Ti/TiN/TiAlN composite coating on surface of cutting tool material and preparation method of Ti/TiN/TiAlN composite coating

A cutting tool and composite coating technology, applied in the field of materials, can solve the problem that the coating cannot meet the requirements of high wear resistance, high thermal stability and high oxidation resistance mechanical properties, affect the cutting performance and service life of TiN coated tools, and attach Poor focus and other problems, to achieve the effect of alleviating internal stress, improving bonding force and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

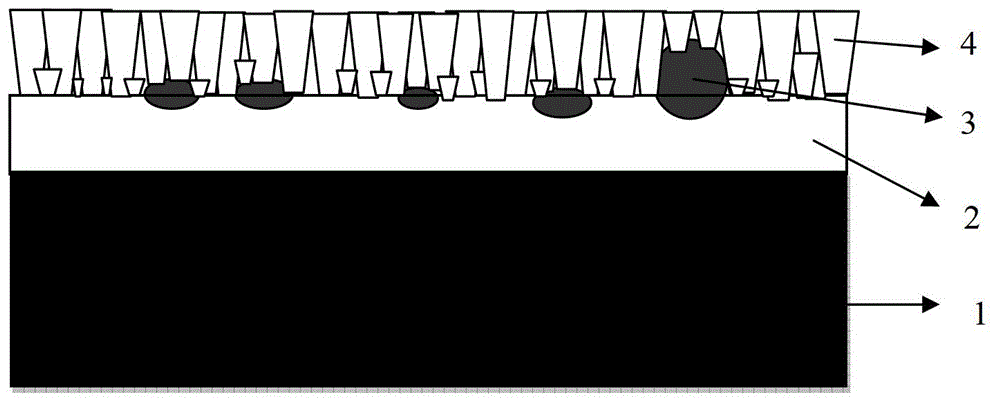

Method used

Image

Examples

Embodiment 1

[0036] AIP-01 multi-arc ion coating machine and JGP-560b magnetron sputtering coating machine are used. The multi-arc ion coating machine is manufactured by Shenyang Yuankehang Co., Ltd., and the magnetron sputtering coating machine is manufactured by Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences. Manufactured by the company, the workpiece used is wire-cut into 10×10×4mm block high-speed steel material (M2 steel).

[0037] (1) Firstly, after the workpiece is mechanically ground and polished, it is cleaned with ultrasonic waves in acetone and alcohol for 15 minutes each, and then dried;

[0038] (2) Put the dried workpiece into the multi-arc ion coating machine, the sample is facing the target source, 150mm away from the target surface, the sample revolves / rotates, and then vacuumizes step by step with a mechanical pump, Roots pump, and diffusion pump to 6.5×10 -3 Pa, the temperature is controlled at 200-230°C, the bias voltage is -70...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is that the coating time in step (4) is 15 minutes.

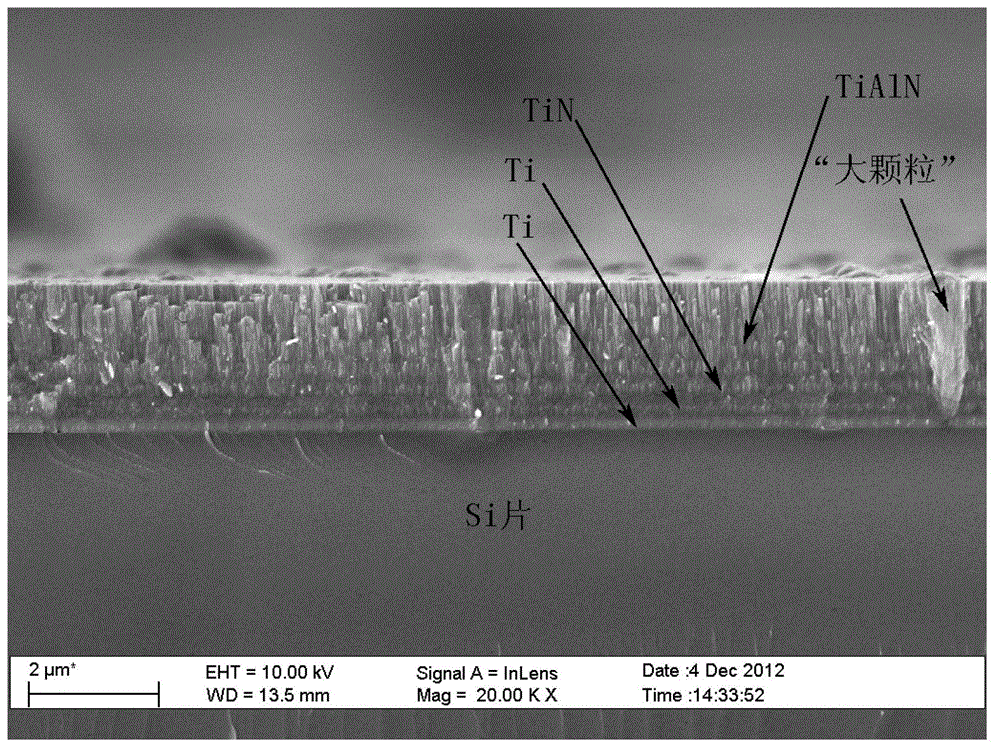

[0045] Figure 4 and Figure 5 They are respectively the cross-section and surface topography diagrams of the composite film prepared on the silicon wafer under the present implementation process observed under the scanning electron microscope.

[0046] The coating thickness is measured by grinding the cross-sectional metallographic sample of the workpiece in Example 2, and measuring it under a scanning electron microscope (SEM). The total thickness of the coating in this example is about 2.8 μm.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is:

[0049] The coating time in step (4) is 30 minutes, after the TiN film is plated, ion cleaning is performed for 3 minutes, the bias voltage is -700 volts, the duty cycle is 40%; the current is 70 A, and the voltage is 25 volts.

[0050] The coating thickness is measured by grinding the cross-sectional metallographic sample of the workpiece in Example 3, and measuring it under a scanning electron microscope (SEM). The total thickness of the coating in this example is about 2.9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com