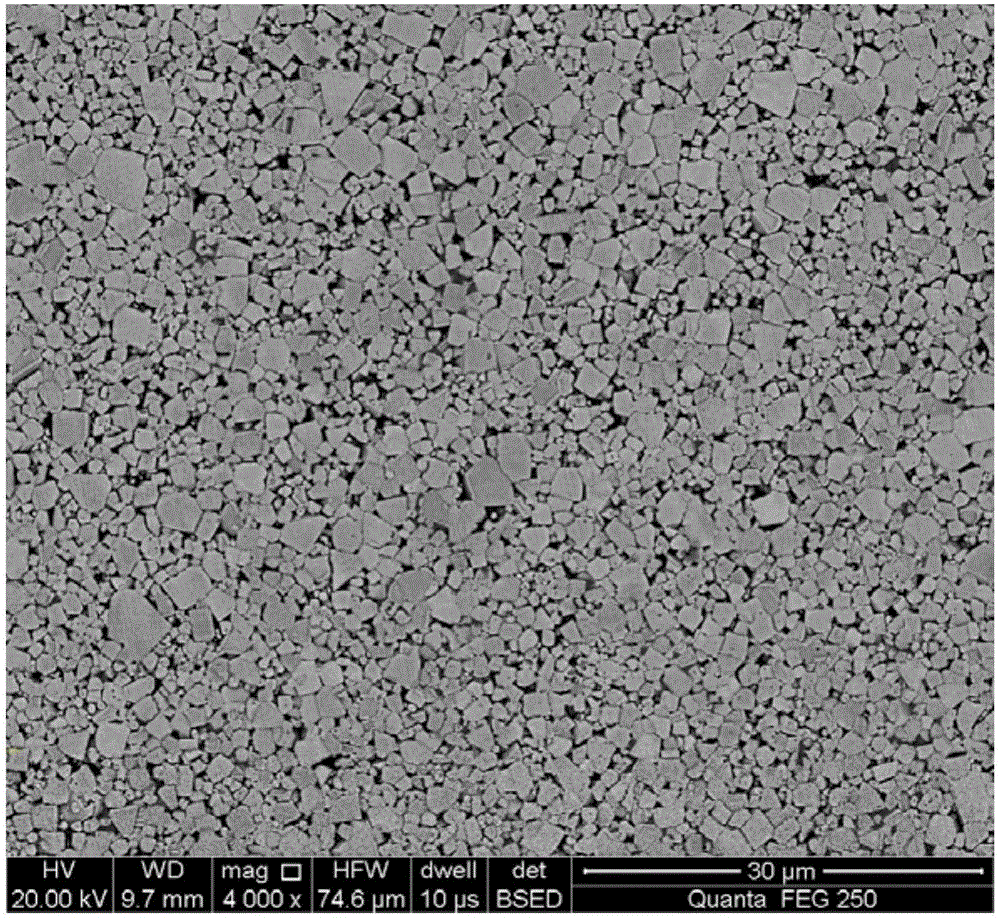

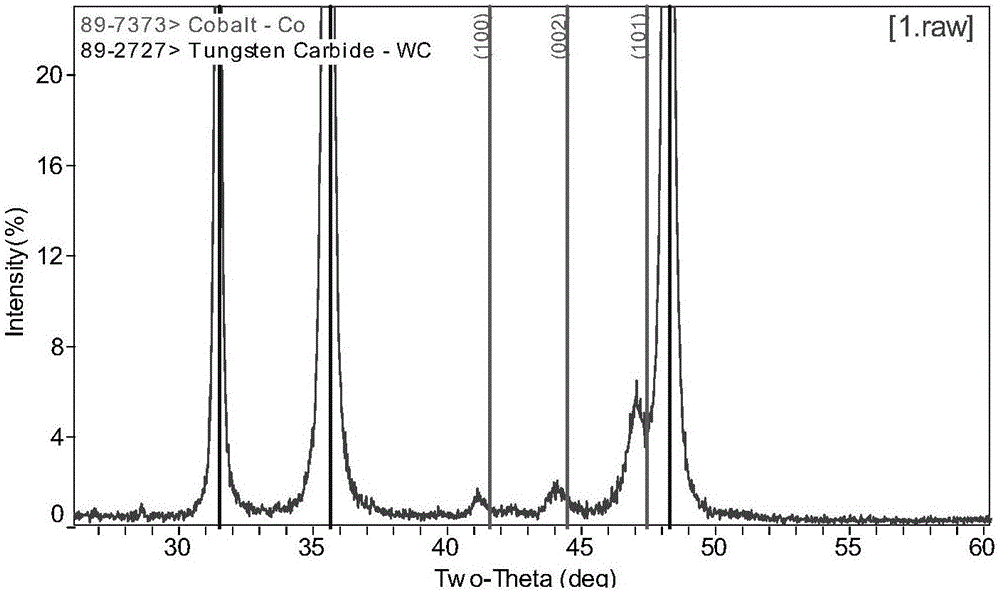

Coating hard alloy matrix and preparation method thereof

ActiveCN106835116AExtended service lifeImprove performanceHeat inorganic powder coatingLattice mismatchCrystal structure

The invention provides a coating hard alloy matrix having high film-based binding force with metal nitride on the basis of design principles of an alloy material for phase lattice mismatch regulation at a film-based interface and regulation effectiveness guarantee and a preparation method of the alloy material. The hard alloy matrix is made of WC-Co-based alloy. WC-based hard phase and Co-based binding phase lattice constants are regulated respectively by adding Mo2C and Ru into the alloy at the same time to promote metal nitride film nucleation and stabilize interface phase crystal structure so as to realize effective regulation of phase lattice mismatch at the film-based interface; each of mass ratio of Mo2C and Co in the WC-Co-based alloy and mass ratio of Ru and Co is (10-15):100, grain size of the WC-based hard phase is smaller than 1.5um, and Co-based binding phase is of a close-packed hexagonal structure. The hard alloy matrix is prepared by adopting processes of wet milling, drying and granulating, pressing for forming and CO-containing pressurizing and sintering.

Owner:河北株冀硬质合金有限公司

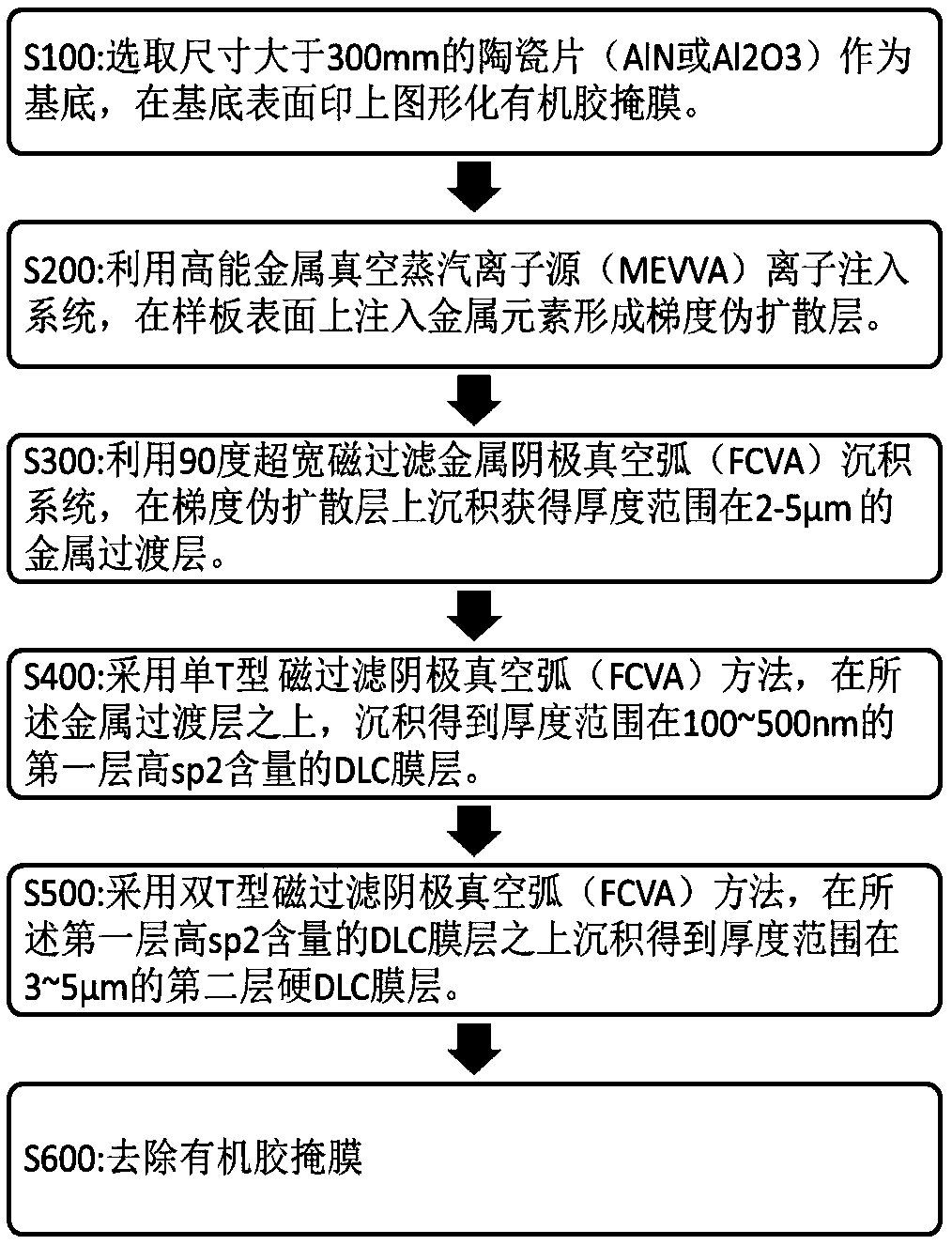

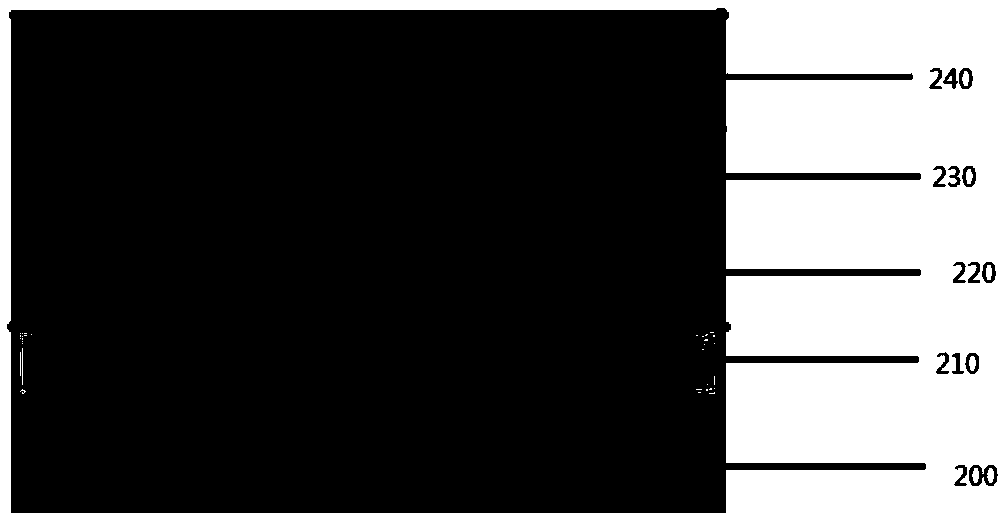

Preparation method and equipment of patterned electrostatic chuck

ActiveCN108842133AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingAdhesiveHigh energy

The invention discloses a preparation method and equipment of a patterned electrostatic chuck. The preparation method comprises the following steps that an ultra-large size (greater than 300 mm) ceramic sheet (AlN or Al2O3) is selected as a substrate, a patterned organic adhesive mask is printed on the substrate, and a high resistivity, high hardness, wear resistance and ion erosion resistance DLCfilm layer is deposited by utilizing an ion beam technology; a deposition method comprises the following steps that a high-energy metal vacuum vapor ion source (MEVVA ) is adopted, a metal element isinjected into the substrate to form a graded pseudo diffusion layer, and then a 90-degree ultra-wide magnetic filtration metal cathode vacuum arc (FCVA) technology is adopted, and a metal transitionlayer is deposited; a single T-shaped magnetic filtration cathode vacuum arc (FCVA) is adopted on the metal transition layer, and a DLC film layer with high sp2 content is obtained through the deposition; and a double-T-shaped magnetic filtration cathode vacuum arc (FCVA) is utilized on the DLC film layer with the high-sp2-content, and a super-hard DLC film layer is obtained through the deposition; and the resistance of the film layer can reach 10-50 megohm, and the hardness can reach 80 Gpa or above. According to the method and the equipment, the electrostatic chuck is enabled to have excellent wear resistance, and the service life is prolonged.

Owner:BEIJING NORMAL UNIVERSITY

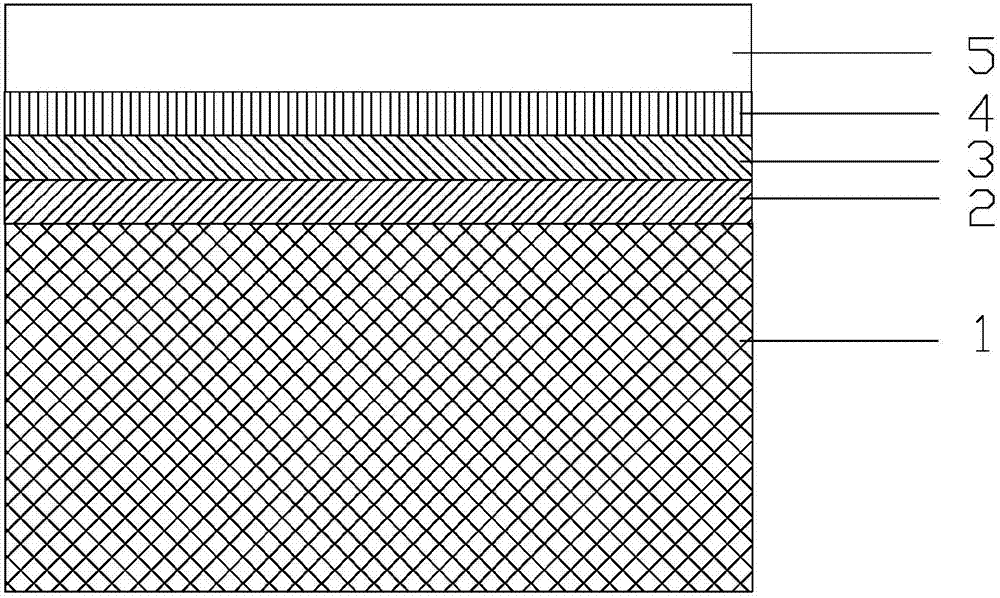

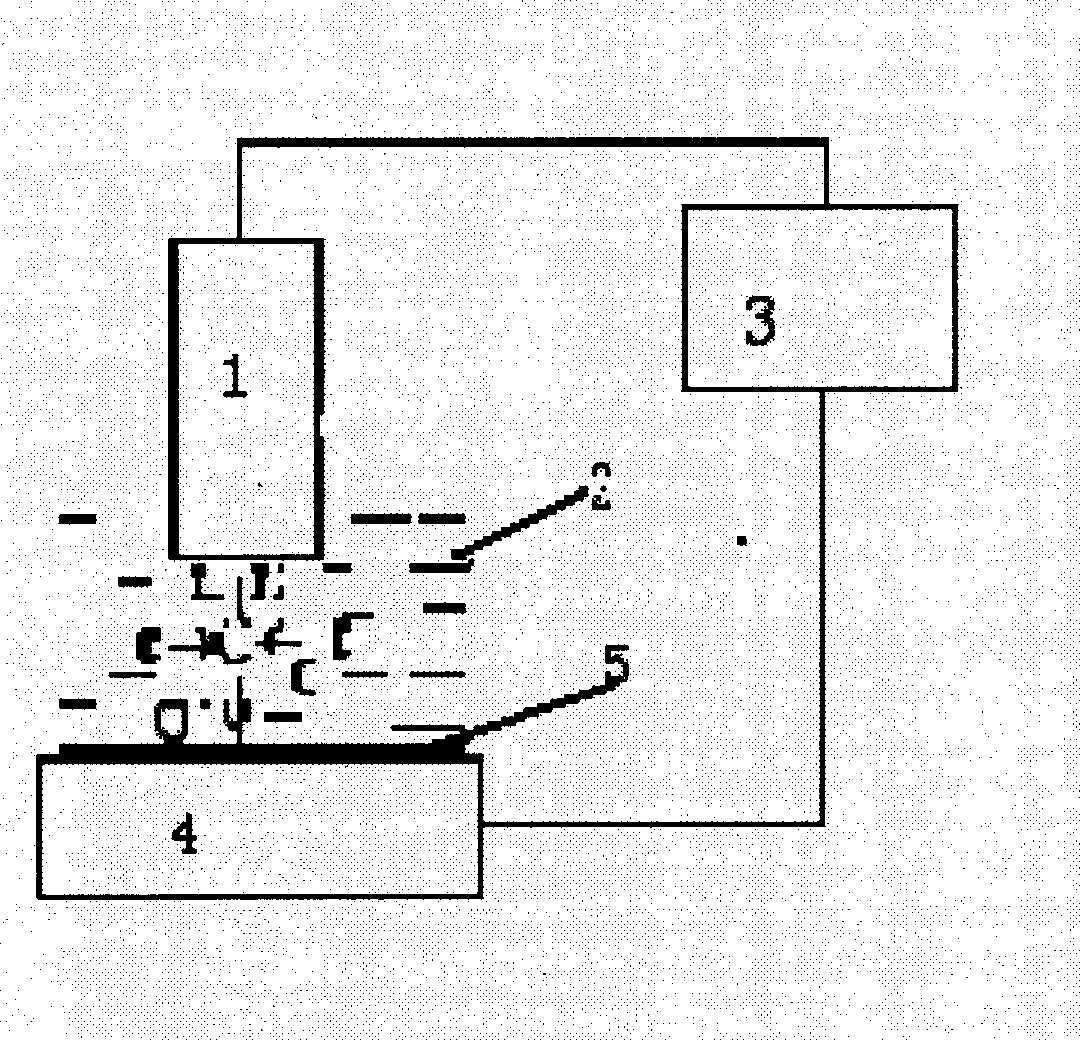

Preparation method of TiC ceramic coating

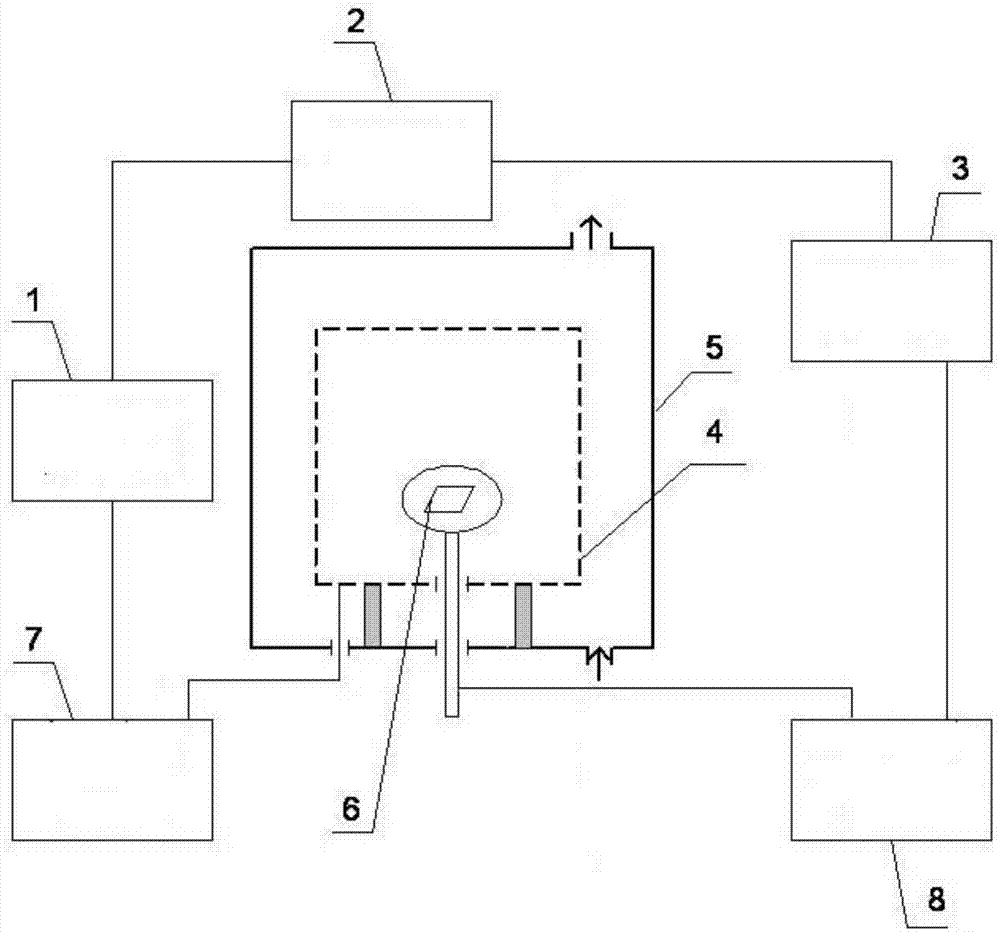

InactiveCN1807700AImprove process stabilityImprove the binding force of membrane baseElectrolytic inorganic material coatingElectrochemical responseCeramic coating

The invention discloses a TiC ceramic coating preparing method, which comprises the following steps: 1) placing block metal Ti electrode(1) and working electrode(4) in coal oil(2); 2) connecting anode of impulsing power source(3) to block metal Ti electrode(1); linking up with cathode of impulsing power source(3) and work electrode(4); 3) making connection with impulsing power source(3); carrying on electrochemical reaction with Ti metallic ion released form metal and C ion ionized from coal oil(2); compounding ceramic coating(5) of ceramic film TiC and depositing on the surface of work electrode. The invention improves the stability of craft and cementing property of basilemma.

Owner:GUANGDONG UNIV OF TECH

Composite multi-mode plasma surface processing device

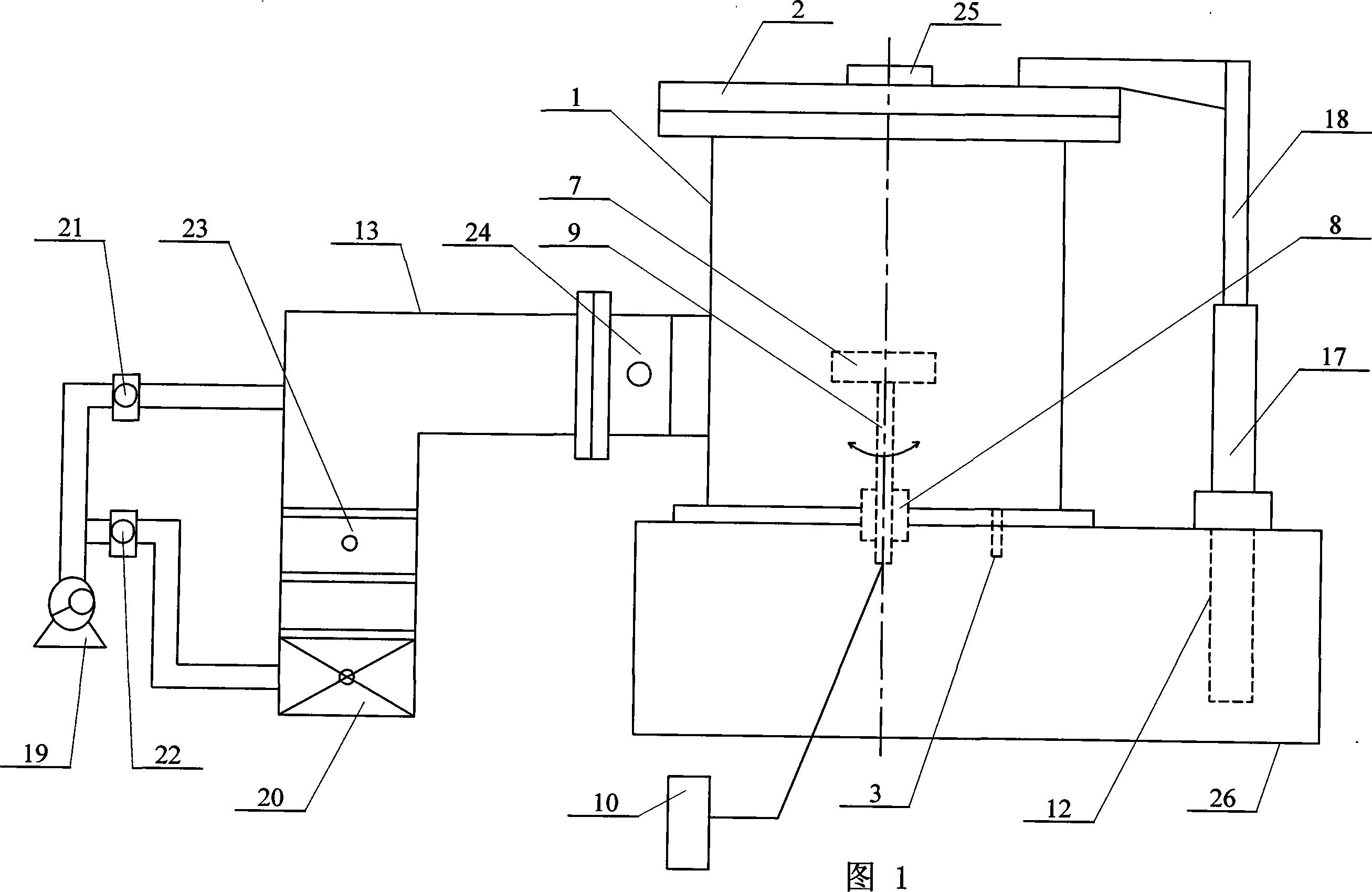

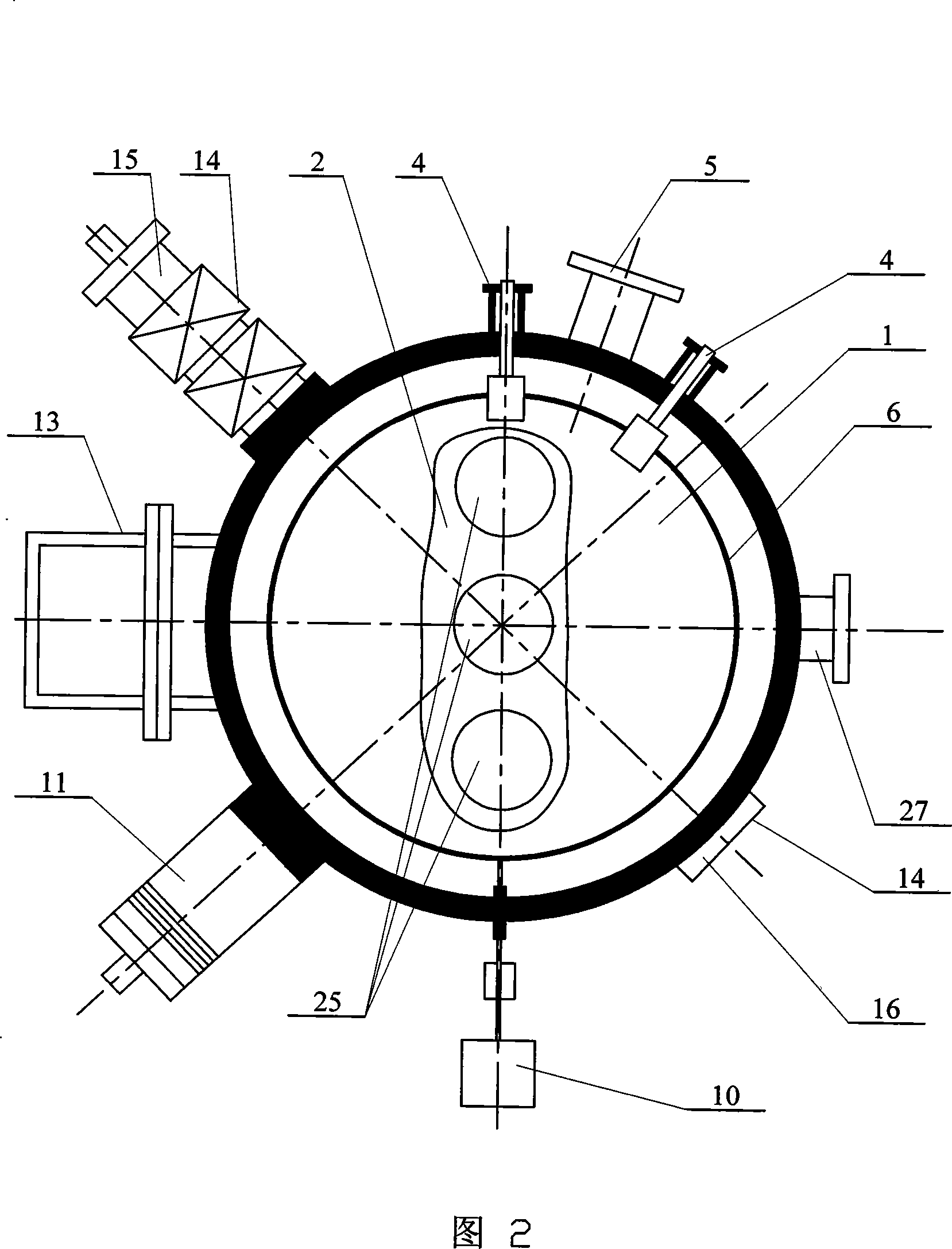

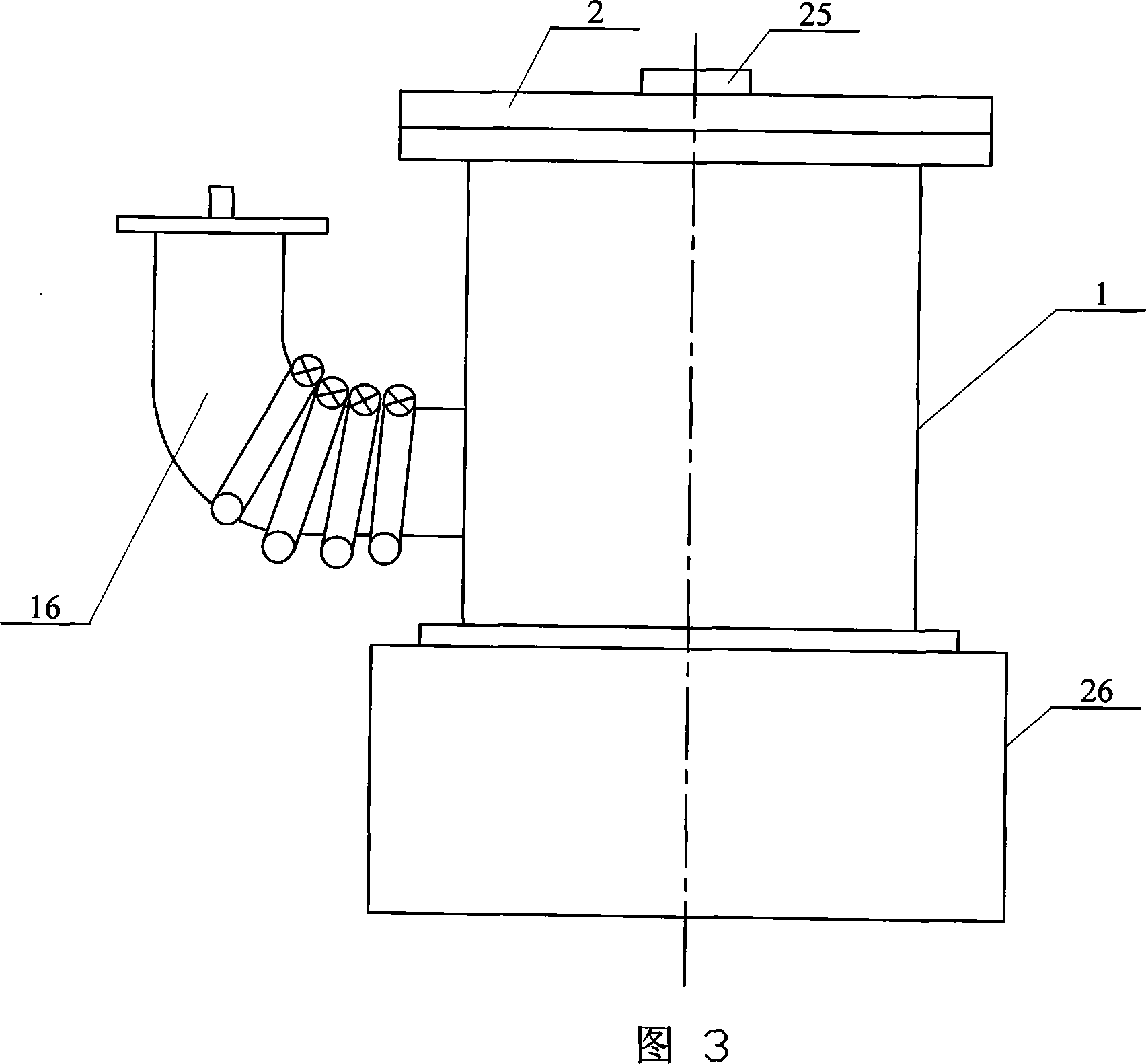

InactiveCN101187004AImprove the binding force of membrane baseOptimizing film structure and performance controlVacuum evaporation coatingSputtering coatingRadio frequencyEngineering

A complex multi-mode plasma surface treatment installation relates to a plasma surface treatment installation which aims at the problem that when work pieces are processed via a complex surface treatment process, the work pieces need to be processed via different processes on two different devices, and the work pieces in the middle procedure are exposed to the air, forming disadvantageous foreign matters, which affects the property of final films. A magnetron sputtering target (4), vacuum cathodic arc source (14), metal ion implantation source (11), low-energy ion source (5) and a pump set (13) are fixedly installed on the outer wall of a vacuum chamber (1) inside which a radio frequency antenna (6) is fixedly installed, the upper end of a center electrode (9) passes through a sealed insulator (8) to be installed inside the vacuum chamber (1), the lower end of the center electrode is connected with a pulsed bias power supply (10), a high voltage target table (7) is fixed on the center electrode (9), and an upper cover (2) of the vacuum chamber is connected with a pneumatic device (12). The invention employs multiple generating means of particles, the work pieces can obtain thicker films as well as a variety of thicker films, thereby increasing the film-substrate cohesion and realizing the surface treatment of special shaped work pieces and the recombination of pluralities of processes.

Owner:辽宁北宇真空科技有限公司

Boron-doped diamond/graphite composite electrode as well as manufacturing method thereof and double-battery reactor

PendingCN108408848AImprove mechanical propertiesGood effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment apparatusComposite electrodeThermal expansion

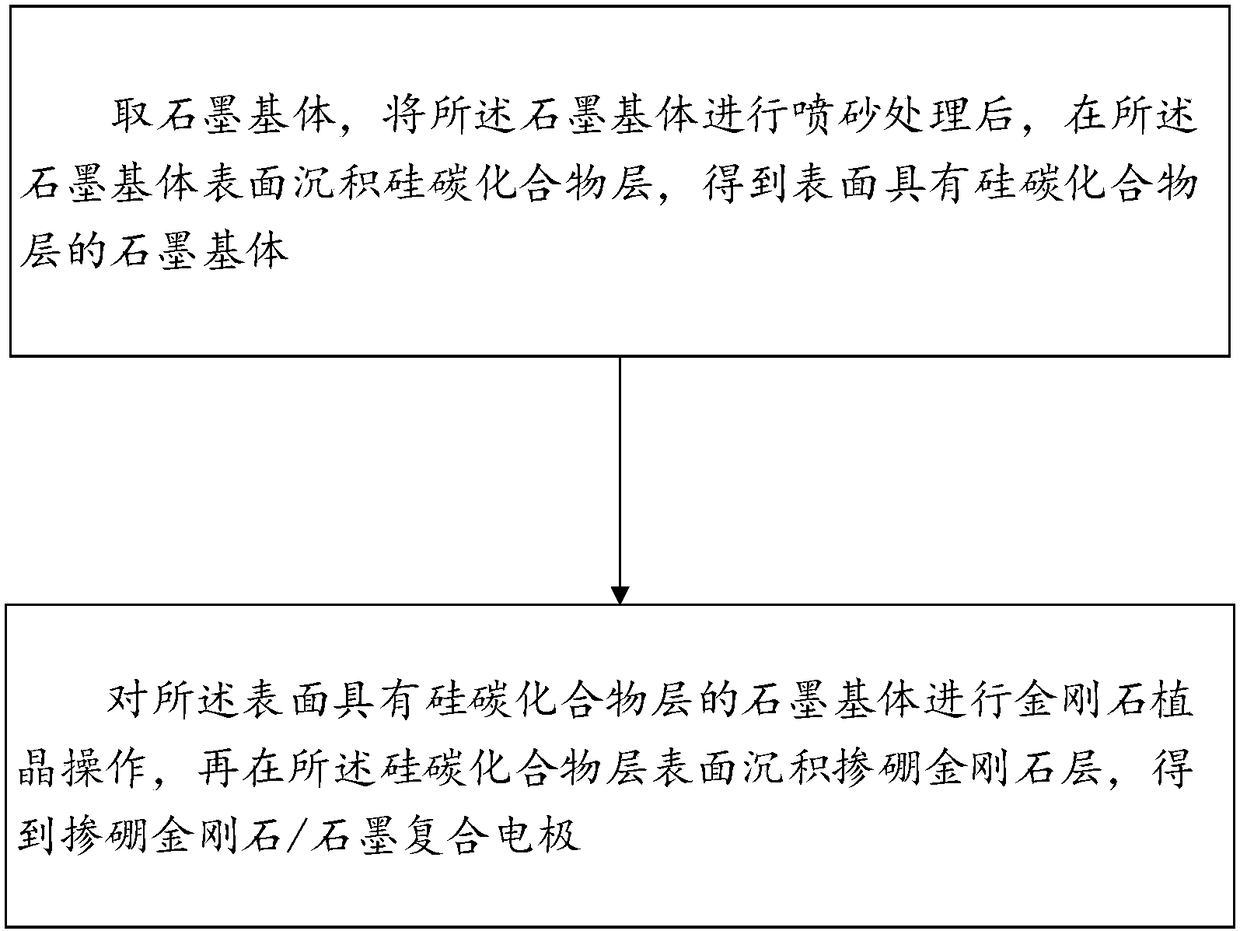

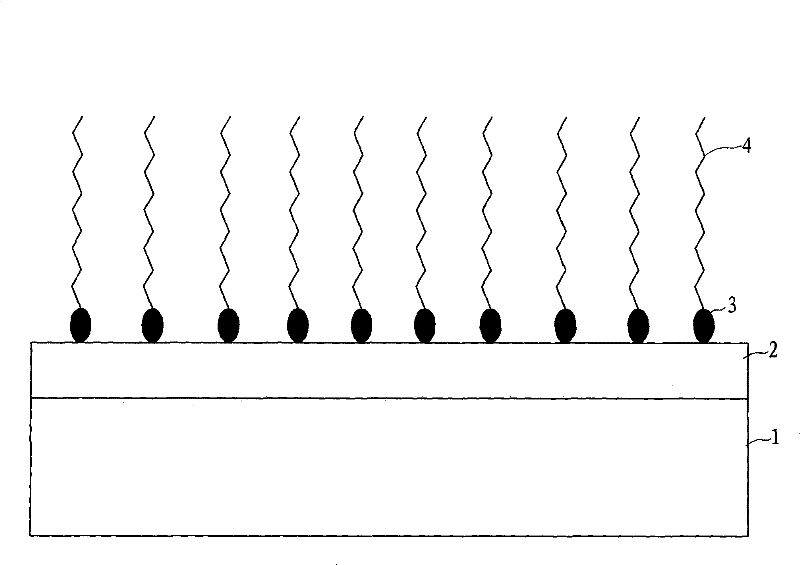

The invention provides a boron-doped diamond / graphite composite electrode. The boron-doped diamond / graphite composite electrode comprises a graphite base body as well as a silicon-carbon compound layer and a boron-doped diamond layer which are sequentially stacked on the graphite base body. A thermal expansion coefficient of the silicon-carbon compound is within an intermediate value range of thethermal expansion coefficient of graphite and boron-doped diamond, and therefore, the silicon-carbon compound is taken as an intermediate transition layer, and difference of thermal expansion coefficients of layers of the boron-doped diamond / graphite composite electrode is reduced. Influences, on film-based binding force, of thermal residual stress are finally reduced, and film-based binding forceof the boron-doped diamond / graphite composite electrode is improved. The invention further provides a manufacturing method for the composite electrode, and the manufacturing method is simple in process, and is low in cost; and the silicon-carbon compound layer is deposited for avoiding pollution on a chamber, so that the industrial applicability is very great.

Owner:SHENZHEN INST OF ADVANCED TECH

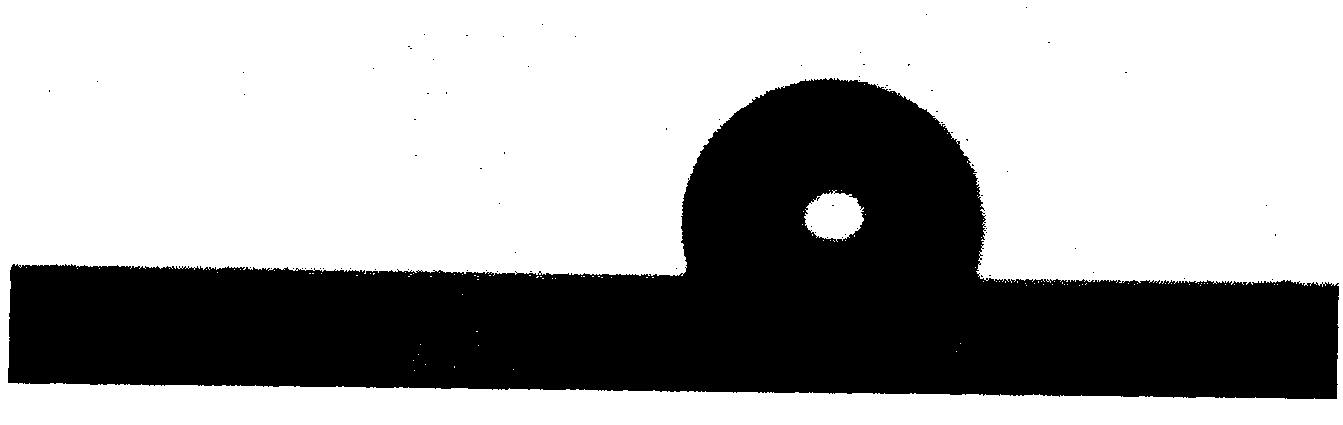

Preparation method of photovoltaic glass surface antireflection film

The invention discloses a preparation method of a photovoltaic glass surface antireflection film, which is characterized by comprising the following steps of firstly, preparing inorganic-organic hybrid silicasol; secondly, coating; thirdly, hydrophobic treatment; and fourthly, solidification treatment. Compared with the prior art, the invention has the advantages that the film-substrate cohesion between an antireflection film and substrate photovoltaic glass is stronger, and therefore, the wiping resistance of the coated photovoltaic glass surface antireflection film is enhanced; a layer of hydrophobic group with low surface energy is formed on the surface of the antireflection film, and therefore, the corrosion of moisture to a film microstructure is reduced, and the long service life ofthe coated photovoltaic glass is ensured; and the invention has low whole process cost and simple technical route and is suitable for industrial and large-scale application.

Owner:CHANGZHOU ALMADEN

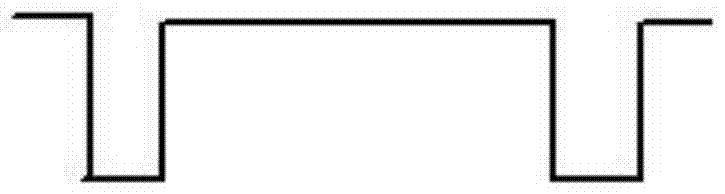

Grid plasma immersion ion deposition dlc method with bias regulation

ActiveCN105112883BRealize the structureEnhanced sputter cleaning actionChemical vapor deposition coatingIon depositionHigh voltage pulse

Bias regulation grid plasma immersion ion deposition DLC method. It involves plasma immersion ion deposition DLC method. The invention aims to solve the problems of poor binding force, difficult adjustment and control of film performance and non-uniformity of DLC film deposited on large or complex parts existing in the existing MPIID method for depositing DLC films. Method: 1. Put the grid and the workpiece in the vacuum chamber, put the workpiece on the sample rack in the grid, insulate the grid from the workpiece, connect the grid to the high-voltage pulse power supply of the grid, and connect the workpiece to the high-voltage pulse power supply of the workpiece; 2. Splash the workpiece 3. Plasma nitriding treatment; 4. Sputtering etching treatment; 5. Preparation of SiC transition layer; 6. Preparation of bias control thin film. The invention is used for preparing DLC film deposited by plasma immersion ion deposition of bias voltage control grid.

Owner:HARBIN INST OF TECH

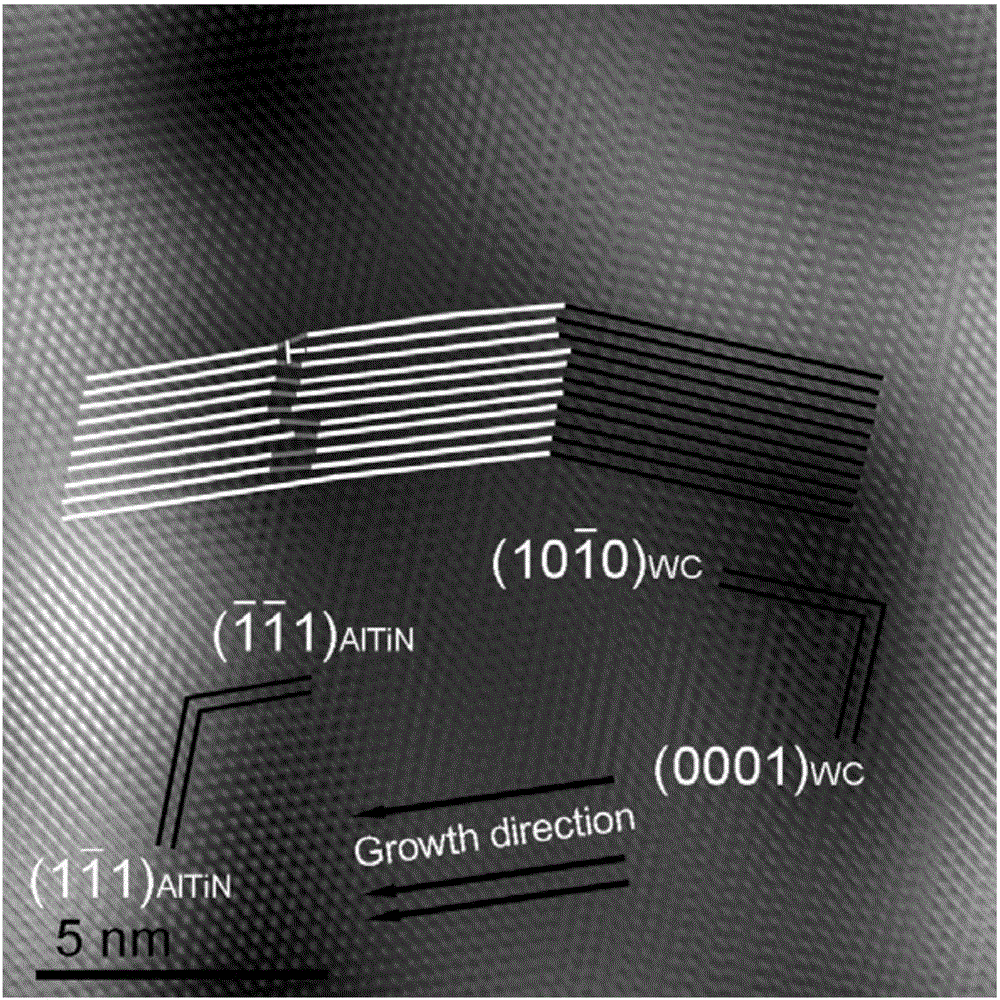

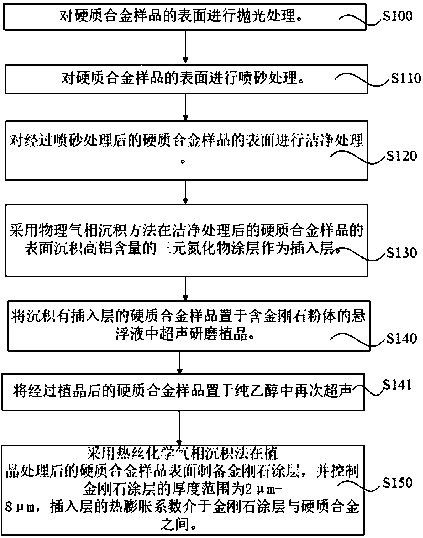

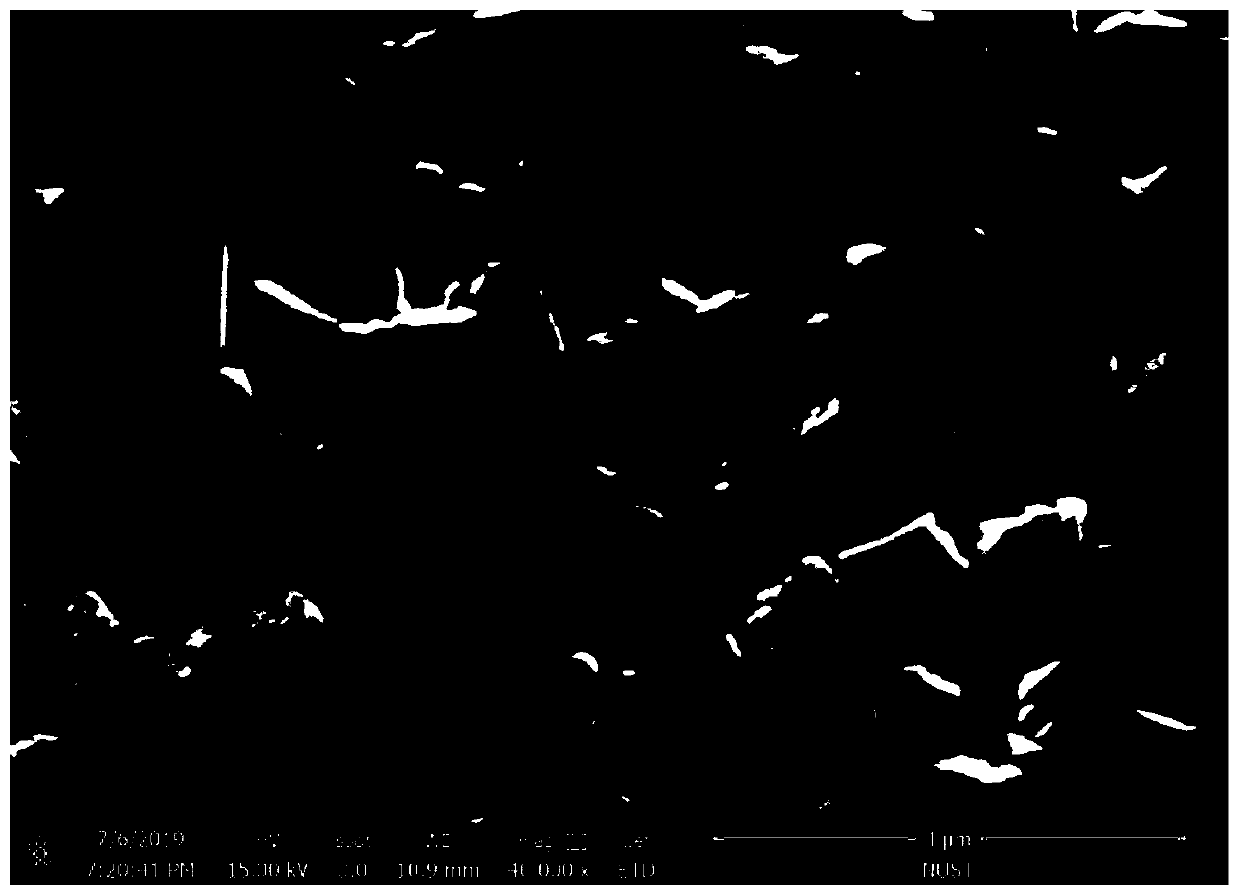

Method for preparing diamond coating on surface of cobalt-containing hard alloy and tool and die with diamond coating

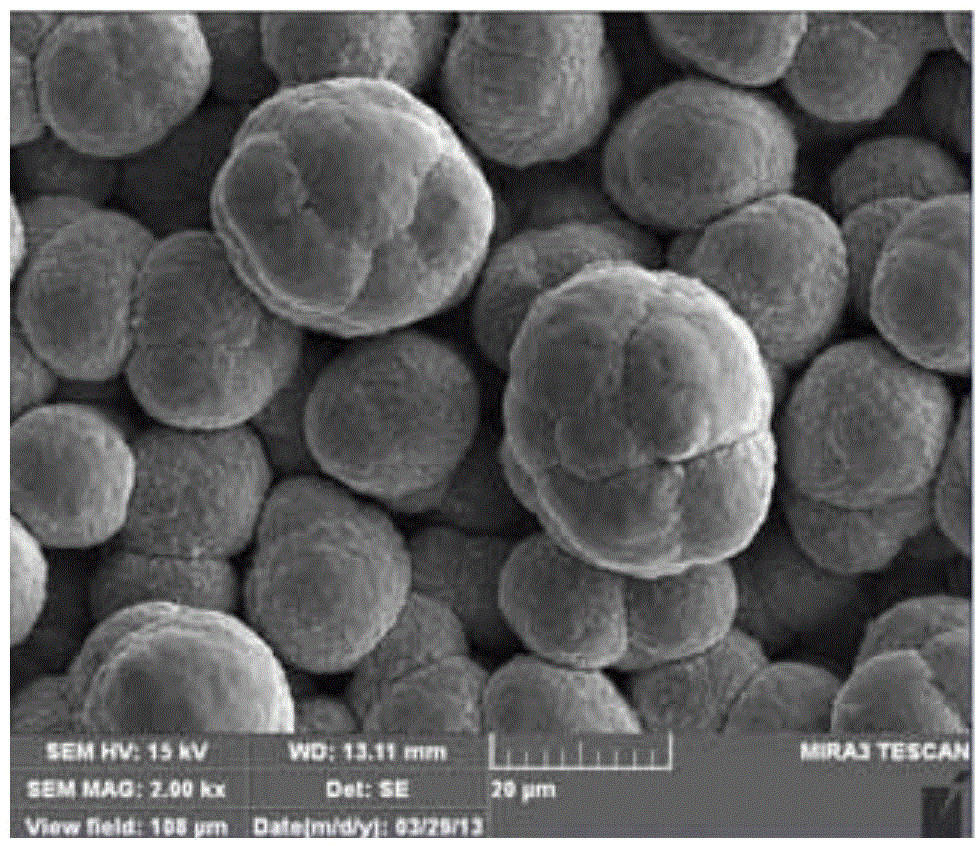

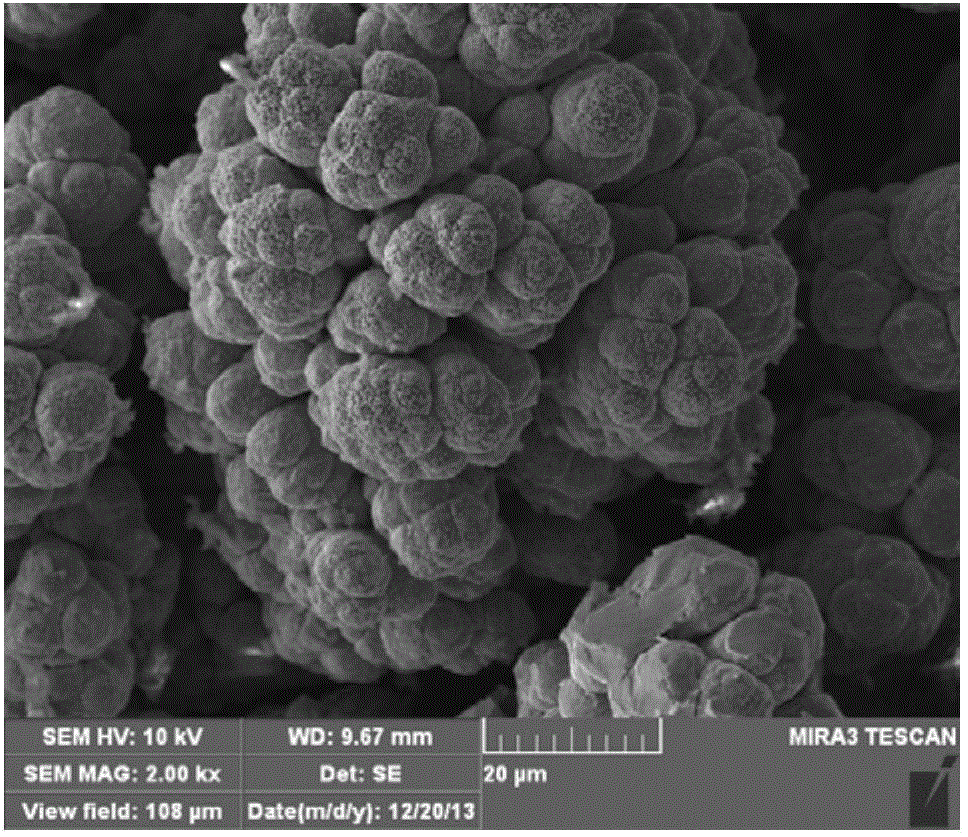

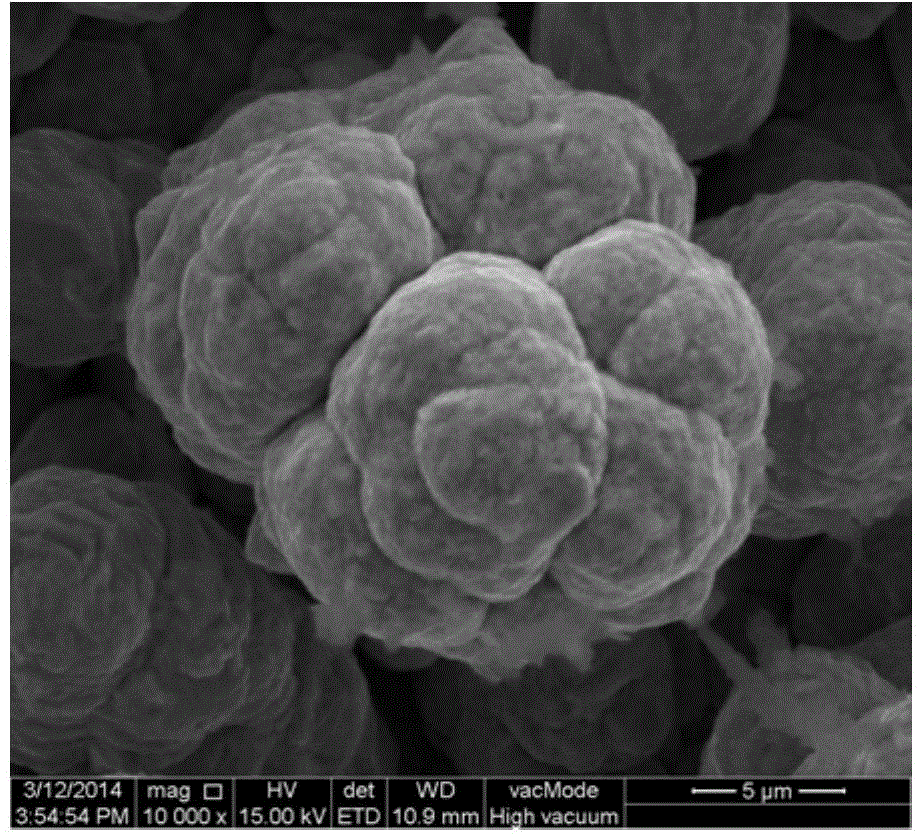

ActiveCN111041448AImprove uniformity of implantationImprove the "mosaic" effectVacuum evaporation coatingSputtering coatingThermal dilatationHigh density

The invention relates to a method for preparing a diamond coating on the surface of cobalt-containing hard alloy and a tool and mold with a diamond coating. According to the invention, the surface ofa sample is subjected to sand blasting and cleaning treatment, an ideal basis is provided for high density and homogenization of diamond particles in an ultrasonic grinding and crystal planting stageand a mechanical riveting 'inlaying' effect of a grown diamond coating, the crystal planting uniformity and the 'inlaying' effect are improved, a ternary nitride coating with high aluminum content isselected as an insertion layer, the insertion layer is stable at high temperature, does not react with a surrounding medium, and has almost zero solid solubility to cobalt, the coefficient of thermalexpansion of the insertion layer is between the coefficient of thermal expansion of the diamond coating and the coefficient of thermal expansion of a hard alloy matrix, a cobalt element in the hard alloy matrix can be effectively prevented from diffusing outwards, the nucleation interface strength of the diamond coating and the quality of the diamond coating are improved, and therefore the film-substrate binding force of the diamond coating and the quality of the diamond coating are effectively improved.

Owner:CONPROFE TECH GRP CO LTD +2

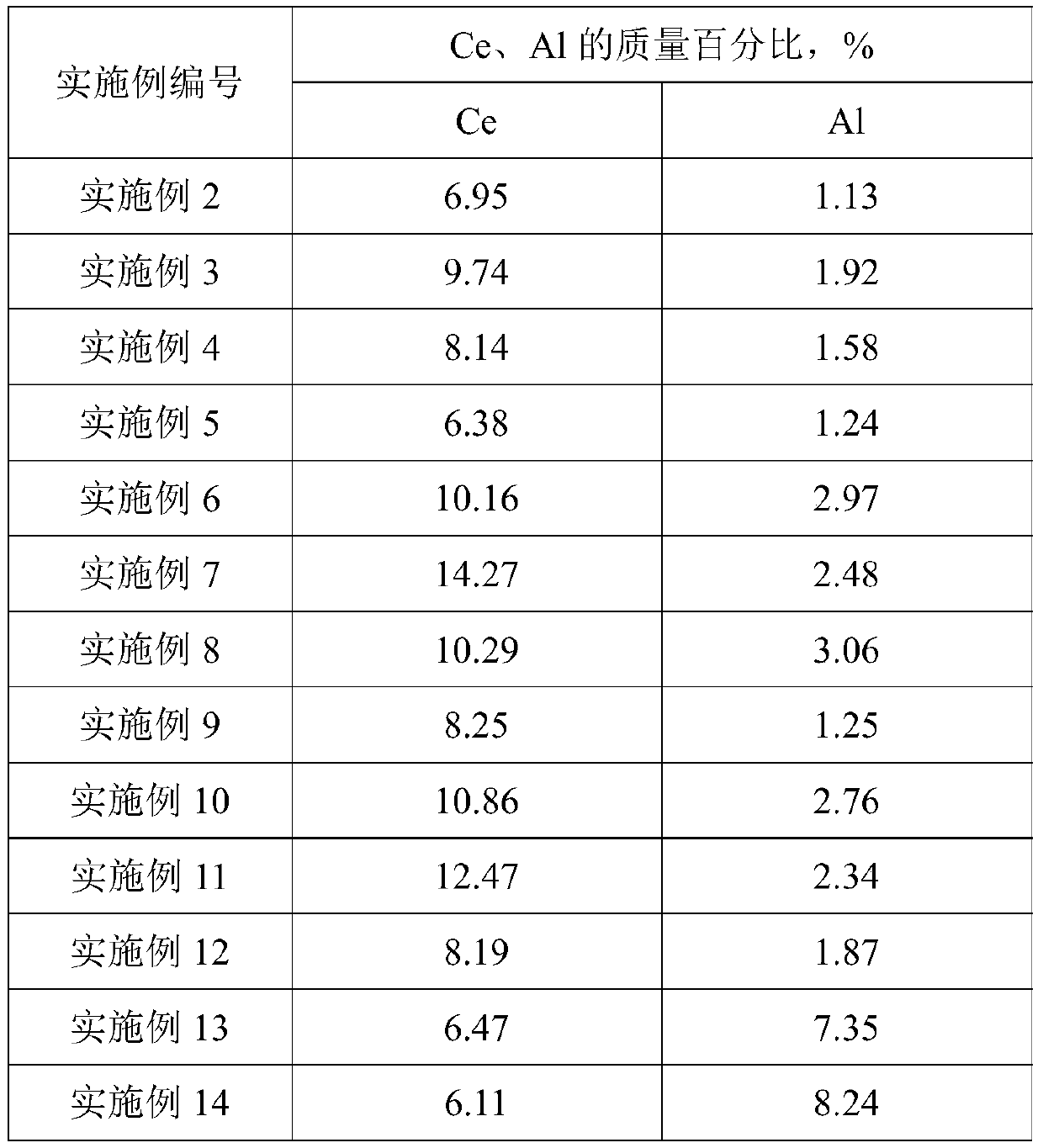

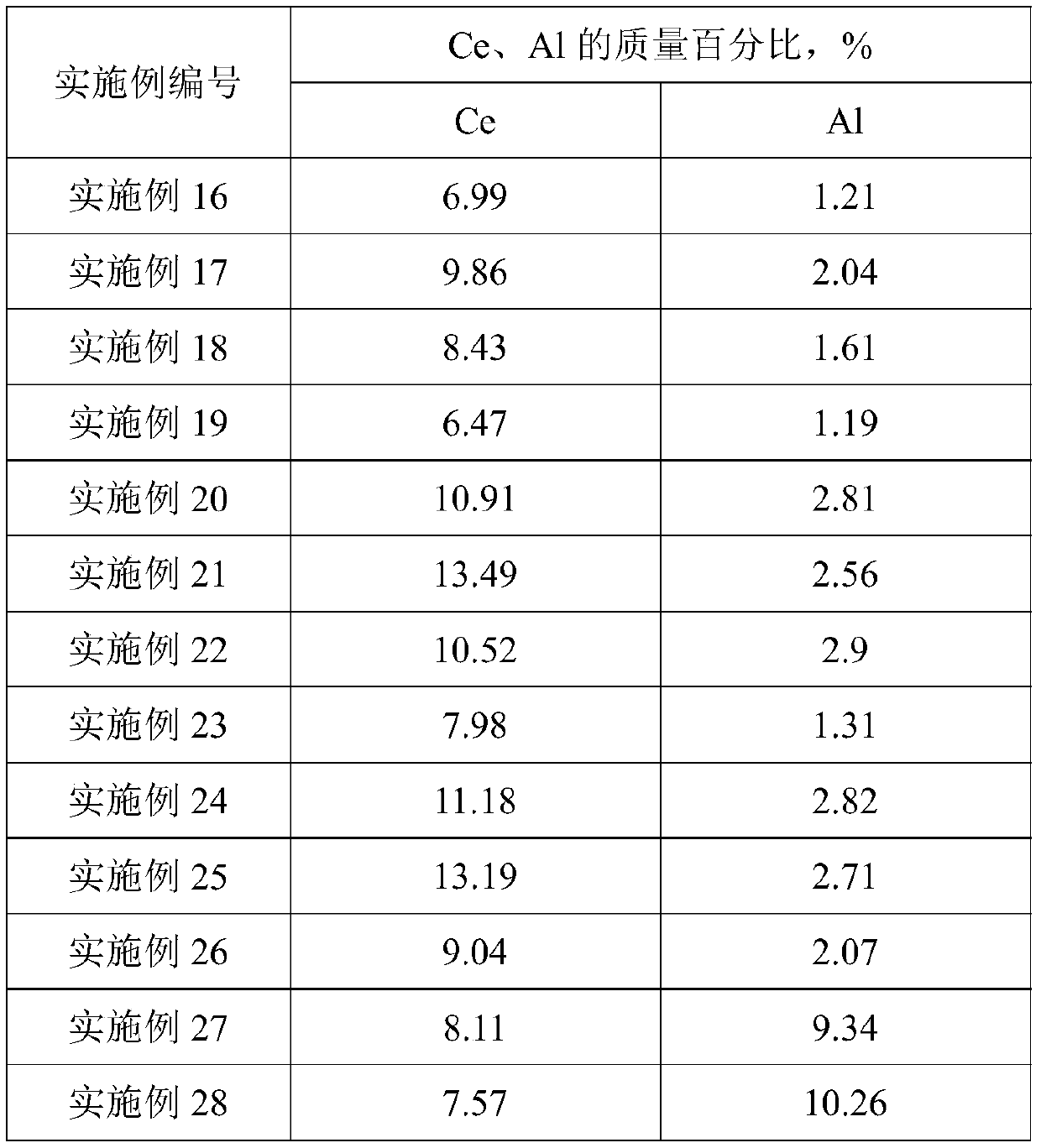

Doped sulfide composite film, preparing method of doped sulfide composite film and workpiece comprising doped sulfide composite film

ActiveCN110578115AImprove mechanical propertiesImprove wear resistanceVacuum evaporation coatingSputtering coatingComposite filmHardness

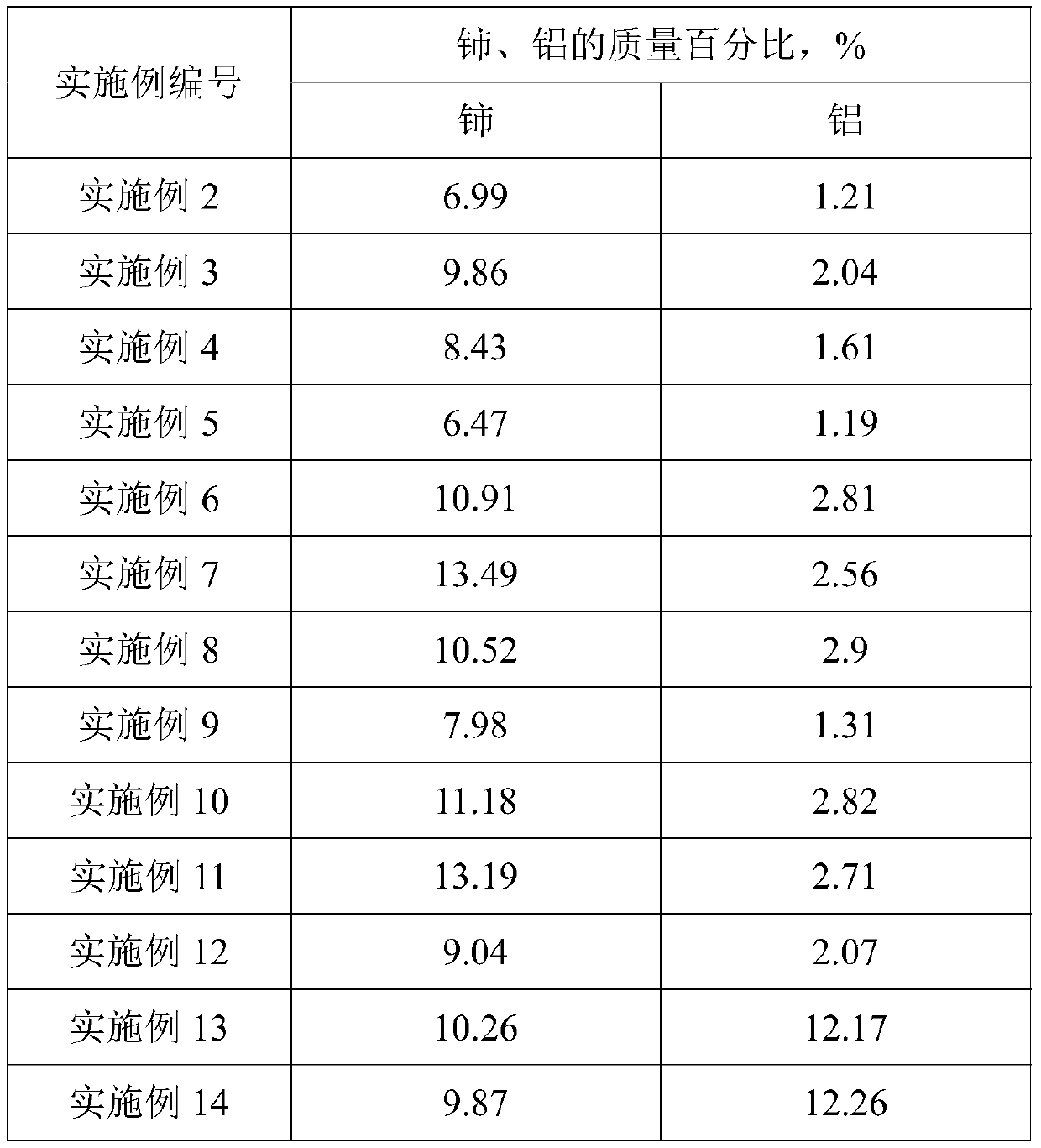

The invention relates to a doped sulfide composite film, a preparing method of the doped sulfide composite film and a workpiece comprising the doped sulfide composite film. The doped sulfide compositefilm is composed of doped elements and sulfide, wherein the doped elements are Ce and Al, and the sulfide is WS2 or MoS2; and the doped sulfide composite film includes, by mass, 6.11%-14.27% of Ce, 1.13%-10.26% of Al and the balance sulfide. The mechanical performance of the doped sulfide composite film is improved, and therefore good wear-resisting performance can be shown; and the crystal strength of the Ce and Al co-doped sulfide base composite film is high, and the elasticity and elasticity modulus are improved by 300% or higher.

Owner:HENAN UNIV OF SCI & TECH

Ion surface etching method for diamond-like coating before preparing

InactiveCN110735107AImprove membrane bindingImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingVacuum pumpingHigh energy

The invention belongs to the field of diamond-like coatings and particularly relates to an ion surface etching method for a diamond-like coating before preparing. The treatment method includes material polishing, vacuum pumping and heating, substrate cleaning and surface etching treatment, wherein two high-purity twin titanium targets are adopted as the target material, an intermediate-frequency magnetron sputtering method is adopted, cooperation of the pulse negative bias is adopted, high-energy titanium ions are adopted for conducting bombarding on the surface of a base body, an etching effect is generated, and the effect of modifying the surface of the base body is achieved. The diamond-like coating is prepared on the base body treated through the method so that good bonding strength and friction performance can be obtained, the coating and base body bonding force is 25.10 N, the friction coefficients of contact friction with silicon nitride and a titanium alloy are 0.14 and 0.12 respectively, and the wear rates are 8.32 E-12 mm<3> / Nm and 1.93 E-11 mm<3> / Nm respectively. The method is adopted as the pretreatment technology for preparing the diamond-like coating, the bonding strength of the coating can be improved, the technology is advanced, production is easy, and promotional value is achieved.

Owner:NANJING UNIV OF SCI & TECH

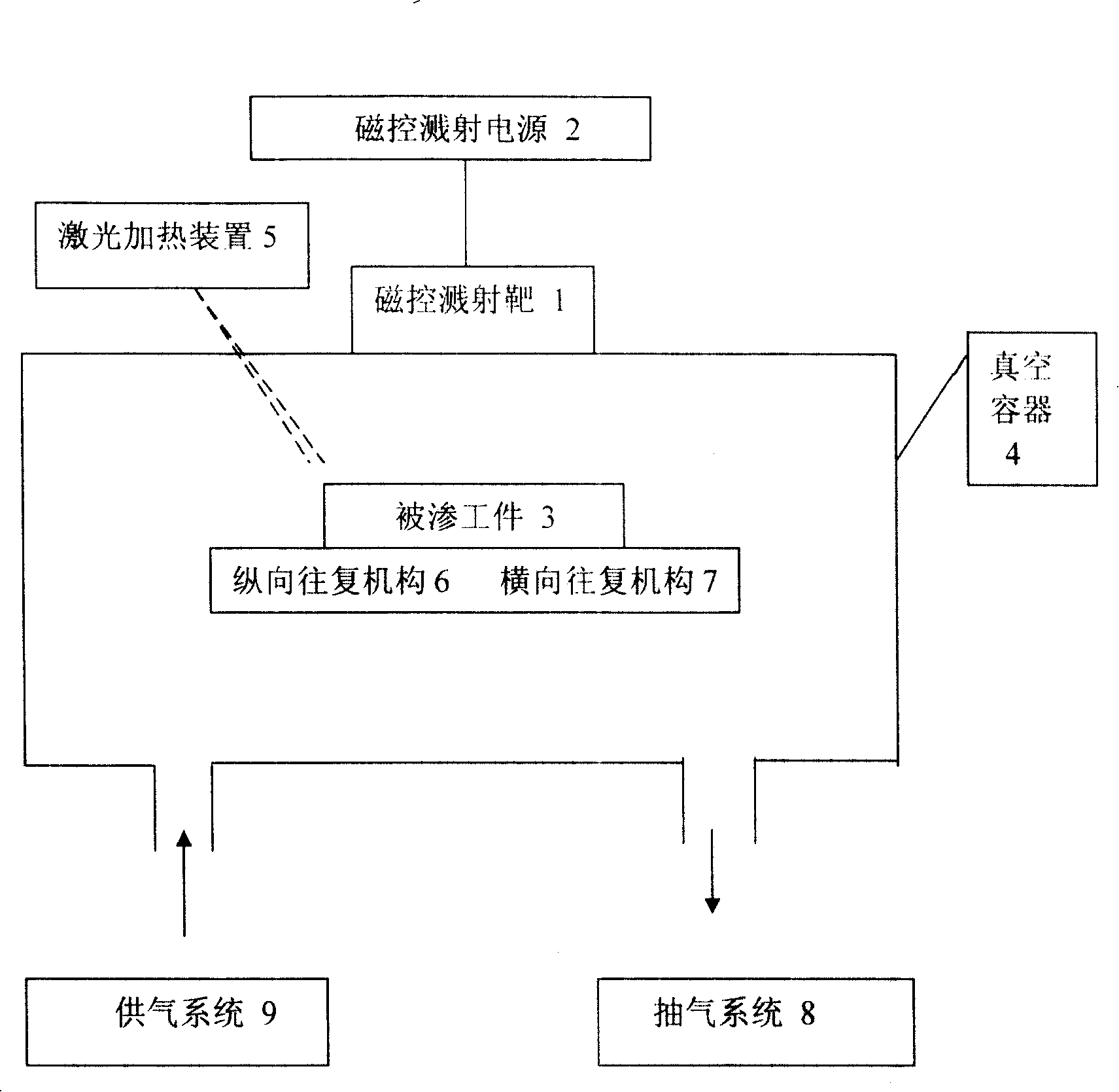

Composite plating process and equipment for magnetron sputtering-laser heating

InactiveCN101195905AMeet the surface depositionSatisfy the needs of infiltrationVacuum evaporation coatingSputtering coatingSputteringDiffusion

The invention discloses the magnetron sputtering-laser heating composite diffusion coating technology and the equipment, by utilizing the magnetron sputtering and a laser heating device, a single diffusion coating layer or a composite diffusion coating layer with a diffusion layer and a sedimentary layer or the diffusion layer plus the sedimentary layer which comprises metal element and nonmetal element is formed on the surface of a conducting workpiece. The invention has the advantages that by utility a magnetron sputtering target, sufficient pre-diffusing alloy element can be provided; by utilizing the laser heating, the diffused material can heated to high temperature in a short time and the diffusing speed is greatly increased; the DEG Cree of vacuum of the metal for diffusing is increased at least one order of magnitude compared with the common alloying method, and the surface quality of the diffused workpiece can be greatly improved; the diffusion coating can be performed continuously, and the production in large area and large scale can be realized.

Owner:GUILIN UNIV OF ELECTRONIC TECH

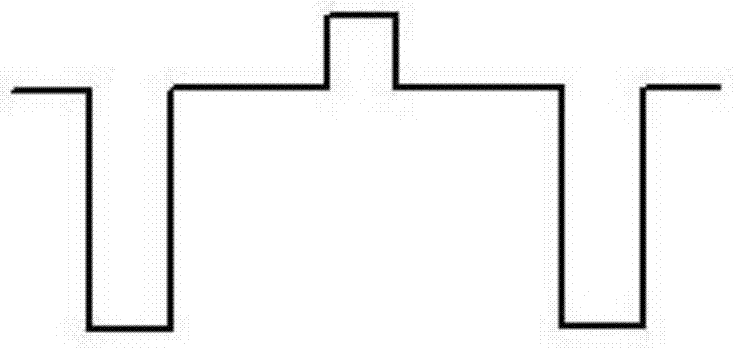

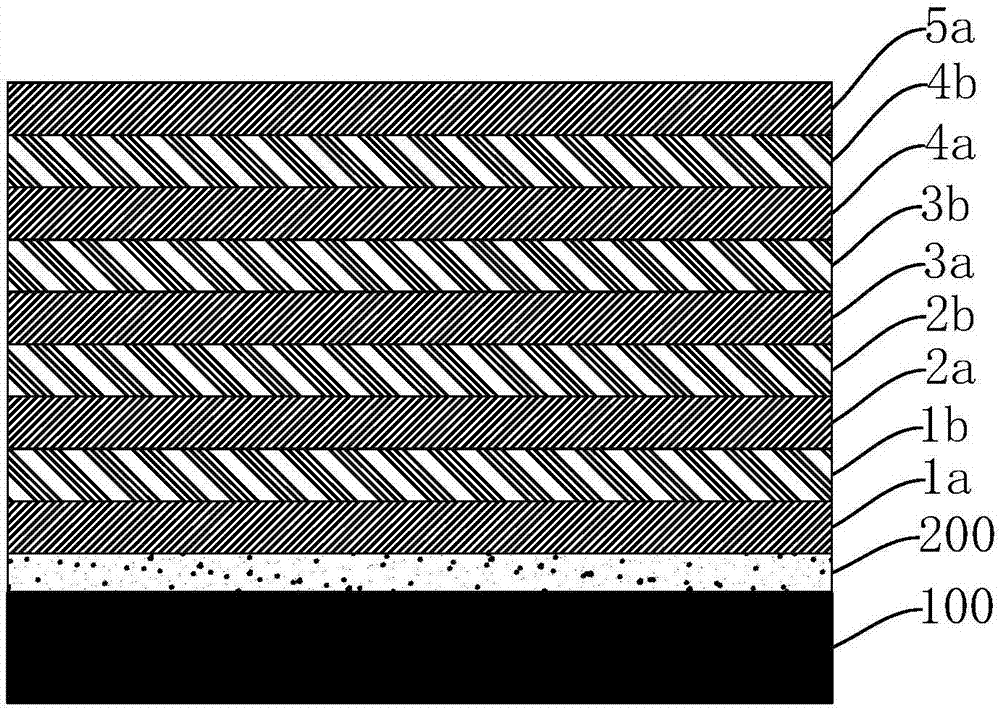

Strength and toughness integrated fullerene-like carbon-nitrogen multilayer composite film and preparation method thereof

ActiveCN108118305AOvercoming difficulties and both high and hardOvercome resilienceVacuum evaporation coatingSputtering coatingSurface engineeringComposite film

The invention relates to a strength and toughness integrated fullerene-like carbon-nitrogen multilayer composite film and a preparation method thereof and belongs to the technical field of surface engineering. The film structure comprises a metal matrix, a soft-hard alternate transition layer and a fullerene-like carbon-nitrogen layer in sequence, wherein the soft-hard alternate transition layer repeatedly alternates by taking one layer of Ti film and one layer of TiN film as one cycle; one layer of Ti film is arranged on the metal matrix; one layer of TiN film is arranged below the fullerene-like carbon-nitrogen layer. The film has the advantages of high hardness, high toughness, high binding force, good deformation capability of the film and the matrix and excellent wear resistance, thereby improving the binding force of a film matrix and wear resistance of the matrix as well as prolonging the life of the matrix. According to the preparation method disclosed by the invention, the soft-hard alternate transition layer is prepared by a direct current pulse magnetron sputtering method; internal stress is reduced and crack propagation is stopped; the method is simple and easy to control.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Self-lubricating composite coating, coating preparation method and product with coating

ActiveCN107513684AReduce stressImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingTribologyMaterials science

The invention discloses a self-lubricating composite coating, a coating preparation method and a product with the coating. The self-lubricating composite coating comprises a plurality of AlSn20Cu layers and a plurality of MoS2 layers which are arranged alternately. According to the self-lubricating composite coating, the MoS2 lubricating layers are introduced into the original AlSn20Cu coatings, so that the coating is diversified in component and structure, the stress of the coating can be effectively reduced, and film-base binding force is increased; and additionally, through introduction of a MoS2 phase, the tribological performance of the coating in the oil-lack and dry-friction environments can be greatly improved while the original lubricating performance of the AlSn20Cu coatings is not changed.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Construction of oxygen ion conductor electrolyte film and its pulse magnetic controlled sputtering prepn. method

InactiveCN1564266AHigh oxygen ion conductivityReduce the use temperatureConductive materialSolid electrolyte fuel cellsElectrical conductorOxygen ions

The invention includes following structures and steps: using YSZ and RCO ceramics target as well as using monocrystalline silicon MgO and Ni-YSZ or Ni-RCO anode plate as substrate, distance between target and substrate as 30-80mm; vacuum degree 1X10-4-1X10-5 Pa, substrate temperature 300 deg.C-800 deg.C; ratio of gas pressure between oxygen and argon as 5%-40%; Thickness of each film is 10-200 nano, and number of layer is larger than or equal to three, the invention also contains other technical parameters. Multiple layers of nano film provides advantages of raising conductivity of oxyanion 10%-50%, optimizing fuel cell performance. The disclosed sputtering technique has features of fast, and high quality.

Owner:DALIAN UNIV OF TECH

Coating method for preventing high-speed impact

ActiveCN111575669AImprove bindingHigh densityVacuum evaporation coatingSputtering coatingCarbon layerEvaporation (deposition)

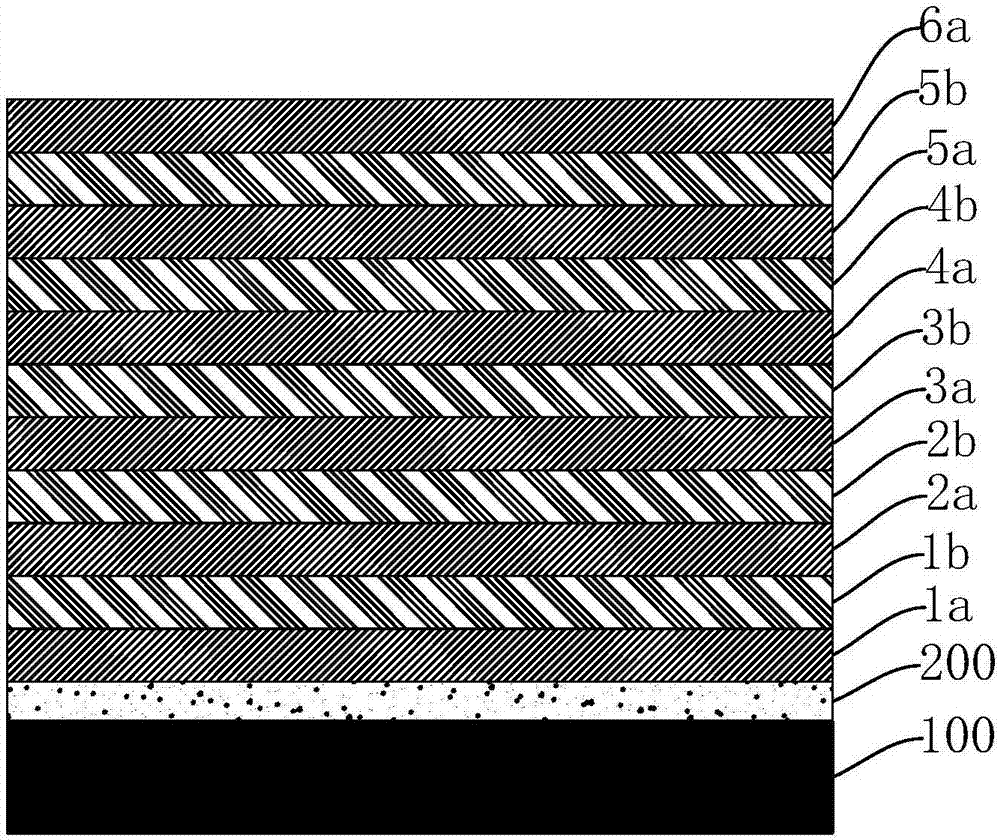

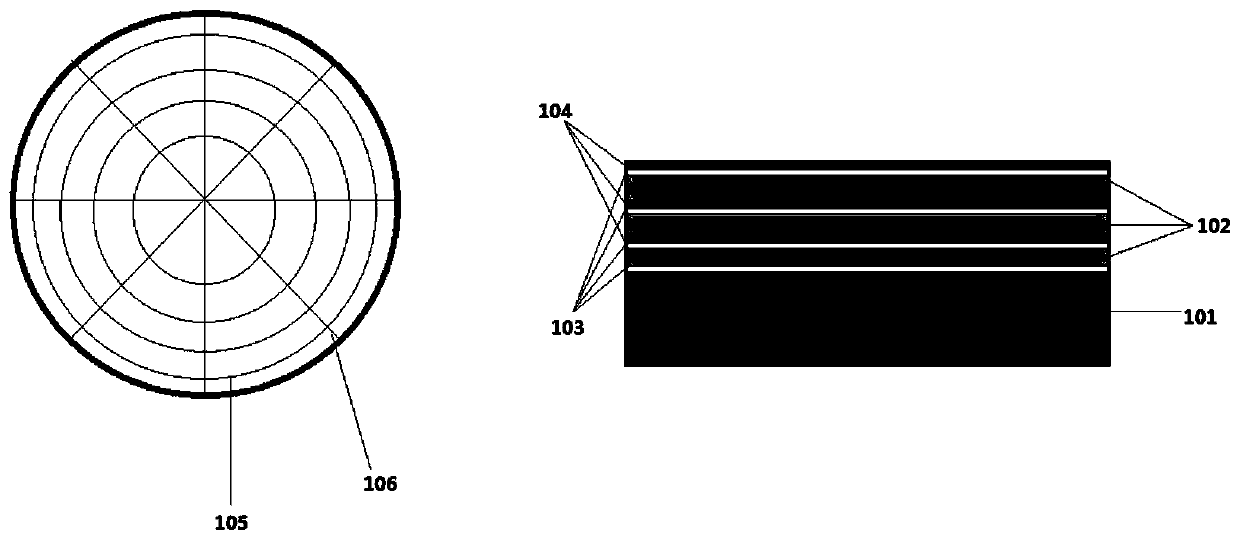

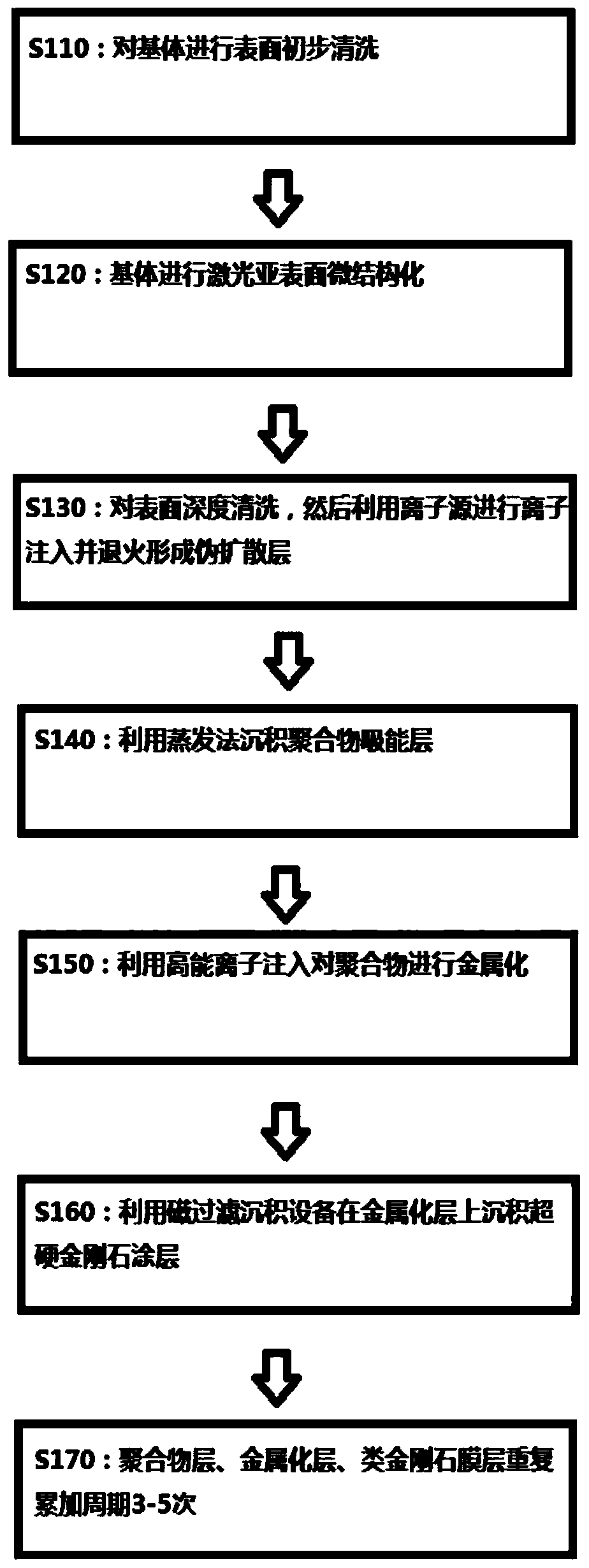

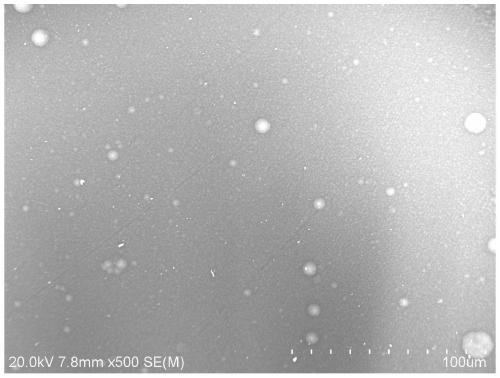

The invention relate to a coating method for preventing high-speed impact. The coating method comprise the following steps that preliminary ion cleaning is carried out on the surface of a substrate; the substrate after surface cleaning is subjected to laser subsurface microstructure; after deep cleaning on a structured surface, ion implantation is carried out and annealing is carried out to form apseudo diffusion layer; a polymer energy-absorbing film layer is deposited on the pseudo diffusion layer by an evaporation method; a polymer layer is metallized by polymer layer by high energy ion implantation; a superhard diamond coating is deposited on a metallized layer by using magnetic filtration deposition equipment; and the polymer layer, the metallized layer and a superhard diamond-like carbon layer are circularly prepared for 3-5 times. According to the coating method provided by the invention, the impact resistance of the matrix against high-speed moving objects is obviously improved by combining a matrix microstructure, ion implantation and deposition coating. The coating method is simple and easy to operate, low in cost and high in efficiency, and thus is very suitable for batch production.

Owner:BEIJING NORMAL UNIVERSITY

Doped graphite-like composite film, preparation method thereof and component comprising doped graphite-like composite film

InactiveCN110578114AImprove mechanical propertiesInhibit rapid growthVacuum evaporation coatingSputtering coatingComposite filmCerium

The invention relates to a doped graphite-like composite film, a preparation method thereof and a component comprising the doped graphite-like composite film. The doped graphite-like composite film comprises doped elements and graphite-like, wherein the doped elements include, by mass, 6.47-13.49% of doped element cerium, 1.21-12.26% of doped element aluminum, and the balance the graphite-like. The mechanical performance of the doped graphite-like composite film is enhanced, and the doped graphite-like composite film shows the excellent wear-resisting performance. The crystallization strengthof the cerium and aluminum co-doped doped graphite-like composite film is high, and the hardness and elasticity modulus of the cerium and aluminum co-doped doped graphite-like composite film are bothimproved by 10% or more.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com